Page 1

KM-4530/5530

SERVICE

MANUAL

Published in Apr.’02

2BC70761

Revision 1

Page 2

CAUTION

DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY REPLACED. REPLACE ONLY WITH

THE SAME OR EQUIVALENT TYPE RECOMMENDED BY THE MANUFACTURER. DISPOSE OF

USED BATTERIES ACCORDING TO THE MANUFACTURER’S INSTRUCTIONS.

ATTENTION

IL Y A DANGER D’EXPLOSION S’IL Y A REMPLACEMENT INCORRECT DE LA BATTERIE.

REMPLACER UNIQUEMENT AVEC UNE BATTERIE DU MÊME TYPE OU D’UN TYPE RECOMMANDÉ PAR LE CONSTRUCTEUR. METTRE AU RÉBUT LES BATTERIES USAGÉES

CONFORMÉMENT AUX INSTRUCTIONS DU FABRICANT.

Page 3

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Page 4

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING:Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION:Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the copier.

Page 5

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. ............................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. .............................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .....

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. ..............

• Do not install the copier near a radiator, heater, other heat source or near flammable material.

This may cause fire. ..........................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ..........

• Always handle the machine by the correct locations when moving it. ..............................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may

cause the copier to move unexpectedly or topple, leading to injury..................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is

accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention

immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain

medical attention. ..............................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. ........................................................................................................................

Page 6

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly...............

• Always follow the procedures for maintenance described in the service manual and other related

brochures. .........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety

mechanisms and protective circuits. .................................................................................................

• Always use parts having the correct specifications...........................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related

brochure when replacing them. Using a piece of wire, for example, could lead to fire or other

serious accident. ...............................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ...............................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. ............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If

it is dirty, clean it to remove the risk of fire or electric shock. ............................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ..............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause

electric shock if handled improperly. .................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections...........................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. .......

• Handle the fixing section with care to avoid burns as it can be extremely hot. .................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures...........................................................................................................

• Do not remove the ozone filter, if any, from the copier except for routine replacement....................

Page 7

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ......................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ..............................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks........

• Remove toner completely from electronic components. ...................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ...................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten

connector, trapped wire and missing screws. ..................................................................................

• Check that all the caution labels that should be present on the machine according to the

instruction handbook are clean and not peeling. Replace with new ones if necessary. ...................

• Handle greases and solvents with care by following the instructions below: ....................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the main

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc...........................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet

immediately. ......................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than

the specified refiner; it may generate toxic gas. ................................................................................

Page 8

CONTENTS

1-1 Specifications

1-1-1 Specifications ........................................................................................................................................ 1-1-1

1-1-2 Parts names and their functions ............................................................................................................ 1-1-5

(1) Copier .............................................................................................................................................. 1-1-5

(2) Operation panel ............................................................................................................................... 1-1-6

1-1-3 Machine cross section ........................................................................................................................... 1-1-7

1-1-4 Drive system ......................................................................................................................................... 1-1-8

(1) Drive system 1 (optical section) ....................................................................................................... 1-1-8

(2) Drive system 2 (paper feed motor drive train) ................................................................................. 1-1-9

(3) Drive system 3 (Deck drive motor drive train) ............................................................................... 1-1-10

(4) Drive system 4 (image formation motor drive train) ....................................................................... 1-1-11

(5) Drive system 5 (Paper conveying motor drive train) ...................................................................... 1-1-12

(6) Drive system 6 (duplex section) .................................................................................................... 1-1-13

(7) Drive system 7 (DF) ....................................................................................................................... 1-1-14

1-2 Handling Precautions

1-2-1 Drum ..................................................................................................................................................... 1-2-1

1-2-2 Developer and toner .............................................................................................................................. 1-2-1

1-2-3 Installation environment ........................................................................................................................ 1-2-1

2BC/D

1-3 Installation

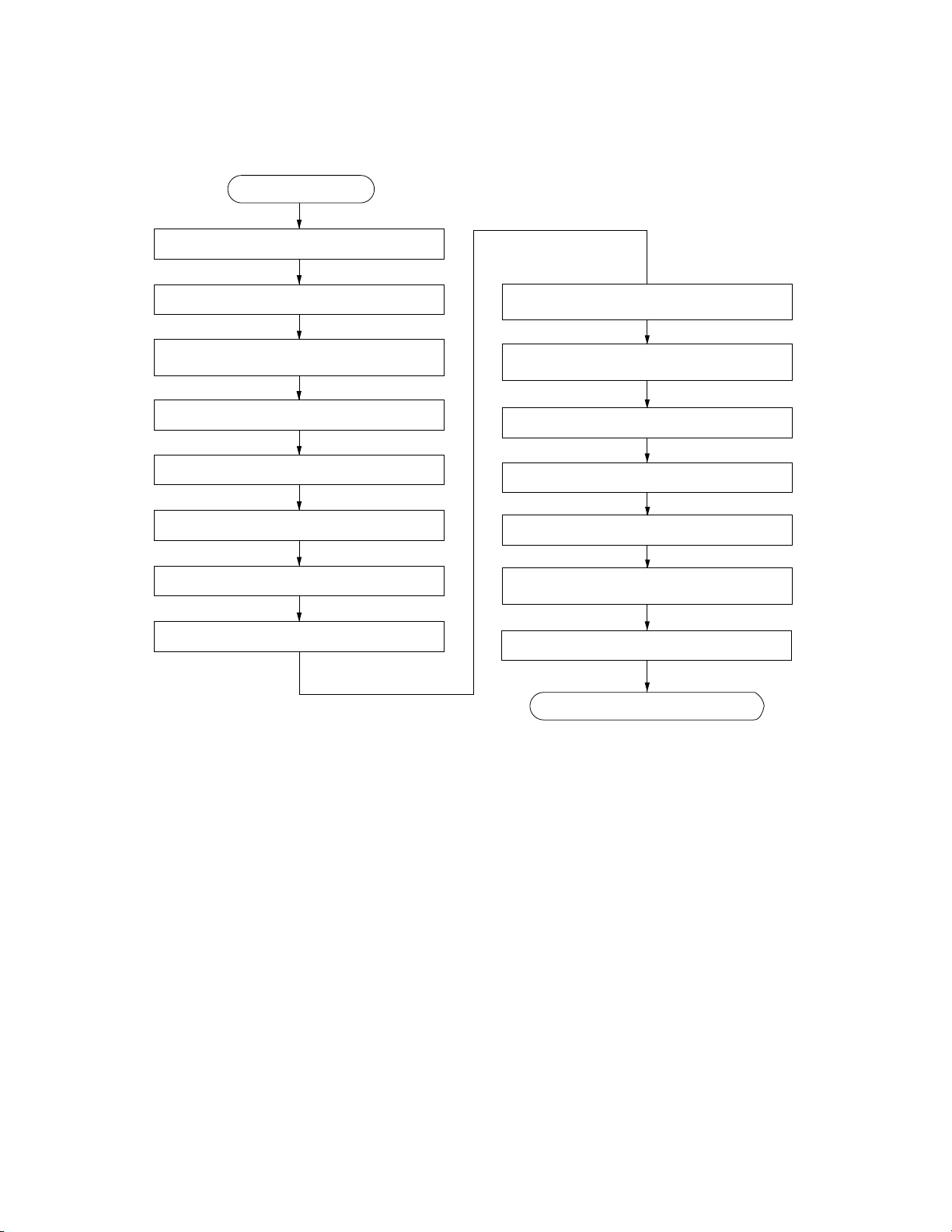

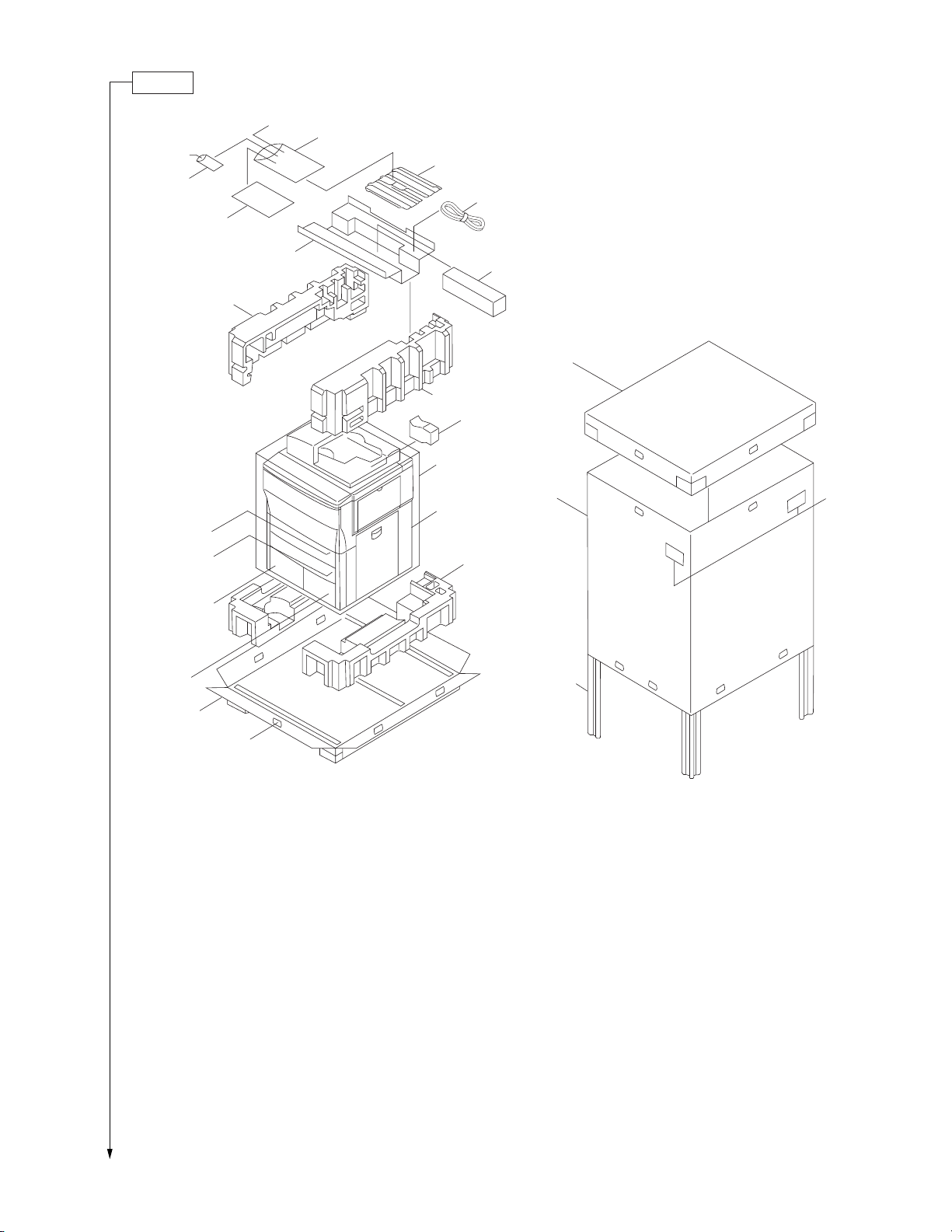

1-3-1 Unpacking and installation .................................................................................................................... 1-3-1

(1) Installation procedure ...................................................................................................................... 1-3-1

1-3-2 Setting initial copy modes ................................................................................................................... 1-3-15

1-3-3 Installing the key counter (option) ....................................................................................................... 1-3-16

1-3-4 Installing the multi/simple finisher (option) .......................................................................................... 1-3-18

1-3-5 Installing the side deck (option) ........................................................................................................... 1-3-24

1-3-6 Installing the Network scanner kit (option) .......................................................................................... 1-3-28

1-3-7 Installing the Printer kit (option) ........................................................................................................... 1-3-30

