Kyocera Mita DF-75 Service Manual

DF-75

SERVICE

MANUAL

Published in Aug.’01

5FG70760

CAUTION

DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY REPLACED. REPLACE ONLY WITH

THE SAME OR EQUIVALENT TYPE RECOMMENDED BY THE MANUFACTURER. DISPOSE OF

USED BATTERIES ACCORDING TO THE MANUFACTURER’S INSTRUCTIONS.

ATTENTION

IL Y A DANGER D’EXPLOSION S’IL Y A REMPLACEMENT INCORRECT DE LA BATTERIE.

REMPLACER UNIQUEMENT AVEC UNE BATTERIE DU MÊME TYPE OU D’UN TYPE RECOMMANDÉ PAR LE CONSTRUCTEUR. METTRE AU RÉBUT LES BATTERIES USAGÉES

CONFORMÉMENT AUX INSTRUCTIONS DU FABRICANT.

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING:Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION: Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the copier.

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. ............................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. .............................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .....

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. ..............

• Do not install the copier near a radiator, heater, other heat source or near flammable material.

This may cause fire. ..........................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ..........

• Always handle the machine by the correct locations when moving it. ..............................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may

cause the copier to move unexpectedly or topple, leading to injury..................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is

accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention

immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain

medical attention. ..............................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. ........................................................................................................................

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly...............

• Always follow the procedures for maintenance described in the service manual and other related

brochures. .........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety

mechanisms and protective circuits. .................................................................................................

• Always use parts having the correct specifications...........................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related

brochure when replacing them. Using a piece of wire, for example, could lead to fire or other

serious accident. ...............................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ...............................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. ............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If

it is dirty, clean it to remove the risk of fire or electric shock. ............................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ..............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause

electric shock if handled improperly. .................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections...........................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. .......

• Handle the fixing section with care to avoid burns as it can be extremely hot. .................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures...........................................................................................................

• Do not remove the ozone filter, if any, from the copier except for routine replacement....................

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ......................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ..............................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks........

• Remove toner completely from electronic components. ...................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ...................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten

connector, trapped wire and missing screws. ..................................................................................

• Check that all the caution labels that should be present on the machine according to the

instruction handbook are clean and not peeling. Replace with new ones if necessary. ...................

• Handle greases and solvents with care by following the instructions below: ....................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the main

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc...........................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet

immediately. ......................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than

the specified refiner; it may generate toxic gas. ................................................................................

