Page 1

INSTRUCTION MANUAL

Current / Voltage Measurement & Recording

KEW LOGGER

Current Logger KEW 5010

Current&Voltage Logger

SERIES

KEW 5020

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Introduction

Thank you for purchasing KEW LOGGER 5010/5020.

Follow the pr

ocedure below and set time on the instrument before use.

1) Install the KEW LOG SOFT 2 and the USB Driver according to the

instructions written in the Install Manual for KEW LOG Soft 2.

2) Run KEW LOG SOFT 2 once install is completed. (Refer to 4. Start

KEW LOG SOFT 2 in the Install Manual.)

3) Confirm that the LOGGER and a PC is firmly connected with a USB

Cable and click Time Synchronizing.

4) Confirm that the Logger connected with the PC is listed on the

List of detected loggers. (The USB Driver might not be installed

correctly when a message No Logger is detected. is displayed.

Refer to the backside of the Cautions for installing USB Driver

install or 6. Trouble shooting (P.8) of the Install Manual and

re-install the USB Driver.)

5) Click Time Synchronizing Button while the LOGGER is powered on

and checks are marked in the box for each connected LOGGER to

set time.

Read this manual and do your desirable settings. (Setting should be done

by using KEW LOG Soft 2. Settings for some Recording modes can be

done on the LOGGER.

Read through 1. Safety Warnings in this manual before using the

LOGGER in order to ensure safe operation of the instrument.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Contents

1. Safety warnings

…………………………………………………………

1

2. Features

…………………………………………………………………

4

3. Instrument layout

………………………………………………………

5

3-1) Panel

………………………………………………………………

5

3-2) LCD

…………………………………………………………………

5

3-3) Displayed message

………………………………………………

7

3-4) Function of Button

…………………………………………………

8

3-5) Range/ Filter function

……………………………………………

9

4. Recording procedures

…………………………………………………

10

Step1: Start-up

………………………………………………………

11

Step2: Confirmation of set value

……………………………………

12

Step3: Preparation before a recording

………………………………

13

Step4: Start of recording

……………………………………………

15

Step5: Stop of recording

………………………………………………

17

5. Recording modes and conditions

………………………………………

18

Normal recording mode

………………………………………………

19

Trigger recording mode

………………………………………………

22

Capture recording mode

………………………………………………

24

Power Quality Analysis mode (only 5020)

……………………………

24

6. Recording modes

………………………………………………………

25

Flashing Detection LED

…………………………………………………

28

7. Simplified Power Integration Function

…………………………………

31

(available on KEW LOG Soft 2)

8. Other settings (Setting2)

………………………………………………

34

9. Confirmation of recorded data (CALL)

…………………………………

39

10. Data transfer to PC

……………………………………………………

43

11. Battery replacement

……………………………………………………

45

12. Auto-power off Function & External power supply

……………………

46

13.Trouble-shooting

…………………………………………………………

47

14.Specification

……………………………………………………………

49

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

1

1. Safety Warnings

This in stru men t has be en des ign ed, ma nufactu red a nd te sted

according to IEC 61010: Safety requirements for Electronic Measuring

apparatus, and deli vered in the best cond ition after passed the

inspection. This instruction manual contains warnings and safety rules

which must be observed by the user to ensure safe operation of the

instrument and retain it in safe condition. Therefore, read through these

operating instructions before using the instrument.

WARNING

Read through and understand the instructions contained in this

manual before using the instrument.

K

eep the manual at hand to enable quick reference whenever

necessary.

The instrument is to be used only in its intended applications.

Understand

and follow all the safety instructions contained in the

manual.

It

is essential that the above instructions are adhered to. Failure to

follow the above instructions may cause injury, instrument damage

and / or damage to equipment under test.

The

symbol

indicated on the instrument means that the user must

refer to the related parts in the manual for safe operation of the

instrument. It is essential to read the instructions wherever the

symbol appears in the manual.

DANGER is reserved for conditions and actions that are likely

to cause serious or fatal injury.

WARNING is reserved for conditions and actions that can cause

serious or fatal injury.

CAUTION is reserved for conditions and actions that can cause

injury or instrument damage.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

2

DANGER

Never make measurement on a circuit in which voltage over AC300V

exists.

Do no t ma k e m e a s ure m e n t wh i l e t h u n der is r u m b ling. Stop

measurement immediately and disconnect the instrument from the

object under test.

D

o not attempt to make measurement in the presence of flammable

gasses. Otherwise, the use of the instrument may cause sparking,

which can lead to an explosion.

T

ransformer jaw tips are designed not to short the circuit under test.

If equipment under test has exposed conductive parts, however, extra

precaution should be taken to minimize the possibility of shorting.

Never attempt to use the instrument if its sur

face or your hand is wet.

Do not exceed the maximum allowable input of any measuring range.

Never open the Battery Cover during a measur

ement.

V

erify proper operation on a known source before use or taking action

as a result of the indication of the device.

WARNING

Never attempt to make measurement if any abnormal conditions, such

as broken case and exposed metal parts are found on the instrument.

Do not install substitut e part s or make a ny modific ation to the

instrument. For repair or re-calibration, return the instrument to your

local KEW distributor from where it was purchased.

D

o not try to replace the batteries if the surface of the instrument is wet.

D

isconnect all the cords and cables from the object under test and

power off the instrument before opening the Battery Cover for Battery

replacement.

CAUTION

Put the instrument on a stable place where is free from vibrations or

shocks.

Keep away Floppy Disks, Mag Cards, PCs and Displays from the

magnet, which is attached to the backside of the instrument.

Do not expose the instrument to the direct sun, high temperature and

humidity or dewfall.

Be

sure to power off the instrument after use. When the instrument will

not be in use for a long period, place it in storage after removing the

batteries.

U

se a cloth dipped in water or neutral detergent for cleaning the

instrument. Do not use abrasives or solvents.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

3

Safety symbols

Refer to the instructions in the manual.

Indicates a Instrument with double or reinforced insulation

Indicates that this instrument can clamp on live bare conductors

when the voltage to be tested is below Circuit – Ground-to-Earth

voltage against the indicated Measurement Category.

〜

Indicates AC

Indicates DC

Measurement categories(Over-voltage categories)

To ensure safe operation of measuring instruments, IEC 61010 establishes

safety standards for various electrical environments, categorized as

CAT.I to CAT.IV, and called measurement categories. Higher-numbered

categories correspond to electrical environments with greater momentary

energy, so a measuring instrument designed for CAT.III environments can

endure greater momentary energy than one designed for CAT.II.

CAT.I : Secondary electrical circuits connected to an AC electrical

outlet through a transformer or similar device.

CAT.II : Primary electrical circuits of equipment connected to an AC

electrical outlet by a power cord.

CAT.III : Primary electrical circuits of the equipment connected directly to

the distribution panel, and feeders from the distribution panel to

outlets.

CAT.IV : The circuit from the service drop to the service entrance, and

to the power meter and primary over-current protection device

(distribution panel).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

4

2. Features

KEW 5020 is a Data Logger capable of measuring Leakage Current,

Load Current and Voltage. (KEW5010 is for measuring Leakage Current

and Load Current).

Following sensors are used for measuring current & voltage.

* Leak/Load Current Clamp Sensor KEW 8146/8147/8148

* Load Current Clamp Sensor KEW 8121/8122/8123

* Voltage Sensor KEW 8309 (for KEW5020)

TRMS measurement & recording of AC Current (50/60Hz) & AC Voltage

(50/60Hz, only on KEW5020)

LED to indicate pre-set current/ voltage value is exceeded.

(Trigger/ Capture Recording, Power Quality Analysis modes)

Can store 60,000 data when using 1ch, and when using all 3ch, can

store 20,000 data at each channel. (Normal recording mode)

Data will not be lost at battery replacement or at low battery voltage as it

is stored in nonvolatile memory.