1-3-8 Installing the tandem kit (option) ......................................................................................................... 1-3-33

1-4 Maintenance Mode

1-4-1 Copier management .............................................................................................................................. 1-4-1

(1) Using the copier management mode ............................................................................................... 1-4-1

(2) Setting department management items ........................................................................................... 1-4-2

(3) Weekly timer .................................................................................................................................... 1-4-2

(4) Copy default .................................................................................................................................... 1-4-3

(5) Machine default ............................................................................................................................... 1-4-5

(6) Bypass setting ................................................................................................................................. 1-4-6

(7) Document management default setting ........................................................................................... 1-4-6

(8) Hard disk management ................................................................................................................... 1-4-7

(9) Report .............................................................................................................................................. 1-4-7

(10) Language ......................................................................................................................................... 1-4-7

1-4-2 Maintenance mode ................................................................................................................................ 1-4-8

(1) Executing a maintenance item ........................................................................................................ 1-4-8

(2) Maintenance mode item list ............................................................................................................. 1-4-9

(3) Contents of maintenance mode items ........................................................................................... 1-4-12

1-5 Troubleshooting

1-5-1 Paper misfeed detection ...................................................................................................................... 1-5-1

(1) Paper misfeed indication ................................................................................................................ 1-5-1

(2) Paper misfeed detection conditions ................................................................................................. 1-5-3

(3) Paper misfeeds ................................................................................................................................ 1-5-9

1-5-2 Self-diagnosis ...................................................................................................................................... 1-5-20

(1) Self-diagnostic function ................................................................................................................. 1-5-20

(2) Self diagnostic codes ..................................................................................................................... 1-5-21

1-1-1

Page 9

2BC/D-1

1-5-3 Image formation problems .................................................................................................................. 1-5-31

(1) No image appears (entirely white). ................................................................................................ 1-5-33

(2) No image appears (entirely black). ................................................................................................ 1-5-33

(3) Image is too light. .......................................................................................................................... 1-5-34

(4) Background is visible. .................................................................................................................... 1-5-34

(5) A white line appears longitudinally. ............................................................................................... 1-5-34

(6) A black line appears longitudinally. ............................................................................................... 1-5-35

(7) A black line appears laterally. ........................................................................................................ 1-5-35

(8) One side of the copy image is darker than the other. .................................................................... 1-5-35

(9) Black dots appear on the image. ................................................................................................... 1-5-36

(10) Image is blurred. ............................................................................................................................ 1-5-36

(11) The leading edge of the image is consistently misaligned with the original. ................................. 1-5-36

(12) The leading edge of the image is sporadically misaligned with the original. ................................. 1-5-37

(13) Paper creases. .............................................................................................................................. 1-5-37

(14) Offset occurs. ................................................................................................................................ 1-5-37

(15) Image is partly missing. ................................................................................................................. 1-5-38

(16) Fixing is poor. ................................................................................................................................ 1-5-38

(17) Image is out of focus. .................................................................................................................... 1-5-38

(18) Image center does not align with the original center. .................................................................... 1-5-38

(19) Image is not square. ...................................................................................................................... 1-5-39

(20) Image contrast is low (carrier scattering). ...................................................................................... 1-5-39

(21) There is a regular error between the centers of the original and copy image

when the DF is used. ..................................................................................................................... 1-5-39

(22) There is a regular error between the leading edges of the original and copy image

when the DF is used. ..................................................................................................................... 1-5-40

(23) There is a regular error between the trailing edges of the original and copy image

when the DF is used. ..................................................................................................................... 1-5-40

(24)

When the duplex unit is used, the center of the original image and that of

the copy image do not align. .......................................................................................................... 1-5-40

(25)

Toner scatters at the leading edge of the image. .......................................................................

1-5-4 Electrical problems .............................................................................................................................. 1-5-41

• Copier .............................................................................................................................................. 1-5-41

(1) The machine does not operate when the main switch is turned on. .............................................. 1-5-41

(2) The image formation motor does not operate (C2000). ................................................................ 1-5-41

(3) Paper feed motor does not operate (C2500). ................................................................................ 1-5-41

(4) The paper conveying motor does not operate (C2550). ................................................................ 1-5-42

(5) The deck drive motor does not operate (C2600). .......................................................................... 1-5-42

(6) The scanner motor does not operate. ........................................................................................... 1-5-42

(7) The paper conveying fan motor does not operate. ........................................................................ 1-5-42

(8) The image formation fan motor does not operate. ........................................................................ 1-5-42

(9) The cooling fan motor does not operate. ....................................................................................... 1-5-43

(10) The fixing fan motor does not operate. .......................................................................................... 1-5-43

(11) Eject fan motor 1 does not operate. .............................................................................................. 1-5-43

(12) Eject fan motor 2 does not operate. .............................................................................................. 1-5-43

(13) The HDD fan motor does not operate. .......................................................................................... 1-5-43

(14) The power supply fan motor does not operate. ............................................................................. 1-5-43

(15) The upper lift motor does not operate (C1010). ............................................................................ 1-5-43

(16) The lower lift motor does not operate (C1020). ............................................................................. 1-5-43

(17) The deck right lift motor does not operate (C1100). ...................................................................... 1-5-44

(18) The deck left lift motor does not operate (C1110). ........................................................................ 1-5-44

(19) The toner feed motor does not operate. ........................................................................................ 1-5-44

(20) The main charger cleaning motor does not operate. ..................................................................... 1-5-44

(21) The toner agitation motor does not operate. ................................................................................. 1-5-44

(22) The transfer charger cleaning motor does not operate. ................................................................ 1-5-44

(23) The registration clutch does not operate. ...................................................................................... 1-5-44

(24) Feed low clutch 1 does not operate. .............................................................................................. 1-5-45

(25) Feed high clutch 1 does not operate. ............................................................................................ 1-5-45

(26) Feed low clutch 2 does not operate. .............................................................................................. 1-5-45

(27) Feed high clutch 2 does not operate. ............................................................................................ 1-5-45

(28) Feed clutch 3 does not operate. .................................................................................................... 1-5-45

1-1-2

1-5-40-1

Page 10

2BC/D

(29) Feed clutch 4 does not operate. .................................................................................................... 1-5-45

(30) Feed clutch 5 does not operate. .................................................................................................... 1-5-45

(31) Paper feed clutch 1 does not operate. ........................................................................................... 1-5-46

(32) Paper feed clutch 2 does not operate. ........................................................................................... 1-5-46

(33) Paper feed clutch 3 does not operate. ........................................................................................... 1-5-46

(34) Paper feed clutch 4 does not operate. ........................................................................................... 1-5-46

(35) The bypass paper feed clutch does not operate. .......................................................................... 1-5-46

(36) The duplex forwarding clutch does not operate. ............................................................................ 1-5-47

(37) The duplex reversing clutch does not operate. .............................................................................. 1-5-47

(38) The deck feed clutch does not operate. ........................................................................................ 1-5-47

(39) The bypass solenoid does not operate. ......................................................................................... 1-5-47

(40) The duplex eject switching solenoid does not operate. ................................................................. 1-5-47

(41) The duplex pressure release solenoid does not operate. .............................................................. 1-5-47

(42) The feedshift solenoid does not operate. ...................................................................................... 1-5-47

(43) The fixing web solenoid does not operate. .................................................................................... 1-5-48

(44) The cleaning lamp does not turn on. ............................................................................................. 1-5-48

(45) The exposure lamp does not turn on. ............................................................................................ 1-5-48

(46) The exposure lamp does not turn off. ............................................................................................ 1-5-48

(47) Fixing heater M or S does not turn on (C6000). ............................................................................ 1-5-48

(48) Fixing heater M or S does not turn off. .......................................................................................... 1-5-48

(49) Main charging is not performed (C5100). ...................................................................................... 1-5-48

(50) Transfer charging is not performed (C5110). ................................................................................ 1-5-49

(51) Separation charging is not performed (C5110). ............................................................................ 1-5-49

(52) No developing bias is output. ........................................................................................................ 1-5-49

(53) The original size is not detected. ................................................................................................... 1-5-49

(54) The original size is not detected correctly. .................................................................................... 1-5-49

(55) The touch panel keys do not work. ................................................................................................ 1-5-50

(56) The message requesting paper to be loaded is shown when paper is present in drawer 1. ......... 1-5-50

(57) The message requesting paper to be loaded is shown when paper is present in drawer 2. ......... 1-5-50

(58) The message requesting paper to be loaded is shown when paper is present in drawer 3. ......... 1-5-50

(59) The message requesting paper to be loaded is shown when paper is present in drawer 4. ......... 1-5-50

(60) The message requesting paper to be loaded is shown when paper is present on the

bypass table. ................................................................................................................................. 1-5-50

(61) The size of paper in drawer 1 is not displayed correctly. ............................................................... 1-5-50

(62) The size of paper in drawer 2 is not displayed correctly. ............................................................... 1-5-51

(63) The size of paper on the bypass table is not displayed correctly. ................................................. 1-5-51

(64) A paper jam in the paper feed, paper conveying or fixing section is indicated on the touch

panel immediately after the main switch is turned on. ................................................................... 1-5-52

(65) The message requesting covers to be closed is displayed when the front and right covers

are closed. ..................................................................................................................................... 1-5-52

(66) Others. ........................................................................................................................................... 1-5-52

• DF .................................................................................................................................................. 1-5-53

(1) The original feed motor does not operate. ..................................................................................... 1-5-53

(2) The original conveying motor does not operate. ........................................................................... 1-5-53

(3) The original feed solenoid does not operate. ................................................................................ 1-5-53

(4) The switchback feedshift solenoid does not operate. .................................................................... 1-5-53

(5) The eject feedshift solenoid does not operate. .............................................................................. 1-5-53

(6) The switchback pressure solenoid does not operate. ................................................................... 1-5-53

(7) The original feed clutch does not operate. .................................................................................... 1-5-54

(8) A message indicating cover open is displayed when the DF is closed correctly. .......................... 1-5-54

(9) An original jams when the main switch is turned on. ..................................................................... 1-5-54

1-5-5 Mechanical problems ......................................................................................................................... 1-5-55

• Copier ............................................................................................................................................ 1-5-55

(1) No primary paper feed. .................................................................................................................. 1-5-55

(2) No secondary paper feed. ............................................................................................................. 1-5-55

(3) Skewed paper feed. ....................................................................................................................... 1-5-55

(4) The scanner does not travel. ......................................................................................................... 1-5-55

(5) Multiple sheets of paper are fed at one time. ................................................................................ 1-5-55

1-1-3

Page 11

2BC/D

(6) No refeed. ...................................................................................................................................... 1-5-55

(7) Paper jams. ................................................................................................................................... 1-5-55

(8) Toner drops on the paper conveying path. .................................................................................... 1-5-56

(9) Abnormal noise is heard. ............................................................................................................... 1-5-56

• DF .................................................................................................................................................. 1-5-57

(1) No primary original feed. ............................................................................................................... 1-5-57

(2) No secondary original feed. ........................................................................................................... 1-5-57

(3) Originals jam. ................................................................................................................................. 1-5-57

1-6 Assembly and Disassembly

1-6-1 Precautions for assembly and disassembly ......................................................................................... 1-6-1

(1) Precautions ...................................................................................................................................... 1-6-1

(2) Running a maintenance item ........................................................................................................... 1-6-2

1-6-2 Paper feed section ................................................................................................................................ 1-6-3

(1) Detaching and refitting the forwarding, upper paper feed and lower paper feed pulleys ................ 1-6-3

(1-1) Detaching and refitting the pulleys of drawers 1, 2, and 3 ...................................................... 1-6-3

(1-2) Detaching and refitting the pulley of drawer 4 ........................................................................ 1-6-7