Contents

CHAPTER 1 GENERAL DESCRIPTION

CONTENTS

1 Features ............................................... 1-1

2 Specifications ...................................... 1-2

2.1 Specifications ............................. 1-2

2.1.1 Finisher/Saddle Assembly.... 1-2

2.1.2 Puncher unit (option) ........... 1-6

3 Names of Parts .................................... 1-8

3.1 Cross Section ............................. 1-8

3.1.1 Finisher Unit ........................ 1-8

3.1.2 Saddle Unit .......................... 1-9

3.1.3 Puncher Unit (option) ........ 1-10

4 Routine Maintenance by the User...... 1-11

CHAPTER 2 OUTLINE OF OPERATION

1 Basic Operations ................................. 2-1

1.1 Specifications .............................2-1

1.2 Outline of the Electrical

Circuitry ..................................... 2-2

1.3 Inputs to and Outputs from the

Finisher Controller PCB ............. 2-3

1.3.1 Inputs to the Finisher Controller

PCB (1/2) ............................. 2-3

1.3.2 Inputs to the Finisher Controller

PCB (2/2) ............................. 2-4

1.3.3 Outputs from the Finisher Con-

troller PCB (1/2) .................. 2-5

1.3.4 Outputs from the Finisher Con-

troller PCB (2/2) .................. 2-6

1.3.5 Inputs to and Outputs from the

Finisher Controller ............... 2-7

1.4 Inputs to and Outputs from the

Punch Controller PCB (option) .. 2-8

1.4.1 Inputs to and Outputs from the

Punch Controller PCB ......... 2-8

1.4.2 Outputs from the Punch Con-

troller PCB ........................... 2-9

2 Feed/Drive System ............................2-10

2.1 Outline ......................................2-10

2.1.1 Normal Delivery ................ 2-11

2.2 Feed/Delivery ........................... 2-15

2.2.1 Outline ............................... 2-15

2.3 Job Offset................................. 2-18

2.3.1 Outline ............................... 2-18

2.3.2 Processing Tray Paper Stacking

Operation ........................... 2-20

2.3.3 Offset Operation ................ 2-21

2.3.4 Stack Delivery Operation ... 2-22

3 Stapling Operation............................. 2-23

3.1 Outline ...................................... 2-23

3.2 Stapling Operation .................... 2-25

3.3 Delivery Operation after

Stapling .................................... 2-27

3.4 Stapler Unit .............................. 2-29

3.4.1 Stapler Movement

Controller ........................... 2-31

4 Delivery Tray Operation.................... 2-35

4.1 Outline ...................................... 2-35

5 Saddle Unit........................................ 2-37

5.1 Basic Operations ...................... 2-37

5.1.1 Outline ............................... 2-37

5.2 Feed/Drive System ................... 2-38

5.2.1 Outline ............................... 2-38

5.3 Paper Feed System ................... 2-43

5.3.1 Outline ............................... 2-43

5.4 Stack Feed System ................... 2-44

5.4.1 Outline ............................... 2-44

5.5 Fold/Delivery System ............... 2-45

5.5.1 Outline ............................... 2-45

5.5.2 Paper Folding ..................... 2-46

6 Puncher Unit (option)........................ 2-49

6.1 Basic Operations ...................... 2-49

6.1.1 Outline ............................... 2-49

CONTENTS

6.2 Punching Operation .................. 2-50

6.2.1 Outline ............................... 2-50

6.2.2 Punching Operation ........... 2-52

6.2.3 Horizontal Registration Opera-

tion ..................................... 2-57

7 Detecting Jams .................................. 2-60

7.1 Outline ...................................... 2-60

7.1.1 Inlet Sensor Delay Jam

(J80) ................................... 2-61

7.1.2 Inlet Sensor Stationary Jam

(J81) ................................... 2-61

7.1.3 Folding Position Sensor Delay

Jam (J83) ........................... 2-61

7.1.4 Folding Position Sensor

Stationary Jam (J84) .......... 2-62

7.1.5 Power-On Jam (J87) .......... 2-62

7.1.6 Door Open Jam (paper present)

(J88) ................................... 2-62

7.1.7 Staple Jam (J86) ................. 2-62

8 Power Supply System ....................... 2-63

8.1 Finisher/Saddle Assembly ........ 2-63

8.1.1 Outline ............................... 2-63

8.1.2 Protective Mechanisms ...... 2-63

8.2 Puncher Unit (option) ............... 2-64

8.2.1 Outline ............................... 2-64

8.2.2 Protective Mechanisms ...... 2-64

CHAPTER 3 MECHANICAL SYSTEMS

1 Finisher/Saddle Unit............................ 3-1

1.1 Externals and Controls ............... 3-1

1.1.1 Removing the Delivery Tray 3-1

1.1.2 Removing the Front Cover ... 3-2

1.1.3 Removing the Rear Cover .... 3-3

1.1.4 Removing the Upper Cover . 3-3

1.1.5 Removing the Processing Tray

Upper Cover ........................ 3-4

1.1.6 Removing the Upper Right

Cover Assembly................... 3-5

1.1.7 Removing the Saddle Guide . 3-6

1.2 Feeding System .......................... 3-7

1.2.1 Removing the Stapler Unit ... 3-7

1.2.2 Adjusting the Stapler Phase . 3-8

1.2.3 Adjusting the Phase of the Gear

in the Saddle Unit ............... 3-13

1.2.4 Removing the Saddle Unit . 3-14

1.2.5 Removing the Processing

Tray Assembly ................... 3-16

1.2.6 Removing the Paddle

Assembly ........................... 3-18

1.2.7 Removing the Staple/Fold

Drive Unit .......................... 3-20

1.2.8 Removing the Feed Motor

Unit .................................... 3-24

1.2.9 Removing the Feed Roller .. 3-24

1.2.10 Removing the Stack delivery

roller (upper) ...................... 3-26

1.2.11 Removing the Paddle ......... 3-28

1.2.12 Removing the Stack delivery

roller (lower)/Delivery Belt 3-30

1.3 PCBs ........................................ 3-32

1.3.1 Removing the Finisher

Controller PCB .................. 3-32

1.3.2 Removing the Slide Home

Position PCB ..................... 3-33

2 Puncher Unit (option)........................ 3-35

2.1 Puncher Driving System .......... 3-35

2.1.1 Removing the Punch Motor 3-35

2.1.2 Removing the Horizontal

Registration Motor ............. 3-35

2.1.3 Removing the Punch Unit .. 3-36

2.2 PCBs ........................................ 3-38

2.2.1 Removing the Punch Controller

PCB ................................... 3-38

2.2.2 Removing the Photosensor

PCB ................................... 3-39

2.2.3 Removing the LED PCB .... 3-40

2.2.4 Removing the Waste-Full

Photosensor PCB ............... 3-41

2.2.5 Removing the Waste Full

LED PCB ........................... 3-42

CONTENTS

CHAPTER 4 MAINTENANCE AND INSPECTION

1 Periodically Replaced Parts ................. 4-1

1.1 Finisher/Saddle Unit ................... 4-1

1.2 Puncher Unit (option) ................. 4-1

2 Consumables and Durables ................. 4-2

2.1 Saddle/Finisher Unit ................... 4-2

3 Scheduled Maintenance ....................... 4-2

CHAPTER 5TROUBLESHOOTING

1 Standards and Adjustments ................. 5-1

1.1 Electrical System

(finisher/saddle unit) ................... 5-1

1.1.1 Adjusting the Folding

Position ................................ 5-1

1.1.2 Adjusting the Middle 2-Point

Stapling Position .................. 5-3

1.2 Electrical System

(puncher unit; option) ................. 5-4

1.2.1 Adjusting the Punch Hole

Position ................................ 5-4

1.2.2 Adjusting the Sensor Output 5-4

1.2.3 Registering the Number of

Punch Hole .......................... 5-5

1.2.4 After Replacing the EEP-ROM

(IC1002) .............................. 5-6

2 Arrangement of Electric Components..5-8

2.1 Finisher/Saddle Unit ................... 5-8

2.1.1 Sensors, Microswitches, and

Clutch ................................... 5-8

2.1.2 Motor PCBs ....................... 5-10

2.2 Puncher Unit (option) ............... 5-12

2.2.1 Sensors .............................. 5-12

2.2.2 Motors ............................... 5-13

2.2.3 PCBs.................................. 5-14

3 LEDs and Check Pins by PCB.......... 5-15

3.1 Finisher Controller PCB ........... 5-15

3.2 Punch Controller PCB .............. 5-16

4 Troubleshooting ................................ 5-17

4.1 Troubleshooting

(finisher/saddle unit) ................. 5-17

4.1.1 C0440, communication

error ................................... 5-17

4.1.2 C8390, Finisher Unit Back-Up

Memory Fault

(detail code: 10) .................. 5-17

4.1.3 C8010, Feed Motor Fault (detail

code: 01/02) ....................... 5-18

4.1.4 C8300, Delivery Motor Fault

(detail code: 01/02) ............. 5-18

4.1.5 C8320, Alignment Motor (Rear)

Fault (detail code: 01/02) .... 5-19

4.1.6 C8340, Staple/fold Motor Fault

(detail code: 01/02) ............. 5-19

4.1.7 C8340, Staple/Fold Motor Fault

(detail code: 03) .................. 5-20

4.1.8 C8340, Staple/Fold Motor Fault

(detail code: 01/02) ............. 5-20

4.1.9 C8340, Staple/Fold Motor Fault

(detail code: 03) .................. 5-21

4.1.10 C8360, Slide Motor Fault

(detail code: 01/02) ............. 5-21

4.1.11 C8330, Alignment Motor (front)

Fault (detail code: 01/02) .... 5-22

4.1.12 C8140, Shift Motor Fault (detail

code: 01) ............................ 5-22

4.1.13 C8140, Shift Motor Fault

(detail code: 02) .................. 5-23

4.1.14 C8140, Shift Motor Fault

(detail code: 03) .................. 5-23

4.1.15 C8370, Paddle Motor Fault

(detail code: 01/02/03/04) ... 5-24

4.2 Troubleshooting (puncher unit,

option) ...................................... 5-25

4.2.1 C8430, Communication

Faulty ................................. 5-25

CONTENTS

4.2.2 C8460, Puncher Back-UP

Memory Fault

(detail code: 20) .................. 5-25

4.2.3 C8480, Puncher Unit Power

Supply Fault (detail code:20)

........................................... 5-25

4.2.4 C8410, Punch Motor Fault

(detail code: 01/02) ............. 5-26

4.2.5 C8450 Punch Sensor (horizontal

registration) Fault (detail code:

01 through 05) ................... 5-26

4.2.6 C8470, Punch sensor (waste

full) Fault (detail code: 06) . 5-27

APPENDIX

1 General Timing Chart ......................... A-1

1.1 Finisher Unit ............................. A-1

1.2 Saddle Unit ................................ A-2

1.3 Puncher Unit (option) ................ A-3

2 Signals and Abbre viations.................. A-5

2.1 Finisher Saddle Unit.................. A-5

2.2 Puncher Unit (option) ................ A-7

3 Finisher/Saddle Unit General Circuit

Diagram.............................................. A-9

3.1 Finisher Controller PCB (1/8) . A-10

3.2 Finisher Controller PCB (2/8) . A-11

3.3 Finisher Controller PCB (3/8) . A-12

4.2.7 C8420, Horizontal Registration

Motor Fault

(detail code: 01/02) ............. 5-27

5 Self Diagnosis ................................... 5-28

5.1 Outline ...................................... 5-28

5.2 Errors ....................................... 5-28

5.2.1 Finisher/Saddle Unit .......... 5-28

5.2.2 Puncher Unit (option) ........ 5-31

5.3 Alarm ................................. 5-32

5.3.1 Finisher/Saddle Unit .......... 5-32

5.3.2 Puncher Unit (option) ........ 5-33

5.4 Host Machine I/O Display ....... 5-34

5.4.1 Finisher/Saddle Unit .......... 5-34

5.4.2 Puncher Unit (option) ........ 5-38

3.4 Finisher Controller PCB (4/8) . A-13

3.5 Finisher Controller PCB (5/8) . A-14

3.6 Finisher Controller PCB (6/8) . A-15

3.7 Finisher Controller PCB (7/8) . A-16

3.8 Finisher Controller PCB (8/8) . A-17

4 Puncher Unit General Circuit

Diagram............................................ A-18

4.1 Punch Controller PCB............. A-19

4.2 LED PCB ................................ A-20

4.3 Photosensor PCB .................... A-21

CHAPTER 1

GENERAL DESCRIPTION

CHAPTER 1 GENERAL DESCRIPTION

1 Features

a. Through-type stapler

Adoption of a through-type stapler allows a stapler to carry out saddle stitching.

b. Three different auto stapling positions

Three different stapling positions (front 1-point stapling, rear 1-point stapling, and middle

2-point stapling) are supported.

c. Saddle stitching

A maximum of ten sheets of paper can be delivered with them stapled and folded in the

middle.

d. Punch mechanism (option).

Installation of a puncher unit enables punching holes in sheets before delivery (64 to 90 g/

2

paper; no transparency).

m

1-1

CHAPTER 1 GENERAL DESCRIPTION

2 Specifications

2.1 Specifications

2.1.1 Finisher/Saddle Assembly

Item

Stacking

Feed reference

Stack paper size

Paper weight

Mode

Stack height (Note 1)

Mixed stack

Paper detection

Control panel

Specifications

2 locations

(1 ) Delivery Tray (descending type; 1 tray)

Face-down

(2 ) Bind Tray (fixed type)

Center reference

A3, A4, A4R, A5, A5R, B4, B5, B5R, 297mm

× 432mm (11” × 17”), LGL, LTR, LTRR,

STMT, STMTR

Finisher assembly: 64 to 90 g/m

Saddle Assembly: 64 to 90 g/m

Non-sort stack

Sort stack

Staple stack

Bind stack

Non-Sort Staple

2

2

Large-size: 500 sheets

Small-size: 1000 sheets (Note 2)

Staple Sort

Large-size: 30 sets or 500 sheets

Small-size: 30 sets or 1000 sheets

Folded stack

Stack of 6 to 10 sheets: 10 sets

Stack of 1 to 5 sheets: 20 sheets

Size mix: 500 sheets (Note 3)

Staple mix: 30 sheets (same paper configuration)

Delivery tray: No

Bind tray: Yes

No

Remarks

Large-size: A3, B4,

279mm × 432mm

(11” × 17”), LGL

Note 1:

The number of sheets is computed based on 80 g/m

Note 2:

Alignment is not guaranteed if the stack consists of 750 sheets or more.

Note 3:

Alignment is not guaranteed if the stack consists of sheets of different sizes.

1-2

2

paper.

CHAPTER 1 GENERAL DESCRIPTION

Item

Display

Size

Weight

Power supply

Maximum power consumption

Stapling

Stapling position

Stapling thickness

Staple supply

Staples

Staple detection

Stapling size

Manual stapling

Folding method

Folding mode

Folding position

Saddling size

Specifications

No

665 (W) × 615 (D) × 555 (H) mm /

26.18(W) × 24.21(D) × 21.85(H) in

27 kg / 59.40 lb (approx.)

24 VDC from host machine

At standby: 13 W

In operation: 84 W (staple sort)

Rotary cam type

See F01-201-01.

Finisher

Large-size: 25 sheets

Small-size: 50 sheets

Saddle: 10 sheets

Cartridge of special staples (5000

staples)

Special staples

Yes (nearly empty: 40 remaining staples)

Front 1-Point Stapling:

A3, A4R, B4, 279 mm × 432 mm (11” ×

17”), LGL, LTRR

Rear 1-Point Stapling:

A3, A4, A4R, B4, B5, 279 mm × 432

mm (11” × 17”), LGL, LTR, LTRR

Middle 2-Point Stapling:

A3, A4, A4R, B4, B5, 279 mm × 432

mm (11” × 17”), LGL, LTR, LTRR

Middle 2-Point Stapling:

A3, A4R, B4, 279 mm × 432 mm (11” ×

17”), LTRR

None

Roller contact

Double-folding (single-sheet non-stapling available)

Middle of sheet

A3, A4R, B4, 279 mm × 432 mm (11” ×

17”), LTRR

Remarks

(excl. installing kit)

(80 g/m

(80 g/m

(80 g/m

With the saddle in use.

Requires a margin of

±5mm / ±0.2in from the

middle of the sheet as a

middle margin.

No special paper.

