Page 1

INSTRUCTION MANUAL

DIGITAL RCD(ELCB) TESTER

KEW 5410

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Contents

1. Safety Warnings ………………………………………………….………….. 1

2. Procedure of removing Cover …………………………………………….… 3

2-1 Method of removing the Cover ………………………………………… 3

2-2 Method of storing the Cover ……………………………………….…. 3

3. Feature …………….…………………………………..…………………….…. 4

4. Specification ……………………………………………..…..…………….…. 5

5. Instrument Layout …………………………………………………………… 8

6. Measurement principle ……………………………………………………

7. Preparation …………………………………………………………………... 11

7-1 Connection of Test Leads ………………………………………….… 11

7-2 Setting of Measurement Range …………………………………….... 11

7-3 Setting of IΔn ……………………………………………………….….. 12

7-4 Setting of Test Polarity …………………………………………….…. 12

7-5 Backlight ………………………………………………………………... 12

8. Measurements ……………………………………………………………... 13

8-1 Connection ………………………………………………………….…. 13

8

-2 Voltage Measurement ……………………………………………….... 13

8-3 RCD Test ………………………………………………………..……... 14

8-4 Remote Test ……………………………………………………...….…. 14

8-5 Operating time ………………………………………………..……..…. 18

9. Battery Replacement …………………………………………………….... 19

10. Strap Belt Assembly ……………………………………………………..… 20

Symbols used on the instrument

Pri mary elec tri cal circuits of equip ment connect ed to an AC

CAT.II

electrical outlet by a power cord.

Primary electrical circuits of the equipment connected directly to the

CAT.III

distribution panel, and feeders from the distribution panel to outlets.

Protected throughout by DOUBLE INSULATION or REINFORCED

INSULATION

User must refer to the explanations in the instruction manual.

.... 10

Earth Ground

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

1. Safety Warnings

This instrument has been designed, manufactured and tested according to

following standards, and delivered in the best condition after passing quality

control tests.

● IEC61010-1 Measurement Category CAT.III 300V / CAT.ll 400V

Pollution degree 2

● IEC61010-031

● IEC61557-1, 6

● IEC60529 IP54

This instruction manual contains warnings and safety rules which have

to be observed by

and to maintain it in safe con dit ion. The ref ore , read through th ese

operating instructions before using the instrument.

● Read through and understand the instructions contained in this manual

before using the instrument.

●

Keep the manual at hand to enable quick reference whenever necessary.

● The instrument is to be used only in its intended applications.

●

Understand and follow all the safety instructions contained in the manual.

It is essential that the above instructions are adhered to. Failure to follow

the above instruction s may cau se injur y, ins tru men t da mag e and/o r

damage to equipment under test.

●

The symbol indicated on the instrument means that the user must refer to the

related parts in the manual for safe operation of the i

read the instructions wherever the

DANGER is reserved for conditions and action s that are likely to

WARNING is reser ved for condi tio ns and acti ons tha t ca n ca use

CAUTION is reserved for conditions and actions that can cause injury

t

he user to ensure safe operation of the instrument

DANGER

symbol appears in the manual.

cause serious or fatal injury.

serious or fatal injury.

or instrument damage.

nstrument. It is essential to

1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

DANGER

● This instrument is designed to measure the earth-to-line voltage 90 ~

264V and the line-to-line voltage up to 440V (50/60Hz). Do not exceed

the maximum allowable input of any measuring range.

● Do not attempt to make measurement in the presence of flammable

gasses. Otherwise, the use of the instrument may cause sparking,

which can lead to an explosion.

● Keep your fingers behind the safe

● Set the Fu nction Switch to any desirable Ran ge before mak ing a

measurement. Do not power on the instrument with it being connected

to the live circuit.

● Never attempt to use the instrument if its surface or your hand are wet.

● Never open the Battery Cover during a measurement.

● Verify proper operation on a known source before use or taking action

as a result of the

● Never attempt to make any measurement if any abnormal conditions,

such as a broken cover or exposed metal parts are present on the

Instrument and test leads.

