Page 1

CONFIDENTIAL

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

Installation Manual for Kyocera iBurst System

(BS1905A-US-A)

April 26, 2004

Revision 1.00

Doc-No. Q05T-AI-BB001E

Kyocera Corp.

2-1-1 Kagahara, Tsuzuki-ku, Yokohama-city, Kanagawa 224-8502, Japan

Telephone:+81-45-943-6176

Fax:+81-45-943-6123

© KYOCERA Corporation 2003

All right reserved.

No part of this publication may be excerpted, reproduced,

translated or edited, in any form by any means, without

the prior written permission of KYOCERA Corporation

pproved

Checked

Checked Prepared

(Page: 1/138)

Page 2

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

Revision History

Revision Description Date Charge

1.00 1st Edition

1. INSTALLATION CRITERIA...................................................................................................... 5

April 26, 2004

Y. Izawa

1.1 P

1.2 L

1.3 PRECAUTIONS FOR HANDLING..............................................................................................6

1.4 D

1.5 INSTALLATION CRITERIA.......................................................................................................6

URPOSE AND POLICY........................................................................................................... 6

AWS ....................................................................................................................................6

ESIGN AND EXECUTION POLICY ..........................................................................................6

1.5.1 General.........................................................................................................................6

1.5.2 Criteria for selecting antenna location.......................................................................8

1.5.2.1 Accuracy of antenna mounting ............................................................................ 8

1.5.2.2 Sequence of mounting antenna............................................................................ 8

1.5.2.3 Interval of antenna............................................................................................... 8

1.5.2.4 Lightening protection........................................................................................... 9

1.5.2.5 Isolation from drain.............................................................................................. 9

1.5.2.6 Isolation from obstacle .......................................................................................10

1.5.2.7 Horizontal sight angle........................................................................................ 10

1.5.2.8 Vertical sight angle............................................................................................. 11

1.5.2.9 Isolation from radio system................................................................................12

1.5.2.10 Isolation from outdoor unit of air conditioner, etc. ...........................................14

1.5.2.11 Isolation from power line ...................................................................................14

1.5.3 Criteria for selecting PA unit location ......................................................................15

1.5.3.1 Mounting direction of PA unit............................................................................15

1.5.3.2 Securing space for PA unit .................................................................................15

1.5.3.3 Lightening protection......................................................................................... 16

1.5.3.4 Isolation from drain............................................................................................ 17

1.5.4 Criteria for selecting GPS unit location ...................................................................17

1.5.4.1 Accuracy of GPS mounting.................................................................................17

1.5.4.2 GPS sight space ..................................................................................................18

1.5.4.3 Lightening protection for GPS........................................................................... 19

1.5.5 Criteria for selecting Base unit location...................................................................20

1.5.5.1 Installation space for Base unit......................................................................... 20

1.5.5.2 Lightening protection for Base unit...................................................................20

1.5.5.3 Isolation from drain............................................................................................ 21

1.5.5.4 Isolation from iBurst antenna ...........................................................................21

1.5.6 Precautions on cabling ..............................................................................................22

1.5.6.1 Ground ................................................................................................................ 22

1.5.6.2 Cable ...................................................................................................................22

1.5.7 Precautions in installation on the roof ..................................................................... 23

(Page: 2/138)

Page 3

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

1.5.8 Separation of power systems.....................................................................................24

1.5.9 Waterproof treatment for connector and bushing.................................................... 25

2 CONFIGURATION OF BASE STATION AND ACCESSORIES.......................................... 26

2.1 C

ONFIGURATION OF BASE STATION.................................................................................... 27

2.1.1 System Diagram ........................................................................................................ 27

2.1.1.1 Star connection................................................................................................... 27

2.1.1.2 Daisy-chain connection.......................................................................................28

2.1.2 Appearance form........................................................................................................ 29

2.1.2.1 PA unit ................................................................................................................ 29

2.1.2.2 Inside LID........................................................................................................... 30

2.1.2.3 GPS unit..............................................................................................................31

2.1.2.4 Base unit............................................................................................................. 32

2.1.3 Connection diagram...................................................................................................37

2.1.3.1 PA unit - Antenna ...............................................................................................37

2.1.3.2 PA unit-Base unit ............................................................................................... 38

2.1.3.3 Base unit – Other equipment.............................................................................42

2.1.4 Pin assignment of cables/connectors.........................................................................43

2.1.4.1 AC Power supply cable....................................................................................... 43

2.1.4.2 PA control cable .................................................................................................. 43

2.1.4.3 Network cable..................................................................................................... 44

2.1.4.4 GPS cable ............................................................................................................ 44

2.1.4.5 GPI cable.............................................................................................................45

2.1.4.6 Master/Slave cable..............................................................................................45

2.2 S

PECIFICATIONS ................................................................................................................. 46

2.2.1 Hardware specifications ............................................................................................46

2.2.2 LED indicators........................................................................................................... 47

2.2.2.1 PA unit ................................................................................................................ 47

2.2.2.2 Base unit............................................................................................................. 47

2.2.3 Accessories ................................................................................................................. 48

2.2.3.1 PA unit ................................................................................................................ 48

2.2.3.2 Base unit............................................................................................................. 48

2.2.4 Cable specification..................................................................................................... 48

2.2.5 Other Parts specification........................................................................................... 49

2.2.6 Handling of cables .....................................................................................................50

2.2.7 Tightening Torque .....................................................................................................50

2.2.8 Tools............................................................................................................................51

3 INSTALLATION ................................................................................................................... 52

3.1 I

NSTALLING ANTENNA SYSTEM (EXAMPLE)........................................................................53

3.1.1 Installing the antenna pole .......................................................................................53

3.2 INSTALLING PA UNIT .........................................................................................................56

3.2.1 Mounting and removing the Eyebolt ........................................................................ 56

3.2.2 Mounting the PA Unit (Example) .............................................................................57

3.2.3 Connecting cables ...................................................................................................... 59

3.2.3.1 Connecting the AC power supply cable ............................................................. 59

3.2.3.2 Connecting the grounding cable. .......................................................................64

3.2.3.3 Connecting the PA control cable ........................................................................ 65

3.2.3.4 Connecting the antenna cable............................................................................70

3.2.3.5 Connecting the Calibration cable ......................................................................72

3.2.3.6 Connecting the PU-BU RF cable .......................................................................79

3.3 I

3.4 I

NSTALLING THE GPS UNIT ...............................................................................................82

NSTALLING THE BASE UNIT ..............................................................................................86

3.4.1 Mounting and removing the Eyebolt ........................................................................ 86

3.4.2 Fixing the Base Unit .................................................................................................88

3.4.3 Connecting cables ...................................................................................................... 89

(Page: 3/138)

Page 4

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

3.4.3.1 Connecting the AC power supply cable ............................................................. 89

3.4.3.2 Fixing the grounding cable ................................................................................94

3.4.3.3 Connecting the PA control cable ........................................................................ 95

3.4.3.4 Connecting the GPS cable................................................................................ 100

3.4.3.5 Connecting the Calibration cable ....................................................................105

3.4.3.6 Connecting the PU-BU RF cable .....................................................................110

3.4.3.7 Connecting the Network cable......................................................................... 114

3.4.3.8 Connecting the Master/Slave cable .................................................................123

3.4.3.9 Attachment of Grounding Kit .......................................................................... 130

3.4.4 Inserting the board.................................................................................................. 130

3.4.4.1 Notes at setting Boards and Power supply .....................................................131

3.4.4.2 Inserting the Power supply.............................................................................. 133

3.4.4.3 Inserting the LoCal board................................................................................ 133

3.4.4.4 Inserting the MoNerd board ............................................................................134

3.4.4.5 Inserting the TRx board................................................................................... 134

3.4.4.6 Inserting the FAN tray.....................................................................................134

3.4.4.7 Removing the Power supply and other boards................................................ 135

3.4.5 Connecting cables to the Power supply and boards ...............................................136

3.4.5.1 Power supply.....................................................................................................136

3.4.5.2 LoCal board.......................................................................................................137

3.4.5.3 MoNerd board................................................................................................... 137

3.4.5.4 TRx the board ................................................................................................... 138

* iBurst is the trademark of ArrayComm.

* All the things in which a size does not have a unit display are mm units.

(Page: 4/138)

Page 5

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

1. Installation Criteria

(Page: 5/138)

Page 6

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

1.1 Purpose and policy

This document is intended to specify a fundamental design criterion for the installation of

iBurst base station, thus ensuring smooth work and providing the customer with appropriate

services and establishing easy-to-maintain system.

1.2 Laws

In executing the work, necessary related laws (Telecommunications Business Law, Wired

Telecommunications Law, Radio Law, Building Standard Law, Electric Work Specialist Law,

Fire Fighting Law, etc. in Japan), other related laws, and licensing conditions must be

observed. In addition, application for permission based on the law must be conducted without

delay.

1.3 Precautions for handling

The iBurst system contains precision components; therefore, do not give any strong shock by

falling or dropping.

Strong shock may result in a failure or badly affect the lifetime or the product.

1.4 Design and execution policy

1.4.1 In designing the work, functionality, reliability, maintainability, economy, etc. must be

fully taken into account.

1.4.2 Not only enhancement of safety mind but also security for the third party must always

be kept in mind.

1.4.3 Be sure to make efforts to complete better work objective in accordance with

technological sense.

1.4.4 Be sure to keep communication with the owner and residents of the building and the

neighboring residents with due consideration not to cause a problem.

1.4.5 Be sure to make efforts to grasp the status of the work, to give an appropriate advice,

and to fulfill a duty of reporting the status.

1.4.6 Be sure to prevent the work from generating a noise or vibration to maintain the living

environment.

1.4.7 Be sure to dispose the waste materials caused from the work in accordance with the

specified method regarding the method, place, etc. of disposal, thereby preventing the

occurrence of accident to be caused by the waste material.

1.4.8 In conducting a negotiation or design, future expansion of equipment should be

considered as much as possible.

1.5 Installation criteria

1.5.1 General

1.5.1.1 Select the location where general public is hard to access but maintenance is

easy.

1.5.1.2 Antenna and mounting stud must be located at a place where dropping or other

accident, if any, may not be harmful for the personnel and general public.

1.5.1.3 In designing a base station, the location shall be determined by the study of

strength against load and work product.

(Page: 6/138)

Page 7

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

1.5.1.4 Do not place antenna, base station, or other obstruction in front of advertising

display such as neon sign and signboard.

1.5.1.5 When conducting the work, select the location of antenna, base station, UPS,

wiring, piping, etc. in consultation with the owner while considering the

appearance.

1.5.1.6 Before implementing the work, check the status of any broken or damaged

portion of the building and facilities associated with the installation area of the

base station together with the owner or the person from the control company.

1.5.1.7 Materials for mounting equipment

1.5.1.7.1 Quality-of-the-material specification used for the mount of outdoor

installation etc. is considered as hot- dip galvanized. Moreover,

quality-of-the-material specification of inside-of-a-house installation is

made into the anti-rust material more than electric zinc plating material,

and a bolt and a nut also apply to this. However, about the place of

conditions, which are easy to generate, such as rust etc., it applies to

outdoor specification.

However, a hot-dip galvanized steel or Dacrotized finishing is recommended

for the bolt directly fixed on PA unit mounting bracket.

1.5.1.7.2 In the connection of various cables, use of cold-shrinkable tube as well as

self-fusing tape is recommended as a method of waterproof treatment.

1.5.1.8 Study the shape of the building and the status of waterproof treatment on the

roof not to cause any problem in the installation on the building.

(Page: 7/138)

Page 8

CONFIDENTIAL

A

A

A

λ

λ

λ

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

1.5.2 Criteria for selecting antenna location

1.5.2.1 Accuracy of antenna mounting

Antenna shall basically be installed vertically within the range of ±2 degrees off the

vertical line.

1.5.2.2 Sequence of mounting antenna

Each PA unit to be connected with the antenna has antenna numbers (ANT1 to ANT3).

The location of ANT1 is not specified specifically.

