Page 1

SO-30

Service and

Maintenance

Manual

Mailbox/sorter

for

Ecosys printers

SO-30

Page 2

Notices

Mailbox/sorter SO-30 Service Manual ©Kyocera Corporation 1998 All rights reserved. Export Edition

Notices

The information in this manual is subject to change without notification. Additional pages may be inserted in future editions. The user is asked to excuse any

technical inaccuracies or typographical errors in the present edition.

No responsibility is assumed if accidents occur while the user is following the

instructions in this manual. No responsibility is assumed for defects in the product's firmware.

The contents of this manual are protected by copyright. No part of this manual

may be reproduced or copied by any means without the permission of the copyright holder. The product's firmware (contents of its read-only memory) is similarly protected by copyright.

Trademark Notice

Prescribe is a registered trademark of Kyocera Corporation. Prescribe IIe, KIR,

Kyocera Image Refinement, Ecosys, and Ecotone are trademarks of Kyocera Corpo-

ration.

Warning

This equipment has been certified to comply with the limits for a Class B computing device, pursuant to Subpart J of Part 15 of FCC Rules. Only peripherals (computer input/output devices, terminals, etc.) certified to comply with the Class B

limits may be attached to this equipment. Operation with non-certified peripherals is likely to result in interference to radio and TV reception.

Conventions

Throughout this manual, the following conventions are used:

Color is available when viewed online to emphasize important notices.

CAPITAL letters are used to name parts and assemblies.

Italic letters refer related chapters or sections or documentations.

Bold letters are also used for emphasis wherever italics may cause a confuse.

This symbol followed by

graph(s) includes precautions which, if ignored, could result in personal injury,

and/or irrevocable damage to the equipment.

When followed by

include the precautions which, if ignored, could result in damage to the equipment.

Caution

Warning

this symbol denotes that the following paragraph(s)

denotes that the following para-

SO-30

ii

Page 3

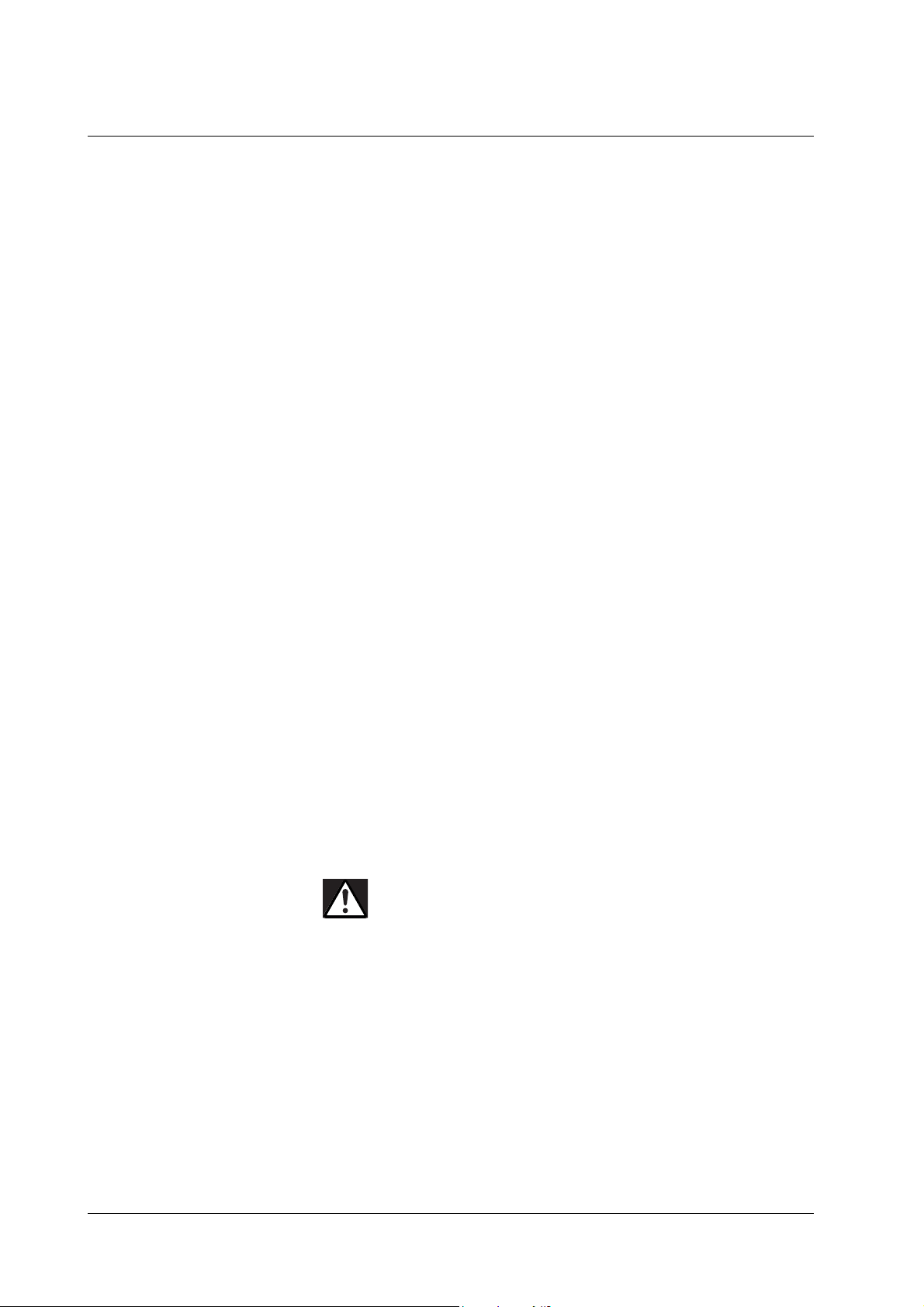

Identification

Identification

iii

SO-30

Page 4

Identification

REVISION HISTORY

Version Date Replaced Pages Remarks

1.0 1-Sep-98 —

VISIT US AT OUR INTERNET HOME PAGE (JAPAN):

FOR AVAILABILITY OF PRINTER DRIVERS AND UTILITIES, ACCESS TO YOUR LOCAL KYOCERA INTERNET SITE.