Long time recording is available by a use of external AC Adaptor

(opti onal part s) Installed ba tteries en ables back up at a temporal ly

electricity failure. Size AA Alkaline Battery: about 10-day measurement.

Can transfer the recorded data to PC via USB cable.

Pr

otected throughout by double (reinforced) insulation

This

instrument provides 3 Recording modes and Power Quality Analysis

mode (only KEW5020). Various insulation monitoring are available with 4

recording modes. Understand characteristic of each recording mode and

select an appropriate mode.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

3. Instrument layout

3-1) Panel

◆

◆

◆

3-2) LCD

Detection LEDs P.28

USB P.43

Port for External power supply P.46

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

6

Mark Details

Channel number (CH No.) : Selected Channel number

is displayed.

Memory Block Number : Memory block (No. 1 to

3) in use is indicated. (P.

38)

Sensor Mark : Displ ayed on the CH No. to Indi cate the

connected Sensor.

Clock Mark : Indicates time

Timer Mark : Timer function is activated.

(Stand-by till the preset time.)

Recording Mark : Recording is being performed.

Auto-power-off is disabled.

(Instrument won't be off automatically.)

Battery Mark : Indicates battery voltage in 4-level

Recording mode

Sub-indication : Indicates Menu items

Date : Month, Day

Main indication : Di s pla ys meas ure d, pre set an d

recording values

Guide mark : Items can be switched with /

button.

One-time : Recording stops when memory becomes full

Endless : Overwrite the old data, and store the latest data.

Range Hold/ Auto Range mark :

Status of the selected

Range

Filter mark : Indicates Filter function is activated.

Mark Details

Channel number (CH No.) : Selected Channel number

is displayed.

Memory Block Number : Memory block (No. 1 to

3) in use is indicated. (P.

38)

Sensor Mark : Displ ayed on the CH No. to Indi cate the

connected Sensor.

Clock Mark : Indicates time

Timer Mark : Timer function is activated.

(Stand-by till the preset time.)

Recording Mark : Recording is being performed.

Auto-power-off is disabled.

(Instrument won't be off automatically.)

Battery Mark : Indicates battery voltage in 4-level

Recording mode

Sub-indication : Indicates Menu items

Date : Month, Day

Main indication : Di s pla ys meas ure d, pre set an d

recording values

メニューガイドマーク: メニ ューモ ード時、

ボタンで項目を切り

替えられることを表す

ワンタイム: 記録容量一杯になったとき の停止

(

ワンタイム) 設定を表示

エンドレス: 記録容量一杯になったとき の継続

(

エンドレス) 設定を表示

単位表示

レンジホールド/オートレンジマーク: 表 示CHの

レ ン ジ ホ

ー ル ド/オ

ー ト レ ン

ジ の 状 態

を表示

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

7

3-3) Displayed message

Message Meaning

Sensor is not connected.

Over-range

Menu: Setting1 (SET.1) P.18

View or change the recording mode/ condition.

Menu: Setting2 (SET.2) P.34

View or change the Location information and

auto-power-off function.

Menu: Recall(CALL) P.39

Recorded qty., Max value reference, Recall

Normal recording mode

Trigger recording mode

Capture recording mode

Power Quality Analysis mode [KEW5020 only]

PC data in transit

Warning of memory clear

Error (improper Sensor is connected under

Power Quality Analysis mode/ KEW5020 only) (P.47)

All the Memory block are occupied. (P.16)

Move the data and clear the memory. (P.34)

Sub-indication Sensor Type

Load current clamp sensor

Voltage Sensor

Leakage & Load current clamp sensor

Leakage current clamp sensor

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

8

3-4) Function of Button

Power ON / OFF

Menu mode

Recording/ Measurement mode

Button Power ON Power OFF

Pressing at least 1 sec

(while the LOGGER is off)

Pressing at least 1 sec

(except for recording status)

Button Function

Enter into Menu mode

Start and stop recording

Switch channels

Switch Range and Filter (P.9

)

Button Menu Setting Change (flashing)

Select Menu Setting change, Enter

Back Cancel

Switch Menu item Increase number

Switch Menu item Decrease number

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

9

3-5) Range/ Filter Function

●

Range Configuration

Range configuration varies depending on each connected Sensor.

Refer to "12. Specification" (P.45) in this manual.

●

Auto-ranging

Auto-ranging is avai lable only in Normal Recording mode. It isn't

available on a Sensor providing one single range.

(e.g. Voltage Sensor "KEW8309" for KEW5020)

●

Range Hold

Select the ranges with

mark to fix measurement range under

Normal Recording mode.

Measurement range in Trigger/ Capture Recording mode is decided

depending on a detection level. Switching of measurement ranges

with the button isn't possible.

●

Filter Function

Lowpass Filter works when Filter Function is ON

(

mark lights up)

and filter out the frequency in higher harmonics band.

(Cutoff Frequency: approx 160Hz, attenuation rate -24dB)

●

Range/ Filter Function for each Recording mode

Recording mode Function

Normal recording

* Switching ranges, On/Off Filter

* Auto-ranging is available.

T

rigger/ Capture

recording

* On/Off Filter

* Range corresponds to detection level

* Auto-ranging isn't available.

Power Quality Analysis

[KEW

5020 only]

* On/Off Filter

* Auto-ranging isn't available.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

10

Following explains the flow of operation: through preparation to the stop

of recording.

P.11

P.12

P.13

P.15

P.17

* The recorded data can be viewed either by the following two methods.

(1) On a PC: Follow the instruction described at "10. Data transfer to

PC" in this manual (P.43) for data transfer, and Help for PC Software

"KEW LOG Soft

2" for operation method.

(2) On the instrument: Refer to Confirmation of recorded data (CALL)

(P.39)

* Press the

button at least 1 sec. to power off the instrument.

(This is because to prevent operational error.)

4. Recording procedures

▼

Step1: Start-up

Step2: Confirmation of the set value

▼

Step3: Preparation before recording

▼

Step4: Start of recoding

▼

Step5: Stop of recording

Se lect the approp riate se nsor, and

connect it to the instrument.

Confirm the recording mode.

Install the instrument and do setups for

each channel.

Star

t recording.

Stop recording.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

11

1. Press the button and power off

th e ins tru men t. Co nne ct a C lam p/

Voltage Sensor to CH1 (for multiple

connection, starting from CH1) while

the instrument is being off. Connect

them firmly with careful attention to the

orientation of the connector.

2. Press the button at least 1 sec.

to power on the instrument. Release

the button when all indic ations are

displayed on the LCD.

Fir s t, ti me is d i spla y e d, an d th en

sensors being connected are displayed.

If incorrect time is displayed whenever

powering on the instrument, internal

battery for clock may be exhausted. In

this case, send back the instrument to

your local KEW distributor for repair.

3. Check the connected Sensors.

Sensor (P.7) and the full-scale value are

displayed.

(beginning from CH1)

◆

Sensor mark is displayed on the CH

No,. to which a Sensor is connected .

◆

Only CH1 is used in Capture REC mode.

◆

Voltage sensor is connected to CH1 in

PQA REC mode (only on KEW5020).

◆

Voltage sensor ca nnot be used wit h

KEW5010.

◆

Power off the instrument and repeat

steps from 1. to re-connect a Sensor.

▼

▼

▼

Step1: Start-up

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

12

4. Can ma ke measurement right afte r

powering on the instrument.

* Each time pressing the button,

CH1 to CH3 switches. When

(non-connect) is displayed on the

LC D, a sensor is not connec ted

to t h e selec ted ch anne l; or the

connection is incorrect.

Check the mark indicating the selected

recording mode. Refer to 5. Recording

modes and conditions in this manual

to change the record ing mode or

condition ( Recording interval / Preset

current)

Recording mode Details Refer to

Normal

Performs c on tinuous measurement /

recording at the pre-set intervals.

