Kyocera Mita FS 1016EN Service Manual

FS-1016MFP

SERVICE

MANUAL

Published in February 2006

2G470760

Revision history

Revision Date Replaced pages Remarks

-

Safety precautions

This booklet provides safety warnings and precautions for our service personne l to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING: Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION: Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the copier.

1.Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. .............................................................................................

• Connect the ground wire to a suitab le g rou nd ing point . No t g roun ding the co pier may cause fir e o r

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. ............................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .......

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. ................

• Do not install the copier near a radiator, heater, other heat source or near flammable material.

This may cause fire. .........................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ...........

• Always handle the machine by the correct locations when moving it. ...............................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may cause

the copier to move unexpectedly or topple, leading to injury. ...........................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain medical

attention. ......................................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. .....................................................................................................................

2.Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly. ...............

• Always follow the procedures for maintenance described in the service manu al and other related

brochures. ....................................... ... ... ... .... ... .......................................... ... ... .... ............................

• Under no circumstances attempt to bypass or disable safety features in cluding safety mechanisms

and protective circuits. .......................................... .... ... ... ... .......................................... ... .................

• Always use parts having the correct specifications. ..........................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related brochure when replacing them. Using a piece of wire, for example, could lead to fire or other serious

accident. ..........................................................................................................................................

• When the service manual or other serious brochure specifies a distance or ga p for inst alla tion of a

part, always use the correct scale and measure carefully. ................................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. .............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If it

is dirty, clean it to remove the risk of fire or electric shock. ..............................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ....................................... ... .... ... ... ... ... .... ... ... .......................................................

• Handle the charger sections with care. They are charged to high potentials and may cause electric

shock if handled improperly. ............................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections. ..........................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. ........

• Handle the fixing section with care to avoid burns as it can be extremely hot. ..................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures. ........................................................................................................

• Do not remove the ozone filter, if any, from the copier except for routine replacement. ....................

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ................................ ... .... ... ... ... .... ... ..............................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. .............................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks. ........

• Remove toner completely from electronic components. ...................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ....................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. S pecial attention shou ld be p aid to any fo rgotte n connector,

trapped wire and missing screws. ...................................................................................................

• Check that all the caution labels that should be present on the machine according to the instruction

handbook are clean and not peeling. Replace with new ones if necessary . ......................................

• Handle greases and solvents with care by following the instructions below: .....................................

Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

Ventilate the room well while using grease or solvents.

Allow applied solvents to evaporate completely before refitting the covers or turning the power switch on.

Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc. .......................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet imme-

diately. ............................................................................................................................................

3.Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than the

specified refiner; it may generate toxic gas. .....................................................................................

This page is intentionally left blank.

CONTENTS

1-1 Specifications

1-1-1 Specifications..........................................................................................................................................1-1-1

1-1-2 Parts names............................................................................................................................................1-1-3

(1) Operation panel.......................................................... ... ....................................... .............................1-1-4

1-1-3 Machine cross section ............................................................................................................................1-1-5

1-2 Installation

1-2-1 Installation environment..........................................................................................................................1-2-1

1-2-2 Unpacking and installation......................................................................................................................1-2-2

(1) Installation procedure........................................................................................................................1-2-2

1-3 Service Mode

1-3-1 Service mode..........................................................................................................................................1-3-1

(1) Printing the system configuration page.............................................................................................1-3-1

1-4 Troubleshooting

1-4-1 Paper misfeed detection.........................................................................................................................1-4-1

(1) Paper misfeed indication............................................ ... .. ........................................ .. ........................1-4-1

1-4-2 Self-diagnosis .........................................................................................................................................1-4-2

(1) Self-diagnostic function.....................................................................................................................1-4-2

(2) Service error message......................................................................................................................1-4-3

1-4-3 Image formation problems....................................................................................................................1-4-14

(1) Completely blank printout................................................................................................................1-4-15

(2) No image appears (entirely black). .................................................................................................1-4-15

(3) Dropouts..........................................................................................................................................1-4-16

(4) Black dots .......................................................................................................................................1-4-16

(5) Black horizontal streaks .................................................................................................................1-4-16

(6) Black vertical streaks ......................................................................................................................1-4-17

(7) Unsharpness ..................................................................................................................................1-4-17

(8) Gray background ............................................................ ........................................ ........................1-4-18

(9) Dirt on the top edge or back of the paper........................................................................................1-4-18

(10) Undulated printing at the right edge (scanning start position).........................................................1-4-18

1-4-4 Electric problems ..................................................................................................................................1-4-19

1-4-5 Mechanical problems............................................................................................................................1-4-22

1-5 Assembly and Disassembly

1-5-1 Precautions for assembly and disassembly............................................................................................1-5-1

(1) Precautions .......................................................................................................................................1-5-1

1-5-2 Outer covers and scanner unit................................................................................................................1-5-2

(1) Detaching and refitting the right cover, left cover and top cover.......................................................1-5-2

1-5-3 Paper feeding/conveying section............................................................................................................1-5-4

(1) Detaching and refitting the paper feed roller .....................................................................................1-5-4

(2) Detaching and refitting the transfer roller..........................................................................................1-5-5

1-5-4 Process section.......................................................................................................................................1-5-6

(1) Detaching and refitting the developer unit and drum unit..................................................................1-5-6

(2) Detaching and refitting the main charger unit....................................................................................1-5-7

1-5-5 Fuser unit................................................................................................................................................1-5-8

(1) Detaching and refitting the fuser unit.................................................................................................1-5-8

(2) Detaching and refitting the heater lamp, heat roller, fuser thermistor, thermal cutout, and

press roller.......................................................................................................................................1-5-10

(3) Detaching and refitting the engine/high voltage PWB and power source PWB..............................1-5-14

(4) Detaching and refitting the laser scanner unit.................................................................................1-5-17

(5) Detaching and refitting the eraser lamp (PWB)...............................................................................1-5-19

(6) Detaching and refitting the drive unit...............................................................................................1-5-20

(7) Detaching and refitting the main motor ...........................................................................................1-5-21

1-5-6 Scanner unit................................ ... ....................................... ................................................................1-5-22

(1) Detaching and refitting the scanner unit..........................................................................................1-5-22

(2) Detaching and refitting the optical module unit ...............................................................................1-5-24

(3) Detaching and refitting the main PWB ............................................................................................1-5-29

(4) Detaching and refitting the exposure lamp......................................................................................1-5-31

(5) Detaching and refitting the inverter PWB .......................................................... ... ...........................1-5-33

(6) Detaching and refitting the scanner home position sensor .............................................................1-5-35

(7) Detaching and refitting the scanner motor......................................................................................1-5-36

1-5-7 Document processor (DP) ....................................................................................................................1-5-37

(1) Detaching and refitting the document processor (DP) ....................................................................1-5-37

(2) Detaching and refitting the pad assembly .......................................................................................1-5-38

(3) Detaching and refitting the original feed roller.................................................................................1-5-39

1-6 Firmware

1-6-1 Updating the firmware on the main PWB................................................................................................1-6-1

2-1 Mechanical construction

2-1-1 Paper feeding/conveying section............................................................................................................2-1-1

(1) Paper feed section ............................................................................................... .............................2-1-1

2-1-2 Drum section...........................................................................................................................................2-1-3

(1) Drum unit...........................................................................................................................................2-1-3

(2) Main charger unit.................................... ...........................................................................................2-1-4

2-1-3 Expose section........................................................................................................................................2-1-5

(1) Laser scanner unit............................................................................................. ................................2-1-5

2-1-4 Developing section..................................................................................................................................2-1-7

(1) Developer unit................................ ... ........................................................................ ........................2-1-7

2-1-5 Transfer section.................................................................................. ....................................................2-1-9

2-1-6 Cleaning section ...................................................................................................................................2-1-10

2-1-7 Fuser section ............................................................. ... ... .................................... ... ..............................2-1-11

(1) Fuser unit ........................................................................................................................................2-1-11

2-1-8 Paper exit section .................................................................................................................................2-1-13

(1) Paper exit section............................................................ ........................................ ........................2-1-13

2-1-9 Scanner section........................................ ... ................................................................ .........................2-1-15

(1) Scanner unit....................................................................................................................................2-1-15

(2) Optical module unit..........................................................................................................................2-1-16

2-1-10 Document processor (DP) section........................................................................................................2-1-17

(1) Document processor (DP)...............................................................................................................2-1-17

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ..............................................................................................................................2-2-1

(1) Electrical parts layout................................ ........................................................................................2-2-1

2-3 Operation of the PWBs

2-3-1 Power source PWB.................................................................................................................................2-3-1

2-3-2 Engine/high voltage PWB .......................................................................................................................2-3-3

2-3-3 Main PWB...............................................................................................................................................2-3-7

2-4 Appendixes

(1) Wiring diagram..................................................................................................................................2-4-1

(2) Repetitive defects gauge...................................................................................................................2-4-2

1-1 Specifications

1-1-1 Specifications

Main body

Printing system...............................Electro-photographic

Originals..........................................Sheets of paper, books and 3-dimensional objects

Copy sizes......................................Paper cassette: A4, B5 (JIS), A5, folio, legal, letter, oficio II

Manual feed tray: A4, B5 (JIS), A5, folio, legal, letter, oficio II, statement, executive,

A6, B6, B5 (ISO), envelope #10, envelope #9, envelope monarch, envelope #6, envelope C5, envelope DL, 16K

Paper types.....................................Paper cassette: Plain paper, recycled paper, thick paper 60 to 105 g/m

Manual feed tray: Plain paper, recycled paper, thick paper 60 to 163 g/m

Transparency, adhesive backed labels, envelopes and post cards supported

Paper feed source capacity............Paper cassette: 250 sheets

Manual feed tray: 1 sheet

Output tray capacity........................100 sheets (face-down)

Photoconductor...............................OPC drum (diameter 30 mm/1

Charging system.............................Scorotron (positive charging)

Developing system .........................Mono component dry developing method

Toner replenishing: Automatic from the toner container

Transfer system..............................Transfer roller (negative-charged)

Separation system..........................Small diameter separation

Fixing system..................................Heat roller system

Charge erasing system...................Exposure by eraser lamp (LED)

Cleaning system.............................Drum: Counter blade

Warm-up time.................................25 seconds or less (power on), 20 s or less (sleep)

Memory................................. .. ........32 MB

Ambient conditions ......................... Temperature: 10 to 32.5

Humidity: 20 to 80 %RH

Altitude: Maximum 2,000 m/6,562 ft

Illumination: 1,500 lux or less

Power source..................................120 V AC, 60 Hz, 8.2 A

220 to 240 V AC, 50 Hz, 3.9 A

Dimensions (W)

× (D) × (H) ...........476 × 392 × 489 mm/18 3/4" × 15 7/16" × 19 1/4"

Weight.............................................Approx. 15 kg/33 lbs

Required space (W)

× (D) ..............479 × 437 mm/18 7/8" × 17 3/16"

3/16")

°C/50 to 95 °F

2G4

2

2

Copying functions

Copying speed................................Platen (1:1)

A4: 16 copies/min.