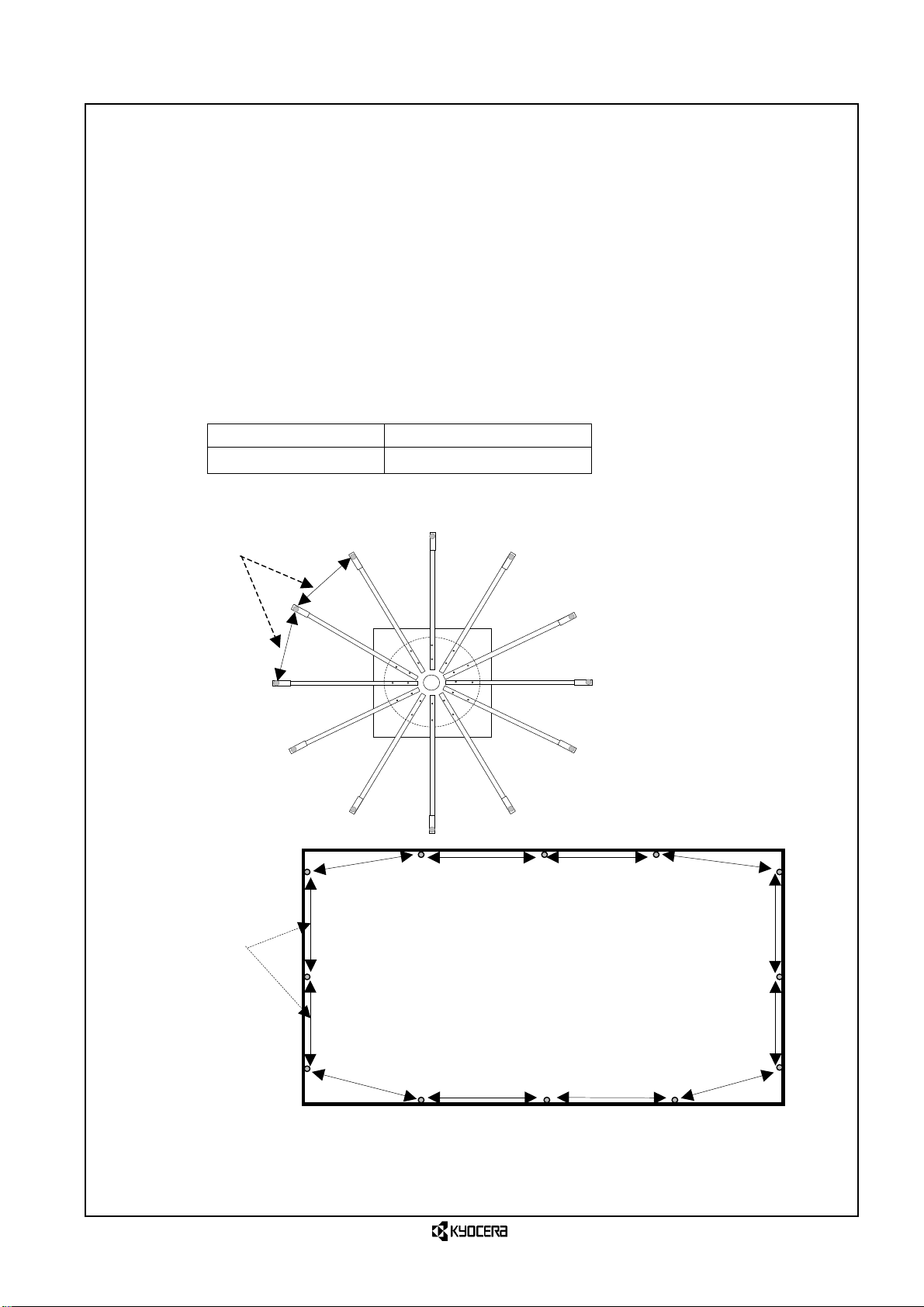

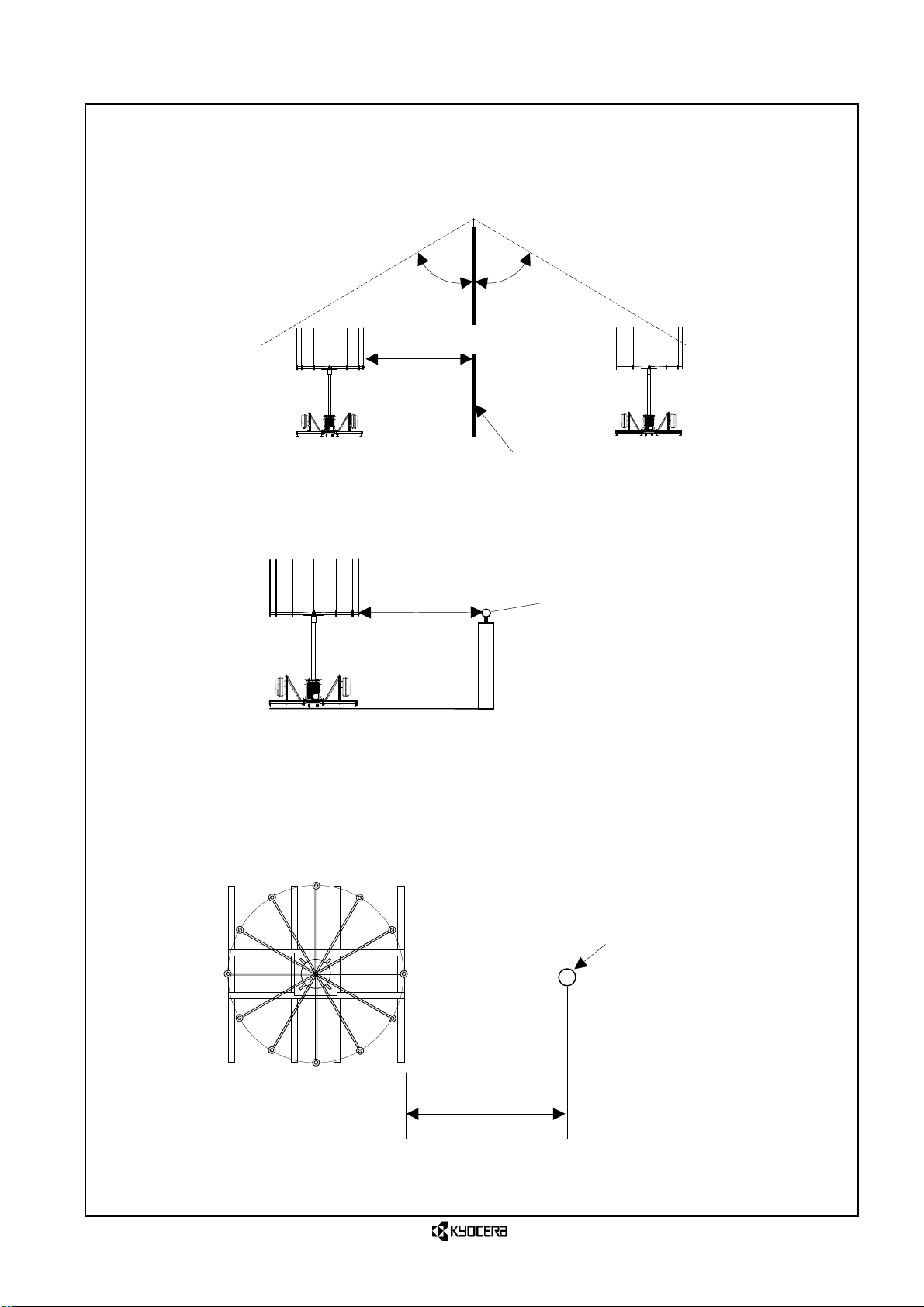

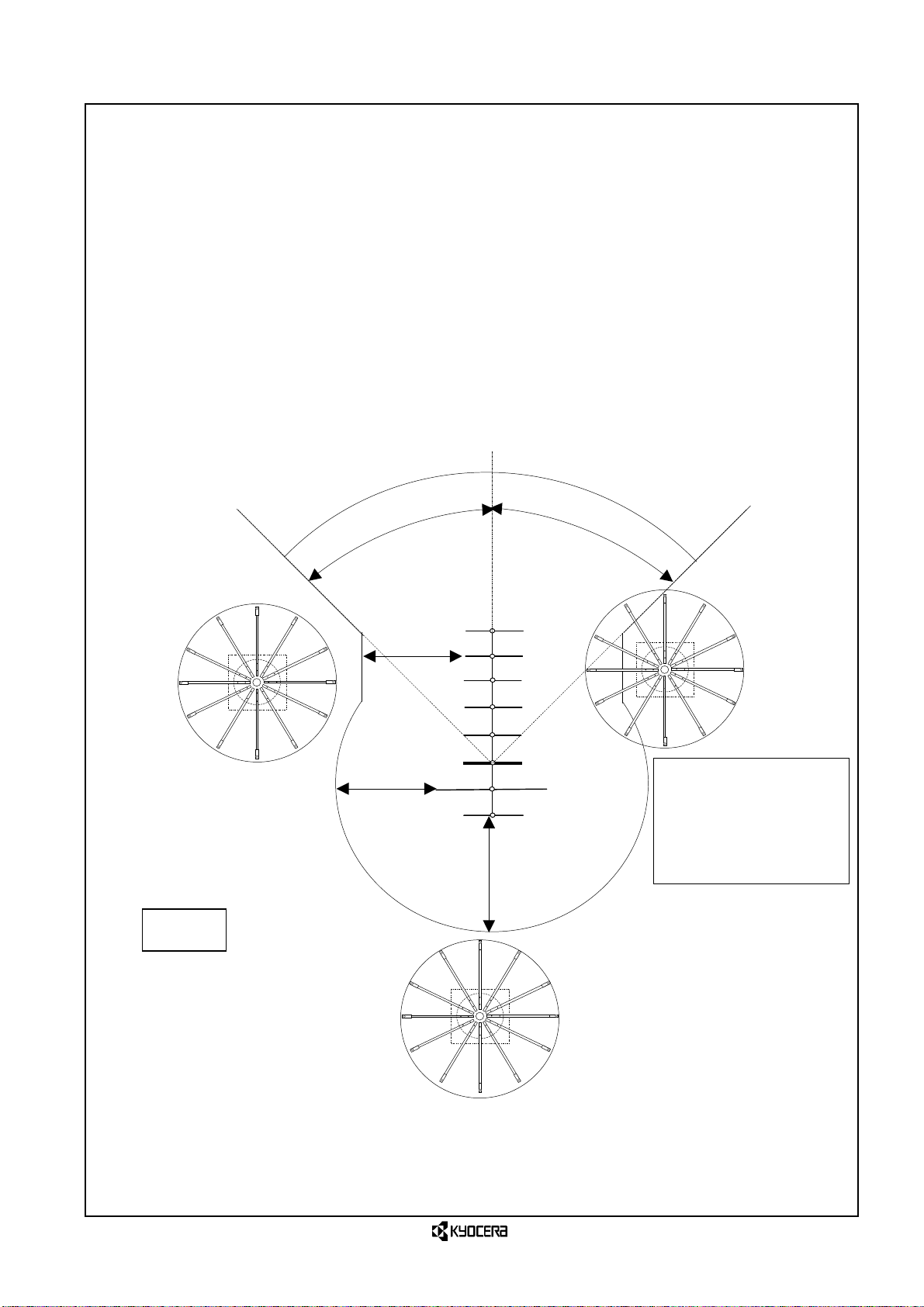

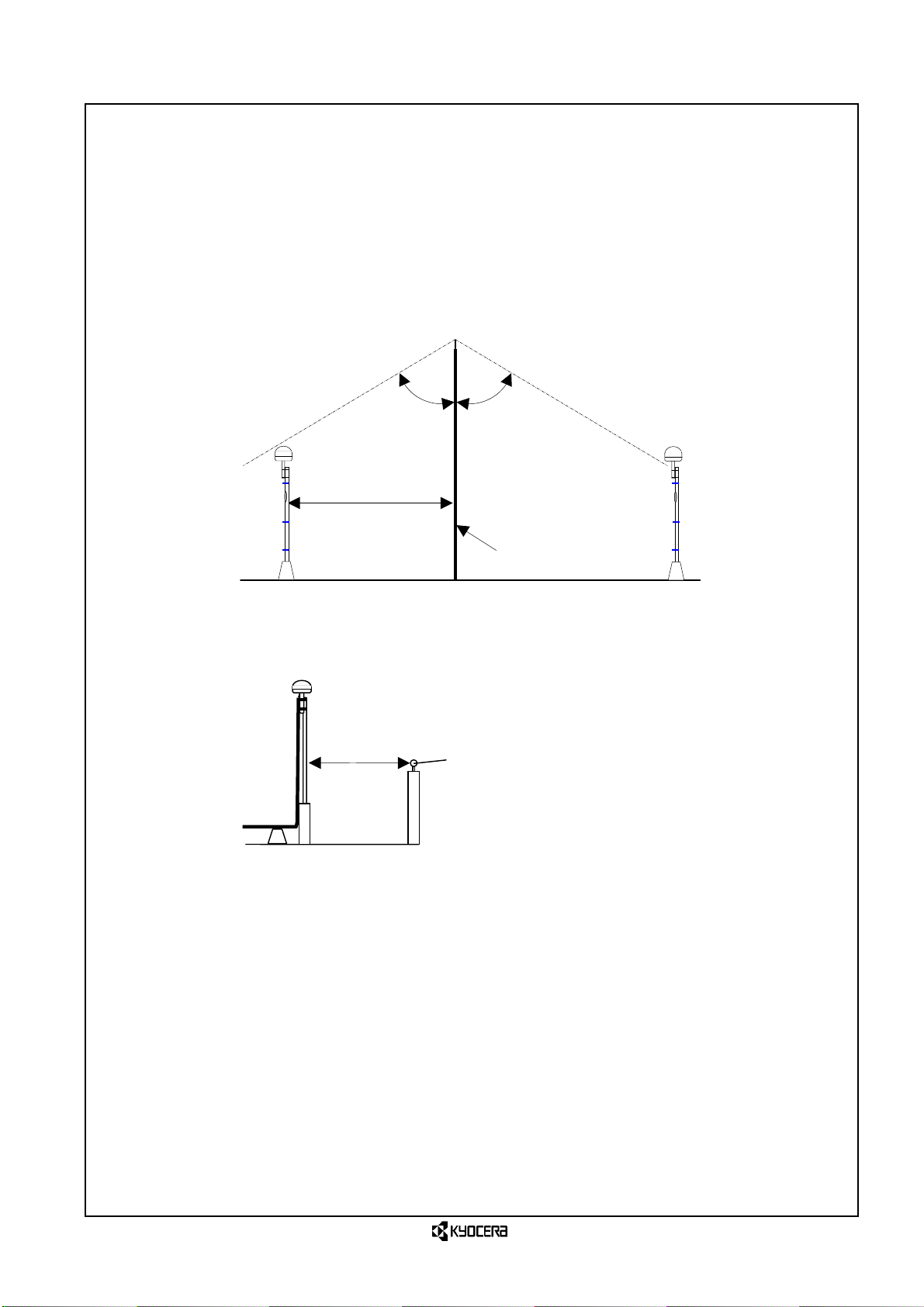

1.5.2.3 Interval of antenna

Antennas shall be separated by more than 3λ from each other as shown below.

An average interval of antenna shall be separated by more than 8λ.

Frequency Isolation (L)

1.9GHz More than 50cm

L

NT1

NT2

NT3

3λ

3λ

3

3λ

L

3λ

3λ

3λ

3λ

3λ

3

3

3λ

Sequence of antenna mounting and interval of antennas

(Page: 8/138)

Page 9

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

1.5.2.4 Lightening protection

Antenna installation shall be designed to be within the protection angle (* 60 degrees) of

the lightening rod.

* Lightening protection method is obeying the law by State regulations.

OK

Lightening protections for antenna - Lightening rod -

Lightening protection for antenna - Raised conductor -

1.5.2.5 Isolation from drain

When installing the antenna on the roof of a building, keep the isolation distance of

more than 1 m to prevent the pedestal from blocking the drain of the roof.

More than 1.5m

More than 1.5m

Isolation distance from roof drain

60°

More than 1m

60°

Lightening rod

Not OK

When using raised conductor

Roof-drain

(Page: 9/138)

Page 10

CONFIDENTIAL

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

1.5.2.6 Isolation from obstacle

When installing the antenna on the building, be sure that there is no object such as roof

buildings or advertising display that may block the electric wave around the antenna.

Obstacle

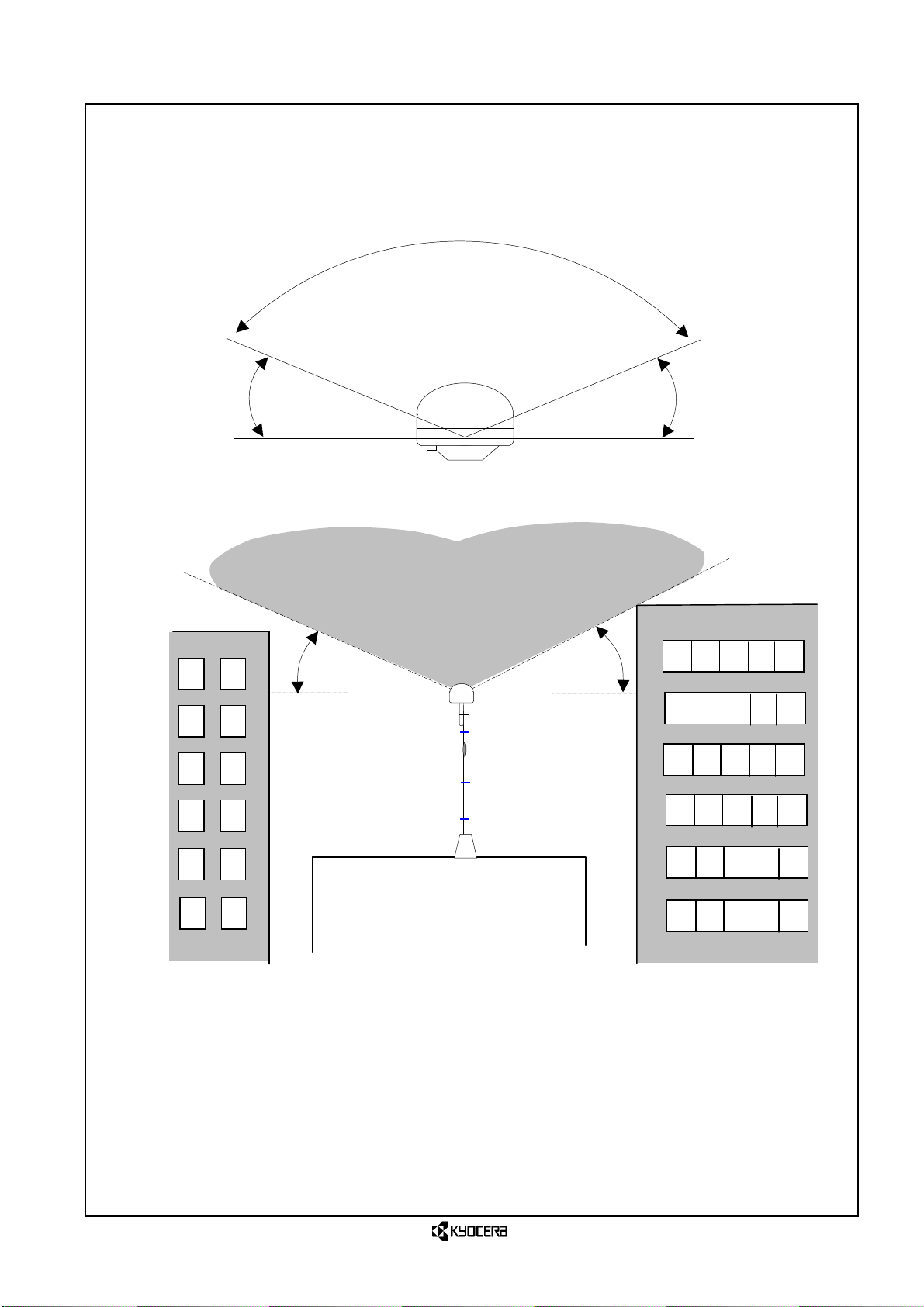

1.5.2.7 Horizontal sight angle

Horizontal sight angle shall be 330 degrees or more for the purpose of enlarging the area.

In addition, there shall be no obstruction along the direction to be covered.

Definition of horizontal sight angle: Horizontal sight angle from the antenna shall be

more than the standard value.

(Angle added by the sight direction in the horizontal angle of 360 degrees around the

antenna excluding the direction that cannot keep the sight due to obstruction on the

roof: See below)

ntenna location

γ

L>2m

L

Isolation from obstacle

Horizontal sight angle

On the horizontal line of antenna center.

