Kyocera Mita FS 1020D Diagram

FS-1020D

SERVICE

MANUAL

Published in Oct. ’03

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING:Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION:Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the copier.

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. ............................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. .............................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .....

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. ..............

• Do not install the copier near a radiator, heater, other heat source or near flammable material.

This may cause fire. ..........................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ..........

• Always handle the machine by the correct locations when moving it. ..............................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may

cause the copier to move unexpectedly or topple, leading to injury..................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is

accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention

immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain

medical attention. ..............................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. ........................................................................................................................

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly. ..............

• Always follow the procedures for maintenance described in the service manual and other related

brochures. .........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety

mechanisms and protective circuits. .................................................................................................

• Always use parts having the correct specifications. ..........................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related

brochure when replacing them. Using a piece of wire, for example, could lead to fire or other

serious accident. ...............................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ...............................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. ............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If

it is dirty, clean it to remove the risk of fire or electric shock. ............................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ..............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause

electric shock if handled improperly. .................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections...........................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. .......

• Handle the fixing section with care to avoid burns as it can be extremely hot. .................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures...........................................................................................................

• Do not remove the ozone filter, if any, from the copier except for routine replacement. ...................

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ......................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ..............................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks. .......

• Remove toner completely from electronic components. ...................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ...................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten

connector, trapped wire and missing screws. ..................................................................................

• Check that all the caution labels that should be present on the machine according to the

instruction handbook are clean and not peeling. Replace with new ones if necessary. ...................

• Handle greases and solvents with care by following the instructions below: ....................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the main

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc. ..........................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet

immediately. ......................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than

the specified refiner; it may generate toxic gas. ................................................................................

1-1-1 Specifications

Type ............................................... Desktop

Printing system............................... Indirect electrostatic system

Paper type ...................................... Cassette: Plain paper (60 - 90 g/m

MP tray: Plain paper (60 - 90 g/m

Special paper: Transparencies, letterhead, colored paper, recycled paper

Note: Use the MP tray for special paper

Paper size ...................................... A4 (210 - 297 mm)

B5 (182 - 257 mm)

A5 (148 - 210 mm)

Letter (8

Legal (8

1

/2" - 11")

1

/2" - 14")

Folio (210 - 330 mm)

Oficio II (216 - 330 mm)

Non-standard size (148 to 210 mm × 210 to 297 mm: cassette),

(70 to 216 mm × 148 to 297 mm: MP tray)

Printing speed ................................ Simplex printing: 20 pages//min. (A4, plain), 21 pages//min. (Letter, plain)

Duplex printing: 10 pages//min. (A4/Letter, plain)

Note: When printing multiple copies of the same page

First print ........................................ Within 10 s (A4/Letter), depends on input data

Warm-up time................................. Within 15 s (room temperature 23°C/73.4°F, humidity 50% RH)

Paper feed system ......................... One universal cassette and one MP tray

Paper loading capacity ................... Cassette: 250 sheets (80 g/m

MP tray: 50 sheets (80 g/m

Paper eject system .........................Face down: 250 sheets (80 g/m

Standard memory .......................... 16 MB, expandable up to 272 MB

Additional memory ......................... 1 slot (16/32/64/128 MB DIMM)

Resolution ...................................... Fast 1200 mode

600 × 600 dpi, with KIR (Kyocera Image Refinement)

300 × 300 dpi, with KIR (Kyocera Image Refinement)

Photoconductor .............................. OPC (drum diameter 30 mm)

Charging system ............................ Single positive corona charging

Developing system ......................... Single element reversing process

Transfer system ............................. Transfer roller

Fixing system ................................. Heat roller

Heat source: halogen heaters (750 W)

Control temperature: 180°C/356°F (at normal ambient temperature)

Abnormally high temperature protection device: thermal cutout

Charge erasing system .................. Exposure by eraser lamp (LED array)

Cleaning system ............................ Cleaning blade

Controller hardware ....................... CPU: Power PC405 (266 MHz)

System ROM: 4 MB

Font ROM: 2 MB (16 Mbit × 1)

Main RAM: 16 MB standard (on-board); expanding up to 272 MB (standard 16 MB

+256 MB) at the maximum by adding optional expansion memory

Optional expansion RAM (DIMM): 1 slot

2

[thick paper mode: 90 - 105 g/m2])

2

[thick paper mode: 90 - 163 g/m2])

2

, 0.11 µm)

2

, 0.11 µm)

2

, 0.11 µm)

2FM

1-1-1

2FM

Controller software ......................... a) Emulation

PCL6 (PCL5e+PCLXL)

KPDL3 (PostScript 3 compatible)

b) Fonts:

Bitmap font:

1 Line Printer bitmap font

Outline fonts:

35 PCL6 (PCL5e/PCL-XL) fonts

45 KPDL2 fonts:

c) Graphic:

(1) Raster graphic:

75, 100, 150, 200*, 300, 600* dpi

(*200 dpi is supported when the resolution is 600 dpi.)

(2) Vector graphic:

Line, Box, Circle, Arc, Fill pattern etc.

(3) Bar code:

One-dimensional bar code: 45 types

Two-dimensional bar code: 1 type (PDF-417)

d) Connectivity

Plug & play, Windows 95/98/Me/NT4.0/2000/XP

Interface ......................................... Parallel: High-speed (bi-directional), IEEE 1284 Nibble/ECP mode

USB: Full-Speed USB2.0

Optional interface (KUIO-LV) × 1: Network interface card IB-20 (10 Base-TX/100

Base-TX/10 Base-2), IB-21E (10 Base-TX/100 Base-TX), wireless LAN card IB-22

must be installed.

Optional serial interface: RS-232C (Max. 115.2 Kbps), Serial interface board IB-11

must be installed.

Dimensions .................................... 378 (W) × 235 (D) × 375 (H) mm

7

14

/8" (W) × 91/4" (D) × 143/4" (H)

Weight ............................................ Approx. 10.5 kg/23

1

/8 lbs

Floor requirements ......................... 496 (W) × 740 (D) mm

9

19

/16" (W) × 293/16" (D)

Power source ................................. 120 V AC, 60 Hz, 7.1 A

220 - 240 V AC, 50/60 Hz, 3.8 A

Power consumption ....................... Max.: 819 W

During sleep mode: 4.5 W (120 V AC), 4.2 W (220 - 240 V AC)

Noise .............................................. Printing: 55 dB(A)

Ready: 32 dB(A)

Options ........................................... Paper feeder, Additional memory (DIMM), Memory card, Network interface card

IB20/IB21E/IB-22, Serial interface board IB-11

1-1-2

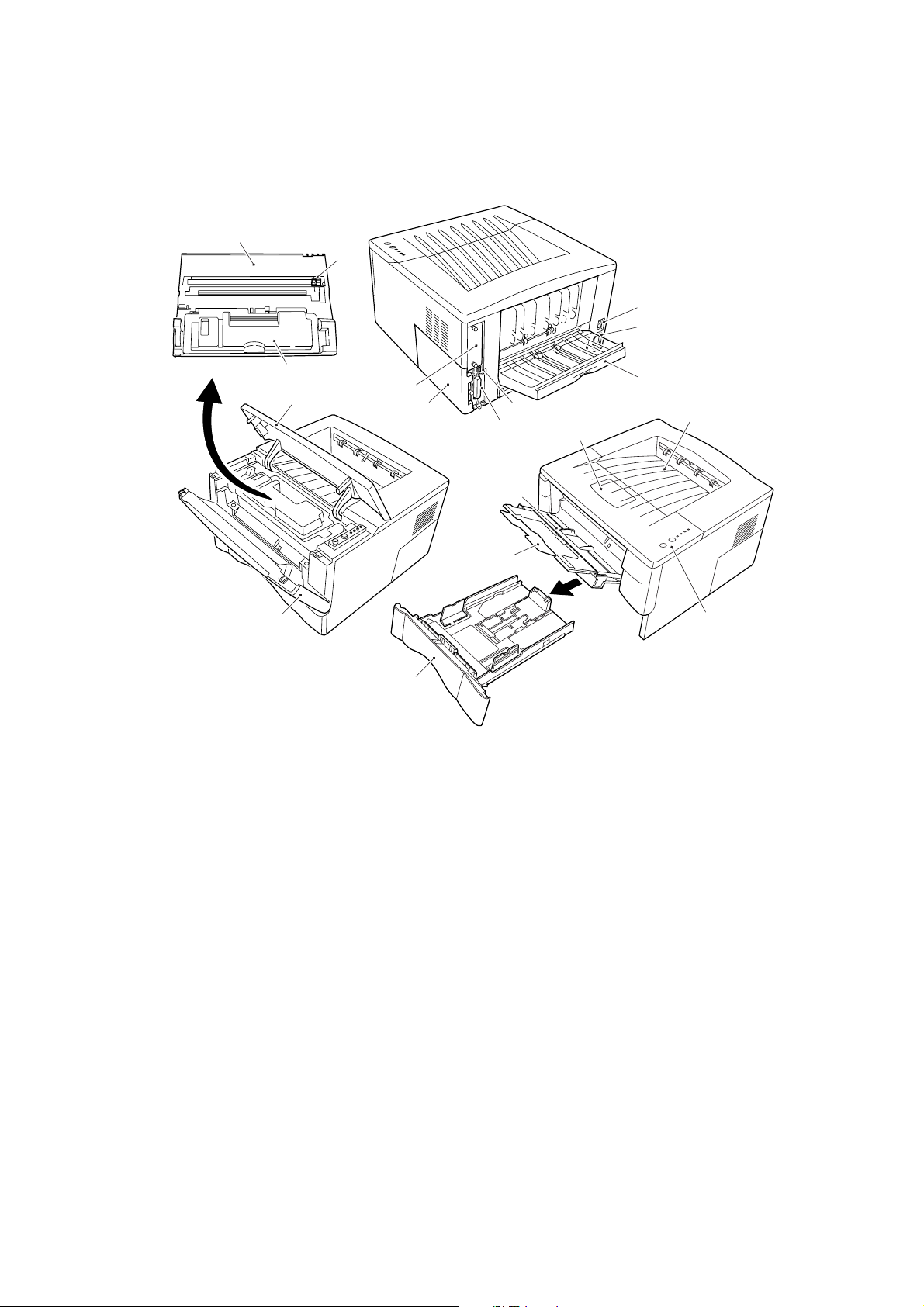

1-1-2 Name of parts

(1) Overall

3

2FM

5

!