(15-kind: 1 sec. to 60min.)

P.19

Trigger

Records 8 data (0.8 sec.) in total with

time information when pre-set detection

level is exceeded.

P.22

Capture

Records 10 (50Hz) to 12 waveforms

(60Hz) when preset detection level is

exceeded.

(Graph can be viewed on PC)

P.24

(PC setting)

Power Quality Analysis

(only 5020)

Records date and time information when

preset Swell, Dip and Short interruption

value are exceeded.

P.24

(PC setting)

Step2: Confirmation of preset value

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

13

1. Clamp on the measured object and fix

the Sensor. Firmly fix it so as not to

easily come off.

Care should be taken, when connecting

the Voltage Sensor designed only for

KE W5020, n ot to s hor t the ob jec t

under test.

2. Fix the instrument.

1) Fix the instrument with magnet :

Can fix the instrument to metallic plate

with the magnet on its backside.

2) Hang the instrument on hook :

Can fix the instrument with a hook or

screw by using the hooking hole on the

top of the instrument.

(Firmly fix it so as not to easily come

off.)

3. Press the button to switch the

di spl a y of mea sur ed va lue a mon g

CH1 to 3. Confirm a proper Sensor is

connected to an appropriate CH.

▼

▼

▼

Step3: Preparation before recording

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

14

4. Check a Range/ Filter

Press the

button to check their on/off

status.

Press t he

but ton to c ha nge the m.

Independent setting of Range & Filter is

available on each CH.

Point

●

At Normal Re cording mod e, Range and

Filter switches each t ime pre ssing the

button.

Auto-ranging is also available.

●

At Trigger/Capture/Power Quality Analysis

mo des, o nly Fil ter on/ off is a vaila ble.

Range is selected automatically based

on the detection level (preset value for

Trigger/ Capture Recording). See Setting1

"SEt.1".

●

Se t tin g c hang e isn't a v ail a ble du ring

recording; setting should be done prior to

a recording.

mark me ans Ra n g e H o l d Func t i o n is

activated.

mark mea ns Aut o-rangi ng F unction is

activated.

5

. Wh en only t he le ftmost segment of the

Ba tte ry ma rk is f las hin g on th e LCD, it

means battery voltage is low.

Repl a c e t h e bat t e r i es wi t h new ones.

Wh en no thi ng is di spl aye d on the L CD,

the batteri es are exhaust ed. Replace the

batteries with new ones.

▼

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

15

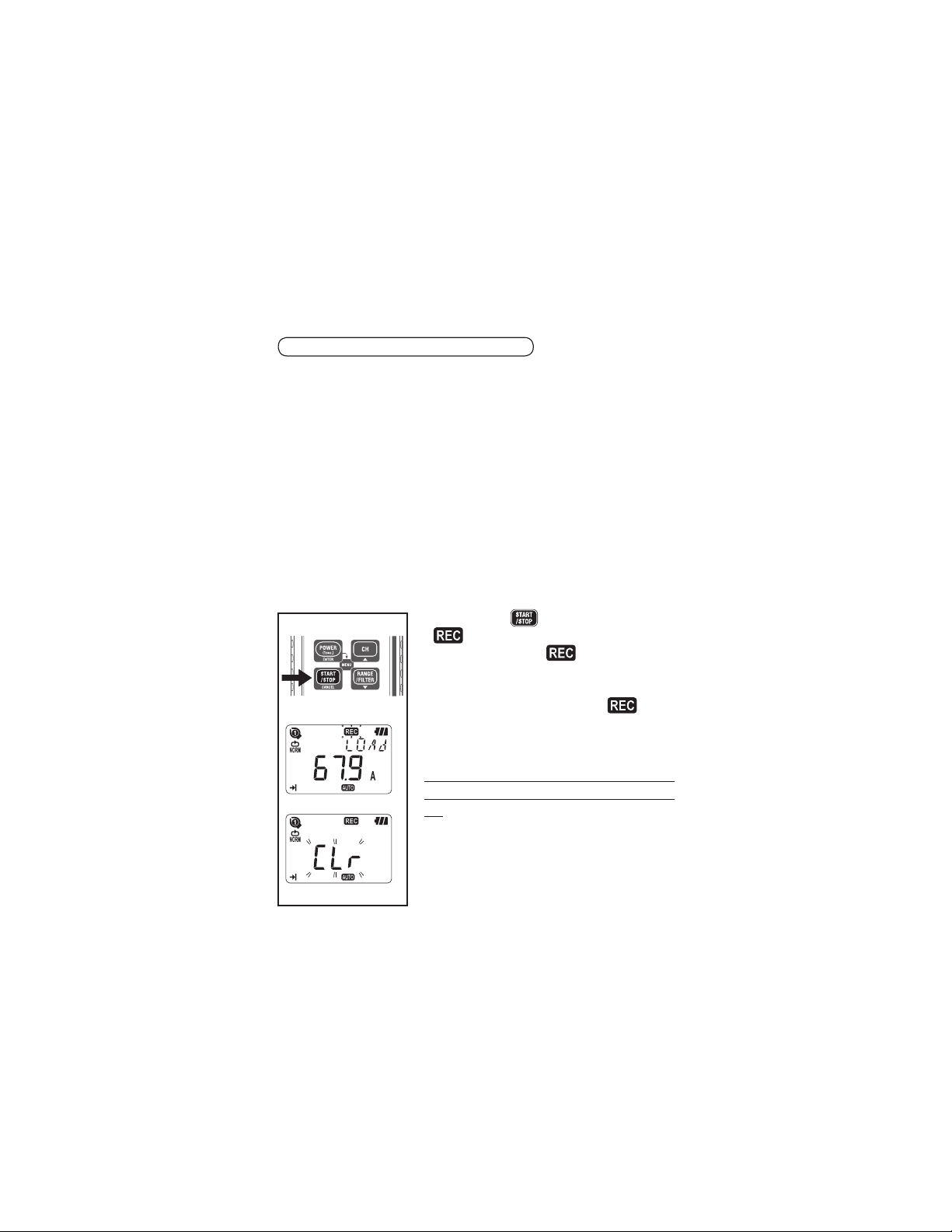

* Settings cannot be changed du ring recording. Ca reful ly check the

settings prior to a recording.

* Prev ious recorded d at a i s c leared and new recording starts when

changing the followings and starts recording. (In this case, "CLr" flashes on

the LCD at a start of recording.)

1) Recording mode is changed.

2) CH for Sensor is changed.

3) Sensor type is changed.

* Transfer important data to your PC first and clear Memory (P.33) since

further recording isn't activated when all the 3 blocks in Memory Block

(P.15) are full.

* Follow the procedure below to start recording.

1. Press down the

button at least 4 sec.

"

" or "CLr" mark flashes. Keep the button

pressed down until "

" mark lights up.

Recording stops when the button is released

while the mark is flashing.

2

. Measured value is displayed and "

" mark

lights up, then measurement starts.

◆

Additional three recordings (Memory Block /

see the next page) are possible.

In this case, one-time is automatically selected

and recording stops when memory becomes

full.

◆

It is recommended to clear the memory before

st arti ng to rec ord if pre viou s data i s not

necessary.

Step3: Preparation before recording

↓

or

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

16

Memory Block

◆

One memory block is used from the start to the end of recording.

◆

3 blocks in the Memory Block are available; it enables 3 different

recordings at different locations.

◆

Transfer important data to your PC first and clear Memory (Setting 2

or via PC) since further recording isn't activated when all the 3 blocks

in Memory Block are used.

◆

Settable Location No. at Setting 2 "SEt.2" is saved in the Memory

Block together with the measured data; and is useful to recognize the

location where the data recorded on your PC.

◆

At Trigger/ Capture/ Power Quality Analysis modes, zero is saved in

Memory Block even when no data is recorded from the start to the end

of recording.