Regarded as obstacle

Plane view of roof

Penthouse

γ: Horizontal sight angle

(Page: 10/138)

Page 11

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

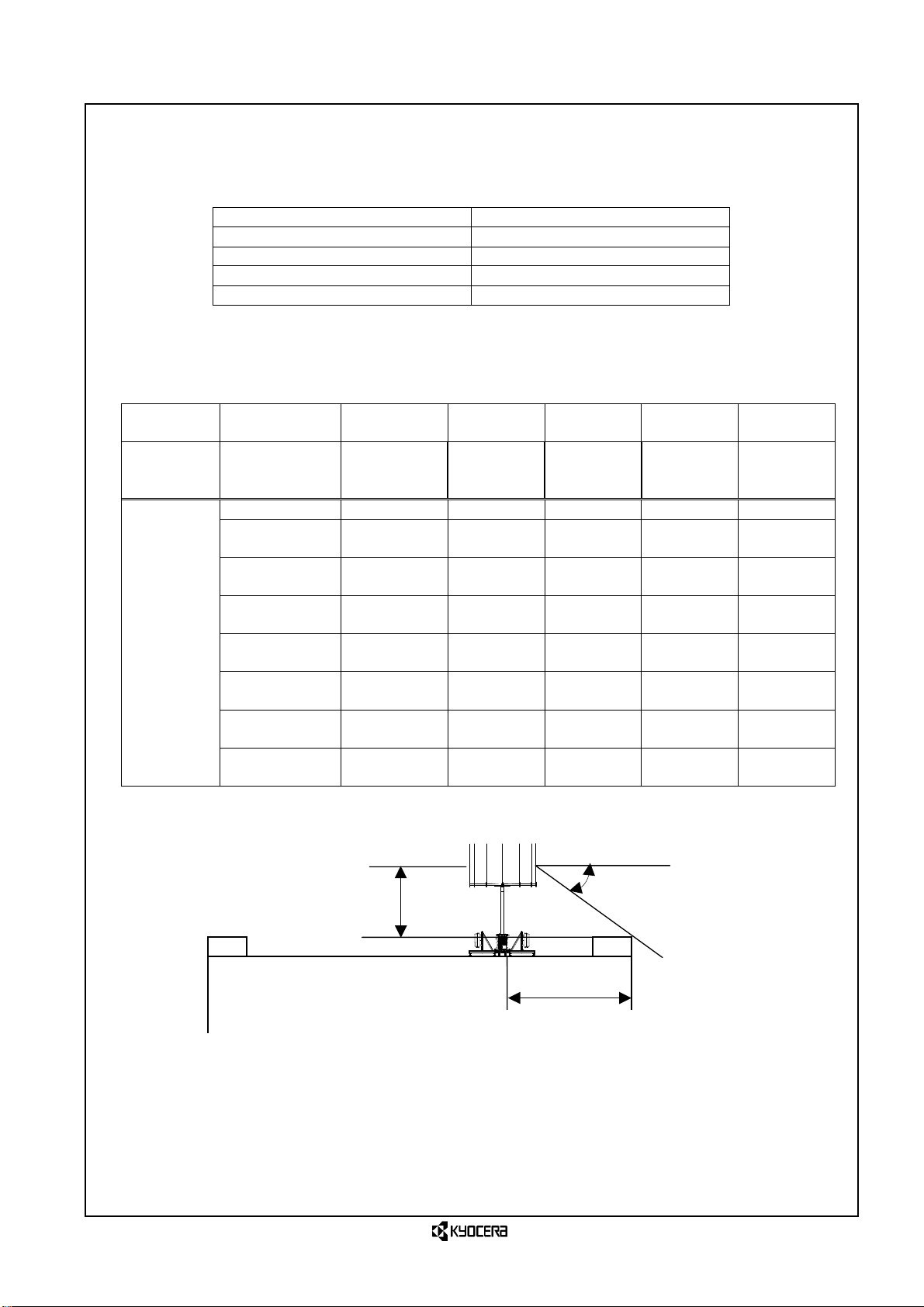

1.5.2.8 Vertical sight angle

The standard value shown in the following table shall be secured for vertical sight angle.

Vertical sight angle standard values

Tilt angle Standard value

7dBi (20 degrees) 30 degrees

9dBi (10 degrees) 20 degrees

11dBi (5 degrees) 10 degrees

11dBi (0 degree) 5 degrees

Upon confirmation of the “distance from edge” of an object, be sure “distance from edge”

is within the corresponding “allowable distance” in the following table.

Vertical sight angle vs. allowable distance

Applied

height (m)

Allowable

sight angle

(degrees)

4 or more 4 45.7 22.7 11.0 6.9

Over 3.5 and

Over 3 and

Over 2.5 and

Allowable

distance

(m) Over 1.5 and

Over 1 and

Over 0.5 and

tan5°=0.0874886, tan10°=0.1763269, tan20°=0.3639702, tan30°=0.5773502

5 10 20 30

below 4

below 3.5

below 3

Over 2 and

below 2.5

below 2

below 1.5

below 1

Calculated

value (m)

3.5 40.0 19.8 9.6 6.1

3 34.3 17.0 8.2 5.2

2.5 28.6 14.2 6.9 4.3

2 22.9 11.3 5.5 3.5

1.5 17.1 8.5 4.1 2.6

1 11.4 5.7 2.7 1.7

0.5 5.7 2.8 1.4 0.9

11dBi

0 degree

11dBi

5 degrees

9dBi

10 degrees

7dBi

20 degrees

Height from floor

(* Applied height)

Sight angle

Distance from edge

(* Must be within allowable distance)

Sight angle and allowable distance

(Page: 11/138)

Page 12

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

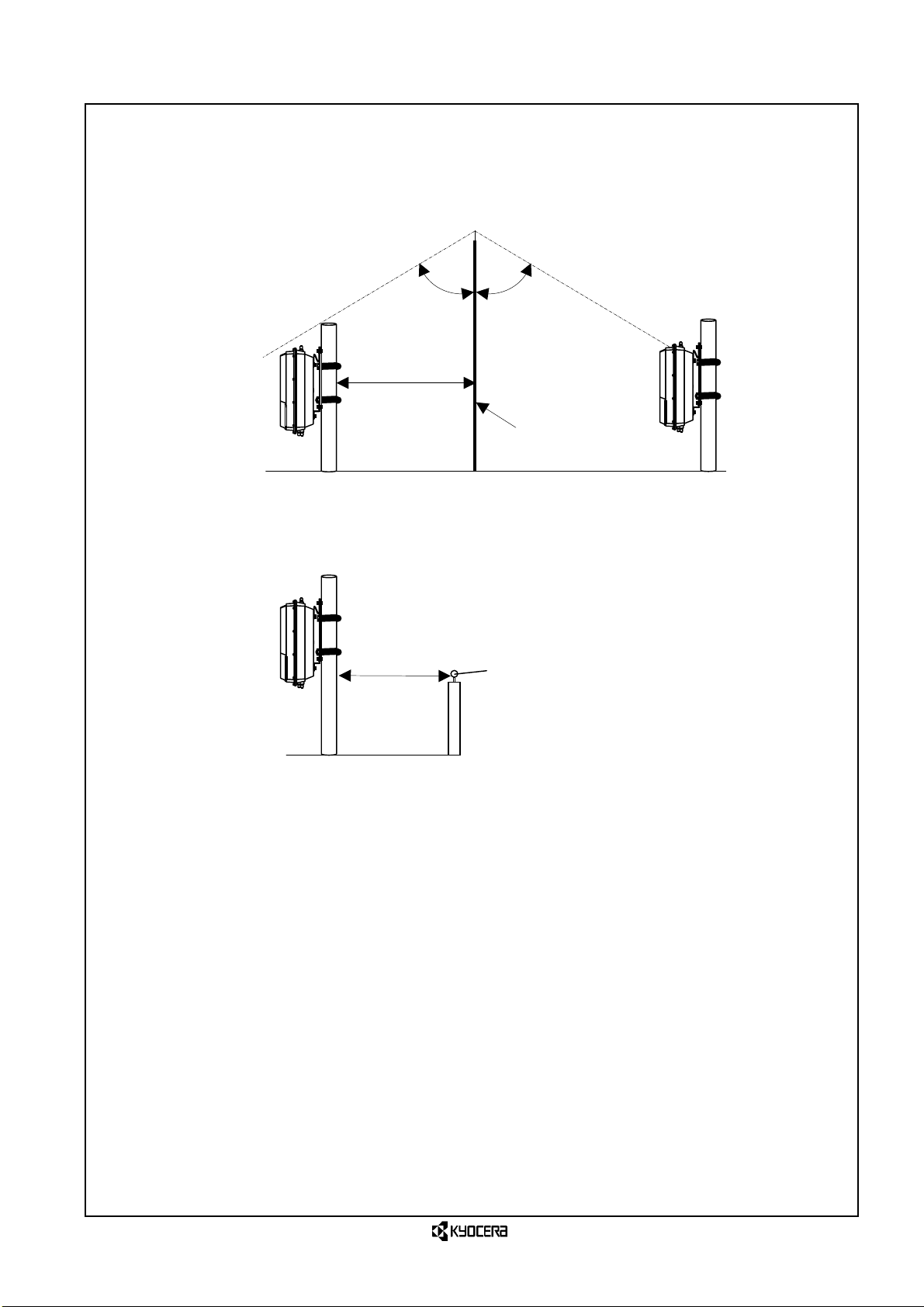

1.5.2.9 Isolation from radio system

When installing a base station, it is necessary to keep enough space so as not to give

damage to other existing base stations.

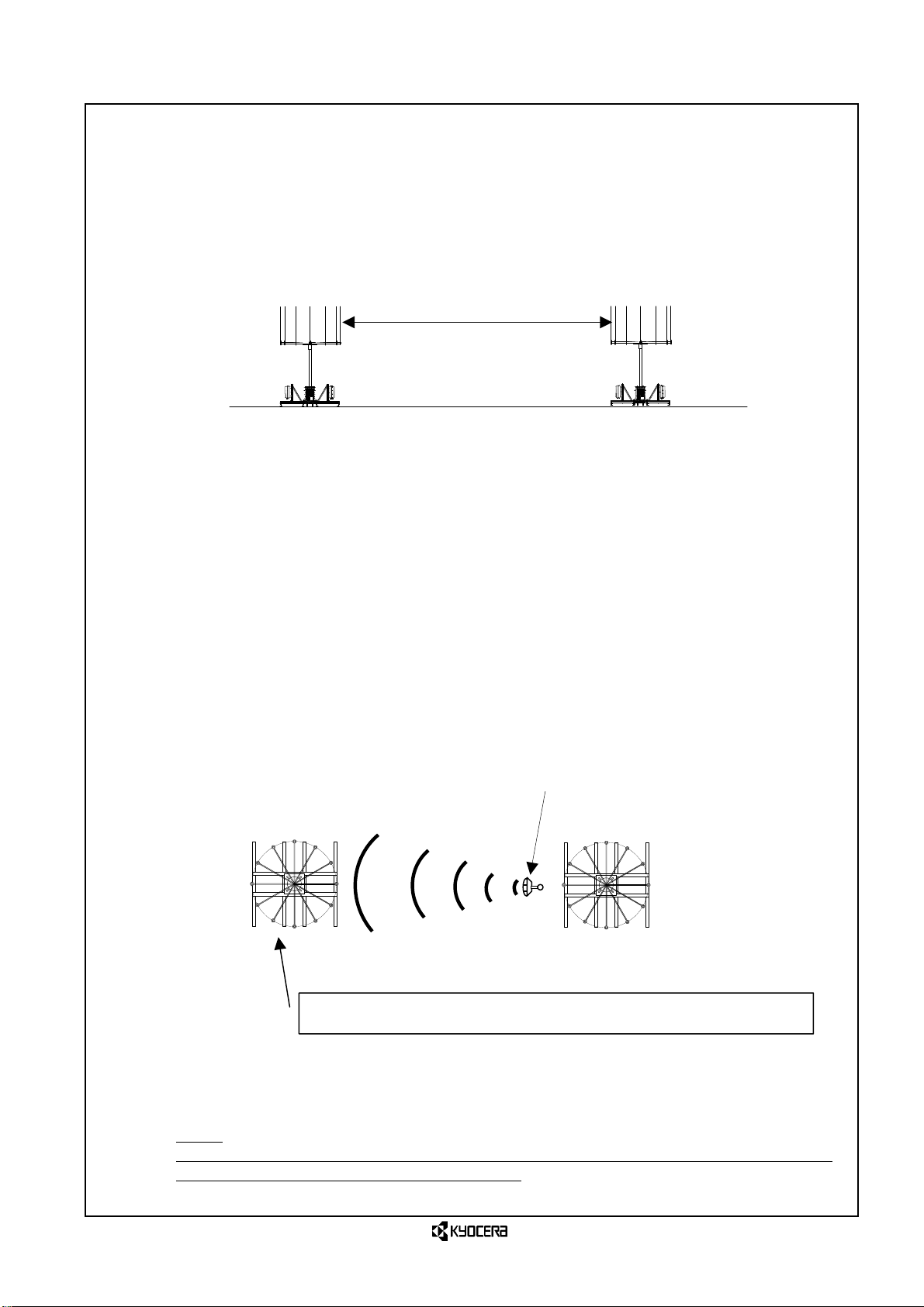

1.5.2.9.1 Isolation from iBurst system

When installing the iBurst systems on the same plane of the roof, keep the specified

isolation distance.

1.5.2.9.2 Isolation from GSM/CDMA base station

When installing the antennas in GSM/CDMA base station close together, sufficient

survey must be conducted

- Do not installing the iBurst antenna to direction of radiation.

- When installing the iBurst antenna to anti-direction of radiation, please make sure

shown below parameter and new calculation of isolation distance will be required.

Radiation pattern of iBurst antenna

Used frequency Rang (Up-link/Down-link) of GSM/CDMA antenna

Output power rating of GSM/CDMA antenna

Characteristic of BPF of GSM/CDMA antenna

Radiation pattern of GSM/CDMA antenna

iBurst Antenna

Interval between iBurst systems

Do not install the iBurst antenna to direction of radiation.

More than 2m

GSM /CDMA Antenna

Direction of radiation

iBurst Antenna

Example of isolation distance from GSM/CDMA base station --Top View

(Note)

When a base station is installed close to other base station, a failure may possibly be

caused on or from the associated base station.

(Page: 12/138)

Page 13

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

1.5.2.9.3 Isolation from other radio system

Regarding the existing antenna of other radio system such as TV antenna, effect on

the associated antenna shall be fully taken into account at the time of installation.

As TV antenna has directivity, no base station shall be located in the direction of the

antenna. There may be the possibility of having an effect even outside the range of

directivity due to the effect of reflection depending on the environment around the

location. Practically, as shown in the following figure, the base station must not be

located within the range of existing antenna direction ±45° on the same roof.

More than 3 m distance (horizontal) shall be allowed from TV antenna and installation

within the range of ±45 degrees from TV antenna direction shall be avoided.

OK

Plane

Directivity of TV antenna

45°

3m

3m

3m

OK

Isolation from TV antenna

45°

Not OK

Installation of this

type is not permitted

as the antenna arm is

considered as a circle.

(Page: 13/138)

Page 14

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

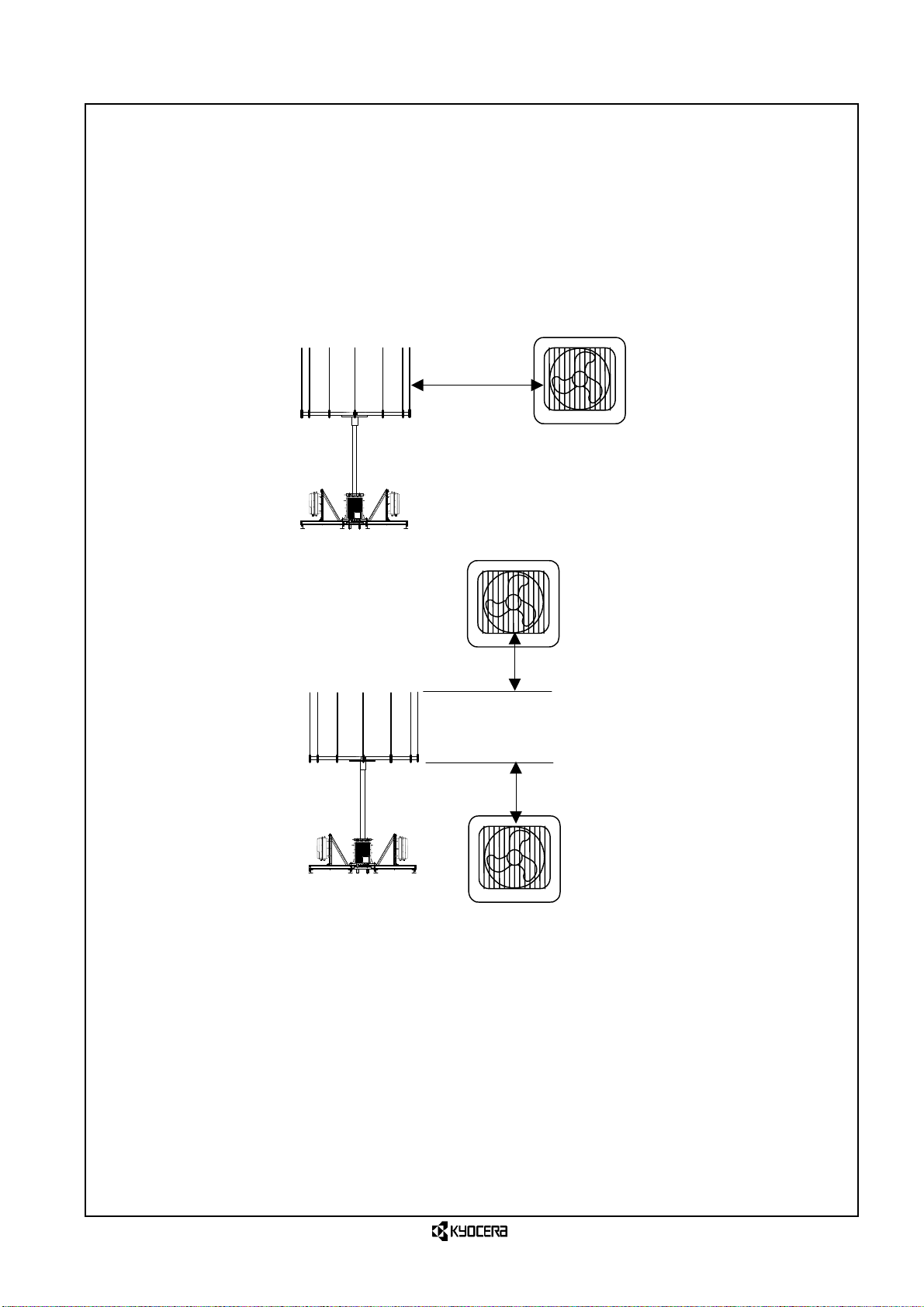

1.5.2.10 Isolation from outdoor unit of air conditioner, etc.

When installing an antenna, it is necessary to keep the antenna away from the rotating

metal such as a heat-dissipating fan of the outdoor unit of air conditioner, ventilating

fan, etc.