http://www.kyocera.co.jp

SO-30

iv

Page 5

Chapter 1 PRODUCT INFORMATION

Contents

Part Names 1-2

Mechanical Section 1-3

Electrical Parts 1-4

Connector Layout 1-5

Page 6

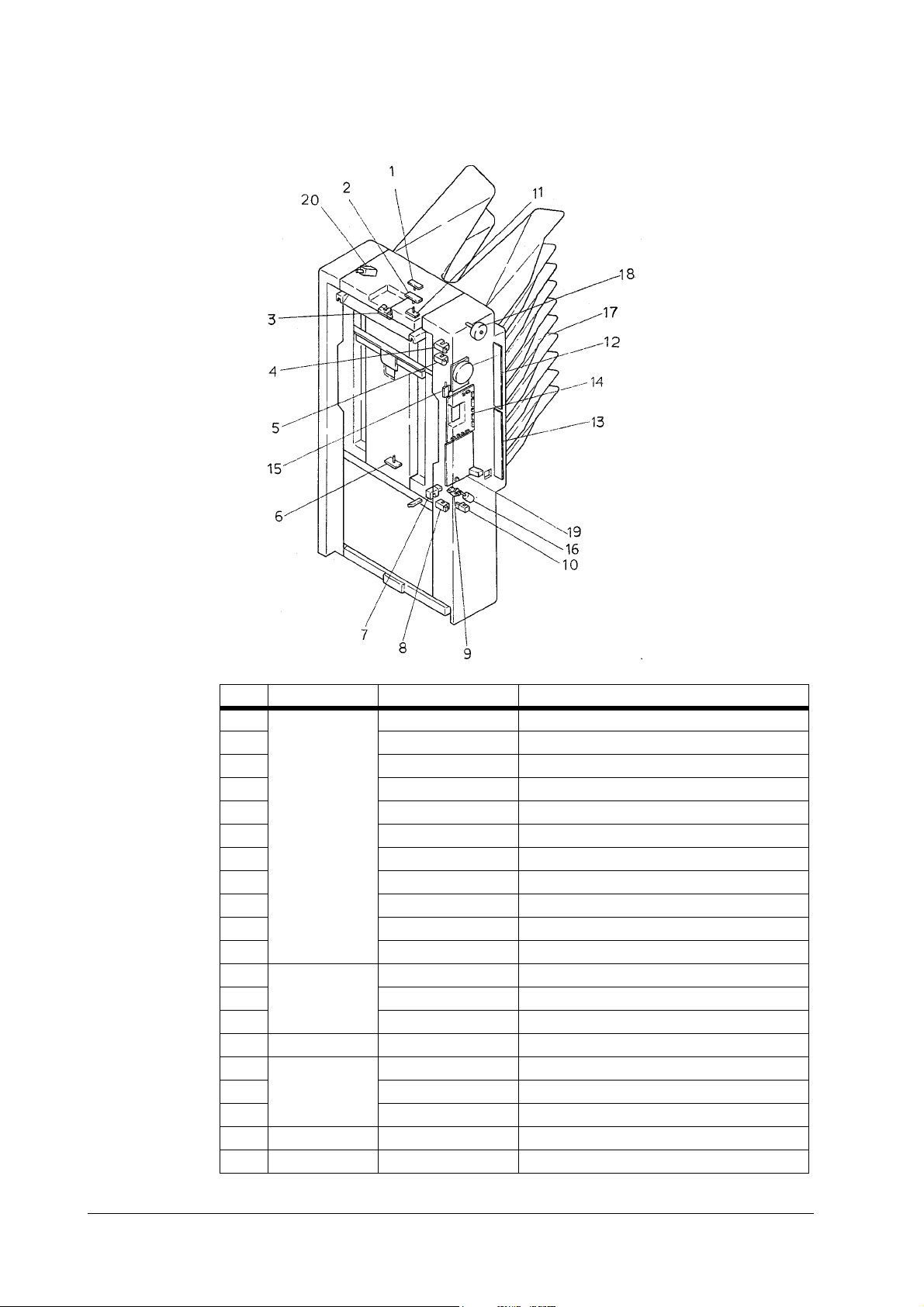

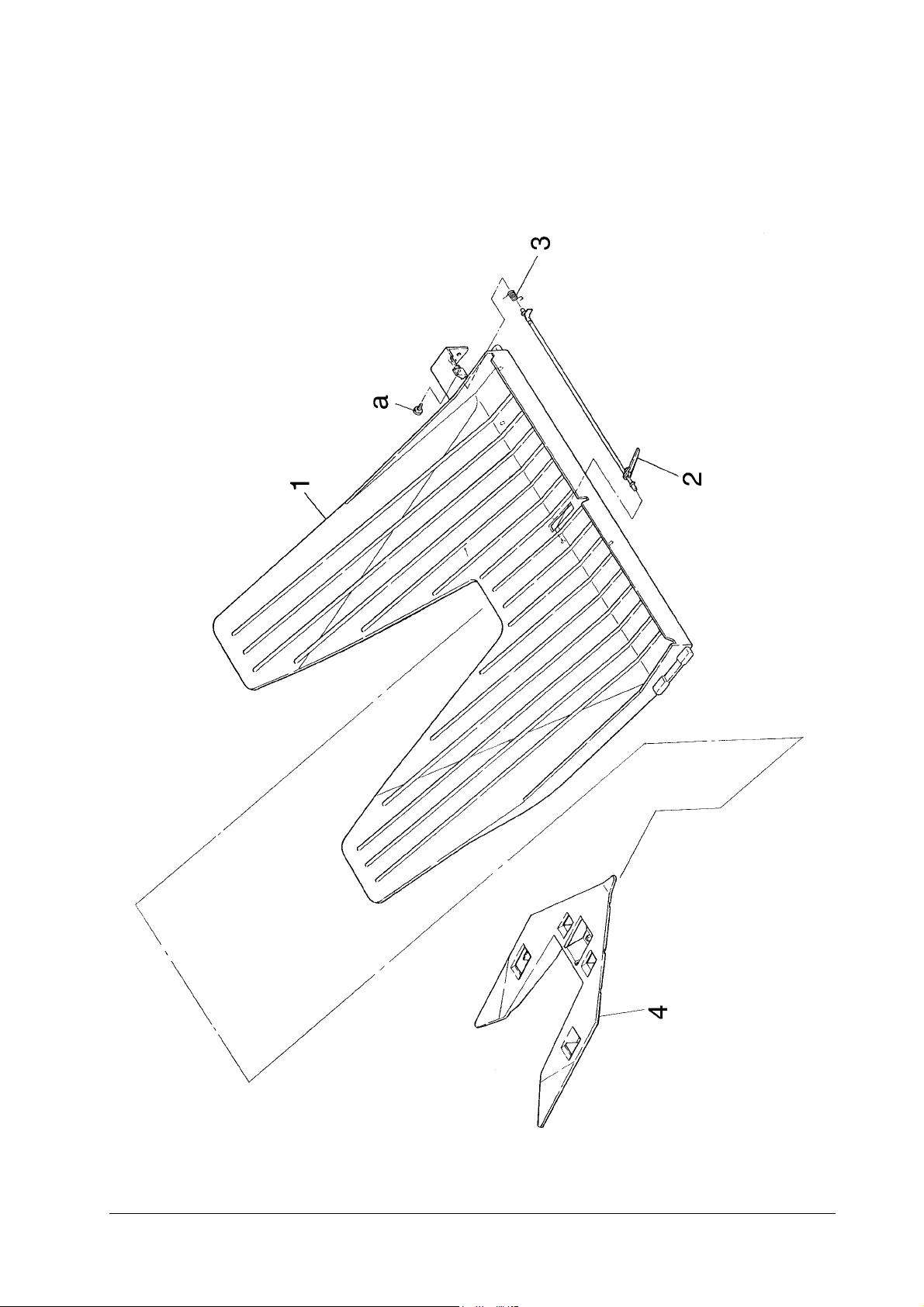

1.1 Part Names

Vertical Transport Unit

Multi Tray

Mail Trays

Slide Rail

Interface Connector

Power Jack

Ground Wire

SO-30

1-2

Page 7

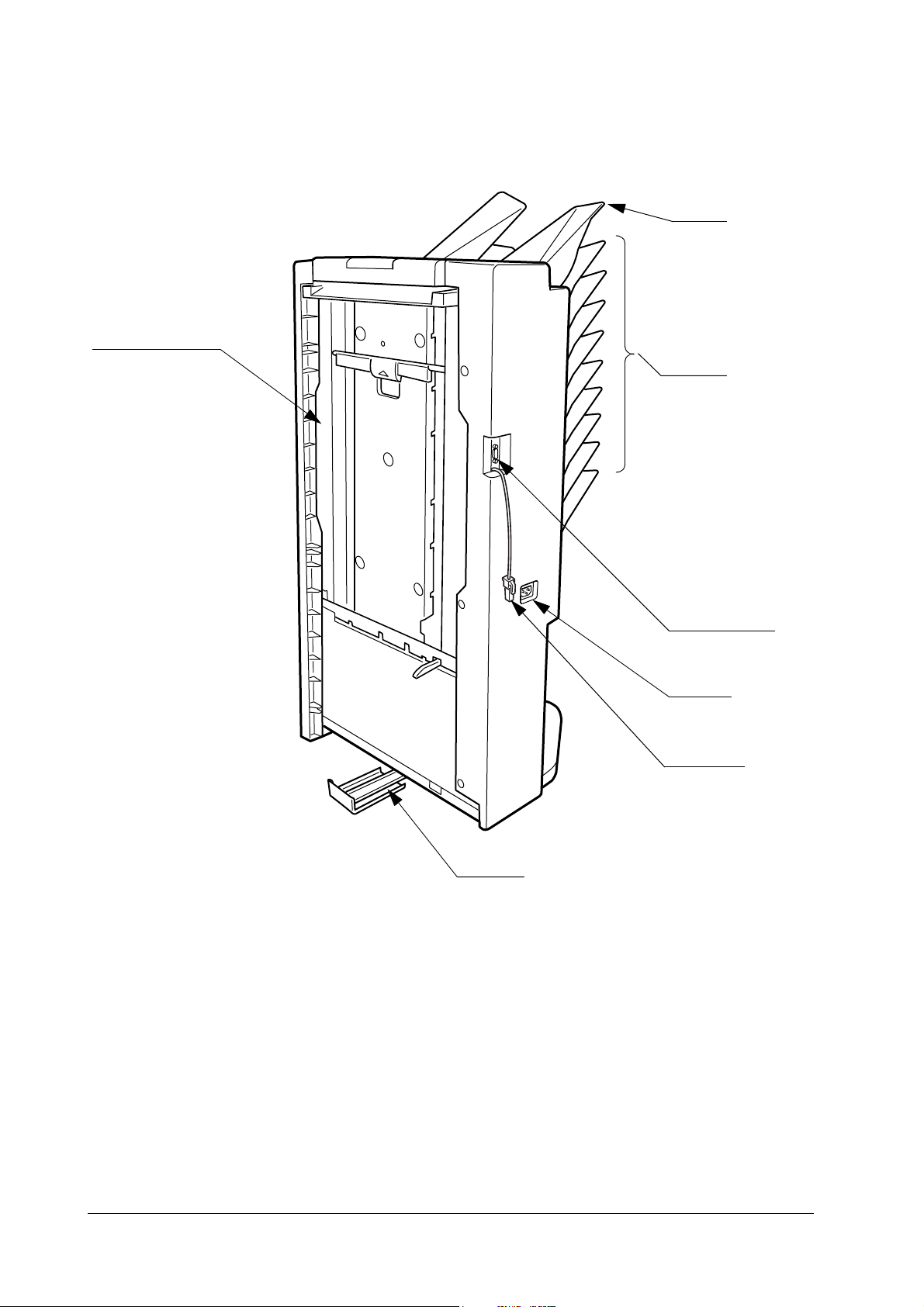

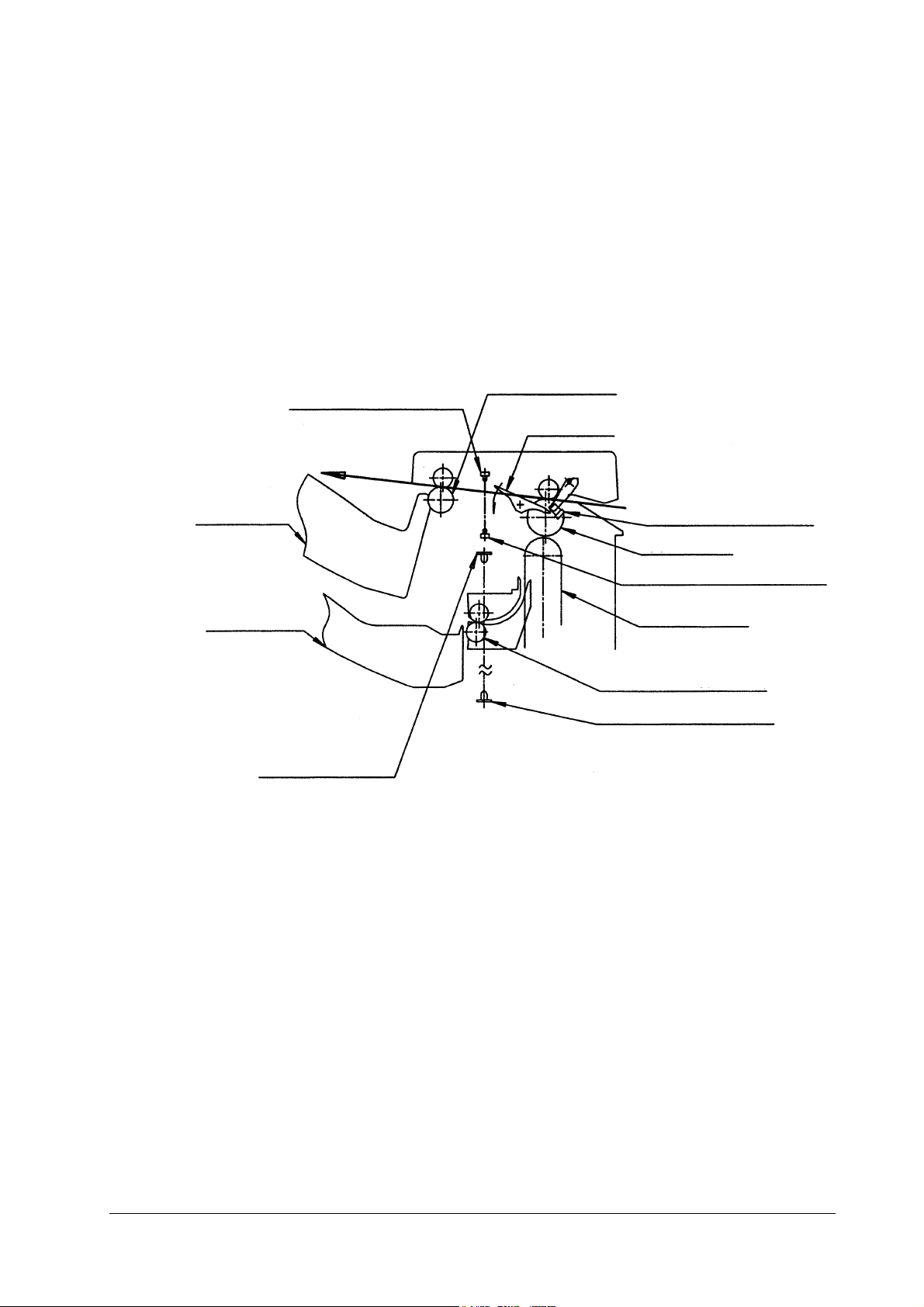

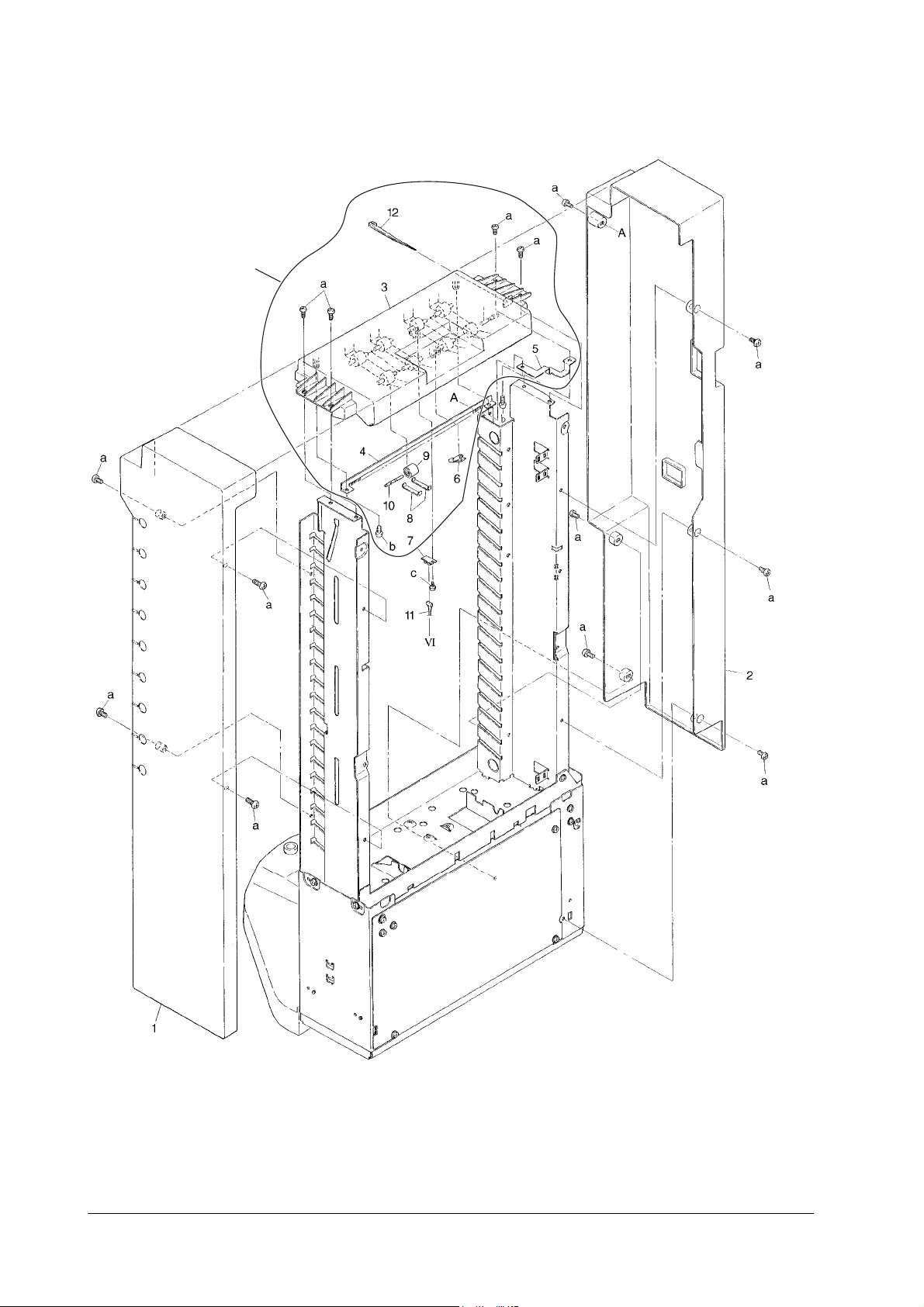

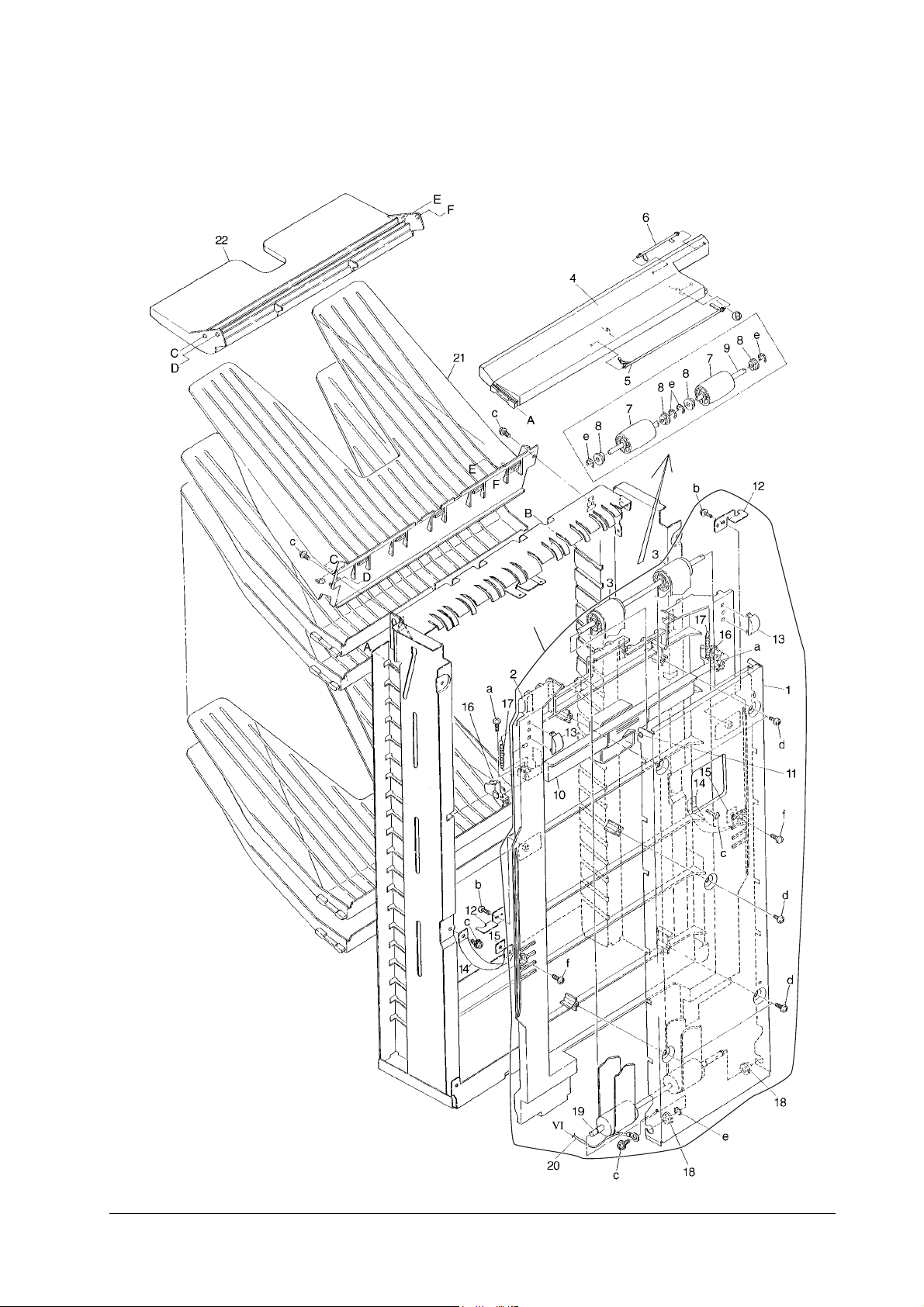

1.2 Mechanical Section

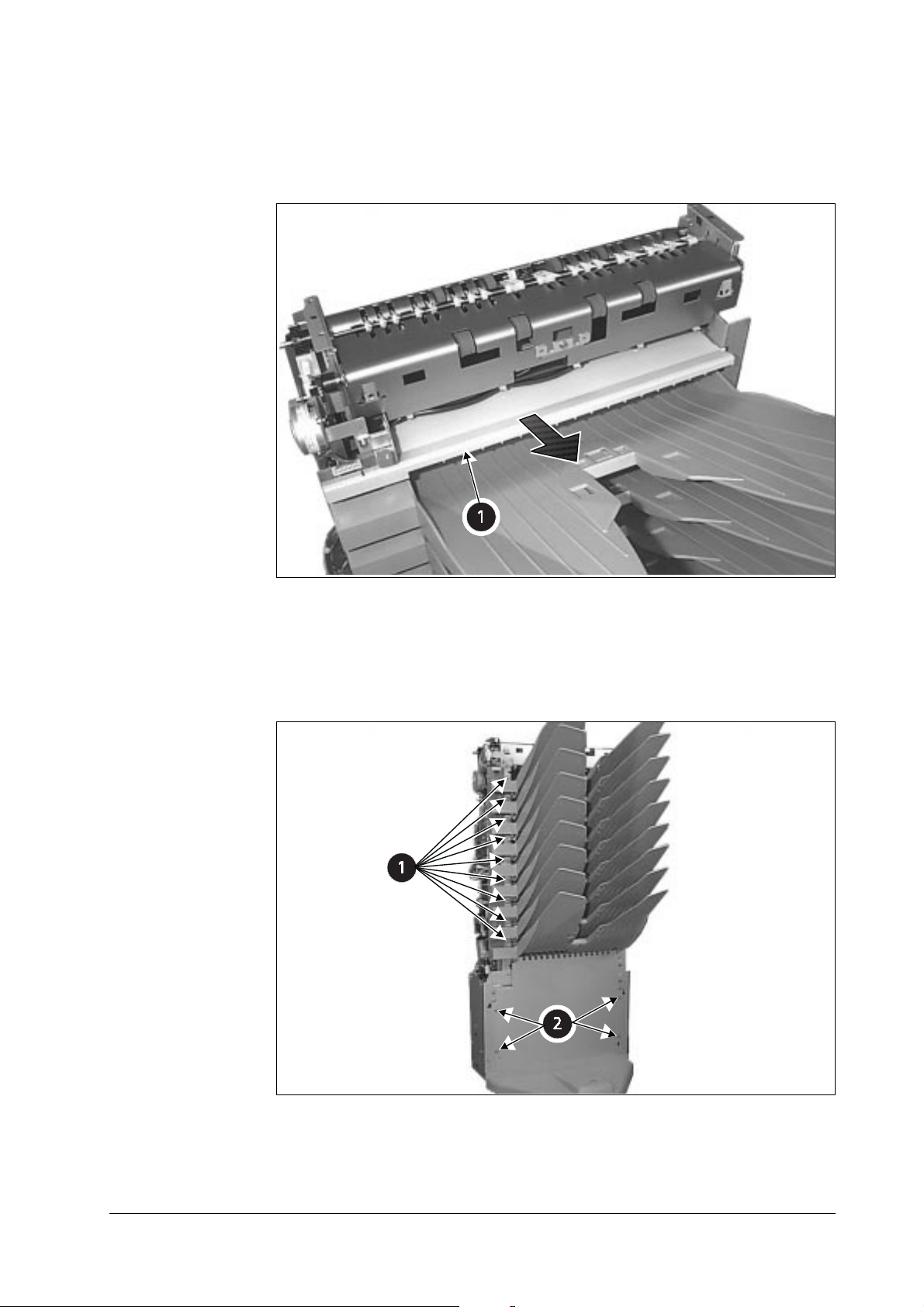

Multi Tray Paper Eject and Reverse Roller Flapper

Vertical Transport Belt

Mail Trays

Entry Roller

Indexer Eject Paper Roller

Vertical Transport

Runners

Indexer

1-3

SO-30

Page 8

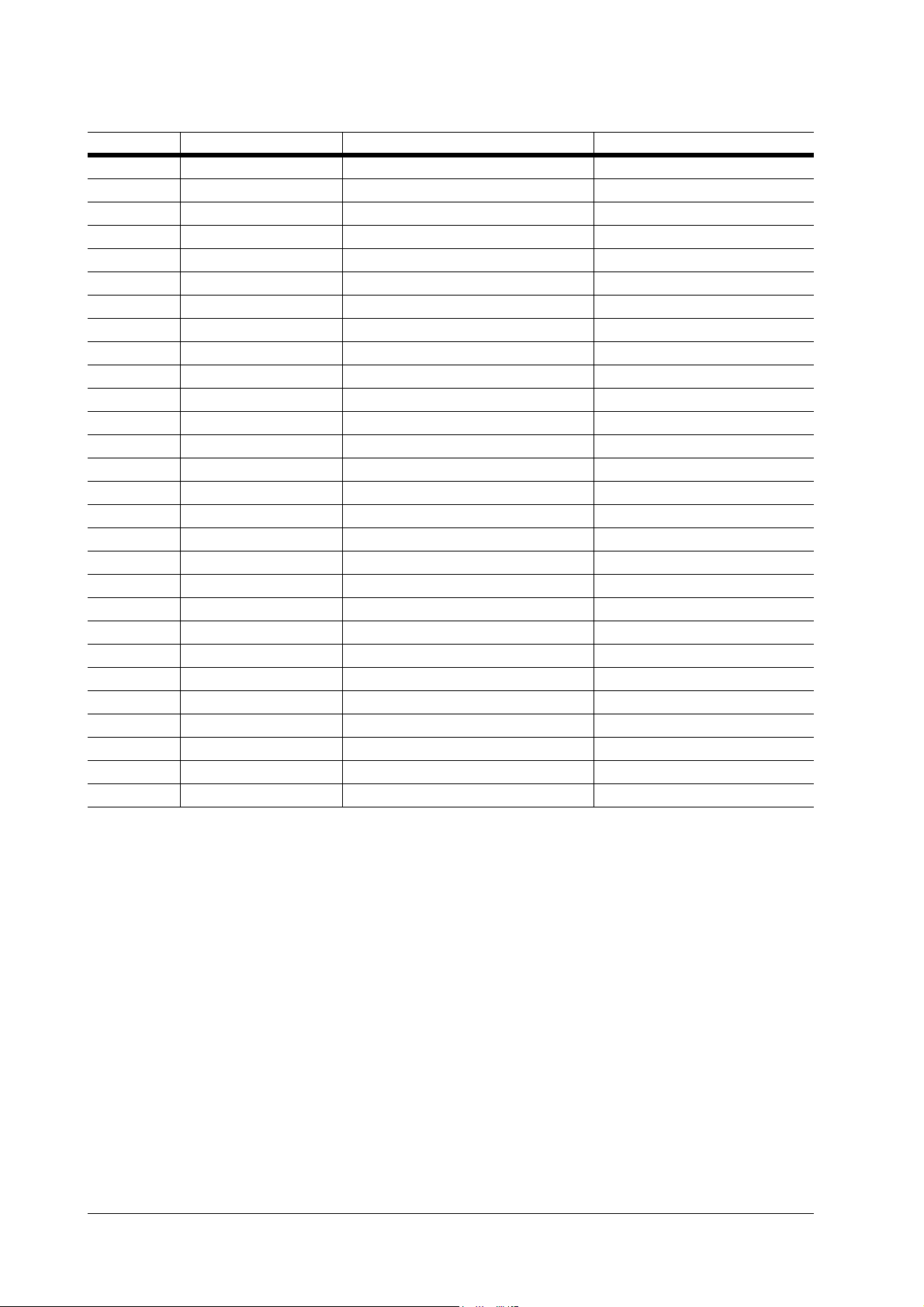

1.3 Electrical Parts

No. Name Symbol Function

1 Sensor LRLED Eject Paper Sensor LED

2 PRSL Paper Reverse Sensor LED

3 PES (S1) Paper Entry Slot Sensor

4 IULS (S2) Indexer Upper Limit Sensor

5 IHPS (S3) Home Position Sensor

6 PT (S4) Eject Paper Sensor Detector

7 SJS (S5) Sorter Joined Sensor

8 ILLS (S6) Indexer Lower Limit Sensor

9 IMCS (S7) Indexer Motor Encoder Cl oc k Se ns or

10 IPS (S8) Indexer Motor Position Detection Sensor

11 PRS (S9) Paper Reverse Sensor Detector

12 Circuit Board PBA-SEN1 Sensor Printed Circuit Board1

13 PBA-SEN2 Sensor Printed Circuit Board2

14 PBA-CONTROL Control PCB

15 Switch DOORSW (SW1) Door Open/Close Switch

16 Motor IM (M1) Indexer Motor

17 PFM (M2) Paper Feeding Motor

18 RMOT (M3) Paper Reverse Motor

19 Power Unit PWS-DENGEN Power

20 Solenoid FSOL (SOL1) Face-Up Solenoid

SO-30

1-4

Page 9

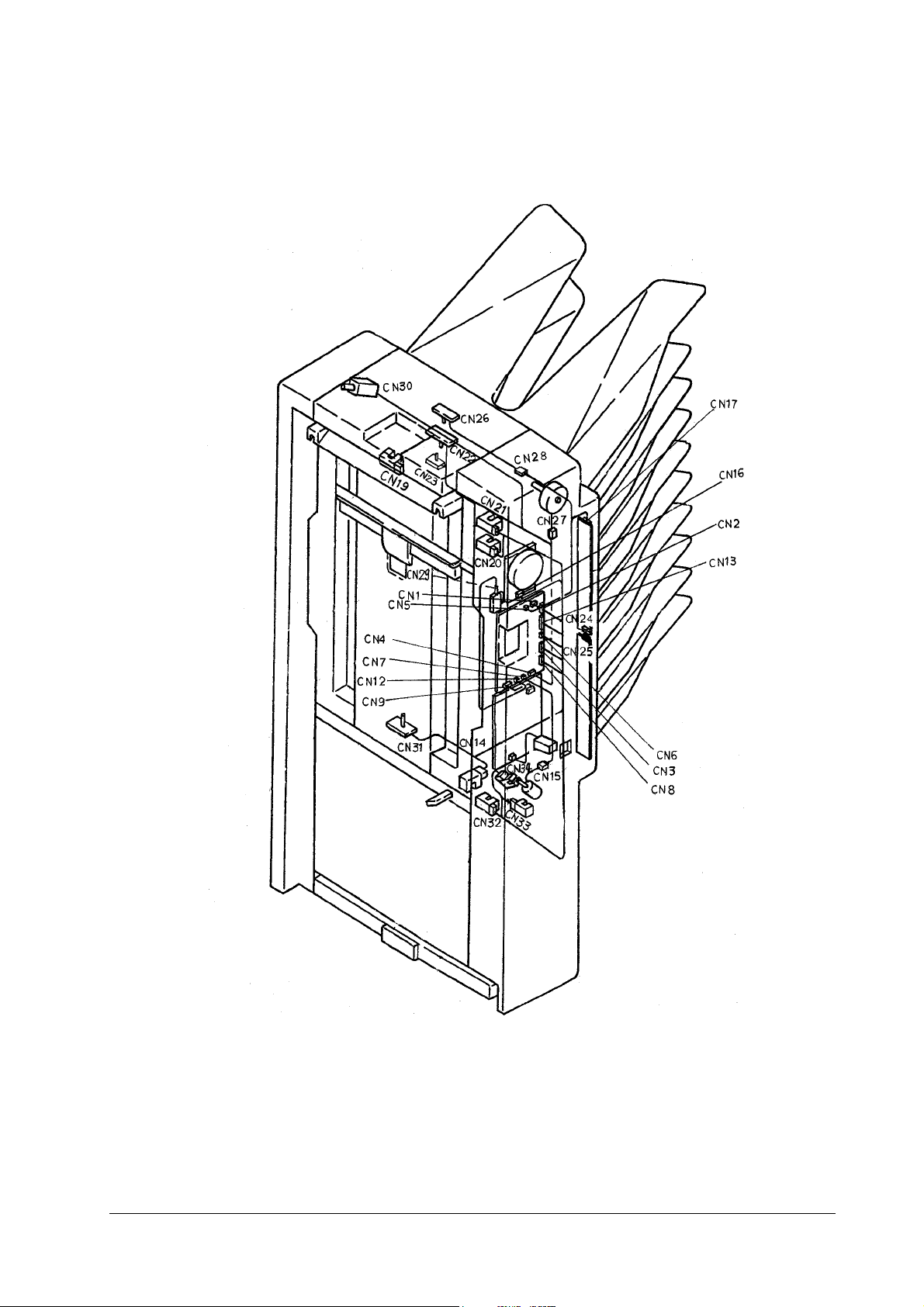

1.4 Connector Layout

1-5

SO-30

Page 10

Chapter 2 MECHANICAL SYSTEM

Contents

General 2-2

Removing the front cover and rear cover 2-3

Removing the top cover 2-3

Removing the cover (black) 2-4

Removing the top tray 2-4

Removing the bracket 2-5

Removing the trays 2-5

Removing the bracket (silver) 2-6

Removing the solenoid 2-7

Removing the motor assembly 2-7

Removing the paper guide 2-8

Removing the bracket (gold) 2-10

Removing the cover 2-11

Removing the index 2-12

Page 11

2.1 General

This chapter explains the mechanical features, operations and procedures for dismantling and

assembling the device. Ensure that the following precautions are observed when proceeding

with these tasks.