(2) Detaching and refitting the bypass forwarding, upper and lower paper feed pulleys .................... 1-6-10

(3) Detaching and refitting the registration cleaner brush ................................................................... 1-6-13

(4) Detaching and refitting the lower registration cleaner ................................................................... 1-6-13

(5) Detaching and refitting the ozone filter .......................................................................................... 1-6-14

(6) Adjustment after roller and clutch replacement ............................................................................. 1-6-15

(6-1) Adjusting the leading edge registration of image printing ..................................................... 1-6-15

(6-2) Adjusting the leading edge registration for memory image printing ...................................... 1-6-16

(6-3) Adjusting the center line of image printing ............................................................................ 1-6-17

(6-4) Adjusting the margins for printing ......................................................................................... 1-6-18

(6-5) Adjusting the amount of slack in the paper at the registration roller ..................................... 1-6-19

(6-6) Adjusting the amount of slack in the paper at the vertical conveying ................................... 1-6-20

1-6-3 Optical section ..................................................................................................................................... 1-6-21

(1) Detaching and refitting the exposure lamp .................................................................................... 1-6-21

(2) Detaching and refitting the scanner wires ..................................................................................... 1-6-22

(2-1) Detaching the scanner wires ................................................................................................ 1-6-22

(2-2) Refitting the scanner wires ................................................................................................... 1-6-25

(3) Detaching and refitting the laser scanner unit ............................................................................... 1-6-27

(4) Detaching and refitting the ISU (reference) ................................................................................... 1-6-30

(5) Adjusting the longitudinal squareness (reference) ........................................................................ 1-6-31

(6) Adjusting scanner image lateral squareness (reference) .............................................................. 1-6-32

(6-1) Adjusting the position of the laser scanner unit .................................................................... 1-6-32

(6-2) Adjusting the position of the ISU .......................................................................................... 1-6-33

(7) Adjusting magnification of the scanner in the main scanning direction ......................................... 1-6-34

(8) Adjusting magnification of the scanner in the auxiliary scanning direction .................................... 1-6-35

(9) Adjusting the scanner leading edge registration ............................................................................ 1-6-36

(10) Adjusting the scanner center line .................................................................................................. 1-6-37

(11) Adjusting the margins for scanning an original on the contact glass ............................................. 1-6-38

1-6-4 Main charging section ......................................................................................................................... 1-6-39

(1) Detaching and refitting the charger wire and main charger grid .................................................... 1-6-39

(2) Detaching and refitting the grid wire cleaning pad and main charger wire cleaning pad ............... 1-6-41

1-6-5 Drum section ....................................................................................................................................... 1-6-42

(1) Detaching and refitting the drum ................................................................................................... 1-6-42

1-6-6 Developing section .............................................................................................................................. 1-6-44

(1) Detaching and refitting the drum ................................................................................................... 1-6-42

1-6-6 Developing section .............................................................................................................................. 1-6-44

(1) Detaching and refitting the developing unit ................................................................................... 1-6-44

(2) Detaching and refitting the developing unit upper seal .................................................................. 1-6-46

(3) Adjusting the position of the magnetic brush (developing roller) (reference) ................................ 1-6-46

(4) Adjusting the position of the doctor blade (reference) .................................................................. 1-6-47

(5) Detaching and refitting the developing duct filter ........................................................................... 1-6-47

1-6-7 Transfer and separation section .......................................................................................................... 1-6-48

1-1-4

Page 12

2BC/D-1

(1) Detaching and refitting the charger wires and cleaning pads ........................................................ 1-6-48

1-6-8 Cleaning section .................................................................................................................................. 1-6-50

(1) Detaching and refitting the drum separation claw and cleaning lower seal ................................... 1-6-50

(2) Detaching and refitting the cleaning blade .................................................................................... 1-6-52

(3) Detaching and refitting the thrust gear .......................................................................................... 1-6-52

(4) Detaching and refitting the cleaning brush, front and rear cleaning seal and bushing brush ........ 1-6-53

1-6-9 Fixing section ...................................................................................................................................... 1-6-55

(1) Detaching and refitting the fixing unit ............................................................................................ 1-6-55

(2) Detaching and refitting the fixing heaters M and S ........................................................................ 1-6-55

(3) Detaching and refitting the heat roller ............................................................................................ 1-6-57

(4) Detaching and refitting the press roller .......................................................................................... 1-6-59

(5) Detaching and refitting the lower cleaning roller ............................................................................ 1-6-60

(6) Detaching and refitting the fixing unit thermistor ........................................................................... 1-6-61

(7) Detaching and refitting the fixing web roller ................................................................................... 1-6-62

(8) Detaching and refitting the heat roller separation claw .................................................................. 1-6-63

1-6-10 Duplex section ..................................................................................................................................... 1-6-64

(1) Cleaning the duplex switchback rollers ......................................................................................... 1-6-64

(2) Adjusting the position of the duplex eject switching solenoid ........................................................ 1-6-65

(3) Setting the switchback drive .......................................................................................................... 1-6-66

1-6-11 DF section ........................................................................................................................................... 1-6-67

(1) Detaching and refitting the DF forwarding pulley and DF feed pulley ........................................... 1-6-67

(2) Detaching and refitting the DF separation pulley ........................................................................ 1-6-67-1

(3)

Adjusting the DF magnification ...................................................................................................... 1-6-68

(4) Adjusting the DF original center line ..............................................................................................

(5)

Adjusting the scanning start position when the DF is used ........................................................... 1-6-70

(5-1)

Adjusting the DF leading edge registration........................................................................... 1-6-70

(5-2)

Adjusting the DF trailing edge registration............................................................................ 1-6-71

(6)

Adjusting the margins for scanning the original from the DF ......................................................... 1-6-72

1-6-69

1-7 Requirements on PCB Replacement

1-7-1 Upgrading the firmware on the main PCB ............................................................................................. 1-7-1

1-7-2 Adjustment-free variable resistors (VR) ................................................................................................ 1-7-2

2-1 Mechanical construction

2-1-1 Paper feed section ................................................................................................................................ 2-1-1

(1) Drawers 1 and 2 paper feed ............................................................................................................ 2-1-1

(1-1) Detecting the paper level ........................................................................................................ 2-1-2

(2) Drawers 3 and 4 paper feed ............................................................................................................ 2-1-6

(2-1) Drawer 3 paper feed ............................................................................................................... 2-1-7

(2-2) Drawer 4 paper feed ............................................................................................................... 2-1-9

(2-3) Raising and lowering the lift .................................................................................................. 2-1-11

(2-4) Detecting the paper level ...................................................................................................... 2-1-12

(3) Paper feed from the bypass table .................................................................................................. 2-1-13

2-1-2 Main charging section ......................................................................................................................... 2-1-15

2-1-3 Optical section ..................................................................................................................................... 2-1-17

(1) Original scanning ........................................................................................................................... 2-1-18

(2) Image printing ................................................................................................................................ 2-1-19

2-1-4 Developing section .............................................................................................................................. 2-1-21

(1) Formation of magnetic brush ......................................................................................................... 2-1-22

(2) Toner density control ..................................................................................................................... 2-1-24

(2-1) Toner empty detection by the toner sensor .......................................................................... 2-1-24

(2-2) Controlling the toner feed motor and toner agitation motor .................................................. 2-1-25

(2-3) Toner empty detection by the toner level sensor .................................................................. 2-1-25

(2-4) Toner control level absolute humidity correction .................................................................. 2-1-26

2-1-5 Transfer/separation and conveying sections ....................................................................................... 2-1-27

2-1-6 Cleaning section .................................................................................................................................. 2-1-29

2-1-7 Charge erasing section ....................................................................................................................... 2-1-30

2-1-8 Fixing section ...................................................................................................................................... 2-1-31

1-1-5

Page 13

2BC/D

2-1-9 Feedshift and eject sections ................................................................................................................ 2-1-33

2-1-10 Duplex section ..................................................................................................................................... 2-1-34

2-1-11 DF ....................................................................................................................................................... 2-1-37

(1) Original feed section ...................................................................................................................... 2-1-37

(1-1) Original feed timing ............................................................................................................... 2-1-38

(2) Original switchback section ........................................................................................................... 2-1-39

(2-1) Operation of original switchback ........................................................................................... 2-1-40

(3) Original conveying section ............................................................................................................. 2-1-41

(3-1) Original switchback/conveying timing ................................................................................... 2-1-42

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ............................................................................................................................ 2-2-1

(1) PCBs ............................................................................................................................................... 2-2-1

(2) Switches and sensors ...................................................................................................................... 2-2-2

(3) Motors .............................................................................................................................................. 2-2-4

(4) Clutches and solenoids ................................................................................................................... 2-2-5

(5) Other electrical components ............................................................................................................ 2-2-6

(6) DF PCBs .......................................................................................................................................... 2-2-7

(7) DF switches and sensors ................................................................................................................ 2-2-8

(8) DF motors ........................................................................................................................................ 2-2-9

(9) DF clutches and solenoids ............................................................................................................ 2-2-10

2-3 Operation of the PCBs

2-3-1 Power source PCB ................................................................................................................................ 2-3-1

2-3-2 Main PCB .............................................................................................................................................. 2-3-6

2-3-3 Engine PCB ......................................................................................................................................... 2-3-11

2-3-4 Scanner drive PCB .............................................................................................................................. 2-3-19

2-3-5 CCD PCB ............................................................................................................................................ 2-3-22

2-4 Appendixes

Timing chart No. 1 ........................................................................................................................................... 2-4-1

Timing chart No. 2 ........................................................................................................................................... 2-4-2

Timing chart No. 3 ........................................................................................................................................... 2-4-3

Timing chart No. 4 ........................................................................................................................................... 2-4-4

Timing chart No. 5 ........................................................................................................................................... 2-4-5

Timing chart No. 6 ........................................................................................................................................... 2-4-6

Timing chart No. 7 ........................................................................................................................................... 2-4-7

Timing chart No. 8 ........................................................................................................................................... 2-4-8

Timing chart No. 9 ........................................................................................................................................... 2-4-9

Timing chart No. 10 ....................................................................................................................................... 2-4-10

Chart of image adjustment procedures ......................................................................................................... 2-4-11

Maintenance parts list ................................................................................................................................... 2-4-14

Periodic maintenance procedures ................................................................................................................. 2-4-15

Optional devices supplied parts list ............................................................................................................... 2-4-19

Functions and settings combination chart ..................................................................................................... 2-4-20

General wiring diagram ................................................................................................................................. 2-4-21

1-1-6

Page 14

1-1-1 Specifications

45 cpm copier

Type ............................................... Console

Copying system.............................. Indirect electrostatic system

Originals ......................................... Sheets and books

Maximum size: A3/11" × 17"

Original feed system ...................... Fixed

Copy paper .................................... Drawers: Plain paper (60 – 80 g/m

Duplex unit: Plain paper (64 – 80 g/m

Bypass table: Plain paper (45 – 200 g/m

Special paper:

Transparencies, tracing paper and colored paper

Note: Use the bypass table for special paper.

Copying sizes ................................. Maximum: A3/11" × 17"

1

Minimum: A6R/5

/2" × 81/2"

During duplex copying

Maximum: A3/11" × 17"

1

Minimum: A5R/5

/2" × 81/2"

Magnification ratios ........................ Manual mode: 25 – 400%, 1% increments

Auto copy mode: Fixed ratios

Metric

1:1, 1:4.00/1:2.00/1:1.41/1:1.27/1:1.06/1:0.90/1:0.75/1:0.70/1:0.50/1:0.25

Inch

1:1, 1:4.00/1:2.00/1:1.54/1:1.29/1:1.21/1:0.78/1:0.77/1:0.64/1:0.50/1:0.25

100% magnification ........................ Copier: ±0.8%

DF: ±1.5%

Enlargement/reduction ................... Copier: ±1.0%

DF: ±1.5%

Copy speed ....................................At 100% magnification in memory copy mode:

1

A4/11" × 8

A4R/8

/2": 45 copies/min.