● Do not insta ll substi tu te parts o r make any mod if icati on to the

instrument. Return the instrument to your local KYORITSU distributor

for repair or re-calibration in case of suspected faulty operation.

● Set the Funct

Cover for battery replacement.

● If the overheat symbol “

instrument from the measuring point and allow to cool down.

● Firmly insert the plugs of test leads to the appropriate terminals.

● Set the Function switch to the OFF position after use, and remove the

batteries if the instrument is to be stored and will not be in use for a

long period.

● Use a damp cloth with neutral detergent for cleaning the inst

Do not use abrasives or solvents.

● Do not store the instrument if it is wet.

indication.

ion Switch to the OFF position when removing the Battery

ty barrier on the test leads.

WARNING

” appears on the display, disconnect the

CAUTION

rument.

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

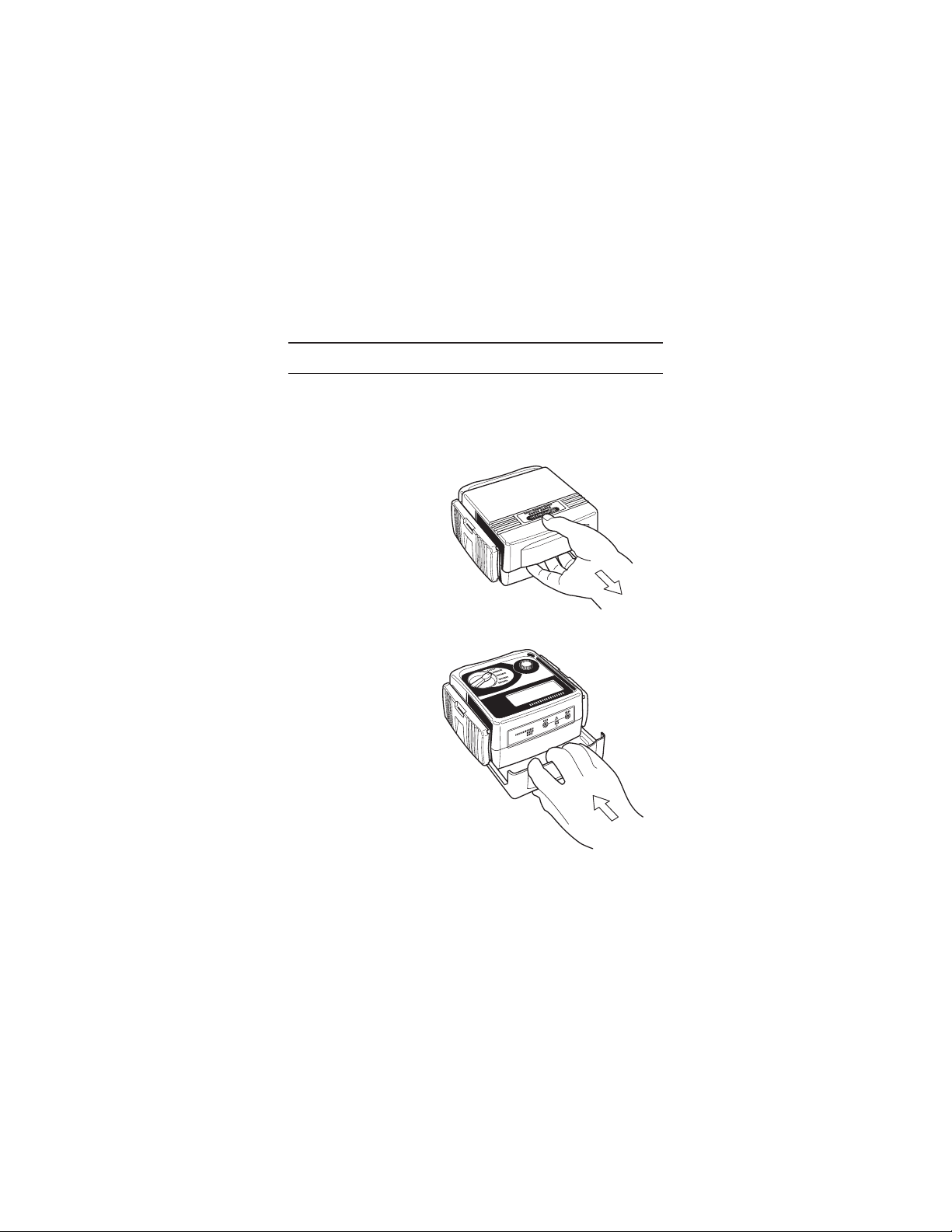

2. Procedure of removing Cover

KEW5410 has a dedicated Cover to protect against impacts from the outside

and preve nt the ope rat ion part, the LCD an d the Connector Block from

becoming dirty. The Cover can be detached and put on the backside of the

main body during measurement.

2-1 Method of removing the Cover

Slide and pull the Cover

in the direction of an arrow.

2-2 Method of storing the Cover

slide and

Cover,

Turn the

push it in the direction of

arrow.

Fig. 1

Fig. 2

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

3. Feature

This instrument is a digital RCD Tester to measure the trip time and trip out

current of RCDs. It also equips the function to measure the voltage.

● Measurement of RCD trip time

Conducting testing of rated residual non-operating currents at x 1/2 Range,

measuring RCD trip time at x1 and x5 Ranges.

● Measurement of trip out current

Measuring trip out current by varying current automati

Remote Test

●

Enabling a user to hold the Test Leads with his both hands by locking the

Test Button.

● Voltage Measurement

Carrying out a constant measurement of voltage in the stand-by mode at

each Range.

● Auto-detection of Contact voltage