Operation during recording

Following operations are available during recording.

◆

Displaying the measured value at each CH →

button

◆

Recording status : Displaying Max recorded valued & RECALL

Refer to 9. Confirmation of recorded data in this manual.

◆

Check of preset values at Setting 1"SEt.1" & Setting 2 "SEt.2".

Following operations aren't available during recording.

◆

Powering off the instrument

◆

Changing the measurement range.

◆

Change of preset values at Setting 1"SEt.1" & Setting 2 "SEt.2".

◆

Data communication with PC

Stop recording to do above operations.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

17

In case that One-time is set to "ON" at Step2: Confirmation and change of

preset value, recording is stopped automatically when Memory becomes

full.

1. Press the button at least 1 sec

to stop recording.

2. Recording stops, and the " " mark

di sap pea rs. T hen the i nst rum ent

goes back into measurement state.

Now, recording completes.

* Press the button at least 1 sec to power off the instrument.

* It is recommended to transfer the important data to a PC.

* The recorded data can be checked on the instrument.

(Refer to : 9. Confirmation of recorded data (CALL) in this manual)

Step5: Stop of recording

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

18

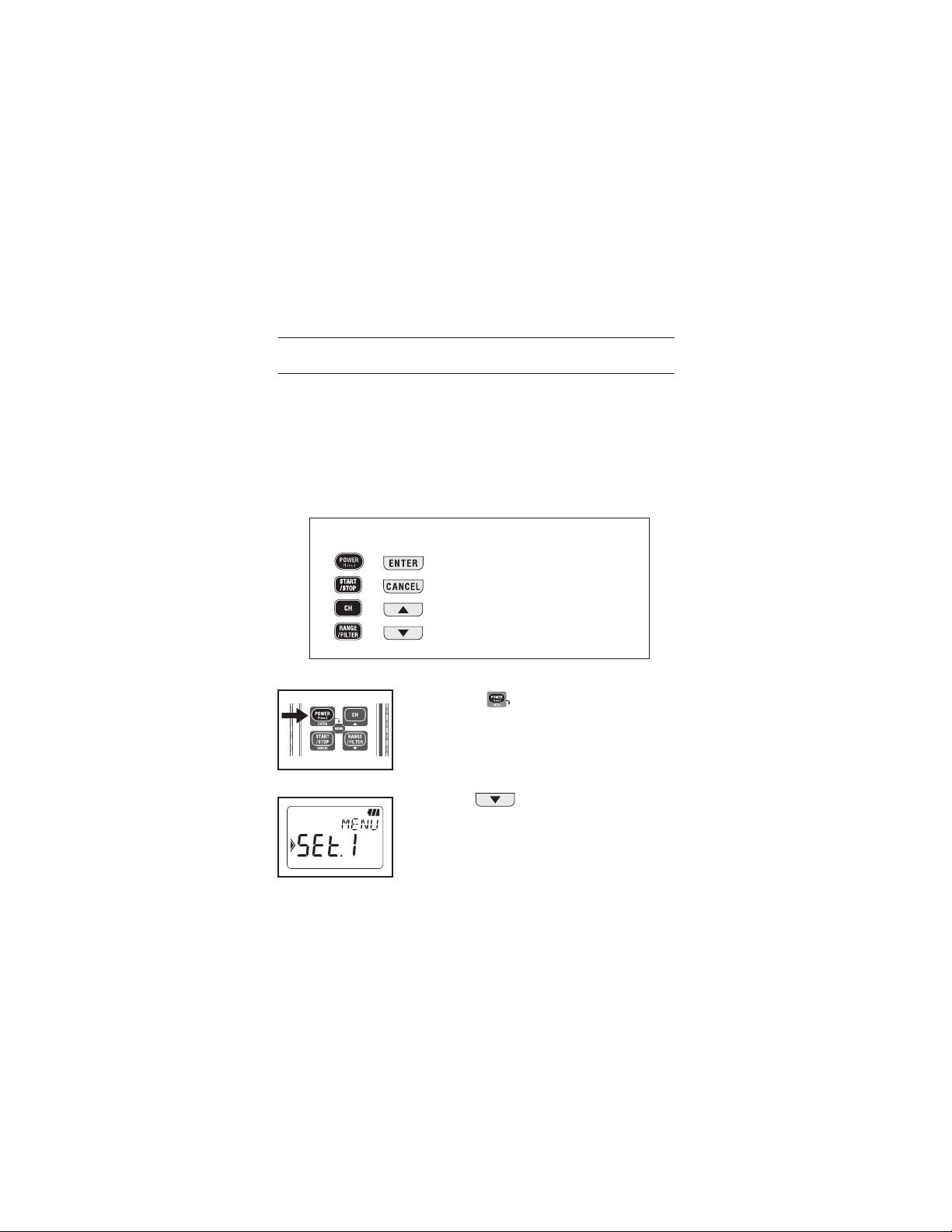

* Recording mode and condition can be set on the instrument ; but PC

software "KEW LOG Soft 2" provides much easier setting.

* Only Normal and Trigger Recording modes can be set on the instrument.

Capture recording and Power Quality Analysis modes need to be set via a

PC. (Recording condition for the Capture Recording mode is changeable

on the instrument.)

●

Setting on the instrument (Menu Mode)

1. Power on the instrument, and press the

button

to enter into Menu Mode.

2

. Select and set desirable recording mode and condition at "SEt.1 on the

Menu. Setting with the instrument is mentioned on the next page.

3. Press the button at "End" on Menu Screen or press the

button and exit from the Menu Screen to return measurement status.

5. Recording modes and conditions

Each button acts as follows at Menu mode.

→ : Select, Change, Enter

→ : Return, Cancel

→ : Switch, Increase values

→ : Switch, Decrease values

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

19

Normalrecordingmode:Recordingintervalof1min.

Max. number of recorded data

Max. recording duration

Setting items

*

Max recording time is dependent on battery life (approx 10-day with size

AA Alkaline battery) Use of optional AC Adopter is recommended for long

time recording.

Using all 3 channels Using 2 channels Using only 1 channel

20,000 data 30,000 data 60,000 data

Recording

interval

Using all 3 channels Using 2 channels Using only 1 channel

1 sec.

5:33:20 8:20:00 16:40:00

2 sec.

11:06:40 16:40:00 1 day / 9:20:00

5 sec.

1 day / 3:46:40 1 day /17:40:00 3 days/11:20:00

10 sec.

2 days/ 7:33:20 3 days/11:20:00 6 days/22:40:00

15 sec.

3 days/11:20:00 5 days/ 5:00:00 10 days/10:00:00

20 sec.

4 days/15:06:40 6 days/22:40:00 13 days/21:20:00

30 sec.

6 days/22:40:00 10 days/10:00:00 20 days/20:00:00

1 min.

13 days/21:20:00 20 days/20:00:00 41 days/16:00:00

2 min.

27 days/18:40:00 41 days/16:00:00 83 days/ 8:00:00

5 min.

69 days/10:40:00 104 days/ 4:00:00 208 days/ 8:00:00

10 min.

138 days/21:20:00 208 days/ 8:00:00 416 days/16:00:00

15 min.

208 days/ 8:00:00 260 days/10:00:00 520 days/ 0:00:00

20 min.

277 days/18:40:00 416 days/16:00:00 833 days/ 8:00:00

30 min.

416 days/16:00:00 625 days/ 0:00:00 1250 days/ 0:00:00

60 min. 833 days/ 8:00:00 1250 days/ 8:00:00 2500 days/ 0:00:00

Item Range for Setting Default

Recording interval

1,2,5,10,15,20,30 sec,

1,2,5,10,15,20,30,60min

1 min

One-time/ Endless One-time/ Endless Endless

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

20

Setting procedure

1. Power o n the instrum en t, and press t he

button. Then the instrument enters into

Menu mode.