When there is any rotating metal on the same horizontal plane, it is necessary to keep

the isolation of more than 1.5 m. If, however, this isolation cannot be secured, isolation

of more than 0.5 m from the top and bottom edges of the antenna must be secured.

1.5.2.11 Isolation from power line

Isolation from power line shall be executed by confirming the details in accordance with

the related laws. As power producer includes electric power company and Train

Company, pay full attention to the surrounding conditions.

More than 1.5m

More than 0.5m

More than 0.5m

Isolation from outdoor unit

(Page: 14/138)

Page 15

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

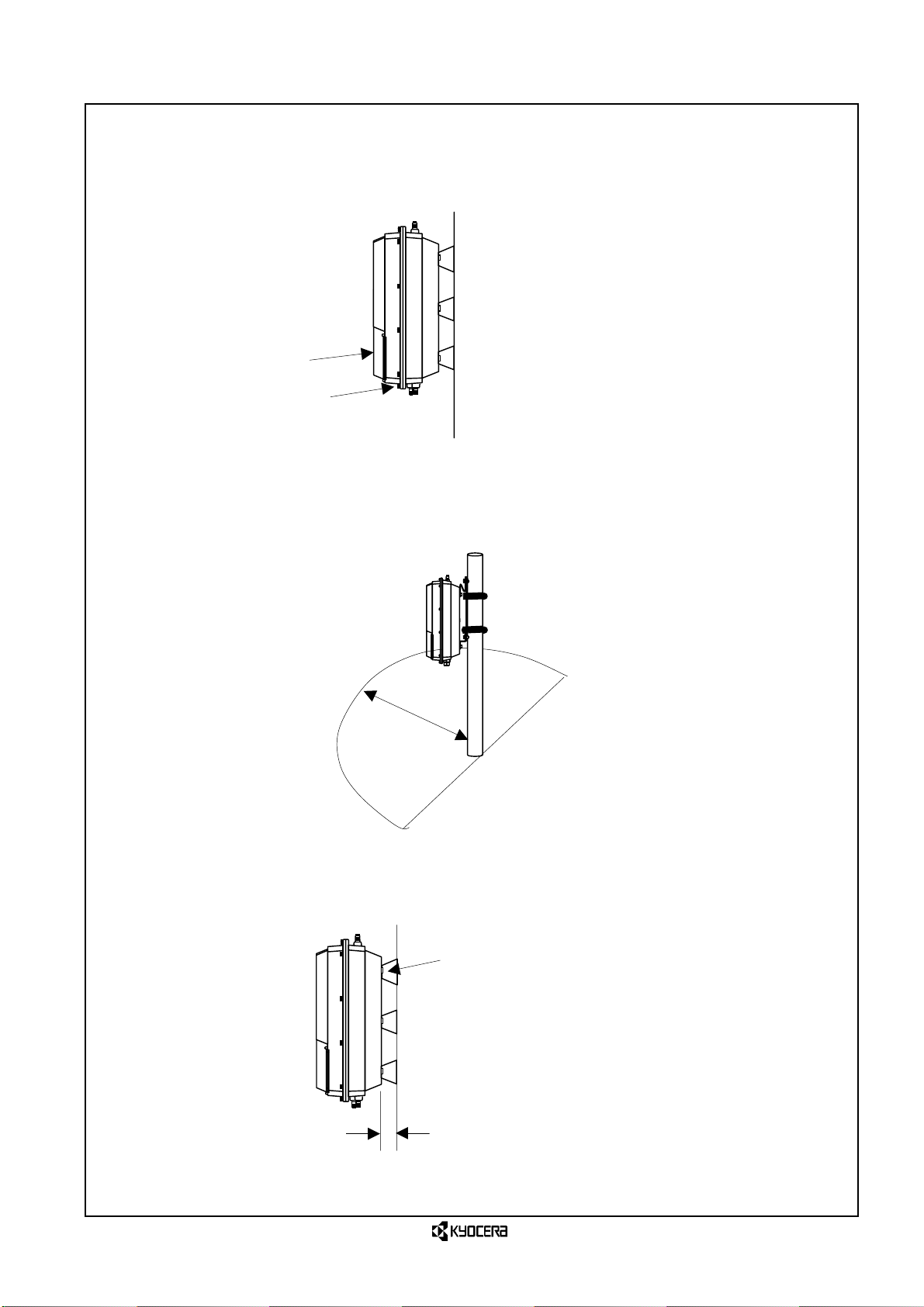

1.5.3 Criteria for selecting PA unit location

1.5.3.1 Mounting direction of PA unit

PA unit can be installed only vertically with the antenna connector up.

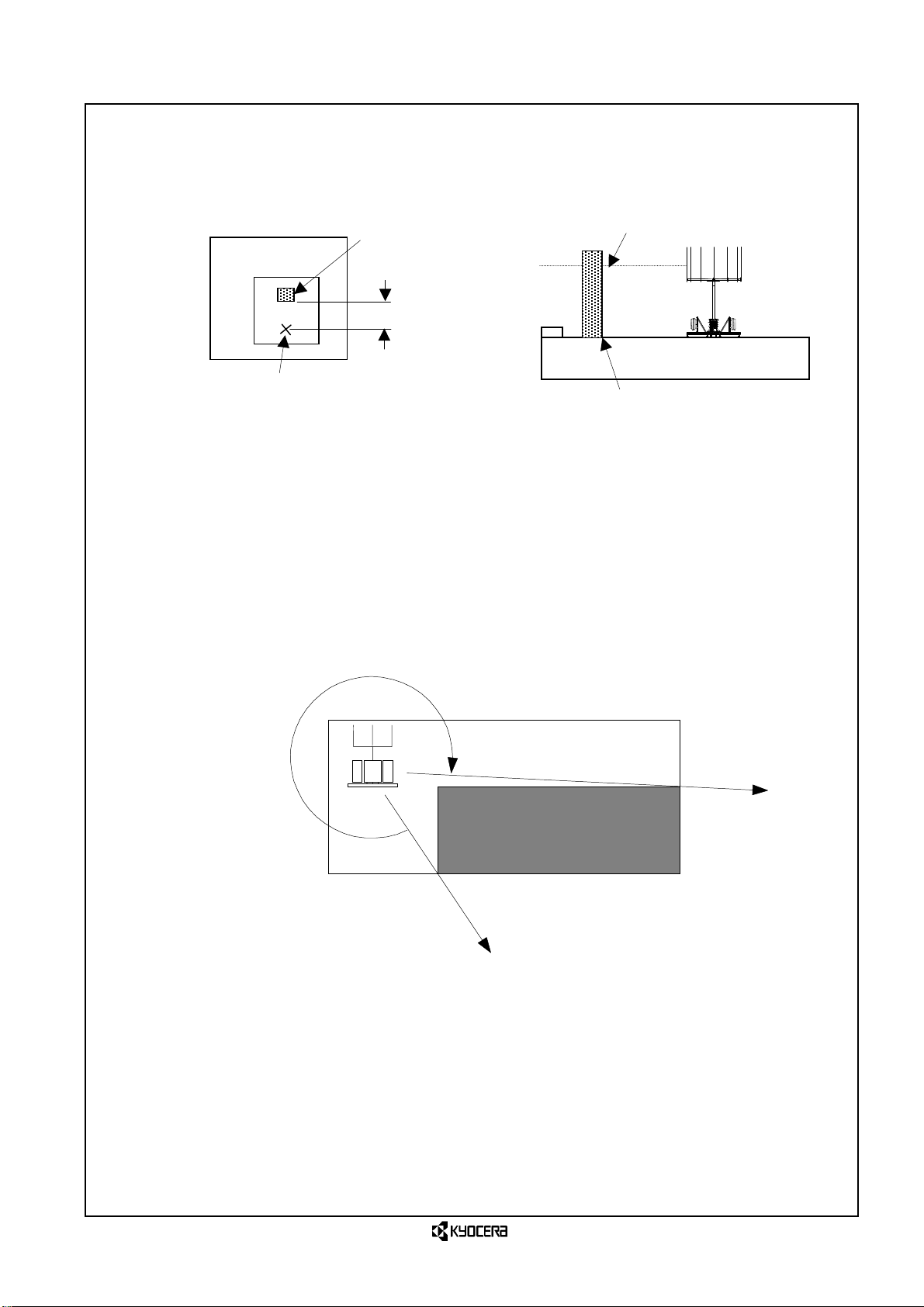

1.5.3.2 Securing space for PA unit

1.5.3.2.1 Workspace

When installing on the roof or the like, keep approx. 1m as a maintenance space

around the PA unit.

1.5.3.2.2 Ventilation space

When installing the PA unit on the wall, allow a ventilation space of more than 15mm.

Lid

Bush

1m

Workspace for PA unit

Pedestal

More than 15mm

Example of ventilation space for PA unit

(Page: 15/138)

Page 16

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

1.5.3.3 Lightening protection

PA unit installation shall be designed to be within the protection angle (* 60 degrees) of

the lightening rod.

* Lightening protection method is obeying the law by State regulations.

OK

Lightening protection for PA unit - Lightening rod-

Lightening protections for PA unit- Raised conductor -

More than 1.5m

More than 1.5m

60°

60°

Not OK

Lightening rod

When using raised conductor

(Page: 16/138)

Page 17

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

1.5.3.4 Isolation from drain

When installing the PA unit on the roof of a building, keep the isolation distance of more

than 1 m to prevent the pedestal from blocking the drain of the roof.

Isolation from drain

1.5.4 Criteria for selecting GPS unit location

1.5.4.1 Accuracy of GPS mounting

Inclination of GPS against the vertical direction shall be 4.5 degrees max.

Accuracy of GPS unit mounting

More than 1m

Within 4.5°

Roof drain

(Page: 17/138)

Page 18

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

1.5.4.2 GPS sight space

There shall be no obstruction at the place of 25 degrees or more from the horizontal

surface at the center (excluding antenna).

25°

Sight should not be obstructed in this range.

Sight should not be obstructed in this range.

25°

GPS sight space

25°

25°

(Page: 18/138)

Page 19

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

1.5.4.3 Lightening protection for GPS

GPS unit installation shall be designed to be within the protection angle (* 60 degrees)

of the lightening rod.

The GPS unit shall be isolated by more than 1.5 m from the lightening rod, lightening

conductor, or raised conductor.

When the GPS mounting pole is made of metal, isolation of more then 1.5 m is

recommended like the above.

* Lightening protection method is obeying the law by State regulations.

OK

More than 1.5m

Lightening protections for GPS - Lightening rod -

More than 1.5m

Lightening protections for GPS - Raised conductor -

60°

60°

Not OK

Lightening rod

When using raised conductor

(Page: 19/138)

Page 20

CONFIDENTIAL

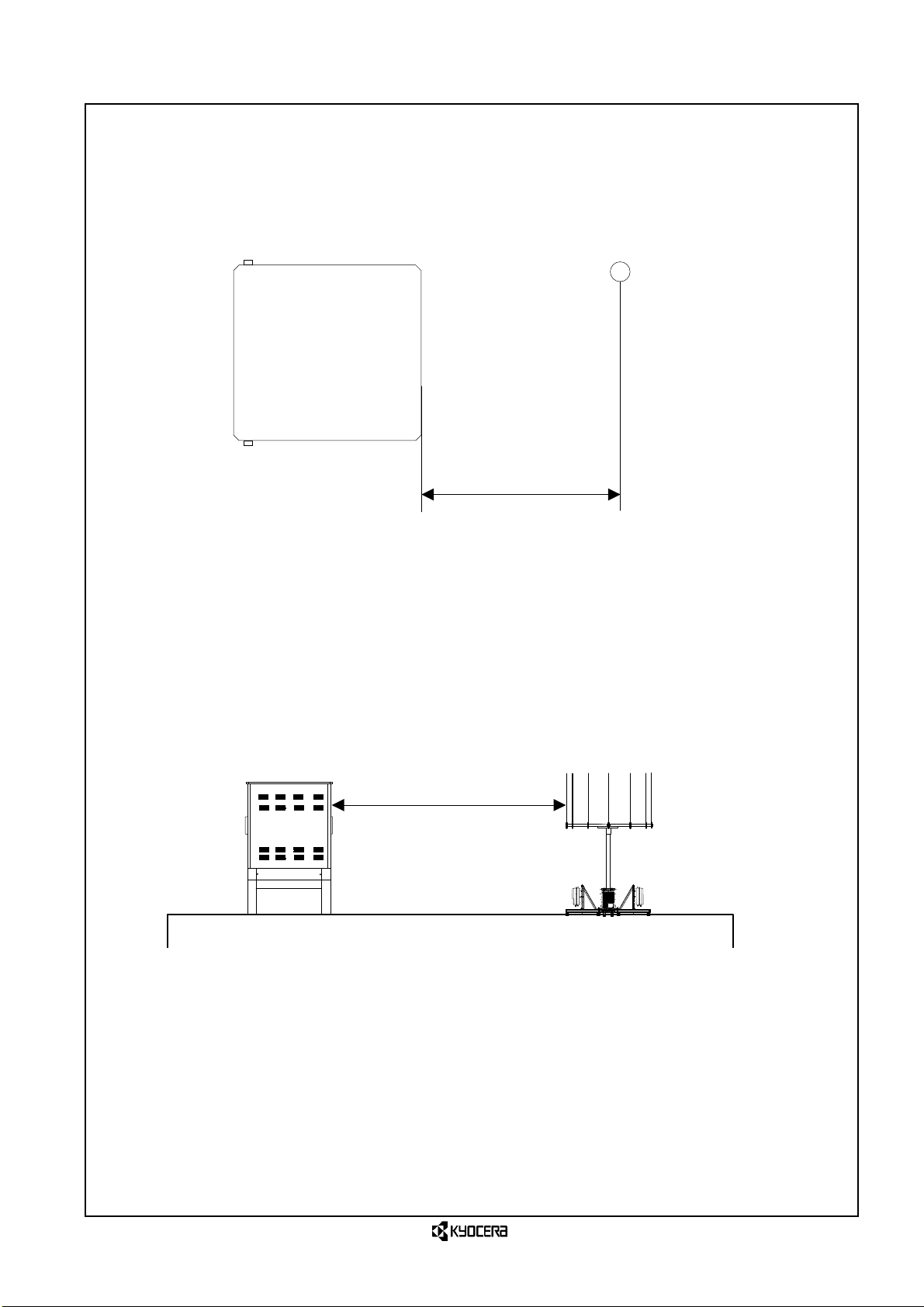

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

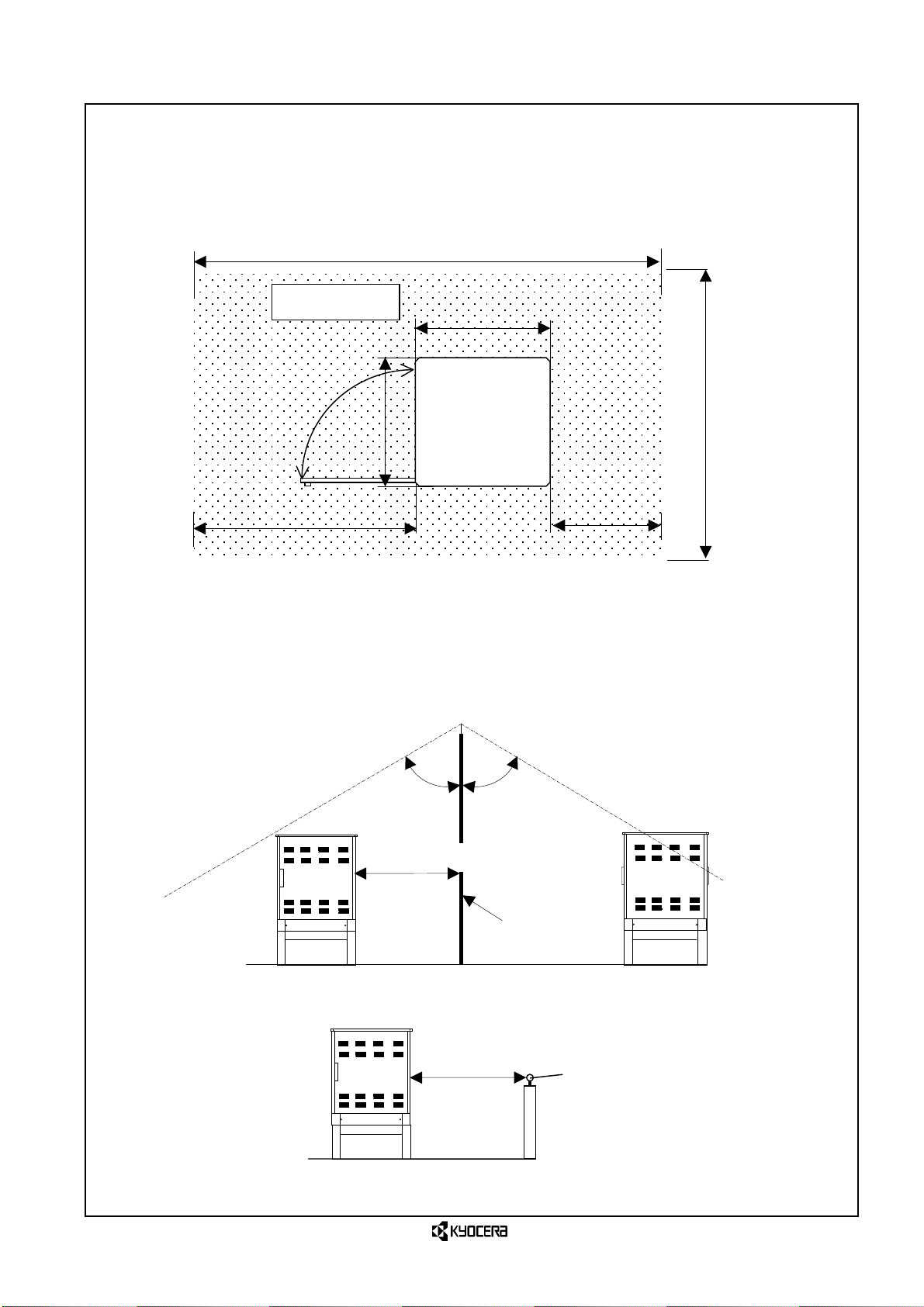

1.5.5 Criteria for selecting Base unit location

1.5.5.1 Installation space for Base unit

A space for installing and maintaining the Base unit shall be secured at the place

confirmed in the site survey.