2

paper)

2

paper)

2

paper)

T01-201-01

1-3

CHAPTER 1 GENERAL DESCRIPTION

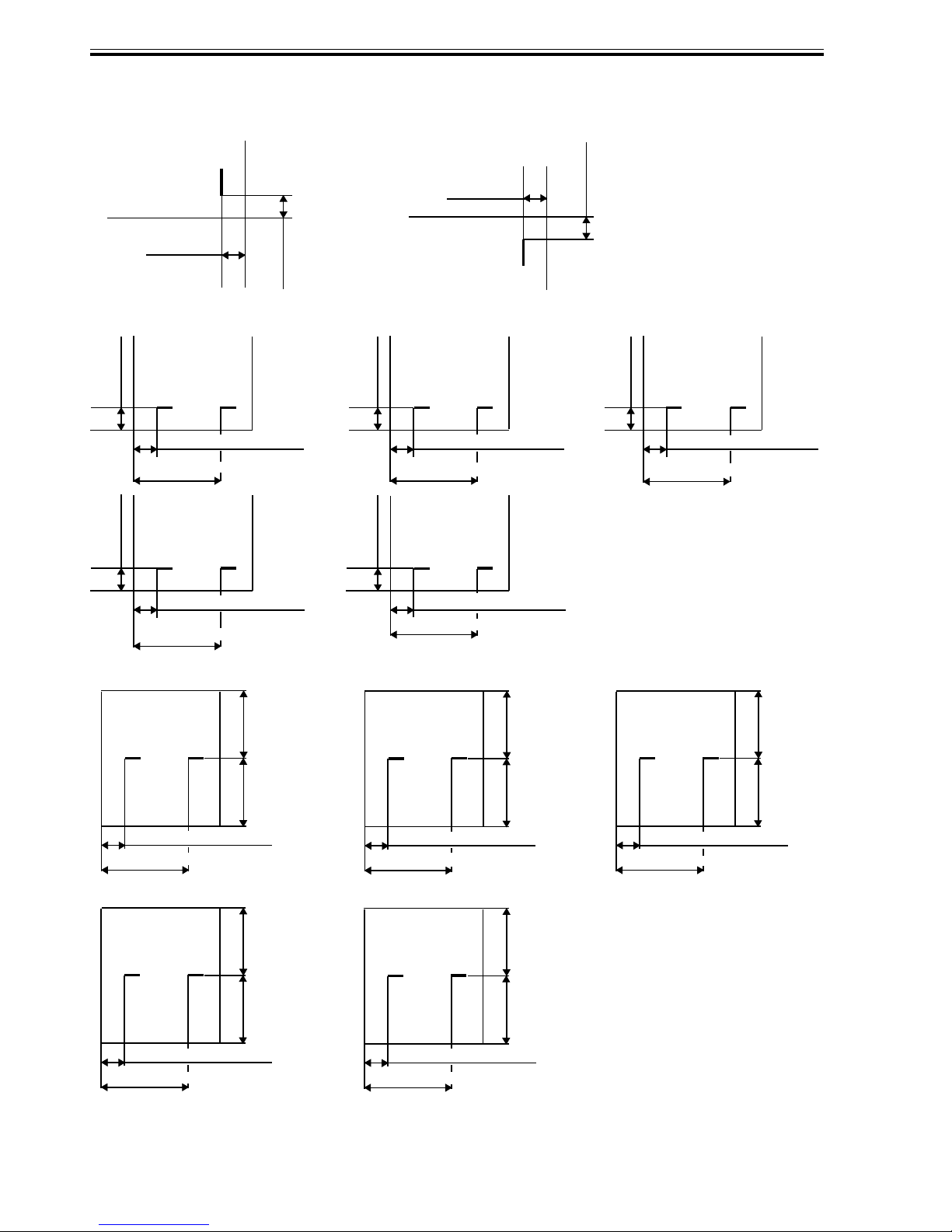

Staple Position

Front 1-point stapling

5±2 mm /

0.2±0.08 in

Middle 2-point stapling

A3 or A4 A4R

5±2 mm /

0.2±0.08 in

82±4 mm / 3.23±0.16 in

202±4 mm / 7.95±0.16 in

279×432 mm

×

17")

(11"

5±2 mm /

0.2±0.08 in

or LTR

5±2 mm /

0.2±0.08 in

Rear 1-point stapling

5±2 mm /

0.2±0.08 in

5±2 mm /

0.2±0.08 in

39±4 mm / 1.54±0.16 in 62±4 mm / 2.44±0.16 in

159±4 mm / 6.26±0.16 in

LGL or LTRR

5±2 mm /

0.2±0.08 in

5±2 mm /

0.2±0.08 in

5±2 mm /

B4 or B5

0.2±0.08 in

182±4 mm / 7.17±0.16 in

73±4 mm / 2.87±0.16 in

193±4 mm / 7.6±0.16 in

Middle 2-point stapling (w/ saddle in use)

A3

82±4 mm / 3.23±0.16 in

202±4 mm / 7.95±0.16 in

[χ1-χ2]≤1 mm

279 mm×432 mm

×

17")

(11"

χ1χ2

39±4 mm / 1.54±0.16 in

159±4 mm / 6.26±6.16 in

[χ1-χ2]≤1 mm

χ1χ2

42±4 mm / 1.65±0.16 in

162±4 mm / 6.38±0.16 in

A4R

LTRR

χ1χ2

χ12

B4

62±4 mm / 2.44±0.16 in

182±4 mm / 7.17±0.16 in

[χ1-χ2]≤1 mm

χ1χ2

73±4 mm / 2.87±0.16 in

193±4 mm / 7.6±0.16 in

[χ1-χ2]≤1 mm

1-4

42±4 mm / 1.65±0.16 in

162±4 mm / 6.38±0.16 in

[χ1-χ2]≤1 mm

F01-201-01

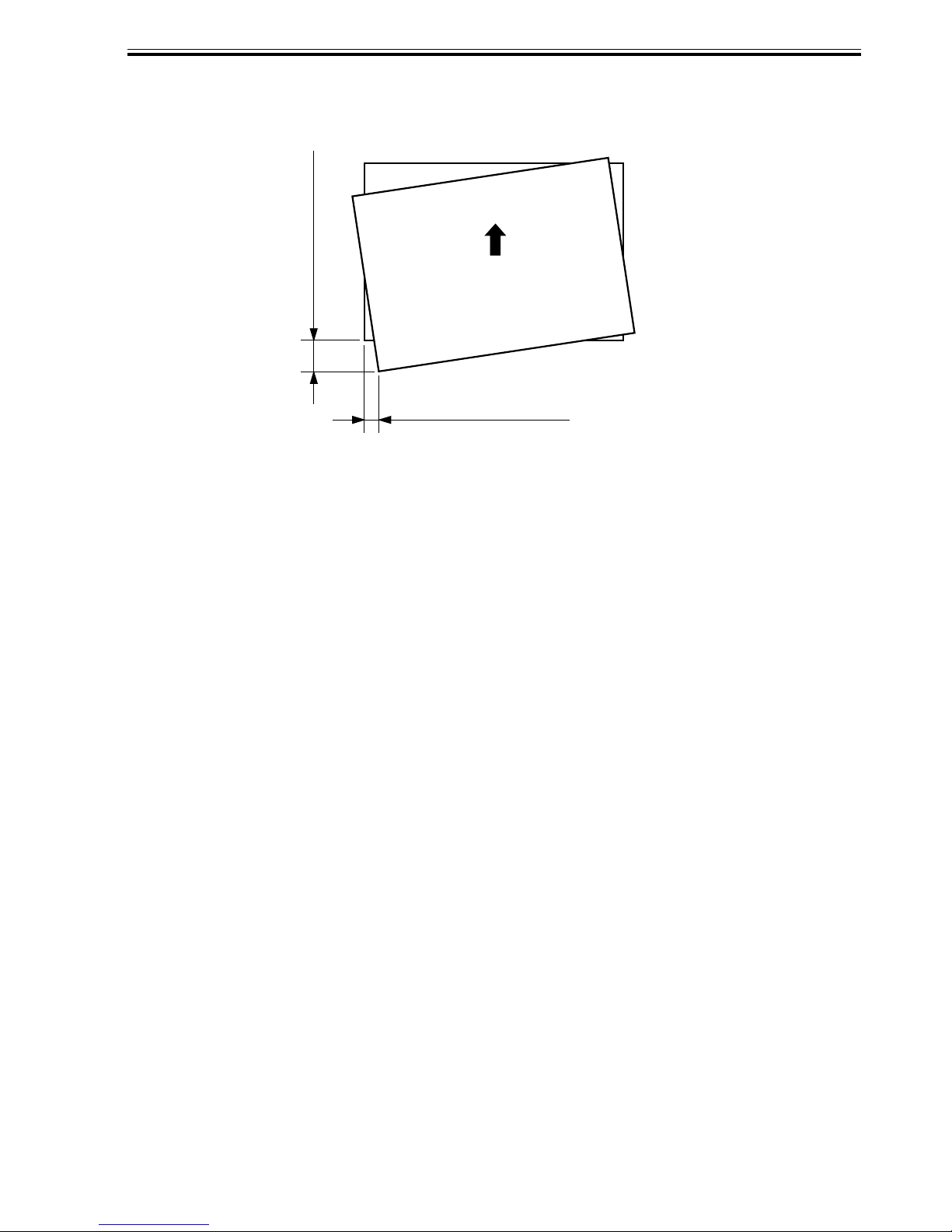

Stacked Paper Alignment

50 mm / 1.97 in max.

CHAPTER 1 GENERAL DESCRIPTION

Delivery direction

20 mm / 0.79 in max.

