Page 1

Wide Format Printer

Operation Guide

Please read the Operation Guide before using the printer.

Keep it in the designated location for easy reference.

Page 2

We have determined as a participating company in the International Energy Star

Program that this product is compliant with the standards laid out in the

International Energy Star Program.

About the International Energy Star Program

International Energy Star Program has as its basic goals the promotion of efficient

energy use and the reduction of the environmental pollution that accompanies

energy consumption by promoting the manufacture and sale of products that fulfill

program standards.

International Energy Star Program standards require that printers come equipped

with a “Sleep Mode”, allowing the device to enter a wait state where energy

consumption is automatically reduced to a minimum after a certain amount of time

elapses since it was last used.

This product is equipped with the following features as a result of its compliance

with International Energy Star Program standards.

• Sleep Mode

The device automatically enters “Sleep Mode” when 90 minutes have passed

since the device was last used. The amount of time of no activity that must pass

before “Sleep Mode” is activated may be lengthened. For more information see

“Auto Shutoff Function”.

• Paper Recycling

The Energy Star Program encourages the use of environmentally friendly

recycled paper. Your sales or service representative can provide information

about recommended paper types.

NOTE

• This Operation Guide applies to models KM-P4845w and KM-P4850w. For the

purposes of this guide, KM-P4845w is a 2.6 ppm (prints per minute) printer (A0

size) while KM-P4850w is a 3 ppm printer (A0 size).

• This Operation Guide contains content for both the inch and metric specification

models of the printer. When messages displayed on the printer’s display differ

only in their capitalization, this guide uses the message from the inch

specification model of the printer. When there are other differences, the metric

version of the message is included in parentheses.

All rights reserved. No part of this material may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including photocopying, recording

or by any information storage and retrieval system, without permission in writing

from the Publisher.

Legal Restriction On Copying

• It may be prohibited to copy copyrighted material without permission of the

copyright owner.

• It is prohibited under any circumstances to copy domestic or foreign currencies.

• Copying other items may be prohibited.

Page 3

Please read this Operation Guide before using the printer. Keep it close to the

printer for easy reference.

The sections of this guide and parts of the printer marked with symbols are safety warnings meant

to protect the user, other individuals and surrounding objects, and ensure correct and safe usage

of the printer. The symbols and their meanings are indicated below.

DANGER: Indicates that serious injury or even death will very possibly result from

insufficient attention to or incorrect compliance with the related points.

WARNING: Indicates that serious injury or even death may result from insufficient attention

to or incorrect compliance with the related points.

CAUTION: Indicates that personal injury or mechanical damage may result from insufficient

attention to or incorrect compliance with the related points.

Symbols

The m symbol indicates that the related section includes safety warnings. Specific points of

attention are indicated inside the symbol.

................. [General warning]

................. [Warning of danger of electrical shock]

................. [Warning of high temperature]

The symbol indicates that the related section includes information on prohibited actions. Specifics

of the prohibited action are indicated inside the symbol.

.................. [Warning of prohibited action]

................... [Disassembly prohibited]

The ● symbol indicates that the related section includes information on actions which must be

performed. Specifics of the required action are indicated inside the symbol.

.................. [Alert of required action]

.................. [Remove the power plug from the outlet]

.................. [Always connect the printer to an outlet with a ground connection]

Please contact your service representative to order a replacement if the safety warnings in this

Operation Guide are illegible or if the guide itself is missing. (fee required)

Page 4

Trademark Information

• Microsoft, Windows, Windows NT and Internet Explorer are registered trademarks of Microsoft Corporation of America and other countries.

• WINDOWS ME is a trademark of Microsoft Corporation of America.

• Adobe, Acrobat and PostScript are registered trademarks of Adobe Systems Incorporated.

• Ethernet is a registered trademark of Xerox Corporation.

• IBM and IBM PC-AT are trademarks of International Business Machines Corporation of America.

All other company and product names contained in this Operation Guide are trademarks or registered trademarks of their respective companies.

The designations ™ and ® will not be used in this guide.

About This Operation Guide

There are two parts to this guide:

• Operation Guide (this booklet)

Contains explanations of content related to setup procedure, printer operation, configuration, and troubleshooting.

• On-Line Manual

Contains explanations on operation from your computer such as how to use related software applications.

The On-Line Manual is prepared as a PDF (Portable Document Format) file on the CD-ROM that is included with the printer. Adobe Acrobat

Reader 4.0 software is required in order to read this On-Line Manual.

i

Page 5

Reading the On-Line Manual for This Machine

Insert the CD-ROM that is included with the printer into the CD-ROM drive of your computer, and then operate in accordance with the message on

the screen.

ii

Page 6

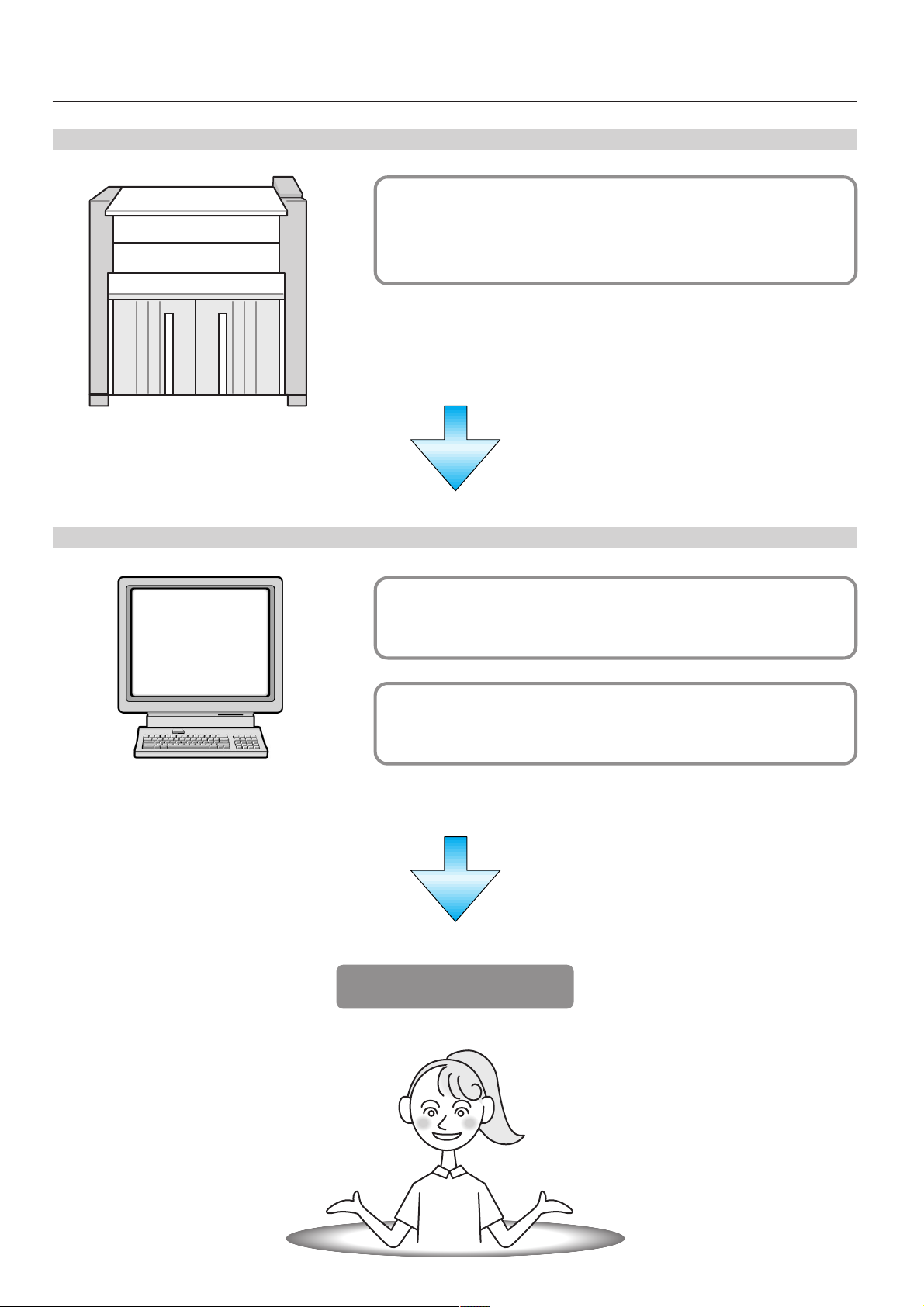

Setting Up the Printer

Configuring the Printer

Configuring Your Computer

1 Network Settings

[Configuring the IP Address, etc.]........................

[DHCP server setting] ......................................... Page 3-4

Page 3-2

Computer

2 Name Settings

[Changing the Work Group and Host Names]..... Page 3-5

3 Installing the Printer Driver

(Refer to the On-Line Manual.)

Printer Set-Up is Complete!

iii

Page 7

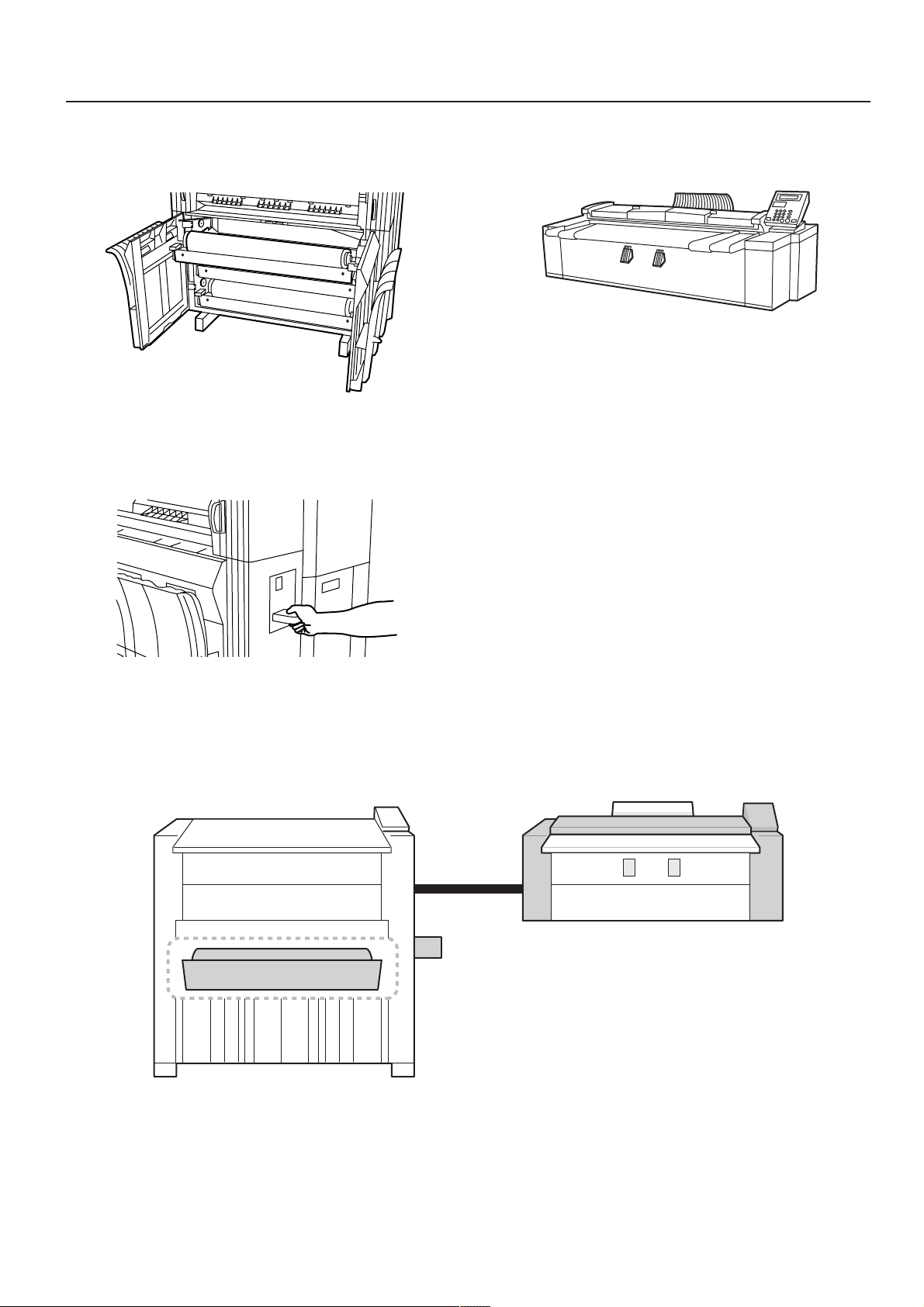

Options

■ <Roll unit>

To add a paper source.

■ <Key counter>

To count the number of sheets output.

■ <Scanner unit>

To add scanner and copier functions.