A5/A6: 10 copies/min.

B5: 14 copies/min.

Letter: 17 copies/min.

Legal: 15 copies/min.

Document processor (1:1)

A4: 16 copies/min.

A5: 10 copies/min.

B5: 14 copies/min.

Letter: 17 copies/min.

Legal: 15 copies/min.

First copy (1:1, Letter/A4)...............Platen

12 seconds or less

Document processor

14 seconds or less

Resolution.......................................Scanning and printing: 600

× 600 dpi

Continuous copying........................1 to 99 sheets

Zoom ratios.....................................Any 1 % increment between 25 and 400 %

1-1-1

2G4

Printing functions

Printing speed .................................A4: 16 pages per minute/Letter: 17 pages per minute

First print.........................................11 seconds or less

Resolution.......................................600

Host Interface .................................USB: 1 port (Hi-speed USB)

Scanning functions

Scanning Speed..............................Monochrome: 16 scan/min.

Resolution.......................................600 × 300 dpi

Color mode.....................................Full color: 24 bit/dot (each color)

File format.......................................PDF, TIFF, JPEG (8-Bit gray mode, 24-Bit color mode), BMP

Host Interface .................................USB (TWAIN): 1 port (Hi-speed USB)

Document processor (DP)

Original feed system.......................Automatic feeding

Originals..........................................Sheets of paper

Original size....................................Maximum: Legal

Original paper weight......................60 to 105 g/m

Maximum number of originals.........50 sheets (50 to 80 g/m2)

× 600 dpi

Full color or grayscale: 4.8 scan/min.

1:1, Letter/A4, 300 dpi

Grayscale: 8 bit/dot

Monochrome: 1 bit/dot

Minimum: Statement and A5R

2

Environmental specifications

Duplex copying...............................Not available

Paper feed......................................Recycled paper made from 100% recycled pulp may be used with this product.

1-1-2

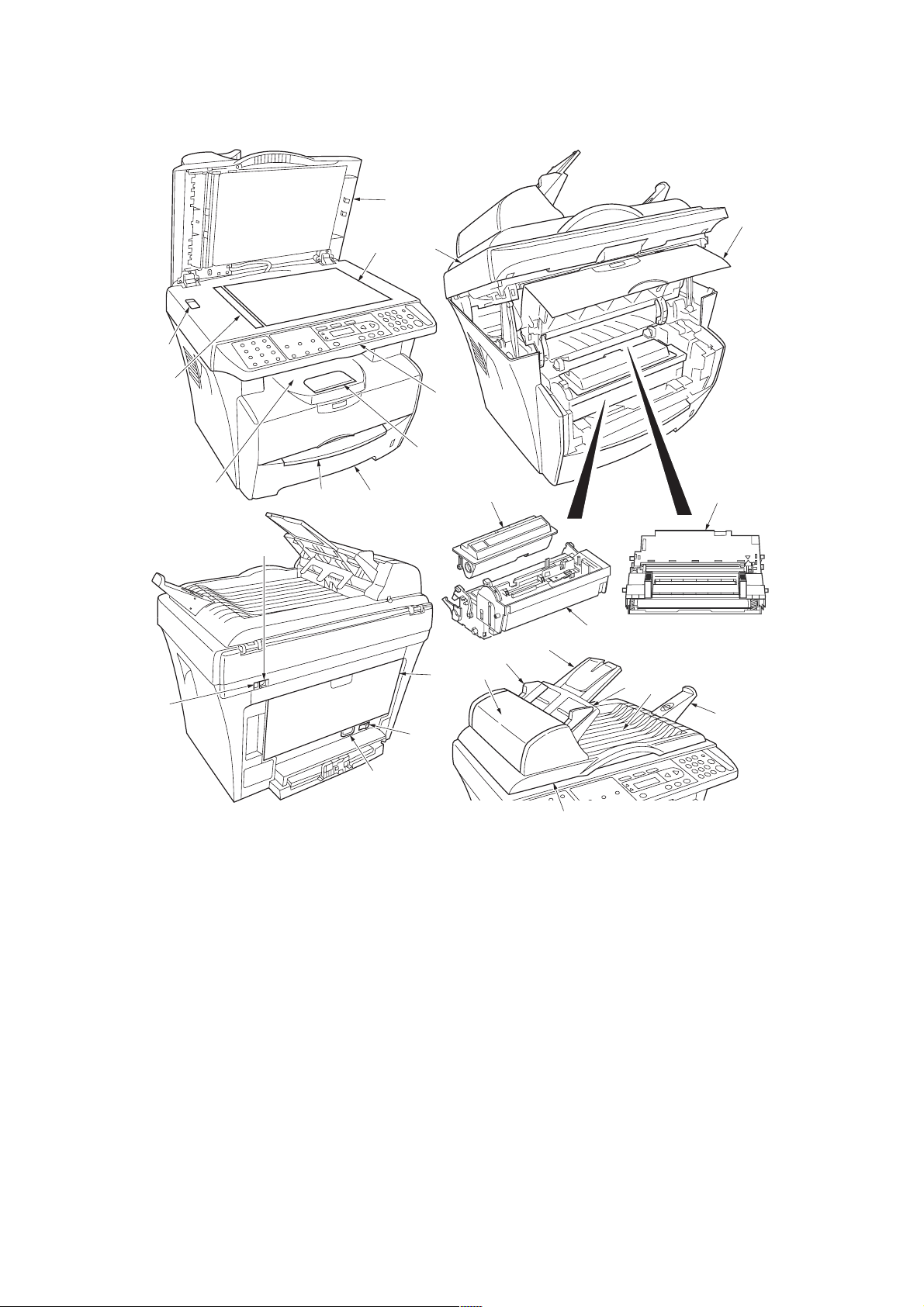

1-1-2 Parts names

2G4

1. Scanner unit

2. Front cover

3. Paper cassette

4. Manual feed tray

5. Toner container

6. Developer unit

7. Drum unit

8. Shipping lock

9. Original size indicator plate

10. Operation panel

1 1. Original cover

12. Platen

13. Outpu t tray

Figure 1-1-1

14. Paper stop per

15. USB Interface connector

16. 5 V DC output (for pri nt server)