1

/2" × 11": 32 copies/min.

A3/11" × 17": 24 copies/min.

B4 (257 × 364 mm)/81/2" × 14": 28 copies/min.

B5: 45 copies/min.

B5R: 36 copies/min.

When the DF is used (at 100% magnification):

1

A4/11" × 8

First copy time ................................ 3.9 s less (A4/11" × 8

/2": 45 copies/min.

1

/2", 100% magnification, drawer 1, manual copy density

control)

Warm-up time................................. 120 s or less (room temperature 20°C/68°F, 65%RH)

With preheat, switchable between 90 s and 30 s (room temperature 20°C/68°F,

65%RH)

Paper feed system ......................... Automatic feed

Capacity:

Two 500-sheet drawers

One 1000-sheet drawer

One 1500-sheet drawer

Manual feed

Capacity:

Bypass: 100 sheets

Multiple copying ............................. 1 – 999 copies

Photoconductor .............................. OPC (drum diameter 78 mm)

Charging system ............................ Single positive corona charging

Recording system .......................... Semiconductor laser

Developing system......................... Dry, reverse developing

Developer: 2-component, ferrite carrier and black toner

Density control: Developer density detection

Toner replenishing: Automatic from a toner bottle

Transfer system ............................. Single minus corona charge

Separation system ......................... AC separation corona charger system

2

)

2

)

2

)

2BC/D

1-1-1

Page 15

2BC/D

Fixing system ................................. Heat roller

Heat source:

Halogen heaters (main 970 W for 120 V specifications/1150 W for 220-240 V

specifications, sub 970 W for 120 V specifications/1150 W for 220-240 V

specifications)

Control temperature: 185°C/365°F (at normal ambient temperature)

Abnormally high temperature protection devices: 150°C/302°F thermostats

Fixing pressure: 265 N

Charge erasing system .................. Exposure by cleaning lamp

Cleaning system ............................ Cleaning blade and fur brush

Scanning system ............................ Flat bed scanning by CCD image sensor

Bitmap memory .............................. 128 MB (standard)

Image storage memory .................. 20.0 GB (standard)

Resolution ...................................... Reading: 600 × 600 dpi

Writing: 1800 equivalent × 600 dpi

Light source ................................... Inert gas lamp

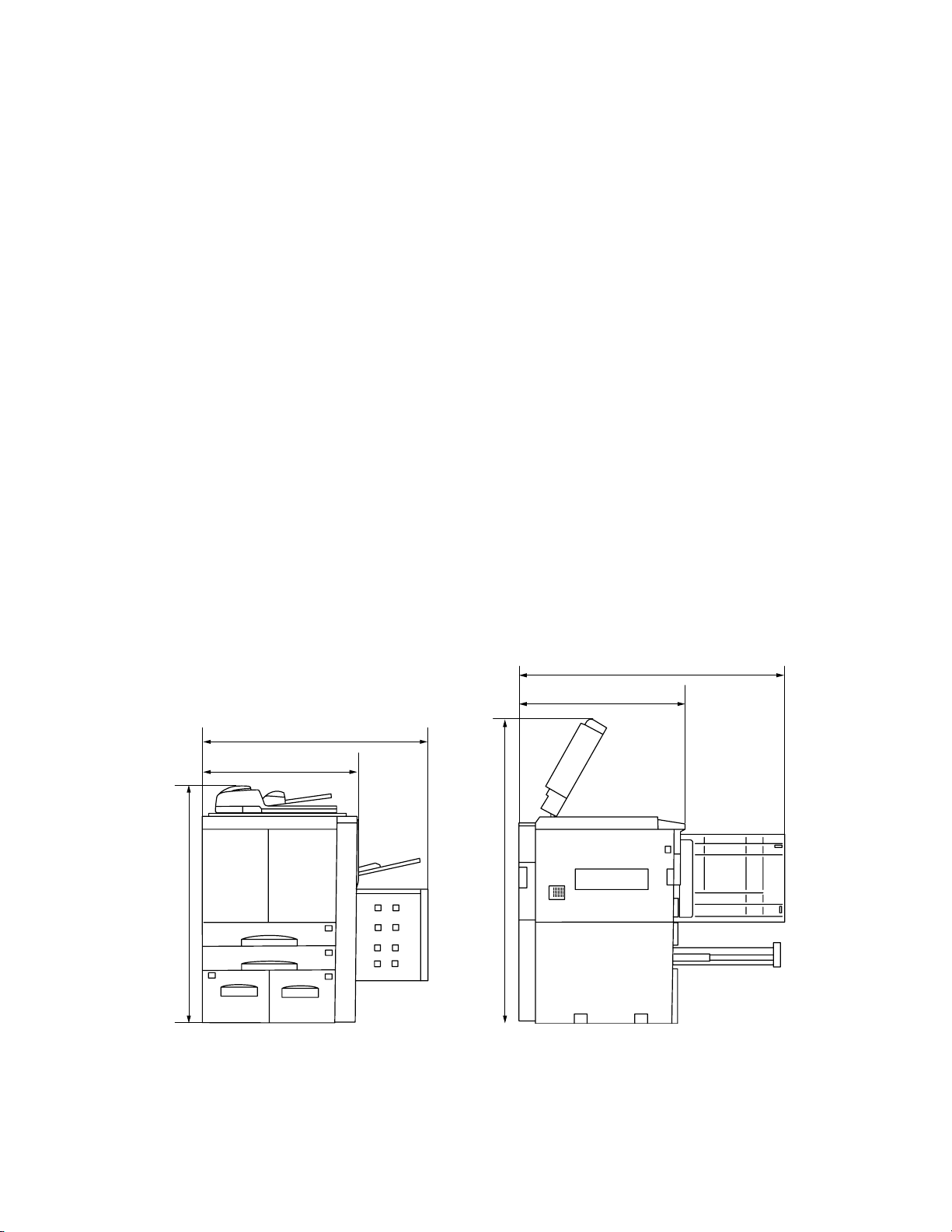

Dimensions .................................... 680 (W) × 804 (D) × 1141 (H) mm

13

/16" (W) × 3111/16" (D) × 4415/16" (H)

26

Weight ............................................Approx. 180 kg/396 lbs

Floor requirements ......................... 1331 mm (W) × 804 (D) mm

7

/16" (W) × 3111/16" (D)

52

Functions........................................ (1) Self-diagnostics

(2) Preheat

(3) Automatic copy density control

(4) Original size detection

(5) Automatic paper selection

(6) Automatic magnification selection

(7) Zoom mode

(8) XY zoom mode

(9) Preset zoom mode

(10) Document management functions

(11) Output management functions

(12) Photo mode

(13) Duplex copy

(14) Margin modes

(15) Memo mode

(16) Border erase modes

(17) Combine/merge copy modes

(18) Booklet stitching modes

(19) Sort/finished mode

(20) Auto selection/filing mode

(21) Copy management function

(22) Language selection function

Power source ................................. 120 V AC, 60 Hz, 12 A

220 – 240 V AC, 50/60 Hz, 7.0 A (max.)

Power consumption ....................... 1500 W (max.)

Options ........................................... Document finisher, key counter, printer kit, network scanner kit and tandem copy kit.

1-1-2

Page 16

55 cpm copier

Type ............................................... Console

Copying system.............................. Indirect electrostatic system

Originals ......................................... Sheets and books

Maximum size: A3/11" × 17"

Original feed system ...................... Fixed

2

Copy paper .................................... Drawers: Plain paper (60 – 80 g/m

Duplex unit: Plain paper (64 – 80 g/m

Bypass table: Plain paper (45 – 200 g/m

)

2

)

2

)

Special paper:

Transparencies, tracing paper and colored paper

Note: Use the bypass table for special paper.

Copying sizes ................................. Maximum: A3/11" × 17"

1

Minimum: A6R/5

/2" × 81/2"

During duplex copying

Maximum: A3/11" × 17"

1

Minimum: A5R/5

/2" × 81/2"

Magnification ratios ........................ Manual mode: 25 – 400%, 1% increments

Auto copy mode: Fixed ratios

Metric

1:1, 1:4.00/1:2.00/1:1.41/1:1.27/1:1.06/1:0.90/1:0.75/1:0.70/1:0.50/1:0.25

Inch

1:1, 1:4.00/1:2.00/1:1.54/1:1.29/1:1.21/1:0.78/1:0.77/1:0.64/1:0.50/1:0.25

100% magnification ........................ Copier: ±0.8%

DF: ±1.5%

Enlargement/reduction ................... Copier: ±1.0%

DF: ±1.5%

Copy speed ....................................At 100% magnification in memory copy mode:

1

A4/11" × 8

A4R/8

/2": 55 copies/min.

1

/2" × 11": 38 copies/min.

A3/11" × 17": 28 copies/min.

B4 (257 × 364 mm)/81/2" × 14": 32 copies/min.

B5: 55 copies/min.

B5R: 40 copies/min.

When the DF is used (at 100% magnification):

1

A4/11" × 8

First copy time ................................ 3.9 s less (A4/11" × 8

/2": 55 copies/min.

1

/2", 100% magnification, drawer 1, manual copy density

control)

Warm-up time................................. 120 s or less (room temperature 20°C/68°F, 65%RH)

With preheat, switchable between 90 s and 30 s (room temperature 20°C/68°F,

65%RH)

Paper feed system ......................... Automatic feed

Capacity:

Two 500-sheet drawers

One 1000-sheet drawer

One 1500-sheet drawer

Manual feed

Capacity:

Bypass: 100 sheets

Multiple copying ............................. 1 – 999 copies

Photoconductor .............................. OPC (drum diameter 78 mm)

Charging system ............................ Single positive corona charging

Recording system .......................... Semiconductor laser

Developing system......................... Dry, reverse developing

Developer: 2-component, ferrite carrier and black toner

Density control: Developer density detection

Toner replenishing: Automatic from a toner bottle

Transfer system ............................. Single minus corona charge

Separation system ......................... AC separation corona charger system

2BC/D

1-1-3

Page 17

2BC/D

Fixing system ................................. Heat roller

Heat source:

Halogen heaters (main 970 W for 120 V specifications/1150 W for 220-240 V

specifications, sub 970 W for 120 V specifications/1150 W for 220-240 V

specifications)

Control temperature: 185°C/365°F (at normal ambient temperature)

Abnormally high temperature protection devices: 150°C/302°F thermostats

Fixing pressure: 265 N

Charge erasing system .................. Exposure by cleaning lamp

Cleaning system ............................ Cleaning blade and fur brush

Scanning system ............................ Flat bed scanning by CCD image sensor

Bitmap memory .............................. 128 MB (standard)

Image storage memory .................. 20.0 GB (standard)

Resolution ...................................... Reading: 600 × 600 dpi

Writing: 1800 equivalent × 600 dpi

Light source ................................... Inert gas lamp

Dimensions .................................... 680 (W) × 804 (D) × 1141 (H) mm

13

/16" (W) × 3111/16" (D) × 4415/16" (H)

26

Weight ............................................Approx. 180 kg/396 lbs

Floor requirements ......................... 1331 mm (W) × 804 (D) mm

7

/16" (W) × 3111/16" (D)

52

Functions........................................ (1) Self-diagnostics

(2) Preheat

(3) Automatic copy density control

(4) Original size detection

(5) Automatic paper selection

(6) Automatic magnification selection

(7) Zoom mode

(8) XY zoom mode

(9) Preset zoom mode

(10) Document management functions

(11) Output management functions

(12) Photo mode

(13) Duplex copy

(14) Margin modes

(15) Memo mode

(16) Border erase modes

(17) Combine/merge copy modes

(18) Booklet stitching modes

(19) Sort/finished mode

(20) Auto selection/filing mode

(21) Copy management function

(22) Language selection function

Power source ................................. 120 V AC, 60 Hz, 12 A

220 – 240 V AC, 50/60 Hz, 7.0 A (max.)