<System diagram with options installed>

Printer

Roll unit

Scanner unit

Key counter

iv

Page 8

Table of Contents

Trademark Information................................................ i

About This Operation Guide ....................................... i

Reading the On-Line Manual for This Machine .......... ii

Setting Up the Printer ................................................ iii

Options ......................................................................iv

CHAPTER 1

IMPORTANT! PLEASE READ FIRST. .1-1

CAUTION LABELS ....................................... 1-1

INSTALLATION PRECAUTIONS .................. 1-2

PRECAUTIONS FOR USE ........................... 1-3

CHAPTER 2

PRIOR TO SET-UP ................................2-1

1. Names of Parts .............................................. 2-1

(1) Main Body ......................................................... 2-1

(2) Operation Panel ................................................ 2-4

2. Required Items............................................... 2-5

3. Energy Saver Function .................................. 2-6

4. Auto Shutoff Function .................................... 2-6

CHAPTER 3

GETTING READY FOR PRINTING.......3-1

1. Setup.............................................................. 3-1

(1) System Configuration ........................................ 3-1

(2) Procedures ........................................................ 3-2

2. Paper ............................................................. 3-6

(1) Paper Type ........................................................ 3-6

(2) How to Set a Paper Roll .................................... 3-7

(3) Dew prevention heater ...................................... 3-9

(4) How to Use the Paper Tray Support Plate ........ 3-9

CHAPTER 5

MANAGEMENT AND SETTING............5-1

1. Machine Default ............................................. 5-1

(1) List of Machine Settings .................................... 5-1

(2) Configuring Machine Setting ............................. 5-4

2. Printer Settings ............................................ 5-11

(1) List of Printer Settings ..................................... 5-11

3. Language Switching..................................... 5-12

CHAPTER 6

TROUBLESHOOTING ..........................6-1

1. If One of These Messages is Displayed... ..... 6-1

2. Replenishing the Toner .................................. 6-3

3. Replacing the Waste Toner Tank ................... 6-5

4. Countermeasures against Call for service

Message ........................................................ 6-6

5. When Paper Jams ......................................... 6-7

(1) Jam Location Display ........................................ 6-7

(2) Cautions ............................................................ 6-7

(3) Removal Procedure .......................................... 6-7

6. Troubleshooting ........................................... 6-11

CHAPTER 7

SPECIFICATIONS .................................7-1

CHAPTER 4

PRINTER OPERATION .........................4-1

1. Basic printing ................................................. 4-1

2. Printing with manually fed media ................... 4-2

3. Making a Test Print ........................................ 4-3

4. Canceling Printing .......................................... 4-4

5. Resetting the printer....................................... 4-5

v

Page 9

CHAPTER 1 IMPORTANT!

PLEASE READ FIRST.

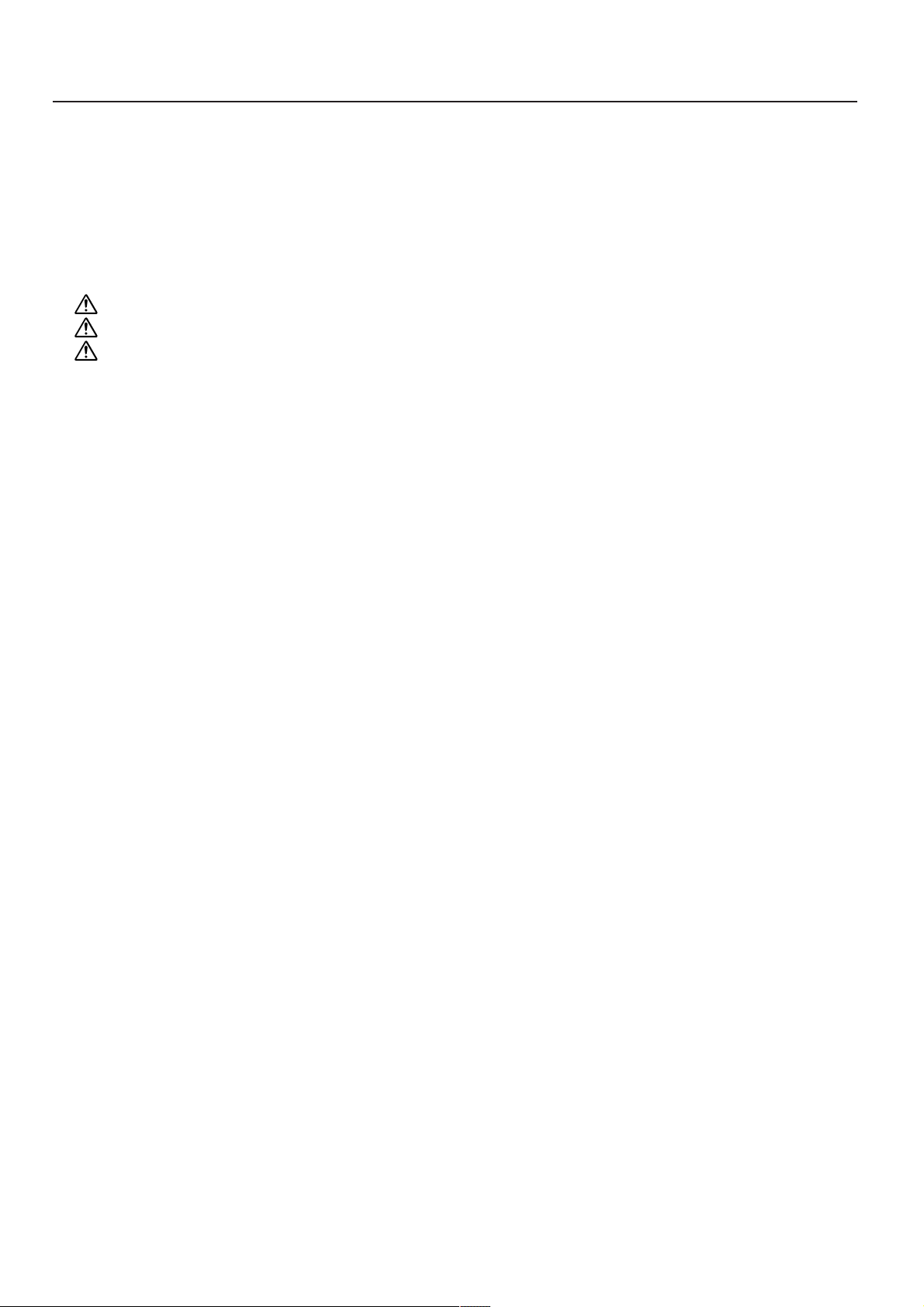

CAUTION LABELS

Caution labels have been attached to the printer at the following locations for safety purposes.

BE SUFFICIENTLY CAREFUL to avoid fire or electric shock when removing a paper jam.

Label 1

High temperature inside. Do not touch

parts in this area, because there is a

danger of getting burned.....................

Label 2 (Inch specification only)

High temperature inside. Do not touch

parts in this area, because there is a

danger of getting burned.....................

Label 3

High temperature inside. Do not touch

parts in this area, because there is a

danger of getting burned.....................

Label 4

High temperature inside. Do not touch

parts in this area, because there is a

danger of getting burned.....................

Label 5, 6, 7

High voltage inside. NEVER touch

parts in this area, because there is a

danger of electric shock. ....................

NOTE: DO NOT remove these labels.

1-1

Page 10

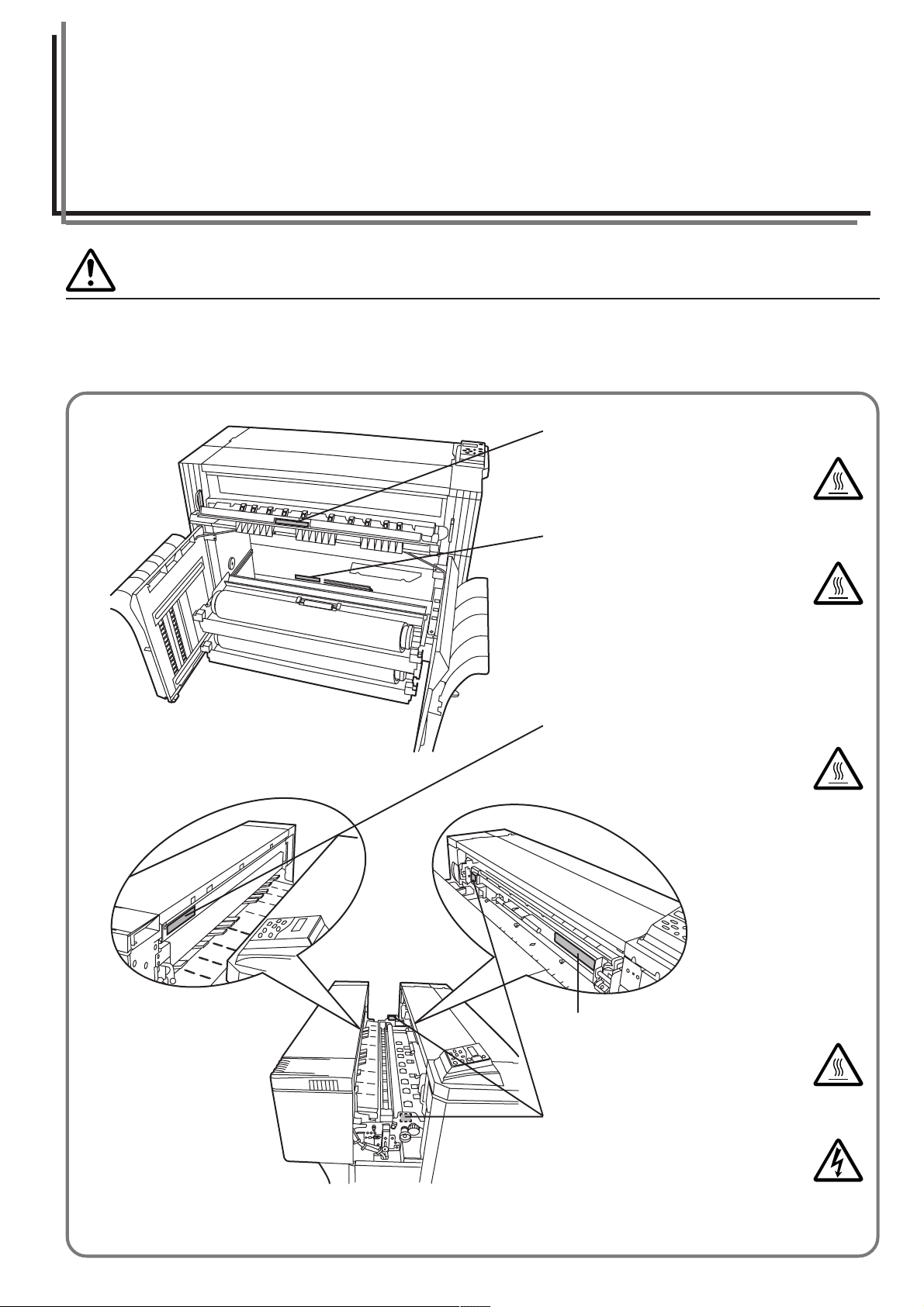

INSTALLATION PRECAUTIONS

■ Environment

CAUTION

• Avoid placing the printer on or in locations which

are unstable or not level. Such locations may

cause the printer to fall down or fall over. This

type of situation presents a danger of personal

injury or damage to the printer. ............................

• Avoid locations with humidity or dust and dirt. If

dust or dirt become attached to the power plug,

clean the plug to avoid the danger of fire or

electrical shock.....................................................

• Avoid locations near radiators, heaters, or other

heat sources, or locations near flammable items,

to avoid the danger of fire. ...................................

• To keep the printer cool and facilitate changing of

parts and maintenance, allow access space as

shown below.

Leave adequate space, especially around the left

right and rear covers, to allow air to be properly

ventilated out of the printer...................................

Rear:

>

11 13/16"

Left:

>

11 13/16"

=

30 cm

Front:

>

31 1/2"

=

80 cm

• Always use the caster stoppers to stabilize the

printer once it is in place to keep it from moving

and/or falling over and causing injury. ..................

Other precautions

• Adverse environmental conditions may affect the safe

operation and performance of the printer. Install in an

air-conditioned room (recommended room temperature:

around 68°F [20°C], humidity: around 65%RH) and

avoid the following locations when selecting a site for

the printer.

.

Avoid locations near a window or with exposure to

direct sunlight.

.

Avoid locations with vibrations.

.

Avoid locations with drastic temperature fluctuations.

.

Avoid locations with direct exposure to hot or cold air.

.

Avoid poorly ventilated locations.

=

30 cm

Right:

>

19 11/16"

=

50 cm

• If the floor is delicate against casters, when this product

is moved after installation, the floor material may be

damaged.

• During printing, some ozone is released, but the amount

does not cause any ill effect to one's health. If, however,

the printer is used over a long period of time in a poorly

ventilated room or when making an extremely large

number of copies, the smell may become unpleasant.