17. Rear cover

18. Power switch

19. AC inlet

20. Original table

21. Original insert guides

22. Left cover

23. Ejection extension

24. Original eject table

25. Document processor (DP)

1-1-3

2G4

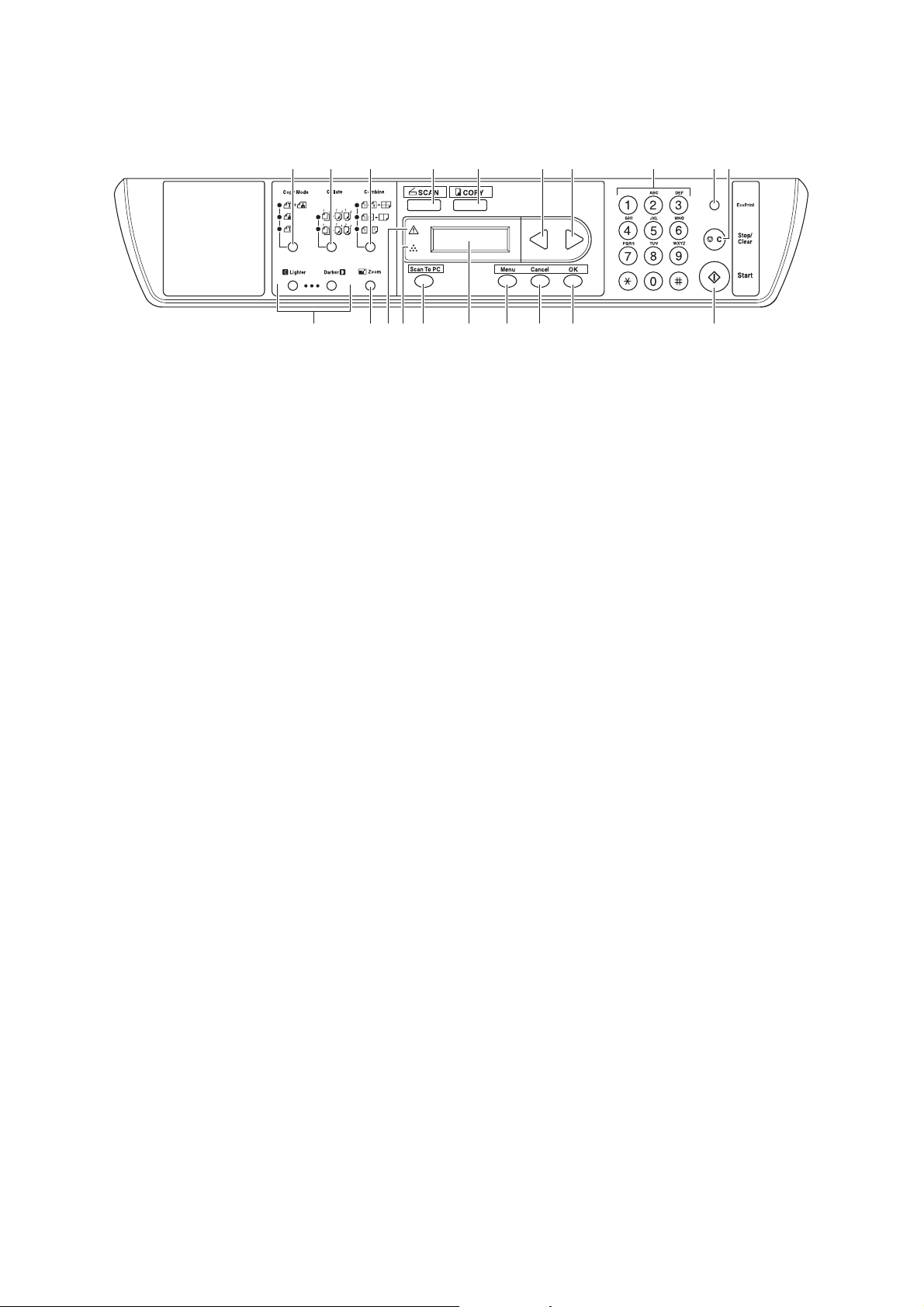

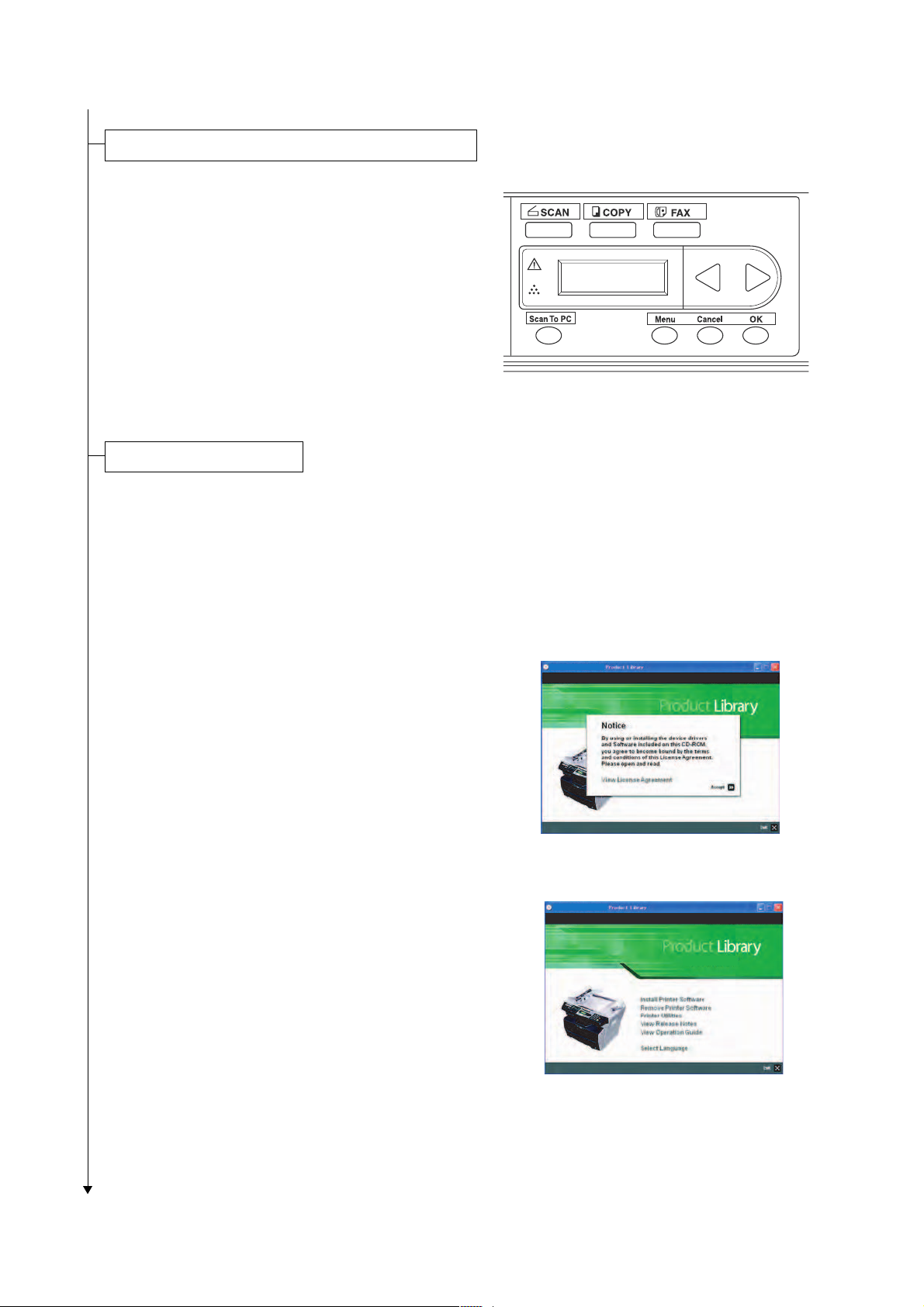

(1) Operation panel

1. Copy mode key and indicator

2. Collate key and indicator

3. Combine key and indicator

4. SCAN key

5. COPY key and indicator

6. W key

7. X key

8. Numeric keys

9. EcoPrint key and indicator

10. Stop/Clear key

/

Figure 1-1-2

11. Exposure adjustment key/Exposure display

12. Z oom key

13. Memory overflow in dicator

14. Toner indicator

15. Scan To PC key

16. Message display

17. Menu key

18. Cancel key

19. OK key

20. Start key

1-1-4

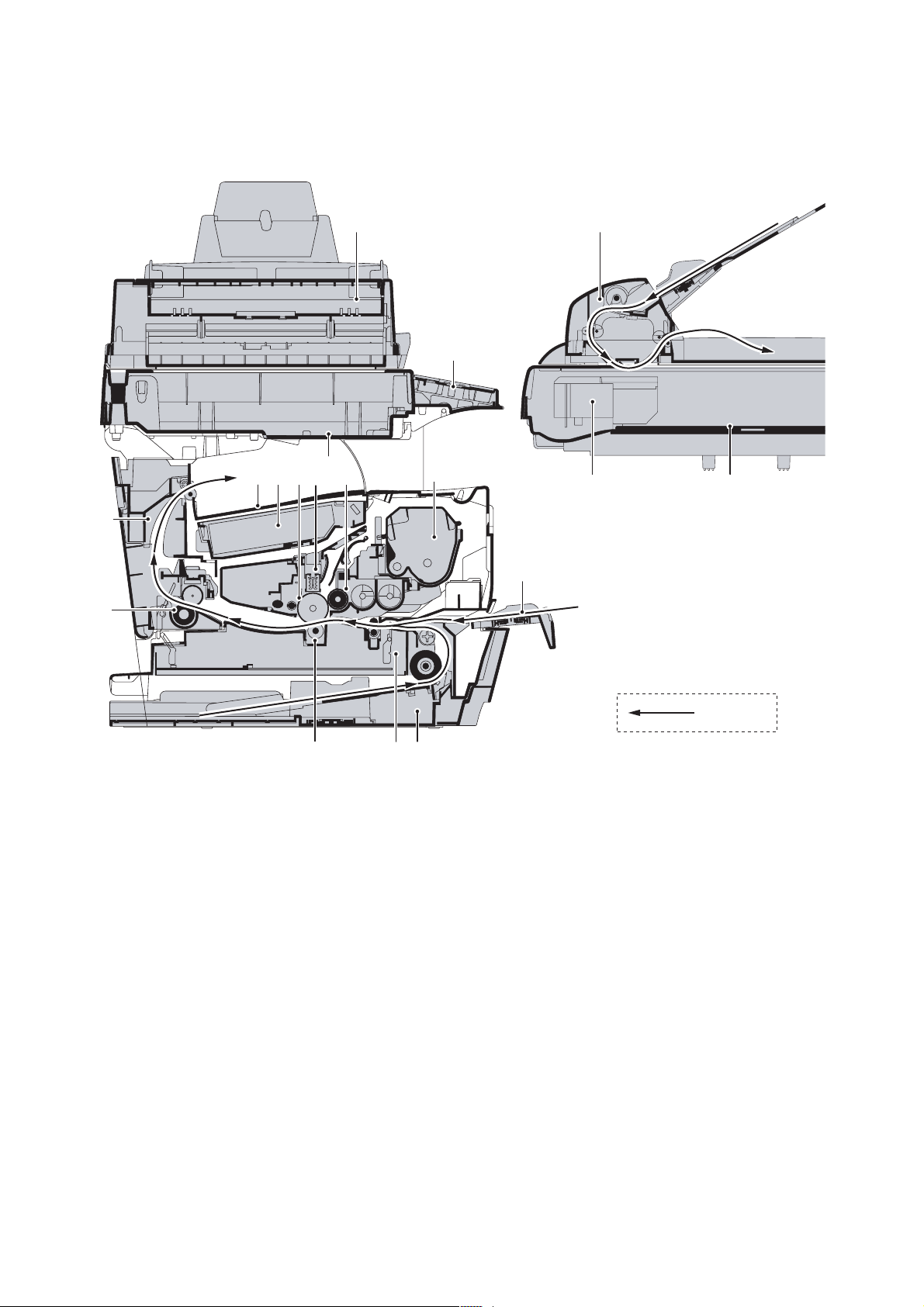

1-1-3 Machine cross section

2G4

Figure 1-1-3 Machine cross section

1. Paper cassette

2. Manual feed tray

3. Paper feeding/conveying

section

4. Toner container

5. Developer unit

6. Main charger unit

7. Drum unit

8. Laser scanner unit

Paper path

9. Transfer section

10. Fuser uni t

11. Paper exit section

12. Output tray

13. Operati on unit

14. Scanner uni t

15. Optical module unit

16. Document processor (DP)

1-1-5

2G4

This page is intentionally left blank.