Detecting the voltage to earth of Earth electrodes or Protective conductors

during RCD test

in order to prevent electr ical shoc ks ca used by the damaged

EARTH

earth.

Measurement will be ceased at AC50V (AC100V “x5 range” only) or more.

● Dust- and Water-proof

Dust- and Water-proof construction (designed to IEC60529 IP54)

● Backlight

Facilitating working at dimly illuminated locations.

-

when applying test currents - at measurement using

4

cally.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

4. Specification

● Measuring range and accuracy

(23℃±5℃ , relative humidity 75% or less)

Range Rated Voltage

x 5

x 1

100V±10%

200V+32%

/-10%

400V±10%

x 1 / 2

AUTO

RAMP

* Only the RCD type G (without trip out time-delay) can be tested at Auto

Voltage Measurement

● Applied standards : IE C610 10-1 M ea sur em ent Ca te gor y CAT.III

● Display : 1999counts (3 1/2digits), Large LCD

50 / 60Hz

(mA)

Ramp Test; type S (time-delay) cannot be tested.

Measuring range Accuracy

80V ~ 450V

50 / 60Hz

Test current

IΔn

15 / 30 / 50

/ 100mA

15 / 30 / 50

/ 100 / 200

/ 500mA

15 / 30 / 50

/ 100 / 200

/ 500mA

300V / CAT.II 400V, Pollution degree 2

IEC61010-031

IEC61557-1, 6

IEC60529 IP54

Measuring

range

Testing time

0ms ~ 200ms

Testing time

0ms ~ 2000ms

Testing time

0ms ~ 2000ms

~11

0% of IΔn

40%

(goes up by 5%)

Testing time

300ms x 15steps

±(2%rdg+4dgt)

Accuracy

Trip Time

±(1%rdg+3dgt)

Test Current

+2% ~ +8%

Trip Time

±(1%rdg+3dgt)

Test Current

+2% ~ +8%

Trip Time

±(1%rdg+3dgt)

Test Current

-8% ~ -2%

Test Current

at each step

-4% ~ +4%

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

● Used location : Altitude up to 2000m, indoor use

● Operating temperature :

& humidity

● Storage temperature :

& humidity

● Withstand Voltage : AC3700V / 1 min

● Insulation resistance : 50MΩ or more / 1000V

● Sleep Functi

● Dimension : 186mm x 167mm x 89mm

● Weight : 9

● Power Source : DC12V / Size AA battery R6P (SUM-3) x 8pcs

● Possible number of : 1200 times or more

Measurements (measure every 30sec at x1/2 Range,

● Accessories : Instruction manual x 1pce

on : 1. Automatically enters Sleep mode in 3 min after

0℃ ~ 40℃ , relative humidity 85%

(no condensation)