F01-201-02

1-5

CHAPTER 1 GENERAL DESCRIPTION

2.1.2 Puncher unit (option)

Item

Punching method

Paper size

Paper weight

Punch hole diameter

Punch waste

Size

Weight

Power supply

Power consumption

Specifications

Reciprocating method

(sequential processing method)

2-hole (Puncher Unit-J1):

A3, A4, A4R, B4, B5, B5R

2-/3-hole (Puncher Unit-K1):

2-hole/LGL, LTRR

3-hole/279 × 432 mm (11”×17”), LTR

4-hole (Puncher Unit-G1/-H1):

A3, A4

64 g/m

2-hole (Puncher Unit-J1):

6.5 mm / 0.26 in

2-/3-hole (Puncher Unit-K1):

2-hole 8.0 mm / 0.31 in

3-hole 8.0 mm / 0.31 in

4-hole (Puncher Unit-G1/-H1):

6.5 mm / 0.26 in

2-hole (Puncher Unit-J1):

3000 sheets

2-/3-hole (Puncher Unit-K1):

2-hole/1500 sheets

3-hole/1500 sheets

4-hole (Puncher Unit-G1/H1) :

1500 sheets

90 (W) × 560 (D) × 170 (H) mm /

3.54 (W) × 22.05 (D) × 6.69 (H) in

2.5 kg / 5.5 lb (approx.)

24 VDC from finisher unit.

Standby: 2 W max.

Operating: 21 W max (punching)

2

~ 90 g/m

Remarks

2

No transparencies.

64 g/m

75 g/m

75 g/m

80 g/m

2

paper

2

paper

2

paper

2

paper

1-6

T01-201-02

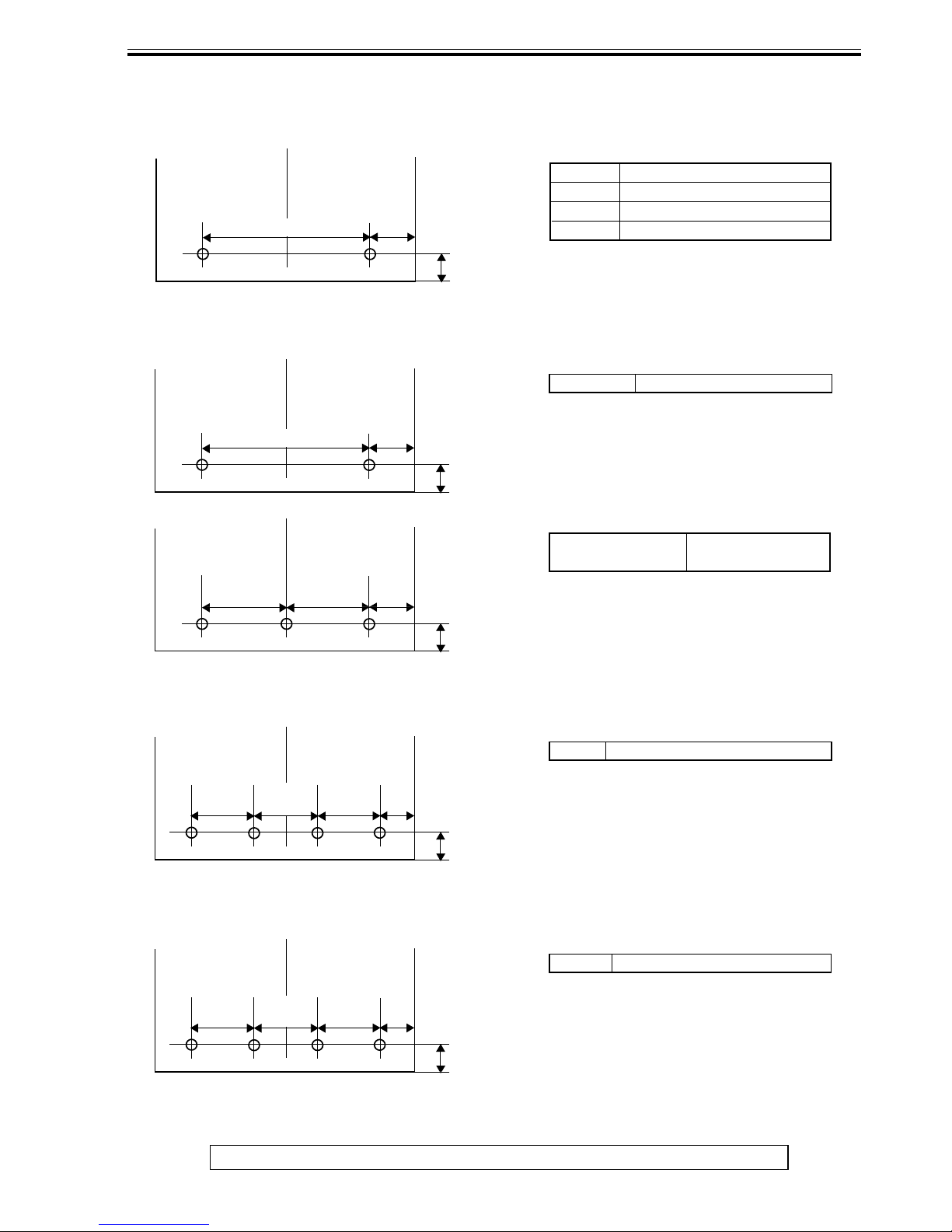

Hole position

[1] 2-Hole (Puncher Unit-J1)

80±1 mm / 3.15±0.04 in

[2] 2-/3-Hole (Puncher Unit-K1)

χ1

CHAPTER 1 GENERAL DESCRIPTION

χ1

A3/A4 108.5±3 mm / 4.27±0.12 in

B5/B4 88.5±3 mm / 3.48±0.12 in

A4R 65±3 mm / 2.56±0.12 in

B5R 51±3 mm / 2.01±0.12 in

12±3 mm /

0.47±0.12 in

χ1

LGL/LTRR 73±3 mm / 2.87±0.12 in

70±1 mm / 2.76±0.04 in

108±1 mm /

4.25±0.04 in

108±1 mm /

4.25±0.04 in

[3] 4-Hole (Puncher Unit-G1)

80±1 mm /

3.15±0.04 in

80±1 mm /

3.15±0.04 in

80±1 mm /

3.15±0.04 in

χ1

χ1

12±3 mm /

0.47±0.12 in

χ1

279 mm×432 mm

(11"×17")/LTR

31.5±3 mm /

1.24±0.12 in

12±3 mm /

0.47±0.12 in

χ1

A3/A4 28.5±3 mm / 1.12±0.12 in

χ

1

12±3 mm /

0.47±0.12 in

[4] 4-Hole (Puncher Unit-H1)

21±1 mm /

0.83±0.04 in

70±1 mm /

2.76±0.04 in

The above specifications are subject to change for product improvement.