*

4

1

2

1 Front top cover

2 Front cover

3 Process unit

4 Toner container

5 Main charger cleaner

6 Cassette

7 Paper stopper

8 Face-down output tray

9 MP tray

$

@

6

Figure 1-1-1

#

^

%

9

0

0 Extension tray

! Power switch

@ Memory cover

# Rear cover

$ Optional interface slot

% Parallel interface connector

^ USB interface connector

& Operator panel

* AC inlet

7

8

&

1-1-3

2FM

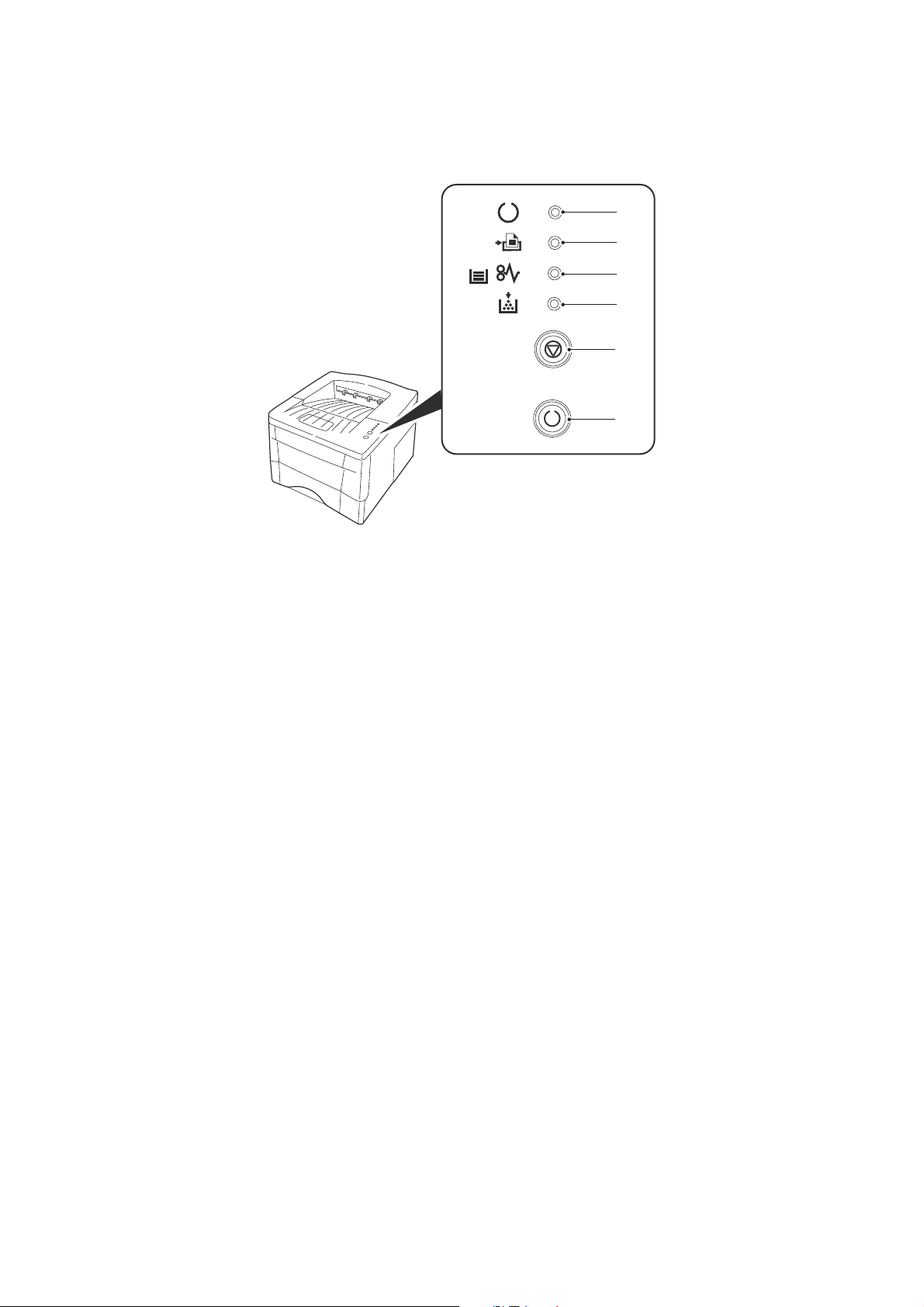

(2) Operator panel

1

2

3

4

5

6

Figure 1-1-2

1 Ready indicator (Green)

2 Data indicator (Green)

3 Attention indicator (Red)

4 Toner indicator (Red)

5 CANCEL key

6 GO key

1-1-4

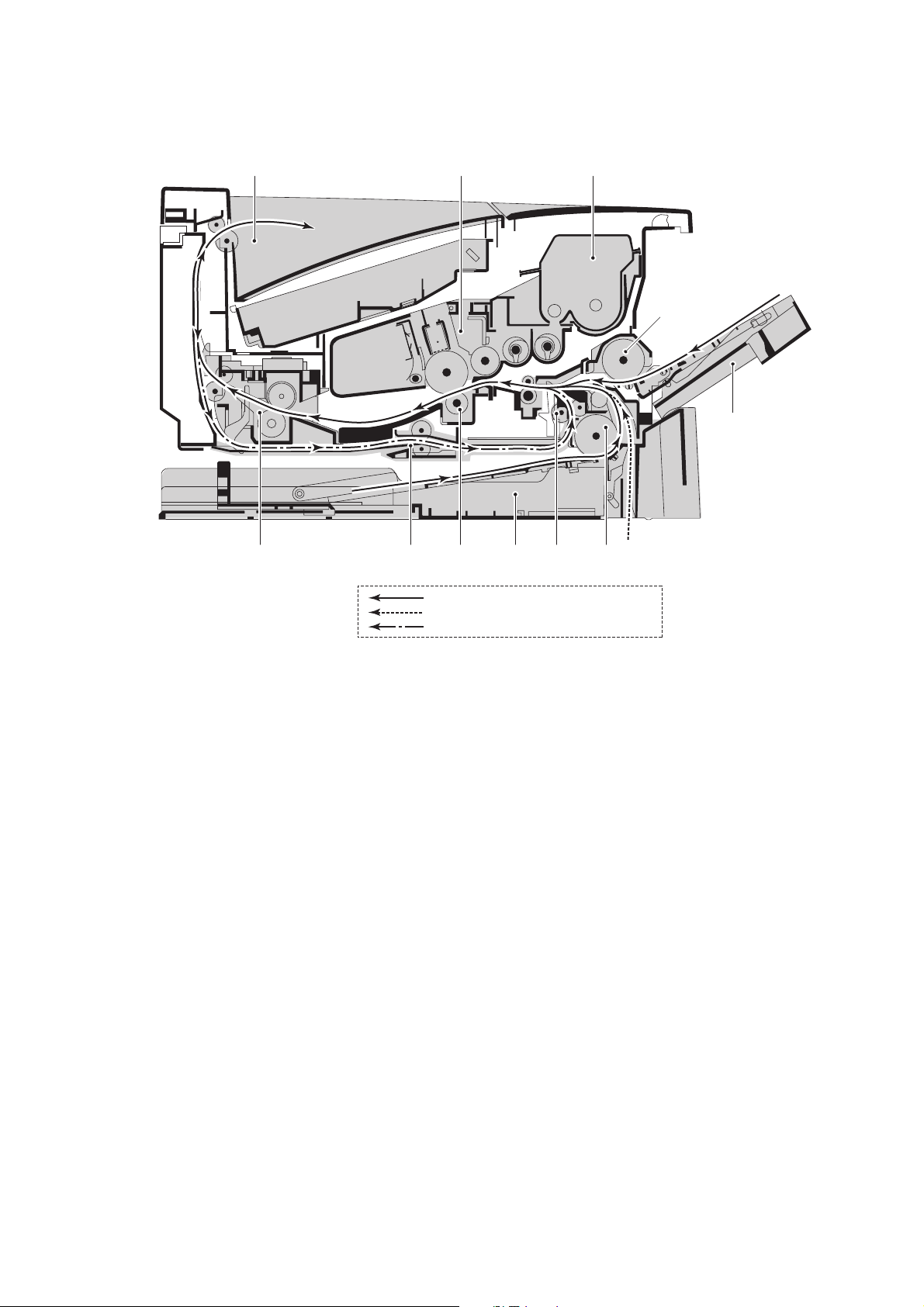

(2) Cross section view

2FM

9

8

Paper path

5

6

0 !7 21

Cassette, MP tray

Optional paper feeder

Switch back and refeed (duplex printing)

4

3

Figure 1-1-2

1 Cassette

2 Paper feed unit

3 MP tray

4 MP tray paper feed unit

5 Process unit

6 Toner container

7 Transfer section

8 Fuser unit

9 Face-down output tray

0 Switch back/conveying section

! Refeed unit

1-1-5

2FM

1-2-1 Process unit (drum)

Note the following when handling or storing the drum.

• When removing the process unit, never expose the drum surface to strong direct light.

• Keep the drum at an ambient temperature between 10°C/50°F and 32.5°C/90.5°F and at a relative humidity not higher

than 80% RH. Avoid abrupt changes in temperature and humidity.

• Avoid exposure to any substance which is harmful to or may affect the quality of the drum.

• Do not touch the drum surface with any object. Should it be touched by hands or stained with oil, clean it.

1-2-2 Installation environment

1. Temperature: 10 - 32.5°C/50 - 90.5°F

2. Humidity: 20 - 80%RH

3. Power supply: 120 V AC, 7.1 A

4. Power source frequency: 50 Hz ±0.3%/60 Hz ±0.3%

5. Installation location

• Avoid direct sunlight or bright lighting. Ensure that the photoconductor will not be exposed to direct sunlight or other

strong light when removing paper jams.

• Avoid extremes of temperature and humidity, abrupt ambient temperature changes, and hot or cold air directed onto

the machine.

• Avoid dust and vibration.

• Choose a surface capable of supporting the weight of the machine.

• Place the machine on a level surface (maximum allowance inclination: 1° ).

• Avoid air-borne substances that may adversely affect the machine or degrade the photoconductor, such as

mercury, acidic of alkaline vapors, inorganic gasses, NOx, SOx gases and chlorine-based organic solvents.

• Select a room with good ventilation.

6. Allow sufficient access for proper operation and maintenance of the machine.

Machine front: 50 mm/19

Machine right: 25 mm/9

Machine above: 30 mm/11

220 - 240 V AC, 3.8 A

11

/16" Machine rear: 40 mm/153/4"

7

/8" Machine left: 25 mm/97/8"

13

/16"

1-2-1

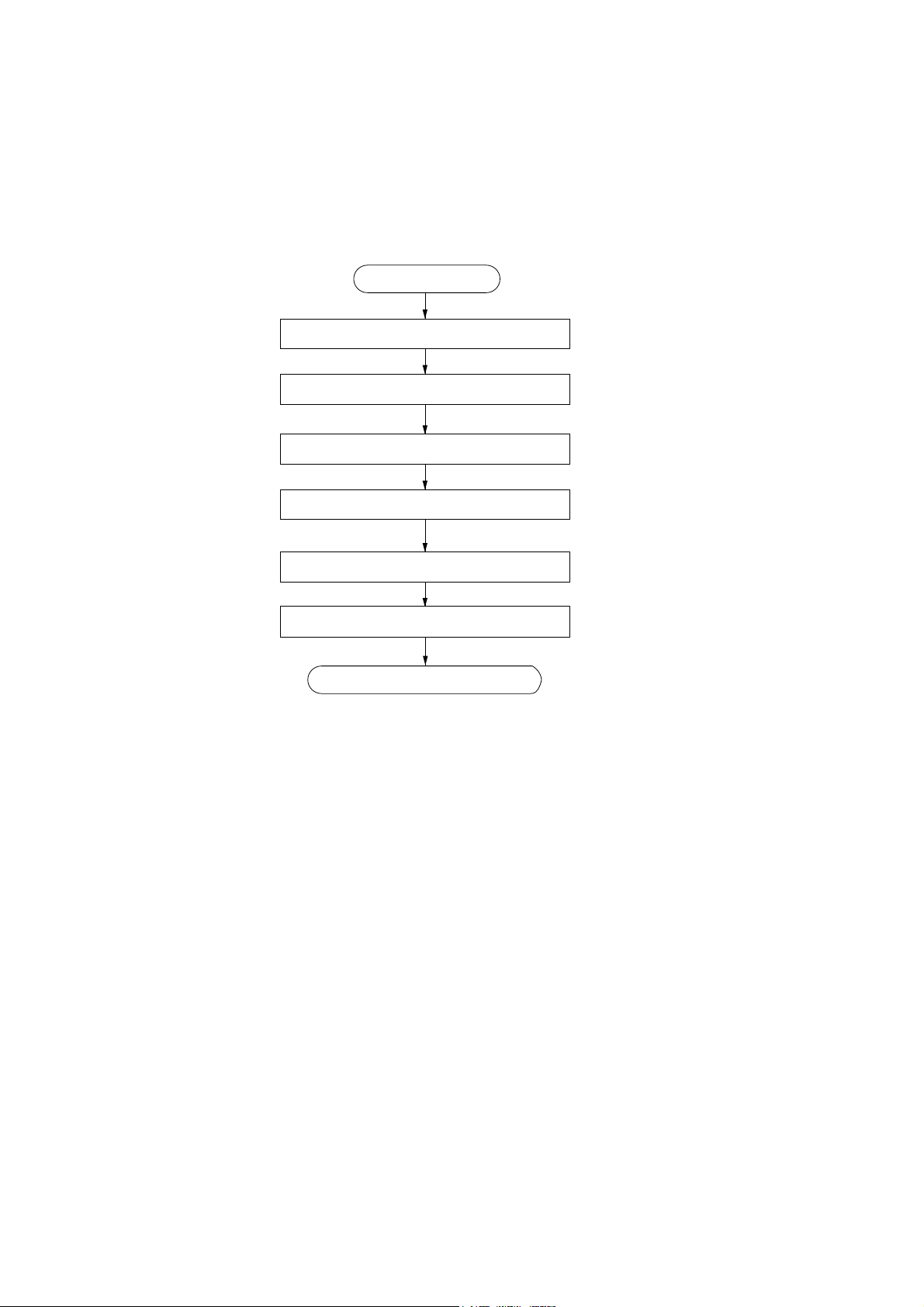

1-3-1 Unpacking and installation

(1) Installation procedure

Remove the tape and protective packing.