Power consumption ....................... 1500 W (max.)

Options ........................................... Side deck, document finisher, key counter, printer kit, network scanner kit and

tandem copy kit.

DF

Original feed system ...................... Automatic feed

Originals ......................................... Sheets

Original weights ............................. Single-sided original mode: 35 – 160 g/m

Double-sided original mode: 50 – 120 g/m

2

2

Original paper ................................ Plain paper, thermal paper, art paper and colored paper

Original sizes.................................. A3 – A5R, folio/11" × 17" – 5

No. of originals ............................... Up to 70 sheets (A3, B4, folio, 11" × 17", 8

Up to 100 sheets (up to A4/11" × 8

1

/2" × 81/2"

1

/2")

1

/2" × 14")

Up to 30 sheets in the auto selection mode

Power source ................................. Electrically connected to the copier

1-1-4

Page 18

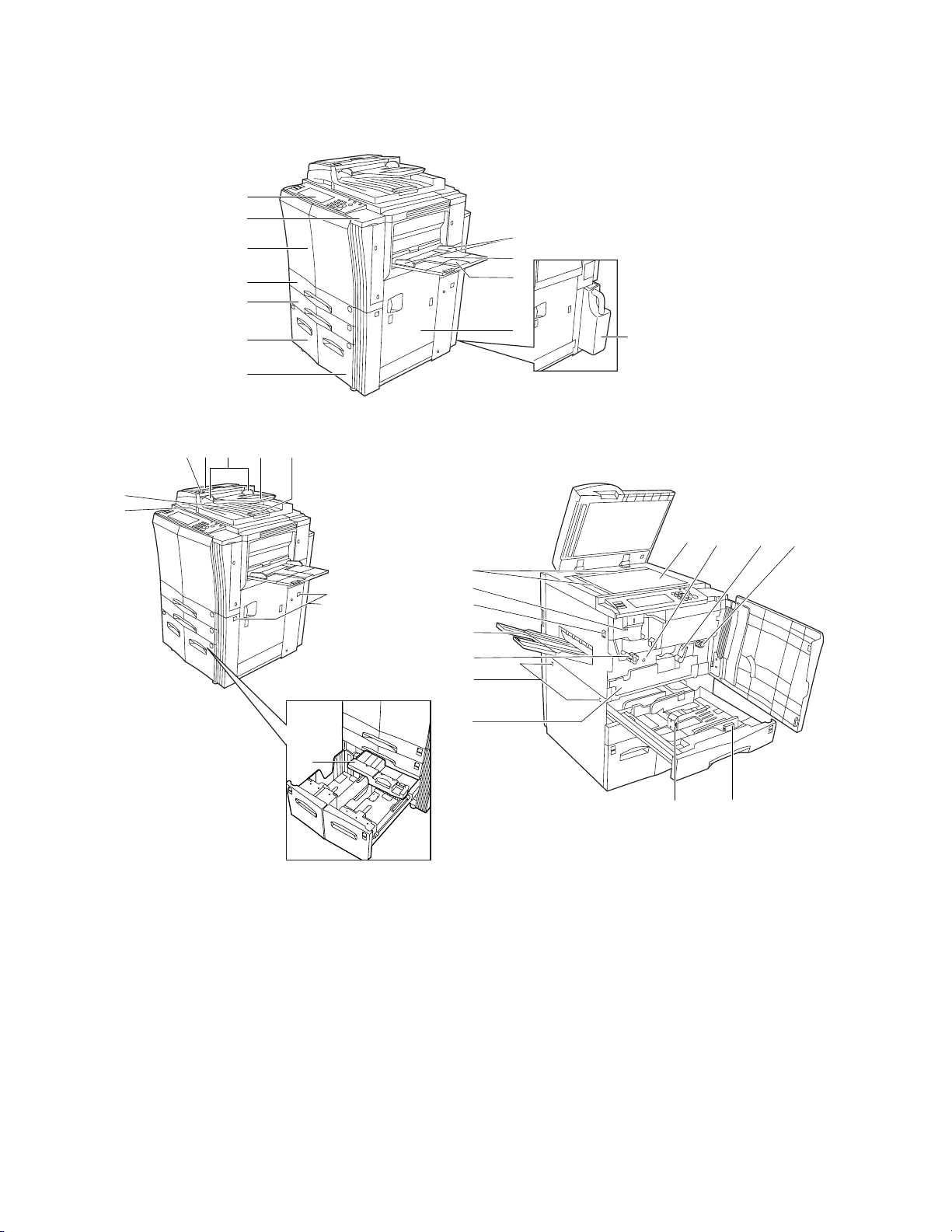

1-1-2 Parts names and their functions

(1) Copier

1

2

3

4

5

2BC/D

9

8

0

&

*

7

!

@

6

%^

$

#

(

‚‹

·

—

¤

›

⁄

fi

fl

‡

⁄

Œ

)

1 Operation panel

2 Operation right cover

3 Front cover

4 Drawer 1

5 Drawer 2

6 Drawer 3

7 Drawer 4

8 Bypass tray

9 Insert guides

0 Bypass extension

! Right cover

@ Waste toner box

Figure 1-1-1

# Original table

$ Original insert guides

% DF original reversing cover

^ Original set indicator

& Original eject table

* DF opening/closing lever

( Ejection extension

) Deck paper conveying unit

⁄ Handles for transport

¤ Original size indicator lines

‹ Contact glass

› Total counter

„

fi Main switch

fl Copy eject tray

‡ Fixing unit handle

— Paper conveying unit handle

· Paper conveying unit release

lever

‚ Paper conveying unit

ΠDuplex unit

„ Paper length guide release

levers

´ Paper width guide release

levers

´

1-1-5

Page 19

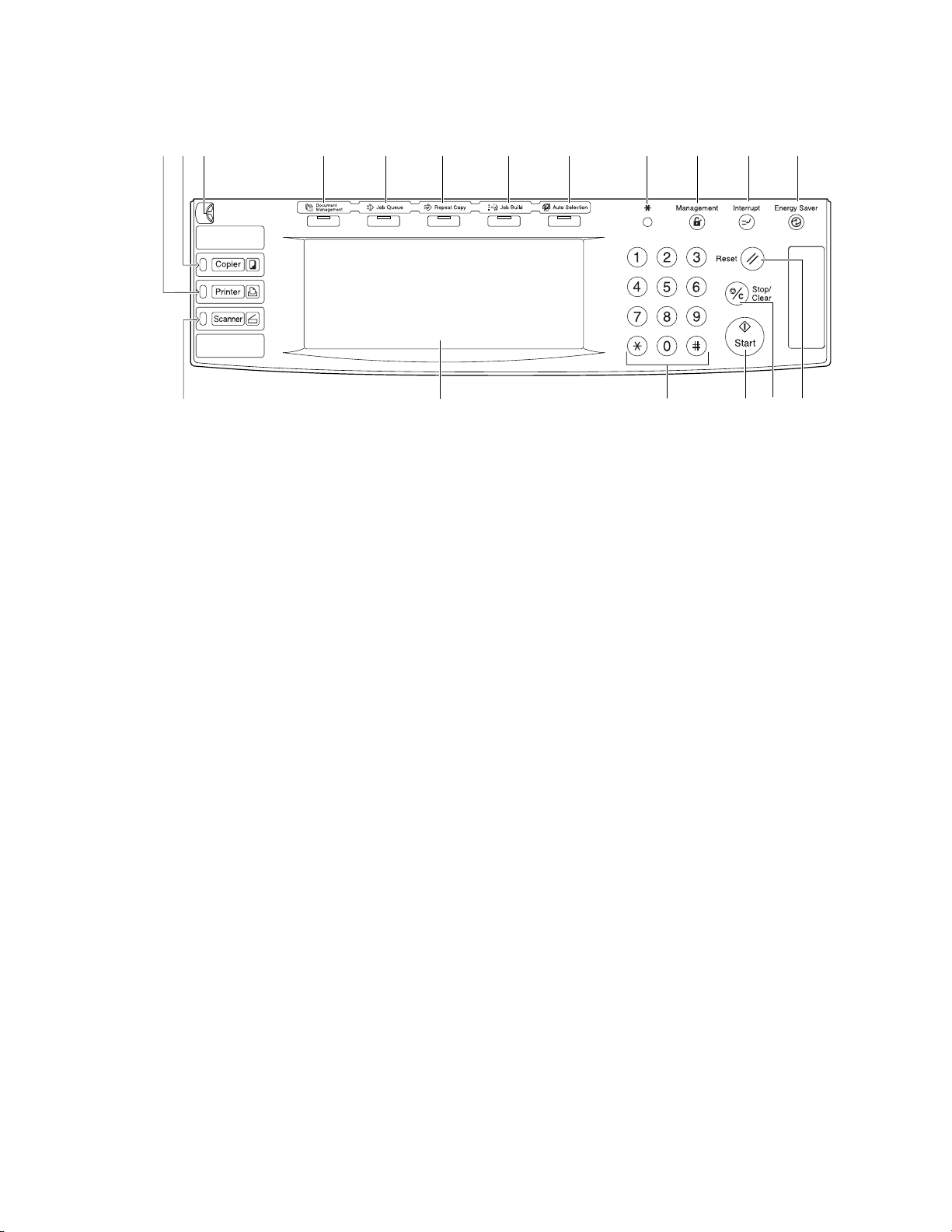

2BC/D

(2) Operation panel

#

1 Start key & indicator lamp

2 Stop/clear key

3 Reset key

4 Energy saver key & indicator lamp

5 Interrupt key & indicator lamp

6 Management key

7 *(default setting) key

8 Numeric key

9 Touch panel

0 Brightness adjustment control dial

! Copier key & indicator lamp

@ Printer key & indicator lamp

9

Figure 1-1-2

7

6 5 4$%^&*0@ !