Caution Always disconnect the power supply from the socket when dismantling or reas-

sembling the device.

Unless otherwise stated, assembly procedures should be performed in the reverse

sequence to dismantling.

Care must be taken not to use the wrong screws (length, diameter) during assembly.

Never attempt to operate the device with parts removed.

Discharge static electricity from the body by touching a metal part of the device

prior to removing or replacing circuit boards to prevent them from being damaged through static electricity.

SO-30

2-2

Page 12

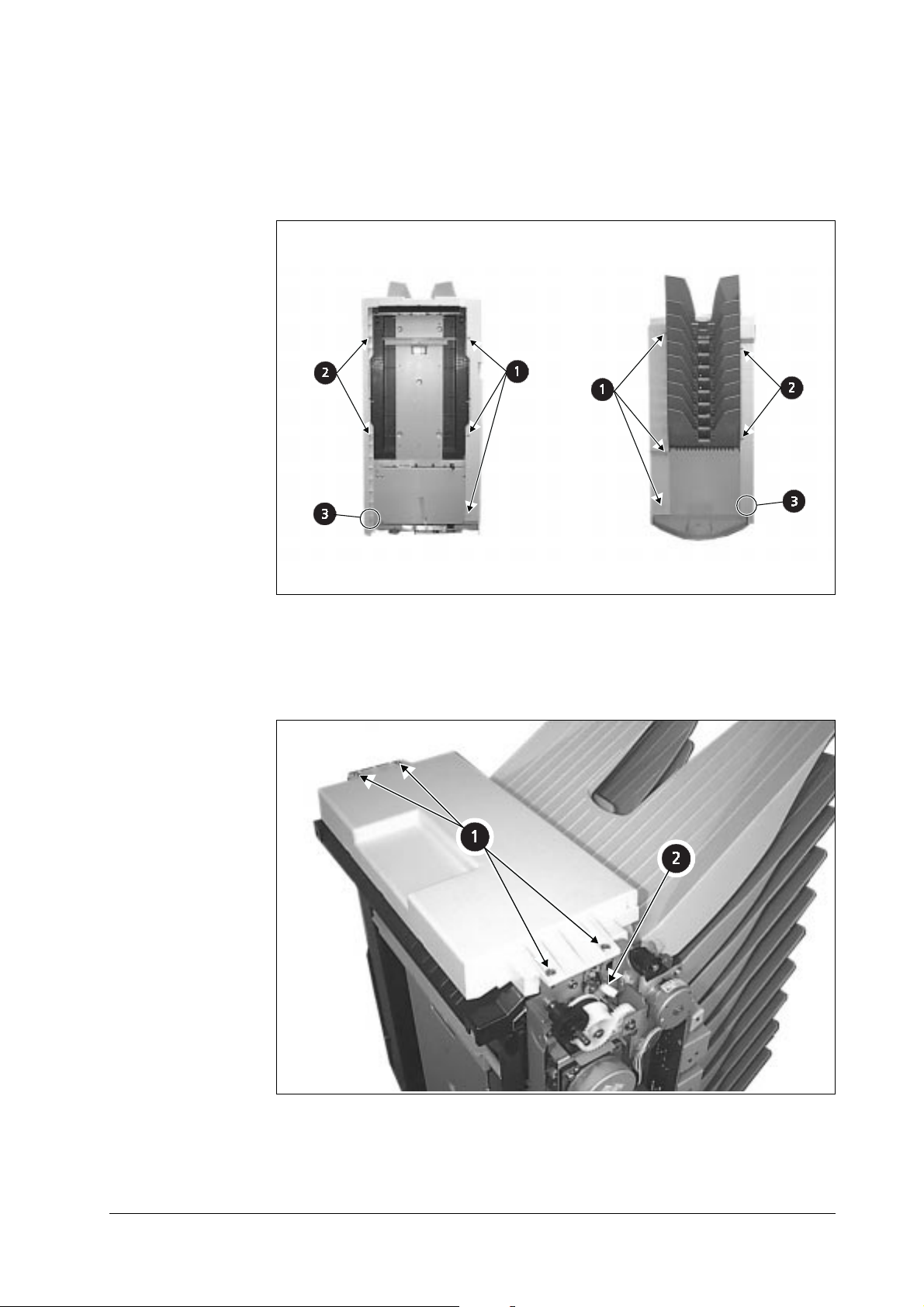

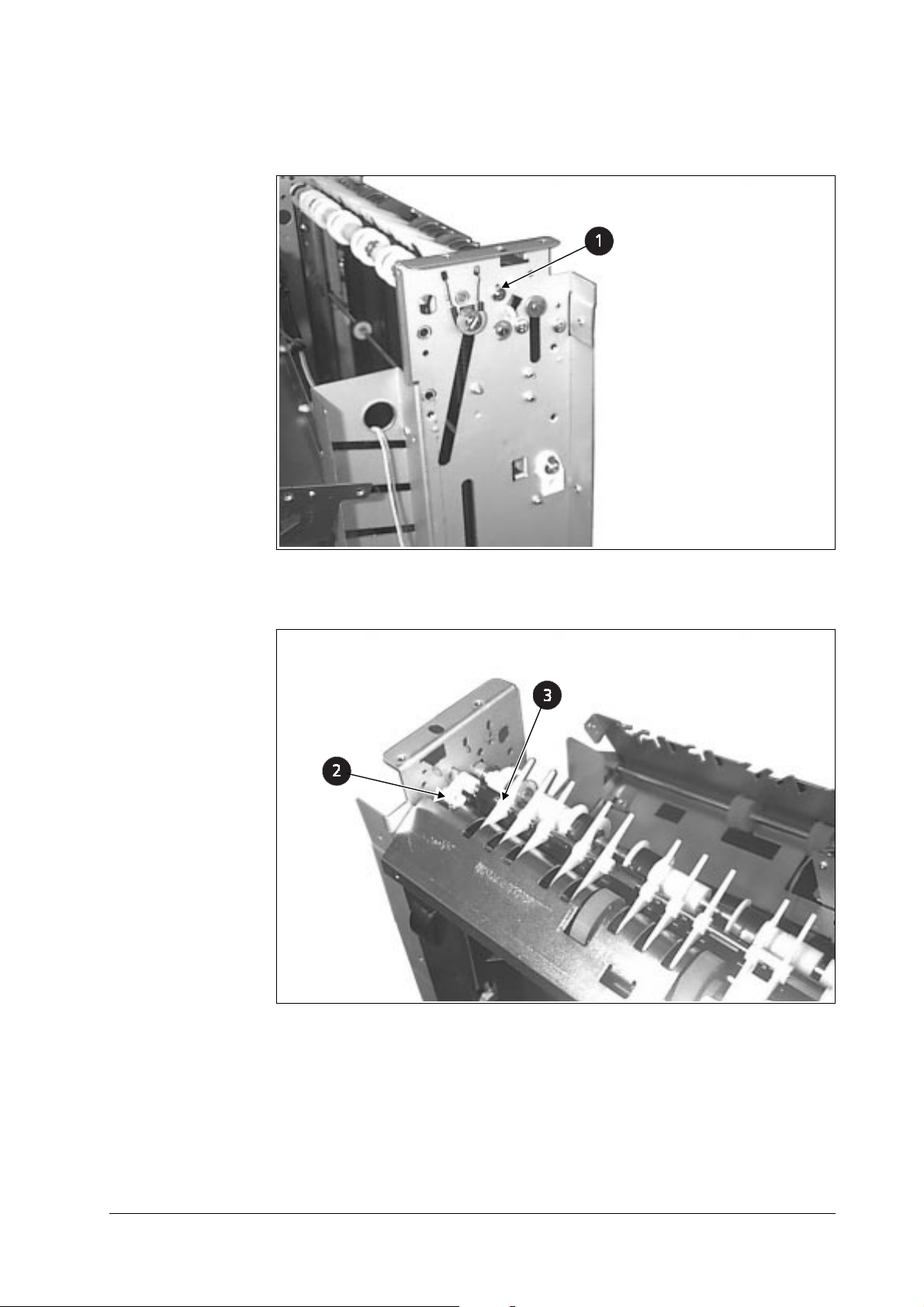

Removing the front cover and rear cover

Remove the six screws (① below).

1

Remove the four screws (② below) and the two tabs (③ below) from the rear cover.

2

2

3

1

1

Removing the top cover

Remove the four screws (① below) and the single connector (② below).

2

3

2-3

1

2

SO-30

Page 13

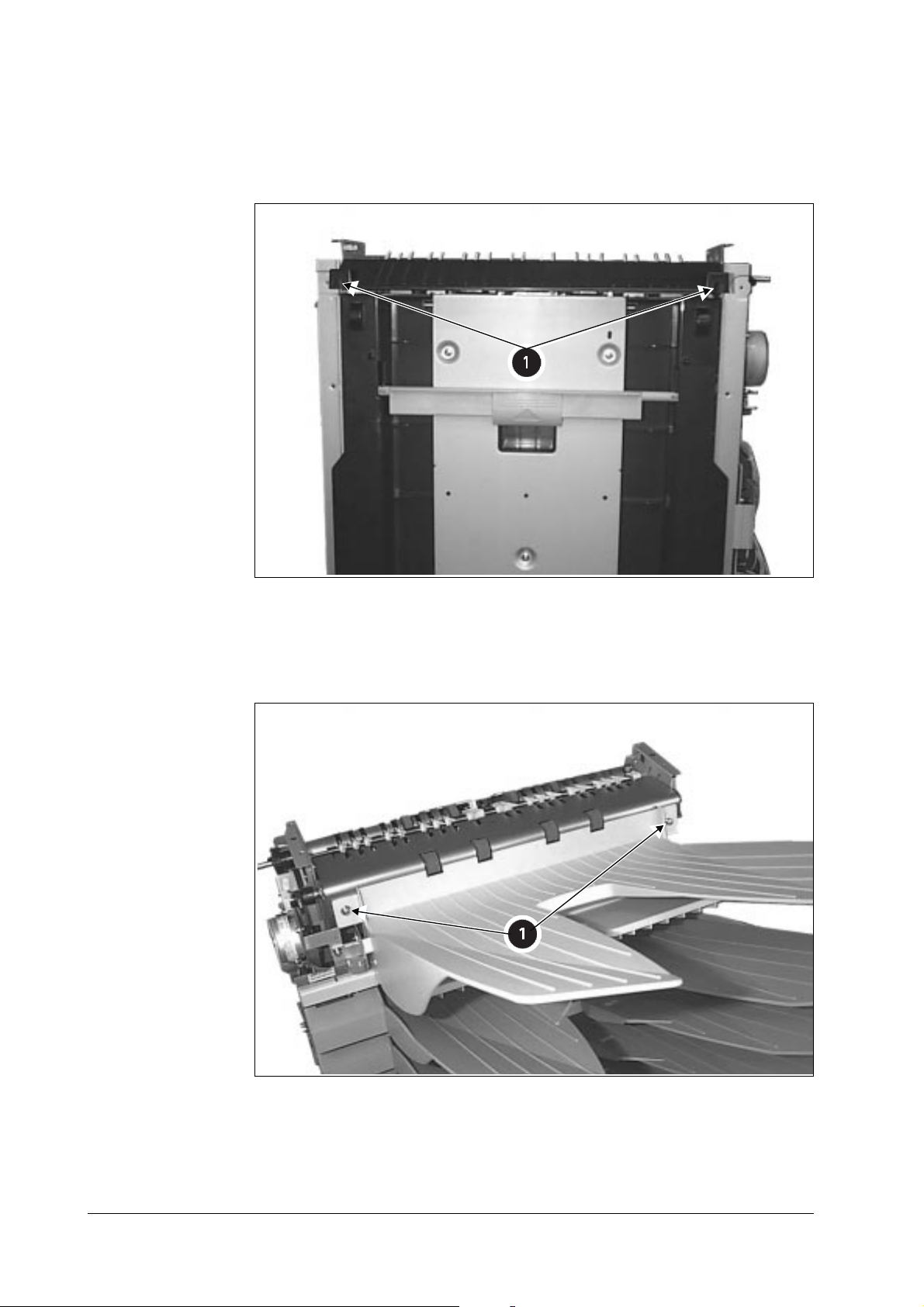

Removing the cover (black)

Remove the two screws (① below).

1

Removing the top tray

Remove the two screws (① below) and pull forward.

1

SO-30

2-4

Page 14

Removing the bracket

Pull the bracket forward (① below).

1

Removing the trays

Remove the screw (① below) from the tray to be removed, then pull the tray forward. (Each tray

is fastened with one screw.) Then remove the four screws (② below) and go to the next step.

1

2

2-5

SO-30

Page 15

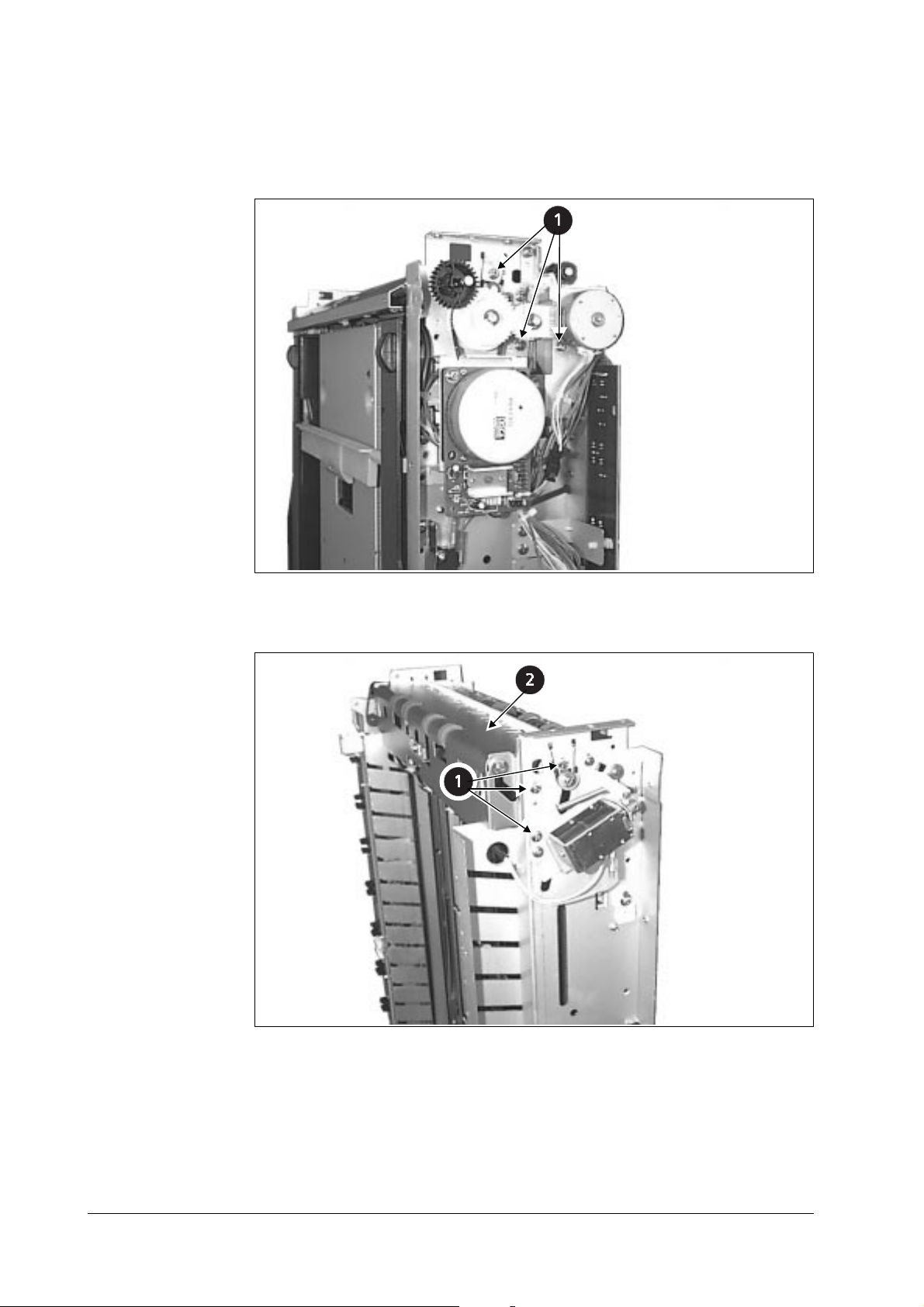

Removing the bracket (silver)

Remove the three screws (① below) from the front.

1

1

Remove the three screws (① below) from the rear, the remove the cover (② below).