Connect the printer cable and power cord.

2FM

Start

Unpack.

Install a toner container.

Load paper.

Inisializing the pirnter and make test print.

Completion of the machine installation.

1-3-1

2FM

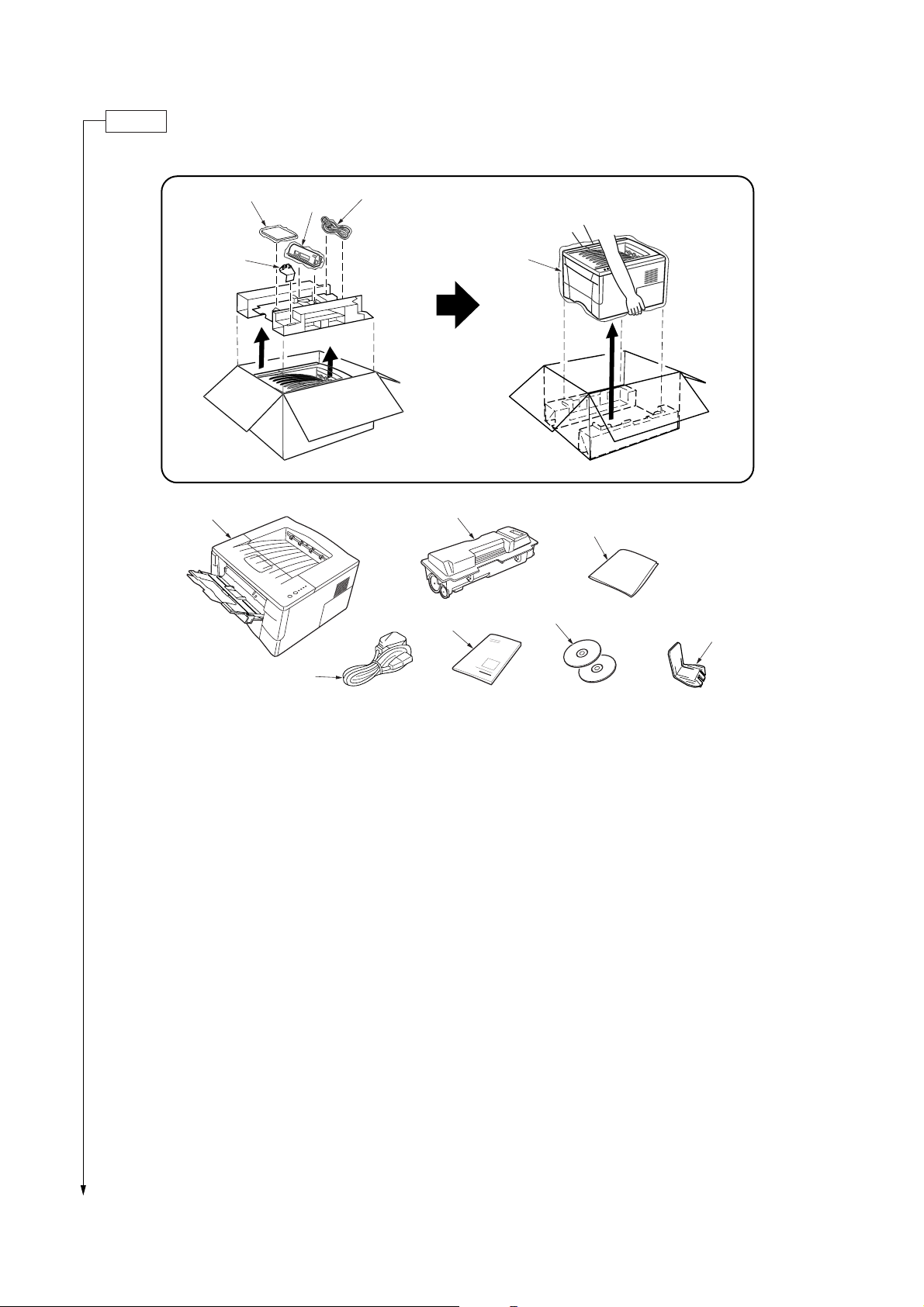

Unpack.

1

7

3

4

2

3

1

4

5

6

7

2

Figure 1-3-1 Unpacking

1 Printer

2 Power cord

3 Installation guide

4 Toner container

5 Cleaning cloth

6 CD-ROMs

7 Extension tray [For U.S.A only]

1-3-2

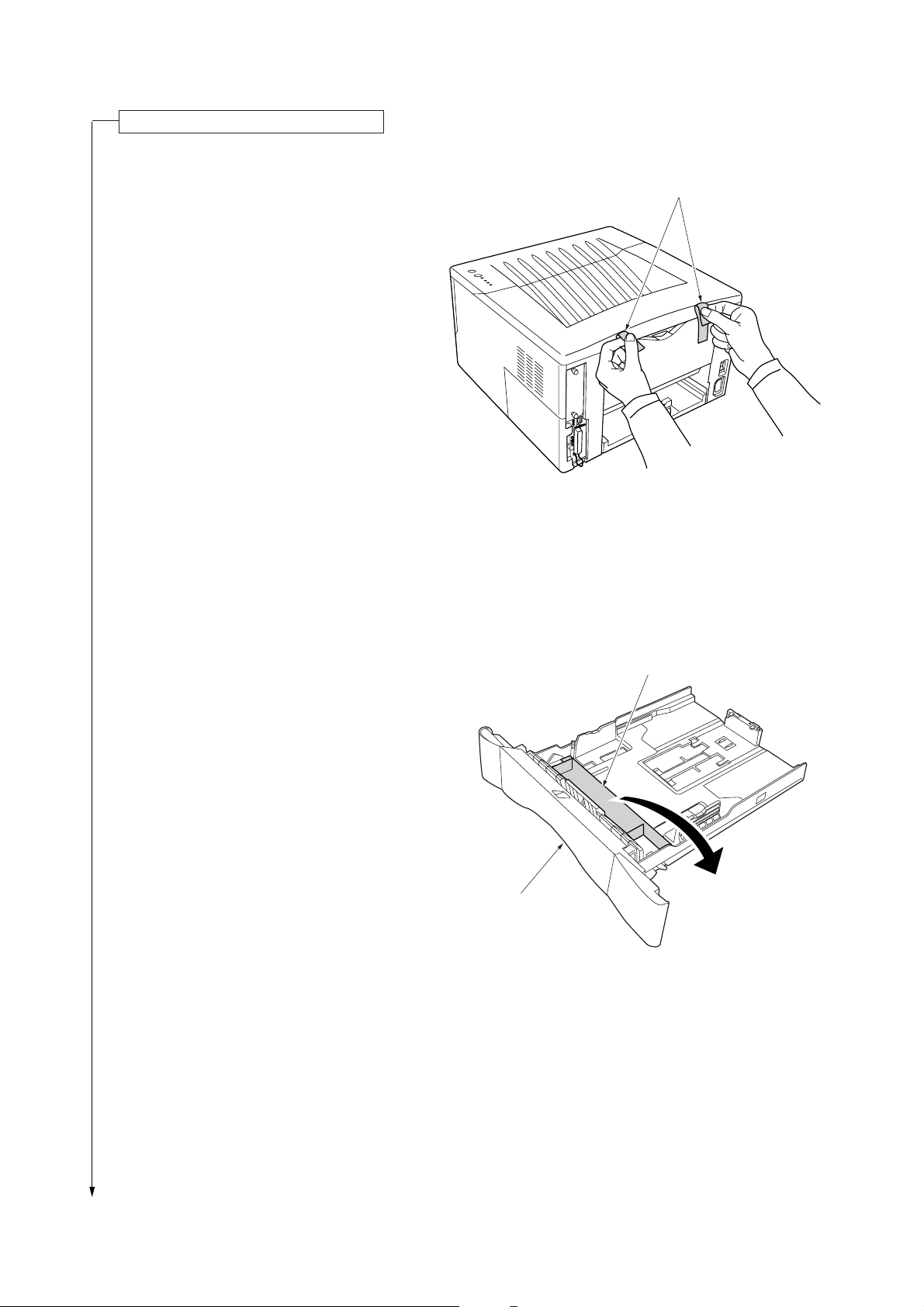

Remove the tape and protective packing

1. Remove the two tape.

2FM

Tape

Figure 1-3-2

2. Pull the cassette out of the printer.

3. Remove the protective packing from inside the

cassette.

Protective packing

Cassette

Figure 1-3-3

1-3-3

2FM

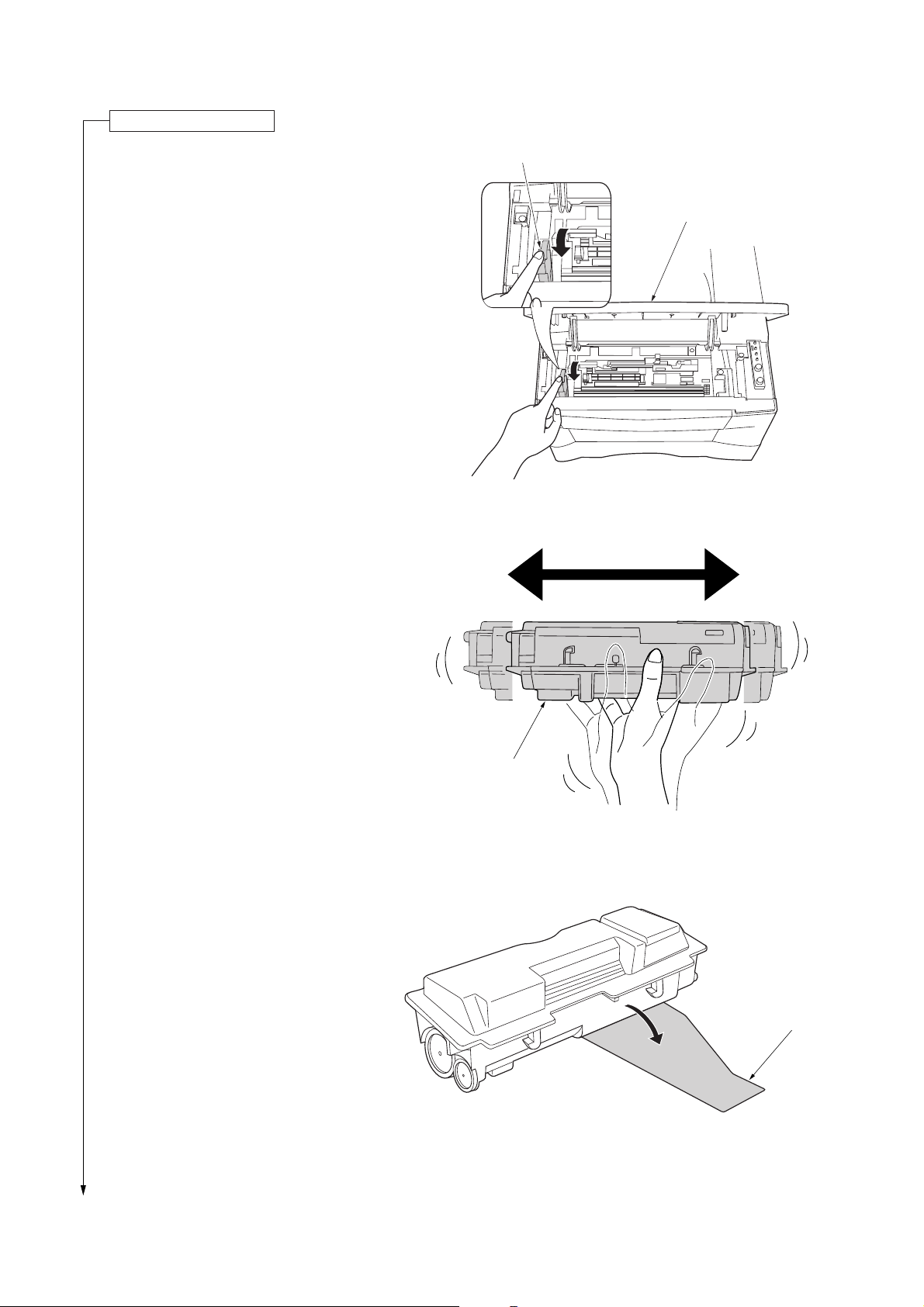

Install a toner container.