1-1-6

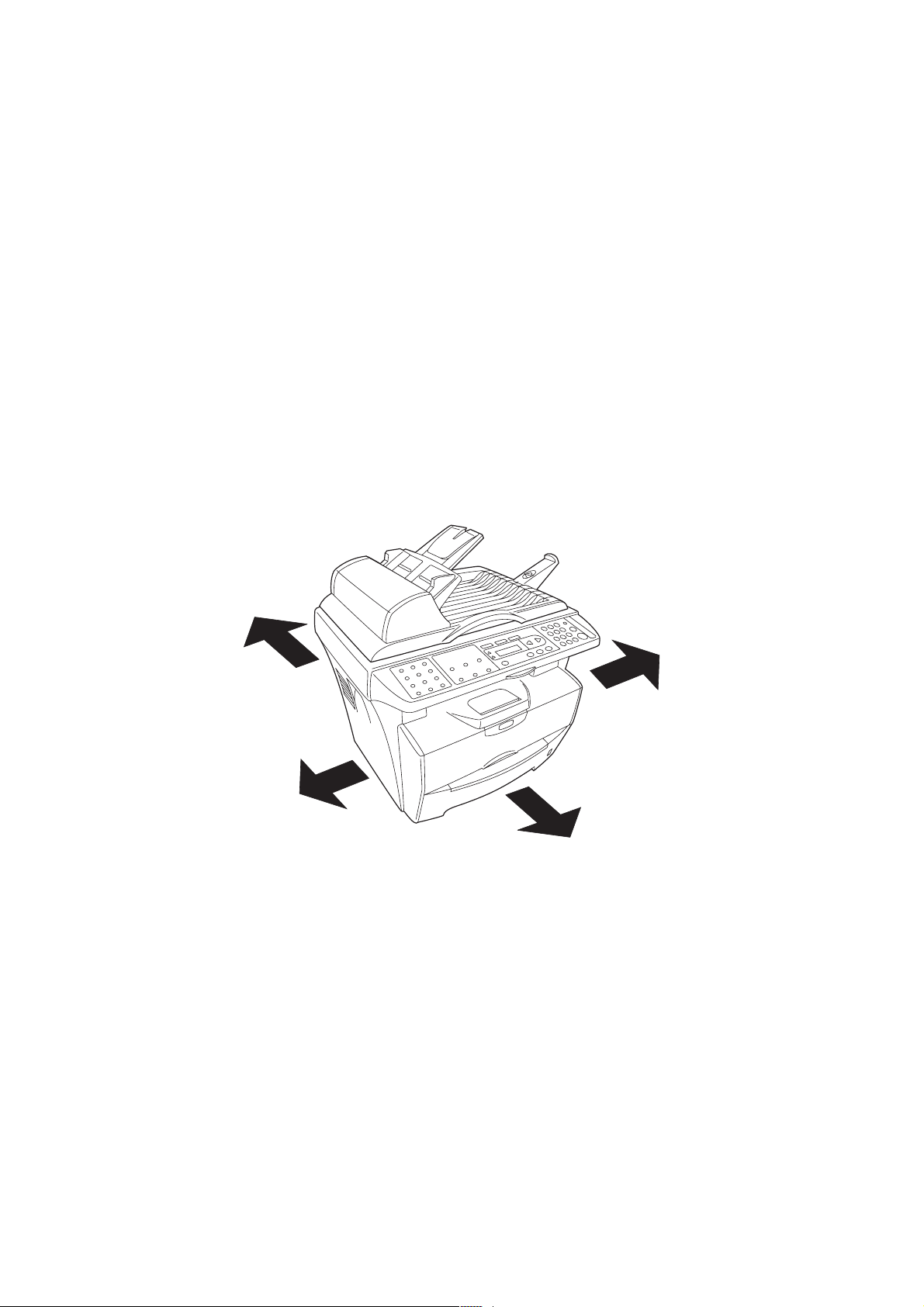

1-2 Installation

1-2-1 Installation environment

1. Temperature: 10 to 32.5°C/50 to 90.5°F

2. Humidity: 15 - 80%RH

3. Power supply: 120 V AC, 9.0 A

220 - 240 V AC, 5.0 A (Average)

4. Power source frequency: 50 Hz ±0.3%/60 Hz ±0.3%

5. Installation location

Avoid direct sunlight or bright lighting. Ensure that the photoconductor will not be exposed to direct sunlight or

other strong light when removing paper jams.

Avoid extremes of temperature and humidity, abrupt ambient temperature changes, and hot or cold air directed

onto the machine.

Avoid dust and vibration.

Choose a surface capable of supporting the weight of the machine.

Place the machine on a level surface (maximum allowance inclination: 1

Avoid air-borne substances that may adversely affect the machine or degrade the photoconductor, such as mercury, acidic of alkaline vapors, inorganic gasses, NOx, SOx gases and chlorine-based organic solvents.

Select a room with good ventilation.

6. Allow sufficient access for proper operation and maintenance of the machine.

Machine front: 100 cm/39

3/8"

Machine rear: 25 cm/9 13/16"

Machine right: 30 cm/1113/16"

Machine left: 30 cm/11

13/16"

°).

2G4

Rear: 25 cm

9 13/16"

Left: 30 cm

11 13/16"

Right: 30 cm

11 13/16"

Front: 100 cm

39 3/8"

Figure 1-2-1

1-2-1

2G4

1-2-2 Unpacking and installation

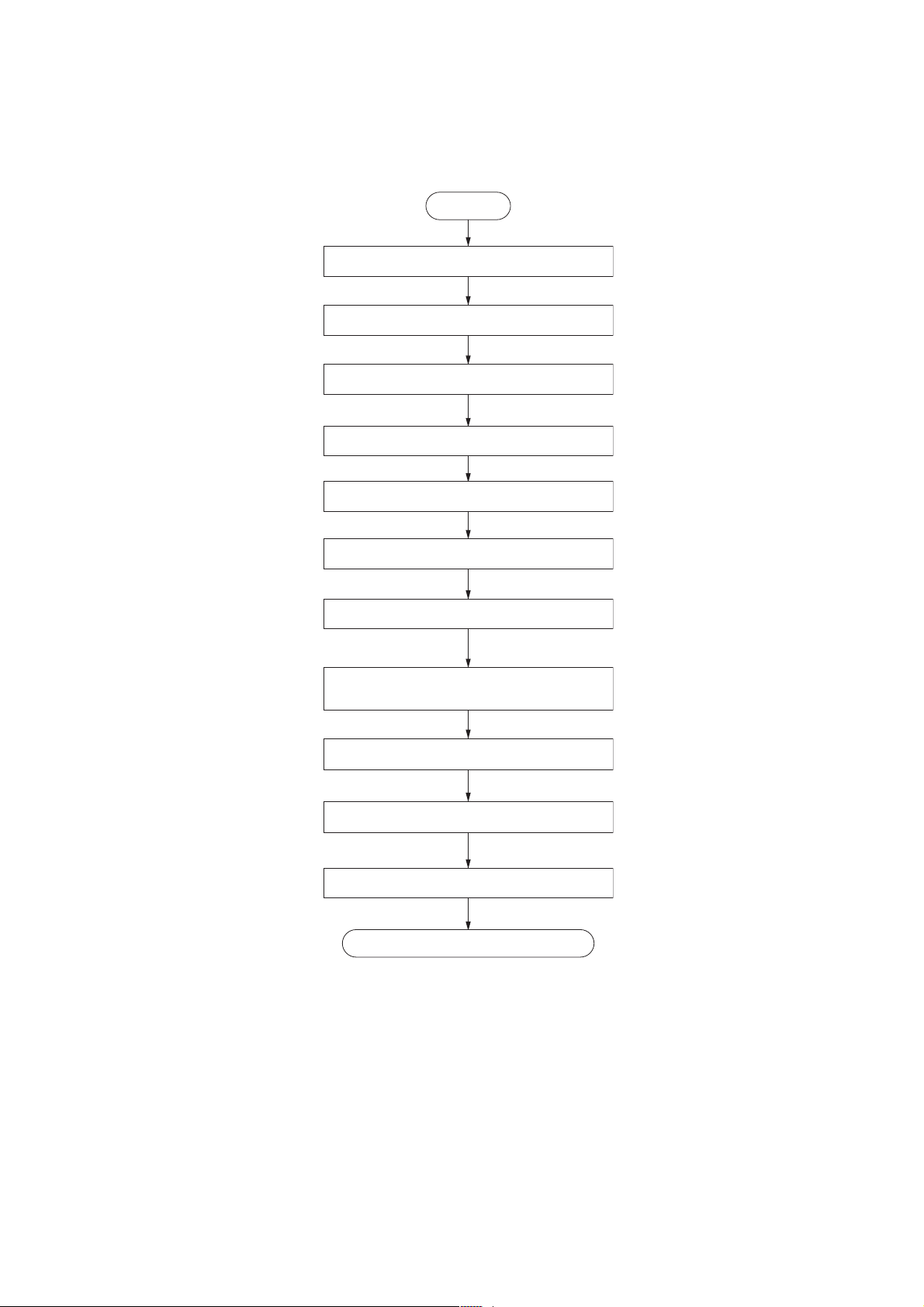

(1) Installation procedure

Start

Unpacking.

Unlocking the shipping lock.

Installing the toner container.

Loading the paper.

Installing the original table and ejection extension.

ttaching the language sheet label sheets.

A

Connecting the cables.

Initializing the printer and printing a report page

Installing the printer software.

Installing the scanner software.

Completion of the machine installation.

for test.

Print a document.

Figure 1-2-2

1-2-2

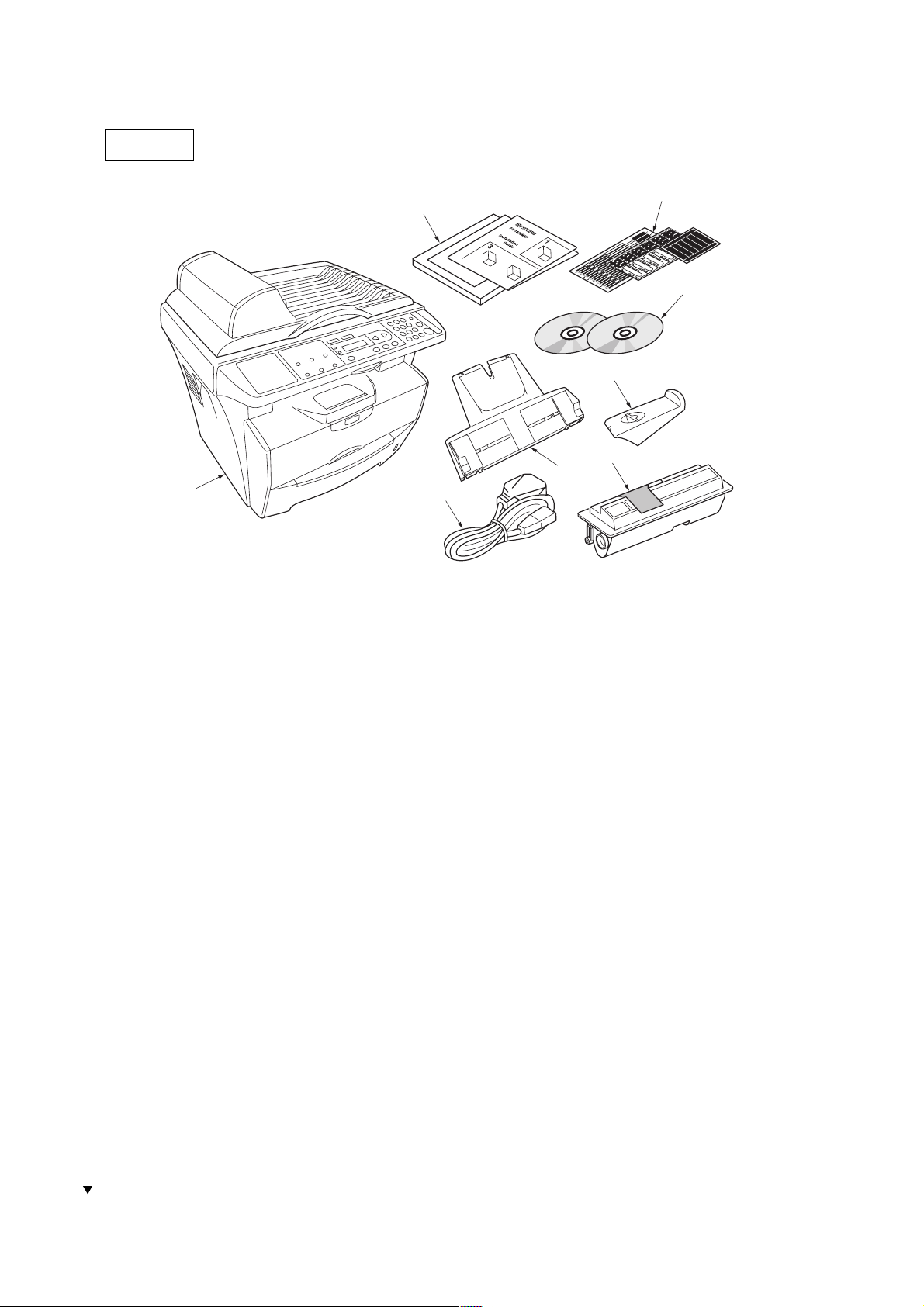

Unpacking.