1.5.5.2 Lightening protection for Base unit

When installing the Base unit outdoors, be sure to design the Base unit to be located

within the protection angle (* 60 degrees) of the lightening rod.

* Lightening protection method is obeying the law by State regulations.

OK

TOP VIEW

665

1150

Installation space for Base unit

60°

More than 1.5m

Lightening protection for Base unit - Lightening rod-

Lightening protection for Base unit - Raised conductor -

pprox. 2300

665

Base unit

Front

60°

Lightening rod

More than 1.5m

Rear

1700

500

Not OK

When using raised conductor

(Page: 20/138)

Page 21

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

1.5.5.3 Isolation from drain

When installing the Base unit outdoor such as on the building roof, keep the isolation

distance of more than 1 m so that the pedestal may not block the neighboring drain or

may not obstruct the flow of wastewater.

1.5.5.4 Isolation from iBurst antenna

When installing both Base unit and antenna on the same plane such as on the roof,

allow an isolation distance of 2m between the antenna and Base unit.

Top View Base Unit

Isolation of 2m

Isolation from antenna

More than 1m

Isolation from drain

Drain

(Page: 21/138)

Page 22

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

1.5.6 Precautions on cabling

1.5.6.1 Ground

1) The grounding terminal of the power cable must be surely connected to the ground.

(Note)

Unless ground connection is completed, noise may be caused during communication or

equipment may be damaged as lightening protection by ground line is disabled.

2) Ground shall be 100 Ω or less.

(Note)

If the ground resistance is more than 100 Ω, sound or image failure may be caused in

other radio equipment.

1.5.6.2 Cable

1) Be sure to lay the network cable and power cable in separate ducts.

(Note)

If the network cable and power cable are laid in a bundle, noise may be caused during

communication or sound or image failure may be caused in other radio equipment.

2) Attach an identification label on the power box, circuit breaker, and Ethernet

switch to indicate the cable belongs to the base station.

(Note)

Unless identification label is attached on the power box and circuit breaker, PA unit,

Base unit power may be turned off erroneously. Or power to other electrical devices

may be turned off erroneously resulting in a good deal of trouble.

Unless identification is attached on the network cable, identification work for network

cable may be difficult.

3) Allow an isolation distance of more than 10 cm between the network cable and

power cable.

(Note)

If the line cable and power cable are laid close together, noise may be caused during

communication.

4) Do not lay power cable within 3 m from the TV antenna.

(Note)

If power cable is close to the TV antenna, TV sound and image may be damaged.

3m

3m

Power cable and TV antenna

3m

3m

3m

(Page: 22/138)

Page 23

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

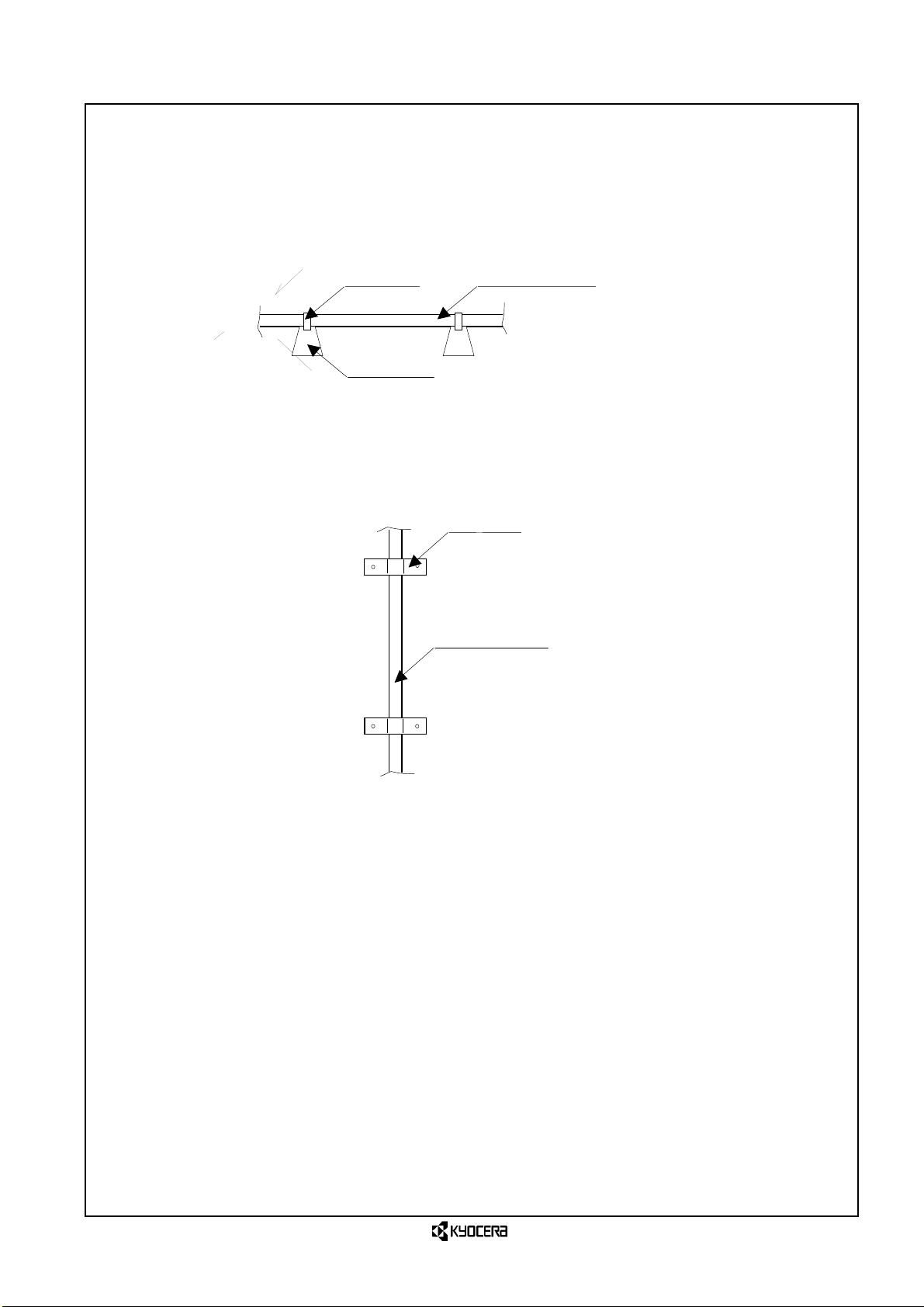

1.5.7 Precautions in installation on the roof

1) When laying the network cable and power cable on the roof, pass them through the

duct for cable protection to the specified places while putting them on the pedestals

for raised cabling.

2) When laying the network cable and power cable along the wall, fix them through

the duct in the same manner as the above.

Bracket

Pedestal

Cabling on the roof - 1 -

Cabling on the roof - 2 -

Protecting duct

Bracket

Protecting duct

(Page: 23/138)

Page 24

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

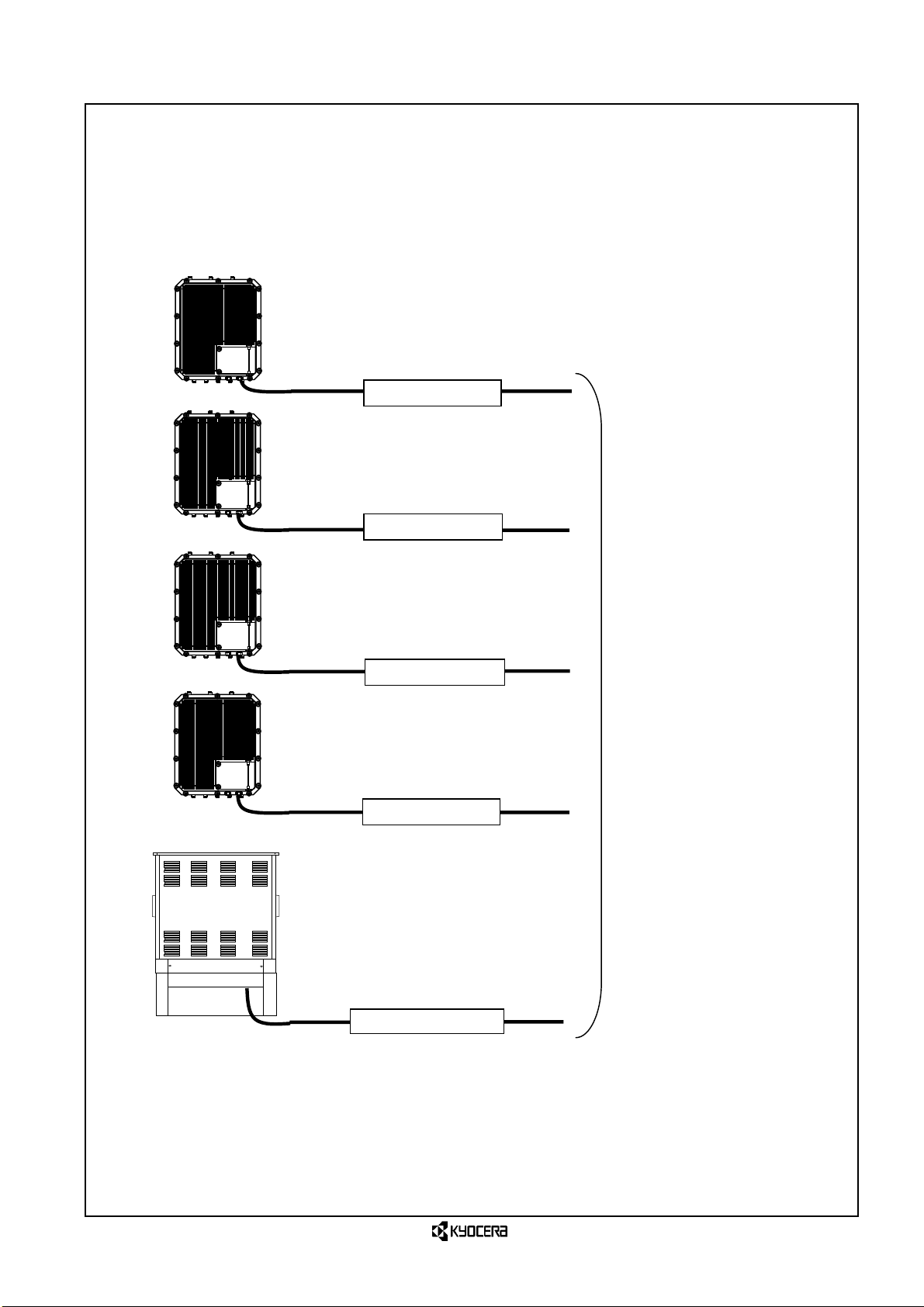

1.5.8 Separation of power systems

1) For the convenience of maintenance, the Base unit and PA unit shall be separately

provided with power cabling. In addition, four PA units shall be provided with

independent power systems each having a specified circuit breaker.

PA unit1 breaker

PA unit2 breaker

PA unit3 breaker

Connect to common distribution

board or master breaker.

PA unit4 breaker

Base unit breaker

Separation of power systems

(Page: 24/138)