8 3

# Scanner key & indicator lamp

$ Auto selection key & indicator lamp

% Job build key & indicator lamp

^ Repeat copy key & indicator lamp

& Job queue key & indicator lamp

* Document management key &

indicator lamp

1

2

1-1-6

Page 20

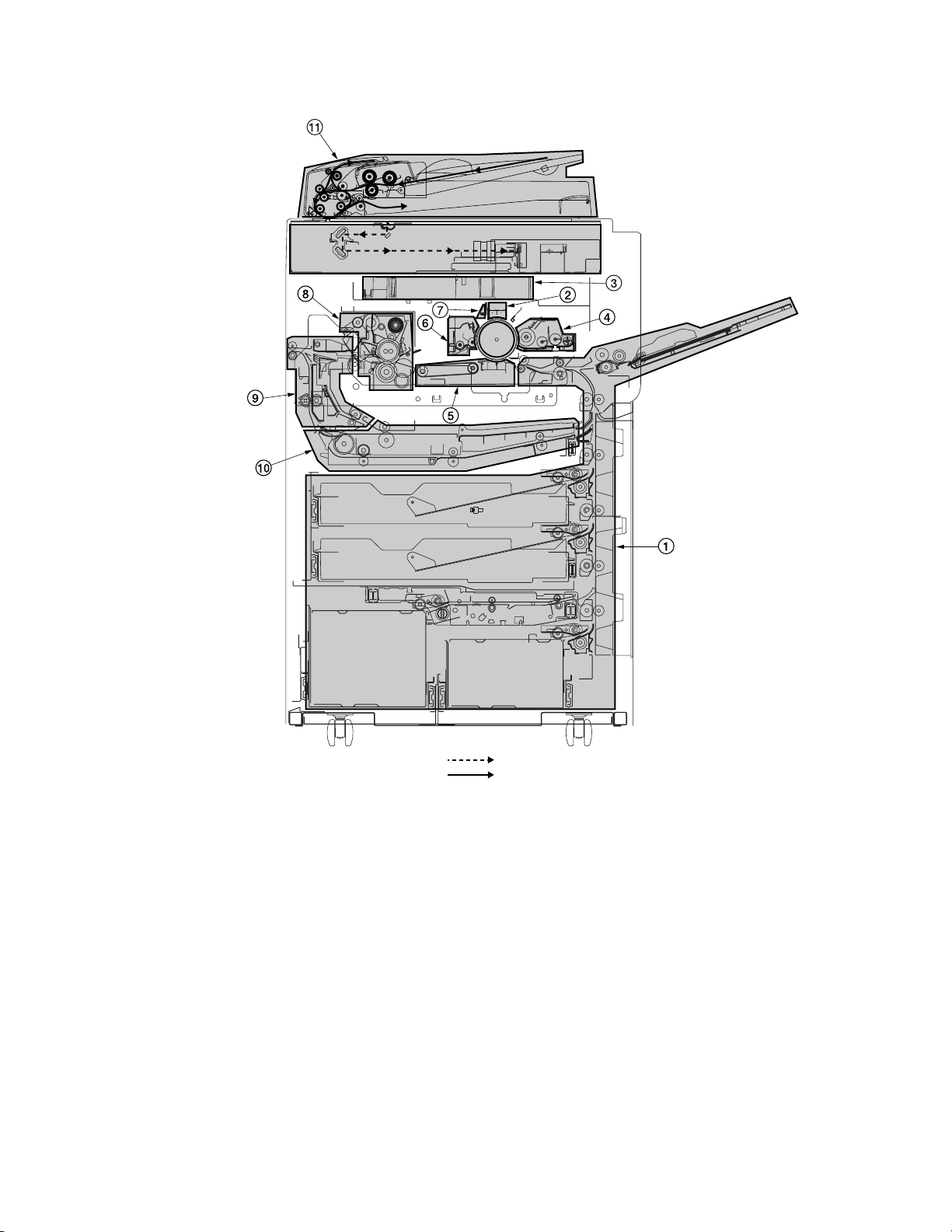

1-1-3 Machine cross section

2BC/D

Figure 1-1-3 Machine cross section

1 Paper feed section

2 Main charging section

3 Optical section

4 Developing section

5 Transfer and paper conveying section

6 Cleaning section

Light path

Paper and original path

7 Charge erasing section

8 Fixing section

9 Feedshift and eject section

0 Duplex section

! DF

1-1-7

Page 21

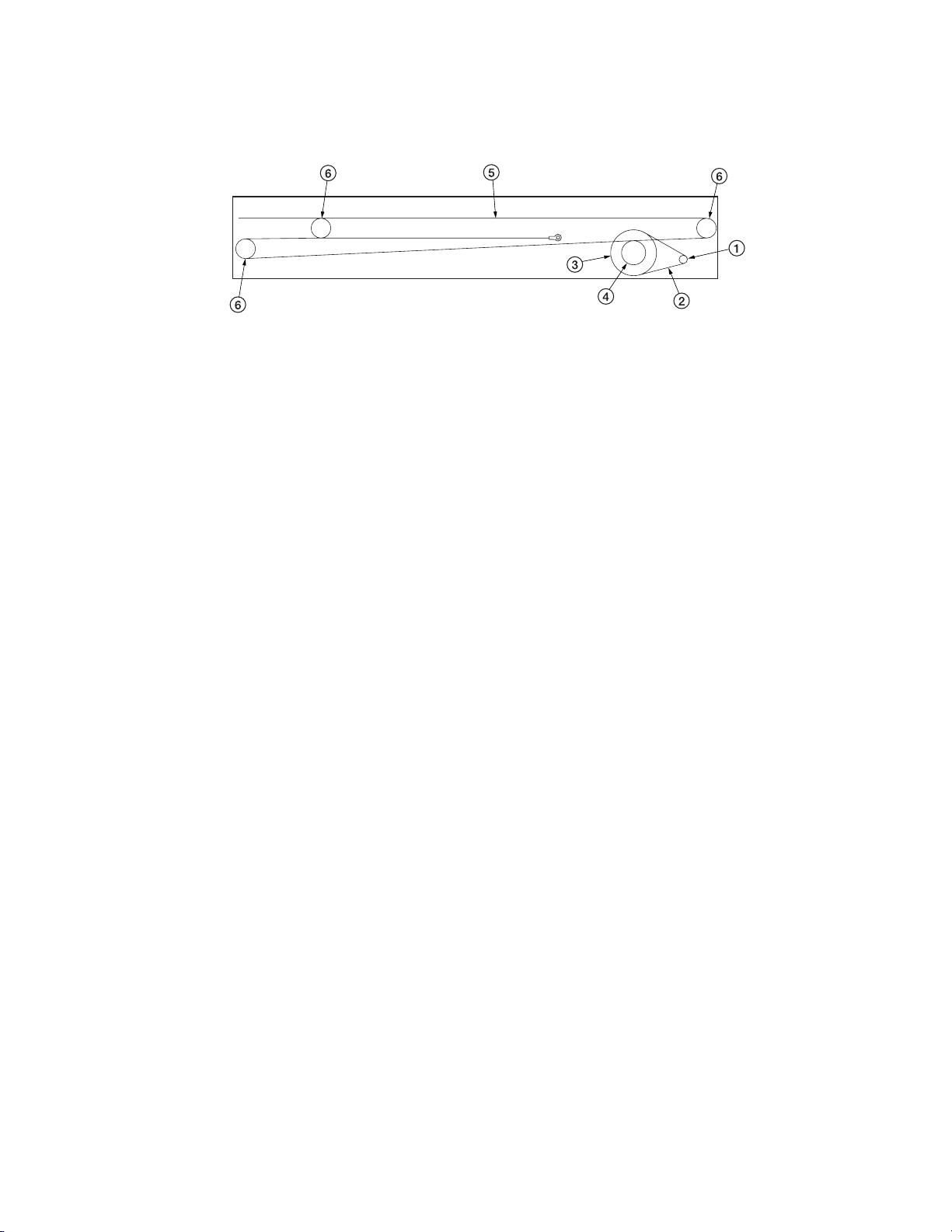

2BC/D

1-1-4 Drive system

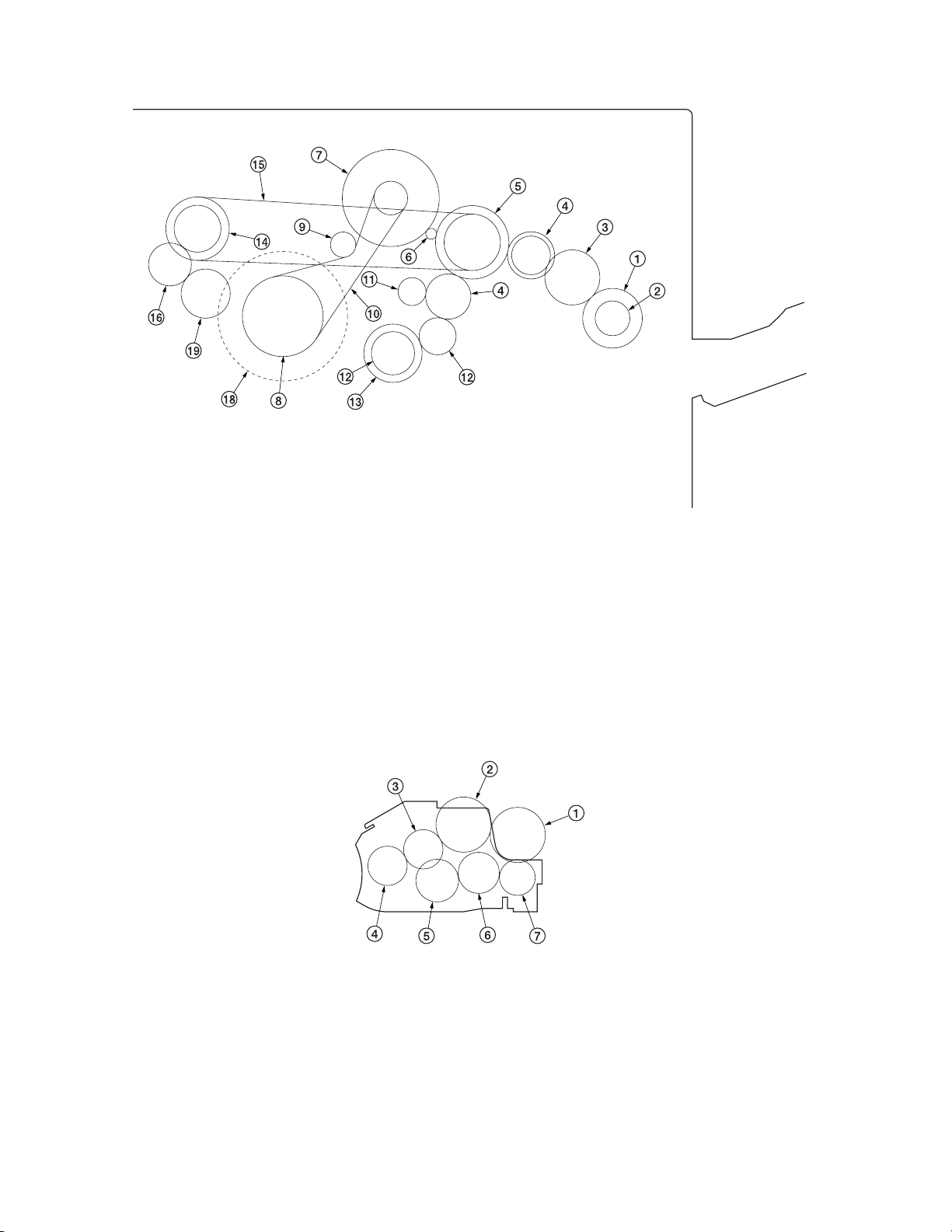

(1) Drive system 1 (optical section)