1. Open the front top cover.

2. Move the lock lever until it is in its unlocked

position (marked “UNLOCK”).

3. Shake the toner container horizontally back

and forth five or six times so that the toner

inside of it becomes evenly distributed.

Lock lever

Front top cover

Figure 1-3-4

4. Remove the orange protective seal.

Toner container

Figure 1-3-5

Protective seal

Figure 1-3-6

1-3-4

2FM

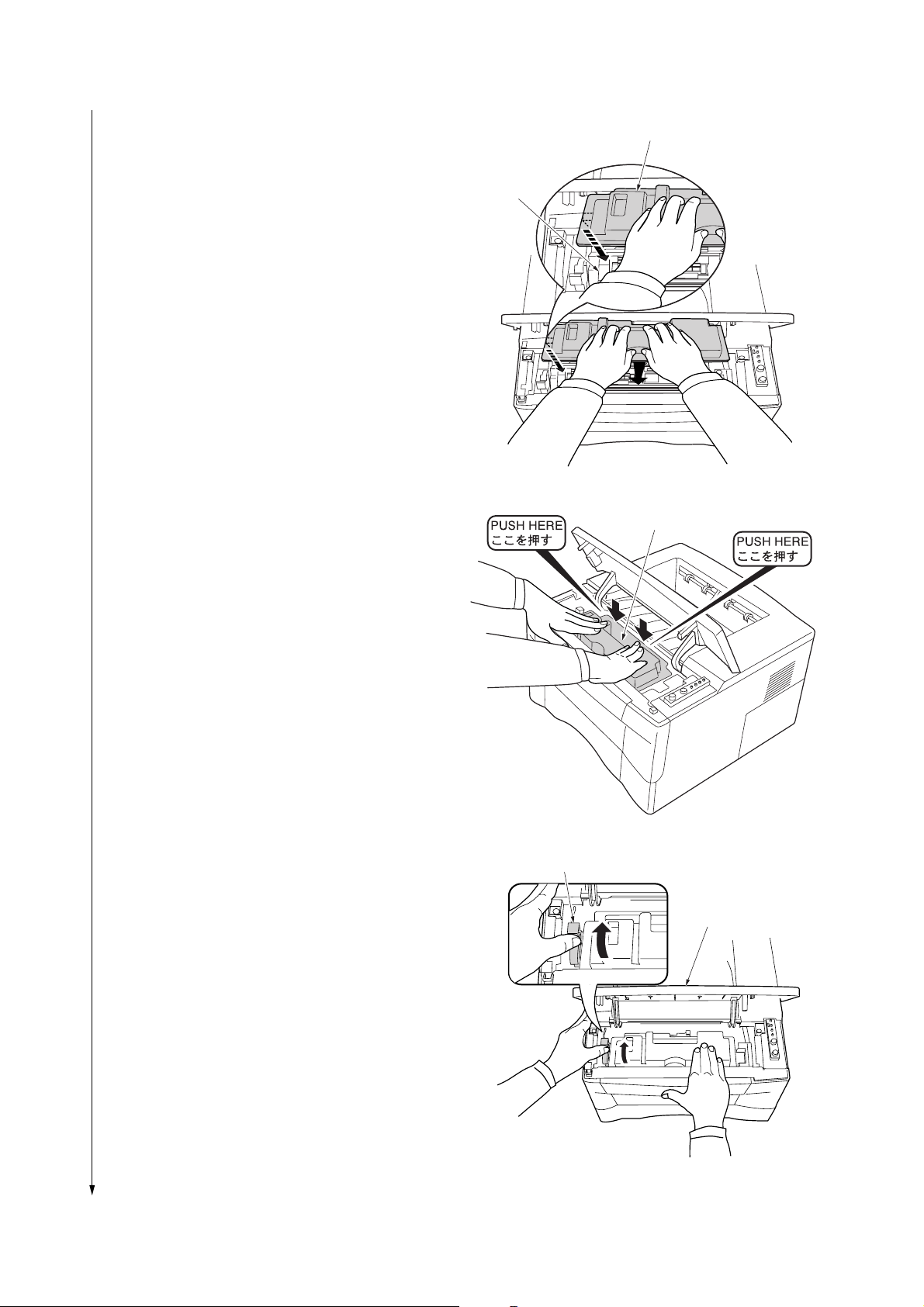

5. Set the toner container into the process unit.

6. Push in on the areas of the toner container marked

“PUSH HERE” until the container clicks into place in

the process unit.

Toner container

Process unit

Figure 1-3-7

Toner container

7. Push the lock lever back into its locked position.

8. Close the front top cover.

Figure 1-3-8

Lock lever

Front top cover

LOCK

UNLOCK

Figure 1-3-9

1-3-5

2FM

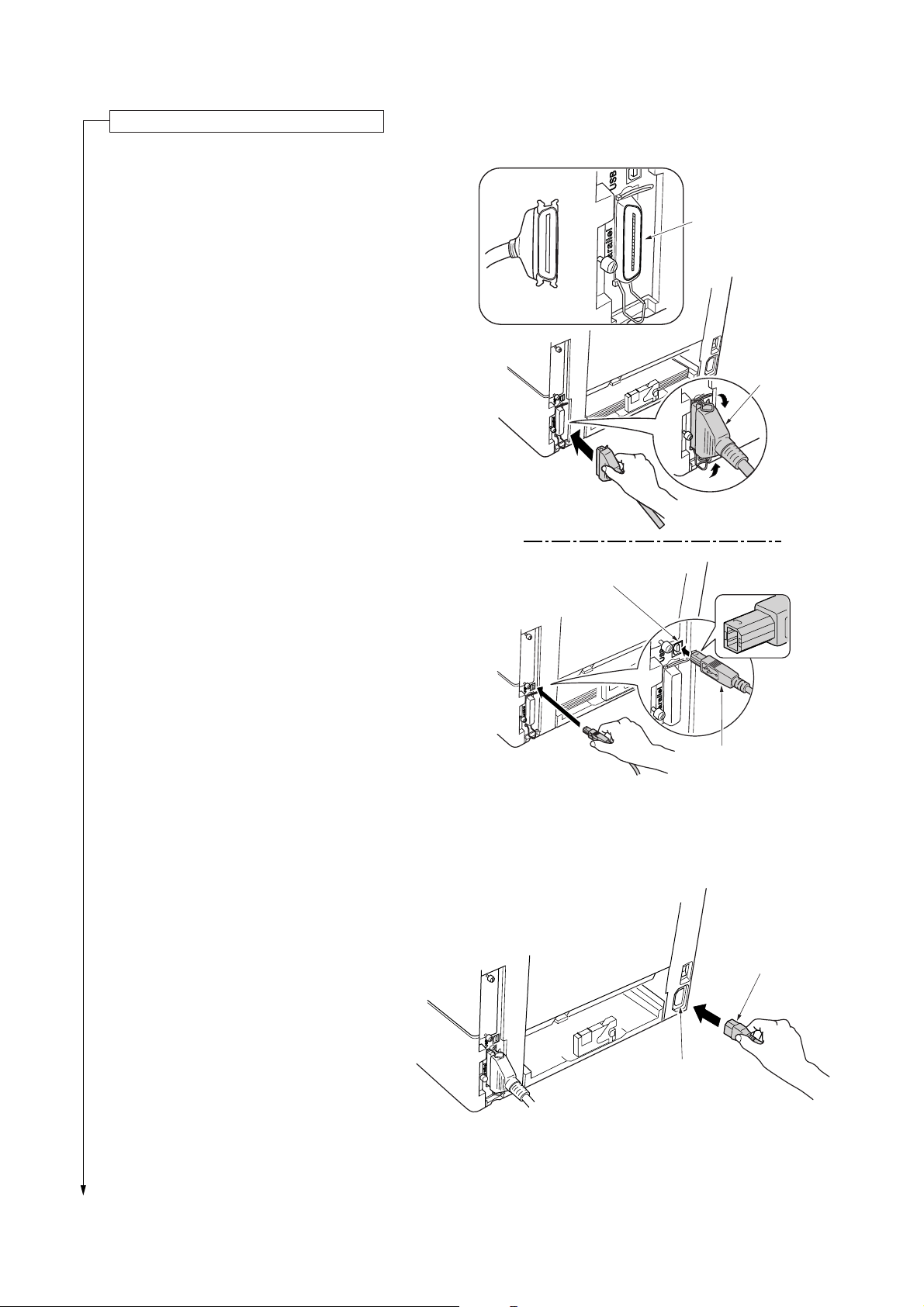

Connect the printer cable and power cord.

1. Connect the printer cable (parallel or USB).

Parallel interface

connector

Parallel

printer cable

2. Connect the power cord.

USB interface

connector

USB cable

Figure 1-3-10

Power cord

1-3-6

AC inlet

Figure 1-3-11

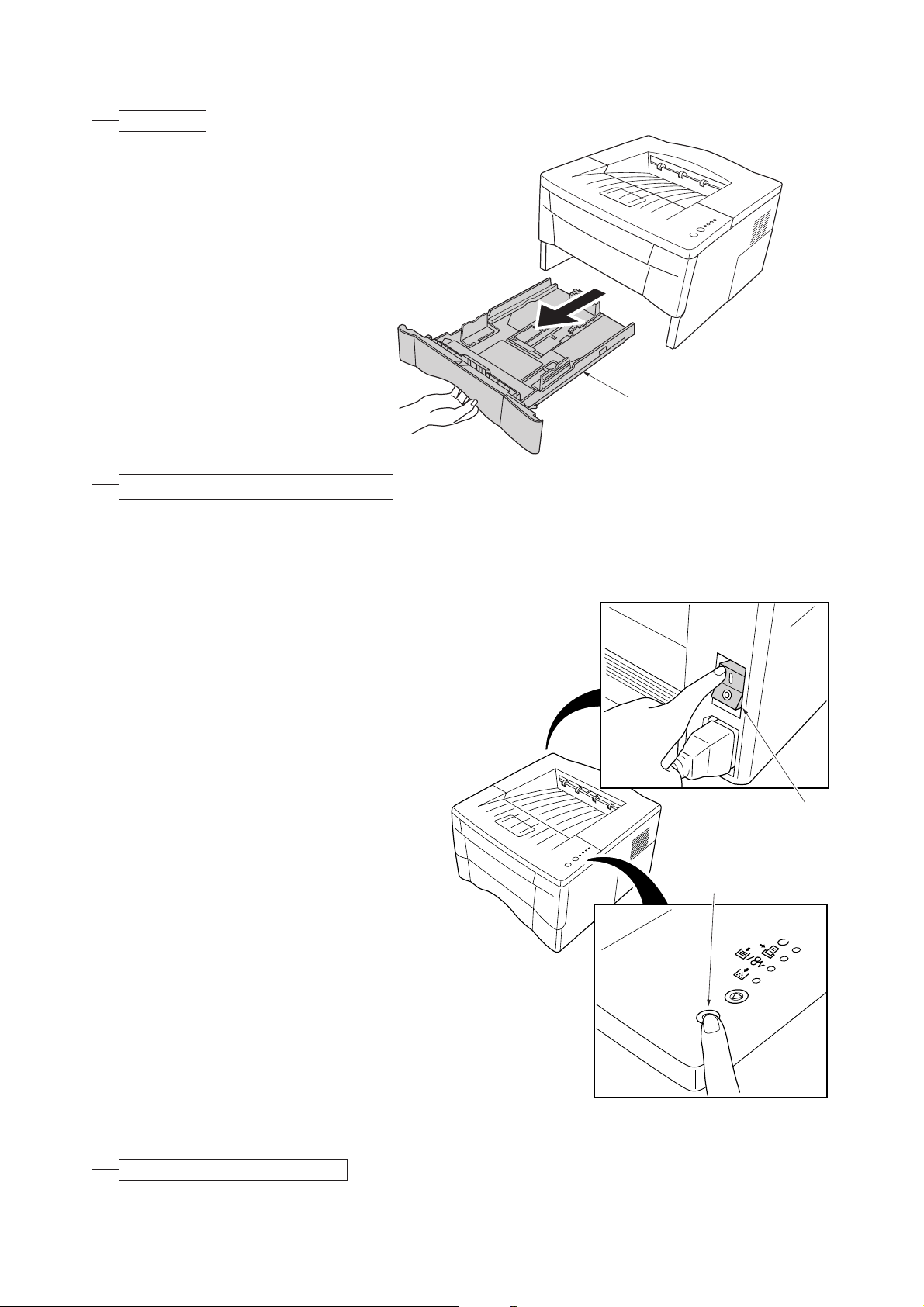

Load paper.