Page 25

CONFIDENTIAL

A

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

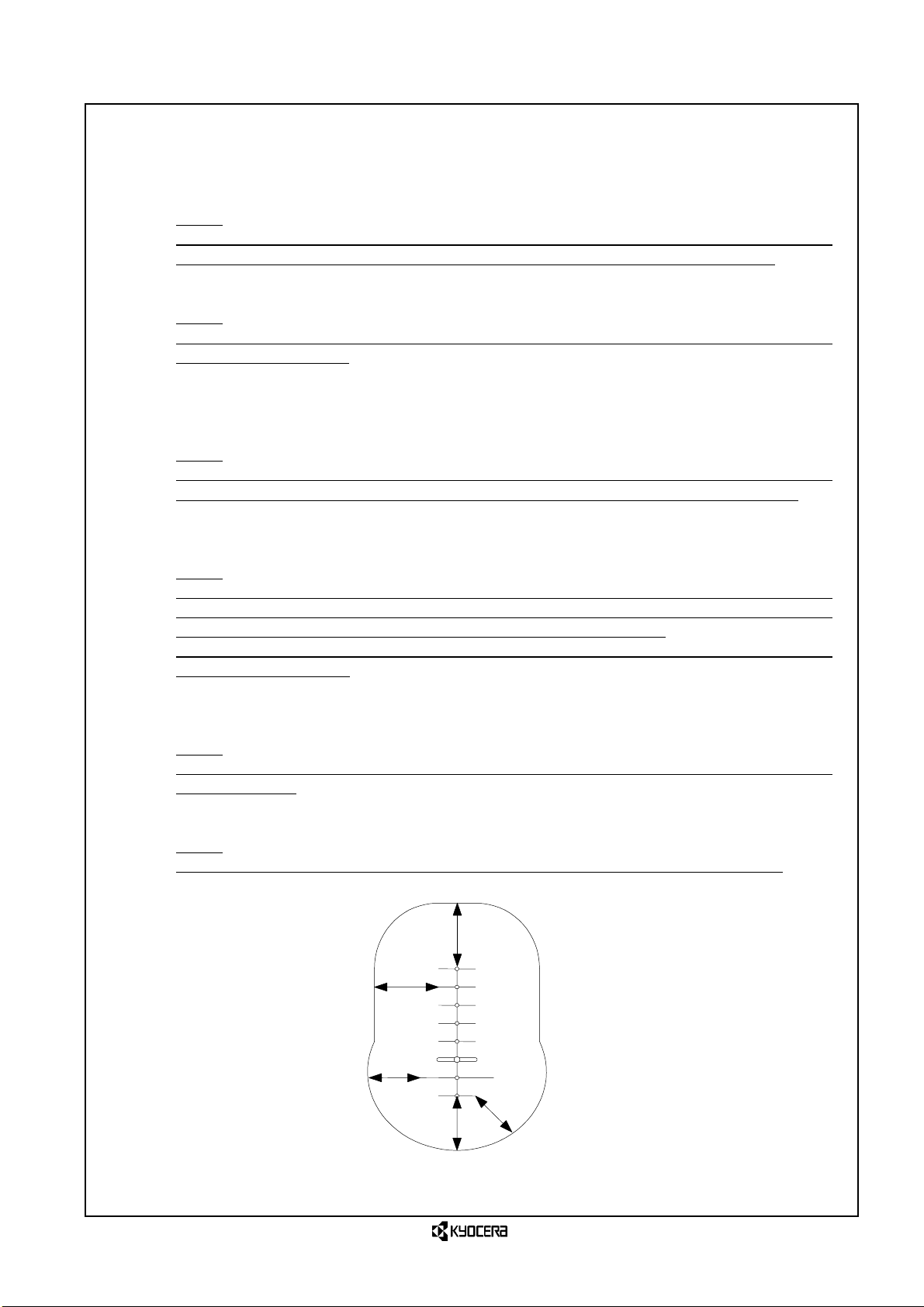

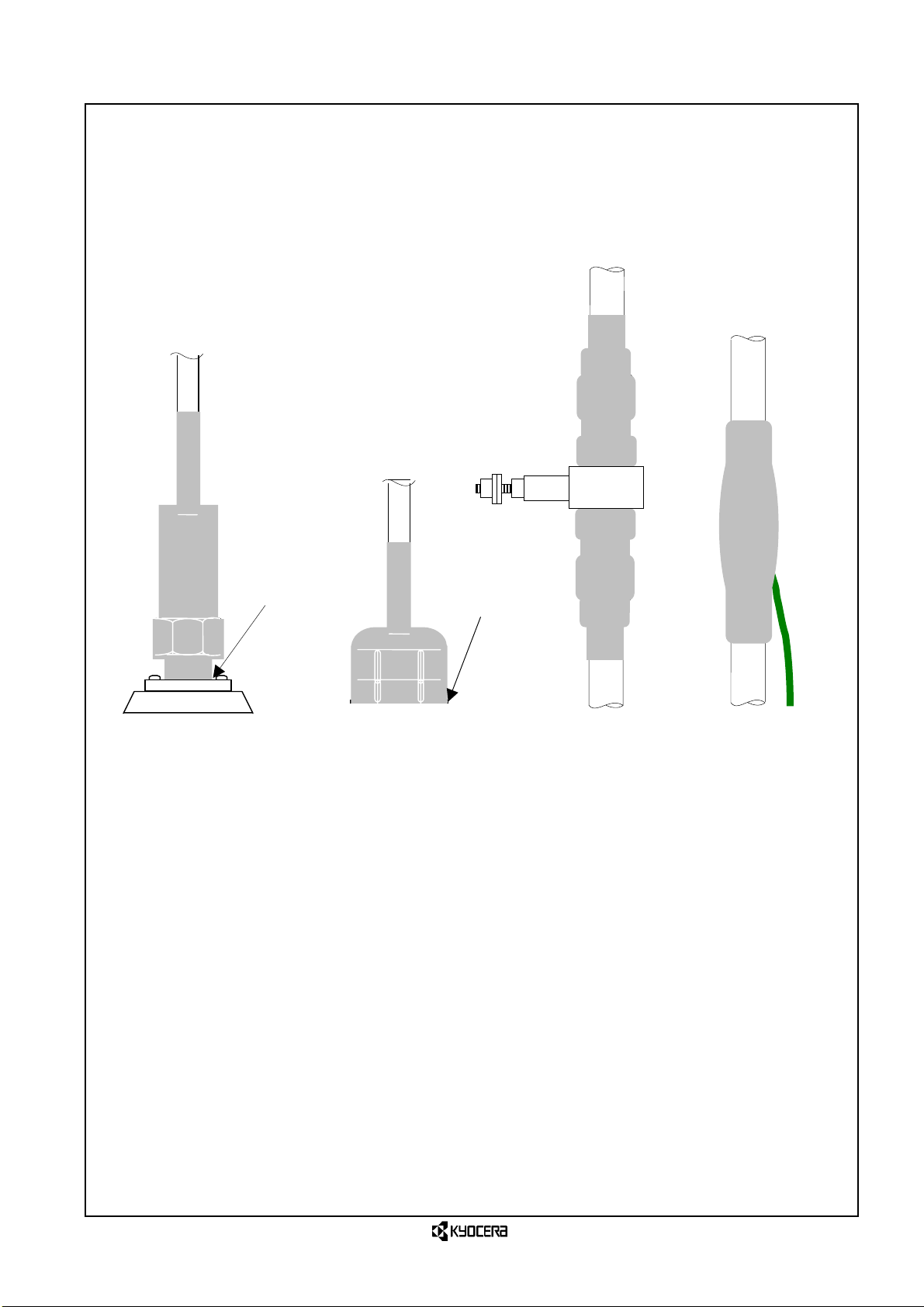

1.5.9 Waterproof treatment for connector and bushing

For connectors and bushing, it is necessary to use appropriate self-shrinkable tube or

wind self-fusing tape and then vinyl tape around them for water preventing measure to

protect the equipment against damage by water immersion.

In waterproof treatment, it is important to cover the root of the connectors and bushings.

See the following figure.

ntenna cable

PU-BU RF cable

Calibration cable

Cover the root

C Power Supply cable

Network cable

GPS cable

PA Control cable

GPI cable

M/S cable

Bushes

Waterproof treatment for connector and bushing

Cover the root

Surge Arrester

Grounding Kit

(Page: 25/138)

Page 26

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2 Configuration of Base Station and Accessories

(Page: 26/138)

Page 27

CONFIDENTIAL

A

A

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1 Configuration of Base Station

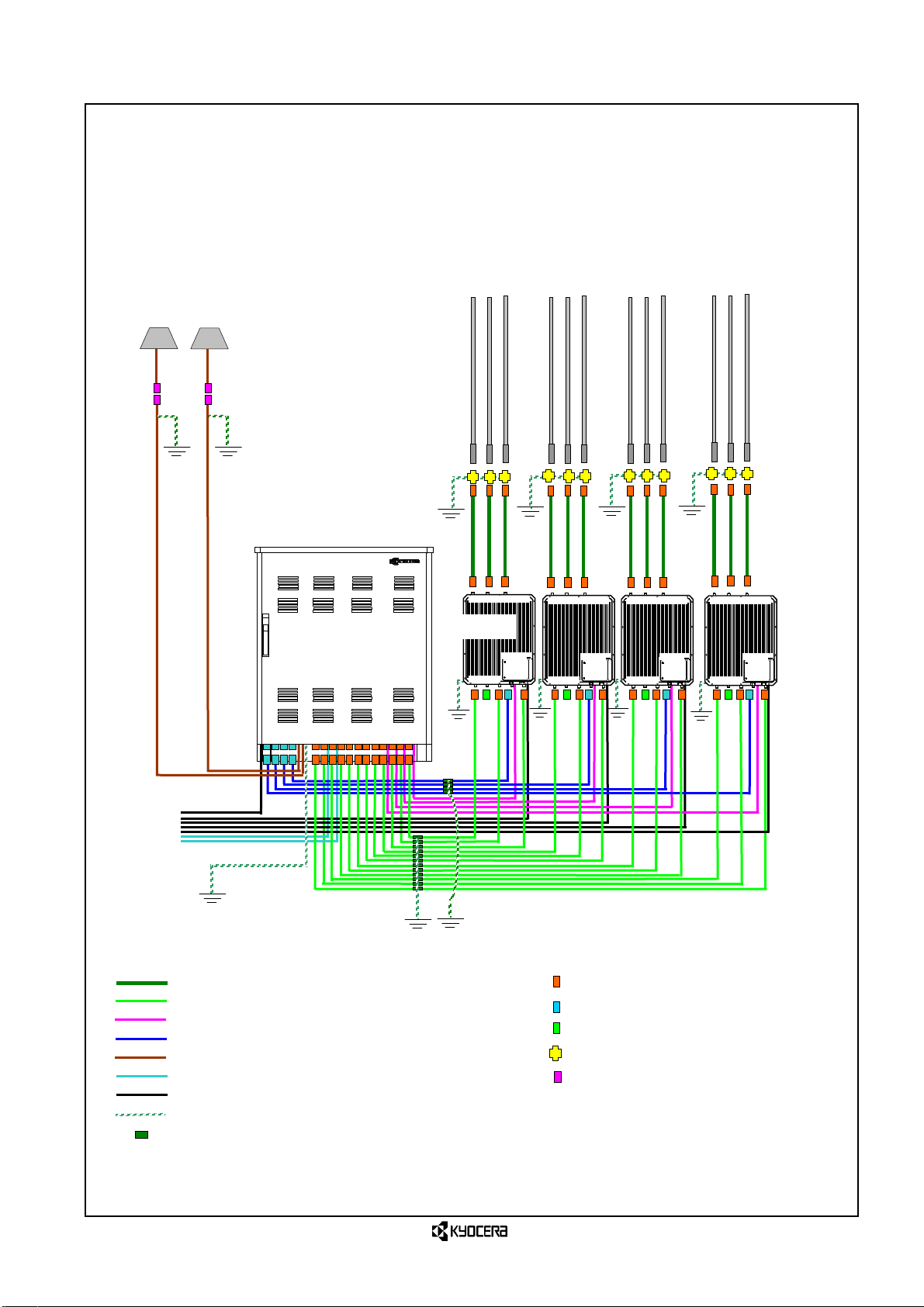

2.1.1 System Diagram

Two connecting types are provided depending on the method of the calibration cable.

One is star connection to connect one Base unit and one PA unit together and the other

is daisy chain connection to connect one Base unit and two PA units in series.

2.1.1.1 Star connection

GPS Antenna

Base Unit

PA Uni t

ntenna Cable

PU-BU RF Cable

PA Control Cable (Shielded Twisted Pair)

Calibration Cable

GPS Cable (Shielded Twisted Pair AWG24)

Network Cable (Shielded Twist Pair)

C Power Cable 3P

Grounding Cable

Grounding Kit

ntenna Unit

N (P) Type Connector

TNC (P) Type Connector

TNC (P) Type Terminator

N (J-J) Type Arrester

MMP Connector

(Page: 27/138)

Page 28

CONFIDENTIAL

A

A

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

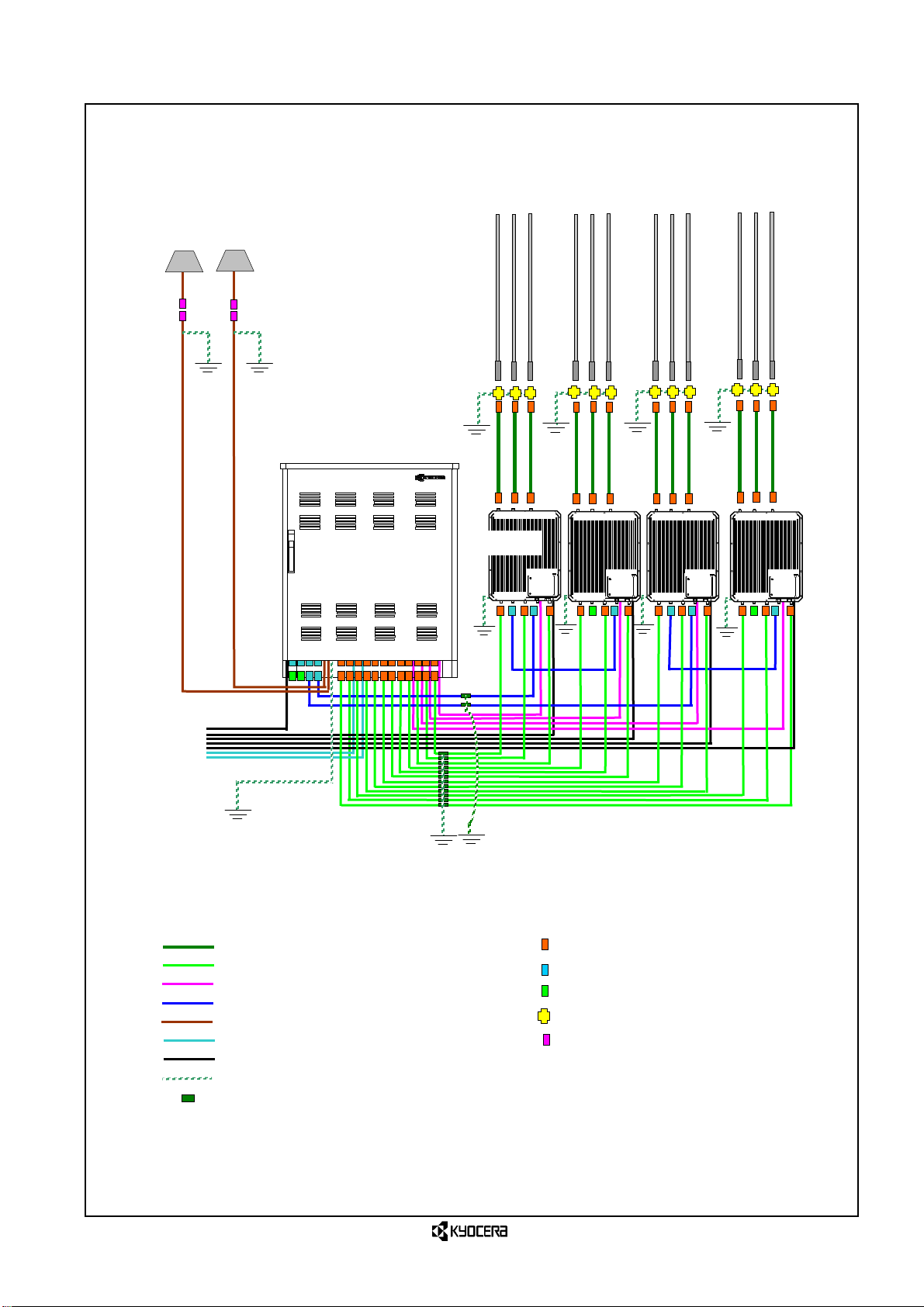

2.1.1.2 Daisy-chain connection

ntenna Unit

GPS Antenna

Base Unit

PA Uni t

ntenna Cable

PU-BU RF Cable

PA Control Cable (Shielded Twisted Pair)

Calibration Cable

GPS Cable (Shielded Twisted Pair AWG24)

Network Cable (Shielded Twist Pair)

C Power Cable 3P

Grounding Cable

Grounding Kit

N (P) Type Connector

TNC (P) Type Connector

TNC (P) Type Terminator

N (J-J) Type Arrester

MMP Connector

(Page: 28/138)