2

2

1

SO-30

2-6

Page 16

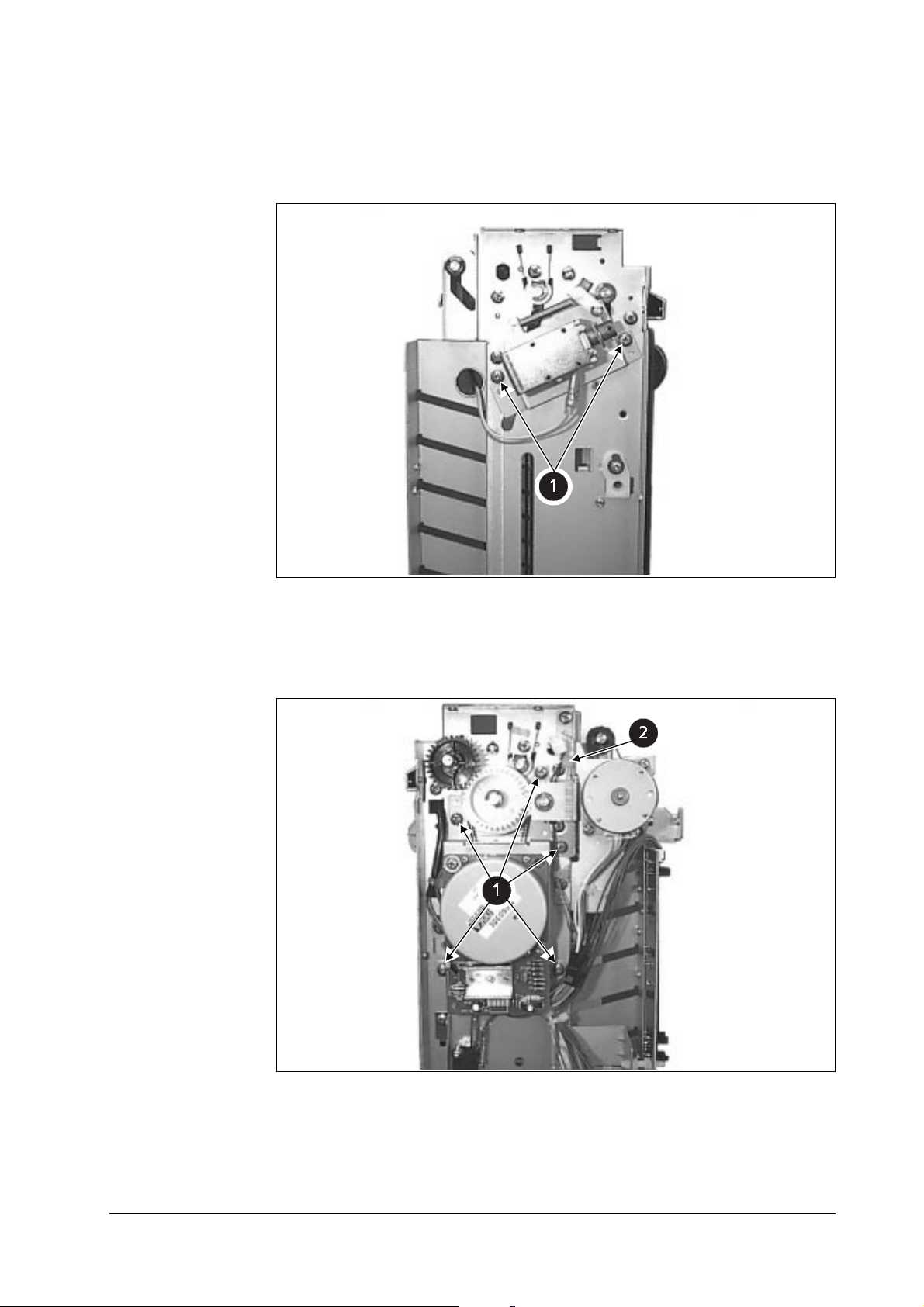

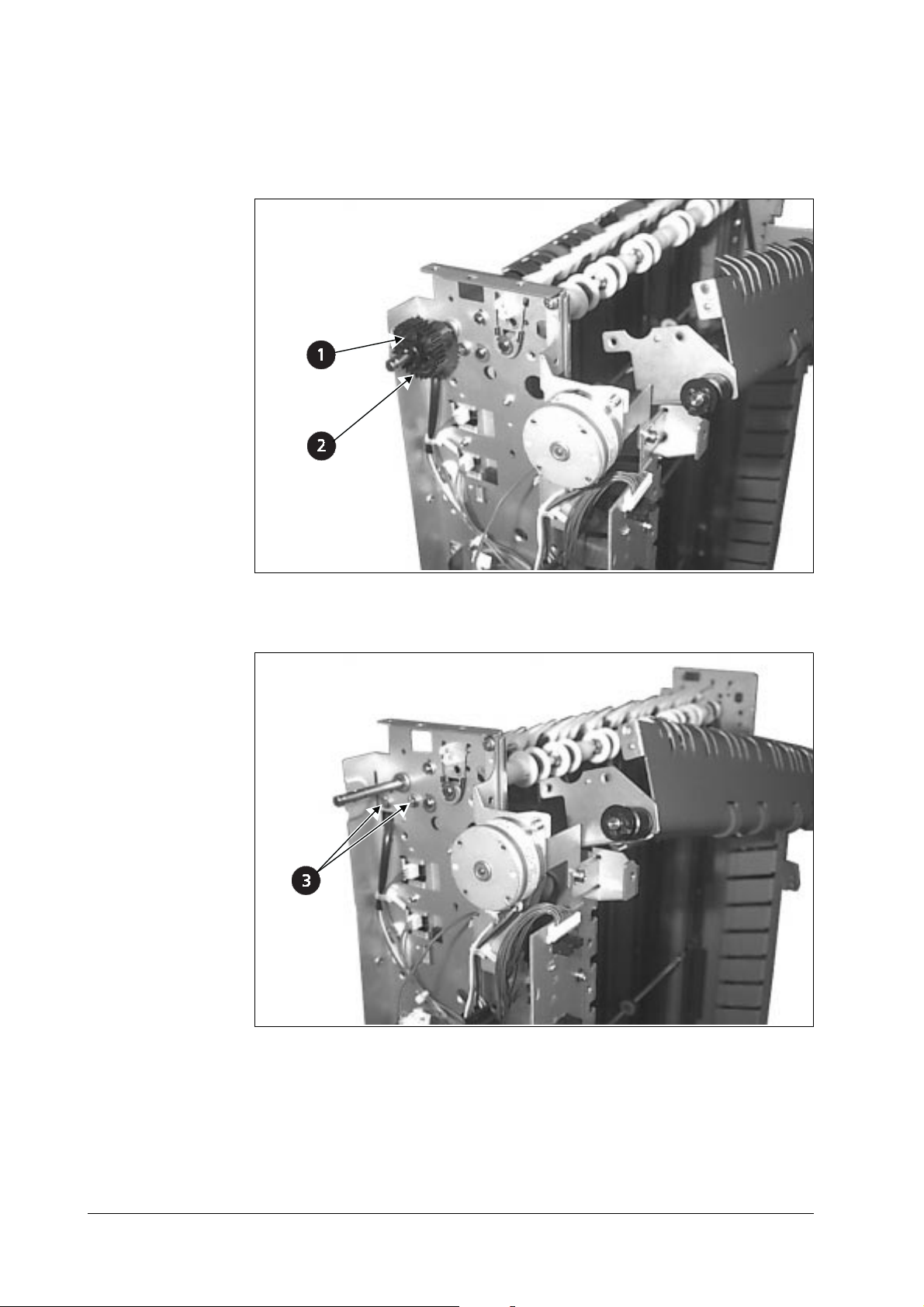

Removing the solenoid

Remove the two screws (① below).

1

Removing the motor assembly

Remove the five screws (① below), then remove the cord clamper (② below).

1

2

1

2-7

SO-30

Page 17

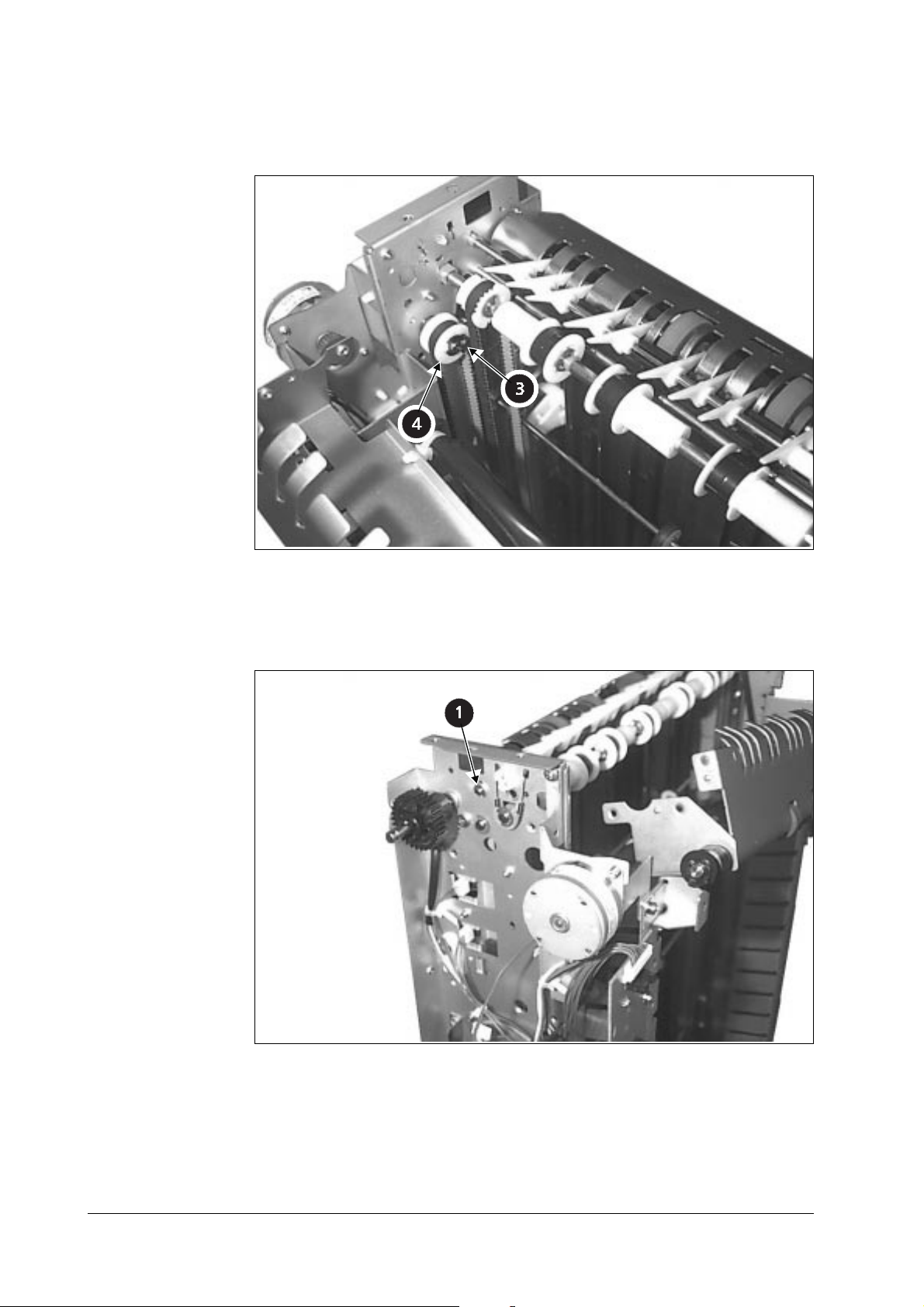

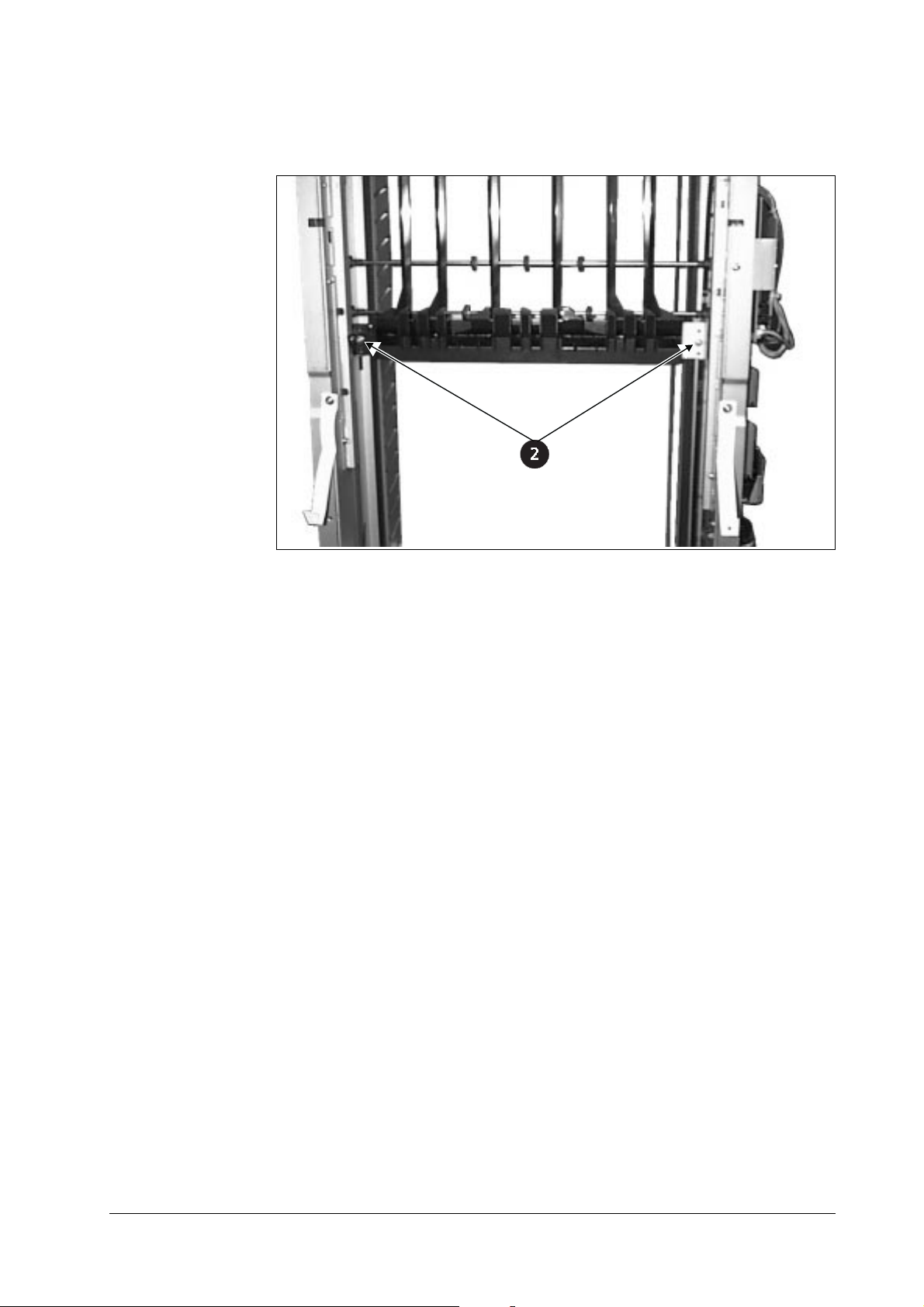

Remove the stop ring (③ below), then remove the gear (④ below).

2

3

4

Removing the paper guide

Remove the front E-ring (① below).

1

1

SO-30

2-8

Page 18

Remove the rear E-ring (① below).

2

1

Remove the spring (② below), then remove the paper guide (③ below).

3

3

2

2-9

SO-30

Page 19

Removing the bracket (gold)

Remove the stop ring (① below), then remove the gear (② below).

1

1

2

Remove the two screws (③ below).

2

3

SO-30

2-10

Page 20

Remove the two rear screws (③ below), then remove the bracket (④ below).

3

4

3

Removing the cover

Remove the two screws (① below).

1

1

2-11

SO-30

Page 21

Loosen the two screws (① below), then remove the ground screw (② below).

2

Slide the two stop rings (③ below) and the two gears (④ below) sideways.

3

Slide the bracket (⑤ below) forward and remove it.

4

4

5

3

4

1

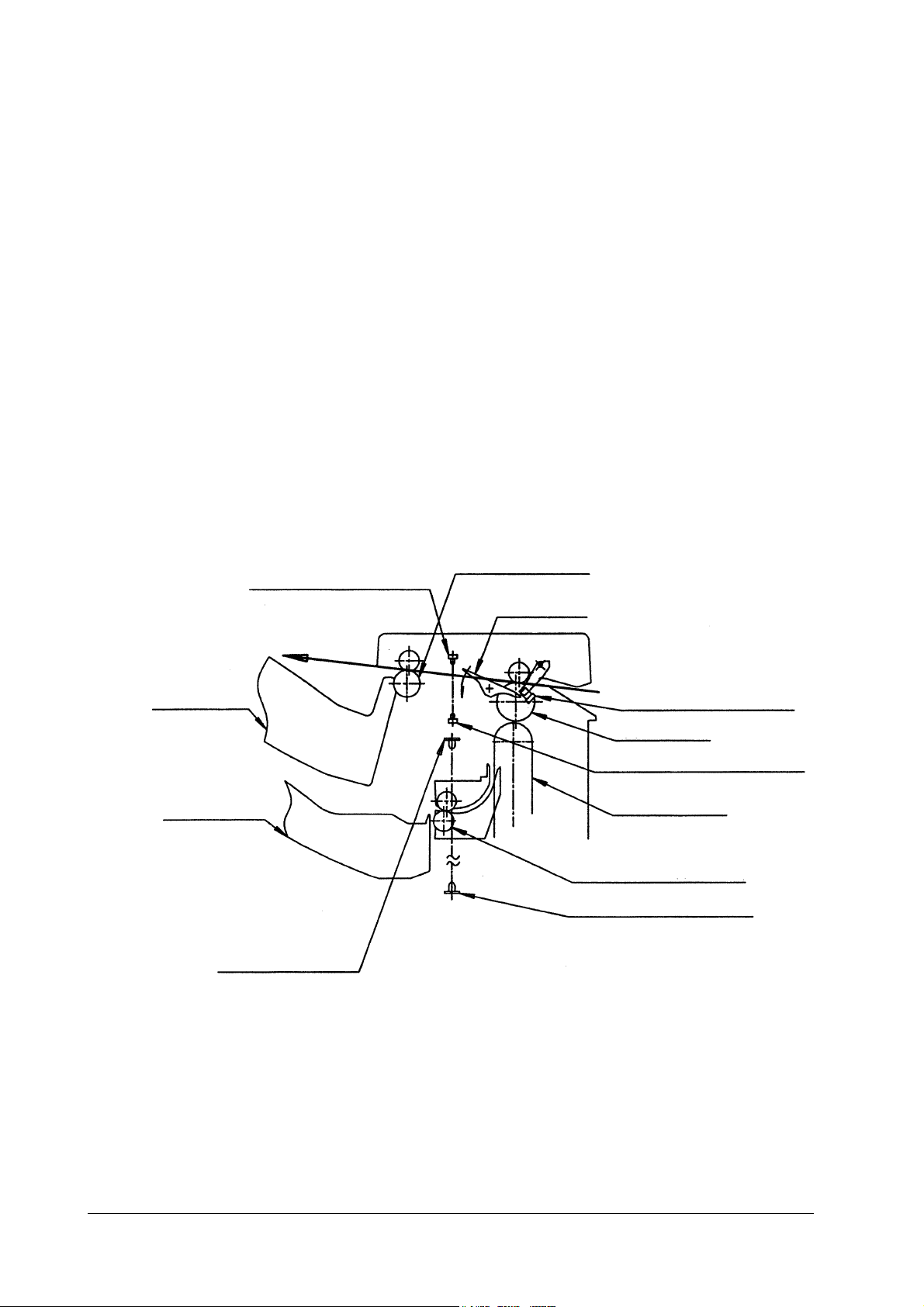

Removing the index

Remove the six screws (① below) and remove the black film.

1

2

SO-30

1

2-12

Page 22

Remove the two screws (② below) and remove the index.

2

2

2-13

SO-30

Page 23

Chapter 3 FUNCTIONAL DESCRIPTION

Contents

Overview 3-2

Multi Bin Paper Eject 3-2

Mail Bin Paper Eject (Reverse Operation) 3-3

Indexer Up/Down Movement 3-4

Circuit Description 3-5

Sensor Connections 3-6

Actuator Connections 3-7

Power 3-8

Overview 3-8

Protection Functions 3-8

Page 24

3.1 Overview

The Indexer Motor (IM) is a DC brush motor, the Paper Feeding Motor (PFM) is a DC brushless motor, and the Paper Reverse Motor (M3) is a stepping motor. Forward and reverse rotation

of these motors is controlled by the microcontroller (CPU) on the Control Board.

The paper feed path contains the Paper Entry Slot Sensor (S1), the Paper Reverse Sensor (S9),

and the Paper Eject Sensor (S4), which detect the presence and transport of the paper. If paper

does not reach or pass each sensor within a certain time, the Control Board detects a jam, stops

operation and notifies the printer that a jam has occurred.