2G4

Figure 1-2-3 Unpacking

1. Machine (main body)

2. Power cord

3. Toner container

4. Original table

5. Ejection extension

6. Operation guide and Installation guide

7. CD-ROMs

8. Language label sheets

1-2-3

2G4

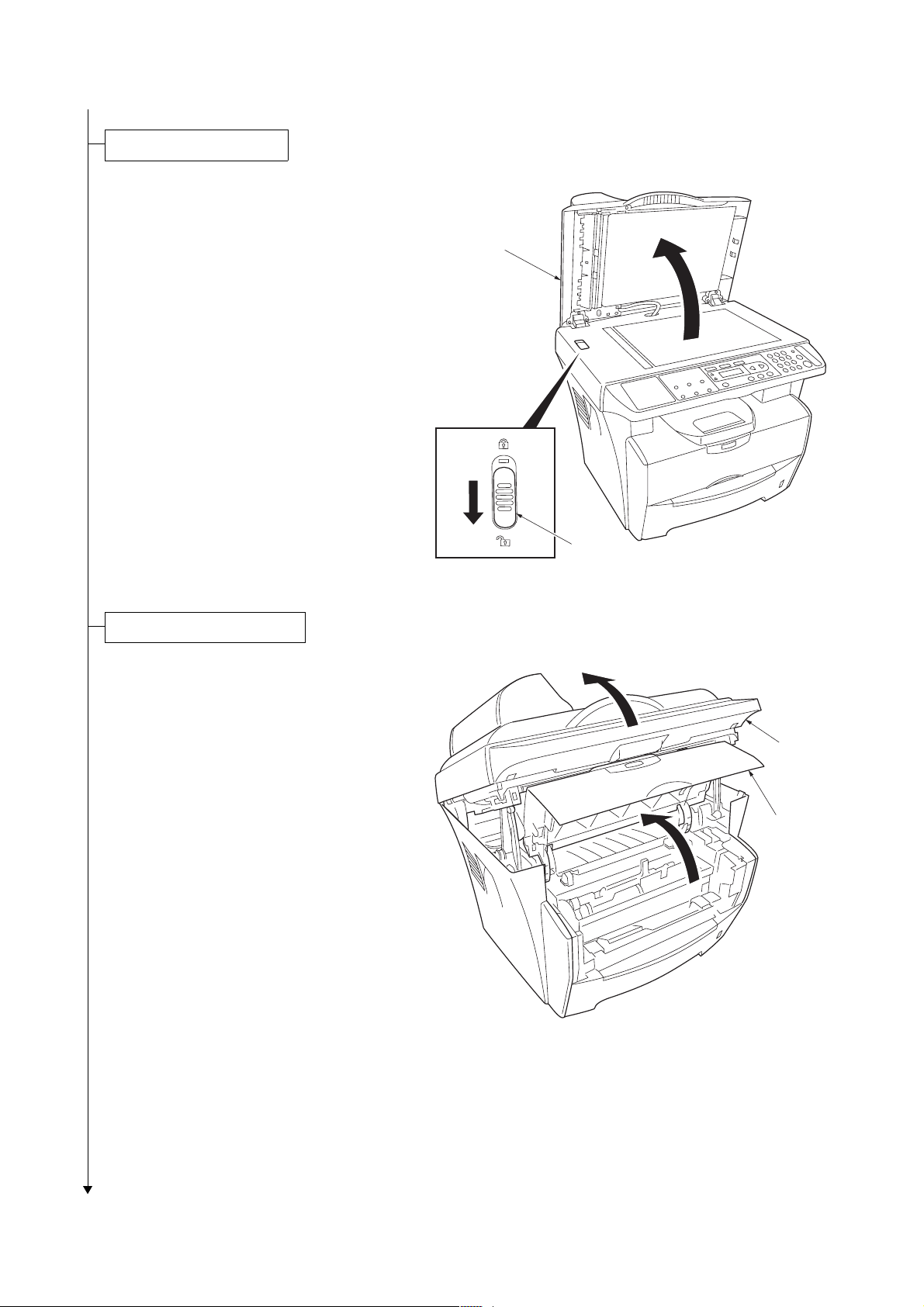

Unlocking the shipping lock.

1. Open the document processor (DP).

2. Unlock the shipping lock.

3. Close the document processor (DP).

Document

processor (DP)

Installing the toner container.

1. Open the scanner unit.

2. Open the front cover.

Shipping lock

Figure 1-2-4

Scanner unit

Front cover

1-2-4

Figure 1-2-5

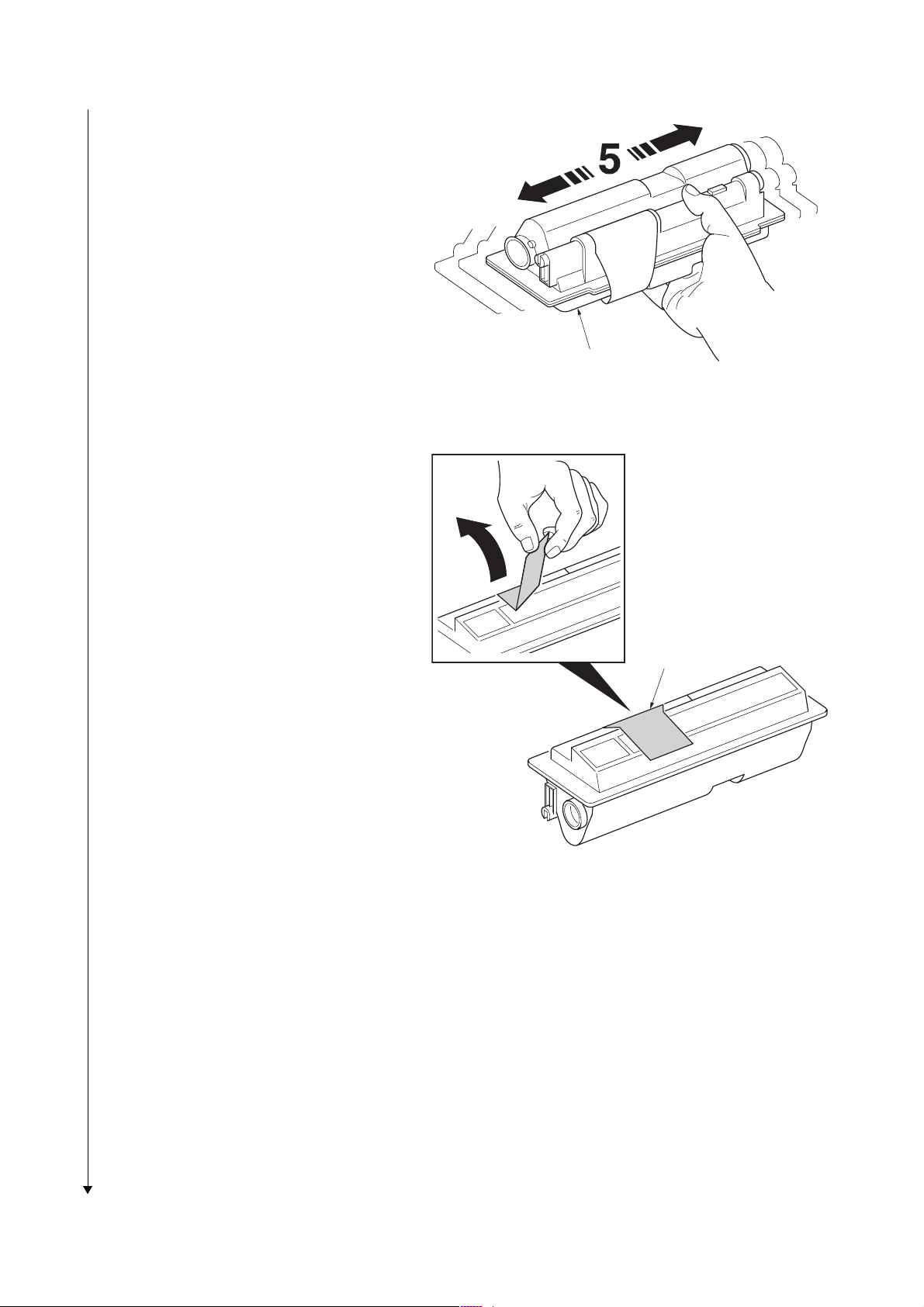

3. Shake the container horizontally to distribute

the toner evenly.