2. Press the button when "SEt.1" is

displayed on the LCD.

3. Selected recording mode is displayed.

◆ When (Normal recording mode) is

displayed on the LCD, press the

button to proceed to the next setting.

◆ In ca s e th at , or is

displayed on the LCD, press the

button. Then the indication on the LCD

flashes.

Press t he or butto n to

ch ange it to

. Press th e

button.

▼

▼

▼

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

21

4. Then recording interval is displayed.

Can be selected from; 1, 2, 5, 10, 15, 20, 30 sec.,

1, 2, 5, 10, 15, 20, 30, 60 min

◆

Press the button and proceed to the

next step when not changing the setting.

◆

To change the setting, press the

bu tton. T hen the i ndi catio n on th e LCD

flashes.

Press the or button to set

the value to the desired one. Then press the

button to confirm it.

5. Next, One-time/ Endless is indicated.

One-time: Re cordi ng s top s whe n mem ory

becomes full.

Endless : Overwrite the old data, and store

the latest data.

◆

Press the button and proceed to the

next step when not changing the setting.

◆

To change the setting, press the

bu tton. T hen the i ndi catio n on th e LCD

flashes.

Press the or button to set

the value to the desired one. Then press the

button to confirm it.

6. Now Setting 1 is complete; "End" is displayed on

the LCD. Press the button to return to

the screen on which "SEt.1" is displayed.

7. Press the button to get the instrument

ready for a measurement.

▼

▼

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

22

Max. number of recorded data

Setting items

Setting procedure

Using all 3 channels Using 2 channels Using only 1 channel

1,600 data 2,400 data 4,800 data

Item Range for Setting

Default

CH1 Detection Level

0 ~ 1000 (Unit depends on Sensor)

15

CH2 Detection Level

0 ~ 1000 (Unit depends on Sensor)

15

CH3 Detection Level

0 ~ 1000 (Unit depends on Sensor)

15

One-time/ Endless

One-time/ Endless

Endless

▼

▼

Triggerrecordingmode:Currentsetvalueof15A

1. Connect a Sensor first prior to do setting.

When Sensor is not connected to the instrument

at setting, connect a Sensor, and then power

off once and on the instrument.

2. Press the button while instrument is on to

enter into Menu mode.

3. Pre ss th e but t o n wh e n "S E t .1" is

displayed on the LCD.

4. The selected recording mode is displayed.

◆

Wh en (Trig ger r eco rdi ng mod e) is

di splay ed o n the LCD , press the

button to proceed to the next setting.

◆

In case that

, or is displayed

on the LCD, press the button. Then

the indication on the LCD flashes. Press the

o r b utt on to ch ang e it to

. Press the button.

▼

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

23

5. Detection level at CH1 is indicated.

Can be set at every 1 from 0 to 1000

◆

To change the setting, press the button.

Then the indication on the LCD flashes.

◆

Press the or button to set the

value to the desired one. Then press the

button to confirm it.

◆

When using Leakage Current Sensor, pressing

the button at 1000m A in d i c a t i o n

changes to 2A, pressing the button at

2A indication changes to 1000mA (1A)

Point

Further detection doesn't start when a value falls

to 50% or less (for voltage sensor: 1% or more)

of the detected level. Set the appropriate value

based on the test prior to recording.

6. Confirm or change the preset current value on

channel 2 and 3 as well.

7. Next, One-time/ Endless is indicated.

One-time: Re cording s top s w hen m emor y

becomes full.

Endless : Overwrite the old data, and store

the latest data.

◆

Press the button and proceed to the

next step when not changing the setting.

◆

To change the setting, press the button.

Then the indication on the LCD flashes.

Pr ess th e or b utto n to set

the value to the desired one. Then press the

button to confirm it.

▼

▼

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

24

8. Now Setting 1 is completed; "End" is displayed on

the LCD. Press the button to return to the

screen on which "SEt.1" is displayed.

9.

Press the

button to get the instrument ready

for a measurement.

Max number of recorded data

* Setting is available only on PC.

Using only 1 channel

345 data

Setting item

Max number of recorded data

* Setting is available only on PC.

Using only 1 channel

4000 data

Setting item

Capturerecordingmode:(SettingonPC)

PowerQualityAnalysis[only5020](SettingonPC)

Item Range for Setting Default

CH1 Detection Level 0 ~ 1000 15

One-time/ Endless One-time/ Endless Endless

Item

Range for Setting

Default

Reference Voltage (System Supply Voltage) 100V〜500V 100V

Swell Detection (Ratio against Reference Voltage)

100%〜200% 110% (110V)

Dip Detection (Ratio against Reference Voltage)

0%〜100% 90% (90V)

Short Interruption Detection

(Ratio against Reference Voltage)

0%〜100% 10% (10V)

Hysteresis (Ratio against Reference Voltage)

0%〜10% 1% (1V)

One-time/ Endless

One-time/ Endless

Endless

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

25

List of recording modes

6. Recording modes

Recoding mode

Normal

Recording

Trigger

Recording

Capture

recording

Power

QualityAnalysis

Details P.26 P.27 P.29 P.30

Application

Status/

Simplified

power monitor

Detection

of abnormal

curr

ent/

voltage

Check of

waveform

Detection of

abnormal voltage

variation(only

5020)

Can record:

60,000 data (1ch)

20,000 data (3ch)

4,800 data (1ch)

1,600 data (3ch)

345 data 4,000 data

Available CH 3 channels at the same time 1 channel only

Recording

Interval

15-kind: 1 sec. to

60 min.

−

Detection

Level

−

0

~ 1000 (Unit depends on Sensor)

RMS measuring

interval

Approx. at every 0.1 sec.

Sampling

Cycle

Appr

ox. 1.65mS/CH

Detection:

Approx. 0.55mS/

WaveformApprox.

1.1mS

Approx.

0.55mS

Sampling

Period

Always

Constantly until curr

ent

detection

Always

Record

timing

At every

interval

When the pr

eset detection value is

exceeded.(irregular)

Measuringmethod

True RMS

Detection: Average value/ (convert the Peak

value (sine) to RMS)

Recording, Indication: True RMS

One-time

system

One-time: Recor

ding stops when memory becomes full.

Endless: Overwrite the old data, and store the latest data.

Battery Life Approx. 10days

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

26

1. Normal Recording mode

●

Sampling period and RMS calculation

Sampling the inputs at every 1.6ms/CH and calculate the measured

value (RMS) at every 100ms. The Peak value (crest value in sampling

data) will be updated and kept.

●

Recor

ding

Average of the measured value is recorded at every recording interval.

RMS measured values, Max, Min and Peak values (sampled crest

value converted to sine RMS value) are recorded at every 10 times of

recording.

●

Display of measured value

Average of RMS value is displayed on the LCD at every 1 sec.

(10 data)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

27

2. Trigger Recording mode

●

Detection and RMS value calculation

Sampling the inputs at every 1.6ms and comparing the Peak value

(sampled crest value converted to sine RMS value) and Detection level.

For current, when the Peak value exceeds the level and for voltage

when the Peak value is below the level; detection is triggered. RMS

value is calculated at every 100ms.

●

Recording

When the Detection level is exceeded, 8 data (for about 0.8 sec)

Including:

-

3 RMS values prior to the cross over point

- RMS value at the cross over point

- 4 RMS values subsequent to the cross over point

are recorded with time information. In case that events exceeding the

Detection level occur continuously, next detection doesn't start until it

drops to 50% or less of the detected value.

(for voltage, 5% or more than the detected value)

●

Display of measured value

Average of RMS value is displayed on the LCD at every 1 sec.

(10 data)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

28

◆

Flashing Detection LED

●

LED on the Sensor connected channel blinks when following Trigger

is detected.

<On KEW5010> Trigger is detected when the measured values

exceed the pre-set detection level under Trigger/ Capture Recording

Mode.