To maintain the appropriate environment for printing

work, it is suggested that the room be properly

ventilated.

■ Power supply/Grounding the printer

WARNING

• DO NOT use a power supply with a voltage other

than that specified. Avoid multiple connections in

the same outlet. These types of situations

present a danger of fire or electrical shock. .........

• Plug the power cord securely into the outlet. If

metallic objects come in contact with the prongs

on the plug, it may cause a fire or electric shock.

• Always connect the printer to an outlet with a

ground connection to avoid the danger of fire or

electrical shock in case of an electric short. If an

earth connection is not possible, contact your

service representative. .........................................

Other precautions

• Connect the power plug to the closest outlet possible to

the printer.

• The power supply cord is used as the main disconnect

device. Ensure that the socket/outlet is located/installed

near the equipment and is easily accessible.

■ Handling of plastic bags

WARNING

• Keep the plastic bags that are used with the

printer away from children. The plastic may cling

to their nose and mouth causing suffocation........

1-2

Page 11

PRECAUTIONS FOR USE

■ Cautions when using the printer

WARNING

• DO NOT place metallic objects or containers with

water (flower vases, flower pots, cups, etc.) on or

near the printer. This type of situation presents a

danger of fire or electrical shock should they fall

inside. ...................................................................

• DO NOT remove any of the covers from the

printer as there is a danger of electrical shock

from high voltage parts inside the printer. ............

• DO NOT damage, break or attempt to repair the

power cord. DO NOT place heavy objects on the

cord, pull it, bend it unnecessarily or cause any

other type of damage.

These types of situations present a danger of fire

or electrical shock. ...............................................

• NEVER attempt to repair or disassemble the

printer or its parts as there is a danger of fire,

electrical shock or damage to the laser................

• If the printer becomes excessively hot, smoke

appears from the printer, there is an odd smell, or

any other abnormal situation occurs, there is a

danger of fire or electrical shock. Turn the main

switch OFF ( ) immediately, remove the power

plug from the outlet and contact your service

representative. .....................................................

• If anything harmful (paper clips, water, other

fluids, etc.) falls into the printer, turn the main

switch OFF ( ) immediately. Next, remove the

power plug from the outlet to avoid the danger of

fire or electrical shock. Then contact your service

representative. .....................................................

CAUTION

• DO NOT pull the power cord when removing it

from the outlet. If the power cord is pulled, the

wires may become broken and there is a danger

of fire or electrical shock. (ALWAYS grasp the

power plug when removing the power cord from

the outlet.) ............................................................

• ALWAYS remove the power plug from the outlet

when moving the printer. If the power cord is

damaged, there is a danger of fire or electrical

shock. ...................................................................

• If the printer will not be used for a short period of

time (overnight, etc.), turn the main switch OFF

( ).

If it will not be used for an extended period of

time (vacations, etc.), remove the power plug

from the outlet for safety purposes during the

time the printer is not in use. ................................

• When moving the printer, turn the leveler bolts to

keep them away from the floor. ............................

• For safety purposes, ALWAYS remove the power

plug from the outlet when performing cleaning

operations. ...........................................................

• If dust accumulates within the printer, there is a

danger of fire or other trouble. It is therefore

recommended that you consult with your service

representative in regard to cleaning of internal

parts. This is particularly effective if accomplished

prior to seasons of high humidity. Consult with

your service representative in regard to the cost

of cleaning the internal parts of the printer. ..........

• DO NOT remove or connect the power plug with

wet hands, as there is a danger of electrical

shock. ...................................................................

• ALWAYS contact your service representative for

maintenance or repair of internal parts. ...............

1-3

Page 12

PRECAUTIONS FOR USE

Other precautions

• DO NOT place heavy objects on the printer or cause

other damage to the printer.

• DO NOT open the front cover, turn off the main switch,

or pull out the power plug during printing.

• When lifting or moving the printer, contact your service

representative.

• Do not touch electrical parts, such as connectors or

printed circuit boards. They could be damaged by static

electricity.

• DO NOT attempt to perform any operations not

explained in this handbook.

• CAUTION : Use of controls or adjustments or

performance of procedures other than those specified

herein may result in hazardous radiation exposure.

■ Cautions when handling

consumables

CAUTION

• DO NOT attempt to incinerate the toner

containers or the waste toner tank. Dangerous

sparks may cause burns. .....................................

• Keep the toner containers and the waste toner

tank out of the reach of children. ..........................

• If toner happens to spill from the toner containers

or the waste toner tank, avoid inhalation and

ingestion, as well as contact with your eyes and

skin. ......................................................................

.

If you do happen to inhale toner, move to a

place with fresh air and gargle thoroughly with a

large amount of water. If coughing develops,

contact a physician.

.

If you do happen to ingest toner, rinse your

mouth out with water and drink 1 or 2 cups of

water to dilute the contents of your stomach. If

necessary, contact a physician.

.

If you do happen to get toner in your eyes, flush

them thoroughly with water. If there is any

remaining tenderness, contact a physician.

.

If toner does happen to get on your skin, wash

with soap and water.

• DO NOT attempt to force open or destroy the

toner containers or the waste toner tank. .............

Other precautions

• After use, ALWAYS dispose of the toner containers and

the waste toner tank in accordance with Federal, State

and Local rules and regulations.

• Store all consumables in a cool, dark location.

• If you will not be using the printer for a prolonged period

of time, remove all paper from the drawer(s) and the

multi-bypass tray and seal in its original packaging.

1-4

Page 13

CHAPTER 2 PRIOR TO SET-UP

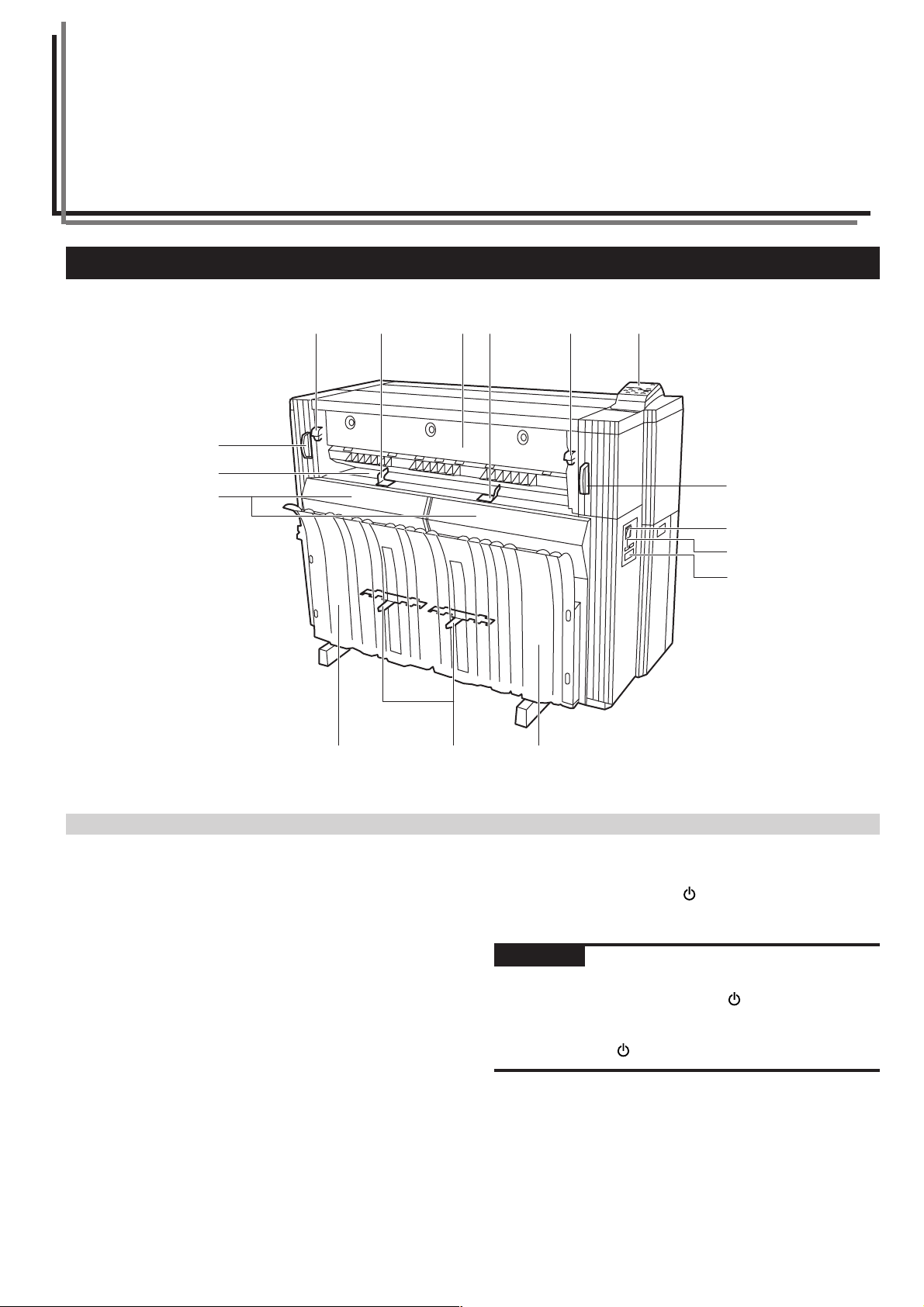

1. Names of Parts

4

5

7

8

3

123 6 6

4

0

!

@

89

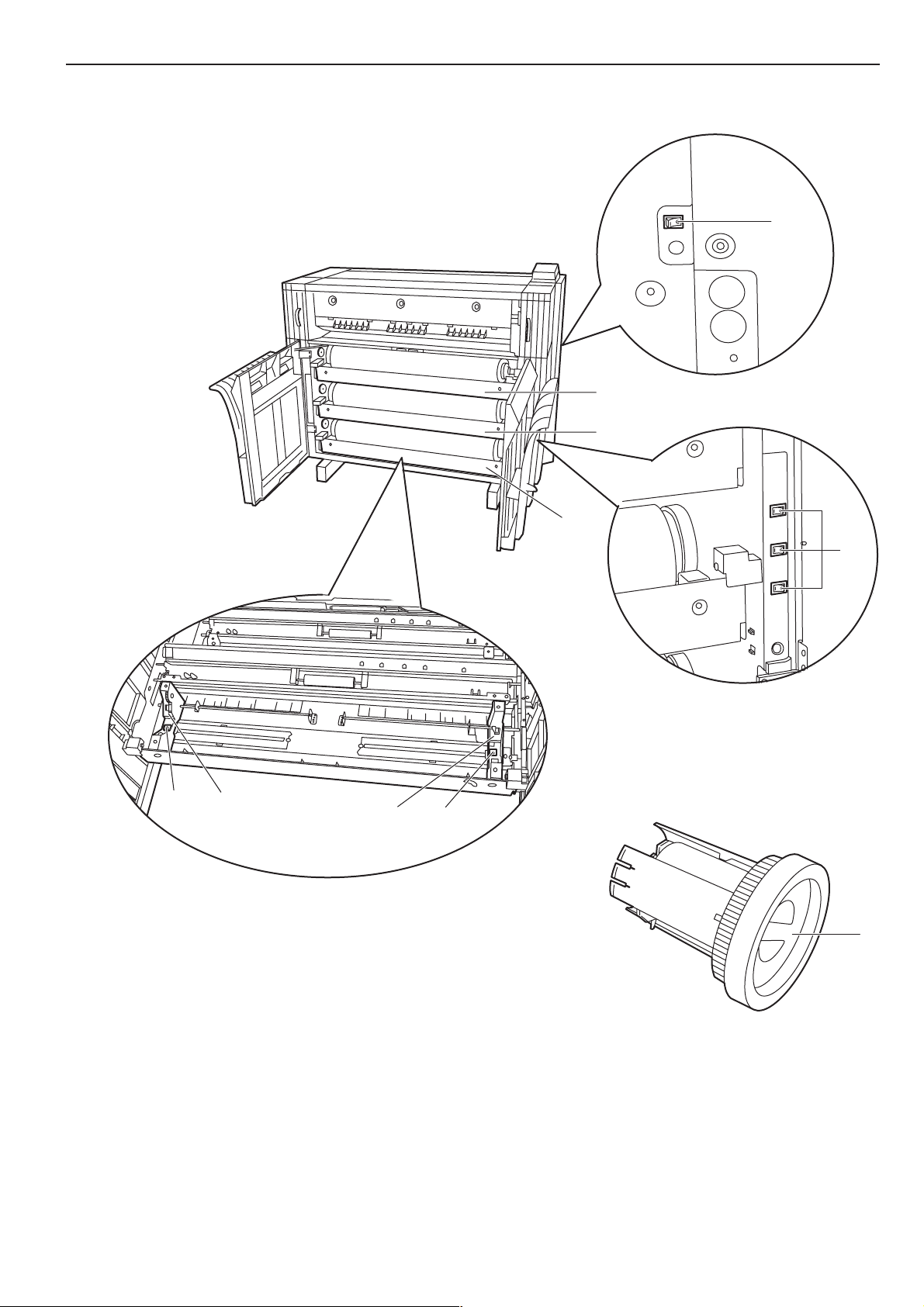

(1) Main Body

1 Operation panel

Use to make settings in the printer.