21±1 mm /

0.83±0.04 in

χ1

A3/A4 92.5±3 mm / 3.64±0.12 in

χ

1

12±3 mm /

0.47±0.12 in

F01-201-03

1-7

CHAPTER 1 GENERAL DESCRIPTION

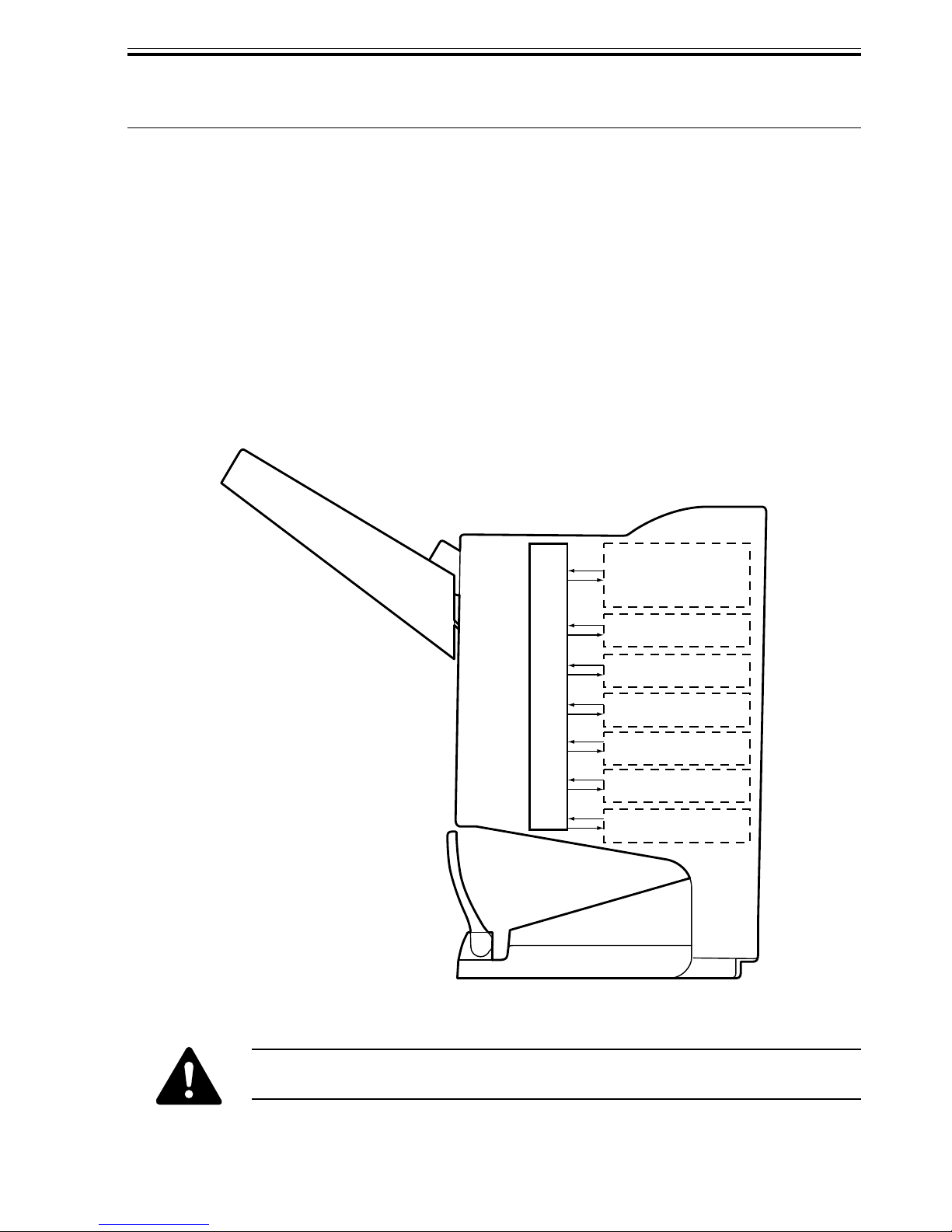

3 Names of Par ts

3.1 Cross Section

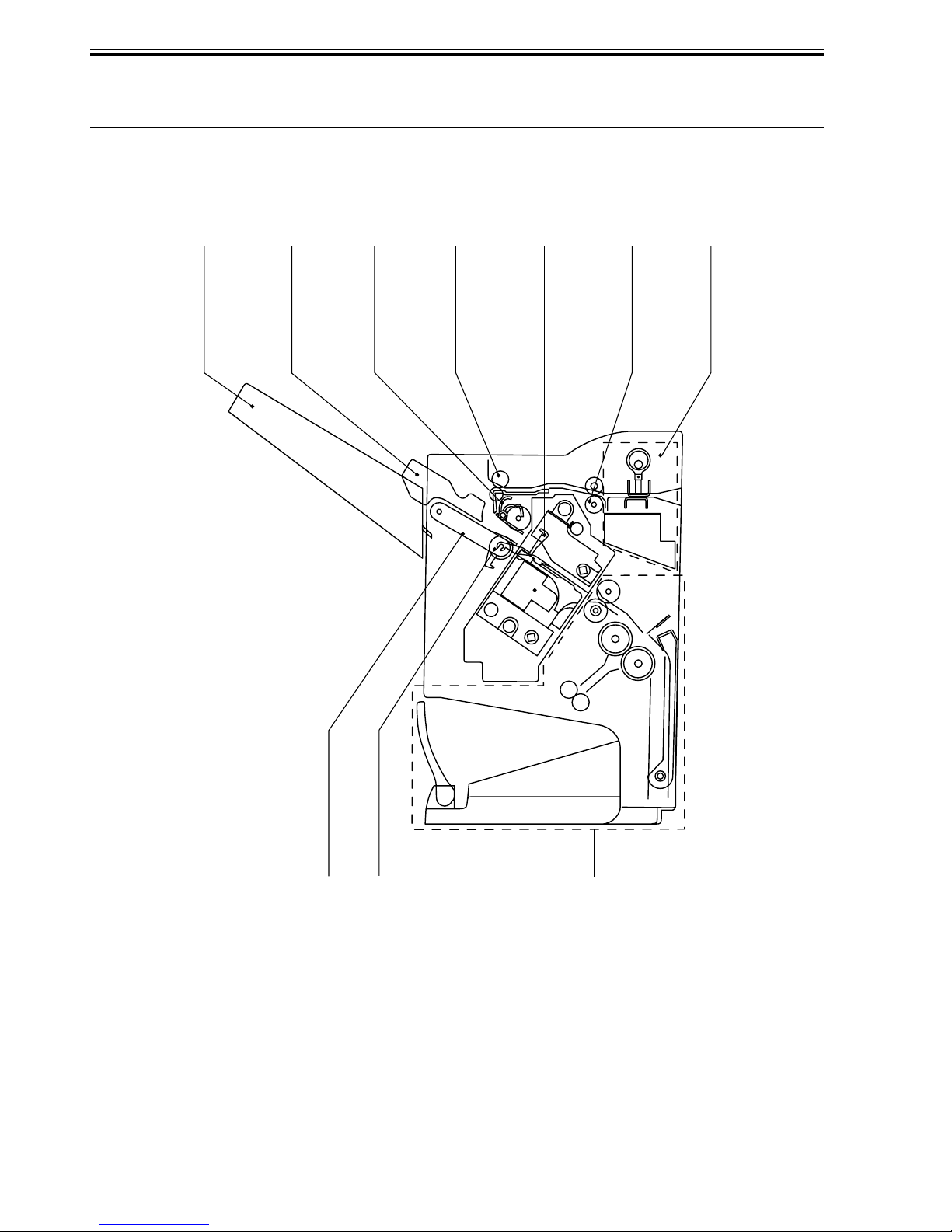

3.1.1 Finisher Unit

[1]

[2]

[3] [7][5][4] [6]

[1] Delivery tray

[2] Aligning plate (front, rear)

[3] Paddle

[4] Delivery roller

[5] Processing tray stopper

1-8

[8]

[9]

F01-301-01

[10]

[11]

[6] Feed roller

[7] Puncher unit (option)

[8] Delivery belt

[9] Stack delivery roller

[10] Stapler

[11] Saddle unit

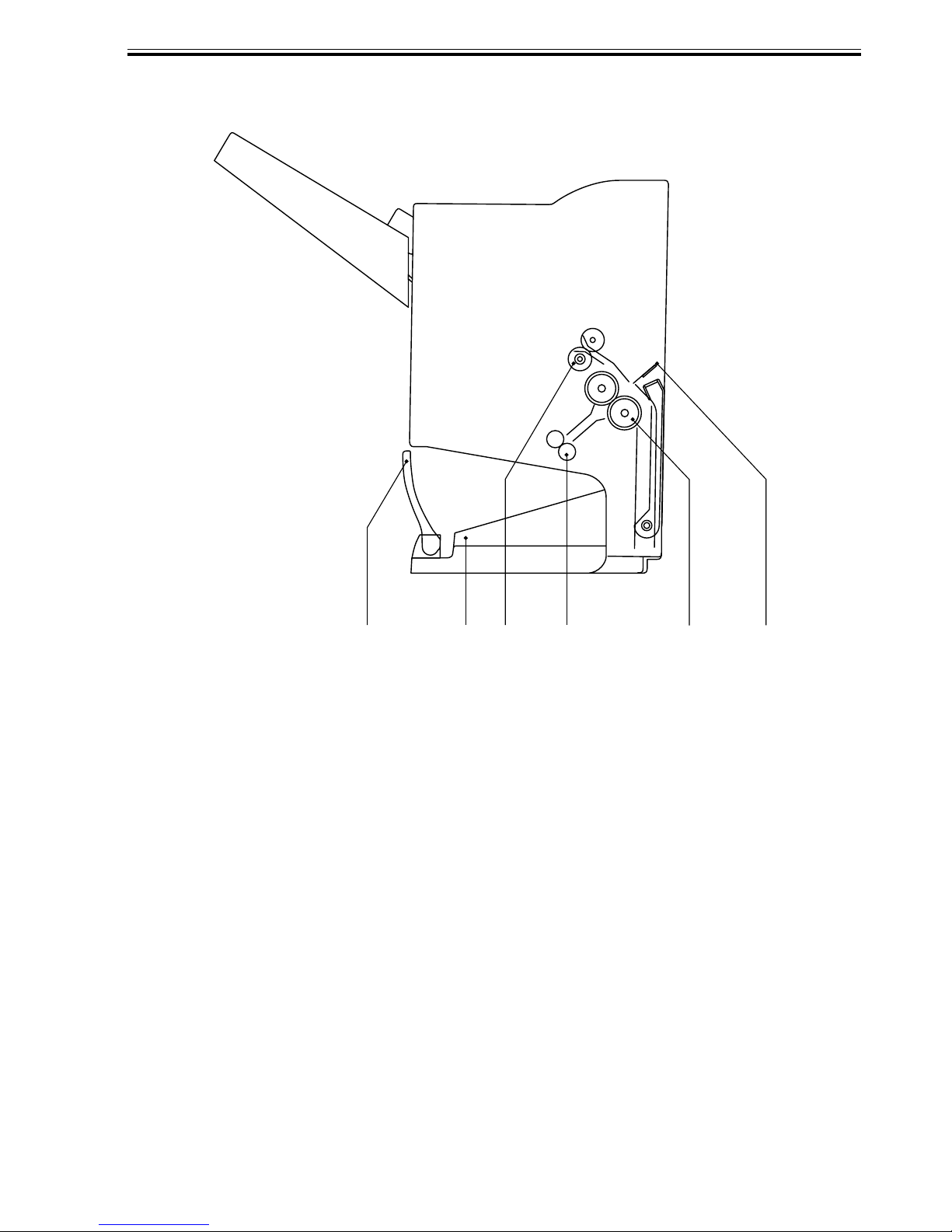

3.1.2 Saddle Unit

CHAPTER 1 GENERAL DESCRIPTION

[1] Bind stopper

[2] Bind tray

[3] Stack feed roller

[1]

[3]

[4] Bind delivery roller

[5] Paper fold roller

[6] Paper pushing plate

F01-301-02

[4][2]

[5]

[6]