<On KEW5020> Trigger is detected when the measured current

values exceed the pre-set detection level under Trigger/ Capture

Recording Mode and Power Quality Analysis Mode.

For volt age value s, Trigge r is det ected whe n it is b elow the

detection level.

●

LED flashes whenever the measured values exceed the pre-set

detection level during measurements.

●

LED blin ks ever y 4 sec during recordings after one de tection

occurs. (When Auto-power off is OFF, it blinks every 2 sec.)

●

To restore the blinking LED during recordings, first press the

button once and enters into Menu mode. Then press the

button to return Measurement mode.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

29

3. Capture Recording mode

●

Detection and RMS value calculation

Sampling the inputs at every 0.55ms only at CH1 and comparing the

Peak value (sampled crest value converted to sine RMS value) and

Detection level. For current, when the Peak value exceeds the level

and for voltage when the Peak value is below the level; detection is

triggered. RMS value is calculated at every 100ms.

●

Recor

ding

When the preset current value is exceeded, instantaneous values

with corresponding time information are recorded for 200ms ( 10 or

12 waveforms) including 50ms prior to and subsequent to the cross

over point. In case that events exceeding the Detection level occur

continuously, next detection doesn't start until it drops to 50% or less

of the detected value. (for voltage, 5% or more than the detected

value)

●

Display of measur

ed value

Average of RMS value is displayed on the LCD at every 1 sec.

(10 data)

(Waveform display is only available on PC. Use the enclosed Software

and transfer the data to your PC.)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

30

4. Power Quality Analysis Mode (only 5020)

●

Detection and RMS value calculation

Sampling the inputs at every 0.55ms only at CH1 and comparing the

Peak value (sampled crest value converted to sine RMS value) at every

10ms and preset value to detect swell, dip and short interruption in

power supply. RMS value is calculated at every 100ms.

●

Recor

ding

When swell, dip or short interruption is detected, the detected value is

recorded as Start (S) with time and date information.

In case that a input becomes c lose to th e reference volt age by

hy steresi s value , it i s recorde d as E nd ( E) w ith tim e and dat e

information.

●

Display of measur

ed value

Average of RMS value is displayed on the LCD at every 1 sec.

(10 data)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

31

The PC software "KEW LOG Soft 2" provides easy calculation of integral

power consumption by use of current and voltage (only on KEW5020)

recorded under Normal Recording mode.

●

On KEW 5010, measures and records current values, and then enter

any voltage value and power factor on "KEW LOG Soft 2" to calculate

simplified power consumption.

●

On KEW 5020, simplified power calculation is available by using Voltage

and Current Sensors; apply any power factor to the recorded voltage and

current values via "KEW LOG Soft 2".

Calculation with any voltage value as same as KEW5010 is also possible.

Example of Connection

◆

Single-phase 2-wire (1Φ2W)

Model Name CH1 CH2 CH3

KEW LOG Soft2

Fixed parameters

KEW

5010 A -

-- --- Voltage value, Power factor

KEW 5020

A -

-- --- Voltage value, Power factor

V A -

-- Power factor

* Can be connected with 3 systems via each channel (1 through3).

7

. Simplified Power Integration

(available via KEW LOG Soft 2)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

32

◆

Single-phase 3-wire (1Φ3W)

Model

Name

CH1 CH2 CH3

KEW LOG Soft2

Fixed parameters

KEW

5010 A1 A2 --- Voltage value, Power factor

KEW 5020

A1 A2 --- Voltage value, Power factor

V A

1 A2 Power factor

◆

Three-phase 3-wire (3Φ3W)

General formula is: P=V×(A1×cos(30°-

Φ

1)+A2×cos(30°+Φ2)),

however, here Φ1=Φ2 is applied.

Therefore: P = √3/2×V×(A1+ A2)×PF

Model

Name

CH1 CH2 CH3

KEW LOG Soft2

Fixed parameters

KEW

5010 A1 A2 --- Voltage value, Power factor

KEW 5020

A1 A2 --- Voltage value, Power factor

V A

1 A2 Power factor

L1

N

L2

A1V A2

SOURCE LOAD

SURCE LOAD

L1

L2

L3

A1V A2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

33

◆

Three-phase 4-wire (3Φ4W)

Model

Name

CH1 CH2 CH3

KEW LOG Soft2

Fixed parameters

KEW

5010 A1 A2 A3 Voltage value, Power factor

KEW 5020 A1 A2 A3 Voltage value, Power factor

* Refer to "KEW LOG Soft 2- HELP" how to operate KEW LOG Soft 2.

The latest "KEW LOG Soft 2" can be downloaded from our web site.

http://www.kew-ltd.co.jp

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

34

●

Recording mode and condition can be set on the instrument; but PC

software "KEW LOG Soft 2" provides much easier setting.

●

Time setting for Year, Month, D ay, Hour, Minute a nd Second is

available on PC, but setting for Hour and Minute only are available on

the instrument.

Menu Setting 2: "SEt.2" Setting items

1) Location information [Default:000]

Set the location no. to identify the measuring and recording place.

2) Auto-power-off

[Default:000]

Enable/ Disable the Auto-power-off function.

3) Time

Capable of adjusting the time between 00:00 and 23:59.

4) Timer

[Default:OFF]

Display and set the timer.

5) Memory Clear

Clear all the recorded data.

8. Other settings (Setting2)

Each button acts as follows at Menu mode.

→ : Select, Change, Enter

→ : Return, Cancel

→ : Switch, Increase values

→ : Switch, Decrease values

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

35

Setting procedure

1. Power on the instrumen t, and press the

button.

2. Press the button when "SEt.1" is displayed

on the LCD.

3. Press the button when "SEt.2" is displayed

on the LCD.

4. "Location information":

Location No. is displayed on the LCD.

Can be selected between "P.000" and "P.999".

◆ Press the button and proceed to the

next step (Auto-power-off) when not changing

the setting.

◆ To chan g e t h e se tting , p ress the

button.

Then the indication on the LCD flashes. Press

the or button to set the value

to the desired one. Then press the

button to confirm it.

Point

● Preset Location No. is saved with a recorded

da ta (1 M emo ry Blo c k). W hen p erfo rmin g

▼

▼

▼

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

36

additional recordings (up to 3 Memory Blocks),

it is recommended to set each Location No.

in advance. It is useful to identify the recorded

locations per Memory Block.

● Location No. is linked to the Location list and

allows to display the Locatio n n ame, whic h

co rre spo ndin g to the Lo cat ion No ., whe n

displaying data on PC Software.

● In ca s e of se t t i ng Loc a t i o n no . on the

instrument, it is recommended to take notes of

the Location No. and the name.

5. "Auto-power-off":

State of Auto-power-off function is displayed.

On : Enables Auto-power-off function.

OFF : Disables Auto-power-off function.

◆

Press the button and proceed to the

next step (Time) when not changing the setting.

◆

To change the setting, press the button.

Then the indication on the LCD flashes. Press

the or button to set the value to

the desired one. Then press the button

to confirm it.

Point

"

" ma rk ap pea rs on the L CD wh en th is

Function is "OFF". Power off the instrument after

use. Instrument powers off about 3 min after the

last Key operation when the Function is "ON".

LCD indication disappears during recording due

to Power Save Function while recording is being

performed.

▼

▼

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

37

6. "Time": Time is displayed.

Can be adjusted between "00:00" and "23:59".

◆

Press the

button and proceed to the

next step (Timer) when not changing the setting.

◆

To change the setting, press the

button.

Then the indication on the LCD flashes.

Press the

or button to set the

value to the desired one. Then press the

button to confirm it.

Point

Connect the instrument to PC and set time and

date via PC software : "KEW LOG Soft 2".

7. "Timer": State of Timer function is displayed.

Can be set between "00:00" and "23:59".

◆

Press the button and proceed to the

next step (Memory Clear) when not changing the

setting.