2 Ejection cover

Open in case of a paper jam.

3 Ejection release lever

Operate this lever in case of a paper jam.

4 Printer body release lever

Operate this lever in case of a paper jam.

5 Bypass table

When printing documents and using the manual paper feed

setting, set paper onto on this table.

6 Bypass guide

7 Front cover

Open to set paper roll or in case of a paper jam.

8 Paper tray

Printed sheets will be stored here.

9 Paper tray support plate

Set in accordance with paper size.

0 Main switch

Turn this switch ON ( | ) in order to use the printer. Conversely,

make sure this switch is OFF ( ) before connecting network

cables.

IMPORTANT

• Once you turn the main switch ON ( | ) wait for at least 20 seconds

or so before attempting to turn it OFF ( ) again. Failure to doing

so may damage the printer.

• Make sure that you wait at least for 5 seconds after turned the

main switch OFF ( ) to remove the power plug from the outlet.

! Total counter

This indicates the paper output length.

@ Key counter insert slot

When a key counter (option) is installed, insert the key counter

here.

2-1

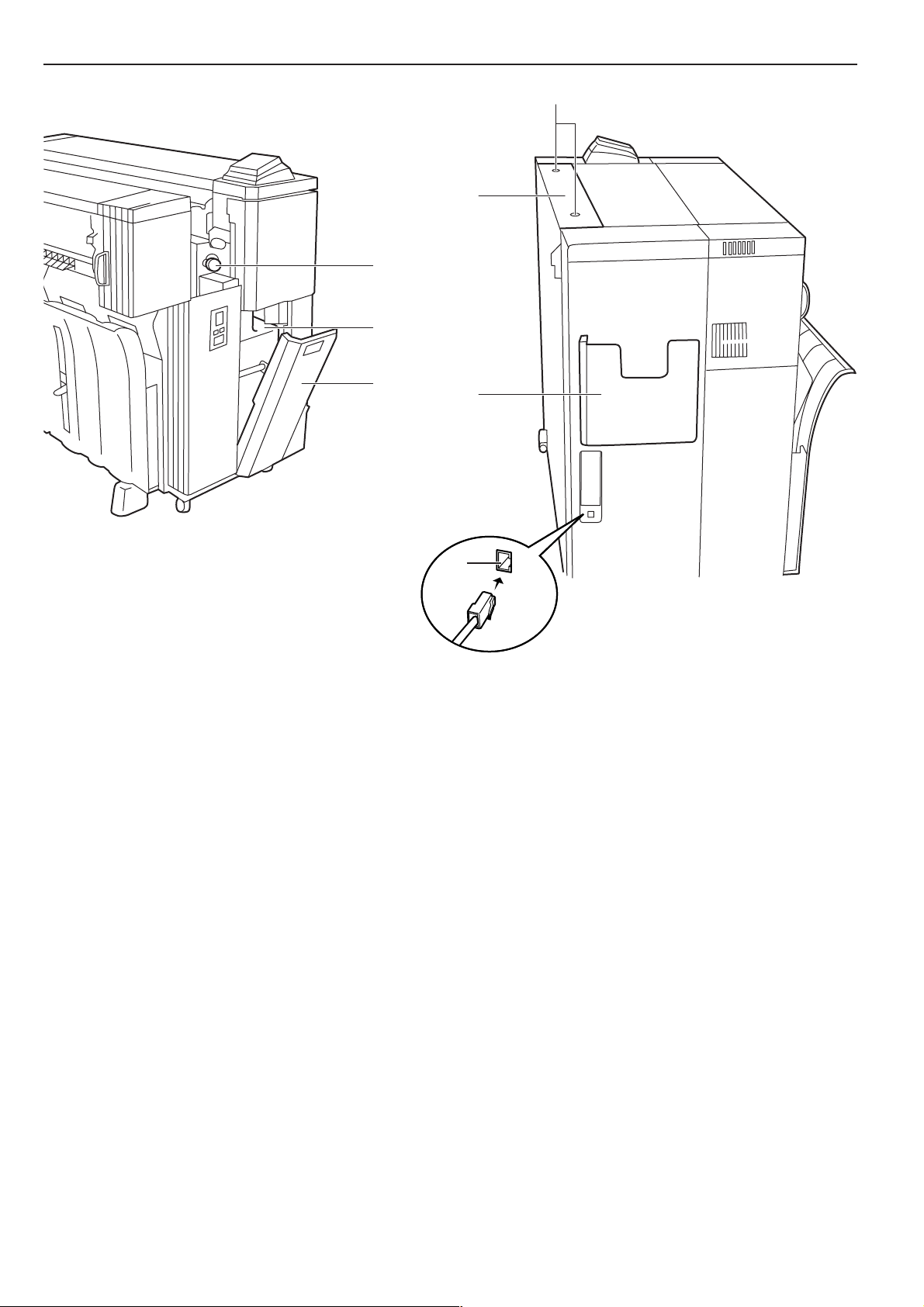

Page 14

CHAPTER 2 PRIOR TO SET-UP

^

%

¤

⁄

$

# Network interface connector

Use to connect the printer to the LAN (Local Area Network) with a

10BASE-T or 100BASE-TX cable.

$ Right cover

Open to replace the waste toner tank.

% Toner replenishing slot

Open to add toner.

^ Toner replenishing slot screw

Turn to open the toner replenishing slot.

& Roll unit (paper source 1: option)

* Roll unit (paper source 2)

( Roll unit (paper source 3)

) Operation Guide box

Keep the Operation Guide here.

)

#

⁄ Waste toner tank

¤ Paper transport knob

Operate this knob in case of a paper jam.

‹ Dew prevention heater switches

Switches for paper sources 1, 2, and 3.

› Main heater switch

If this switch is turned off, the dew prevention heaters will be

turned off even if the dew prevention heater switches inside the

front cover are on.

fi Flanges

Set these on both sides of the paper roll.

fl Release levers

‡ Flange guides

2-2

Page 15

CHAPTER 2 PRIOR TO SET-UP

&

*

(

‹

›

fl

fl

‡

‡

fi

2-3

Page 16

CHAPTER 2 PRIOR TO SET-UP

5

6

1

2 3 4

@

#

$

%

7

^

8

99

0!

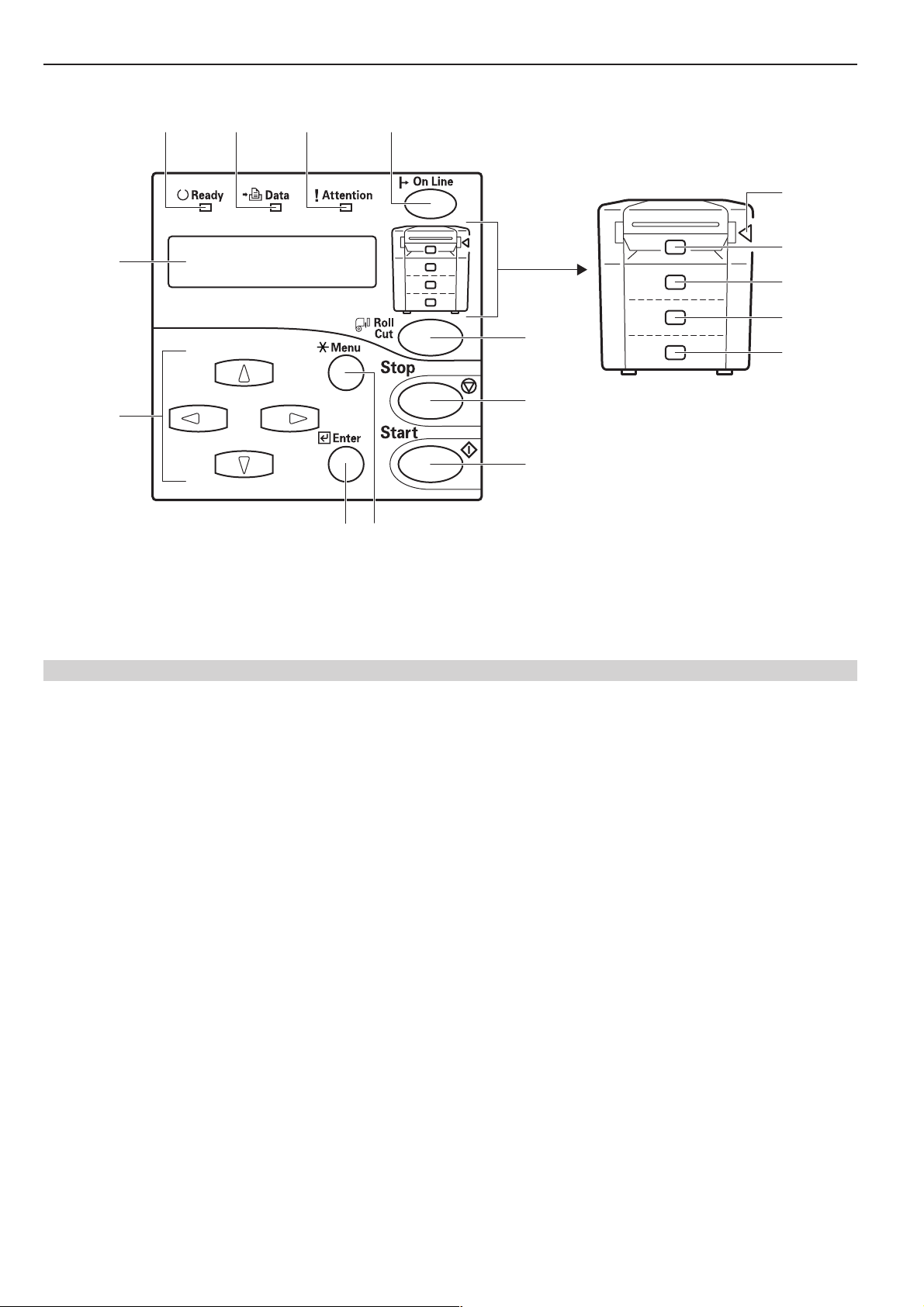

(2) Operation Panel

1 Ready indicator

This indicator is lit when the printer is on-line and goes out when it

is off-line. In addition, the indicator flashes while the internal server

computer is starting up.

2 Data indicator

This indicator flashes during printing.

3 Attention indicator

This indicator is lit when an error has occurred.

4 On Line key

Press this key when you want to switch the printer on- and off-line.

5 Message display

Machine status and errors are indicated on the message display.

6 MNOP Cursor keys

Use these cursor keys in order to select the various setting modes.

In addition, the N or M key may be used to select a paper tray.

7 Roll Cut key

Press this key when a new paper roll is set. Also press to force a

roll cut during output and to cancel printing.

8 Stop key

This key is used to cancel printing as well as in the configuration of

some settings to clear entered values.

9 Start key

Press this key to print to the currently set paper roll when the print

data’s page size and/or media type do not match those of the

current roll.

0 Enter key

Press this key when you want to register a setting. The Enter key

is also used to return to the printer to standard mode from energy

saver or sleep mode (Page 2-6).

! */Menu key

Press this key to configure the printer’s settings and output test

prints. (When the */Menu key has been pressed and one of the

printer setting screens is being displayed, the Ready indicator will

go out and the printer will be off-line.)

@ Internal paper jam indicator

This indicator is lit when a paper jam has occurred inside the

printer.

# Manual feed indicator

This indicator is lit when the manual feed has been selected and

when a paper jam has occurred in the manual feed mechanism.

$ Paper tray 1 indicator

This indicator is lit when the optional roll unit has been installed

and paper tray 1 has been selected, as well as when a paper jam

has occurred in paper tray 1.

% Paper tray 2 indicator

This indicator is lit when paper tray 2 has been selected as well as

when a paper jam has occurred in paper tray 2.

^ Paper tray 3 indicator

This indicator is lit when paper tray 3 has been selected as well as

when a paper jam has occurred in paper tray 3.

2-4

Page 17

2. Required Items

The following items are not included with the printer and must be

purchased separately.

• Network cable

(Twisted-pair 10BASE-T or 100BASE-TX [category 5])

NOTE

Be sure to use a “shielded type” network cable.