1-9

CHAPTER 1 GENERAL DESCRIPTION

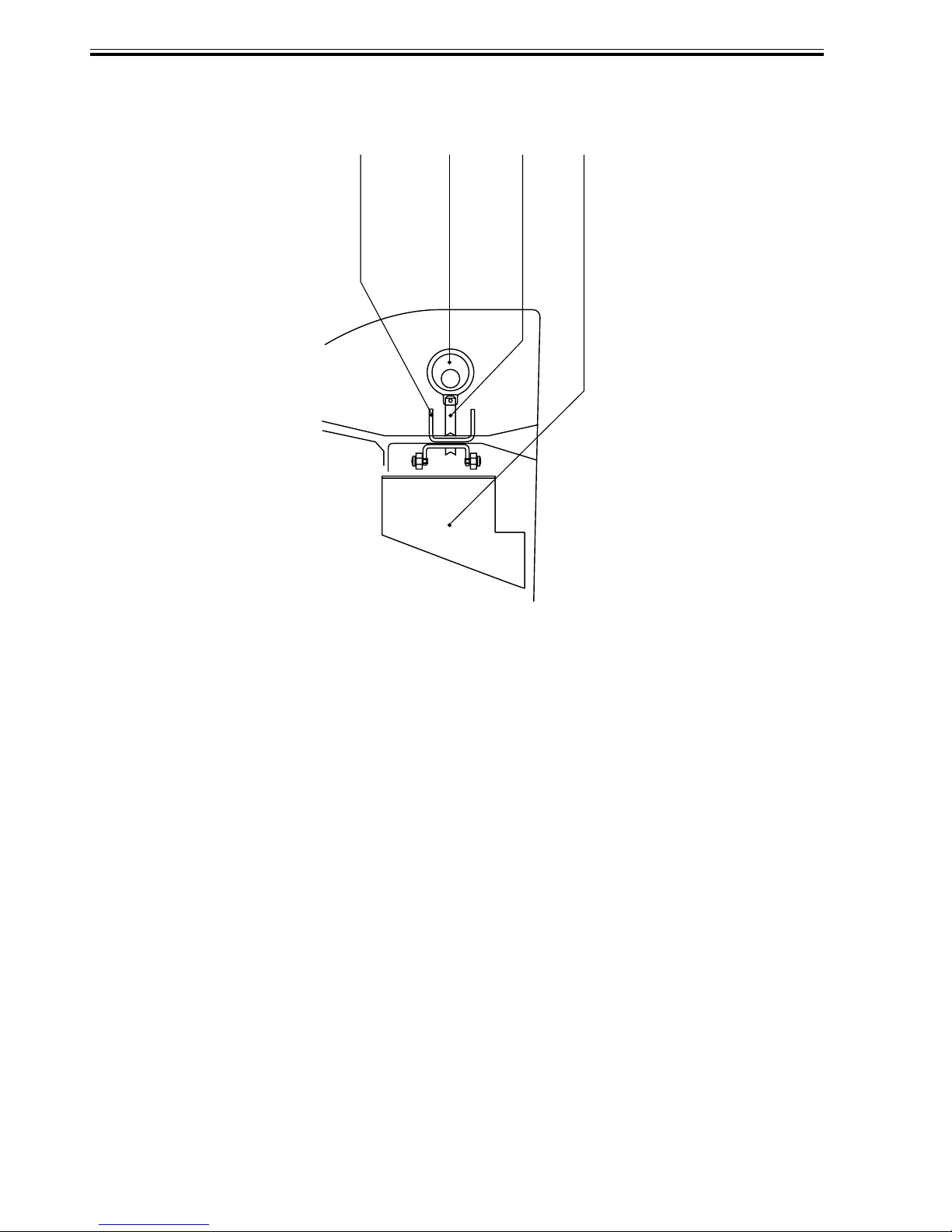

3.1.3 Puncher Unit (option)

[2]

[3][1]

[4]

[1] Die

[2] Cam

[3] Hole puncher (Punch blade)

[4] Punch waste case

F01-301-03

1-10

CHAPTER 1 GENERAL DESCRIPTION

4 Routine Maintenance by the User

No.

1

2

Item

Staple cartridge (replacement)

Punch waste removal (optional)

T01-400-01

Timing

When prompted (indicator on host

machine control panel)

When prompted (indicator on host

machine control panel)

As of February, 2001

1-11

CHAPTER 2

OUTLINE OF OPERATION

CHAPTER 2 OUTLINE OF OPERATION

1 Basic Operations

1.1 Specifications

The finisher serves to deliver sheets coming from its host machine. The mode of delivery

may be non-sort stack, job offset*, or staple delivery.

The saddle unit built into the finisher is used to fold a stack of sheets coming from the fin-

isher unit in half for delivery.

All these operations are controlled by various commands sent by the host machine in addi-

tion to the commands from the finisher controller PCB.

The puncher unit (option) is designed for installation to the pickup assembly of the finisher,

and is used to punch holes in sheets coming from the host machine.

The above operations are controlled with various commands from the finisher controller

PCB as well as the commands from the punch controller PCB.

Puncher unit drive

system (puncher unit;

option)

Alignment drive system

Stapler drive system

Delivery drive system

Control system

Feed drive system

Tray drive system

Saddle unit

drive system

The position of delivery is shifted to the front/rear for each stack to assist

sorting.

F02-101-01

2-1

CHAPTER 2 OUTLINE OF OPERATION

1.2 Outline of the Electrical Circuitry

The sequence of finisher operations is controlled by the finisher controller PCB. The finisher controller PCB is a 16-bit microprocessor (CPU), and is also used for combination with

the host machine (serial).

The finisher controller PCB drive motors and other loads in response to the various commands from the host machine. It also communicates such data as on the states of various sensors and switches to the host machine by way of the serial communication line.

The ICs mounted to the finisher controller PCB have the following functions:

• IC13 (CPU)

Controls sequence of operations.

• IC12 (EEP-ROM)

Backs up adjustment settings.

• IC6 (EP-ROM)

Stores sequence programs.

F02-102-01 shows the flow of signals between finisher and options controller:

• IC11 (communication IC)

Communicates with the host machine.

• IC1 (regulator IC)

Generates 5 V.

Finisher unit

Finisher

controller

PCB

IC13

CPU

IC12

EEP-ROM

IC11

Communica-

tion IC

IC6

EP-ROM

IC1

Regulator IC

Host machine DC

controller PCB

CPU

Motor

Clutch

Switch

Sensor

Puncher unit (option)

Sensor

Punch controller

PCB

Motor

2-2

F02-102-01

CHAPTER 2 OUTLINE OF OPERATION

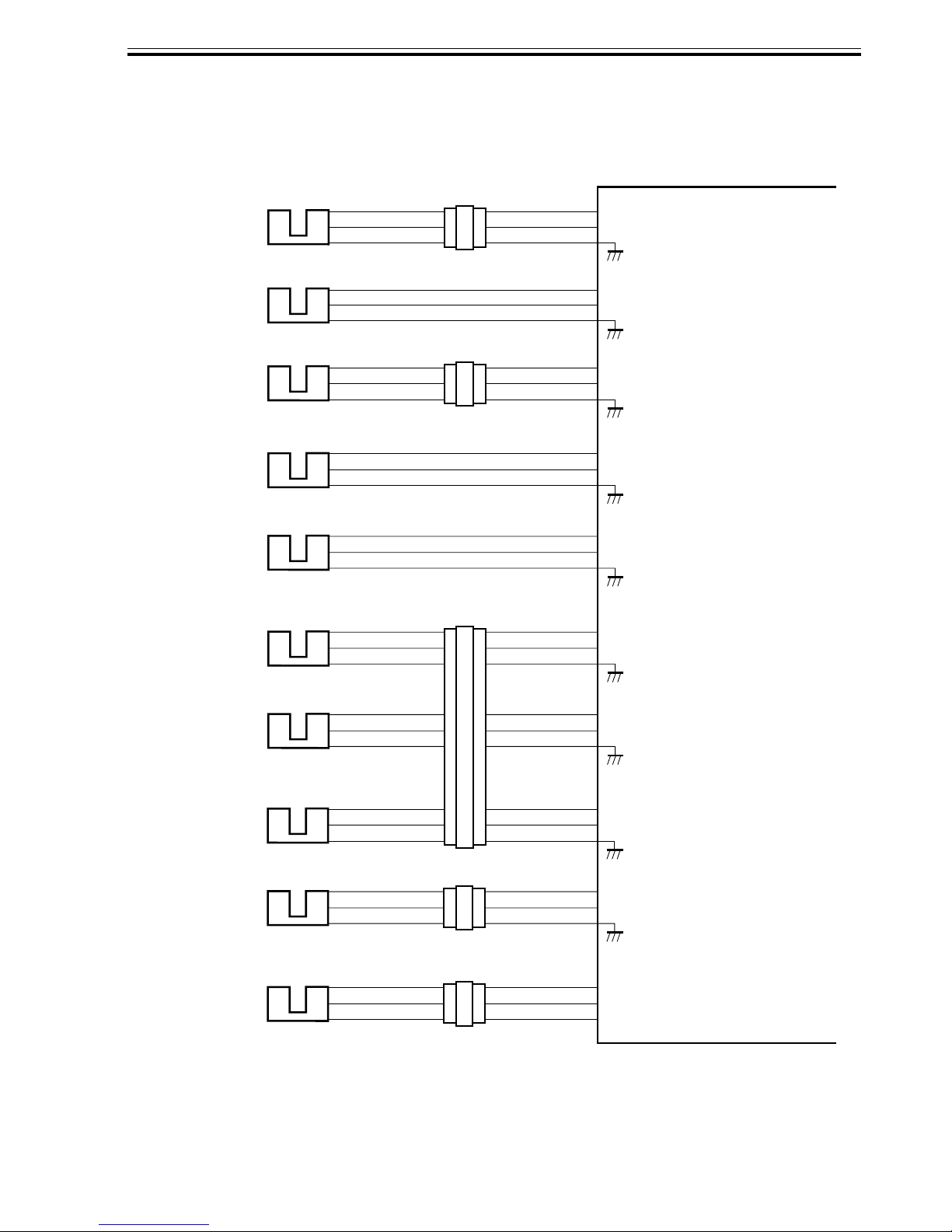

1.3 Inputs to and Outputs from the Finisher Controller PCB

1.3.1 Inputs to the Finisher Controller PCB (1/2)

Finisher controller PCB

Inlet sensor

Paddle home

position sensor

PI1

PI2

CN44-3

CN51-1

-1

-2

-3

-2

CN43-1

-3

-2

CN42-3

-1

-2

CN16-10

-12

-11

CN9-1

-3

-2

+5 V

ENT_S

+5 V

PDL_HP

When the sensor

detects paper, ‘1’ .