4. Remove the seal from the toner container.

5. Remove the seal from the toner container.

2G4

Toner container

Figure 1-2-6

Seal

Figure 1-2-7

1-2-5

2G4

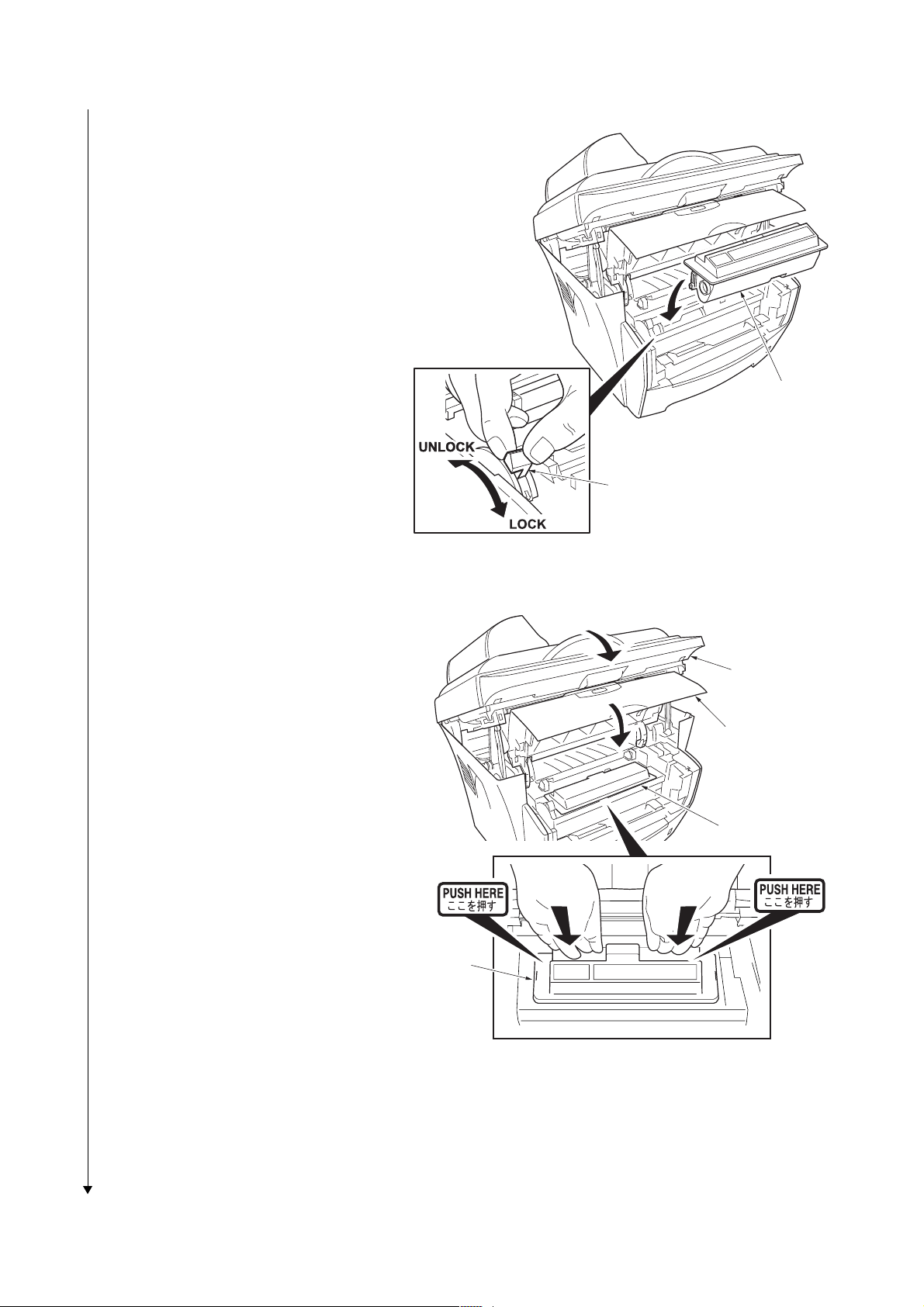

6. Turn the toner container release lever to the

[UNLOCK] position.

7. Install the toner container in the printer.

Toner container

Toner container

release lever

8. Push firmly on the top of the container at the

positions marked [PUSH HERE] until you

hear a click.

9. Turn the toner container release lever to the

[LOCK] position.

10.Close the front cover.

11.Close the scanner unit.

Figure 1-2-8

Scanner unit

Front cover

Toner

container

Toner

container

1-2-6

Figure 1-2-9

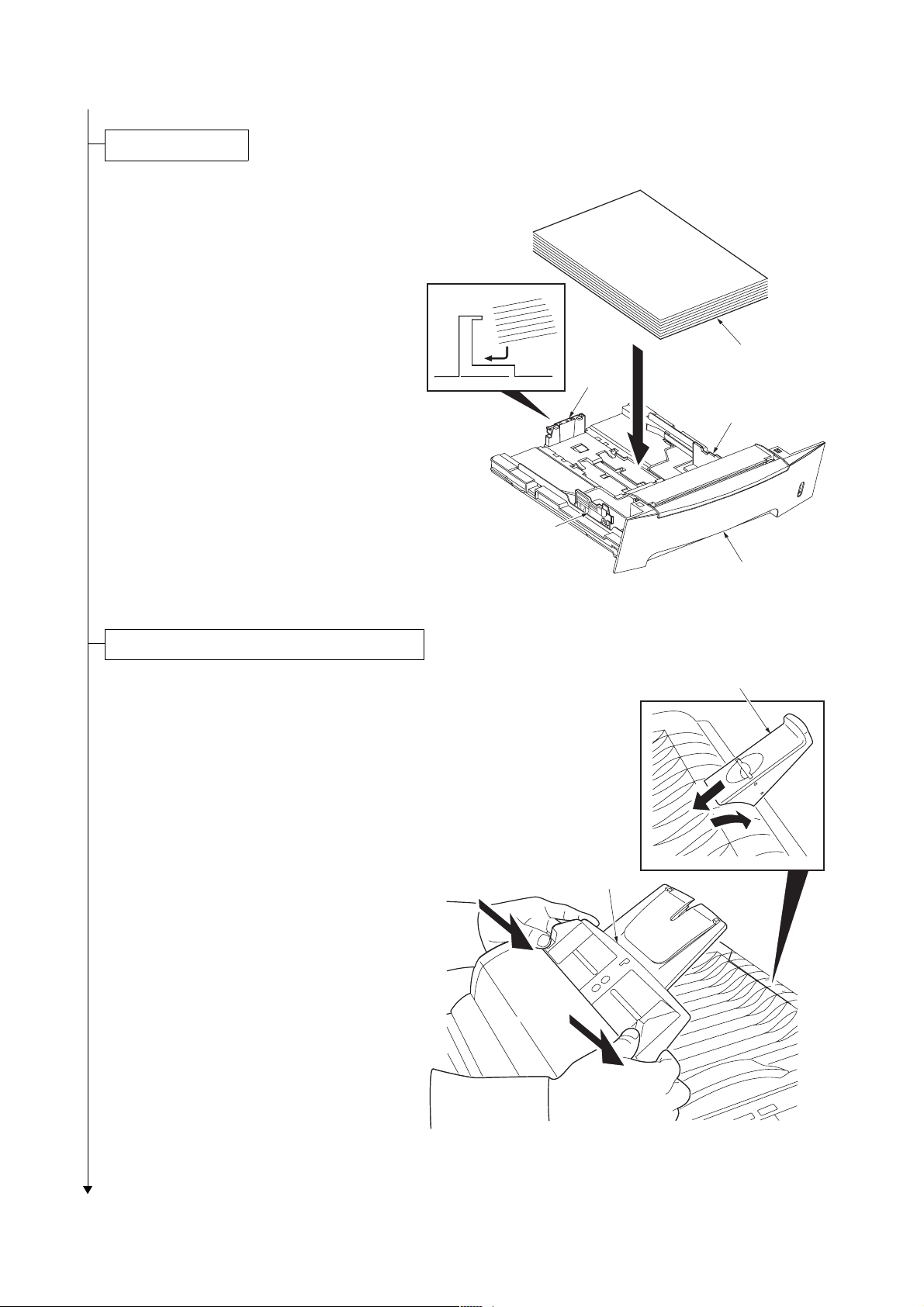

Loading the paper.

1. Pull the paper cassette completely out of the

machine.

2. Press the release button and adjust the

paper length guide to the paper size

required.

3. Adjust the position of the width guides

located on the left and right side s of the

paper cassette. Press the release button on

the left guide and slide the guides to the

paper size required.

4. Load the paper in the paper cassette.

5. Push the paper cassette back into the

machine until it stops.

Length

guide

2G4

Paper

Width guide

Installing the original table and ejection extension.

1. Install the original table.

2. Install the ejection extension.

Width guide

Paper cassette

Figure 1-2-10

Ejection extension

Original table

Figure 1-2-11

1-2-7

2G4

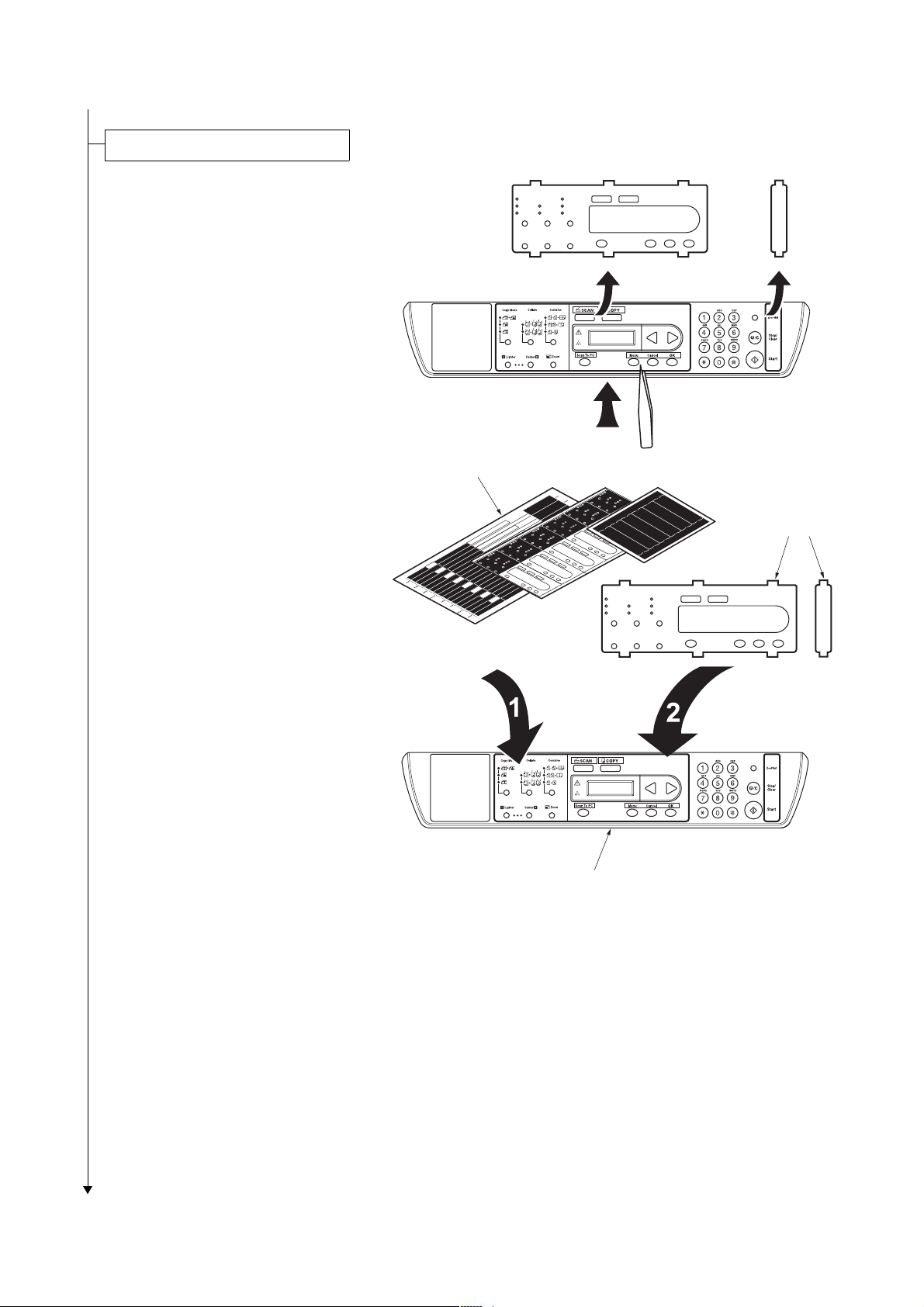

Attaching the language label sheets.