-20℃ ~ 60℃ , relative humidity 85%

(no condensation)

(between electrical circuit and enclosure)

(between electrical circuit and enclosure)

the last switch operation (current consumption

75uA). This function doesn't work at voltage

measurements. To exit from the Sleep mode,

se t th e Fu n ct i on swi t ch to OF F po si t ion

once, and re-set it to the Range at which a

measurement to be conducted.

2. Backlight turns off in 1 min after it lights up.

65g

IΔn =100mA)

Strap belt x 1pce

Test lead M7128 x 1set (red & black cords)

Test lead with alligator clip M7129 x 1 set

Cord case x 1pce

Long pin M8017 x 2pcs

Size AA battery R6P(SUM-3) x 8pcs

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

● Operating error

Operating error (B) is an e rro r obtain ed under the nom inal ope rating

conditions, and calculated with the intrinsic error (A), which is an error of

the instrument used, and the error (En) due to variations.

2

2

2

2

B=±(

A +1.15

----------------

E

+E

+E

1

2

√

3

+E

2

+E

5

8

)

A : Intrinsic error

: Variation due to changing the position

E

1

: Variation due to changing the supply voltage

E

2

: Variation due to temperature

E

3

: Variation due to the resistance of Probe *

E

5

: Influence by the variation in System Voltage

E

8

* Probe = auxiliary Earth electrode to be used for the sampling of

electric potentials during measurements

IΔn Probe resistance

15mA Less than 200Ω

30mA Less than 100Ω

50/100/200/500mA Less than 20Ω

KEW5410 Max Operating Error (IEC61557)

Range Max Operating Error

x 5

x 1

test current 0% ~ +10%

time measurement ±10%

test current 0% ~ +10%

time measurement ±10%

x 1/2 test current -10% ~ 0%

AUTO RAMP (mA) ±6%

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

5. Instrument Layout

1

2

3

4

1. LCD

2. 0° / 180° Button (Polarity change)