• Network hub

CHAPTER 2 PRIOR TO SET-UP

2-5

Page 18

CHAPTER 2 PRIOR TO SET-UP

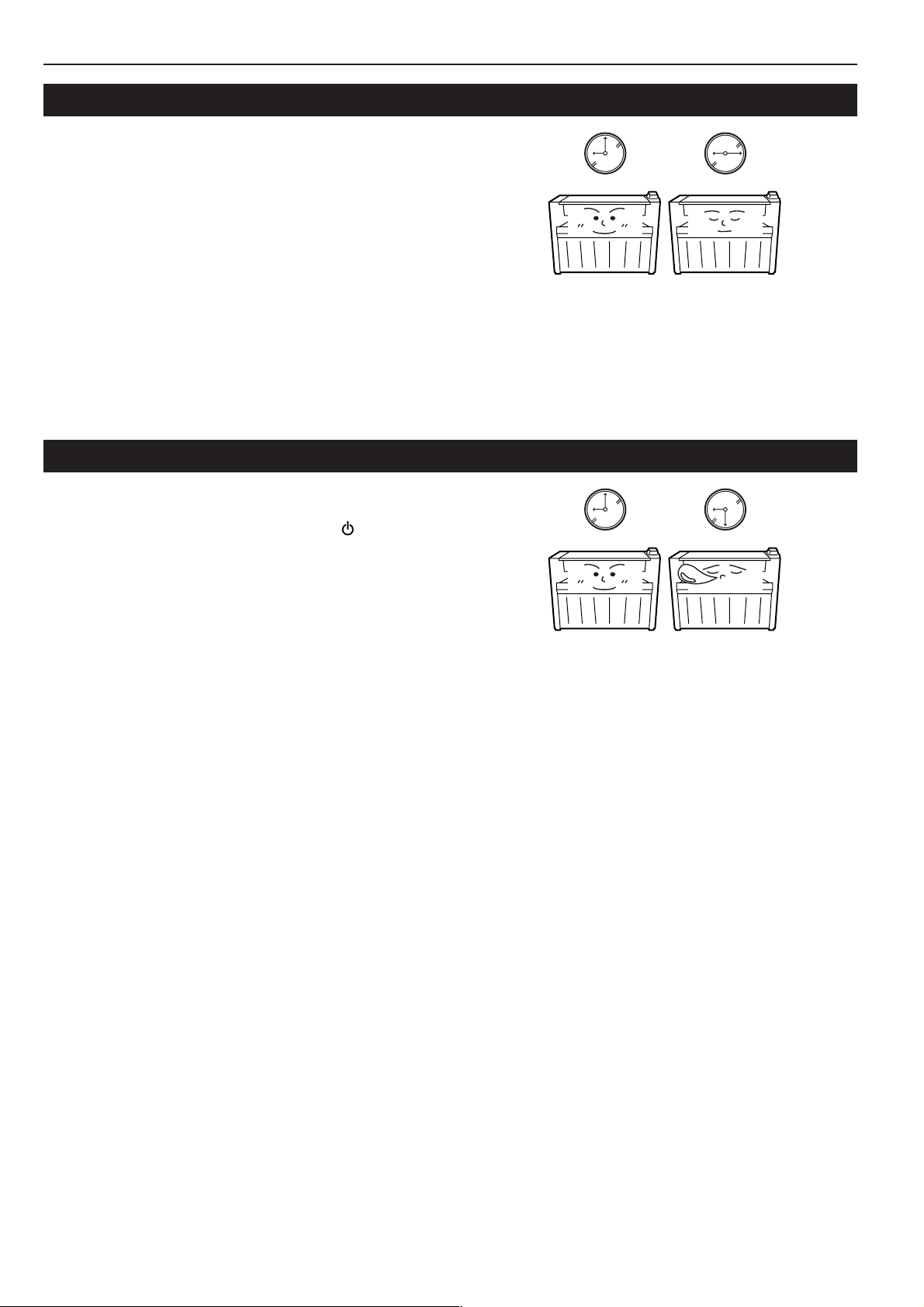

3. Energy Saver Function

The automatic energy saver function automatically sets the printer to

a low energy consumption mode when the printer has not been used

for a specific period of time. When in energy saver mode the

message “Pre heating” [“Now preheating”] will be displayed.

Upon detection of a print signal from the computer, the printer

automatically returns to its standard mode and starts printing.

Pressing the Enter key will also cause the printer to return to standard

mode. The time until the energy saver function activates (auto energy

saver time) is set to a factory default of 15 min. This value can be set

in the machine setting “6. Timer set” from 5 to 45 min., in 5 min.

increments (Page 5-8).

4. Auto Shutoff Function

The auto shutoff function consists of shutoff mode and sleep mode.

The factory default is set to sleep mode.

• Shutoff mode: Power is automatically turned OFF ( ) when the

printer has not been used for a specific period of time.

To return to normal operation from shut-off mode, turn ON ( | ) the

main switch.

• Sleep mode: The printer enters a sleep state when it has not been

used for a specific period of time. The message “Sleeping” will be

displayed when the printer is in sleep mode.

Upon detection of a print signal from the computer, the printer

automatically wakes up and starts printing. Pressing the Enter key

will also cause the printer to wake up.

The auto shut-off function can be configured in the machine setting

“5. Auto shutoff” (Page 5-7). The time until the auto shutoff feature

activates (auto shutoff time) is set to a factory default of 90 min.

This value can be set in the machine setting “6. Timer set” from 15 to

120 min., in 5 min. increments (Page 5-8).

2-6

Page 19

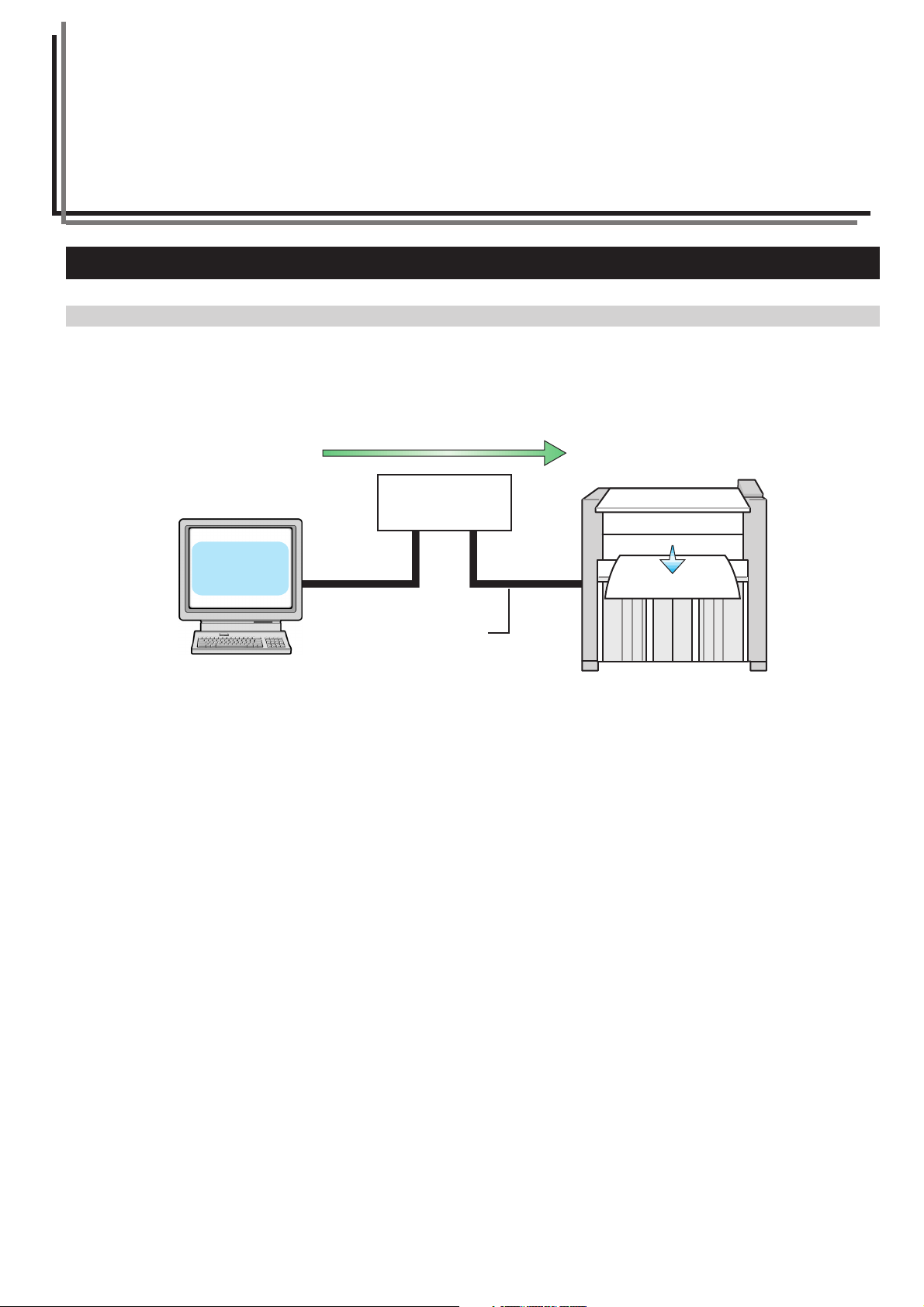

CHAPTER 3 GETTING READY FOR

PRINTING

1. Setup

(1) System Configuration

● Printing from Windows

Print command

Network hub

Printer driver

Printout

Computer

100BASE-TX

(or 10BASE-T) cable

3-1

Page 20

CHAPTER 3 GETTING READY FOR PRINTING

(2) Procedures

● Connecting the Printer to Your Network

Perform this procedure in order to connect the printer to the network

hub.

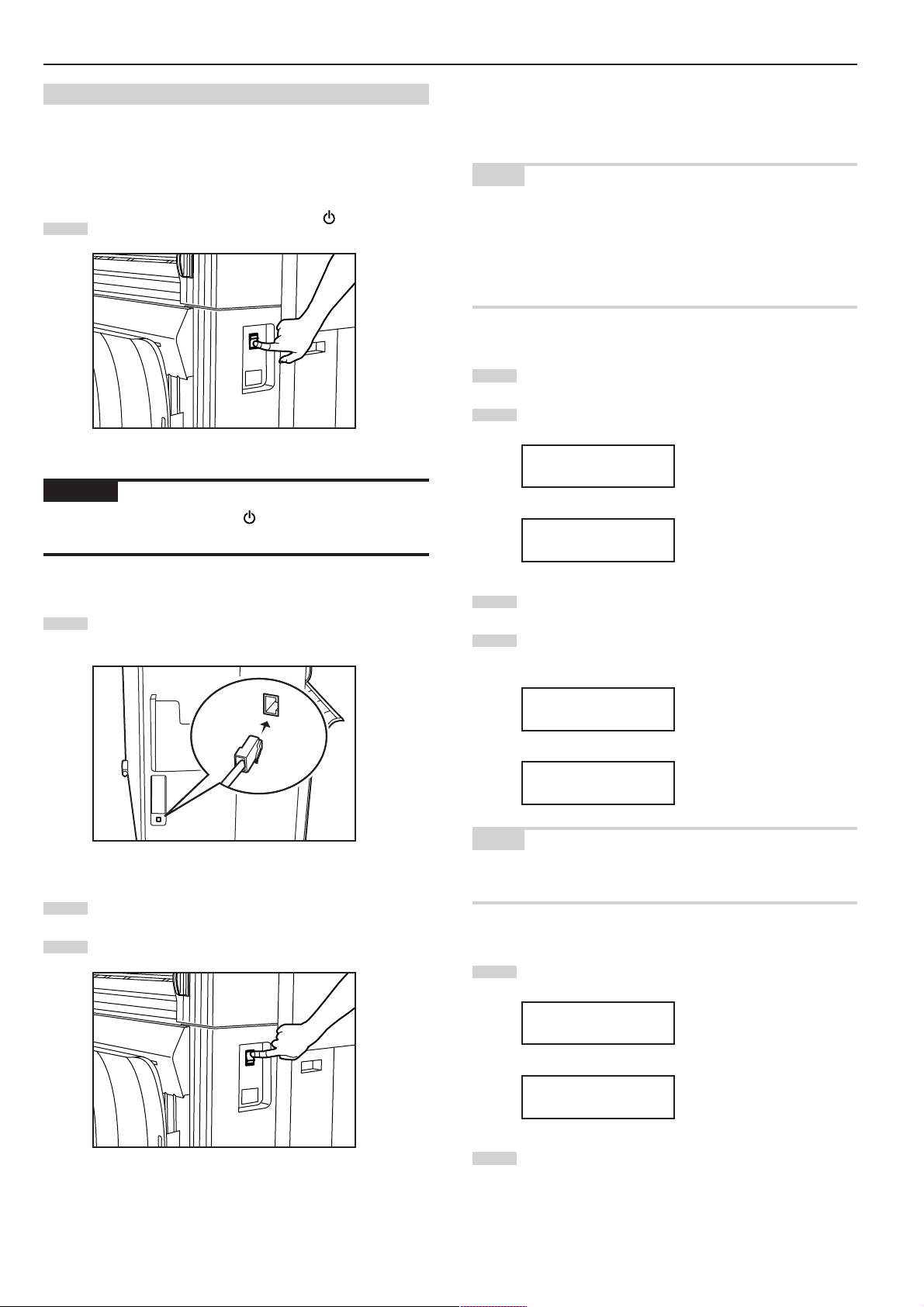

Turn the main switch on the printer OFF ( ).