◆

To change the setting, press the button.

Then the indication on the LCD flashes.

Pr ess th e or b utto n to se t

the value to the desired one. Then press the

button to confirm it.

Point

Press the button at least 1 sec.

after setting Timer. Then the instrument goes into

stand-by mode for recording.

Recording starts at the preset time.

▼

▼

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 41

38

8. "Memory Clear": Clear the recorded data.

◆

Press the button to end Setting 2 when

you don't clear the Memory.

◆

Pressi n g th e b u tton fla s h e s th e

indication on the LCD.

Recorded data isn 't deleted by pressing the

button, while "no" is displayed on the

LCD. Press the button to change the

indication to "CLr", and then press the

button to clear the recorded data. Message "O

DATA" is indicated and back to "CLr" indication

when data is cleared.

9. Now Setting 2 is completed; "End" is displayed on

the LCD. Press the button to return the

screen on which "SEt.2" is displayed.

10. Press the button to get the instrument

ready for a measurement.

▼

▼

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

39

1. Pressing the Button during recording enters

into Menu mode.

2

. Press the

Button twice while "SEt.1" is

displayed on the LCD.

*

"CALL" is displayed on the LCD while recording

is being performed. Proceed to the next.

9. Confirmation of recorded data (CALL)

Details of data in the present Memory Block can be viewed during

recording and when recording is completed.

◆

Display of percentage of recorded data against memory capacity.

◆

Capable of checking max, min, instant Peak/ Detection value at

each channel with time & date information.

◆

RE C ALL: c a n ch eck th e l ates t 10 data wi t h time and da t e

information.

▼

▼

Each button acts as follows at Menu mode.

→ : Select, Change, Enter

→ : Return, Cancel

→ : Switch, Increase values

→ : Switch, Decrease values

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

40

3. Press the Button while "CALL" is displayed

on the LCD.

4

. Check of <Recorded qty.>

Percentage of recorded data agains t memory

capacity is displayed.

* Memory block with recorded data is indicated

by the Marks:

❶❷❸

. When all 3 marks are lit

up, all the Memory blocks are used. Transfer the

important data to a PC and clear the Memory to

perform next recording.

Pressing the

Button proceeds to the

next.

5

. Display of the number of the recorded data at

CH1/ the number of detected current & voltage

data in case of Trigger Recording mode.

◆

Pressing

Button moves to CH2.

◆

Press the

Butt on to ch eck max, min

and peak values on CH1 with time and date

inform at ion. See P.42 <<MAX, MIN , Instant

PEAK/ detected value>>.

◆

Pre ss the

Button un til the indi cation

becomes "5:RCL" for RECALL and proceed to

step 8.

▼

▼

▼

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

41

6. Display of the number of the recorded data at

CH2/ the number of detected current & voltage

data in case of Trigger Recording mode.

Pressing the Button moves to CH3.

◆

Pr ess th e Butto n to ch eck ma x ,

mi n a n d pe ak valu e s wi th time an d d a te

information. See P.42 <<MAX, MIN, Instant

PEAK/ detected value>>.

7. Display of the number of the recorded data at

CH3/ the number of detected current & voltage

data in case of Trigger Recording Mode.

Pressing the Button moves to "RECALL".

◆

Pre s s t h e Bu t ton to check ma x ,

mi n a n d pe ak valu e s wi th time an d d a te

information. See P.42 <<MAX, MIN, Instant

PEAK/ detected value>>.

8. <RECALL> checks the latest 10 recorded data.

Press the But ton to c heck the late st

recorded data and preceding 9 data, [R01] to

[R10]. Refer to P.42 <<RECALL>>

9. That's all for CALL Function to call the recorded

da ta. Pre ssi ng t he B utt on retu rns t o

the window with "CALL" message; pressing the

Button closes Menu mode and gets ready

for measurement.

▼

▼

▼

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 45

42

*

Pressing the Button changes the information

about the selected channel in following sequence.

MAX「Mon.Day'Year

」→「

Time:Min'Sec"

」→「

Max」→MIN

「

Mon.Day'Year

」→「

Time:Min'Sec"

」→「

Min

」→

Instant Peak/Detected value「Mon.Day'Year

」→

「

Time:Min'Sec"

」→「

Instant Peak/Detected value

」

◆

Indication of 「- - - -」 stands for no data at the

selected channel.

◆

P

ressing the Button returns to the window

with "Number of data".

<<Reference of MAX, MIN, Instant PEAK/ Detected value>>

* Pressing the Button can check

「

Mon.Day'Year

」 →「

Time:Min'Sec"

」 →「

CH1

Data

」→「

CH2 Data

」→「

CH3 Data」 from R01

to the latter data. Pressing the Button

afte r displa ying 「CH3 Data」 dis pl ays data i n

「

R02」. Repeat this step to check the latest data

「

R10」.

◆

Indication of 「- - - -」 stands for no data at the

selected channel.

◆

Pressi ng t he

But ton retur ns t o the

window with 【CALL】.

<<Reference of RECALL>>

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 46

10. Data transfer to PC

●

Install PC software "KEW LOG Soft 2" on your PC to enable data

communication between the instrument and your PC. Refer to the

HELP contained in "KEW LOG Soft 2" which shows how to install the

software. It will be on the Desktop after installing the software, or

found in the folder of "KEW" from "Start" → "Program".

●

When connecting the logger to PC for the first time, your PC will

recognize this new hardware and install the USB driver.

Follow the instructions described in the instruction manual for "KEW

LOG Soft 2" and install it on your PC.

10-1 Connection of USB cable

(1) Connect the USB cable to the available USB port of PC.

(2) Connect the other end of USB cable to the USB terminal on the

right side of this instrument.

Note:

Remove the protective cover

of USB terminal carefully, and

connect a cable to it. When the

cover is damaged, it may cause

poor contact due to dust, etc.

43

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 47

44

10-2 Preparation for data transmission

(1) Power on the instrument, and get the instrument ready for a

measurement.

( No te: Data can not be tr ansfe rred whil e the ins tru ment is

performing a recording.)

(2) Start up the PC software: KEW LOG Soft 2.

10-3 Operation of PC software

Refer to the supplied instruction manual for "KEW LOG Soft 2" or

"Help" and transfer the data to your PC. The PC may not detect

the connected Logger or error message is displayed during data

transfer, even if the PC and the Logger are connected correctly

because of static electricity.

In this case, a message is displayed on the PC screen. Disconnect/

connect the USB cable once accordingly, and transfer the data

again.

10-4 Multiple connections

By using commercially available USB hub, multiple Loggers can be

connected to your PC.

◆

With PC software "KEW LOG Soft 2", the data can be transferred

to PC by selecting one Logger from the list of detected Logger.

You do not have to connect and disconnect a USB cable one by

one.

◆

Synchronization via 「KEW LOG Soft 2」 enables synchronized time

setting on multiple LOGGERs at once.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 48

45

WARNING

In order to avoid electrical shock, remove sensors from the instrument

when replacing batteries.

CAUTION

Do not mix new and old batteries.

In st all bat terie s in the ori entat ion as s hown i nside the bat te ry

compartment, observing correct polarity.

When only the leftmost segment of the Battery mark is flashing

on the LCD, it means battery voltage is low. Replace the batteries with

new ones. There is no influence on the measurement accuracy even

if this warning mark is flashing. Nothing even the Battery mark is

displayed on the LCD if the batteries are completely exhausted.

Replace the batteries with new ones.

(1) Loosen two Battery-cover -fixing

screws on the backside of the

instrume n t an d re m o v e the

cover.

(2) Replace the batteries with new

ones.

(Battery : Alkaline, LR6, 1.5V)

(3) Instal l the Bat te ry cover, and

tighten up the screws.