3. IΔn Button

4. Test Button

5. Backlight Button

6. Function Switch

Connector Block LCD

Fig. 3

8

5

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

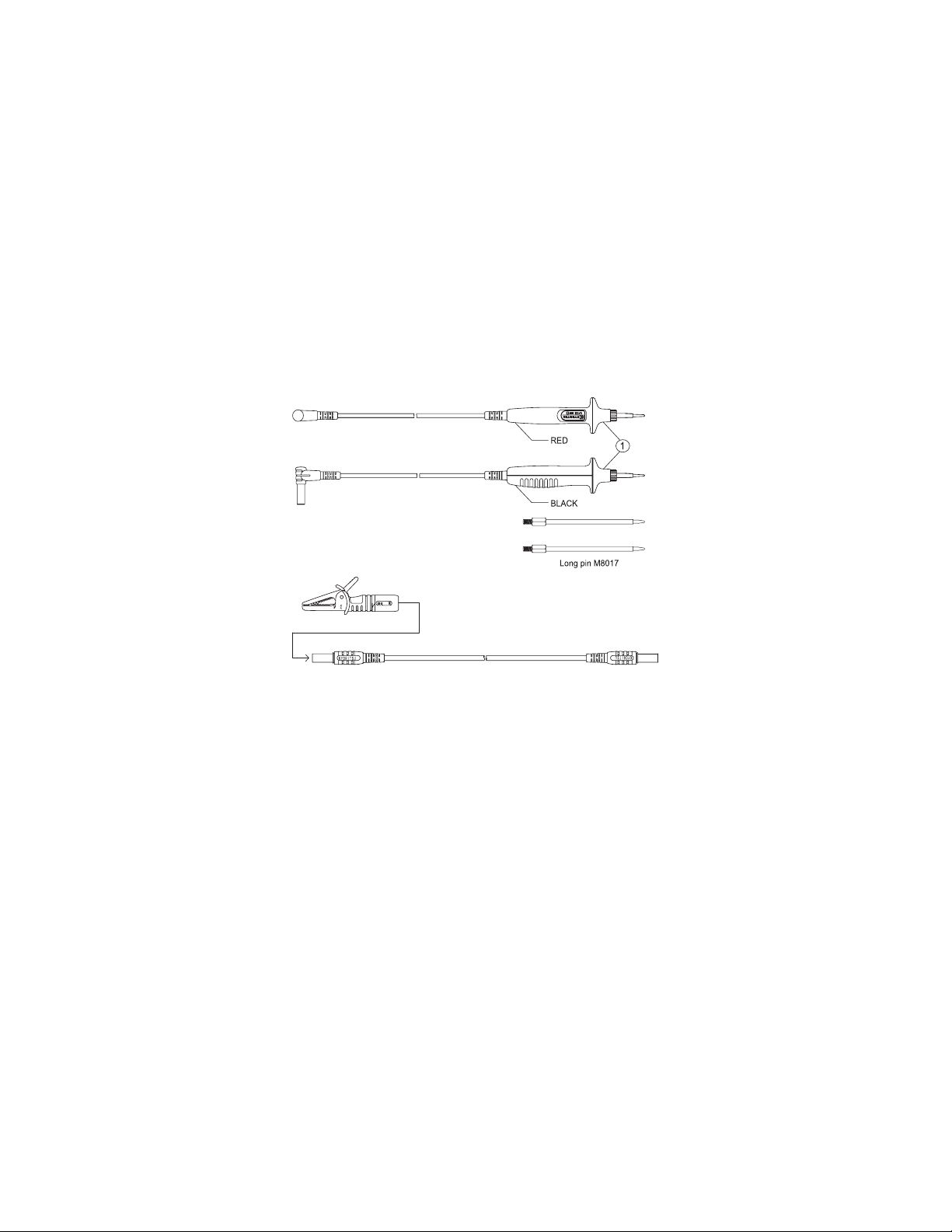

Test Lead

1. Test Lead M7128

2. Test lead with alligator clip M7129

Fig. 4

* Long pin for M7128

The Tip pin of M7128 can be replaced with the Long pin M8017.

(1) Unscrew and remove ① shown in Fig.4 and remove the Tip pin.

(2) Install the Long pin and tighten ①.

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

6. Measurement principle

This instrument has a constant current circuit, and drives leakage currents (I)

between LINE-NEUTRAL as illustrated in Fig.5 to activate RCDs, moreover,

can output and measure leakage currents flowing to the earth as shown in

Fig.6.

● Trip time measurement:

Measure and displ ay the time be tween th e start of d riv ing leaka ge

currents (I) and trip of the RCD.

● Trip out cur

Increase the leakage current gradually from the 40% of IΔn, the current

value when RCD trips is displayed.

Influence of the fluctuations in system voltages is less on this instrument due

to the incorporated constant current circuit.

rent measurement:

Fig. 5 Fig. 6

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

7. Preparation

7-1 Connection of Test Leads

Connect the test lead properly.

● Connect the test lead M7128; red cord to the load of the Connector

block and black cord to the power supply.

● When using the test lead with Alligator clip, connect the test lead M7128

(red) to the load of Connector block and M7129 to the power.

7-2 Setting of Measurement Range

Turn the Fun ction Sw itch and power on the in

appropriate Ranges.

Range construction: There are 4 Ranges on this instrument.

For trip time measurement :

x 5

Apply a current 5 times bigger than IΔn to measure RCD trip

time.

For trip time measurement :

x 1

Apply IΔn to measure RCD trip time.

For the test - rated residual non-operating current :

x 1/2

Apply a half of IΔn to confirm the RCD under test doesn't trip.

AUTO

RAMP

Do not power on the instrument with it being connected to the live circuit.

For trip out current measurement :

Vary a testing current in the range of 40% ~ 110% of IΔn to

measure the trip

out current on the RCD.