3.2 Multi Bin Paper Eject

When the Control Board receives a Paper Eject signal from the printer, it turns the Paper Feeding Motor (M2) forward, moving the Entry Slot Roller, Vertical Transport Belt and Inde xer

Roller. When the Paper Entry Slot Sensor (S1) detects the edge of the paper, the Paper Reverse

Motor (M3) turns the Eject Paper Reverse Roller forward. The Paper Entry Slot Sensor (S1)

detects the rear edge of the paper, and after the required feeding time, ejects the printed pap er to

the Multi Tray.

Paper Eject and Reverse Roller

Reverse Paper Sensor LED

Flapper

Multi Tray Paper Entry Slot Sensor (S1)

Entry Roller

Paper Reverse Sensor (S9) Detector

Mail Trays

Paper Eject Sensor LED

Vertical Transport Belt

Indexer Eject Paper Roller

Paper Eject Sensor Detector (S4)

SO-30

3-2

Page 25

3.3 Mail Bin Paper Eject (Reverse Operation)

When the Control Board receives an Eject signal from the printer, it turns the Paper Feeding

Motor (M2) forward, moving the Entry Roller, Vertical Transport Belt and Ind exer Roller.

When the Paper Entry Slot Sensor (S1) detects the edge of the paper, the Paper Reverse Motor

(M3) turns the Eject Paper Reverse Roller forward . When the Paper Rev erse Sensor ( S1) detects

the rear edge of the paper, the Paper Reverse Motor (M3) stops. The pap er is fe d to the Reverse

position, and the Paper Reverse Motor (M3) turns in reverse so the paper feeds to the Vertical

Transport Belt. The Vertical Transport Belt carries the paper to the Reverse Roller and the

Indexer Eject Paper Roller. The rear edge of the printed paper is detected by the Paper Eject

Sensor (S4), and after the required feeding time, it is ejected to one of the Mail Bins.

Paper Eject and Reverse Roller

Reverse Paper Sensor LED

Flapper

Multi Tray

Mail Trays

Paper Entry Slot Sensor (S1)

Entry Roller

Paper Reverse Sensor (S9) Detector

Vertical Transport Belt

Indexer Eject Paper Roller

Paper Eject Sensor Detector (S4)

Paper Eject Sensor LED

3-3

SO-30

Page 26

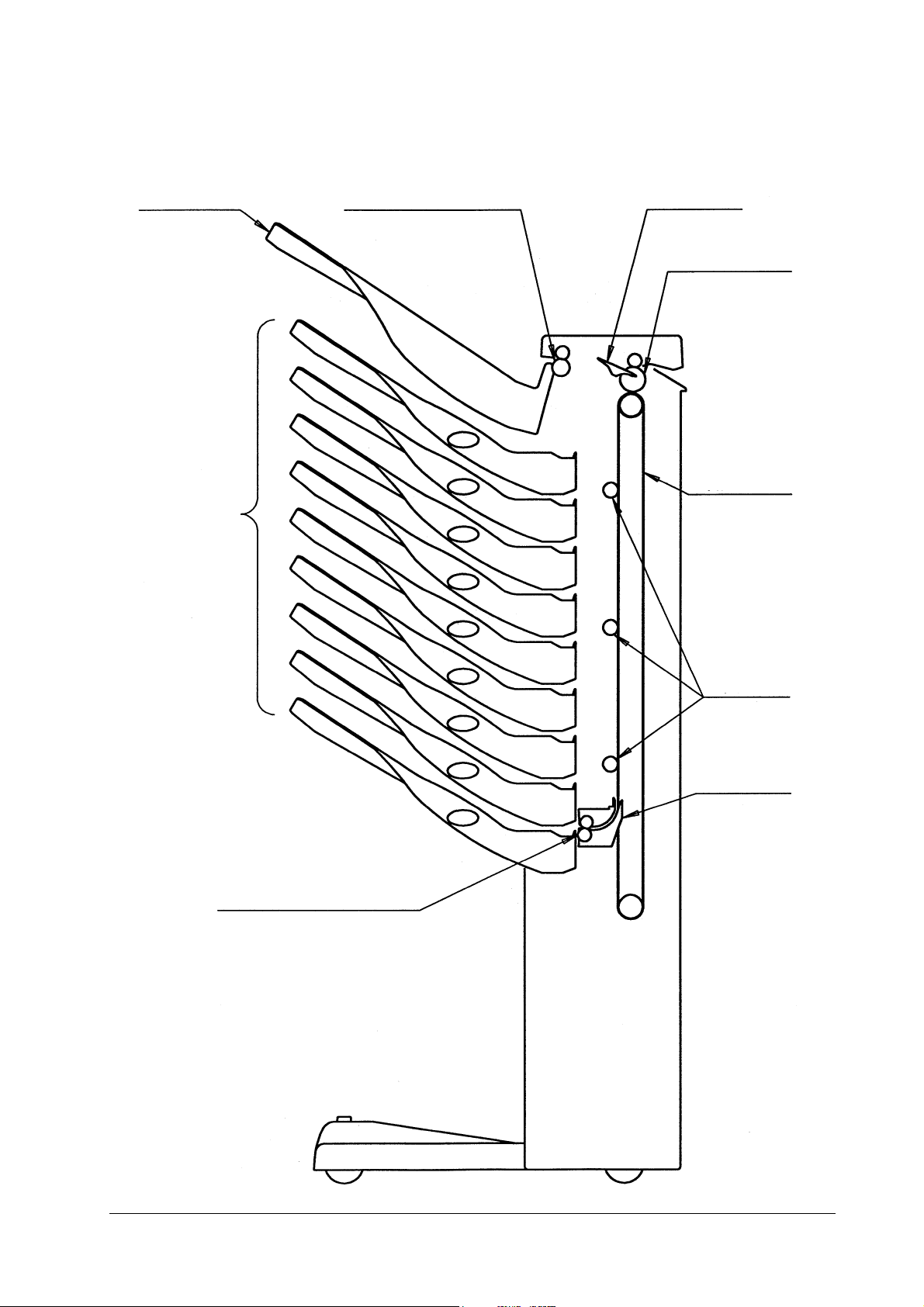

3.4 Indexer Up/Down Movement

The Indexer Motor (M1) moves the Indexer up and down. When the Indexer Motor turns in

reverse direction, the Indexer moves downward, and when it turns forward, the Indexer moves

upward. The Indexer Motor Encoder Clock Sensor (S7) regulates the speed of the Indexer

Motor. The Indexer stopping position for each mail tray is detected by the Indexer Motor Position Sensor (S8), and the Indexer Motor (M1) is controlled according to the clock pulses generated by the sensor. The Home Position Sensor (S3) indicates the initial index e r sensor position.

The range of movement of the indexer is monitored by the Indexer Upper Position Sensor (S2)

and the Indexer Lower Limit Sensor (S6).

Indexer Upper Limit Sensor (S2)

Home Position Sensor (S3)

Indexer

Indexer Motor Encoder Clock Sensor (S7)

Indexer Motor (M1)

Indexer Lower Limit Sensor (S6)

Indexer Motor Position Sensor (S8)

Mail Trays

SO-30

3-4

Page 27

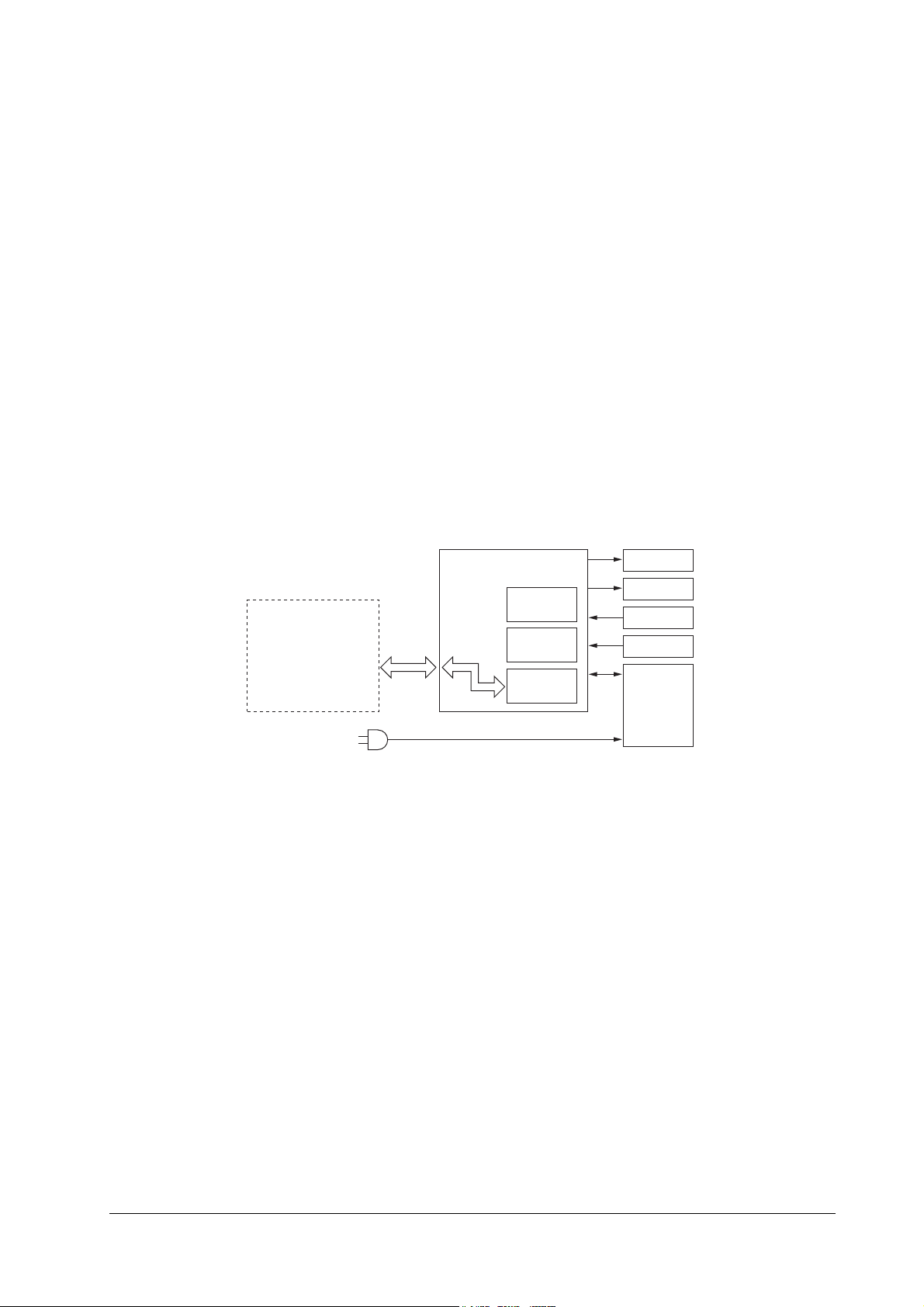

3.5 Circuit Description

i

The operating sequence of the Mailbox Sorter is controlled by the Control Board. A 16-bit

microcontroller (CPU) controls the circuitry, performs sequence control and serial communications.

The Control Board operates the solenoid and the motors in response to various commands sent

from the option (host) controller through the serial commu nications circuit.

The Control Board also advises the option controller of the states of the various sensors and

switches through the serial circuit.

The roles of the ICs on the Control Board are as follows.

•Q1 (CPU)

Sequence Control

•Q2 (EP-ROM)

Internal Sequence Program Firmware

•Q3 (IPC)

Communications Control

The signal flow between the Mailbox Sorter and the printer is shown below.

Printer

Control Board

Q1

CPU

Q2

EP-ROM

Q3

IPC

Motors

Solenoid

Switch

Sensors

Power

Supply Un

3-5

SO-30

Page 28

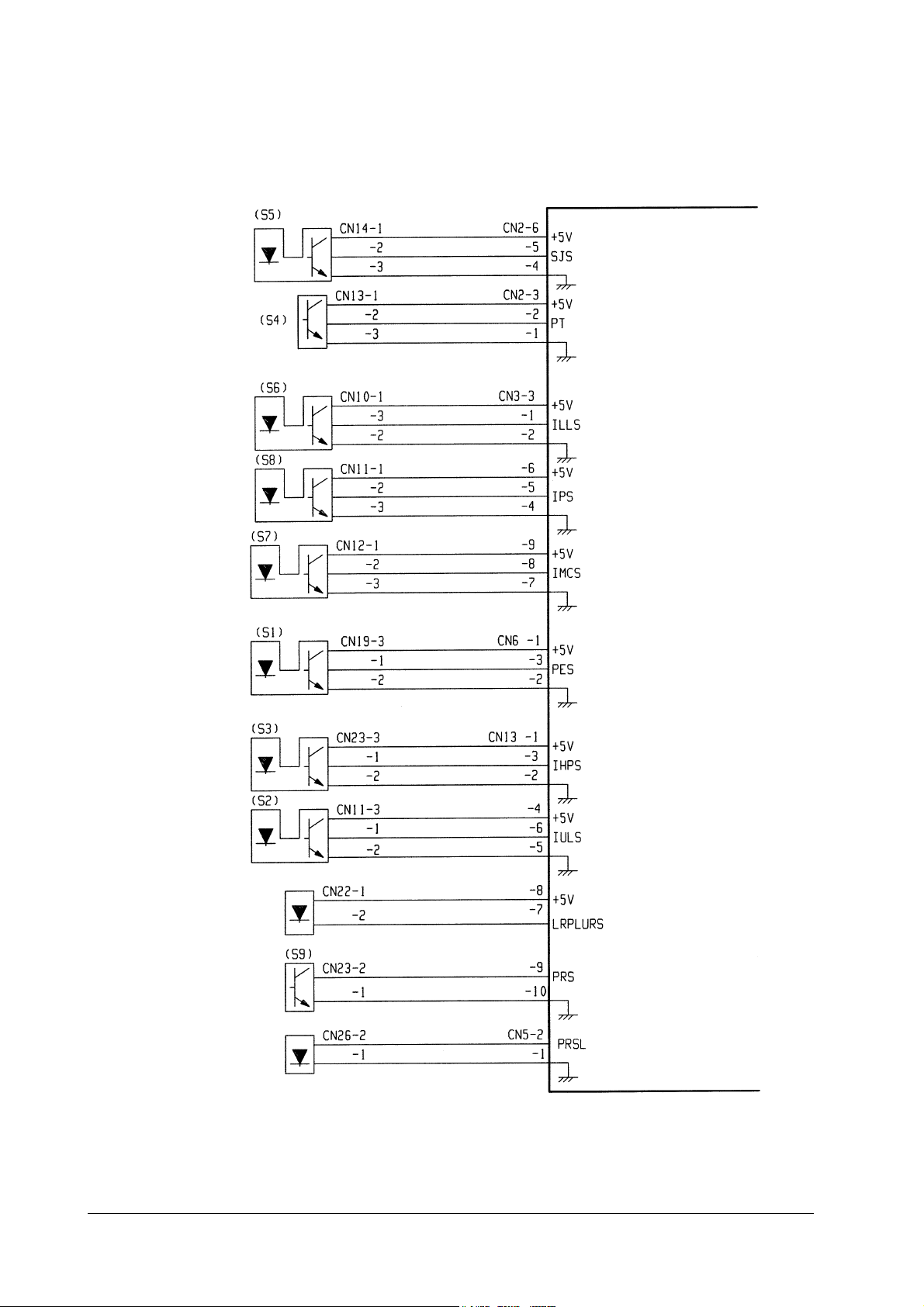

3.6 Sensor Connections

Mailbox Sorter Control Board

Sorter Joined Sensor

Eject Paper Sensor

Detector

Indexer Lower Limit

Sensor

Indexer Motor Position

Sensor

Indexer Motor Encoder

Clock Sensor

Paper Entry Slot Sensor

"L" when joined to printer

"L" when paper detected

"H" when lower limit detected

Pulses according to speed of

indexer motor positioning

Pulses according to speed of

indexer motor encoder

"L" when paper detected

Home Position Sensor

Indexer Upper Limit

Sensor

Eject Paper Sensor LED

Reverse Paper Sensor

Detector

Reverse Paper Sensor LED

"H" when the indexer detects

the home position

"H" when the indexer detects

the upper limit

"L" when the sensor detects paper

SO-30

3-6

Page 29

3.7 Actuator Connections

Indexer Motor

Paper Feeding Motor

Reverse Paper Motor

Mailbox Sorter Control Board

Indexer Motor Control Signals

Feeding Motor Control Signals

Face-Up Solenoid

Door Open/Close Switch

Reverse Paper Motor Control Sign

Face-Up Solenoid Control Signal

3-7

SO-30

Page 30

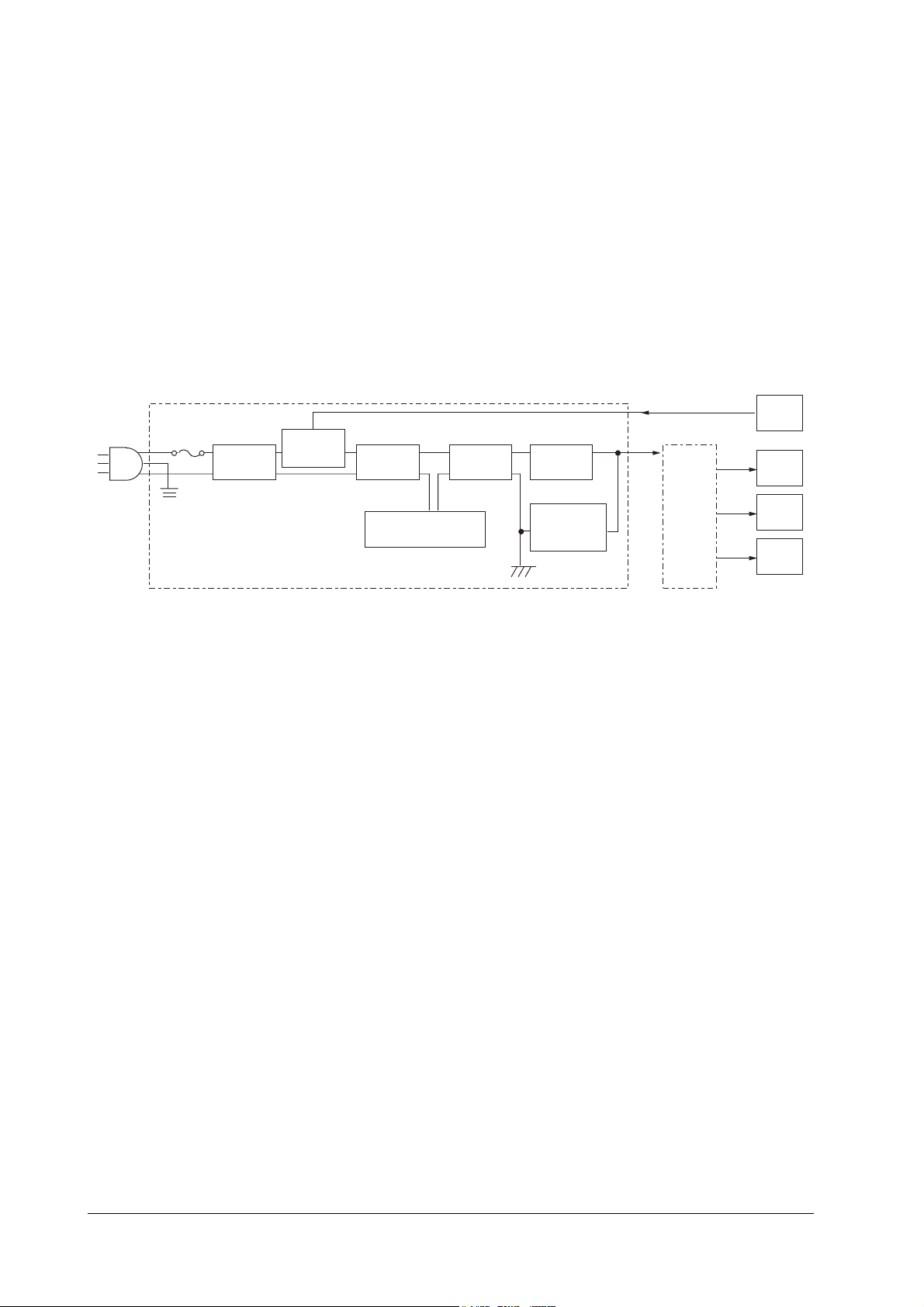

3.8 Power

e

i

Overview

Electrical power to this unit is controlled by a remote switching system .