1

CAUTION

Make sure the main switch is OFF ( ) before connecting the

network cable.

● Network Settings [Configuring the IP Address, etc.]

Perform this procedure in order to register the required network

settings.

NOTE

• The IP address to be used for the printer will differ depending upon

your network. Confirm the address that you need to use in advance

with your network manager.

• When you input the network address, be sure to check in advance

that the DHCP server setting is OFF.

• The “*” in a list of setting options indicates the current setting.

Press the */Menu key.

1

Press the N or M key to select “3. Set/manager”.

2

Inch specifications

Menu:

3.Set/manager

Metric specifications

Menu:

3.Set/manager

Plug the network cable into the Network Interface Connector

2

which is located on the left side of the printer.

Plug the other end of the network cable into the network hub.

3

Turn the main switch on the printer back ON ( | ).

4

Press the Enter key.

3

Use the MNOP cursor keys to input the pin code (the

4

default setting is qQrR).

Inch specifications

Enter pin code.

_ _ _ _

Metric specifications

Enter pin code.

_ _ _ _

NOTE

The pin code may be changed (see “11. Mgr. code change” on

page 5-10).

Press the N or M key to select “2. Set printer”.

5

Inch specifications

Set/manager:

2.Set printer

3-2

Metric specifications

Set/manager:

2.Set printer

Press the Enter key.

6

Page 21

CHAPTER 3 GETTING READY FOR PRINTING

Press the N or M key to select “4. IP address”.

7

Inch specifications

Set printer:

4.IP address

Metric specifications

Set printer:

4.IP address

Press the Enter key.

8

Use the MNOP cursor keys to input the IP address.

9

Inch specifications

IP address:

0. 0. 0. 0

Metric specifications

IP address:

0. 0. 0. 0

In order to set the IP address to “192.168.0.1”, perform the

following procedure.

1 Press the N or M key to display “192”.

Inch specifications

IP address:

192. 0. 0. 0

Metric specifications

IP address:

192. 0. 0. 0

2 Press the P key. The next value will flash.

Inch specifications

IP address:

192.

0. 0. 0

4 Press the P key. The next value will flash.

Inch specifications

IP address:

192.168.

Metric specifications

IP address:

192.168.

0. 0

0. 0

5 Press the P key. The next value will flash.

Inch specifications

IP address:

192.168. 0.

Metric specifications

IP address:

192.168. 0.

0

0

6 Press the N or M key to display “1”.

Inch specifications

IP address:

192.168. 0.

Metric specifications

IP address:

192.168. 0.

NOTE

Press the Stop key if you want to enter the address once again from

the beginning. The displayed IP address will return to its previous

value.

1

1

Metric specifications

IP address:

192.

0. 0. 0

3 Press the N or M key to display “168”.

Inch specifications

IP address:

168. 0. 0

192.

Metric specifications

IP address:

168. 0. 0

192.

Press the Enter key.

10

Use the same procedure in order to set the “5. Subnet

11

mask”, “6. Gateway”, and “7. DNS server” information.

Once you have completed all of the required settings, press

12

the N or M key to select “End” and then press the Enter key.

Inch specifications

Set printer:

End

Metric specifications

Set printer:

End

3-3

Page 22

CHAPTER 3 GETTING READY FOR PRINTING

Press the N or M key to select “End” [“back”] and press the

13

Enter key.

Inch specifications

Set/manager:

End

Metric specifications

Set/manager:

back

Press the N or M key to select “End” and press the Enter

14

key.

Inch specifications

Menu:

End

Metric specifications

Menu:

End

● DHCP server setting

If you use a DHCP server to assign the IP address of this machine,

perform this procedure in order to enable the DHCP server.

Press the */Menu key.

1

Press the N or M key to select “3. Set/manager”.

2

Inch specifications

Menu:

3.Set/manager

Press the N or M key to select “2. Set printer”.

5

Inch specifications

Set/manager:

2.Set printer

Metric specifications

Set/manager:

2.Set printer

Press the Enter key.

6

Press the N or M key to select “3. DHCP server”.

7

Inch specifications

Set printer:

3.DHCP server

Metric specifications

Set printer:

3.DHCP server

Press the Enter key.

8

The selected item will flash. Press the N or M key to select

9

“ON”.

Inch specifications

DHCP server:

Metric specifications

DHCP server:

ON

ON

Metric specifications

Menu:

3.Set/manager

Press the Enter key.

3

Use the MNOP cursor keys to input the pin code (the

4

default setting is qQrR).

Inch specifications

Enter pin code.

_ _ _ _

Metric specifications

Enter pin code.

_ _ _ _

NOTE

The pin code may be changed (see “11. Mgr. code change” on

page 5-10).

Press the Enter key.

10

Press the N or M key to select “End” and then press the

11

Enter key.

Inch specifications

Set printer:

End

Metric specifications

Set printer:

End

Press the N or M key to select “End” [“back”] and press the

12

Enter key.

Inch specifications

Set/manager:

End

Metric specifications

Set/manager:

back

3-4

Page 23

Press the N or M key to select “End” and press the Enter

13

key.

Inch specifications

Menu:

End

Metric specifications

Menu:

End

● Name Settings [Changing the Work Group and Host

Name]

Perform this procedure in order to register the required name settings

[the Work Group and host name].

* Refer to the On-Line Manual in the included CD-ROM for more

detailed information.

CHAPTER 3 GETTING READY FOR PRINTING

3-5

Page 24

CHAPTER 3 GETTING READY FOR PRINTING

2. Paper

(1) Paper Type

Note the following restrictions on paper that can be used in this

machine.

● Compatible paper

1. Paper source 1 (option), paper source 2, and paper source 3

• Paper roll width: 17" to 36" [210 to 920 mm]

• Paper roll outer diameter: 6 3/4" [180 mm] or less

• Paper roll inner diameter: 3" [76 mm (75.2 to 77.2 mm)]

• Acceptable paper roll types

Plain paper (64 to 80 g/m2)

Vellum

Film

In case of Memory...

Paper length differs depending on the memory used for this Printer.

Available

128 MB

256 MB

512 MB

memory

3.0 ppm

printer

2.6 ppm

printer

2. Bypass

• Paper sizes (standard paper): 8 1/2" x 11" to 36" x 48"

[A4 portrait to A0]

• Paper width: 8 1/2" to 36" [210 to 920 mm]

• Paper length: 11" to 48" [297 to 1189 mm]

• Acceptable paper materials

Plain paper (64 to 80 g/m2)

Vellum

Film

11" to 48"

[297 to 1189

mm]

(as Standard)

11" to 118"

[297 to 3000

mm]

(as Standard)

Not available

11" to 236"

[297 to 6000

mm]

Not available

● Unacceptable paper

• Paper other than the paper described in “● Compatible paper”

• Paper with staples, etc.

• If paper is wrinkled, folded or broken, unroll the paper until the

problem disappears and cut the paper before using it.

● Automatic paper width detection

If the paper roll that has been set is of a standard size, the paper

width will be automatically detected. The following sizes can be

detected.

Inch specifications

<Architecture>

36"

30"

24"

18"

15"

12"

9"

<Engineering>

34"

30"

22"

17"

15"

11"

8 1/2"

NOTE

• Automatic detection will not function for the bypass.

• Paper width of non-standard sizes can be registered. See “1. Paper

width” in the default setting. (Page 5-6)

• For switching between standard sizes (architecture/engineering

[A sizes/ B sizes]), see “9. Standard size” in the default settings.

(Page 5-9)

Metric specifications

<A sizes>

A0: 841mm

A1: 594mm

A2: 420mm

A3: 297mm

A4: 210mm

<B sizes>

B1: 728mm

B2: 515mm

B3: 364mm

B4: 257mm

● Storage of paper

If the machine is not used for an extended period time, remove the

paper roll and return it to its original packaging and reseal it.

IMPORTANT

• Vellum

Since vellum is very susceptible to its environment, when it is not

used, put it in a plastic bag and seal it.

• When using vellum at a high humidity or at a low temperature,

vellum will become fragile, resulting in wrinkles prints or missing

images. If images are not properly printed, perform the following

procedure.

* When using cut vellum:

Change the orientation of the paper (portrait or landscape).

* When using a vellum roll:

Unroll 1 length of paper and cut the paper before using it.

• When using roll paper whose surface is contaminated with

adhesive, remove the adhesive or unroll the paper until the adhesive

is no longer visible and cut off the unusable length.

3-6

Page 25

CHAPTER 3 GETTING READY FOR PRINTING

(2) How to Set a Paper Roll

Use the same procedure when replacing a paper roll.

IMPORTANT

When replacing a paper roll, turn the flanges on both sides to rewind

the paper.

Open the front cover until it locks.

1

Grasp the roll unit handles A to release the lock and pull out

2

the roll unit until it stops.

A

A

Grasp the flange and turn its lever in the direction indicated

5

by the arrow to align the inside and outside m marks on the

flange. The flange will be secured to the paper roll.

IMPORTANT

If the lever of the flange is not easily turned, attach the included

flange handle B and turn the flange handle in the direction indicated

by the arrow to align the inside and outside m marks on the flange.

* Also if the lever of the flange is not easily turned when the flange is

removed, use the flange handle.

Lift up the release levers 1 and adjust the flange guides 2

3

on both sides to the paper size.

2

1

Insert an included flange into the core of the new roll.

4

B

Secure the other flange to the paper roll similarly.

6

Set the paper roll in the roll unit by aligning it with the flange

7

guides 2.

After setting the paper roll, check that the flange tray has not

moved.

2

2

3-7

Page 26

CHAPTER 3 GETTING READY FOR PRINTING

Grasp both paper roll insertion latches 3 and open the

8

paper roll insertion cover 4.

3

4

3

Insert the leading edge of the paper under the paper roll

9

insertion guide and advance the edge past the guide

approximately 1/2" [10 mm] as shown in the illustration.

1/2"

[10mm]

IMPORTANT

If the paper roll that has been set is slackened, grasp the flange and

wind the paper roll to remove the slack. If not, the paper may be fed

obliquely.

Insert the roll unit securely into the main body of the

11

machine.

Close the front cover.

12

NOTE

If the leading edge of the paper roll is folded or broken, cut a clean

edge using a cutter.

Grasp the paper roll insertion latches and close the paper roll

10

insertion cover securely.

To align the leading edge of the paper roll, use the N or M

13

key to select a paper tray and press the Roll Cut key. The

leading edge of the paper roll will be ejected from the paper

eject slot.

NOTE

• Paper is normally cut in lengths of 11" [279 mm]. If the temperature

in the machine is lower than 15 °C, however, vellum will be cut in

lengths of 31" [800 mm].

• When a paper roll has been replaced during printing, press the On

Line key to place the printer offline and then press the Roll Cut key.

To continue printing press the On Line key once more to place the

printer online.

3-8

Page 27

CHAPTER 3 GETTING READY FOR PRINTING

(3) Dew prevention heater

If the humidity is high (more than 70 %RH) or drastic temperature

change occurs, turn on ( l ) the dew prevention heater switch when

using the machine. Even if the main switch is off ( ), the dew

prevention heater switch can be on ( l ).

IMPORTANT

When using vellum or film, be sure to turn off ( O ) the dew prevention

heater switch. If not, paper may be wrinkled or curled.

(4) How to Use the Paper Tray Support Plate

Set the paper tray support plate based on the paper to be used for

printing.

Incline the paper tray support plate and slide it to the size

1

indication on the size label of the paper tray.

After setting the paper tray support plate to the desired size,

2

return it to a horizontal state.

Follow the same procedure to set the other paper tray

3

support plate to the same height.

Depending on the paper to be used and the environment, the

support plate may not be contained at the position of the size

label. In this case, adjust the position of the paper tray

support plate upward or downward.

3-9

Page 28

CHAPTER 3 GETTING READY FOR PRINTING

3-10

Page 29

CHAPTER 4 PRINTER OPERATION

1. Basic printing

Perform this procedure in order to send commands to the printer from

your computer.

Turn the main switch on the printer ON ( | ).

1

The printer will begin to warm up and “Ready to print.” will be

displayed once warm-up is complete.

CAUTION

Make sure that the Ready indicator is lit.

2

Perform the appropriate printing procedure on your

3

computer.

NOTE

Refer to the On-Line Manual for more detailed information on printing

from your computer.

If the printer will not be used for a short period of time

(overnight, etc.), turn the main switch OFF ( ). If it

will not be used for an extended period of time

(vacations, etc.), remove the power plug from the

outlet for safety purposes during the time the printer

is not in use.