WARNING

11

strument, then select any

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

7-3 Setting of IΔn

Balance the IΔn of the instrument and of the RCD by using the IΔn Button.

● Default value : 30mA

● Selectable values at x 5 Range are 15, 30, 50 and 100mA;

200 and 500mA are not available (Black arrow mark “▼” on the LCD

indicates the selected value). In case that 200 or 500 mA is selected at

any Ranges other than x 5 Range and set the Function Switch to x 5

Range, the value

7-4 Setting of Test Polarity

Press the 0° /180° Button and select the polarity for test.

When the instrument is connected as illustrated in Fig.7, 8; current flows from

the load to power in positive half cycle at 0° and flows from the load to power

in negative half cycle at 180° , and when it is connected as illustrated in Fig.9;

current flows from the load to earth i

the load to earth in negative half cycle at 180° .

● Default polarity : 0°

7-5 Backlight

Press the Backlight Button and turns on the backlight to facilitate working at

dimly illuminated location.

● Backlight turns off automatically in 1 min after it lights up.

Press the button again to turn it on.

automatically restores to 30mA.

positive half cycle at 0° and flows from

n

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

8. Measurements

8-1 Connection

Connect the instrument according to Fig. 7, 8, 9.

DANGER

This instrument is designed to measure the earth-to-line voltage 90 ~

264V and the line-to-line voltage up to 440V (50/60Hz). Do not exceed

the maximum allowable input of any measuring range.

● Power on the instrument before connecting to the measuring point.

Prior to a measurement, confirm that the instrument isn't in the Sleep

●

mode. If it is in the sleep mode, set the Function Switch to OFF position

first and do p reparation for measurement according to “ Chapter 7.

Preparation ”.

Then connect the instrument to the measuring point.

Dis connect the lo ad of the RCD to be teste d be for e co nnecting the

instrument. Otherwise, it may influence on the test results.

8-2 Voltage Measurement

nstrume nt au tomatic ally measure voltages when it detects input of

The i

voltage.

Indication of “Lo V” is displayed on the LCD when the measured voltage

is less than 80V; “H i V” is displayed with audible wa rni ng when the

measured voltage is 450V or higher. Disconnect the instrument from the

measuring point immediately when “Hi V” is displayed on the LCD, and

stop further measurements. The Test But

“Hi V” is displayed on the LCD, and RCD test cannot be performed.

WARNING

CAUTION

DANGER

ton is disabled while “Lo V” or

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

8-3 RCD test

Press the Test Button while voltage is displayed on the LCD, then RCD test

starts.

● x1/2, x1, x5 Ranges

Measured RCD trip time will be displayed on the LCD. When the RCD

under test doesn't trip, “OL ms” will be displayed instead.

Test results must be matched with the operating times mentioned at

clause 8.5.

● AUTO RAMP Range

Measured trip out current will be displayed on t

under test doesn't trip, “OL mA” will be displayed instead.

Measured results are kept displayed until the Function Switch, IΔn Button

or 0° /180° Button is operated. Restore the tripped RCD and apply voltages;

then a Voltage measurement can be re-started.

8-4 Remote Test

Connect the instrument as illustrated in Fig.7, 8, 9 with th e Test Button

pressed down & locked.

Then voltage m

automatically.

Restore the tripped RCD with the Test Button on the instrument turned &

locked, and apply voltages. Then the instrument measures voltages for about

1 sec and starts RCD test automatically again.

urement is conducted for about 1 sec and RCD test starts

eas

LCD. When the RCD

he

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

DANGER

● Voltage to earth of Earth electrodes or Protective conductors is auto-

matically detected during RCD test

at measurement using EARTH in order to prevent electrical shocks

caused by the damaged earth. When the detected voltage at RCD test

exceeding AC50V (AC100V “x5 range” only), “

after pressing the Test Button and halt the measurements.

● When overheat symbol “

instrument from the measuring point and allow to cool down.

● Replace the batteries with new ones immediately when the Low battery

warning “

● Setting of IΔn may not be proper or the instrument isn't connected to

the object under test correctly when “no” is displayed on the LCD.