11. Battery replacement

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 49

46

1) Auto-power off Function

LOGGER is automatically powered off in about 3 min after the last

key operation while Auto-power off Function is "ON" at Setting 2. This

function doesn't work during recording (LCD with

mark) although

readings aren't displayed on the LCD due to Power-saving Function.

In case of using an external power supply for making measurement,

disable the Auto-power off Function. Then long period measurement is

possible. (Be sure to power off the LOGEER after use.)

2) External power supply AC Adopter (optional)

WARNING

Use MODEL 8320 (S-8458 or TAS2903 AC Adopter made by KAGA

COMPONENTS co) only.

Use the Power cord supplied with the AC Adopter.

Confirm

the voltage of power supply and the rated voltage of the AC

Adopter, and then connect the Power Cord.

Disconnect the Power cord of the AC Adopter from the outlet when the

LOGGER isn't used for a long period.

Do not put any heating object or others on the AC Adopter or Power

Cord.

Hold the Plug part (other than cord) when disconnecting the Power

Cord from the outlet in order to prevent a break in the cord.

Specification of AC Adopter

Rated supply voltage, Frequency : AC100V / 240V,50/60Hz

Supply voltage, Range of Frequency variation

: 90~264VAC,45~66Hz

Rated output voltage of AC Adopter

: DC9.0V

Rated max Output curr

ent of AC Adopter : 1.4A

Use the optional AC Adopter for long period recordings. Installing batteries

in the Case located at the backside of the unit provides power at temporary

electricity failure. Be sure to check the battery level in advance.

Battery mark with full level will be displayed while using the AC Adaptor.

Disconnect the Adaptor to check the battery voltage level.

12.

Auto-power off Function & External Power Supply

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 50

47

When defect or breakdown of the instrument is suspected, check the

following points first. If your problem isn't listed in this section, contact your

local Kyoritsu distributor.

Symptom / Check

1. Unable to measure.(

is displayed.)

Check if a sensor is connected to the pr

operly.

Insert the sensor into the connector terminal firmly.

KEW 5010 doesn't recognize the voltage Sensor

2. Unable to measure. (

is displayed.)

Sensor

other than Voltage Sensor may be connected to CH1 under

the setting for Power Quality Analysis mode for KEW 5020.

Only the Voltage Sensor can be used under Power Quality Analysis

mode.

3

. Inaccurate readings

Check

if a clamp sensor is connected properly.Insert the sensor into

the connector terminal firmly.

Check if the jaws are closed properly.

Check if an object stick to the jaw tips.

4

. Nothiing is displayed in the LCD

5. Battery symbol is blinked in the LCD.

6. The readings fluctuate.

Check the battery voltage.

If the voltage is low

, replace the batteries.

13. Troubleshooting

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 51

48

7. When the logger is connected to the PC using the USB cable, the

logger connected is not detected in the logger list.

Check if the USB cable is connected corr

ectly.

Check if the USB driver is installed.

Check if the USB driver is failed to be installed on the PC.

If the installation is failed, firstly delete the USB driver installed and

re-install it according to the procedure stated in the USB Notice sheet

or Install Manual.

8

. When installing the USB driver with the hardware Windows XP, the

following remark appears.

"The softwar

e you are installing for this hardware:

KEW LOGGER 5010/5020 has not passed Windows Logo testing to

verify its compatibility with Windows XP."

Click "Continue Anyway" to continue the installation.

As operation check was done, no problem shall happen.

(Windowsis a registered trademark of Microsoft of the United Sates.)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 52

49

14. Specification

Measuring Range and Accuracy

<RMS accuracy>

(

AC 50/60Hz,Sine wave, Input: 10% or more of the range at CH1)

Range

KEW 8146 (30A) :100.0mA/1000mA/10.00A/30.0A

KEW 8147 (70A) :100.0mA/1000mA/10.00A/70.0A

KEW 8148 (100A) :100.0mA/1000mA/10.00A/100.0A

KEW 8121 (100A) :10.00/100.0A

KEW 8122 (500A) :50.00/500.0A

KEW 8123 (1000A) :100.0/1000A

KEW 8309 (600V) :600.0V (only 5020)

Digit number

4-digit

Effective

InputRange

0

% ~ 100% of each Range

Display Range

0% ~ 105% of each Range (OL is displayed over 105%.)

Accuracy

100

.0mA Range: ±2.0%rdg±0.9%f.s. + Accuracy of Sensor

Other ranges : ±1.5%rdg±0.7%f.s. + Accuracy of Sensor

Crest

Factor

2

.5 or less :RMS accuracy (sine) + 2%rdg+1%f.s.

(95% or less of each Range)

<Accuracy at Trigger Recording Mode (AC 50/60Hz sine wave)

Accuracy

100.0mA Range: ±3.5%rdg±2.2%f.s. + Accuracy of Sensor

Other ranges : ±3.0%rdg±2.0%f.s. + Accuracy of Sensor

<Accuracy at Capture/ Power Quality Analysis mode>

<Accuracy of instantaneous value at Capture Recording mode>

Accuracy

100.0mA Range: ±3.0%rdg±1.7%f.s. + Accuracy of Sensor

Other ranges : ±2.5%rdg±1.5%f.s. + Accuracy of Sensor

NOTE:

- Refer to the Instruction Manual attached to the Sensor for the specification of each

Sensor.

- Electromagnetic compatibility(EMC)

EN61000-4-2 Electrostatic discharge immunity(ESD) / Performance criteria: B

- Max, Min and Instant Peak values in Normal Recording mode are just reference

values; their accuracies aren't guaranteed.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 53

50

Operating system : Successive Approximation

(CH1 single synchronized sampling)

Rated max. working voltage : AC9.9Vrms, 14V peak value

Number of input channel

: 3ch

Measuring method

: True RMS

RMS measuring interval

: approx. 100ms.

Sampling interval

Normal/T

rigger mode : approx. 1.65ms/CH

Capture mode : approx. 0.55ms (waveform: at every 1.1ms)

P.Q.A mode : approx. 0.55ms

Display : Liquid crystal display

Low battery warning

: Battery mark display (in 4 levels)

Over-range indication

: "OL" mark is displayed when exceeding the

measuring range.

Auto power off : Power-off function operates automatically after

a switch remains for 3min. (when recording is

stopped)

Location for use

: Indoor use, Altitude up to 2000m

T

emperature & humidity range(guaranteed accuracy):

23℃±5℃ / Relative humidity 85% or less (no

condensation)

Operating temperatur

e & humidity range:

-10℃~50℃ / Relative humidity 85% or less (no

condensation)

Storage temperatur

e & humidity range:

-20℃~60℃ / Relative humidity 85% or less (no

condensation)

Battery : DC

6V: Alkaline battery(LR6) x 4pcs

External supply DC9V (Special AC Adapter)

Current consumption : approx. 10mA

Possible measurement time

: Approx.10days (with alkaline LR6 batteries)

Applicable standar

ds : IEC 61010- 1:2001 CAT I I I 300V Po l l u t i o n

degree2

IEC 61326 (EMC standard)

Overload pr

otection : 120%MAX/ 10sec of rated current/ voltage of

each Sensor

Withstand voltage : AC3540V (RMS 50/60Hz)/ for 5sec.

Insulation r

esistance : 50Mohm or more / 1000V

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 54

51

Dimension : 111(H) x 60(W) x 42(D)mm

W

eight : Approx.265g

Accessories

: Alkaline battery LR6 x 4pcs

PC software "KEW LOG Soft 2 : 1pce

USB cable: 1pce., Carrying case

Instruction manual, Quick manual

Install manual, USB Notice sheet

Option Leakage & Load curr

ent Clamp Sensor

(KEW 8146/8147/8148)

Load current Sensor (KEW 8121/8122/8123)

Voltage Sensor (KEW 8309) [only KEW5020]

AC Adapter (M- 8320)

Carrying Bug (M-9135)

Extension cord for sensor (M-7185)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...