When the paddle is at

home position, ‘1’.

Swing guide

home position

sensor

Aligning plate

home position

sensor (front)

Aligning plate

home position

sensor (rear)

Processing

tray sensor

Delivery belt

home position

sensor

Tray paper sensor

PI3

PI4

PI5

PI6

PI7

PI8

CN55-3

CN23-3

CN36-3

CN30-3

CN31-3

CN32-3

-1

-2

-1

-2

-1

-2

-1

-2

-1

-2

-1

-2

CN54-1

-3

-2

CN29-1

-3

-2

-4

-6

-5

-7

-9

-8

CN53-3

CN28-9

-1

-2

-7

-8

-6

-4

-5

-3

-1

-2

CN9-7

CN4

CN5-13

-15

-14

CN5-1

+5 V

-9

BDL_ROL_HP

-8

+5 V

-3

F JOG_HP

-2

+5 V

R JOG_HP

+5 V

-3

ADJ_TRAY_S

-2

-4

+5 V

-6

EJCT_BLT_HP

-5

-7

+5 V

-9

TRY_EMPS

-8

When the swing guide

is at home position, ‘1’.

When the aligning

plate (front) is at

home position, ‘1’.

When the aligning

plate (rear) is at

home position, ‘1’.

When the sensor

detects paper, ‘1’.

When the delivery belt

is at home position, ‘1’.

When paper is present

on the tray, ‘1’.

Paper surface

PI9

sensor

PI10

Folding position

sensor

CN35-3

CN39-3

-1

-2

-2

-1

CN34-1

-3

-2

CN38-1

-2

-3

CN33-3

-1

-2

CN37-9

-8

-7

F02-103-01

CN5-10

-12

-11

CN16-1

-2

-3

+5 V

LVL_S

+5 V

BIND_P

BIND_L

When the paper

surface is detected,

‘1’.

When paper is

detected, ‘0’.

When LED is lit, ‘1’.

2-3

CHAPTER 2 OUTLINE OF OPERATION

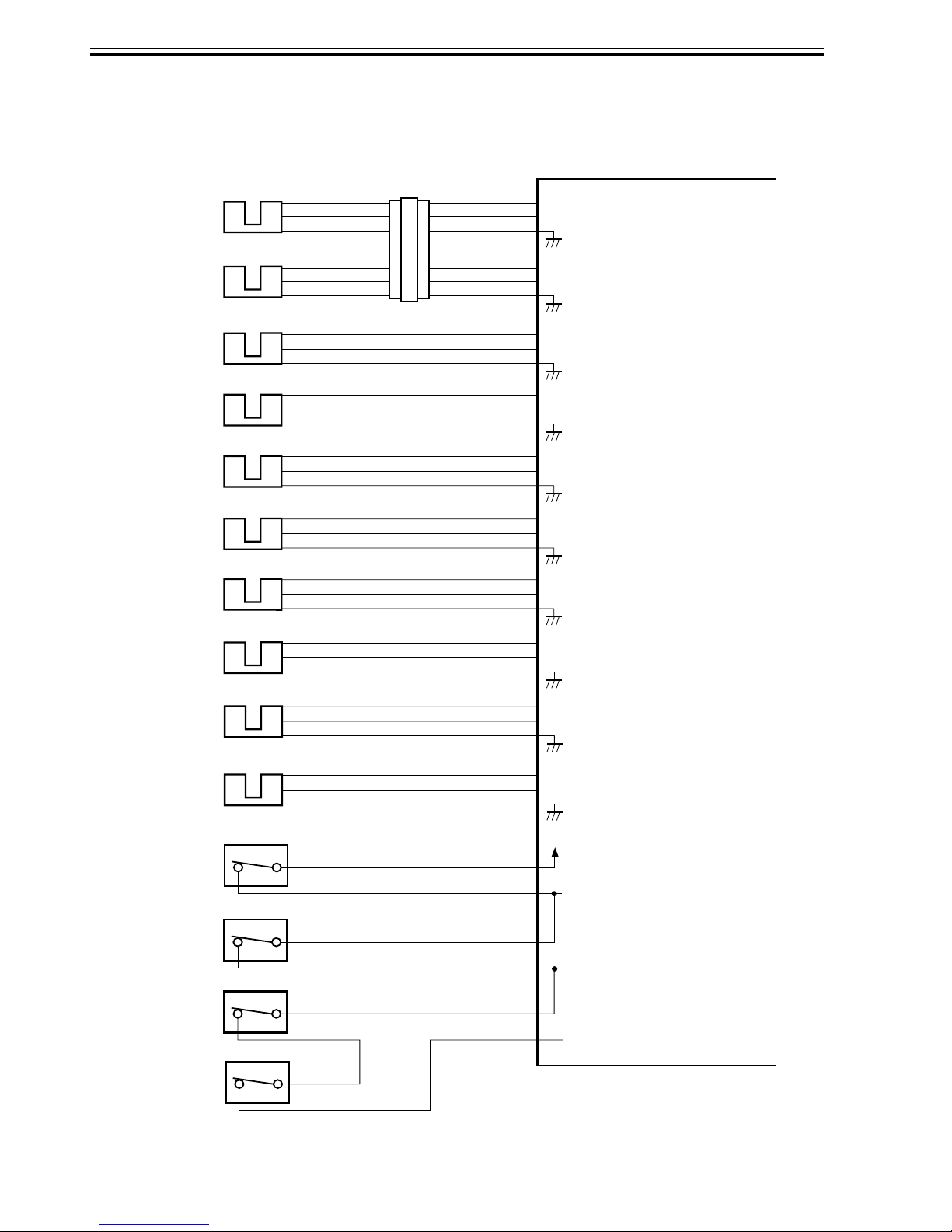

1.3.2 Inputs to the Finisher Controller PCB (2/2)

Finisher controller PCB

Folding home

position sensor

Stack feed roller

(upper) home

position sensor

Bind tray sensor

Staple/fold motor

clock sensor

Shift upper limit

sensor

Shift lower limit

sensor

Shift motor clock

sensor

Front door sensor

PI11

PI12

PI13

PI14

PI15

PI16

PI17

PI22

CN40-3

CN41-3

CN47-3

CN52-1

CN50-3

CN49-3

CN48-3

CN25-3

-1

-2

-1

-2

-1

-2

-2

-3

-1

-2

-1

-2

-1

-2

-1

-2

CN38-4

-6

CN37-6

-5

-7

-9

-8

CN16-4

-4

-5

-3

-1

-2

CN15-1

CN15-10

CN15-7

CN15-4

CN9-6

-12

-11

CN4-7

+5 V

-6

BIND_HP

-5

-7

+5 V

-9

BIND_ROL_HP

-8

+5 V

-3

BIND_EMPS

-2

+5 V

-5

BIND_CLK

-4

+5 V

SIFT_UPLMT

+5 V

-9

SIFT_DNLMT

-8

+5 V

-6

SIFT_CLK

-5

+5 V

-9

FDOOR_S

-8

When at folding home position, ‘0’.

When the stack feed roller

(upper) is at home position, ‘1’.

When the sensor

detects paper, ‘1’.

When the staple/fold motor is

rotating, alternates between

‘1’ and ‘0’.

When the tray is at the

upper limit, ‘1’.

When the tray is at the

lower limit, ‘1’.

While the shift motor

is rotating, alternates

between ‘1’ and ‘0’.

When the front door

is open, ‘1’.

Upper cover sensor

Full stack sensor

Joint switch

Front door switch

Stapler safety

switch

Stapler safety

switch(F)

PI23

PI24

MS2

N. O.

MS1

N. O.

MS3

N. O.

MS4

N. O.

CN24-3

CN73-3

CN69-2

CN68-2

CN66-2

CN75-2

CN4-4

-1

-2

CN19-1

-1

-2

CN8-6

-1

CN8-4

-1

CN8-2

-1

-1

+5 V

-6

TOPCOV_S

-5

+5 V

-3

PAPER_F

-2

+24 VP

-5

-3

-1

JOINT SW

FRONT SW

STPLSAFE SW

When the upper cover

is open, ‘1’.

When the paper is

full, ‘1’.

When connected to

the host machine, ‘1’.

When the front

door is closed, ‘1’.

When the swing

guide is closed, ‘1’.