The IΔn of the instrumen t and the RCD und er test should be the

same. Check the connection prior to measurements.

● Me as ur ed res ul ts ma y be influ en ce d by a presen ce of vol ta ge

between protective conductors and EARTH at measu rement using

protective conductors. When testing the circuit with earthed Neutral

wire, check the connection between Neutral and Earth before starting

measurements. Measured results may be influenced by a presence of

voltage between Neutral and EARTH.

● Measured results may be influenced by a presence of leakage current

in the circuit under test. Presence of leakage current may be doubt if

any electric

● Resis tance of ea rt hed elect rodes in the circuit under test with a

Probe

100Ω(IΔn=30mA) / 20Ω(IΔn=50/100/200/500mA ), or less.

● Equipment following the RCD, e.g. capacitors or rotating mashinery,

may cause a significant lengthening of the measured trip time.

” starts flashing.

field exists in the other earth equipments.

-

auxiliary earthed electrode - should be 200Ω (IΔn=15mA) /

-

when applying test currents -

Hi V” is displayed

WARNING

” app ears on the LCD, disconnect the

CAUTION

rements.

15

● Restore the tested RCD after measu

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

● Neutral - Line

Connect the “PRIMARY” of the C onnector Block to the Neutral of the

power of RCD, and the “SECONDARY” of the Connector Block to the Line

of the load of RCD.

Fig. 7

DANGER

This instrument is designed to measure the earth-to-line voltage 90 ~

264V and the line-to-line voltage up to 440V (50/60Hz). Do not exceed

the maximum allowable input of any measuring range.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