1. Pull the cassette out of the copier.

2. Set the paper in the cassette.

2FM

Cassette

Initializing the printer and make test print.

1. Turn on the printer’s power switch. Upon turning

on the power, the printer’s 4 indicators flash in

sequence until printer initialization is complete,

then the indicator ( [on line]) lights steadily.

2. The printer can print two different types of status

page standard and service-purpose. A servicepurpose status page contains more detailed

information about printer settings than a standard

status page.

• To print a standard status page, press

the GO key for at least 3 seconds and

the indicators light in sequence from

top to bottom.

• To print a service-purpose status

page, press the GO key for more than

10 seconds and the indicators light in

sequence twice from top to bottom.

Figure 1-3-12

Power switch

GO key

Completion of machine installation.

Figure 1-3-13

1-3-7

2FM

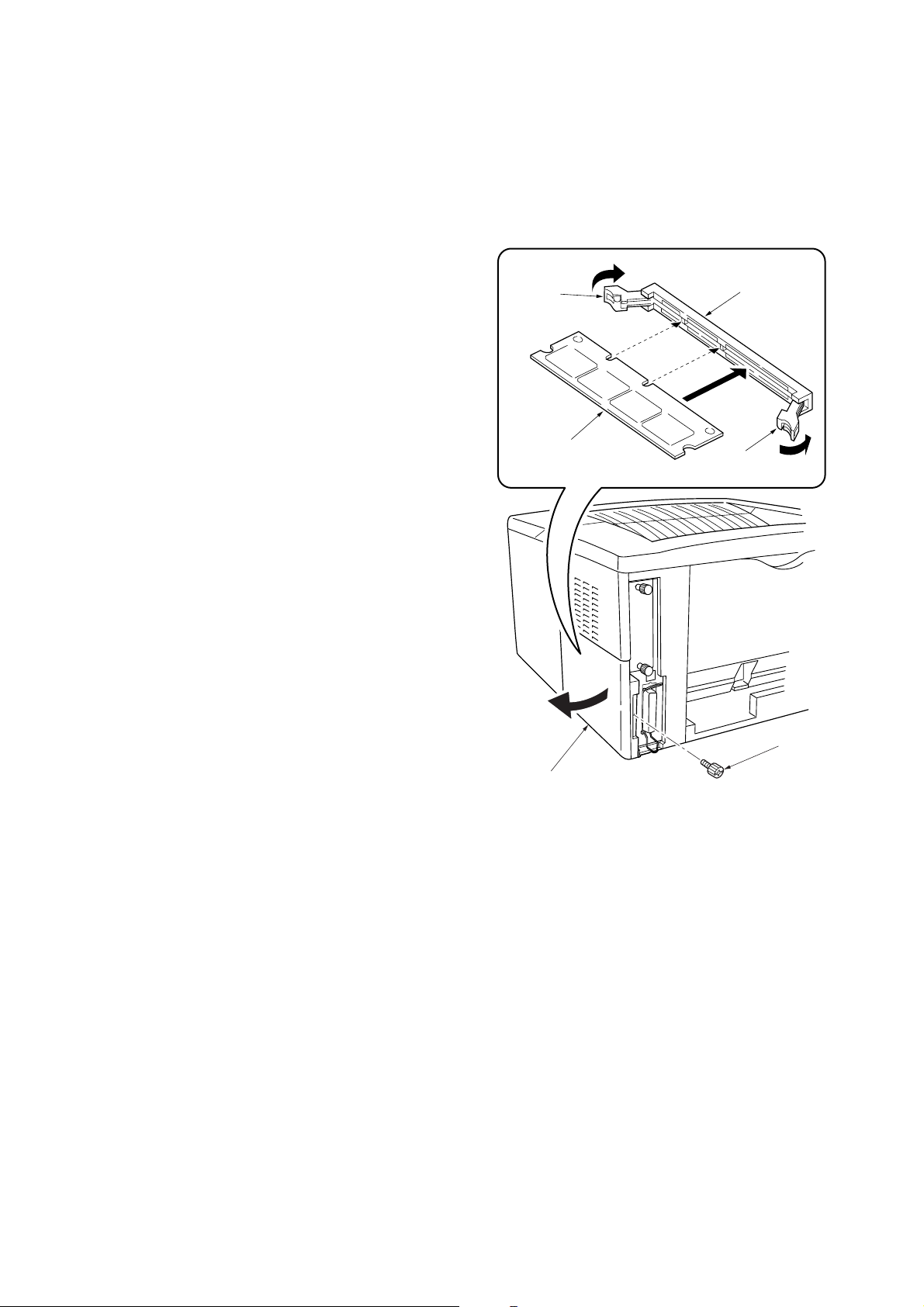

1-3-2 Installing the expanding memory (option)

The main board of the printer is equipped with one

socket for memory expansion. Expansion memory is

available in the form of DIMM (Dual In-line Memory

Module).

CAUTION

Take precautions that no foreign substances such as

metal chips or liquid get inside the printer during the

installation process. Operation of the printer during the

presence of a foreign substance may lead to fire or

electric shock.

WARNING

Turn the printer’s power switch off. Unplug the printer’s

power cable.

Clip

Memory socket

Procedure

1. Remove the one screw and then remove the

memory cover.

2. Open the clips on both ends of the DIMM socket.

3. Insert the DIMM into the DIMM socket so that the

notches on the DIMM align with the corresponding

protrusions in the slot.

4. Close the clips on the DIMM slot to secure the

DIMM.

DIMM

Memory cover

Figure 1-3-14 Inserting the DIMM

Clip

Screw

1-3-8

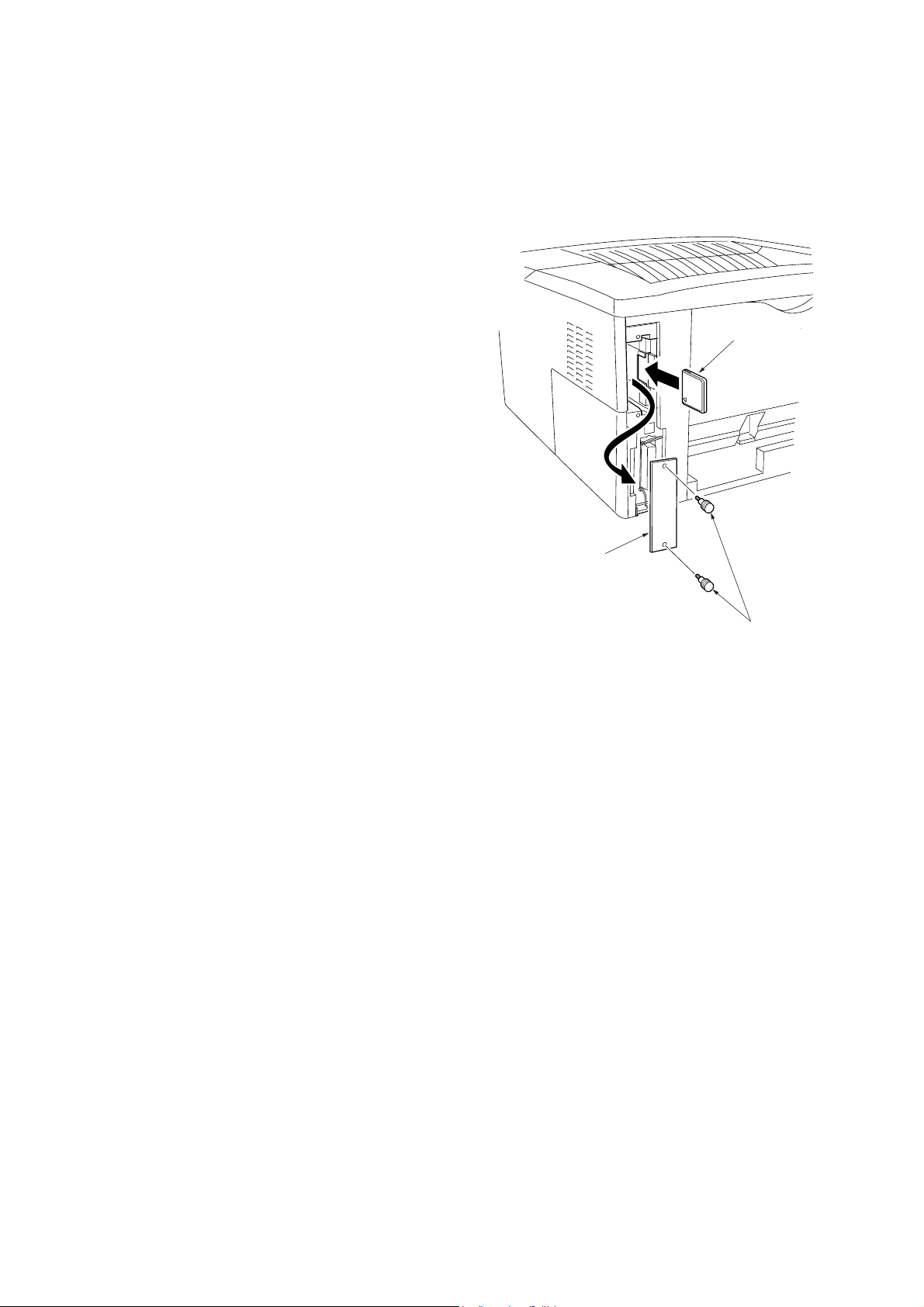

1-3-3 Installing the memory card (option)

The main board of the printer is equipped with one

slot for memory card.

CAUTION

Take precautions that no foreign substances such as

metal chips or liquid get inside the printer during the

installation process. Operation of the printer during the

presence of a foreign substance may lead to fire or

electric shock.

2FM

WARNING

Turn the printer’s power switch off. Unplug the

printer’s power cable and disconnect the printer from

the computer or the network. Never insert or remove a

memory card while the printer power is ON.

Failure to turn the power switch OFF will immediately

halt the printer with a [Memory card err20]

message (this message may not always appear). It

also could result in any damage to the printer’s

electronic parts or the memory card. Turn the power

switch ON again to restart the printer.

Procedure

1. Remove the two screws and then remove the

option interface slot cover (or network interface

card/serial interface board).

2. Insert the memory card in the slot. Push it in all

the way.

3. Secure the option interface slot cover (or network

interface card/serial interface board) by using two

screws.