When the printer power is turned on, the printer outputs remote signal (RMOT), which turns the

unit on. Both +24 and +5 V are supplied to the Control Board when RMOT is H.

The +24V runs the Feeding Motor, Eject Paper Motor and the Solenoid. The +5V supplies the

sensors and ICs on the Control Board.

The following block diagram shows the power supply circuitry.

Power Supply Unit

Noise Filter

Remote

Control

Circuit

Smoothing

Circuit

Control IC Overcurrent

Protection Circuit

Trans-

former

Smoothing

Circuit

Overvoltage

Protection

Circuit

RMOT

+24V

Control

Board

+5V

+24V

+24V

Print

Sensor

Soleno

Motors

Protection Functions

The +24V power circuitry includes an overcurrent protection function to prevent damage by

shutting off the output voltage automatically when a short-circuit-type fault occurs at the load

side causes excessive current drain.

When the overcurrent protection function is triggered and DC voltage is removed from the output of the power circuitry, printer power should be turned off until th e fault on the load side is

repaired.

SO-30

3-8

Page 31

Chapter 4 TROUBLESHOOTING

Contents

Power Does Not Turn On 4-2

Paper Reverse Sensor Fault 4-3

Eject Paper Sensor Fault 4-3

Door Open/Close Switch Fault 4-4

Paper Feeding Motor Fault 4-4

Paper Reverse Motor Fault 4-5

Indexer Motor Fault 4-5

Face-Up Solenoid Fault 4-5

Page 32

Observe the following precautions when performing the troubleshooting procedures in this

chapter.

When measuring voltages specified at various connector terminals, confirm that the connector

is making proper contact.

When handling the circuit board, be careful to avoid damage to the board from static electricity: before starting work, touch the printer’s metal chassis with your hand to discharge static.

4.1 Power Does Not Turn On

Possible Causes:

Specified voltage is not present at the mains outlet.

1

Solution: Advise the user that mains voltage is not present.

The power plugs at the printer, Mail Sorter or outlet are not connected correctly.

2

Solution: Re-insert the power plugs.

The Power-On signal is not being input because of bad connection at the interface connec-

3

tor.

Solution: Reconnect the interface connector

The Power-On signal is not available.

4

Solution: Turn on the printer, and measure the voltage on the Control Board between

connectors CN9-1 (RMOT) and CN9-3 (GND). If the voltage is not about 3V,

check the printer.

Blown fuse

5

Solution: Remove the Power Supply Unit and replace the fuse.

Power Supply Unit fault

6

Solution: Turn off the printer and remove connector CN9 from the Control Board.

Connect the power cord to the Power Supply Unit, tu rn th e printer on, and

measure the DC output at connector CN9 (be careful to avoid short circuits).

If the specified voltage is not present, replace the Power Supply Unit.

Wiring, DC Loads and Control Board

7

Solution: Turn off the printer, and ch eck th e wiring an d DC load s served by the Control

Board. If the wiring and DC loads check okay, replace the Control Board.

SO-30

4-2

Page 33

4.2 Paper Reverse Sensor Fault

Possible Causes:

Bad Paper Reverse Sensor signal line connection

1

Solution: Reconnect connectors CN13 and CN5 on the Control Board. Also reconnect

connector CN23 at the detector side of the Paper Reverse Sensor, CN26 at the

LED side of the Paper Reverse Sensor, and relay connector CN28.

Bad Paper Reverse Sensor

2

Solution: Measure the voltages between connectors CN13-10 (SGND) and CN13-9, and

CN5-2 on the Control Board.

(1) About 120 mV should be present at CN13-10 and CN13-9 (relative to

GND).

(2) About 1.2 V should be present between CN5-1 and CN5-2.

If the above voltages are not present, replace the LED side of the Paper

Reverse Sensor (PRSL) and the detector side of the Paper Reverse Sensor

(PRS).

Bad Control Board

3

Solution: Replace the Control Board.

4.3 Eject Paper Sensor Fault

Possible Causes:

Bad Eject Paper Sensor signal line connection

1

Solution: Reconnect connectors CN13 and CN2 on the Control Board. Also reconnect

connector CN31 for th e detect or s ide o f t h e Ej ect P aper S ens or, and CN22 for

the LED side of the Eject Paper Sensor.

Bad Eject Pap er Sensor

2

Solution: Measure the voltages at co nnectors CN13-7 (*LRPLUS) on the Mailbox

Sorter and the Driver Board, and CN13-8 and CN2-2.

(1) About 5 V should be present at CN13-7 and CN13-8.

(2) About 4.5 V should be present between CN2-1 and CN3-2.

If the above voltages are not present, replace the LED side of the Eject

Paper Sensor (LRLED) and the detector side of the Eject Paper Sensor

(PT).

Bad Control Board

3

Solution: Replace the Control Board.

SO-30

4-3

Page 34

4.4 Door Open/Close Switch Fault

Possible Causes:

Bad Door Open/Close Switch signal line conn ection

1

Solution: Reconnect CN12 on the Control Board. Also reconnect connector CN29 on

the Door Open/Close Switch.

Bad Door Open/Close Switch

2

Solution: Remove connector CN12 on the Control Board, and measure the resistance

between CN12-1 and CN12-2 on the switch side. When the Vertical Transpo rt

Unit is closed, the resistance should be 0 (, and when opened, the resistance

should be infinite. Otherwise, replace the Door Open/Close Switch.

4.5 Paper Feeding Motor Fault

Possible Causes:

Bad Paper Feeding Motor signal line connection

1

Solution: Reconnect connector CN8 on the Control Board. Also reconnect connector

CN16 on the Paper Feeding Motor.

Bad Paper Feeding Motor

2

Solution: Activate the test mode by turning on DIP switches 3 and 4 on the Control

Board, to confirm whether the Paper Feeding Motor operates or not. If the

motor does not operate, replace it.

Bad Control Board

3

Solution: Replace the Control Board.

SO-30

4-4

Page 35

4.6 Paper Reverse Motor Fault

Possible Causes:

Bad Paper Reverse Motor signal line connection

1

Solution: Reconnect connector CN4 on the Control Board. Also reconnect connector

CN27 on the Paper Reverse Motor.

Bad Paper Reverse Motor

2

Solution: Remove connector CN4 on the Control Board, and measure the resistance

between at the motor side of the connector as follows:

(1) Between CN4-1 and CN4-5, and between CN4-1 and CN4-6.

(2) Between CN4-2 and CN4-3, and between CN4-2 and CN4-4.

If any measurement is not about 15 (, replace the Paper Reverse Motor.

Bad Control Board

3

Solution: Replace the Control Board.

4.7 Indexer Motor Fault

Possible Causes:

Bad Indexer Motor signal line connection

1

Solution: Reconnect connector CN7 on the Control Board. Also reconnect connector

CN15 on the Paper Reverse Motor.

Bad Indexer Motor

2

Solution: Remove connector CN7 on the Control Board, and measure the resistance

between at the motor side of the connector between CN7-1 and CN7-2. If the

resistance is not about 8.6 (, replace the Indexer Motor.

Bad Control Board

3

Solution: Replace the Control Board.

SO-30

4.8 Face-Up Solenoid Fault

Possible Causes:

Bad Face-Up Solenoid signal line connection

1

Solution: Reconnect connector CN4 on the Control Board. Also reconnect connector

CN30 on the Face-Up Solenoid.

Bad Face-Up Solenoid

2

Solution: Remove connector CN4 on the Control Board, and measure the resistance

between at the solenoid side of the connector between CN4-7 and CN4-8. If

the resistance is not about 115 (, replace the solenoid.

Bad Control Board

3

Solution: Replace the Control Board.