4-1

Page 30

CHAPTER 4 PRINTER OPERATION

2. Printing with manually fed media

When printing through the bypass slot, perform the following

procedure.

NOTE

• Only one sheet of paper can be set onto the bypass table at a time.

• When using curled paper, smooth the paper. If the curling persists,

place the paper with the curled surface up.

Adjust the bypass guides to the paper size indications on

1

both sides of the bypass table.

Perform the appropriate printing procedure on your

3

computer.

NOTE

Refer to the On-Line Manual for more detailed information on printing

from your computer.

When the message “Set paper. bypass” appears, refer to

4

Step 2 and set the next sheet onto the bypass table. Printing

will start. Repeat this procedure to set sheets one at a time

onto the bypass table until the required number of sheets

has been loaded and printed.

Set the paper face down all the way into the feed slot aligned

2

with the paper size indication.

When placing paper in the bypass table, set the paper

quickly all the way into the feed slot. Once the paper is fed,

release the paper. If the paper is not set properly, a paper

jam may be detected.

If the paper is set obliquely, pull the paper out and then insert

it again.

4-2

Page 31

3. Making a Test Print

CHAPTER 4 PRINTER OPERATION

Perform this procedure to send a test print command from the

printer’s operation panel.

NOTE

In order to make a test print, ensure that paper roll of a width of

210 mm or more is set in paper source 2.

Press the */ Menu key.

1

Press the N or M key to select “2. Test print”.

6

Inch specifications

Set printer:

2.Test print

Metric specifications

Set printer:

2.Test print

Press the Enter key.

7

A test print will be automatically output.

NOTE

Making a test print from the Web Manager interface

It is possible to use an Internet Web browser on a client computer to

access the Web Manager interface and print out a list of setting

information.

For a more detailed explanation, refer to the On-Line Manual.

Press the N or M key to select “2. Set/user”.

2

Inch specifications

Menu:

2.Set/user.

Metric specifications

Menu:

2.Set/user

Press the Enter key.

3

Press the N or M key to select “2. Set printer”.

4

Inch specifications

Set/user:

2.Set printer

Metric specifications

Set/user:

2.Set printer

Press the Enter key.

5

4-3

Page 32

CHAPTER 4 PRINTER OPERATION

4. Canceling Printing

If “Processing data.” or “Printing” [“Now printing.”] is shown in the

message display, press the Stop key. The current print job will be

cancelled.

Inch specifications

Processing data.

Printing

Metric specifications

Processing data.

Now printing.

Press the Roll Cut key to cut the sheet being printed and immediately

stop printing.

4-4

Page 33

5. Resetting the printer

CHAPTER 4 PRINTER OPERATION

If the printer operation stops or becomes unstable, reset the printer

and reboot the internal server computer.

Press the */Menu key.

1

Press the N or M key to select “2. Set/user”.

2

Inch specifications

Menu:

2.Set/user.

Metric specifications

Menu:

2.Set/user

The selected option will flash. Press the N or M key to

8

select “Yes”.

Inch specifications

Reset?

Metric specifications

Reset?

Press the Enter key.

9

All scheduled print jobs will be canceled.

Yes

Yes

Press the Enter key.

3

Press the N or M key to select “2. Set printer”.

4

Inch specifications

Set/user:

2.Set printer

Metric specifications

Set/user:

2.Set printer

Press the Enter key.

5

Press the N or M key to select “1.Reset”.

6

Inch specifications

Set printer:

1.Reset

Metric specifications

Set printer:

1.Reset

Press the Enter key.

7

4-5

Page 34

CHAPTER 4 PRINTER OPERATION

4-6

Page 35

CHAPTER 5 MANAGEMENT AND

SETTING

The */Menu key on the operation panel can be used to configure settings such as the paper width and media type for each of the paper trays, the

printer’s IP address, etc.

Based on their content, settings are divided into “Machine settings” that configure the printer’s operation and “Printer settings” that configure the

printer’s IP address and related network information. In addition they are divided according access privilege: there is a subset that offers limited

control to any “User”, while full access to all settings is reserved for the “Manager”. Input of the pin code is required for the manager to configure

settings.

For a description of each setting, see “(1) List of Machine Settings” and “(1) List of Printer Settings” (Page 5-11).

1. Machine Default

(1) List of Machine Settings

● Settings common to user/manager

Setting

1. Paper width

2. Media Type

[Pre-set Temp.]

3. Paper type

[Paper

material]

Description

If this item is set to “Input size”, a non-standard paper width

can be set. Use the N or M key to enter the paper width for

each paper source.

If this item is set to “ON”, a media type can be registered for

each paper source. Fixing temperature, print size, and fix/

unfix of roll end will be set based on the registered paper

material.

If “2. Media Type [Pre-set Temp.]” is set to “ON”, a media

type can be set for each paper source including the bypass

table.

If “Custom” is selected, fixing temperature, print size, etc. will

be set based on “8. Custom paper”.

Selectable values

For each paper

source:

Auto size/

Input size (17"~36"

[210mm~920mm])

ON/OFF

For each paper

source:

Plain/Vellum/

Film/Custom

Default

Auto size

OFF

Plain

Page

5-6

5-6

5-6

4. Roll end

This item sets whether or not paper roll end is fixed to the

core of the roll. If “Fixed” is selected, paper will be

automatically cut when paper runs out.

For each paper

material:

Unfix [Unfixed]/

Fixed

Unfix [Unfixed]

(Film: Fixed)

5-7

5-1

Page 36

CHAPTER 5 MANAGEMENT AND SETTING

● Settings accessible by manager

Setting

5. Auto shutoff

6. Timer set

7. Fusing temp.

Description

This setting allows the selection of two modes of

operation that take effect when the printer has

not been used for a specific period of time:

shutoff mode, which automatically turns off the

printer (Page 2-6), or sleep mode, which

automatically places the printer in a sleep state

(Page 2-6). You may also choose “OFF” if you

will not be using the auto shutoff feature.

This item sets the time that elapses before auto

energy saver (Page 2-6) or auto shutoff

(Page 2-6) is activated.

If the printer is used frequently, it is

recommended that the time for auto shutoff be

longer. If the printer is not used for long periods

of time, it is recommended that the time be

shorter.

The fixing temperature can be changed for each

media type. Set a higher temperature for thick

paper and a lower temperature for thin paper.

* For custom paper, a fixing temperature for the

paper material selected in “8. Custom paper”

can be selected.

Selectable values

Shutoff mode/

Sleep mode/OFF

Auto energy saver time:

5 to 45 minutes in 5 minute

increments

Auto shutoff time:

15 to 120 minutes in 5 minute

increments

Plain:

145 °C, 155 °C, 165 °C

Vellum:

165 °C, 175 °C, 185 °C

Film:

150 °C, 160 °C, 170 °C

Custom:

The media type configured in

“8. Custom paper” and its

respective fixing temperatures.

Default

Sleep mode

15 minutes

90 minutes

155 °C

175 °C

150 °C

Vellum

165 °C

Page

5-7

5-8

5-9

8. Custom paper

This setting allows the selection of a media type

for custom paper. The selection made here is

linked to the “7. Fusing temp.” custom settings.

Plain/Vellum/Film

Vellum

5-9

5-2

Page 37

CHAPTER 5 MANAGEMENT AND SETTING

Setting

9. Standard size

10. Buzzer

Description

Select either “Architecture” or “Engineering” [“A sizes” or “B

sizes”] for the paper size. This will change the media widths

that are automatically detected by the printer.

When the printer runs out of paper or experiences a paper

jam during printing, this status can be conveyed by a buzzer

in addition to the messages displayed on the operation

panel. This feature is particularly convenient when the

printer is not located in the immediate vicinity of the operator.

The buzzer sounds at the following conditions:

• When the printer runs out of paper during printing;

• When the data page size and/or media type differ from

those of the selected paper tray;

• When there is a paper jam;

• When the printer runs out of toner;

• When the waste toner tank is full;

• When the “Call service” message is displayed;

• When another printer error has activated the Attention

indicator on the operation panel.

* To stop the buzzer, press the Stop key or open and close

the front cover.

Selectable values

Architecture/

Engineering

[A sizes/B sizes]

ON/OFF

Default

Architecture

[A sizes]

ON

Page

5-9

5-10

11. Mgr. code

change

The password setting for manager can be changed.

* Using the MNOP cursor keys, select a 4-symbol

combination of the up/down/left/right arrows to set the pin

code.

* When changing the pin code, it is recommended that you

make a note of the new code.

– – – – –

qQrR

5-10

5-3

Page 38

CHAPTER 5 MANAGEMENT AND SETTING

(2) Configuring Machine Setting

● Configuration by user

Press the */Menu key.

1

Press the N or M key to select “2. Set/user”.

2

Inch specifications

Menu:

2.Set/user.

Metric specifications

Menu:

2.Set/user

Press the Enter key.

3

Press the N or M key to select a setting and press the Enter

6

key.

Inch specifications

Set Machine:

1.Paper width

Metric specifications

Set Machine:

1.Paper width

Configure each item, referring to the following pages:

1. Paper width···Page 5-6

2. Media Type [Pre-set Temp.]···Page 5-6

3. Paper type [Paper material]···Page 5-6

4. Roll end···Page 5-7

* The “*” in a list of setting options indicates the current

setting.

To configure another item, return to step 6.

7

To complete configuration, press the N or M key to select

“End” [“back”] and press the Enter key.

NOTE

• After each item has been configured, press the */Menu key to return

to the “Ready to print.” screen.

• If you make a mistake when configuring an item, press the */Menu

key. The display will return to the “Ready to print.” screen, leaving

the setting unchanged.

Press the N or M key to select “1. Set machine”.

4

Inch specifications

Set/user:

1.Set machine

Metric specifications

Set/user:

1.Set machine

Press the Enter key.

5

Press the N or M key to select “End” and press the Enter

8

key.

5-4

Page 39

CHAPTER 5 MANAGEMENT AND SETTING

● Configuration by manager

Press the */Menu key.

1

Press the N or M key to select “2. Set/manager”.

2

Inch specifications

Menu:

3.Set/manager

Metric specifications

Menu:

3.Set/manager

Press the Enter key.

3

Use the MNOP cursor keys to input the pin code (the

4

default setting is qQrR).

Inch specifications

Enter pin code.

_ _ _ _

Metric specifications

Enter pin code.

_ _ _ _

Press the N or M key to select “1. Set machine”.

5

Inch specifications

Set/manager:

1.Set machine

Metric specifications

Set/manager:

1.Set machine

Press the Enter key.

6

Press the N or M key to select a setting and press the Enter

7

key.

Inch specifications

Set Machine:

1.Paper width

Metric specifications

Set Machine:

1.Paper width

Configure each item, referring to the following pages:

1. Paper width···Page 5-6

2. Media Type [Pre-set Temp.]···Page 5-6

3. Paper type [Paper material]···Page 5-6

4. Roll end···Page 5-7

5. Auto shutoff···Page 5-7

6. Timer set···Page 5-8

7. Fusing temp.···Page 5-9

8. Custom paper···Page 5-9

9. Standard size···Page 5-9

10. Buzzer···Page 5-10

11. Mgr. code change···Page 5-10

* The “*” in a list of setting options indicates the current

setting.

NOTE

The pin code may be changed (see “11. Mgr. code change” on

page 5-10).

To configure another item, return to step 6.

8

To complete configuration, press the N or M key to select

“End” [“back”] and press the Enter key.

NOTE

• After each item has been configured, press the */Menu key to return

to the “Ready to print.” screen.

• If you make a mistake when configuring an item, press the */Menu

key. The display will return to the “Ready to print.” screen, leaving

the setting unchanged.

Press the N or M key to select “End” and press the Enter

9

key.

5-5

Page 40

CHAPTER 5 MANAGEMENT AND SETTING

● Configuring of each item

1. Paper width

Press the N or M key to select the desired paper source.

1

*When the optional roll unit is not installed, “Drawer 1” [“1st

paper”] may not be selected.

Inch specifications

Paper width:

1.Drawer 2

Metric specifications

Paper width:

1.2nd paper

Press the Enter key.

2

The selected item will flash. To enable automatic detection,

3

press the N or M key to select “Auto size”and proceed to

step 6.

To enter the paper width, select “Input size”and proceed to

the next step.

Inch specifications

Drawer 2:

Auto size*

Metric specifications

2nd paper:

Auto size*

Press the Enter key.

4

Enter a paper width between 17" and 36" (210 mm –

5

920 mm).

The paper width is entered one digit at a time. Use the O or

P key to select a digit and then use the N or M key to enter

the desired value.

Inch specifications

input size:

Drawer 2

Metric specifications

input size:

2nd paper

Press the Enter key. The display will show “set (

6

return to the step 1 screen.

36.0”*

920mm*

value

) *” and

2. Media Type [Pre-set Temp.]

The selected item will flash. To enable registration of media

1

types for each paper source, press the N or M key to select

“ON”.