Memory card

Option interface

slot cover

Screws

Figure 1-3-15 Inserting the memory card

1-3-9

2FM

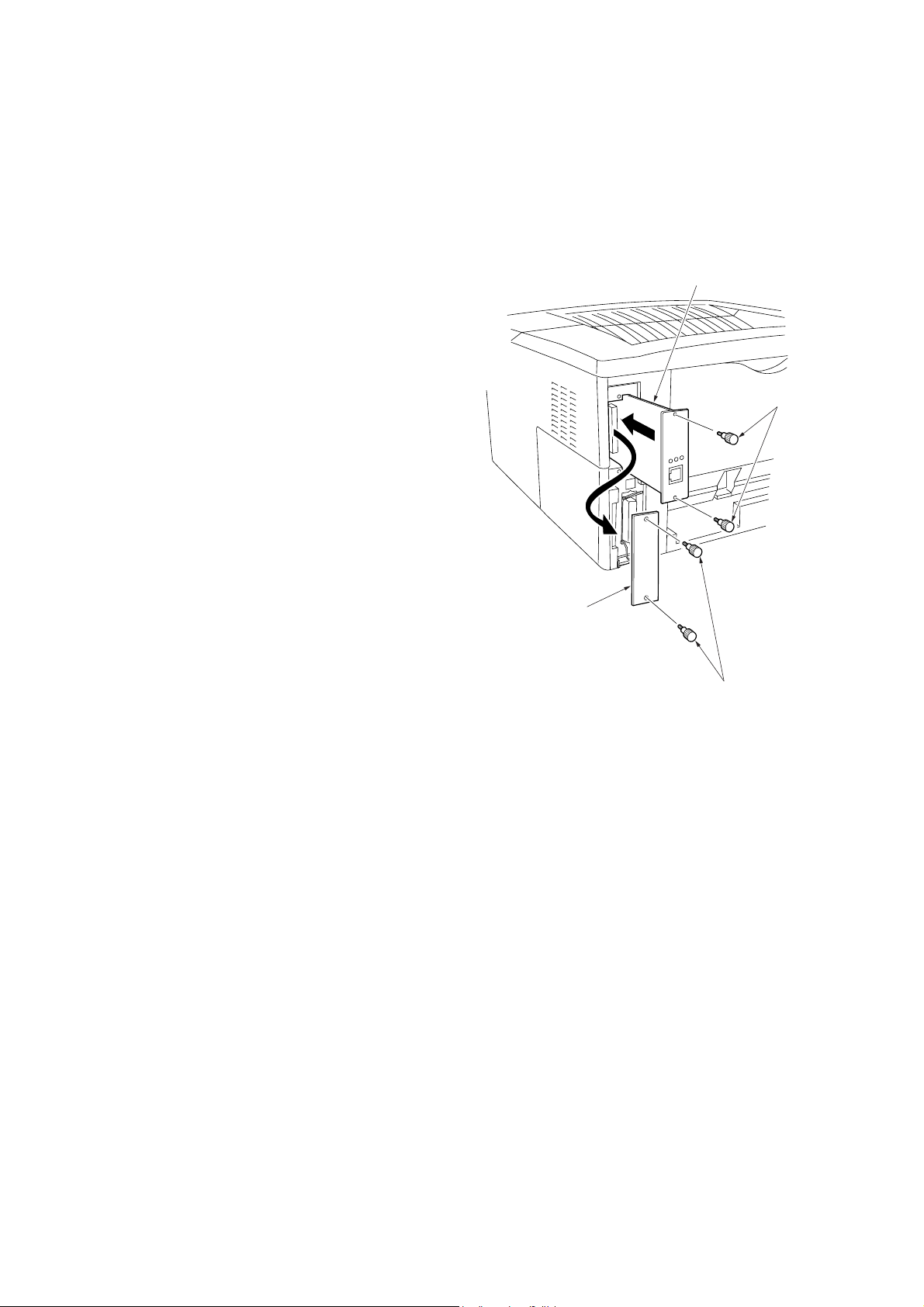

1-3-4 Installing the network interface card (option)

If the serial interface board kit is installed, remove it to use the network interface card.

CAUTION

Take precautions that no foreign substances such as

metal chips or liquid get inside the printer during the

installation process. Operation of the printer during the

presence of a foreign substance may lead to fire or

electric shock.

WARNING

Turn the printer’s power switch off. Unplug the printer’s

power cable.

Procedure

1. Remove the two screws and then remove the option

interface slot cover (or the serial interface board).

2. Insert the network interface card in the slot. Push it in

all the way.

3. Secure the network interface card by using two

screws.

Network interface card

Screws

Option interface

slot cover

Screws

Figure 1-3-16 Inserting the network interface card

1-3-10

2FM

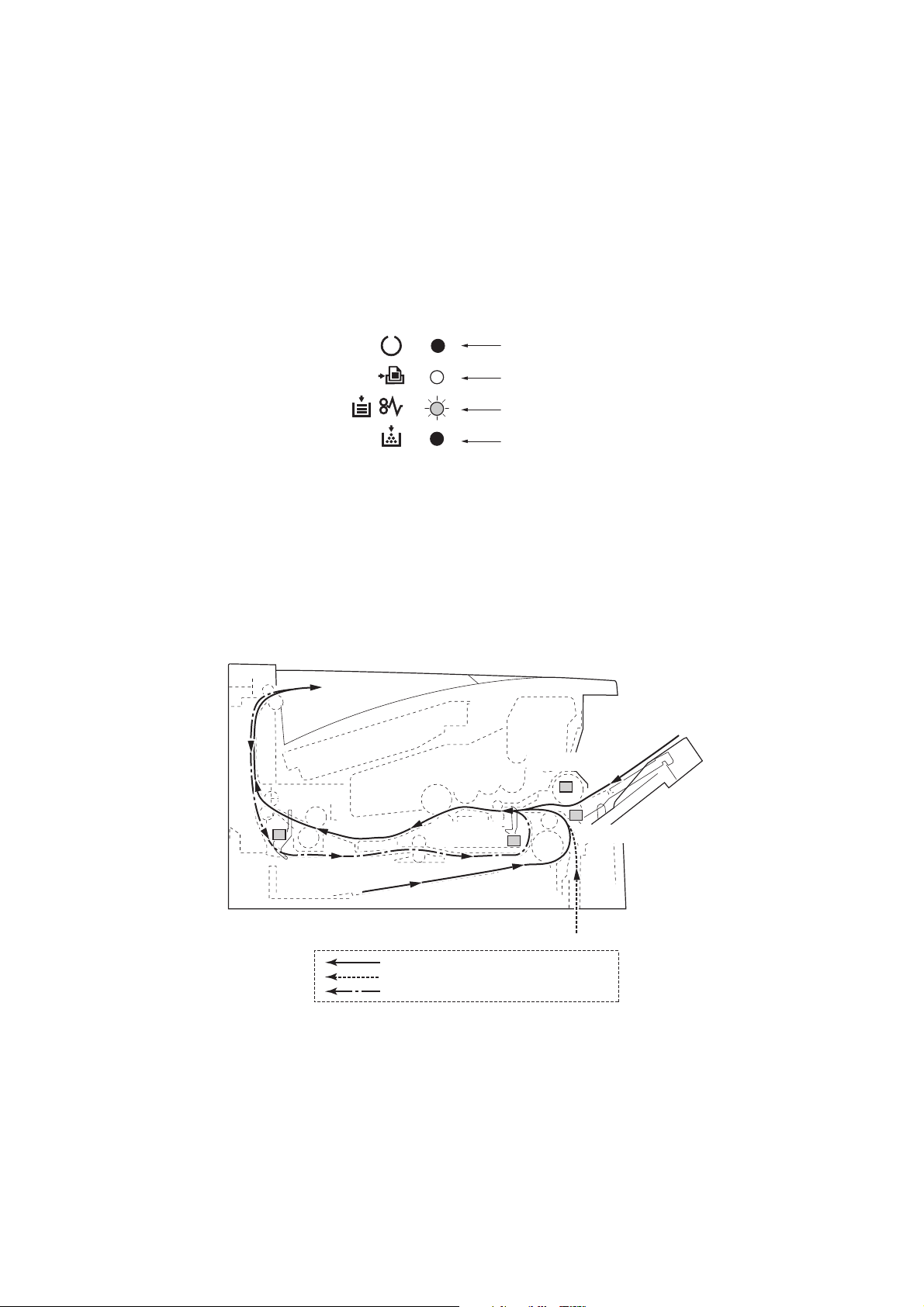

1-4-1 Paper misfeed detection

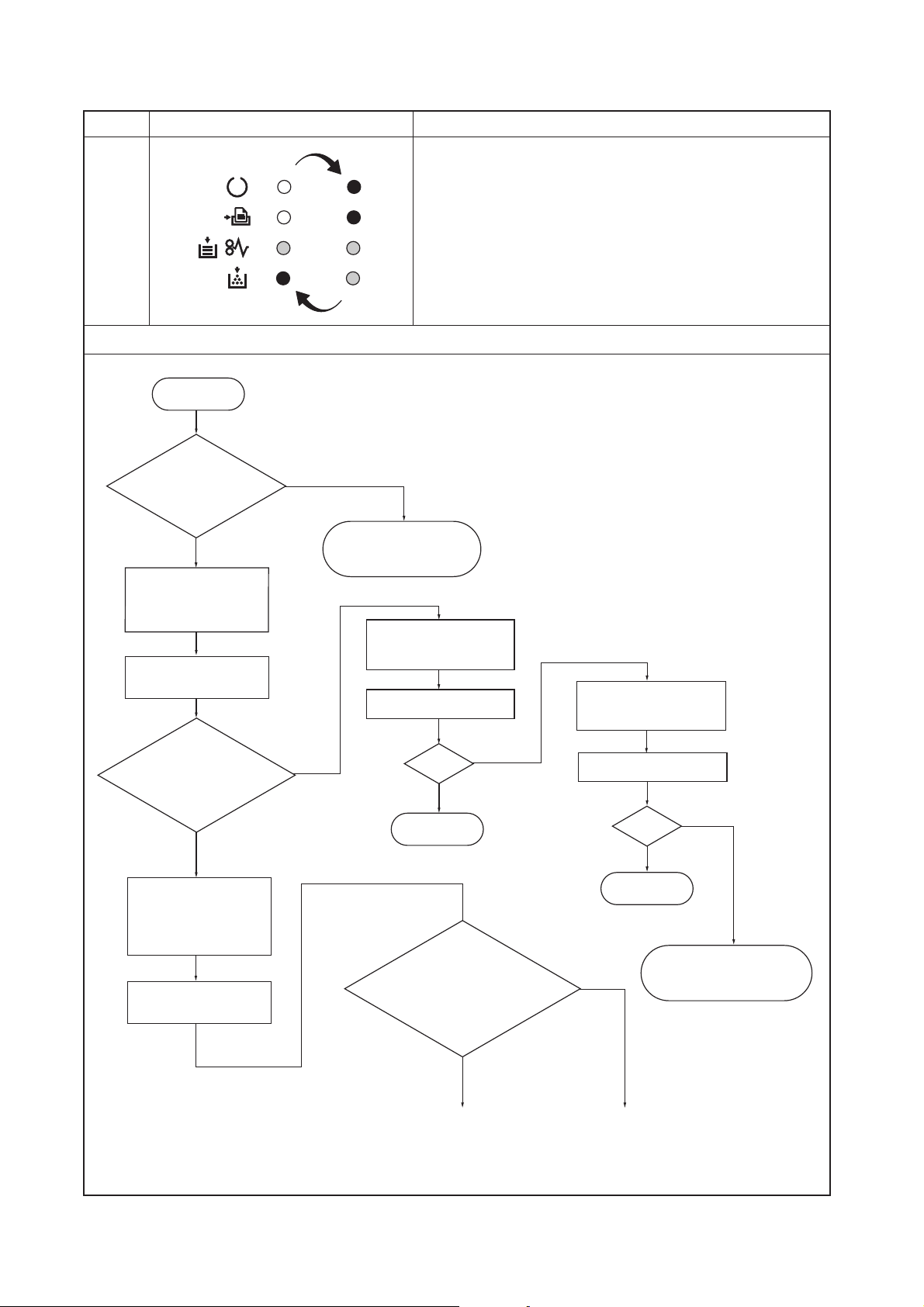

(1) Paper misfeed indication

If a paper jam occurs while printing, the printer notifies it by the following combination of the four indicators. Remove the

jammed paper as described below. After removal, open and close the top cover once to initialize the jam sensing.