16

Page 19

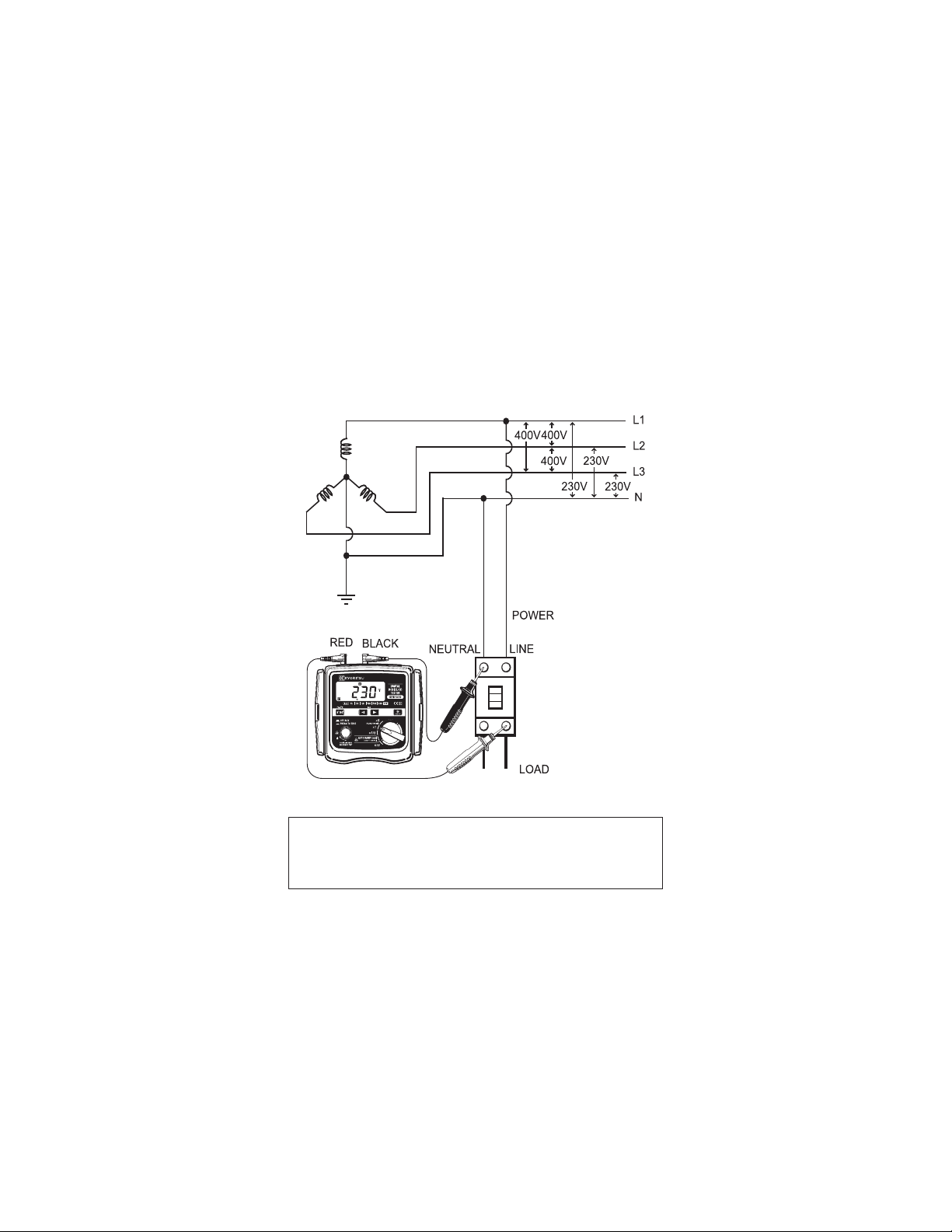

● Line - Line

Connect the “PRIMARY” of the Connector Block to L2 of the power of

RCD, and the “SECONDARY” of the Connector Block to L1 of the load of

RCD.

Fig. 8

DANGER

This instrument is designed to measure the earth-to-line voltage 90 ~

264V and the line-to-line voltage up to 440V (50/60Hz). Do not exceed

the maximum allowable input of any measuring range.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

17

Page 20

● Earth - Line

Co nne ct the “P R IM A RY” of the C on n ec tor B lo ck to Ear t h, a nd t he

“SECONDARY” of the Connector Block to Line of the load of RCD.

Connection using Earth

Lea kage cu rrent s may flow to RCD (A),

which is installed in the power supply of the

RCD (B) under test, when current flows to

Fig. 9

Extra caution should be taken when applying current to EARTH for tests

since the other RCDs (see Fig.10) may operate and damage the devices

connected to the instrument and cause accidents.

the EARTH; so RCD (A) may trip as well.

Fig. 10

DANGER

8-5 Operating time

Trip ping ti me is t he time needed by the RCD to

operating current of IΔn. The standard values of tripping time are defined by

IEC 61009 and IEC 61008 are listed in the table below for IΔn and 5IΔn.

Type of RCD IΔn (x1) 5IΔn (x5)

General(G)

Selective(S)

300ms

max allowed value

500ms

max allowed value

130ms

min allowed value

18

tri p at a rate d residual

40ms

max allowed value

150ms

max allowed value

50ms

min allowed value

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

9. Battery Replacement

DANGER

● Do not open the Battery Cover if the instrument is wet.

● Never replace the batteries during measurements. Set the Function

swit ch to the OFF positi on and disconnect the test leads from the

instrument, when replacing batteries, in order to preve nt electrical

shocks.

● Do not mix new and old batteries.

● In st all bat ter ie s in the ori entat io n as shown insi de the bat ter y

compartment, observing correct polarity.

1. Set the Function switch to the OFF position, and disconnect the Test leads

from the Connector Block.

Loosen 2 pcs of Battery Cover fixing screws, and remove the Battery Cover.

2.

3. Replace all 8 pcs of batteries . Ins tall new batte ries observing correc t

polarity. Battery : R6P (size AA) x 8 pcs

4. Install the Battery Cover, and tighten up the screws.

CAUTION

Fig. 11

19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

10. Strap Belt Assembly

Correct assembly is shown in Fig.12. By hanging the instrument round

the neck, both hand let free for testing.

Fig. 12

Pass the Strap belt down through

the si de pan el of the main bod y

from the top, and up thr oug h the

slo ts of the Pro be case from the

bottom.

Pass the Strap through the buckle,

ad ju st th e strap for le ngth and

secure.

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...