1. Remove the language label sheet.

2. Attach the language label sheet on the oper-

ation panel.

Language

label sheet

Language

label sheet

1-2-8

Operation panel

Figure 1-2-12

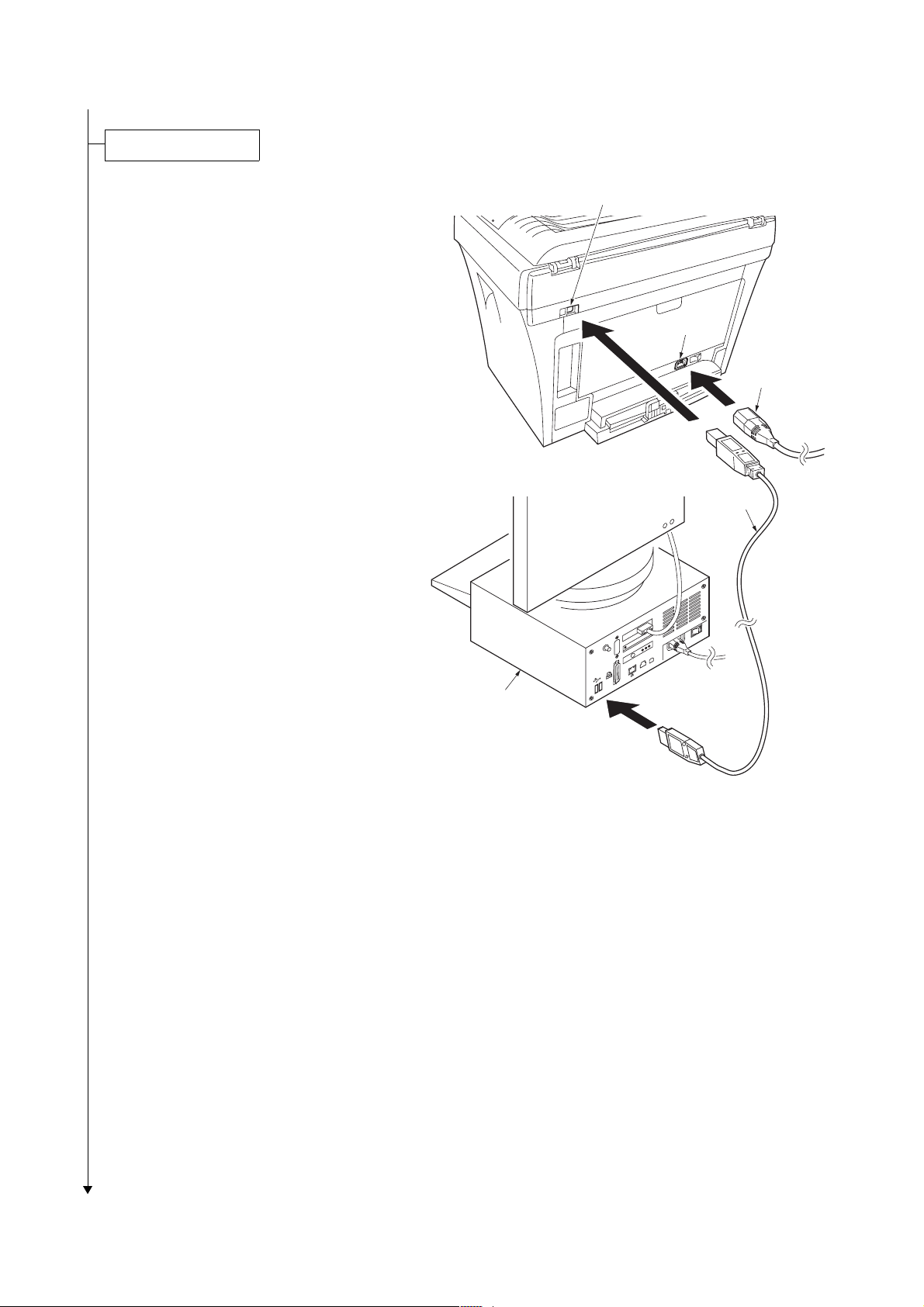

Connecting the cables.

2G4

1. Connect the printer cable to the USB inter-

face connector.

2. Connect the other end of the printer cable to

the PC’s USB interface connector.

3. Connect the power cord to the printer AC

inlet.

4. Connect the power cord to the wall outlet.

USB interface connector

AC inlet

Power cord

USB cable

PC

Figure 1-2-13

1-2-9

2G4

Initializing the printer and printing a report page for test.

1. Turn the power switch on. The machine will

begin to warm up after which the basic

screen is displayed.

2. Press the Menu key.

3. Press the W or X key to select [3. Report.]

4. Press the OK key.

5. Press the W or X key to select [31. Configu-

ration], [32. Menu Map] or [33. Usage

report].

6. Press the OK key.

Printing of the report will begin.

The display returns to the [3. Report]

screen.

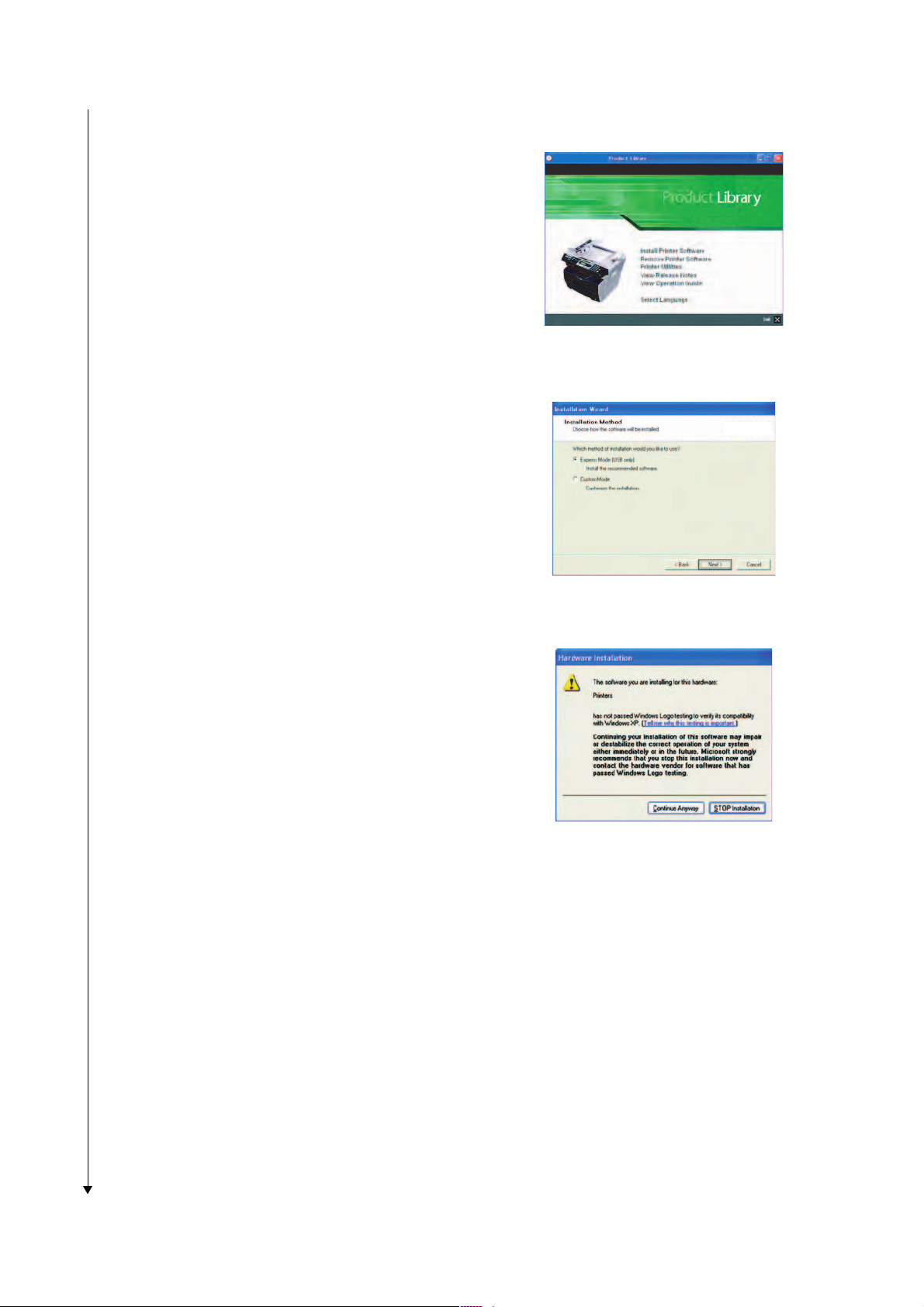

Installing the printer software.

Ensure the machine is plugged in and connected to the PC’s USB port before installing software from the CD-ROM.

Required operating systems (OS) for using

the Software: Microsoft Windows 98SE/Me/

2000/XP

Figure 1-2-14

1. Switch on the PC and activate Windows.

NOTE: If the Welcome to the Found New

Hardware Wizard dialog box displays, select

Cancel.