Off

Lit

Fast flashing

Off

(2) Paper misfeed detection

Paper path

Exit sensor

Figure 1-4-1 Paper misfeed indication

MP paper sensor

Registration

sensor

Cassette, MP tray

Optional paper feeder

Switch back and refeed (duplex printing)

Paper sensor

Figure 1-4-2

1-4-1

2FM

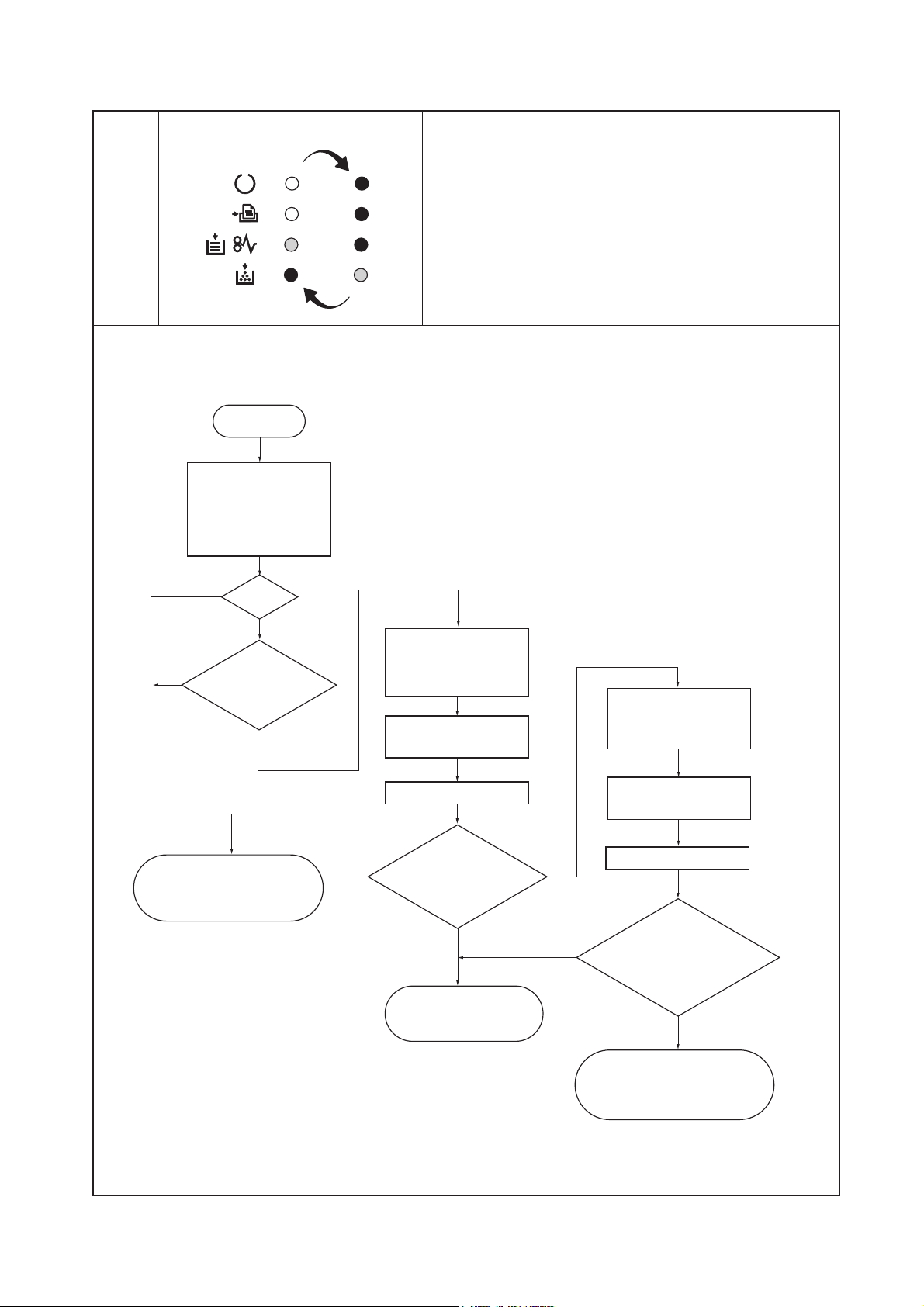

1-4-2 Self-diagnosis

(1) Self-diagnostic function

Service errors are represented by the alternating flashing of the indicators (LEDs). Each error is represented by the notation

of four digits code and can be monitored on the Remote Operation Panel utility. e.g. Call service 2000 is for the main motor

error.

(2) Self diagnostic inidication

Call service 2000

(Lit)

(Lit)

(Lit)

(Off)

(Off)

(Off)

(Off)

(Lit)

Figure 1-4-1 Self diagnostic inidication

Red

Green

1-4-2

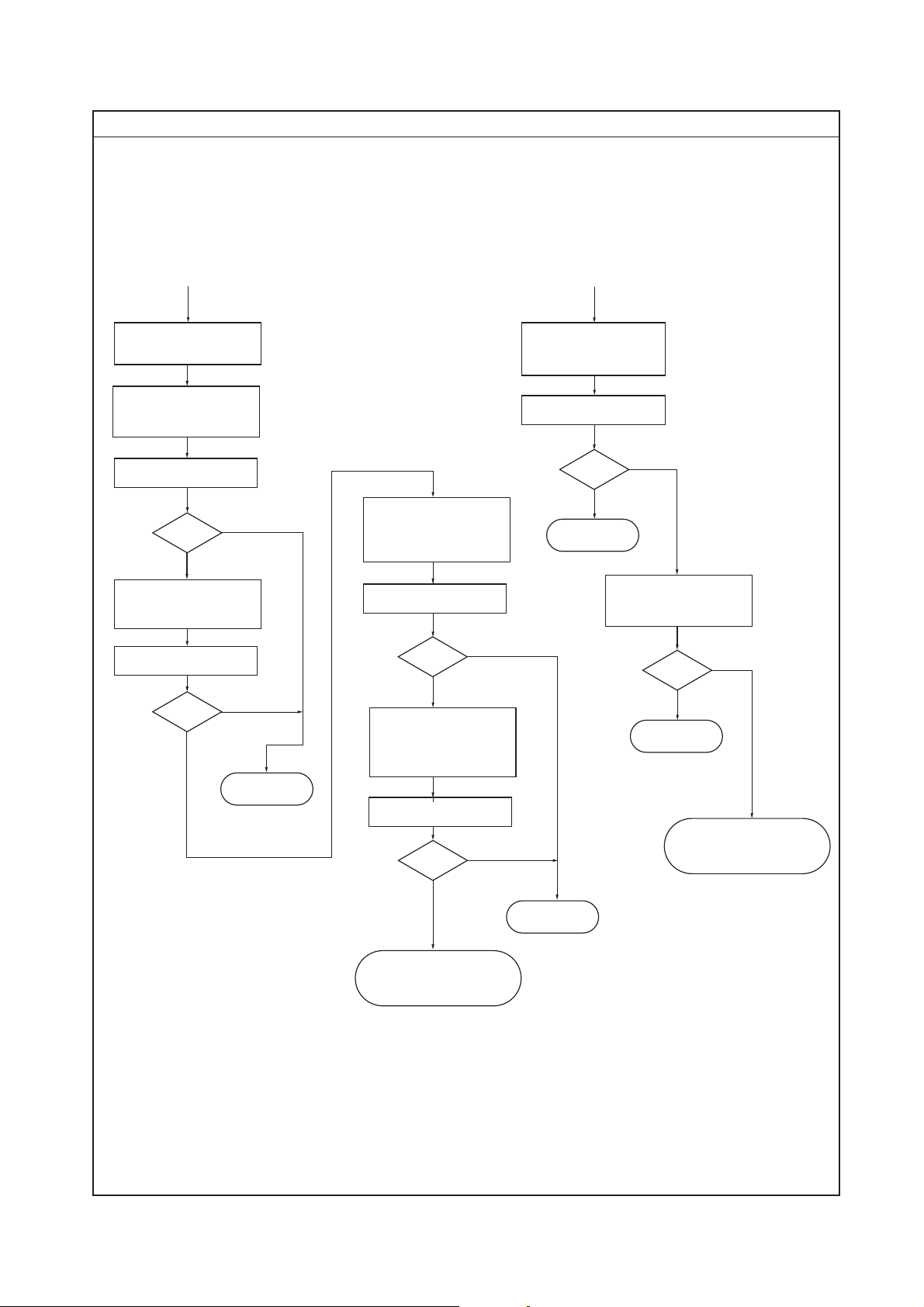

Code Error indications Contents

2000

Main motor error

Check procedures/corrective measures

START

Remove and check

harness (2DC2711)

between engine board

(KP-1046) and main

motor at pins 6 to 9 on

both ends.

2FM

No

No

Replace harness (2DC2711)

between engine board (KP-

1046) and main motor.

OK?

Yes

+24 V DC at

pin 9 of CN1 on

main motor?

Yes

Connect circuit tester to

pin 8 (MOTORN) of

YC04 on engine board

(KP-1046) and ground.

Turn printer power off,

then on.

Print status page.

Does

pin 8 (MOTORN)

of YC04 on engine board

(KP-1046) goes high,

then low?

No

Replace engine board

(KP-1046). See page 15-9.

Connect oscilloscope to

pin 8 (MOTORN) and

pin 7 (MRDYN) of CN1

on main motor.

Turn power switch off,

then on.

Yes

No

Print status page.

Does

pin 7 (MRDYN)

of CN1 on main motor goes

high, then low, within 3 seconds

from pin 8 (MOTORN)

goes low?

Yes

Replace main motor. See

page 1-5-15. If not solved,

check or replace drive unit.

See page 1-5-15.

1-4-3

2FM

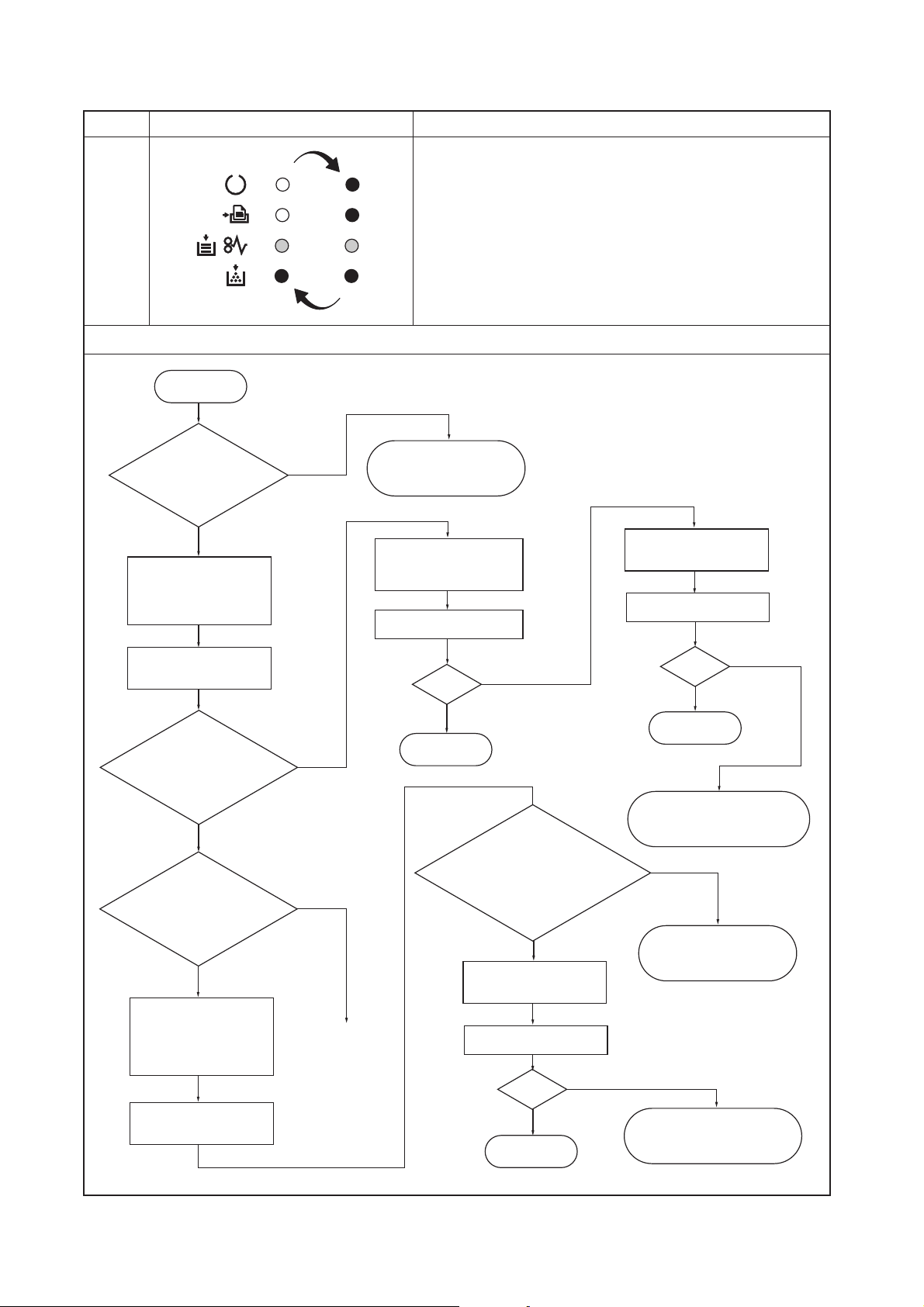

Code Error indications Contents

4000 Laser scanner unit [Polygon motor] error

Check procedures/corrective measures

START

+24 V DC at pin 5 of

YC06 on engine board

(KP-1046) ?

Yes

Connect oscilloscope to

pin 1 (PLGCLK) and pin

3 (PLGDRN) of YC06 on

engine board (KP-1046).

Turn power switch off,

then on.

Does

pin 3 (PLGDRN) of

YC06 on engine board

(KP-1046) goes high,

then low?