Figure 1-1-4

1 Scanner motor pulley

2 Scanner drive belt

3 Scanner drive pulley

4 Scanner wire drum

5 Scanner wire

6 Scanner wire pulley

1-1-8

Page 22

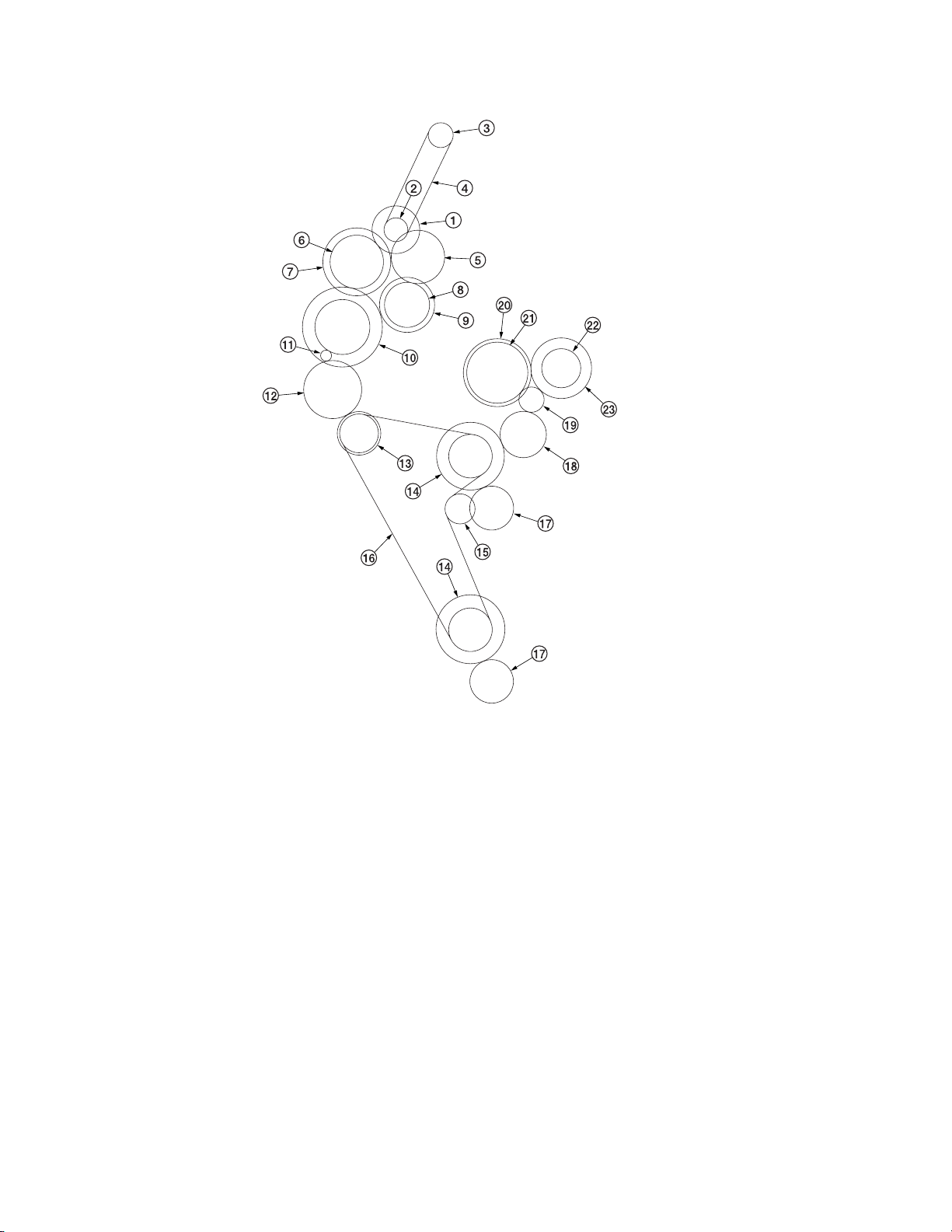

(2) Drive system 2 (paper feed motor drive train)

2BC/D

Figure 1-1-5

1 Idle gear 30

2 Pulley 16

3 Pulley 20

4 Developing agitation drive belt

5 Gear 32

6 Feed gear 42

7 Registration clutch gear

8 Feed gear 27

9 Feed low clutch 1 gear 34

0 Feed gear 49/65

! Paper feed motor gear

@ Paper feed gear 68

# Paper feed drive pulley 29/52

$ Idle pulley 31/42

% Tension pulley 20

^ Paper feed drive belt

& Idle gear 26

* Gear 26

( Gear 19

) Feed high clutch 2 gear

⁄ Gear 40

¤ Gear 24

‹ Feed low clutch 2 gear

1-1-9

Page 23

2BC/D

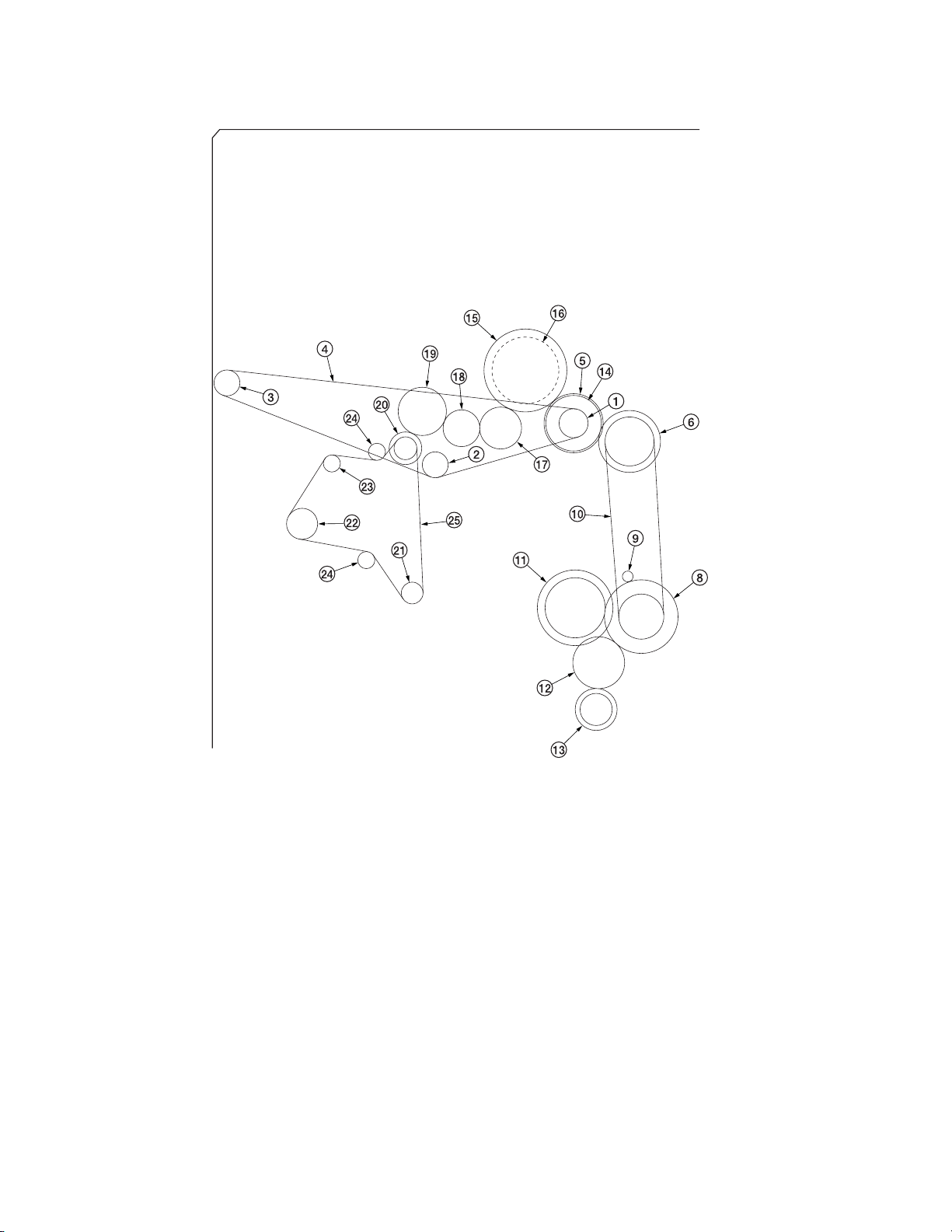

(3) Drive system 3 (Deck drive motor drive train)

1-1-10

Figure 1-1-6

1 Pulley 26

2 Tension pulley

3 Paper feed drive belt

4 Idle gear 26

5 Paper feed clutch 3 gear

6 Feed clutch 5 gear

7 Deck paper feed drive pulley

8 Tension pulley 20

9 Deck paper feed drive belt

0 Feed gear 49/65

! Deck drive motor gear

@ Pulley 20

# Deck conveying belt

$ Deck feed clutch gear

% Deck gear 27/45

^ Idle gear 48

& Paper feed clutch 4 gear

* Paper feed pulley drive gear

( Gear 21

) Gear 16

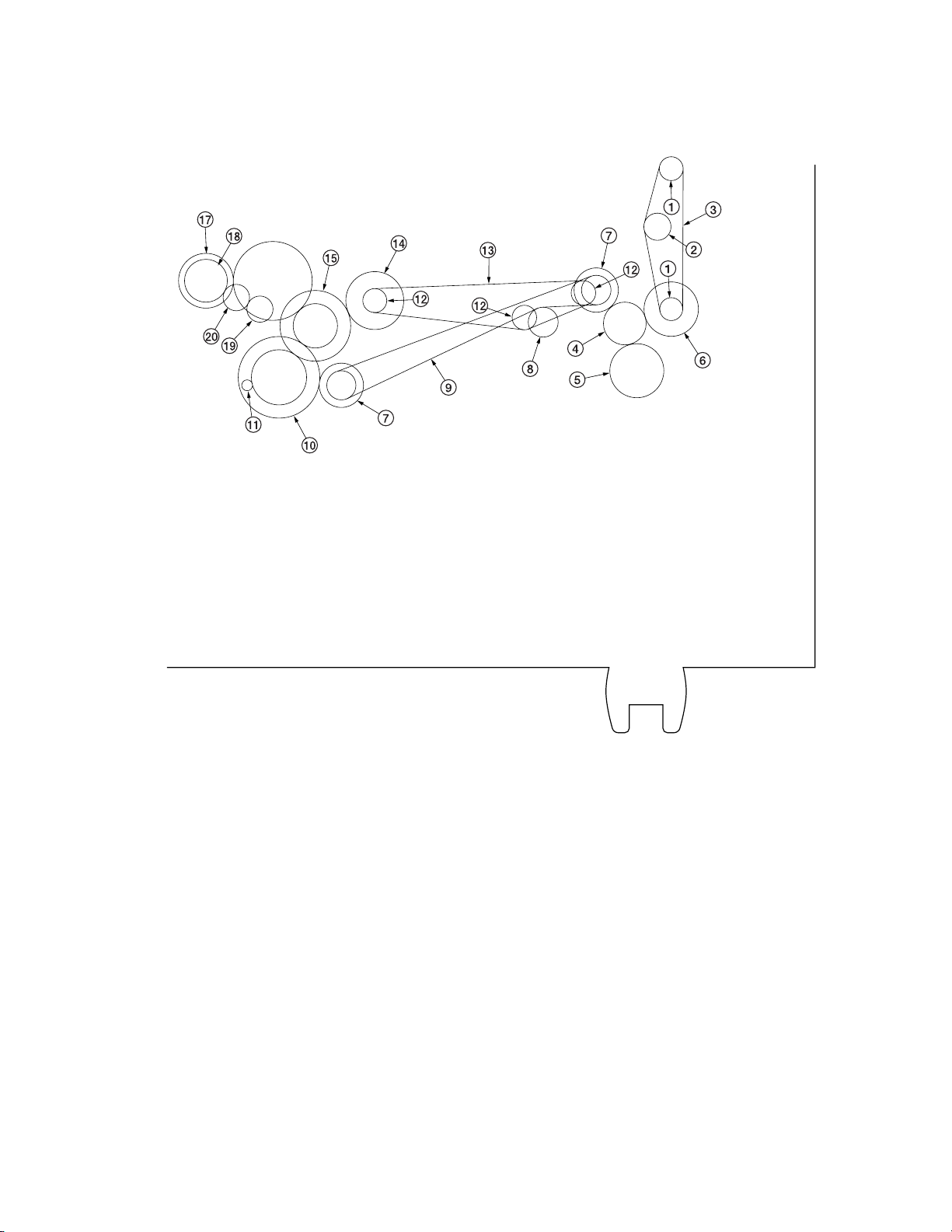

Page 24

(4) Drive system 4 (image formation motor drive train)