2. Insert the CD-ROM (Product Library FS-

1016MFP) into the CD-ROM drive. Once the

installation program launches, the License

Agreement Notice is displayed.

NOTE: If the installation program fails to

launch, use Windows Explorer to access the

CD-ROM and double-click Setup.exe.

3. Click View License Agreement to display

and read it.

4. Click Accept to proceed.

5. Click Select Language.

Figure 1-2-15

1-2-10

Figure 1-2-16

6. Click the language to be used.

7. Click Install Printer Software. The Installa-

tion Wizard starts.

8. Click Next.

9. For the simple, default installation, select

Express Mode and click Next.

2G4

Figure 1-2-17

NOTE: If you selected Custom Mode, select

Universal Serial Bus (USB) to select the

connection method, and follow the onscreen instructions.

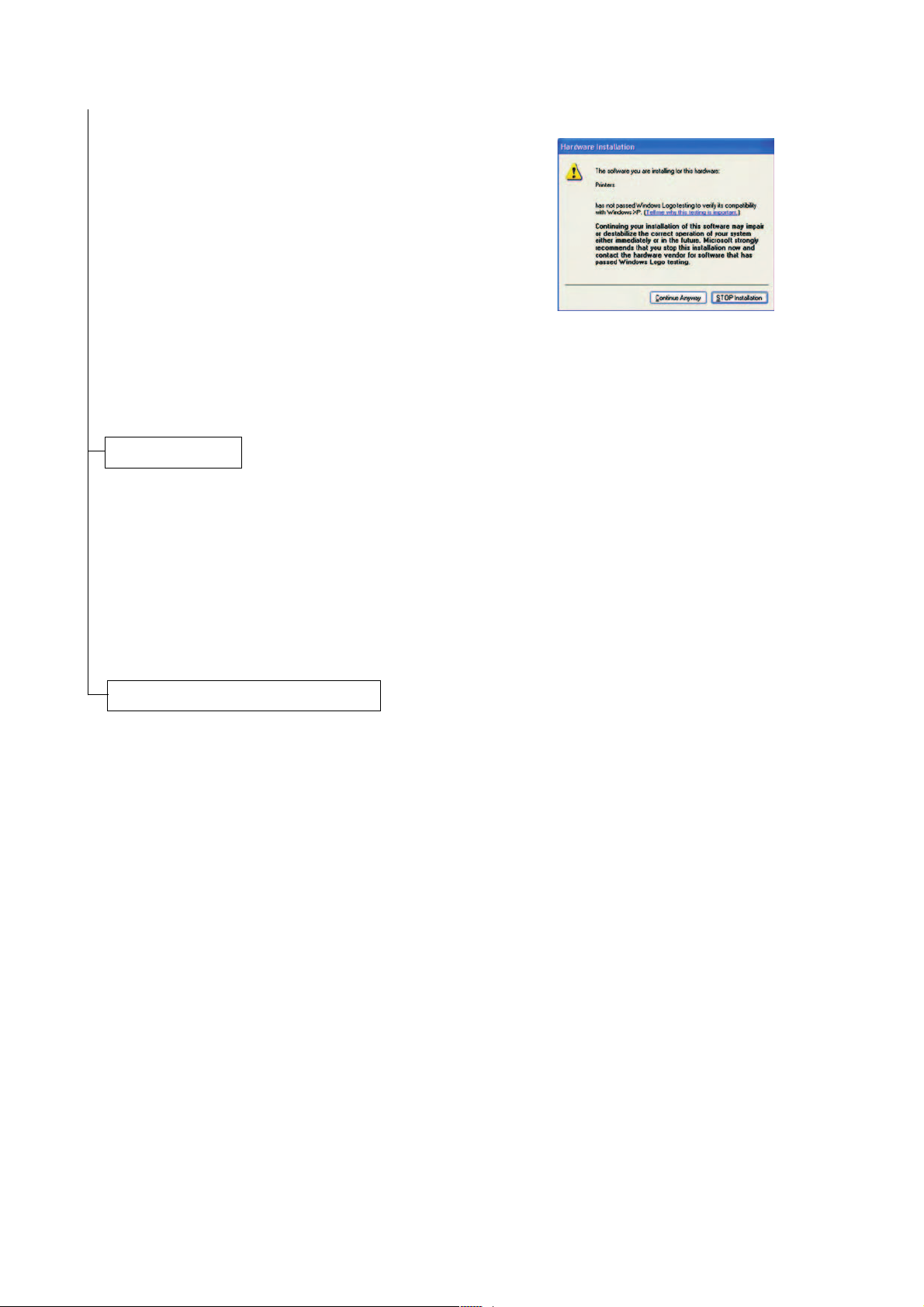

When installing software for Windows XP, if

a software installation warning for an

unsigned device driver is displayed, click

Continue Anyway to bypass the warning and

install the driver. All device drivers have

been fully tested.

10.Click OK. The installation program installs

the software.

11. When the installation is complete, the Instal-

lation Completed Successfully window is

displayed. Click Finish to leave the install

program and return to the disc main menu.

Figure 1-2-18

Figure 1-2-19

1-2-11

2G4

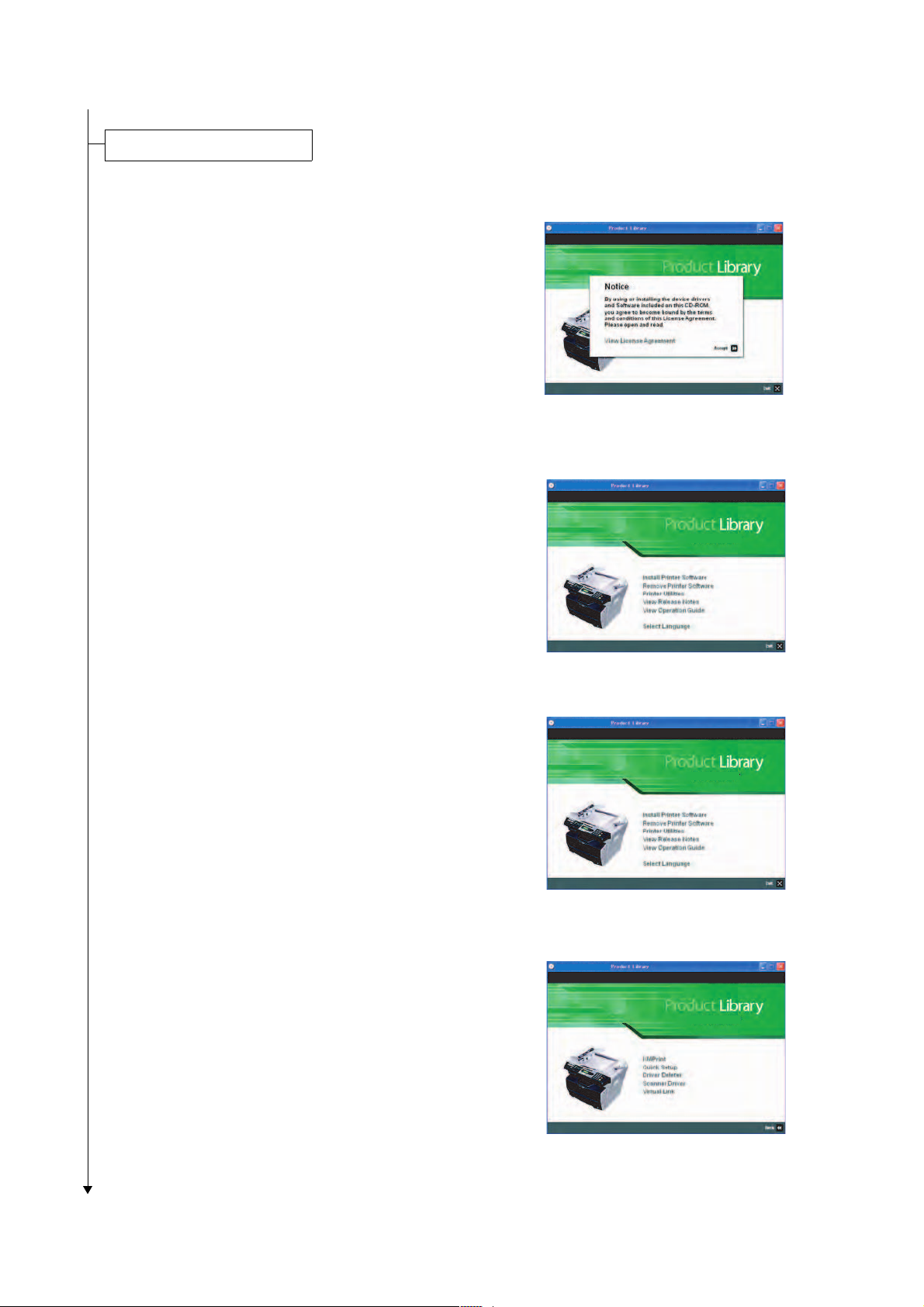

Installing the scanner software.

1. Switch on the PC and activate Windows.

NOTE: If the Welcome to the Found New

Hardware Wizard dialog box displays, select

Cancel.

2. Insert the CD-ROM (Product Library FS-

1016MFP) into the CD-ROM drive. Once the

installation program launches, the License

Agreement Notice is displayed.

NOTE: If the installation program fails to

launch, use Windows Explorer to access the

CD-ROM and double-click Setup.exe.

3. Click View License Agreement to display

and read it.

4. Click Accept to proceed.

5. Click Select Language.

6. Click the language to be used.

Figure 1-2-20

7. Click Printer Utilities.

8. Click Scanner Driver.

9. Select the language and click OK. The Kyo-

cera MFP Setup starts.

10.Click Next. The installation program installs

the software.

Figure 1-2-21

Figure 1-2-22

1-2-12

Figure 1-2-23

11.NOTE: When installing software for Win-

dows XP, if a software installation warning

for an unsigned device driver is displayed,

click Continue Anyway to bypass the warning and install the driver. All device drivers

have been fully tested.

12.When the installation is complete, the Install

Shield Wizards Complete window is displayed. Click Finish to leave the install program and return to the Printer Utilities menu.

Print a document.

1. From the application File menu, select Print.

The Print dialog box displays.

2. Select the drop down list of printer names.

All the printers installed are listed. Select the

FS-1016MFP.

3. Select the options required, enter the num-

ber of copies required and if printing more

than one set, select Collate. Select OK to

start printing.

2G4

Figure 1-2-24

Completion of the machine installation.

1-2-13

2G4

1-2 Maintenance M

This page is intentionally left blank.

1-2-14

Loading...

Loading...