4-5

Page 36

Appendice PARTS CATALOGUE

Contents

External Covers A-2

Paper Conveying Assembly A-4

Frame Assembly A-7

Tray Mail Assembly 1-8 A-9

Tray Mail Assembly 9 A-11

Drive Assembly A-13

Multi Tray, Door Assembly A-17

Base Assembly A-19

Wiring Diagram A-21

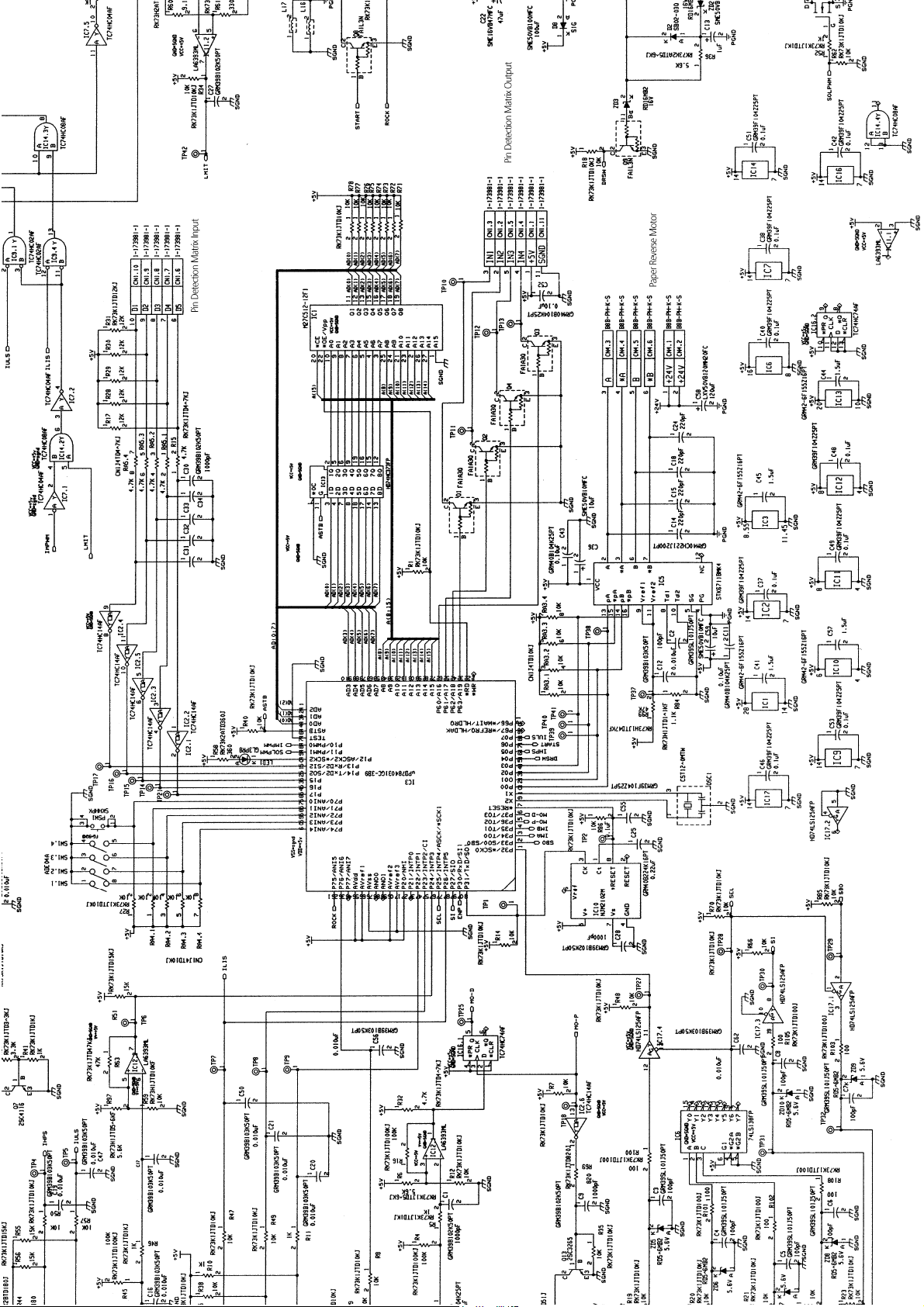

Schematic Diagram A-22

Page 37

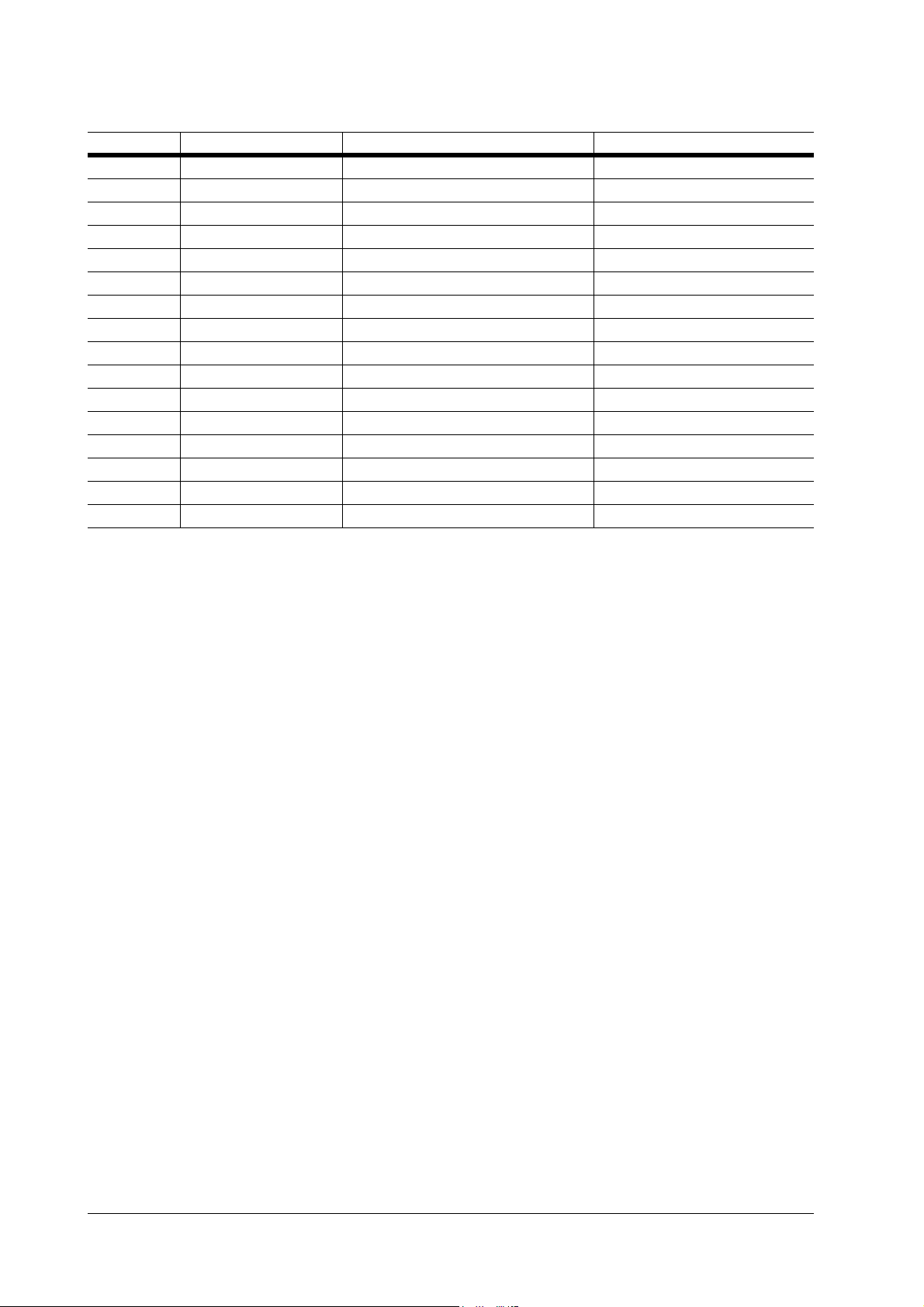

A-1 External Covers

A

SO-30

A-2

Page 38

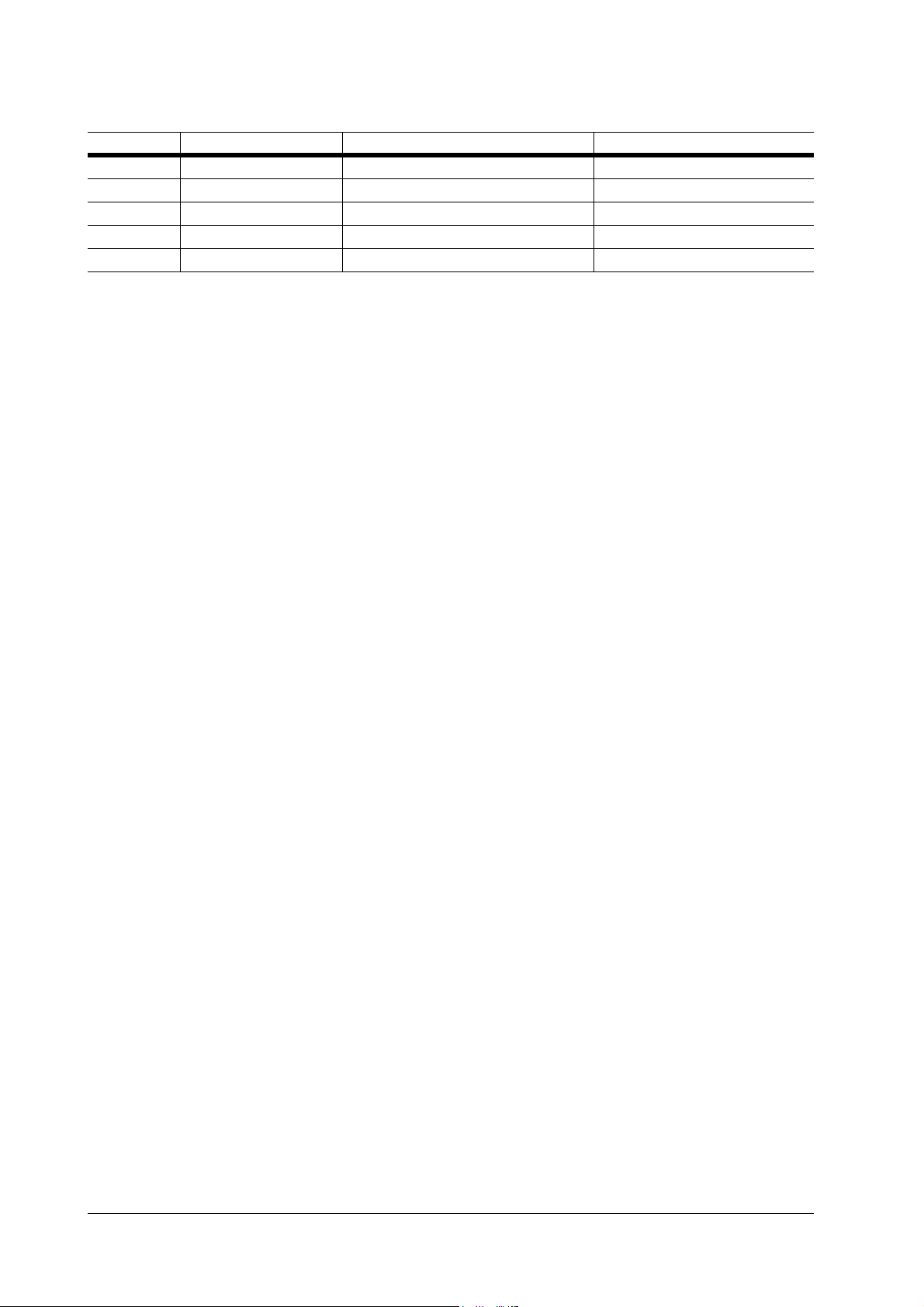

Ref. No. Part code Description Remarks

01-A 5SNSASO30E32 COVER TOP ASSEMBLY

01-001 5SNSP0012739 COVER FRONT

01-002 5SNSP00127 40 COVE R REAR

01-003 5SNSP0012698 COVER TOP

01-004 5SNSP0012703 BRUSH EXIT

01-005 5SNSP0012704 PLATE EARTH EXIT

01-006 5SNSP0012702 LEVER SENSOR TOP

01-007 5SNSASO30E19 PWB SENSOR TOP

01-008 5SNSP0012699 PLATE SPRING ROLLER

01-009 5SNSP0012700 ROLLER TOP

01-010 5SNSP0012701 SHAFT ROLLER TOP

01-011 5SNSASO30E20 CONN. ASM-CK2

01-012 5SNSP0012750 CLAMP WIRE

01-a 5MBSPB4008NN BIND HD SCREW

01-b 5MBTPB4010WZ BIND T-T SCREW

01-c 5MBTPB3008WZ BIND T-T SCREW

SO-30

A-3

Page 39

A-2 Paper Conveying Assembly

SO-30

B

F

A-4

Page 40

Ref. No. Part code Description Remarks

02-B 5SNSASO30E33 INDEXER ASSEMBLY

02-F 5SNSASO30E37 REEL FILM ASSEMBLY

02-001 5SNSP00127 05 SHAFT GUIDE 2

02-002 5SNSP00127 10 GUIDE UPPER

02-003 5SNSP00127 08 SHAFT GUIDE 1

02-004 5SNSP00127 09 GUIDE C ENT ER

02-005 5SNSP00127 06 ROLLER GUIDE

02-006 5SNSP0012707 GUIDE LOWER

02-007 5SNSP00126 56 ROLLER INDEXER

02-008 5SNSP0012633 FLAPPER

02-009 5SNSP0012634 GUIDE FLAPPER

02-010 5SNSP0012636 SPRING FLAPPER

02-011 5SNSP00126 37 GUIDE PAPER EXIT

02-012 5SNSASO30E07 PWB LR43

02-013 5SNSP0012749 SENSOR TLP1241

02-014 5SNSASO30E04 CONN. CORD ASSEMBLY PES

02-015 5SNSP00126 09 GUIDE PAPER ENTRANCE

02-016 5SNSP0012608 BUSHING 6

02-017 5SNSP0012657 FRAME INDEXER UPPER

02-018 5SNSP0012667 BRUSH INDEXER LOWER

02-019 5SNSP0012638 ROLLER EXIT

02-020 5SNSP0012658 PLATE INDEXER

02-021 5SNSP0012662 GUIDE INDEXER I

02-022 5SNSP00126 60 ROLLER INDEXER W

02-023 5SNSP00126 59 ROLLER INDEXER A

02-024 5SNSP00126 61 SPRING INDEXER A

02-025 5SNSP0012629 FILM PAPER GU IDE

02-026 5SNSP0012631 GUIDE FILM 2

02-027 5SNSP0012630 GUIDE FILM 1

02-028 5SNSP0012649 HOLDER INDEXER

02-029 5SNSP00126 52 ROLLER INDEXER BELT

02-030 5SNSASO30E10 BKT INDEXER

02-031 5SNSP0012664 PULLEY GEAR Z31

02-032 5SNSP0012665 FLANGE PULLEY

02-033 5SNSP0012666 GEZR Z20

02-034 5SNSP00126 63 PLATE EARTH INDEXER 1

02-035 5SNSP0012653 FRAME INDEXER LOWER

02-036 5SNSP0012654 RIB FRONT INDEXER

02-037 5SNSP0012655 RIB REAR INDEXER

02-038 5SNSP0012755 BUSHING 4

02-039 5SNSP0012744 WIRE CLAMP

02-040 5SNSP0012750 WIRE CLAMP

02-041 5SNSP00126 10 CUSHION SENSOR

02-042 5SNSP0012585 SHEET

SO-30

A-5

Page 41

Ref. No. Part code Description Remarks

02-043 5SNSP00126 70 PLATE EARTH INDEXER 2

02-044 5SNSP0012800 CUSHION GUIDE ROLLER

02-045 5SNSP0012669 BRUSH INDEXER UPPER

02-046 5SNSP00126 50 PLATE EARTH HOLDER 1

02-047 5SNSP00126 51 PLATE EARTH HOLDER 2

02-048 5SNSP00126 11 GUIDE PAPER ENTRANCE

02-049 5SNSP0012635 BUSHING 4

02-050 5SNSP0012639 BKT SENSOR

02-051 5SNSASO30E05 PWB SENSOR

02-052 5SNSP0012640 HOLDER SENSOR

02-053 5SNSP0012675 PULLEY S2M-20

02-054 5SNSP0012674 FLANGE PULLEY

02-055 5SNSP0012648 CLIP 5

02-056 5SNSP00125 92 COVE R SENSOR

02-a 5MBTPB3008WZ BIND T-T SCREW

02-b 5MBSPB4006TZ BIND T-T SCREW

02-c 5MBSPC3006NZ CEMS SCREW

02-d 5MBSPB3003NZ BIND HD SCREW

02-e 5MBSPC3006NZ CEMS SCREW

02-f 5MBCE3060XSP E STOP RING

02-g 5MBP2010WXSP SPRING PIN

02-h 5MBCE5060XSP E STOP RING

02-I 5MBP1208WXSP SPRING PIN

02-j 5MBP1206WXSP SPRING PIN

02-k 5SNSP0012588 M4X7 ROUNDED END

02-l 5MBSPB3006NZ BIND HD SCREW

SO-30

A-6

Page 42

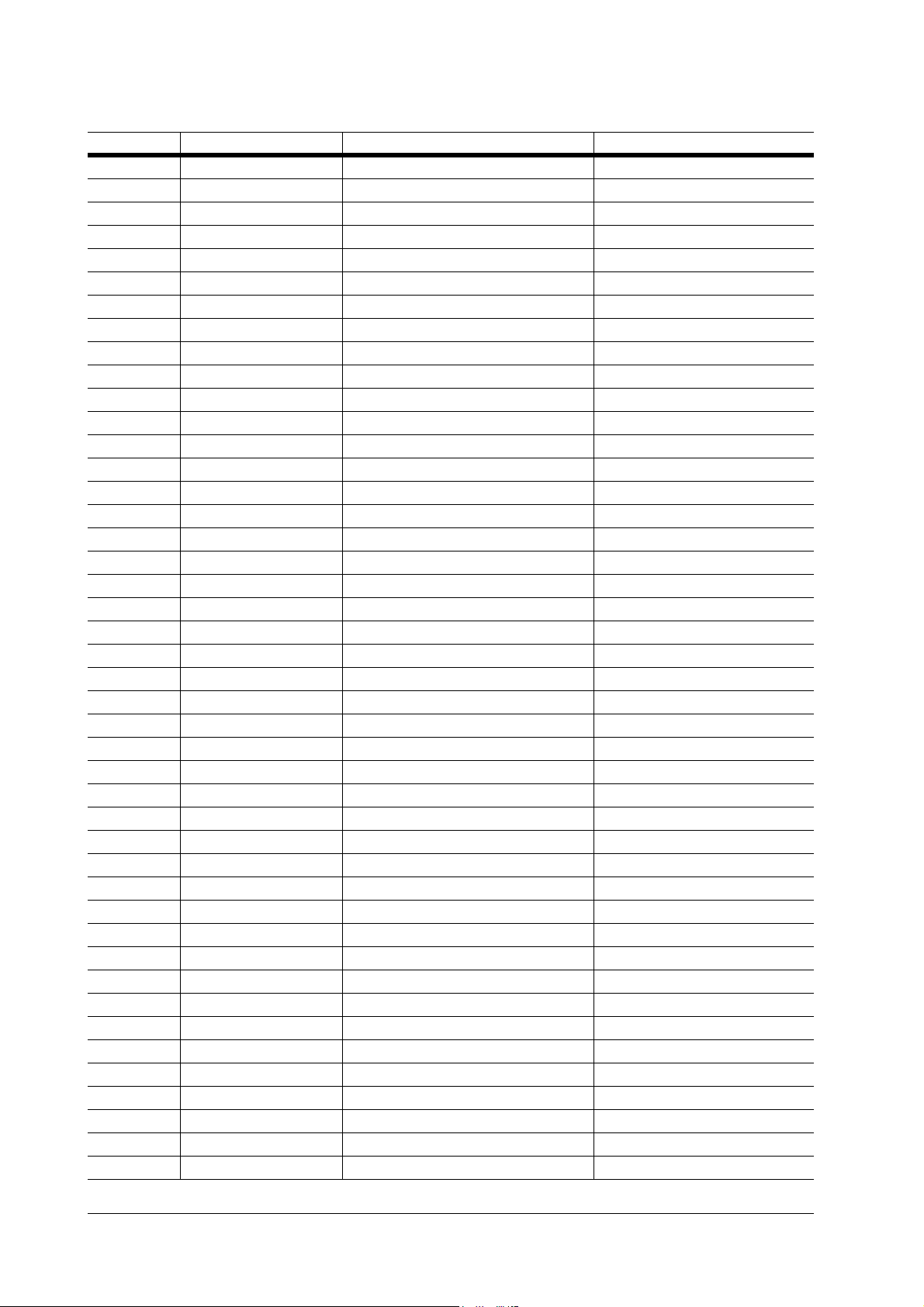

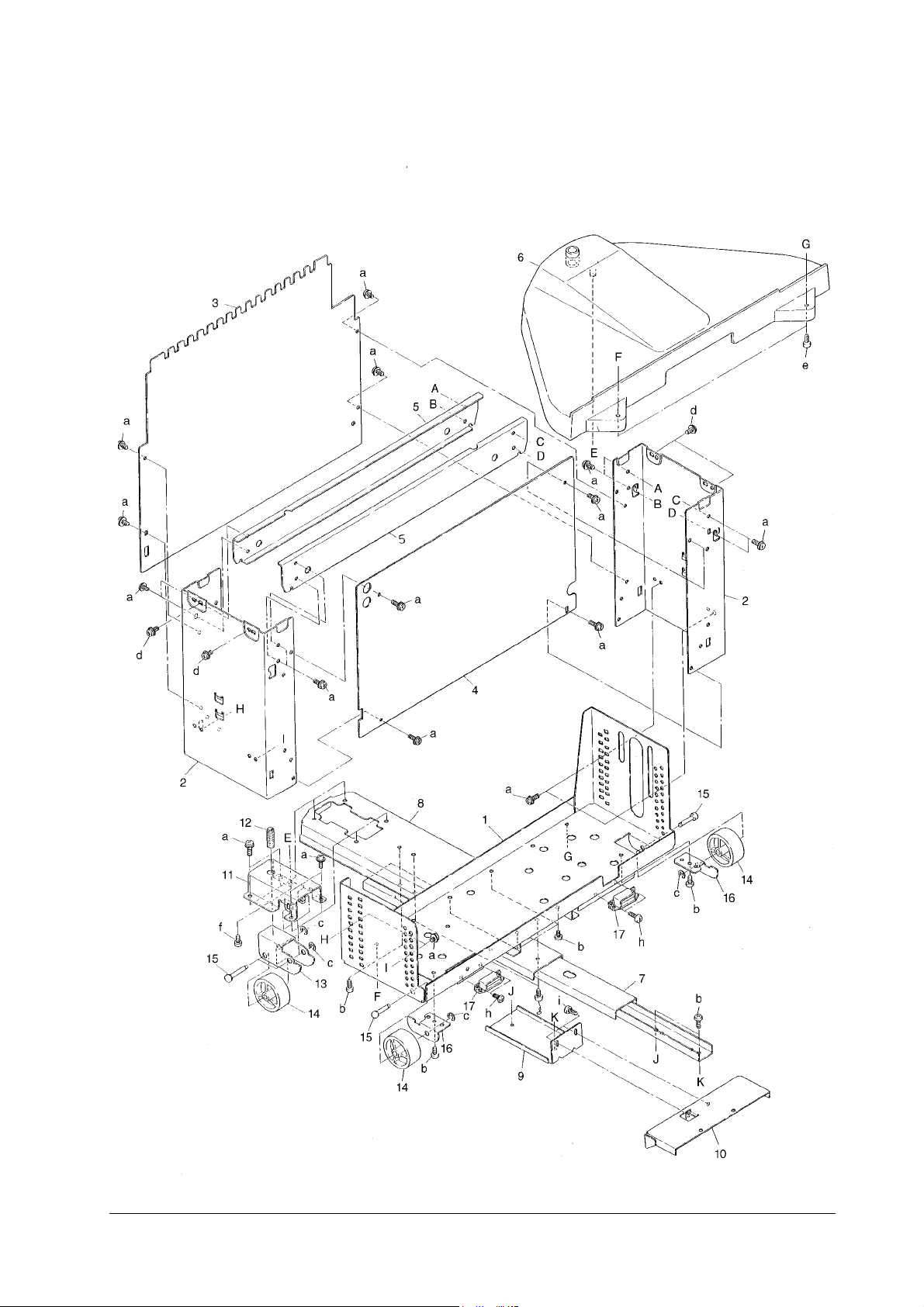

A-3 Frame Assembly

A-7

SO-30

Page 43

Ref. No. Part code Description Remarks

03-01 5SNSP0012599 RAIL INDEXER

03-02 5SNSP001 2711 GUIDE A RAIL

03-03 5SNSP0012605 GUIDE B RAIL

03-04 5SNSP0012596 PIN ROCK

03-05 5SNSP0012597 ACTUATOR K

03-06 5SNSP0012584 BKT SENSOR

03-07 5SNSP0012585 SHEET SENSOR

03-08 5SNSP0012743 SENSOR GP1S74P

03-09 5SNSP001 2592 COVER SENSOR

03-10 5SNSP0012593 FILM SENSOR

03-11 5SNSP0012589 PLATE B STOPPER F

03-12 5SNSASO30E01 PWB PT43

03-13 5SNSP0012586 LEVER SENSOR

03-14 5SNSP0012591 PLATE B STOPPER R

03-15 5SNSP0012600 GUIDE C RAIL

03-16 5SNSP0012594 FRAME FRONT

03-17 5SNSP0012602 FRAME REAR

03-18 5SNSASO 30E02 CONN. CORD ASSMBLY PT

03-19 5SNSP0012744 CLAMP WIRE

03-20 5SNSP0012595 MAT CUSHION

03-21 5SNSP0012587 SPRING LEVER

03-22 5SNSP0012808 COVER CASTER

3-a 5MBSPX4006NZ BRAS. TAP SCREW

3-b 5MBSPX4006NZ BRAS. TAP SCREW

3-c 5SNSP0012590 M4X9 ROUNDED END

3-d 5SNSP0012588 M4X7 ROUNDED END

3-e 5MBSP84010NZ CEMS SCREW W/FW

3-f 5MBSPC3008NZ CEMS SCREW W/FW

3-g 5SNSP0012598 M4X5 ROUND END

SO-30

A-8

Page 44

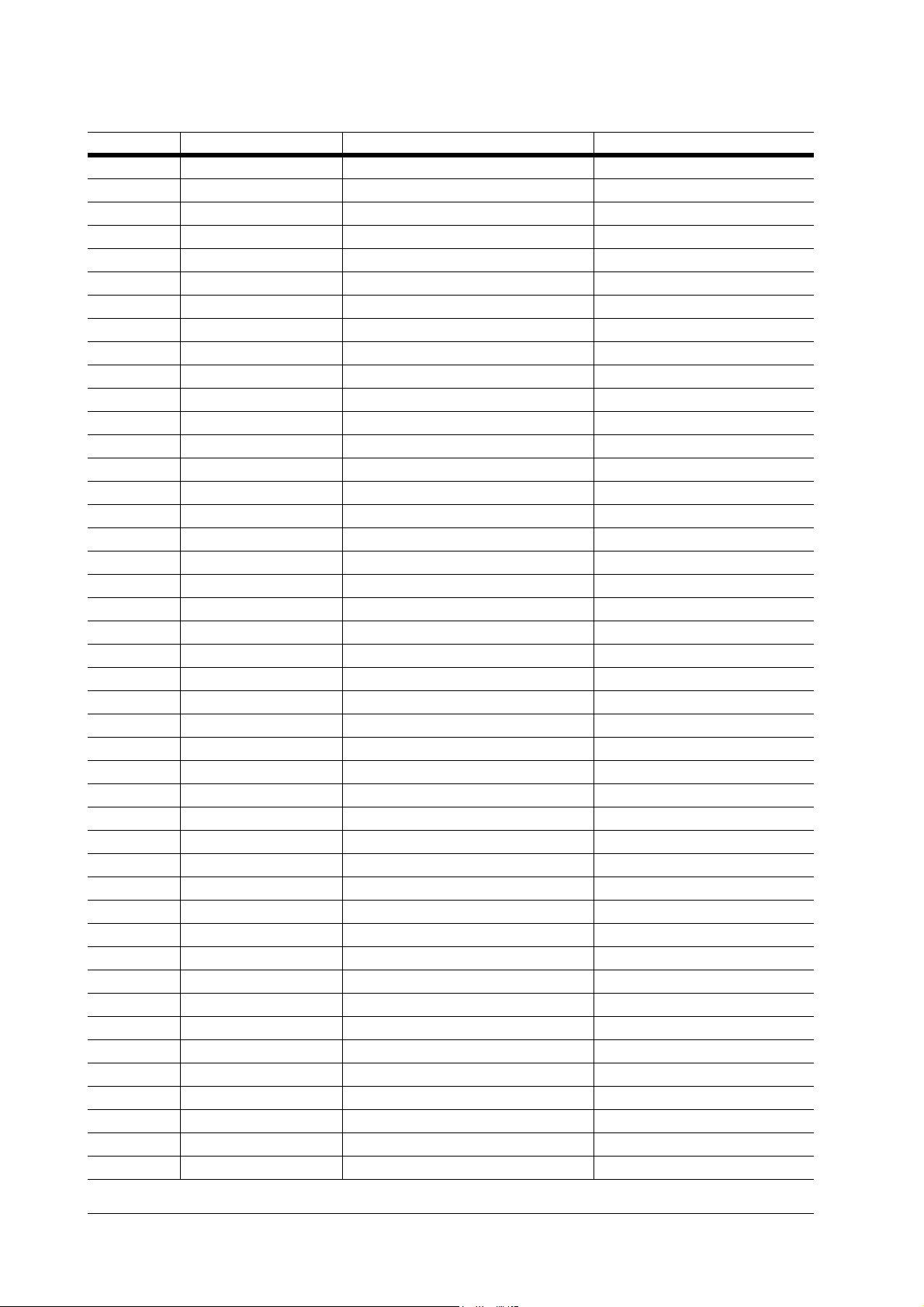

A-4 Tray Mail Assembly 1-8

A-9

SO-30

Page 45

Ref. No. Part code Description Remarks

04-01 5SNSP0012731 TRAY MAIL

04-02 5SNSP0012732 LEVER EMPTY

04-03 5SNSP0012734 LEVER FULL 1

04-04 5SNSP0012735 LEVER FULL 2

04-05 5SNSP0012801 SPRING LEVER EMPTY

04-06 5SNSP0012802 ADDITIONAL MAIL TRAY

4-a 5MBSPC4008NZ CEMS SCREW

SO-30

A-10

Page 46

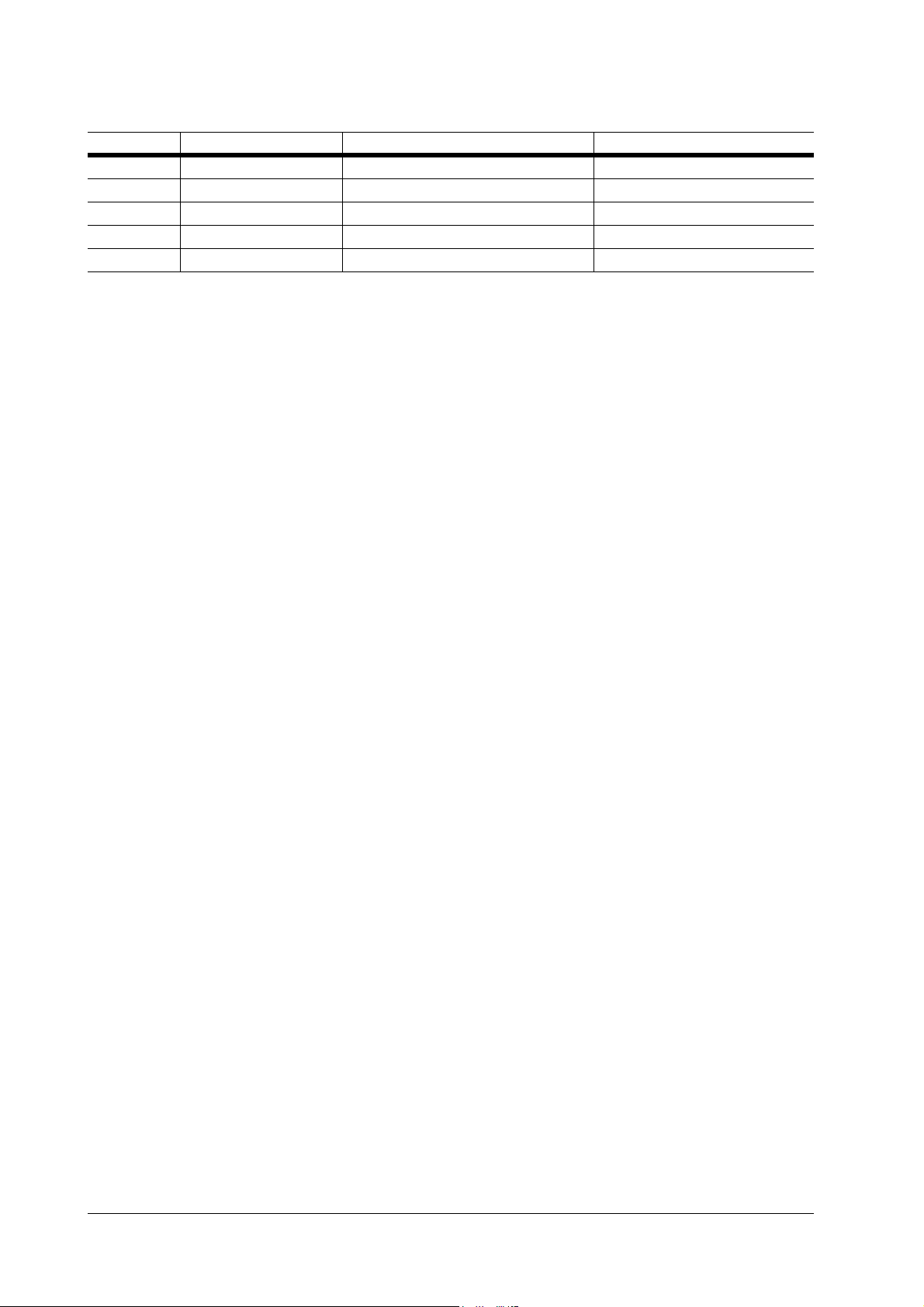

A-5 Tray Mail Assembly 9

A-11

SO-30

Page 47

Ref. No. Part code Description Remarks

05-01 5SNSP0012731 TRAY MAIL

05-02 5SNSP0012732 LEVER EMPTY

05-03 5SNSP0012801 SPRING LEVER EMPTY

05-04 5SNSP0012802 ADDITIONAL MAIL TRAY

5-a 5MBSPC4008NZ CEMS SCREW

SO-30

A-12

Page 48