Page 29

CONFIDENTIAL

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.2 Appearance form

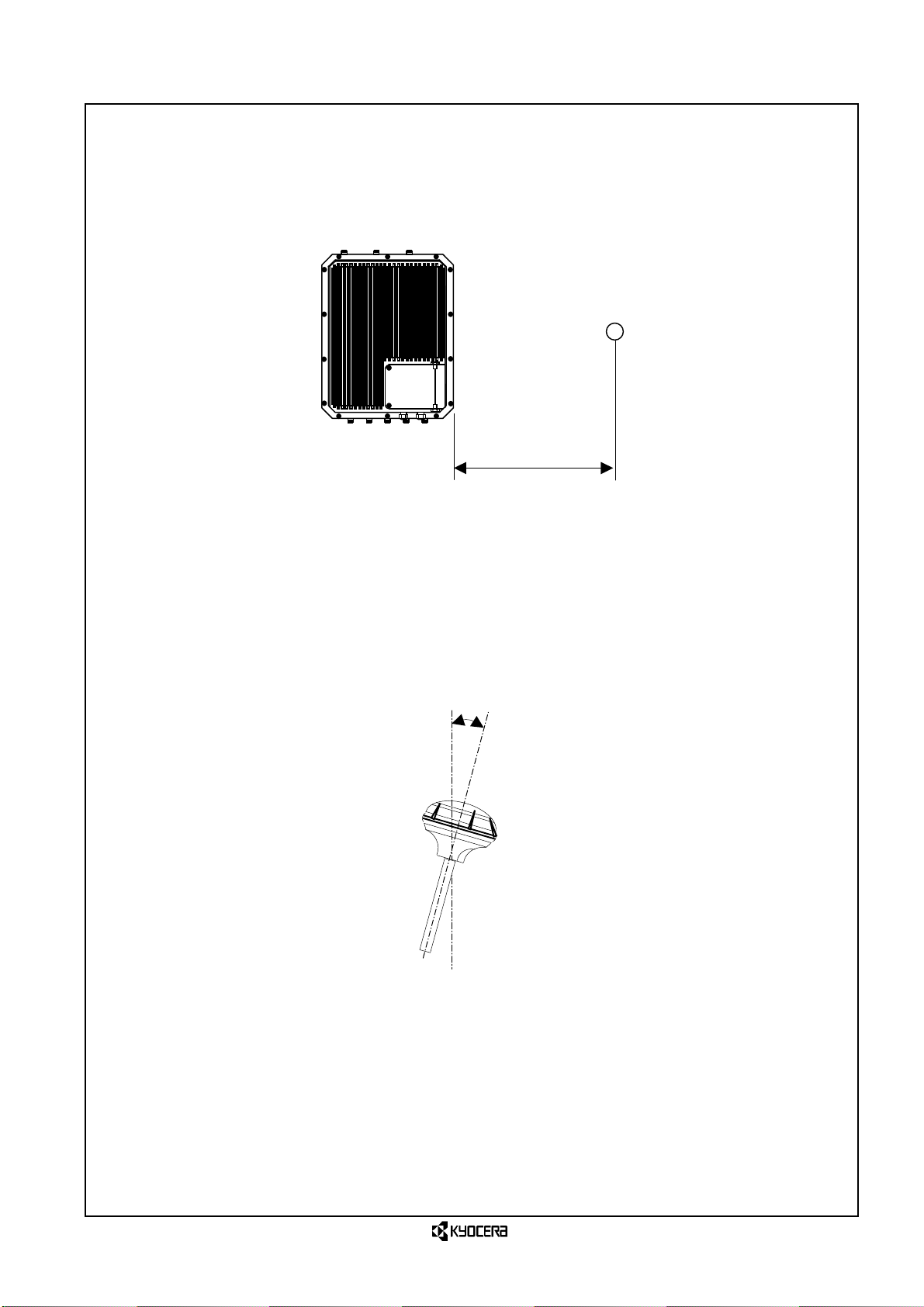

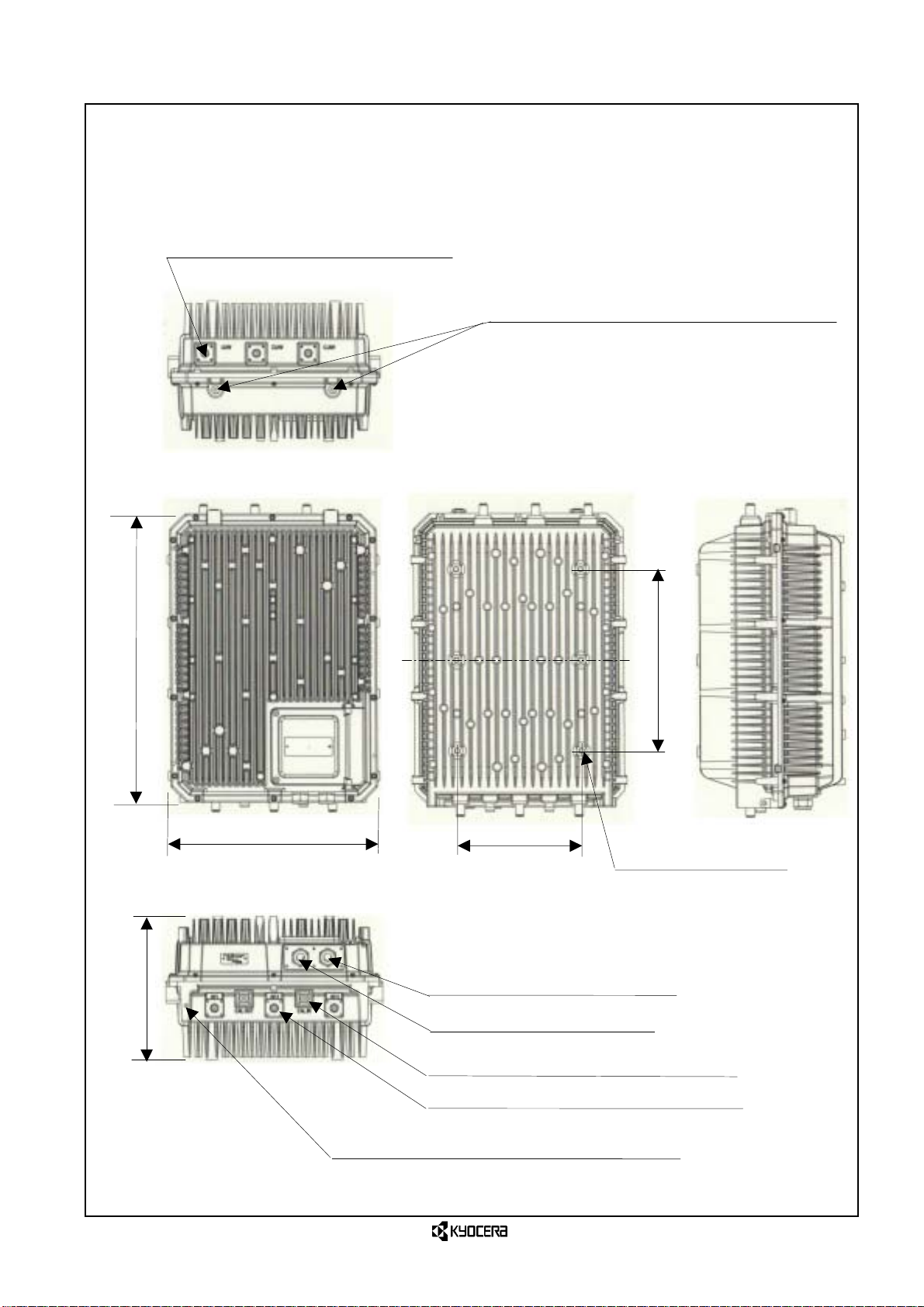

2.1.2.1 PA unit

550

Connector for Antenna Cable (N-J x 3)

Top View

Front View

390

Bottom View

256

Screw hole for fixing the lug of grounding cable (M6)

M6 x P1.0 x 15deep

Screw hole for fixing the Eyebolt (M10) or

Cap bolt (M10)

2‐M10 x P1.5 x 19deep

Left Side View

340±0.5

231±0.5

6-M10 x P1.5 x 30 deep

Bushing for

Bushing for PA Control Cable

Connector for Calibration Cable (TNC-J x 2)

Connector for PU-BU RF Cable (N-J x 3)

C Power supply Cable

(Page: 29/138)

Page 30

CONFIDENTIAL

–

–

–

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.2.2 Inside LID

Lid screws

LED for Status

Interface for AC Power Supply (Live)

Interface for AC Power Supply (GND)

Interface for AC Power Supply (Neutral)

+

TXD

+

RXD

+

FS

L

N

Clamp for PA Control Cable

Clamp for AC Power supply Cable

Interface for PA Control Cable (DDK 232D-02P1B x 3)

(Page: 30/138)

Page 31

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.2.3 GPS unit

Smart Antenna RS422_Cable Mount Type

Mount Adaptor

Note) This mounting adaptor is not an accessory of the GPS unit.

96

304

φ115

1.00-14UNS-2B X 1.00 deep

Recommended mating connector

Manufacturer: DEUTSCH ECD

Plug: MMP26C-2212S1

Contact: 6862-201-22278, 12pcs

Boot: 6810-204-2001

520

500

450

50

25

1.00-14UNS-2A

Mounting Adaptor

Mounting pipe length: 520mm

Mounting pipe inside diameter: 20.5-21.5mm

Materials to be used for the mount adaptor shall

be hot-dip galvanized steel.

(Page: 31/138)

Page 32

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.2.4 Base unit

Bottom View

Top View

665

900

500

*Installation Base Unit is not included in the Base Unit.

575

665

535

See detailed drawing A.

See detailed drawing B.

See detailed drawing C.

4-φ14

(Page: 32/138)

Page 33

CONFIDENTIAL

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.2.4.1 Bottom details

This figure looked from bottom side

Detailed drawing A

TNC-J type Connector Entry

Detailed drawing B

N-J type Connector Entry

PA Uni t 3

PA Uni t 1

CAL3

CAL1

RF3

RF2

RF1

RF3

RF2

RF1

CAL2 CAL4

Calibration

RF3

RF2

PA Uni t 4

RF1

RF3

RF2

PA Uni t 2

RF1

Detailed drawing C

Bushing type Entry

GPS2

GPS

GPS1

Master

Slave

GPI

LAN2

LAN1

100Base-TX

PA

Unit 4

PA

Unit 3

PA Con t rol

PA

Unit 2

PA

Unit 1

C INPUT

GPO

MODEM

Front Side

Blind Cap

(Page: 33/138)

Page 34

CONFIDENTIAL

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.2.4.2 Inside Base unit

LoCal Board

MoNerd Board

Surge Board (PA CT L )

TRx Board

Surge Board (Network)

Surge Board (GPI)

Surge Board (GPS)

Surge Board (M/S)

This Surge Board (M/S) is not used.

FAN Tray

Power Supply

Combiner Module

C Terminal

(Page: 34/138)

Page 35

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.2.4.3 Surge board

Frame-

Frame+

Rx-

Rx+

Tx-

Tx+

Frame-

Frame+

Rx-

Rx+

Tx-

Tx+

Frame-

Frame+

Rx-

Rx+

Tx-

Tx+

Frame-

Frame+

Rx-

Rx+

Tx-

Tx+

unused

Reserve1-

unused

Reserve1+

unused

Reserve2-

unused

Reserve2+

RxD-

RxD+

TxD-

TxD+

unused

Reserve1-

unused

Reserve1+

Reserve2-

unused

unused

Reserve2+

RxD-

RxD+

TxD-

TxD+

GND2

GPI2

GND1

GPI1

GND0

GPI0

Rx-

Rx+

Tx-

Tx+

GND

+12V

RxD-

RxD+

TxD-

TxD+

1PPS-

1PPS+

GND

+12V

RxD-

RxD+

TxD-

TxD+

1PPS-

1PPS+

PA1

PA2

PA3

PA4

LAN1

LAN2

GPI

M/S

GPS1

GPS2

2.1.2.4.4 AC terminal

L

N

L

N

ETH

FG

(Page: 35/138)

Page 36

CONFIDENTIAL

K

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.2.4.5 Display LED and Connector

LED

STATUS

LED

POWER

STATUS

LED

STATUS

MASTER

LED

POWER

POWER

STATUS

FAN

STATUS

STATUS

STATUS

STATUS

RF1

RF1

RF1

STATUS

MASTER

RF1

NETWORK

COM

STATUS

MASTER

NETWORK

COM

STATUS

MASTER

STATUS

MASTER

POWER

POWER

POWER

RF2

RF2

RF2

RF2

CAL

100Base-TX

CAL

100Base-TX

AC INPUT

AC INPUT

AC INPUT

RF3

TRx

Connecter

Connecter

RF3

RF3

TRx

TRx

RF3

100Base-TX

RF3

TRx

MoNerd

Connecter

MoNerd

LoCal

Cal

LoCal

Power Supply

STATUS

MASTER

NETWOR

COM

Power Supply

Power Supply

LED

Connecter

C INPUT

Connecter

(Page: 36/138)

Page 37

CONFIDENTIAL

A

A

A

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.3 Connection diagram

2.1.3.1 PA unit - Antenna

ntenna

Surge Arrester

N type connector

ntenna Cable

PA Unit

NT1 ANT2 ANT3

N type connector

NT1 ANT2 ANT3

(Page: 37/138)

Page 38

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.3.2 PA unit-Base unit

2.1.3.2.1 Star connection

2.1.3.2.1.1 Base unit – PA unit1,2

PA Unit 1

PA Unit 2

CAL OUT CAL IN

RF1 RF2 RF3

CAL OUT CAL IN

RF1 RF2 RF3

Base Unit

PA Uni t 3

PA Uni t 1

CAL3

CAL1

RF3

RF2 RF1

RF3

RF2 RF1

CAL4

Calibration

CAL2

RF3

RF2

PA Uni t 4

RF1

RF3

RF2

PA Uni t 2

RF1

This figure looked from bottom side

Front Side

PA

Unit 4

PA

Unit 3

PA Con t rol

PA

Unit 2

PA

Unit 1

PU-BU RF Cable w/ NP Connectors

Calibration Cable w/ TNCP Connectors

PA Control Cable w/ 232D

TNCP type Terminator

(Page: 38/138)

Page 39

CONFIDENTIAL

P

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.3.2.1.2 Base unit – PA unit3,4

PA Unit 3

PA Unit 4

CAL OUT CAL IN

RF1 RF2 RF3

CAL OUT CAL IN

RF1 RF2 RF3

Base Unit

PA Uni t 3

PA Uni t 1

CAL3

CAL1

RF3

RF2 RF1

RF3

RF2 RF1

CAL4

Calibration

CAL2

RF3

RF2

PA Uni t 4

RF1

RF3

RF2

PA Uni t 2

RF1

This figure looked from bottom side

Front Side

PA

Unit 4

PA

Unit 3

Unit 2

PA Con t rol

A

PA

Unit 1

PU-BU RF Cable w/ NP Connectors

Calibration Cable w/ TNCP Connectors

PA Control Cable w/ 232D

TNCP type Terminator

(Page: 39/138)

Page 40

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.3.2.2 Daisy-chain connection

2.1.3.2.2.1 Base unit-PA unit1,2

PA Unit 1

PA Unit 2

CAL OUT CAL IN

RF1 RF2 RF3

CAL OUT CAL IN

RF1 RF2 RF3

Base Unit

PA Uni t 3

PA Uni t 1

CAL3

CAL1

RF3

RF2 RF1

RF3

RF2 RF1

CAL4

Calibration

CAL2

RF3

RF2

PA Uni t 4

RF1

RF3

RF2

PA Uni t 2

RF1

This figure looked from bottom side

Front Side

PA

Unit 4

PA

Unit 3

PA Con t rol

PA

Unit 2

PA

Unit 1

PU-BU RF Cable w/ NP Connectors

Calibration Cable w/ TNCP Connectors

PA Control Cable w/ 232D

TNCP type Terminator

(Page: 40/138)

Page 41

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.3.2.2.2 Base unit – PA unit3,4

PA Unit 3

PA Unit 4

CAL OUT CAL IN

RF1 RF2 RF3

CAL OUT CAL IN

RF1 RF2 RF3

Base Unit

PA Uni t 3

PA Uni t 1

CAL3

CAL1

RF3

RF2 RF1

RF3

RF2 RF1

CAL4

Calibration

CAL2

RF3

RF2

PA Uni t 4

RF1

RF3

RF2

PA Uni t 2

RF1

This figure looked from bottom side

PA

Unit 4

PA

Unit 3

PA Con t rol

PA

Unit 2

PA

Unit 1

PU-BU RF Cable w/ NP Connectors

Calibration Cable w/ TNCP Connectors

PA Control Cable w/ 232D

TNCP type Terminator

(Page: 41/138)

Page 42

CONFIDENTIAL

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.3.3 Base unit – Other equipment

GPS Antenna

Deutsch MMP26C-2212S1 Connector

GPS Cable

Base Unit

GPS2

GPS

GPS1

Master

Slave

GPI

LAN2

LAN1

100Base-TX

PA

Unit 4

PA

Unit 3

PA Con t rol

PA

Unit 2

PA

Unit 1

C INPUT

Network Cable

Ethernet Switch

This figure looked from bottom side

Front Side

(Page: 42/138)

Page 43

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.4 Pin assignment of cables/connectors

2.1.4.1 AC Power supply cable

PA Unit AC Terminal

GND

Live

Neutral

Base Unit AC Terminal

L

N

L

N

ETH

FG

L

N

Live

Neutral

GND

2.1.4.2 PA control cable

PA Unit side

LED

PA Control Cable

TXD +

TXD –

RXD +

RXD –

FS +

FS –

Base Unit Surge Board

Frame –

Frame +

Rx –

Rx +

Tx –

Tx +

PA unit Connection place Base unit

TXD + Rx +

TXD – Rx –

RXD + Tx +

RXD – Tx –

FS + Frame +

FS – Frame –

(Page: 43/138)

Page 44

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.4.3 Network cable

RJ45

8

Network Cable

7

6

5

4

3

2

1

Base Unit Surge Board

Reserve1–

Reserve1+

Reserve2–

Reserve2+

RxD –

RxD +

TxD –

TxD +

2.1.4.4 GPS cable

Connector of GPS unit side

(Pin side view)

5

10

12

9

6

7

8

4

11

3

2

1

GPS Cable

Base Unit Surge Board

GND

+12V

RxD –

RxD +

TxD –

TxD +

1PPS –

1PPS +

GPS connector pin No. Connection place Base Unit

Surge Board

No.1 + 12

No.2 TxD –

No.3 TxD +

No.4 RxD –

No.5 RxD +

No.6 NONE

No.7 NONE

No.8 NONE

No.9 GND

No.10 NONE

No.11 1PPS +

No.12 1PPS –

(Page: 44/138)

Page 45

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.1.4.5 GPI cable

Customer’s UPS

Dry Contact2

Base Unit Surge Board

GND2

GPI2

Dry Contact1

Dry Contact0

GND1

GPI1

GND0

GPI0

Customer’s UPS Connection place Base Unit

GND2 Dry Contact2

GPI2

GND1 Dry Contact1

GPI1

GND0 Dry Contact0

GPI0

2.1.4.6 Master/Slave cable

Master Base Unit Surge Board

Slave Base Unit Surge Board

Rx–

Rx+

Tx–

Tx+

Rx–

Rx+

Tx–

Tx+

Master Base Unit Connection place Slave Base unit

Tx + Rx +

Tx – Rx –

Rx + Tx +

Rx – Tx –

(Page: 45/138)

Page 46

CONFIDENTIAL

A

A

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.2 Specifications

2.2.1 Hardware specifications

Number of antennas 12

Shape

Dimensions

Weight

Power consumption

Dimensions

Weight

Power consumption 600W

Dimensions

Weight

Power consumption 1.8 W/unit

Network I/F

Installation environment

Operating temperature

PA unit

390 (W) x 256 (D) x 550 (H)

450W/unit

Base unit

665 (W) x 665 (D) x 900 (H)

GPS unit

115 (diameter) x 96 (H)

100Base-TX (Options are available.)