2-4

CHAPTER 2 OUTLINE OF OPERATION

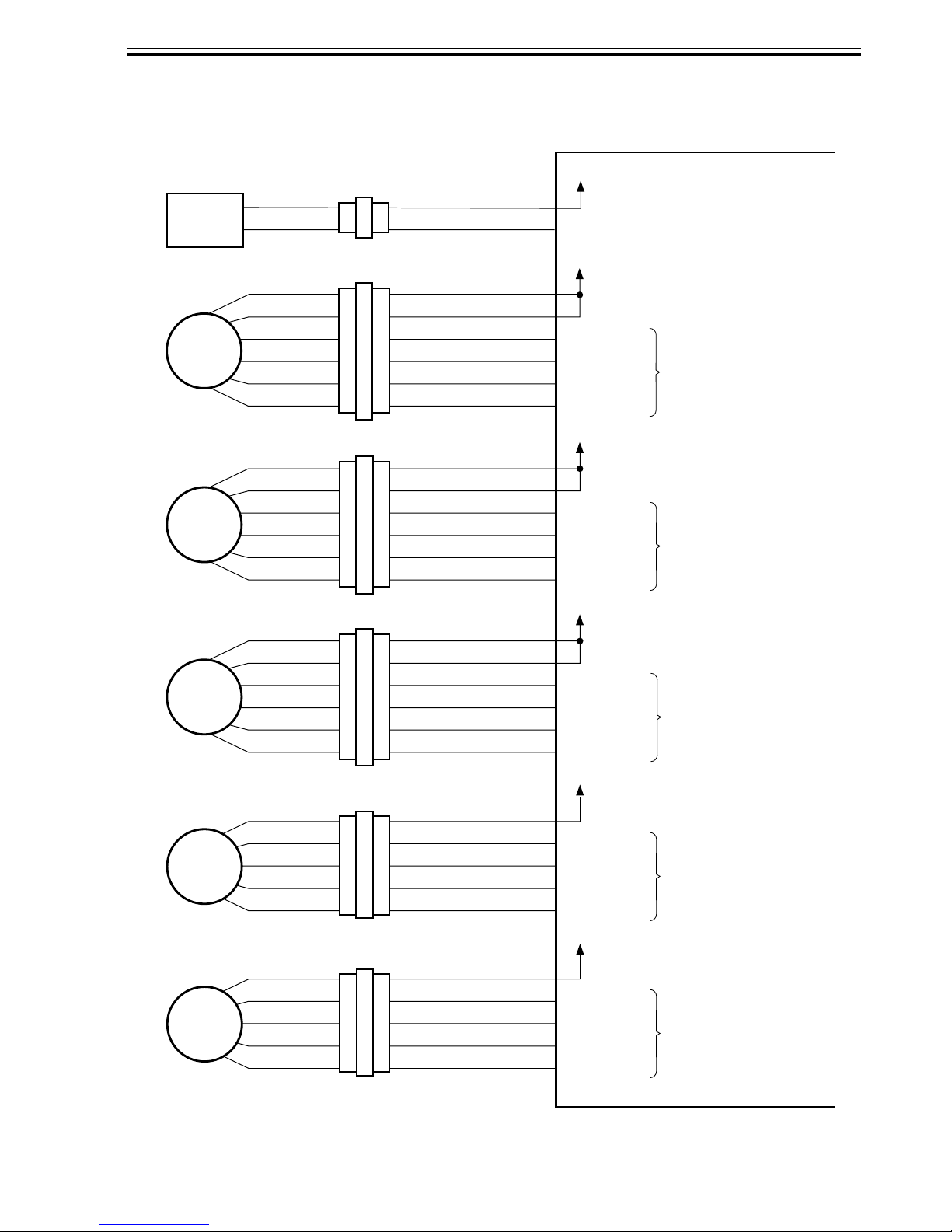

1.3.3 Outputs from the Finisher Controller PCB (1/2)

Finisher controller PCB

Binding clutch

CL1

Feed motor

M1

Paddle motor

M2

Delivery motor

M3

+24 V

-1

-2

-6

-5

-4

-3

-2

-1

-6

-5

-4

-3

-2

-1

-6

-5

-4

-3

-2

-1

CN72

CN56

CN57

CN59

-2

-1

-1

-2

-3

-4

-5

-6

-1

-2

-3

-4

-5

-6

-1

-2

-3

-4

-5

-6

CN18-1

CN10-1

CN10-7

-10

-11

-12

CN13-1

-2

B_CLU

+24 V

-2

-3

FEEDMTR_A

-4

FEEDMTR_*A

-5

FEEDMTR_B

-6

FEEDMTR_*B

+24 V

-8

-9

PDLMTR_A

PDLMTR_*A

PDLMTR_B

PDLMTR_*B

+24 V

-2

-3

EJCTMTR_A

-4

EJCTMTR_*A

-5

EJCTMTR_B

-6

EJCTMTR_*B

When the drive is transmitted,

‘1’.

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

Alignment motor

(front)

M4

Alignment motor

(rear)

M5

CN63-1

-2

-3

-4

-5

CN65-1

-2

-3

-4

-5

CN62-5

-4

-3

-2

-1

CN64-5

-4

-3

-2

-1

CN3-1

CN3-6

-10

F02-103-03

+24 V

-2

FJOGMTR_A

-3

FJOGMTR_*A

-4

FJOGMTR_B

-5

FJOGMTR_*B

+24 V

-7

RJOGMTR_A

-8

RJOGMTR_*A

-9

RJOGMTR_B

RJOGMTR_*B

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

2-5

CHAPTER 2 OUTLINE OF OPERATION

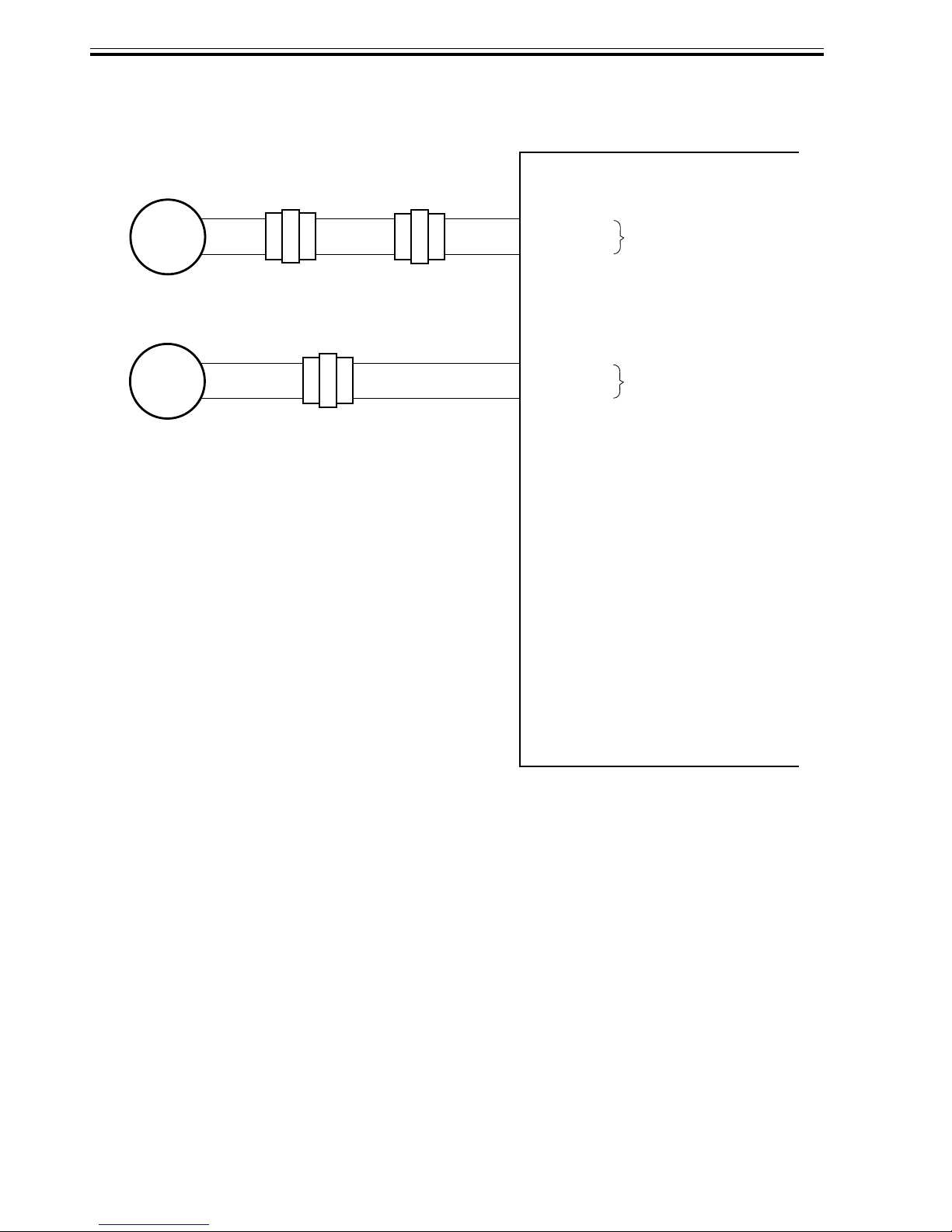

1.3.4 Outputs from the Finisher Controller PCB (2/2)

Shift motor

M6

Staple/fold motor

M7

-2

-1

CN70

-2

-1

-2

-1

CN71

-2

-1

-2

-1

CN70

-2

-1

CN6-1

CN6-3

SIFTMTR_1

-2

SIFTMTR_0

BINDMTR_1

-4

BINDMTR_0

Finisher controller PCB

Switches between ‘+’ and

‘–’ according to the

direction of motor rotation.

Switches between ‘+’ and

‘–’ according to the

direction of motor rotation.

2-6

F02-103-04

Loading...

Loading...