Yes

Does

pin 1 (PLGCLK) of

YC06 on engine board

(KP-1046) output

square-wave*

signal?

Yes

Connect oscilloscope to

pin 2 (PLGRDYN) and

pin 3 (PLGDRN) of

YC06 on engine board

(KP-1046).

No

No

No

*: 1417 Hz

(705 µs)

Continued

to next page.

Replace engine board

(KP-1046). See page 5-

11.

Replace engine board

(KP-1046). See page 15-9.

Turn power switch on.

A

OK?

End.

No

Yes

Does pin 2

(PLGRDYN) of YC6 on

engine board (KP-1046) goes

high, then low, within 8 seconds

after pin 3 (PLGDRN)

goes high, then

low?

No

Replace laser scanner

unit. See page 5-29.

Turn power switch on.

OK?

No

Replace laser scanner

unit. See page 1-5-28.

Turn power switch on.

OK?

End.

Replace harness (2DC2714)

between engine board and

laser scanner unit.

Yes

Replace engine board

(KP-1046). See page 15-9.

No

Yes

1-4-4

Turn power switch off,

then on.

End.

Yes

Replace harness (2DC2714)

between engine bard and

laser scanner unit.

Check procedures/corrective measures

Continued

from previous page.

A

Replace engine board

(KP-1046). See page 15-9.

Turn power switch on.

2FM

OK?

End.

Yes

No

Replace main board

(KP-1050). See page 15-10.

Turn power switch on.

OK?

End.

No

Yes

Replace harness

(2FM2602) between engine

board and main board.

1-4-5

2FM

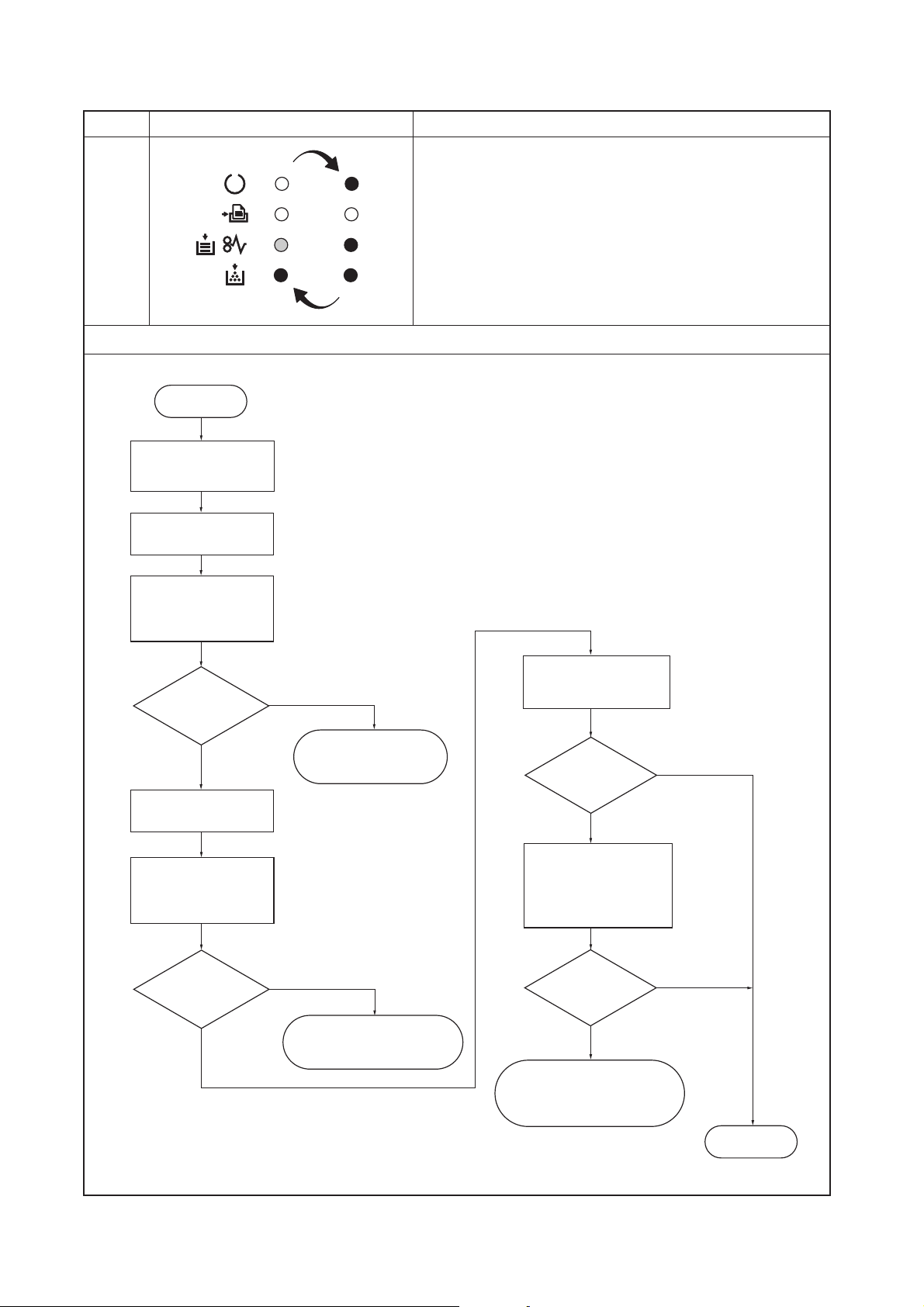

Code Error indications Contents

4200 Laser scanner unit [Pin photo diode] error

Check procedures/corrective measures

START

+5 V DC at pin 6 of

YC07 on main board

(KP-1050) ?

Yes

Connect oscilloscope to

pin 4 (OUTPEN) of

YC07 on main board

(KP-1050).

Turn power switch off,

then on.

Does

pin 4 (OUTPEN) of

YC06 on main board (KP-

1050) goes high, then low

before "4200"

error?

Yes

Connect oscilloscope to

pin 4 (OUTPEN) and

pin 8 (PDN) of YC07 on

main board (KP-1050).

Turn power switch off,

then on.

No

Replace main board

(KP-1050). See page 15-10.

Replace main board

(KP-1050). See page 15-10.

Turn power switch on.

No

main board (KP-1050) output

pulse signal*, within 0.1 second

after pin 4 (OUTPEN) goes

*: Pin photo diode

detect horizontal

synchronization signal

(Frequency: 1417 Hz,

Low level width: 10 µs)

OK?

End.

Does pin 8

(PDN) of YC06 on

high, then

No

Yes

low?

No

B

Continued

to next page.

Replace engine board

(KP-1051). See page 15-9.

Turn power switch on.

OK?

End.

Yes

No

Yes

Replace harness

(2FM2602) between main

board and engine board.

C

Continued

to next page.

1-4-6

Check procedures/corrective measures

2FM

Continued

from previous page.

B

Replace laser scanner

unit. See page 1-5-28.

Replace main board

(KP-1050). See page 15-10.

Turn power switch on.

OK?

Replace engine board

(KP-1046). See page 15-9.

Turn power switch on.

OK?

No

Yes

Yes

No

End.

Replace harness

(2DC2714) between

engine board and laser

scanner unit.

Turn power switch on.

OK?

Replace harness

(2DC2714) between

main board and laser

scanner unit.

Turn power switch on.

OK?

Yes

No

Yes

Continued

from previous page.

C

Replace main board

(KP-1050). See page 15-10.

Turn power switch on.

OK?

End.

No

Yes

Replace engine board

(KP-1046). See page 15-9.

OK?

End.

No

Yes

Replace harness

(2FM2602) between main

board and engine board.

No

Replace harness

(2FM2602) between main

board and engine board.

End.

1-4-7

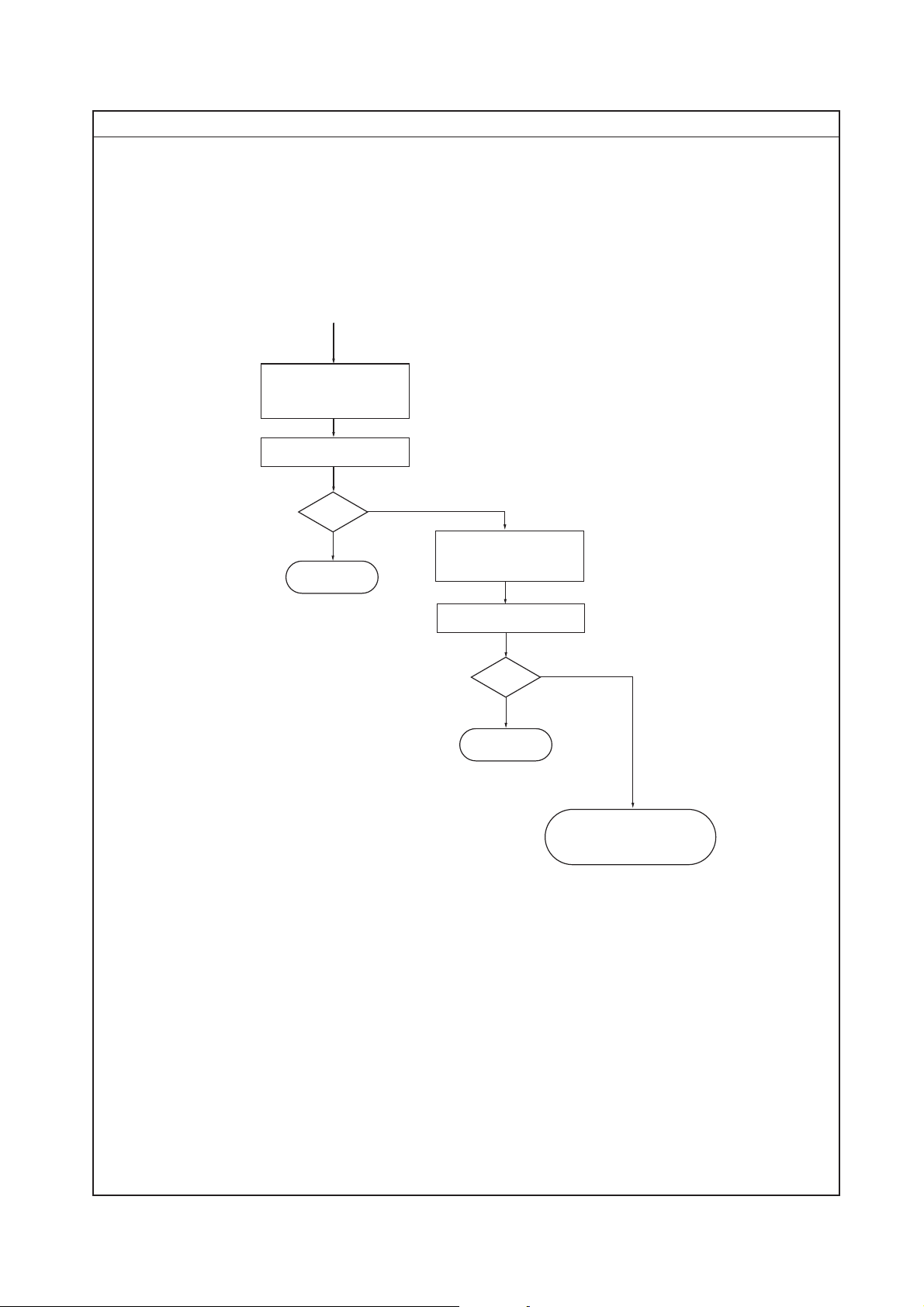

2FM

Code Error indications Contents

6000 Fuser unit error

Check procedures/corrective measures

START

Turn power switch off,

and remove power

cable.

Detach connector CN4

on power supply board.

Measure resistance

between pins 1 and 2

of the detached

connector.

Open (infinite)?

No

Detach connector CN1

on power supply board.

Measure resistance

between pins 1 and 3

of the detached

connector.

No

Open (infinite)?

No

Yes

Replace fuser thermistor.

See page 1-5-25.

Yes

Replace thermal cutout or

heater lamp. See page 1-526 or 1-5-22.

Replace engine board

(KP-1046). See page

1-5-9.

"6000" error

shown?

Yes

Replace harness

(2FM2601) between

engine board (KP-1046)

and bias board (KP-

1051).

"6000" error

shown?

Yes

Replace bias board or high

voltage board or power

supply board. See page 1-513 or 1-5-12.

No

No

End.

1-4-8

Loading...

Loading...