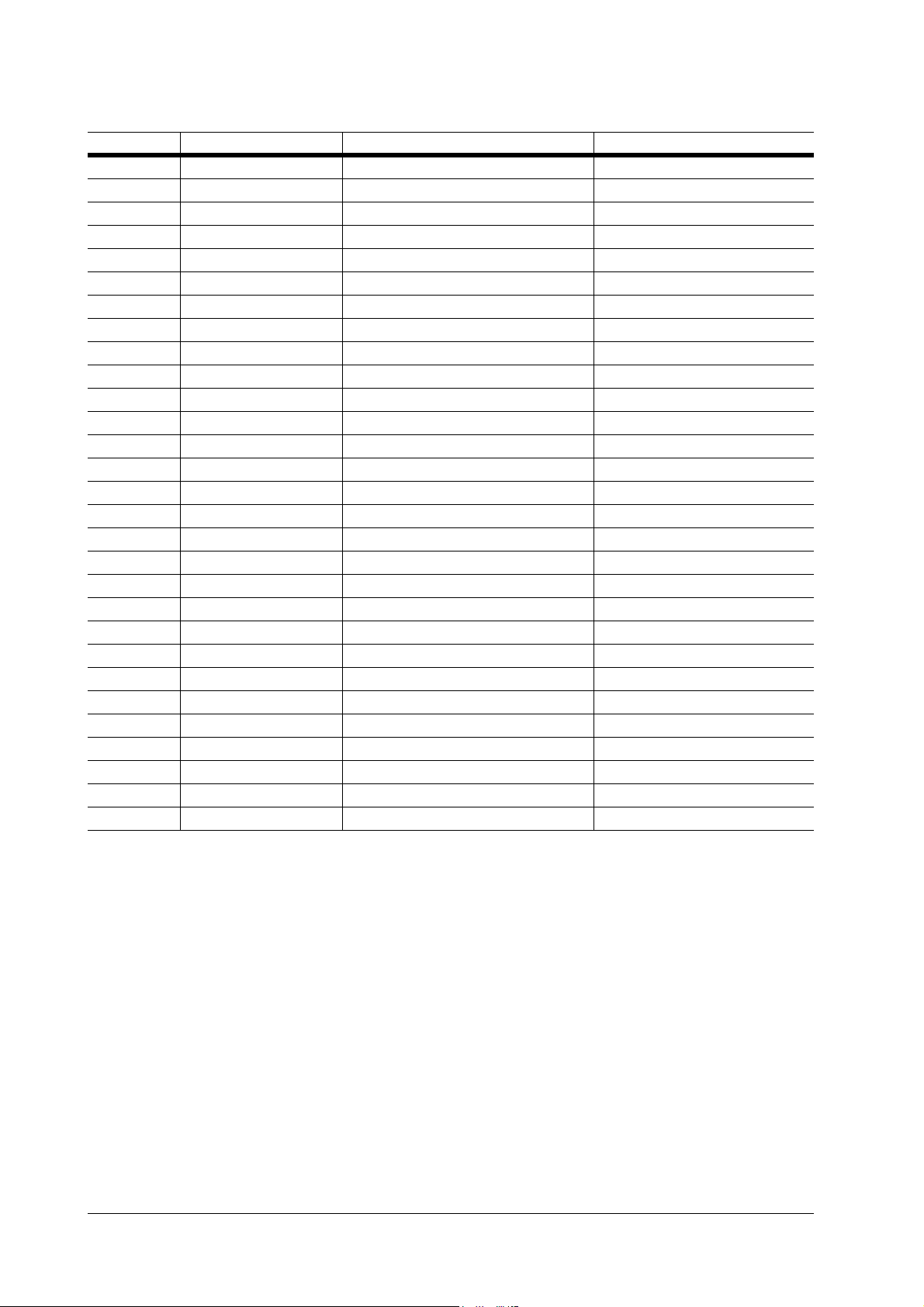

A-6 Drive Assembly

G

A-13

SO-30

Page 49

Ref. No. Part code Description Remarks

06-01 5SNSASO30E25 PWB SENSOR A

06-02 5SNSP0012607 ROLLER ENTRANCE

06-03 5SNSP0012632 SHAFT HANGER FILM

06-04 5SNSP0012621 SHAFT REEL FILM

06-05 5SNSP0012624 ARBOR REEL FILM

06-06 5SNSP0012622 PULLEY REEL FILM

06-07 5SNSP0012746 SPACER KGLS-18S

06-08 5SNSP0012623 SPRING REEL FILM

06-09 5SNSP0012626 SPRING REEL FILM R

06-10 5SNSP0012617 BELT S3M 442 60

06-11 5SNSP0012615 BELT S3M 430 60

06-12 5SNSP0012613 PULLEY S3M 18 A

06-13 5SNSP0012619 PULLEY S3M 18 B

06-14 5SNSP0012627 REEL ADJUST ARBOR

06-15 5SNSP0012628 SPRING REEL ADJUST

06-16 5SNS P0012752 BUSHING MF

06-17 5SNS P0012608 BUSHING 6

06-18 5SNSP0012641 SPRING REEL SHAFT

06-19 5SNSP0012612 SHAFT DRIVE LOWER

06-20 5SNSP0012614 PULLEY S3M 23

06-21 5SNSP0012648 CLIP 5

06-22 5SNSP0012756 WIRE CLAMP

06-23 5SNSP0012616 BELT S3M 57 60

06-24 5SNSP0012743 SENSOR GP1S74P

06-25 5SNSP0012713 BKT CONN. INTER

06-26 5SNSASO30E23 PWB CONT SUB

06-27 5SNSASO 30E24 EPROM Assembly

06-28 5SNSP001 2712 SWITCHING REG.

06-29 5SNSP001 2676 MOTOR INDEXER

06-30 5SNSP0012680 PLATE ENCODER 40

06-31 5SNSP0012679 COLLAR MOTO R

06-32 5SNSP0012678 GEAR WORM

06-33 5SNSP0012677 BKT MOTOR INDEXER

06-34 5SNSP001 2681 BKT SENSOR INDEXER

06-35 5SNSP0012748 SENSOR TLP1225

06-36 5SNSP0012671 PLATE ENCODER 4

06-37 5SNSP0012620 GEAR Z30

06-38 5SNSP0012747 SPACER KGLS-16S

06-39 5SNSP0012618 SHAFT DRIVE INDEXER

06-40 5SNSP0012604 PLATE CONT. PWB

06-41 5SNSP0012745 SW INDEXER POSITION

06-42 5SNSP0012603 BKT PWB SENSOR

06-43 5SNSP0012675 GEAR LIMIT

06-44 5SNSP0012750 WIRE CLAMP SKB-1M

SO-30

A-14

Page 50

Ref. No. Part code Description Remarks

06-45 5SNSASO30E09 BKT MOTOR CONVEYING

06-46 5SNSP0012646 SHAFT DR IVE UPPER

06-47 5SNSP0012647 GEAR Z23

06-48 5SNSP0012754 BEARI NG MF106ZZ

06-49 5SNSP0012753 BE LT S2M 60

06-50 5SNSP0012643 PULLEY IDLER GEAR

06-51 5SNSP0012644 MOTOR CONVEYING

06-52 5SNSP0012645 PU LLEY S2M 16

06-53 5SNSASO30E26 CONN. CORD BIN 2

06-54 5SNSASO30E28 PWB SENSOR B

06-55 5SNSP0012672 BKT MOTOR REVERSE

06-56 5SNSP0012744 WIRE CLAMP

06-57 5SNSP0012803 BE LT S2M 56-40

06-58 5SNSP0012804 MOTOR REVERSE

06-59 5SNSP0012805 BKT REAR COVER

06-60 5SNSASO30E16 BKT SOLENOID

06-61 5SNSP0012682 LEVER FLAPPER

06-62 5SNSP0012683 SOLENOID NS38

06-63 5SNSP0012684 SPRING SOLENOID

06-64 5SNSP0012606 BKT SE NSOR COVER

06-65 5SNSASO30E13 CONN. CORD SENSOR 2

06-66 5SNSASO30E22 CONN. CORD REG.

06-67 5SNSASO30E03 CONN. CORD SW

06-68 5SNSASO30E14 CONN. CORD MOTOR

06-69 5SNSASO30E06 CONN. CORD INDEXER

06-70 5SNSASO30E27 CONN. CORD BIN

06-71 5SNSASO30E15 CONN. CORD MOTOR

06-72 5SNSASO30E12 CONN. CORD TOP

06-73 5SNSP0012585 SHEET SENSOR

06-74 5SNSASO30E08 CONN. CORD REVERSE

06-75 5SNSP0012757 SPACER KGLS-6S

6-a 5MBSPC3006NZ CEMS SCREW

6-b 5MBSPC4012NZ CEMS SCREW

6-c 5MBSPC4008NZ CEMS SCREW

6-d 5MBCG5080XSP G STOP RING

6-e 5SNSP0012588 M4X7 ROUNDED END

6-f 5MBWK30705SZ FLAT S WASHER

6-g 5MBCE3060XSP E STOP RING

6-h 5MBCE5060XSP E STOP RING

6-I 5MBSPC4010NZ CEMS SCREW

6-j 5MBP2010WXSP SPRING PIN

6-k 5MBP2012WXSP SPRING PIN

6-l 5MBVH94008NP HEXA SET SCREW

6-m 5MBSPX4006NZ BRAS. TAP SCREW

A-15

SO-30

Page 51

Ref. No. Part code Description Remarks

6-n 5MBSPC300 6NZ CEMS SCRE W

6-o 5SNSP0012751 WASHER T

6-p 5MBSPB4006NN BIND HD SCREW

6-q 5MBSPC301 6NZ CEMS SCRE W

6-r 5SNSP0012625 FC PARALLEL PIN

SO-30

A-16

Page 52

A-7 Multi Tray, Door Assembly

H

A-17

SO-30

Page 53

Ref. No. Part code Description Remarks

07-01 5SNS P0012691 FRAME DOOR

07-02 5SNSP001 2685 COVER DOOR

07-03 5SNSP0012688 BELT CONVEYING

07-04 5SNSP001 2737 COVER SENSOR

07-05 5SNSP0012734 LEVER FULL 1

07-06 5SNSP0012735 LEVER FULL 2

07-07 5SNSP0012690 ROLLER IDLER

07-08 5SNS P0012608 BUSHING 6

07-09 5SNSP0012689 SHAFT ROLLER IDLER

07-10 5SNSP0012693 LEVER JAM

07-11 5SNSP0012694 SEAL LEVER JAM

07-12 5SNSP001 2686 BKT INTERLOCK JAM

07-13 5SNSP001 2687 SUPPORT DOOR LOCK

07-14 5SNSP0012601 STOPPER DOOR

07-15 5SNSP001 2697 PLATE STOPPER DOOR

07-16 5SNSP0012696 LOCKER DOOR

07-17 5SNSP0012695 SPRING LEVER JAM

07-18 5SNSP0012806 BEARING LF1360ZZ

07-19 5SNSP0012692 ROLLER CONVEYING BELT

07-20 5SNSASO 30E18 CONN. CORD

07-21 5SNSP0012738 TRAY MULTI

07-22 5SNSP001 2807 GUIDE TRAY MULTI

7-a 5MBTPB4010XZ BIND T-T SCREW

7-b 5MBTPB4008WZ BIND T-T SCREW

7-c 5MBSPC4008NZ CEMS SCREW

7-d 5MBTPB4008WZ BIND T-T SCREW

7-e 5MBCE5060XSP E STOP RING

7-f 5MBSPB4008NN BIND HD SCREW

SO-30

A-18

Page 54

A-8 Base Assembly

A-19

SO-30

Page 55

Ref. No. Part code Description Remarks

08-H 5SNSASO30E39

08-01 5SNSP001 2714 BKT HEIGHT ADJUST

08-02 5SNSP0012715 FRAME KC

08-03 5SNSP0012729 PLATE COVER L

08-04 5SNSP0012730 PLATE COVER R

08-05 5SNSP0012716 REINFORCEMENT SIDE

08-06 5SNSP0012726 COVER CASTER

08-07 5SNSP0012725 RAIL

08-08 5SNS P0012723 FRAME ADJUST

08-09 5SNSP0012724 PLATE JOINT

08-10 5SNSP001 2741 BKT JOINT

08-11 5SNSP001 2722 BKT ADJUST CASTER

08-12 5SNSP001 2728 SCREW ADJUST

08-13 5SNSP0012719 PLATE

08-14 5SNSP0012720 ROLLER CASTER

08-15 5SNSP0012721 SHAFT CASTER

08-16 5SNSP0012717 PLATE

08-17 5SNSP001 2718 MAGNET CATCH

8-a 5MBTPX4006TZ BRAS. TAP SCREW

8-b 5SNSP0012588 M4X7 ROUNDED END

8-c 5MBCE4060XSP E STOP RING

8-d 5MBTPX4008TZ BRAS. TAP SCREW

8-e 5MBSPB4008NZ BIND HD SCREW

8-f 5SNSP0012727 SCR4X10 WAVE

8-g 5SNSP0012590 M4X9 ROUNDED END

8-h 5MBSPP4006NZ PAN HEAD SCREW

8-I 5MBSPB4008NN BIND HD SCREW

DOOR ASSEMBLY

SO-30

A-20

Page 56

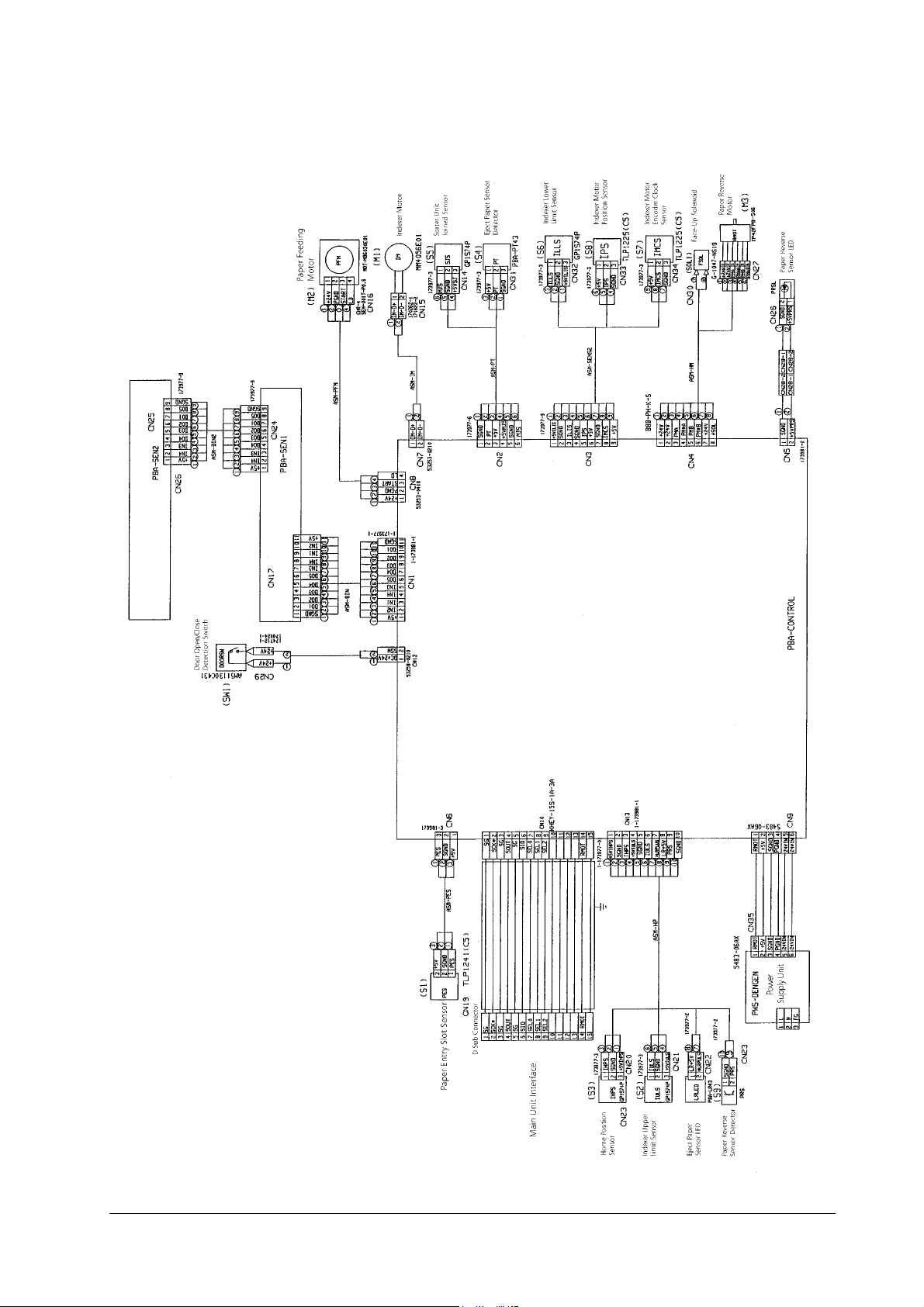

B-1 Wiring Diagram

A-21

SO-30

Page 57

Loading...

Loading...