2BC/D

Figure 1-1-7

1 Bypass paper feed idle gear

2 Gear 20

3 Gear 30

4 Gear 39/25

5 Drum drive pulley 23/84

6 Image formation motor gear

7 Gear 63/35

8 Drum pulley 51

9 Tension pulley

0 Drum drive belt

! Gear 19

@ Registration gear 24

# Registration clutch gear

$ Pulley 40/28

% Cleaning drive belt

^ Gear 26

& Gear 30

* Drum

Figure 1-1-8 Developing section

1 Toner supply gear

2 Developing idle gear

3 Developing input gear

4 Developing sleeve gear

5 Spiral gear A

6 Spiral gear B

7 Spiral gear C

1-1-11

Page 25

2BC/D

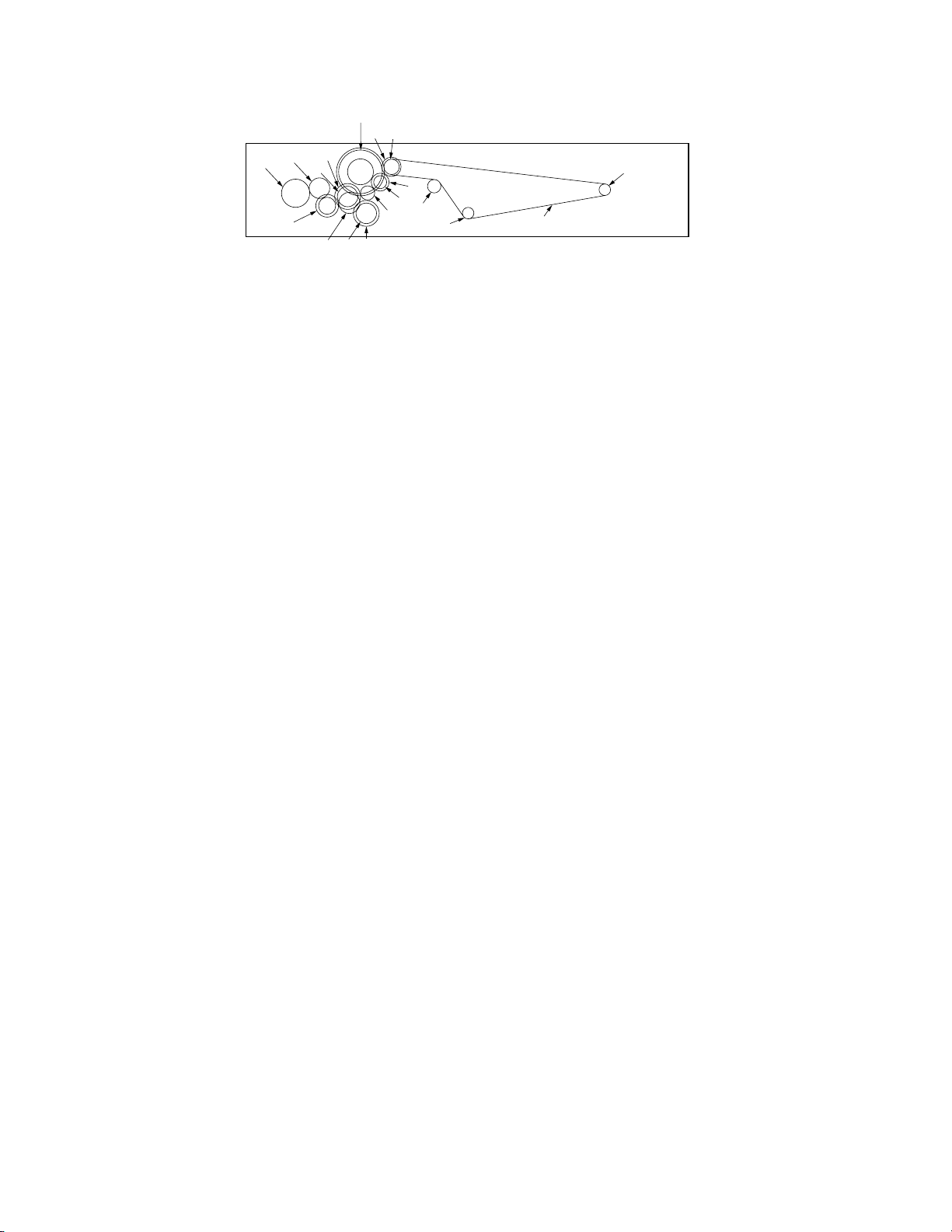

(5) Drive system 5 (Paper conveying motor drive train)

1-1-12

Figure 1-1-9

1 Pulley 32

2 Pulley 24

3 Pulley 22

4 Eject drive belt

5 Eject drive gear

6 Fixing gear 35

7 Fixing pulley 34

8 Fixing gear 63/32

9 Paper conveying motor gear

0 Fixing drive belt

! Duplex gear 45/30

@ Duplex gear 29/42

# Gear 18/26

$ Fixing joint gear

% Heat roller gear

^ Heat roller

& Gear 26

* Gear 25

( Fixing eject joint gear

) Pulley 22

⁄ Switch back pulley 20

¤ Pulley 30

‹ Feed shift belt pulley

› Feed shift belt

Page 26

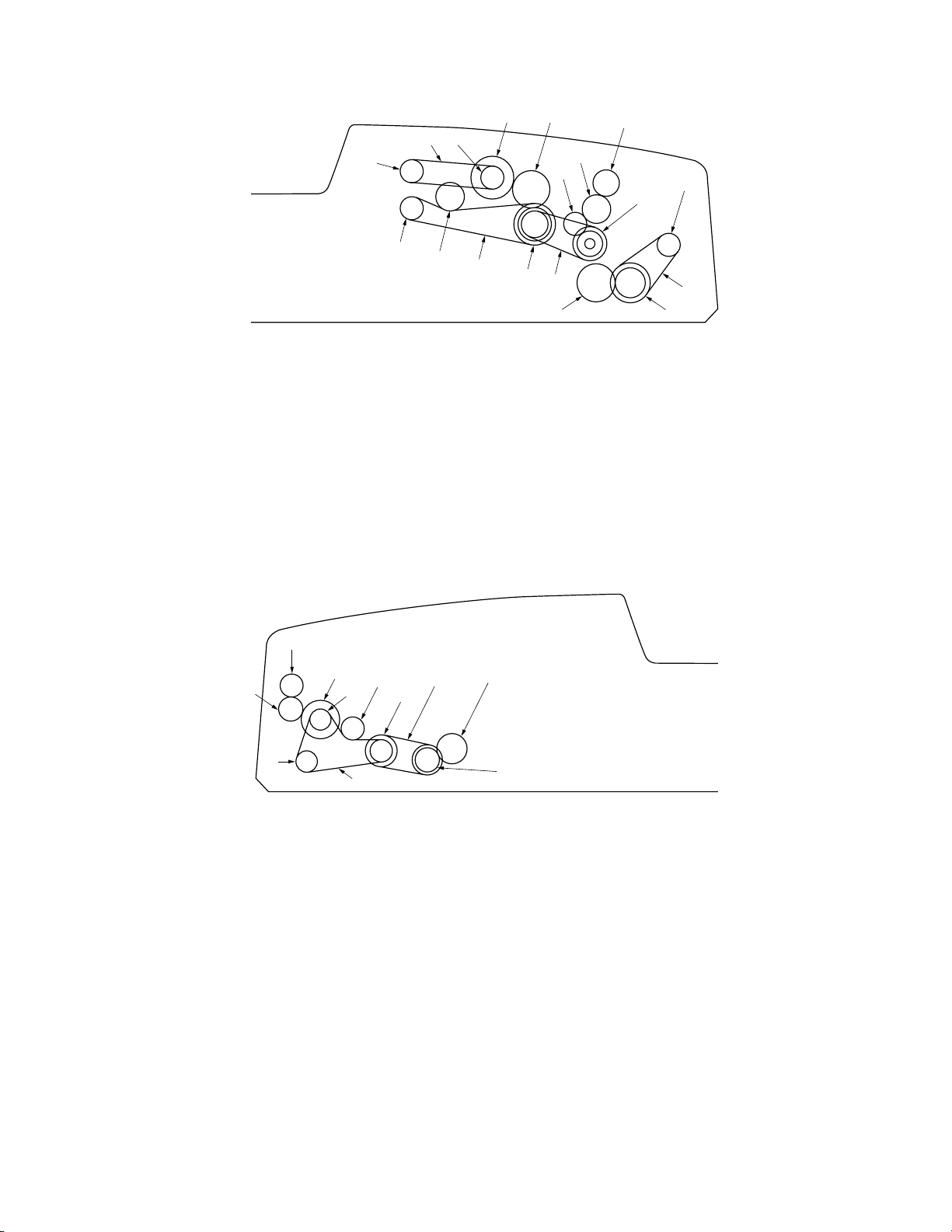

(6) Drive system 6 (duplex section)

9

0

&

8

1

2

^

7%$

3

#

@

!

5

6

Figure 1-1-10

2BC/D

7

4

1 Duplex joint gear

2 Clutch gear 26

3 Paper conveying pulley 40

4 Paper conveying drive belt

5 Paper conveying tension pulley

6 Paper conveying pulley 20

7 Paper conveying pulley 20

8 Duplex registration gear 20/30

9 Clutch gear 26

0 Front transfer drive gear

! Gear 22

@ Gear 18

# Gear 17

$ Gear 40

% Duplex forwarding clutch gear

^ Gear 40

& Duplex reversing clutch gear

1-1-13

Page 27

2BC/D

(7) Drive system 7 (DF)

6

1

Figure 1-1-11 DF (inside rear of machine)

1 Original feed motor pulley

2 Pulley 35/22/22

3 Idle gear 26

4 Original feed clutch gear

5 DF original feed pulley 18

6 DF forwarding pulley 18

7 Tension pulley

8 Original feed drive belt

9 DF forwarding belt

9

7

5

43

#

@

!

0

8

2

$

&

As viewed from machine rear

0 DF registration pulley 28/18

! Idle gear 15

@ Idle gear 20

# Switch back gear 18

$ DF registration drive belt

% Gear 22/35

^ Original conveying motor pulley

& Gear 28

* Original conveying drive belt 1

^

*

%

8

7

6

5

9

0

1

4

!

Figure 1-1-12 DF (inside front of machine)

1 Lower original conveying pulley 25/18

2 Gear 18/25

3 Eject gear 18

4 Middle original conveying pulley 18

5 Upper original conveying pulley 18

6 JAM release gear 24

3

2

As viewed from machine front

7 Joint gear 14

8 JAM release gear 14

9 Tension pulley

0 Eject drive belt

! Conveying drive belt 2

1-1-14

Page 28

2BC/D

1-2-1 Drum

Note the following when handling or storing the drum.

• When removing the image formation unit, never expose the drum surface to strong direct light.

• Keep the drum at an ambient temperature between –20°C/–4°F and 40°C/104°F and at a relative humidity not higher

than 90% RH. Avoid abrupt changes in temperature and humidity.

• Avoid exposure to any substance which is harmful to or may affect the quality of the drum.

• Do not touch the drum surface with any object. Should it be touched by hands or stained with oil, clean it.

1-2-2 Developer and toner

Store the developer and toner in a cool, dark place. Avoid direct light and high humidity.

1-2-3 Installation environment

1. Temperature: 10 - 35°C/50 - 95°F

2. Humidity: 15 - 85%RH

3. Power supply: 120 V AC, 12 A

4. Power source frequency: 50 Hz ±0.3%/60 Hz ±0.3%

5. Installation location

• Avoid direct sunlight or bright lighting. Ensure that the photoconductor will not be exposed to direct sunlight or other

strong light when removing paper jams.

• Avoid extremes of temperature and humidity, abrupt ambient temperature changes, and hot or cold air directed onto

the machine.

• Avoid dust and vibration.

• Choose a surface capable of supporting the weight of the machine.

• Place the machine on a level surface (maximum allowance inclination: 1° ).

• Avoid air-borne substances that may adversely affect the machine or degrade the photoconductor, such as

mercury, acidic of alkaline vapors, inorganic gasses, NOx, SOx gases and chlorine-based organic solvents.

• Select a room with good ventilation.

6. Allow sufficient access for proper operation and maintenance of the machine.

Machine front: 1000 mm/39