Inch specifications

Media Type:

Metric specifications

Pre-set Temp.:

Press the Enter key. The display will show “set (

2

return to machine settings screen.

3. Paper type [Paper material]

NOTE

When “2. Media Type [Pre-set Temp.]” is set to “OFF”, this item

cannot be set.

Press the N or M key to select a paper source.

1

*When the optional roll unit is not installed, “Drawer 1” [“1st

paper”] may not be selected.

Inch specifications

Paper type:

2.Drawer 2

Metric specifications

Paper material:

2.2nd paper

Press the Enter key.

2

The selected item will flash. Press the N or M key to select

3

a media type.

Inch specifications

Drawer 2:

Metric specifications

2nd paper:

OFF*

OFF*

value

Plain*

Plain*

) *” and

7

8

5-6

Press the N or M key to select “End” [“back”].

Press the Enter key. The printer will return to the machine

settings screen.

Page 41

CHAPTER 5 MANAGEMENT AND SETTING

Press the Enter key. The display will show “set (

4

return to the step 1 screen.

Press the N or M key to select “End” [“back”].

5

Press the Enter key. The printer will return to the machine

6

settings screen.

4. Roll end

Press the N or M key to select a media type.

1

Inch specifications

Roll end:

1.Plain

Metric specifications

Roll end:

1.Plain

Press the Enter key.

2

The selected item will flash. Select whether the paper’s

3

trailing edge is attached to the roll core by pressing the N or

M key to select “Fixed” or “Unfix” [“Unfixed”].

Inch specifications

Plain:

Unfix*

value

) *” and

5. Auto shutoff

The selected item will flash. Press the N or M key to select

1

the desired auto shutoff mode.

Inch specifications

Auto Shutoff:

Shutoff mode*

Metric specifications

Auto shutoff:

Shutoff mode*

Press the Enter key. The display will show “set (

2

return to machine settings screen.

value

) *” and

Metric specifications

Plain:

Press the Enter key. The display will show “set (

4

return to the step 1 screen.

Press the N or M key to select “End” [“back”].

5

Press the Enter key. The printer will return to the machine

6

settings screen.

Unfixed*

value

) *” and

5-7

Page 42

CHAPTER 5 MANAGEMENT AND SETTING

6. Timer set

NOTE

• If “5. Auto shutoff” is set to “OFF”, the auto shutoff timer cannot be

set.

• When setting the auto energy saver time, do not set a longer time

than the auto shutoff time. When the auto energy saver time

exceeds the auto shutoff time, the auto shutoff function will engage

without the auto energy saver function having operated.

Press the N or M key to select the function for which the

1

timer is to be set.

Inch specifications

Timer set:

1.Auto pre heat

Metric specifications

Timer set:

1.Auto preheat

Press the Enter key.

2

Press the Enter key. The display will show “set (

4

return to the step 1 screen.

Press the N or M key to select “End” [“back”].

5

Press the Enter key. The printer will return to the machine

6

settings screen.

value

) *” and

Press the N or M key to set the time that elapses before the

3

selected function is activated.

> If “1. Auto preheat” has been selected, set the time to from

5 minutes to 45 minutes.

Inch specifications

Auto preheat:

Metric specifications

Auto preheat:

> If “2. Auto shutoff” has been selected, set the time to from

15 minutes to 120 minutes.

Inch specifications

Auto Shutoff:

Metric specifications

Auto Shutoff:

15min.*

15min.*

90min.*

90min.*

5-8

Page 43

CHAPTER 5 MANAGEMENT AND SETTING

7. Fusing temp.

Press the N or M key to select a media type.

1

Inch specifications

Fusing temp.:

1.Plain

Metric specifications

Fusing temp.:

1.Plain

Press the Enter key.

2

The selected item will flash. Press the N or M key to select

3

the fixing temperature for each media type.

> If “Plain” has been selected, select from 145 °C, 155 °C,

and 165 °C.

Inch specifications

Plain:

Metric specifications

Plain:

> If “Vellum” has been selected, select from 165 °C, 175 °C,

and 185 °C.

> If “Film” has been selected, select from 150 °C, 160 °C,

and 170 °C.

155° C*

155° C*

8. Custom paper

The selected item will flash. Press the N or M key to select

1

a media type.

Inch specifications

Custom paper:

Metric specifications

Custom paper:

Press the Enter key. The display will show “set (

2

return to machine settings screen.

9. Standard size

Press the N or M key to select the type of standard size.

1

For an inch specification printer, select “Architecture” or

“Engineer”. For a metric specification printer, select “A sizes”

or “B sizes”.

Inch specifications

Standard size:

Architecture*

Metric specifications

Standard size:

Vellum*

Vellum*

A sizes*

value

) *” and

> If “Custom” has been selected, the temperature that has

been set for the custom media type will be displayed.

Press the Enter key. The display will show “set (

4

return to the step 1 screen.

Press the N or M key to select “End” [“back”].

5

Press the Enter key. The printer will return to the machine

6

settings screen.

value

) *” and

Press the Enter key. The display will show “set (

2

return to machine settings screen.

value

) *” and

5-9

Page 44

CHAPTER 5 MANAGEMENT AND SETTING

10. Buzzer

The selected item will flash. To enable the buzzer press the

1

N or M key to select “ON”.

Inch specifications

Buzzer:

Metric specifications

Buzzer:

ON*

ON*

Press the Enter key. The display will show “set (

2

return to machine settings screen.

11. Mgr. code change

The arrows will flash. Use the MNOP cursor keys to input

1

the pin code

Inch specifications

Mgr.code change:

q Q r R *

Metric specifications

Mgr.code change:

q Q r R *

Press the Enter key. The display will show “set (

2

return to machine settings screen.

value

value

) *” and

) *” and

5-10

Page 45

2. Printer Settings

(1) List of Printer Settings

● Settings common to user/manager

CHAPTER 5 MANAGEMENT AND SETTING

Setting

1. Reset

2. Test print

Resets the printer. Use when rebooting the internal server

computer.

Allows the output a test print using the printer’s operation

panel.

● Settings accessible by manager

Setting

3. DHCP server

Toggles the DHCP server ON/OFF.

* Configuration of this setting depends on the environment in

which the printer will be used. Consult your network

administrator in advance.

Description

Description

Selectable values

– – – – –

– – – – –

Selectable values

ON/OFF

Default

– – – – –

– – – – –

Default

OFF

Page

4-5

4-3

Page

3-4

4. IP address

5. Subnet mask

6. Gateway

7. DNS server

Configures the printer’s IP address, Subnet mask, Gateway,

and DNS server settings.

* Configuration of these settings depends on the

environment in which the printer will be used. Consult your

network administrator in advance.

– – – – –

0. 0. 0. 0

3-2

5-11

Page 46

CHAPTER 5 MANAGEMENT AND SETTING

3. Language Switching

The printer’s message can be displayed in “English (USA)”, “English”,

“DEUTSCH” (German), “FRANCAIS” (French), “SPANISH”,

“ITALIANO” (Italian) and “NEDERLANDS” (Dutch).

Press the */Menu key.

1

Press the N or M keys to select “1. Language.”.

2

Inch specifications

Menu:

1.Language.

Metric specifications

Menu:

1.Language.

Press the Enter key.

3

The selected item will flash. Press the N or M key to select

4

the desired language.

Inch specifications

Language:

English(USA)*

Metric specifications

Language:

Press the Enter key. The display will show “set (

5

return to “Ready to print” screen.

English*

value

) *” and

5-12

Page 47

CHAPTER 6 TROUBLESHOOTING

1. If One of These Messages is Displayed...

When any message shown below appears in the message display of the operation panel, follow the appropriate procedure.

Message

“Please close. front cover.”

“Please close. eject cover.”

[“Please close. output cover.”]

“Please close. toner cover.”

“Please close. right cover.”

“Please close. fuser unit.”

[“Please close. fix. unit.”]

“Paper misfeed.”

Remedy

The front cover is open. Close the front cover securely.

The eject cover is open. Close the eject cover securely.

The toner tank cover is open. Close the toner tank cover securely.

The right cover is open. Close the right cover securely.

The main body of the machine is open. Close the machine securely.

A paper jam has occurred. Remove the jammed paper in accordance with the

message.

Page

—

—

—

—

—

6-7

“Add roll” [“Place paper.”]

“Reverse paper.”

“Close drawer”

[“Set drawer.”]

“Maintenance”

Paper in the roll unit has run out. Replace the paper roll with a new one.

Paper in the roll unit has run out. Open the front cover, rewind the remaining paper

roll, and replace it with a new one.

A roll unit is not securely inserted. Open the front cover and push the roll unit in

securely.

Maintenance of the machine is needed. Contact your service representative.

3-7

3-7

—

—

6-1

Page 48

CHAPTER 6 TROUBLESHOOTING

Message

“Add roll Drawer X XX"” [“Set paper.

X paper XX mm”] and “Start key to

go” are alternately displayed.

“Check waste toner tank.”

“Add toner.”

“Call service”

“Cannot set now.”

Remedy

The data’s page size and the size of the paper roll loaded in the printer do not match.

Load the roll for the indicated paper tray. To print from the currently loaded roll, press

the Start key. To cancel printing, press the Stop key.

The waste toner tank is full or the tank is not properly installed. Replace it with a new

tank or install the tank properly.

When this message is displayed with the “Ready to print” message, printing is

possible for a short period of time. However, when only the “Add toner” message is

displayed and the Attention indicator on the operation panel is lit, printing is no

longer possible. Replenish toner promptly.

A problem has occurred inside the printer body.

See “5. Countermeasures against Call for service Message”.

A function or a default setting that cannot be set now is accessed. See the procedure

for configuring the appropriate setting.

Page

—

6-5

6-3

6-6

—

“Bad code.”

[“Code incorrect”]

The pin code is incorrect. Use the MNOP cursor keys to input the pin code again.

—

6-2

Page 49

2. Replenishing the Toner

When toner is insufficient the message “Add toner” is displayed.

When “Ready to print” is also displayed, printing is possible for a short

period of time; however, when the only “Add toner” message is

displayed and the Attention indicator on the operation panel is lit,

printing is no longer possible. Replenish toner promptly.

When several consecutive prints contain large areas of saturated

black, large quantities of toner are used at once and the message

“Add toner” may be displayed even when a supply of toner remains in

the printer. In this case, open and then close the toner replenishing

slot. The printer will perform toner replenishment.

Inch specifications

Ready to print.

Add toner.

Metric specifications

Ready to print.

Add toner.

Turn the screws on both sides of the toner replenishing slot

1

and align them as shown to open the toner replenishing slot.

CHAPTER 6 TROUBLESHOOTING

CAUTION

DO NOT attempt to incinerate the toner containers or

the waste toner tank. Dangerous sparks may cause

burns.

CAUTION

DO NOT attempt to force open or destroy the toner

containers or the waste toner tank.

Shake the replenishment toner bottle up and down 10 times,

3

and grasp it horizontally and shake it side to side 10 times.

Grasp the replenishment toner bottle upside down and tap

2

the bottom of the bottle 10 times.

Align the ▼ portion of the toner bottle with the pin 1 (metal

4

protrusion) of the opening to insert the bottle as shown in the

illustration.

1

6-3

Page 50

CHAPTER 6 TROUBLESHOOTING

While pressing the toner bottle down, turn it clockwise 90

5

degrees to replenish the toner.

Tap the side of the toner bottle 10 times to loosen any

6

remaining toner.

10

● After use, ALWAYS dispose of the toner containers

and the waste toner tank in accordance with

Federal, State and Local rules and regulations.

Press the toner bottle down, turn it to the original position

7

and gently remove it.

Close the toner replenishing slot and turn the toner

8

replenishing slot screws to the location shown in the

illustration to secure the cover.

6-4

Page 51

3. Replacing the Waste Toner Tank

CHAPTER 6 TROUBLESHOOTING

When the waste toner tank becomes full the message “Check waste

toner tank” is displayed. Since the Attention indicator on the operation

panel will be lit and printing will be disabled, replace the waste toner

tank with a new tank.

Inch specifications

Check waste

toner tank.

Metric specifications

Check waste

toner tank.

Open the right cover and remove the waste toner tank by

1

pulling it out toward you.

Insert a new waste toner tank into the machine.

3

Close the right cover.

4

*Toner in the waste toner tank cannot be reused.

● After use, ALWAYS dispose of the toner containers

and the waste toner tank in accordance with

Federal, State and Local rules and regulations.

Seal the waste toner tank opening with the seal located on it.

2

CAUTION

DO NOT attempt to incinerate the toner containers or

the waste toner tank. Dangerous sparks may cause

burns.

CAUTION

DO NOT attempt to force open or destroy the toner

containers or the waste toner tank.

6-5

Page 52

CHAPTER 6 TROUBLESHOOTING

4. Countermeasures against Call for service Message