Outdoor/Indoor

-20°C to +50°C

pprox. 40kg/unit

pprox. 100 kg

pprox. 0.55kg/unit

(Page: 46/138)

Page 47

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.2.2 LED indicators

2.2.2.1 PA unit

Unit Module LED Name Status Mean Comments

PA Unit

PA Control

STATUS

Off Power Off Ready for replacement

Amber Initializing/operation

suspended

Green Normal operation

Red Abnormal

2.2.2.2 Base unit

Unit Module LED Name Status Mean Comments

Base Unit

TRx

MoNerd

LoCal

FAN

STATUS

STATUS

MASTER

NETWORK

STATUS

MASTER

STATUS

Off

Amber Initializing/operation

Green Normal operation

Red Abnormal

Off

Amber Initializing

Green Normal operation

Red Abnormal

Off Slave is operating

Amber Initializing

Green Master is operating

Off Network is abnormal

Amber Initializing

Green Network is alive

Off

Amber Initializing

Green Normal operation

Red Abnormal

Off Slave is operating

Green Master is operating

Off Abnormal Power Supply STATUS

Green Normal operation

Off Power is abnormal POWER

Green Power is normal

Amber Initializing

Green Normal operation

Red Abnormal

Board is ready for

removal

suspended

Board is ready for

removal

Board is ready for

removal

(Page: 47/138)

Page 48

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.2.3 Accessories

2.2.3.1 PA unit

Accessory name Quantity Purpose of use

Eyebolt M10

Cap bolt M10 2 Fixed on the top of PA Unit and used for waterproof.

2

Fixed on the top of PA Unit and used for transporting or fixing the

main body.

2.2.3.2 Base unit

Accessory name Quantity Purpose of use

Eyebolt M12

TNC terminating connector 4 To terminate the unconnected portion of calibration cable.

FAN tray fixing screw 6 Screw for fixing FAN tray

BU door key 2 Key for locking Base Unit door

L-shaped wrench for

hexagonal hole

4

1 For tightening or removing a Base panel fixing screw.

Fixed on the top of Base Unit and used for transporting

or fixing the main body.

2.2.4 Cable specification

Reference value of cable attenuation: FSJ1-50A Æ 0.277dB/m, FSJ2-50 Æ 0.191dB/m,

FSJ4-50B Æ 0.171dB/m, at 1.9GHz made by Andrew

Type of cable Purpose of use Specifications Q’ty

Antenna cable

PU-BU RF cable From Base unit to

AC power cable

Calibration cable

From PA unit to

Antenna

PA unit

From PA unit to

Breaker

From Base unit to

Breaker

From Base unit to

PA unit

Daisy-chain connection

From PA unit to PA

unit

(Daisy-chain

connection only.)

Recommend the attenuation less than 1dB.

e.g. The cable equivalent to

FSJ2-50 Æ Length: within 5m

Keep the attenuation less than 13dB.

e.g. The cable equivalent to

FSJ1-50A Æ Length: within 46.5m

FSJ2-50 Æ Length: within 68m

FSJ4-50B Æ Length: within 76m

Copper-shielded cable (3 lines)

Cross-section: 1.25 - 2.0mm

Diameter over jacket: 7 - 10.5mm

Copper-shielded cable (3 lines)

Cross-section: 1.25 - 2.5mm

Diameter over jacket: 7-10.5mm

Star connection

Keep the attenuation less than 21dB.

Disparity of the longest cable and the shortest cable

is kept within 3dB in attenuation.

e.g. The cable equivalent to

FSJ1-50A Æ Length: within 75.5m

Keep the attenuation less than 15dB.

Disparity of the longest cable and the shortest cable

is kept within 3dB in attenuation.

e.g. The cable equivalent to

FSJ1-50A Æ Length: within 54m

Keep the attenuation less than 3dB.

e.g. The cable equivalent to

FSJ1-50A Æ Length: within 10.5m

2

2

12

12

4

1

4

2

2

(Page: 48/138)

Page 49

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

PA control cable

Network cable

GPS cable

GPI cable From UPS to Base

Master/Slave

cable

Ground cable

From Base unit to

PA unit

From Base unit to

Ethernet Switch or

Router

From Base unit to

GPS unit

unit

From Master Base

unit to Slave Base

unit

PA unit to Ground Soft copper twist cable of more than 6mm

BU unit to Ground Soft copper twist cable of more than 6mm

GPS unit to Ground Soft copper twist cable of more than 6mm

Copper-shielded twist pair cable (4 pairs or more)

Diameter: 0.5mm or 0.65mm

Length: within 75m

Diameter over jacket: 7-10.5mm

Copper-shielded twist pair cable (4 pairs or more)

Diameter: 0.5mm or 0.65mm

Length: within 100m

Diameter over jacket: 7-10.5mm

Copper-shielded twist pair cable (4 pairs or more)

The maximum allowable end to end resistance is

5.4Ω or less.

AWG24 (7/0.203) or AWG26 (7/0.16)

Diameter over jacket: 7-10.5mm

The example of reference: The case of 84.21Ω

(AWG24)/km is 64m or 133.9Ω (AWG26)/km is 40m.

Copper-shielded twist pair cable (3pairs or more)

Diameter: 0.5mm or 0.65mm

Diameter over jacket: 7-10.5mm

Length: within 100m

Copper-shielded twist pair cable (3pairs or more)

Diameter: 0.5mm or 0.65mm

Diameter over jacket: 7-10.5mm

Length: within 100m

Reference resistance: Less than 3.1Ω/km (at 70

degrees in Celsius)

Reference resistance: Less than 3.1Ω/km (at 70

degrees in Celsius)

Reference resistance: Less than 3.1Ω/km (at 70

degrees in Celsius)

2

2

2

4

2

2

1

1

4

1

2

2.2.5 Other Parts specification

Type of parts Purpose of use Specifications Q’ty

N type RF connector PU-BU RF cable

Antenna cable

TNC type connector Calibration cable TNC type Male 8

TNC type Terminator PA unit CAL port (CAL OUT) TNC type Male 4

232D connector PA Control cable at both sides

Network cable in surge box of BU

GPS cable in surge box of BU

GPI cable in surge box of BU

M/S cable in surge box of BU

MMP connector

Plug

Contact

Boot

Surge Arrester

“O” shaped type

Term in al

GPS mount adaptor Fixing and Grounding for GPS

GPS cable at GPS side

Equipment surge protection

Grounding cable for PA unit

Grounding cable for Base unit

Grounding cable for GPS unit

N type Male 24

12

232D-02S1B-DA2 24

8

8

3

2

Deutch

Plug: MMP26C-2212S1

Contact: 6862-201-22278,12pcs

Boot: 6810-204-2001

N type Female/Female

λ /4 Stub type Arrester or

Gas Tube type Arrester

M6 type

M6 type

M6 type

Specification of a screw part:

1.00-14UNS-2A

2

2

2

12

4

1

2

2

(Page: 49/138)

Page 50

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

Mounting pipe length: 520mm

(Including screw part)

Mounting pipe inside diameter:

20.5-21.5mm

Hot-dip galvanized steel

With Hex bolt (M6)

2.2.6 Handling of cables

Install cables considering the possible flexibility, pressure resistibility, and stretching

strength. Strength of the coaxial cable is shown below.

Items FSJ1-50A FSJ2-50 FSJ4-50B

Minimum Bending Radius More than 25mm More than 25mm More than 32mm

Tensile Strength 68kg 95kg 80kg

Bending Moment

Others Don’t bend Cable below –10 degrees in Celsius

1.1N⋅m 2.3N⋅m 2.7N⋅m

2.2.7 Tightening Torque

Appropriate cable diameters and Tightening Torque for Bushes and Connectors on each side

are shown below.

Connecting point Suitable diameter of the

Cable

Antenna connector (N type Connector)

Bush for AC power cable 7 to 10.5mm

Bush for Network cable 7 to 10.5mm

Bush for PA Control cable 7 to 10.5mm

Bush for GPS cable 7 to 10.5mm

Bush for GPI cable 7 to 10.5mm

Bush for M/S cable 7 to 10.5mm

PU-BU RF cable (N type connector)

Calibration cable (TNC type connector)

Tightening Torque of the

Bush and Connector

1.96 to 2.94 N⋅m

2.45N⋅m

2.45N⋅m

2.45N⋅m

2.45N⋅m

2.45N⋅m

2.45N⋅m

1.96 to 2.94 N⋅m

0.45 to 0.69N⋅m

(Page: 50/138)

Page 51

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2.2.8 Tools

Tool name Specifications Purpose of use

Monkey wrench Max. opening 24 mm For fixing hex nuts, etc.

Torque wrench

Adjustable type torque wrench

Torq u e dri v er

Flat-head screwdriver

Cross-shaped (Philips) screwdriver

Allen wrench

Hex lobe screwdriver T30

L-shaped wrench for hexagonal hole Size 3 for M5

Wrist strap F-50

GPS connector assembly tools

Crimping tool DANIELS MH860

Positioner

Insertion and removal tool

Soldering iron 150W Soldering a TNC type connector.

1-5N・m

5-25N・m

1-5N・m

3 mm wide

No.1

No.2

No.3

3mm

10mm

T30

F-50

M22520/7-01

M22520/7-06

M81969/14-01

For torque control.

For holding the cage clamp when

connecting power cable to power

terminal board.

For tightening or removing

Cross-shaped (Phillips) screw.

For opening or closing the Lid of

PA Unit.

For removing or installing Allen

screws of Base Unit.

For tightening or removing a

tamper proof screw.

For tightening or removing a

Base panel fixing screw. *1

For preventing static electricity

when inserting or removing a

board.

For caulking MMP connector.

Base unit

*1

Base panel fixing screw

(Page: 51/138)

Page 52

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

3 Installation

(Page: 52/138)

Page 53

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

3.1 Installing Antenna System (Example)

Assemble the antenna base (H-section steel) on the place determined by site survey.

3.1.1 Installing the antenna pole

1) Fix the antenna base (H-section steel) by using bolts.

H-section steel

2) Fixing the antenna pole to the antenna base (H-section steel)

3) Fixing the mast to the antenna pole

Fix the H-section steel with bolts.

Fix it to the H-section steel

with bolts

Fix the mast with bolts.

(Page: 53/138)

Page 54

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

4) Fixing the antenna arm to the mast

5) Fixing the antenna to the antenna arm

Top vi ew

Fix with a reinforcing plate and bolts.

Fix the antenna with bolts.

(Page: 54/138)

Page 55

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

6) Connecting the surge arrester

Connect the surge arrester between the antenna cable connector and the extension

cable.

ÆTightening torque: 1.96 to 2.94N⋅m

7) Waterproof treatment for the surge arrester connector

8) Connecting the surge arrester to the ground

Install a ground bar or use the grounding directly through the cable.

Ground bar

Fix the surge arrester to the ground bar.

Cold shrinkable tube

(Page: 55/138)

Page 56

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

3.2 Installing PA Unit

3.2.1 Mounting and removing the Eyebolt

1) Mounting the Eyebolt

Insert the Eyebolt to the screw hole for the Eyebolt (M10) at the upper portion of the

PA Unit and turn it to fix.

Eyebolt (M10)ÆTightening torque: 4.41 to 5.39N⋅m

Cap boltÆ Tightening torque: 2 to 3N⋅m

ANT1

ANT2ANT3

Screw hole for fixing the Eyebolt (M10) or

Cap bolt (M10)

Eyebolt (M10)

(Page: 56/138)

Page 57

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

3.2.2 Mounting the PA Unit (Example)

When fixing the PA Unit to a fitting, tighten it with a specified torque. (Seven or more

threads of the bolt must screw in and fit to the thread on the PA unit effectively.)

Recommending bolt: Hot-dip galvanized steel or Dacrotized finishing.

Tightening with excessive torque may cause broken screw.

1) Fixing the PA Unit and a mounting bracket

Put the PA Unit with its front down to prevent damage to the connector and attach the

mounting bracket.

Fix it with bolts supplied with the mounting bracket

for the PA Unit.

ÆTightening torque: 22N⋅m to 27N⋅m

(Page: 57/138)

Page 58

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

2) Fixing the mounting bracket

Attach the U bolts of the mounting bracket to the fixing plate and fix it with nuts.

(Page: 58/138)

Page 59

CONFIDENTIAL

–

–

–

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

3.2.3 Connecting cables

3.2.3.1 Connecting the AC power supply cable

Before connecting the AC power supply cable, verify that the supply voltage of the

power distributor is within the range of ±15% of the nominal voltage.

And distribute the AC power supply cable so that the power for each PA unit can be

turned on or off separately through the breaker.

1) Opening/closing the Lid of the PA Unit

Loosen the hexagonal recessed bolts (2 places) on the Lid using a hexagon wrench (3

mm) and open it

Lid open/close screw

ÆTightening torque: 1.5N⋅m

2) Removing the cable clamp for the AC power supply cable

Remove the cable clamp fixing screw (M4) with a “+” screwdriver and remove the cable

clamp.

+

TXD

+

RXD

+

FS

L

N

Cable clamp

(Page: 59/138)

Page 60

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

3) Removing the dome nut for the AC power supply cable

Remove the dome nut for the AC power supply cable at the bottom of the PA Unit and

remove the cable packing.

Cable packing

CAL OUT CAL IN

RF3 RF2 RF1

Dome nut

4) Pre-finishing the AC power supply cable

Put the AC power supply cable through the cold shrinkable tube, the dome nut and the

cable packing in this order.

(See the following figure for the direction.)

Cold shrinkable tube

Dome nut

Cable packing

Lid side

Peel the sheath off the AC power supply cable to expose the conductor.

ÆPeeling length of the sheath: 15 to 20 cm

15 to 20cm

(Page: 60/138)

Page 61

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

Loosen the copper shield and coil it around the conductor at the shield root part by

more than 4 turns.

Peel the sheath off 3 conductors.

Æ Peeling length of the sheath: 10 mm

5) Inserting the AC power supply cable

Insert the AC power supply cable into the Lid through the bushing for the AC power

supply cable.

CAL OUT CAL IN

10mm

RF3 RF2 RF1

(Page: 61/138)

Page 62

CONFIDENTIAL

–

–

–

A

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

6) Fixing the cable clamp

Position the copper shield of the cable at the arrow marking in the following figure and

fix it with the cable clamp and a fixing screw (M4).

ÆTightening torque: 1.5N·m

B

+

TXD

+

RXD

+

FS

L

N

Fix the cable clamp with a fixing screw

(M4).

The attachment position of a cable clamp

changes by the diameter of a cable.

When the diameter of a cable is from6 to

8mm, it attaches at A-side.

When the diameter of a cable is from7 to

10.5mm, it attaches at B-side.

B

7) Tightening the dome nut

After inserting the cable packing, tighten the dome nut by hand and then retighten it

using a torque wrench.

ÆTightening torque: 2.45N⋅m

Fixing part of bushing

Dome nut

(Page: 62/138)

Page 63

CONFIDENTIAL

–

–

–

–

–

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

8) Connecting the AC power supply cable to the AC terminal

With keeping the AC terminal depressed by a finger, insert the AC power supply cable

and then release the finger.

After insertion, verify that the cable cannot be removed.

In the following figure, Neutral, Ground and Live cables are arranged in this order

from the right side.

+

TXD

+

RXD

+

FS

L

N

Press the AC terminal with a finger.

Insert the AC power supply cable until it reaches the far end of the inlet port.

9) Treatment of the AC power supply cable

Form the AC power supply cable along the inside of the Lid so that the Lid does not

clip the cable.

+

TXD

RXD

- +

+

FS

L

N

(Page: 63/138)

Page 64

CONFIDENTIAL

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

10) Waterproof treatment for the AC power supply cable connector

Cover the cold shrinkable tube over the root of the connector and shrink it.

Cold shrinkable tube

3.2.3.2 Connecting the grounding cable.

Crimp the grounding cable (More than

it.

Æ Tightening torque: 3.29 to 4.12N⋅m

Bottom View

Clamping the lug

fter removing a Hex bolt at once, a

ground cable is fixed with a Hex bolt.

6mm2) to the terminal and fix the bolt (M6) with

Grounding cable (More than 6mm2)

(Page: 64/138)

Page 65

CONFIDENTIAL

L

–

–

–

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

3.2.3.3 Connecting the PA control cable

1) Removing the cable clamp for the PA control cable

Remove the cable clamp fixing screw with a “+” screwdriver and remove the cable

clamp.

Cable clamp

+

TXD

+

RXD

+

FS

2) Removing the dome nut for the PA control cable

Remove the dome nut for the PA control cable at the bottom of the PA Unit and remove

the cable packing.

Cable packing

Dome nut

(Page: 65/138)

Page 66

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

3) Pre-finishing the PA contorol cable

Put the PA control cable through the cold shrinkable tube, the dome nut and the cable

packing in this order.

(See the following figure for the direction.)

Peel the sheath off the PA control cable to expose the conductor.

ÆPeeling length of the sheath: 10 to 15 cm

Loosen the copper shield and coil it around the conductor at the shield root part by

more than 4 turns.

For PA control cable, 3 pairs of twisted-pair cables are used.

If there are 4 pairs of cables, coil the cable with a tape to prevent the extra one pair

from short circuit.

Cold shrinkable tube

Dome nut

Cable packing

Lid side

10 to 15cm

Coil the cable with a tape to

prevent from short circuit.

(Page: 66/138)

Page 67

CONFIDENTIAL

A

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

4) Inserting the PA control cable

While bending the PA control cable along the direction of the Lid interior beforehand,

insert it into the Lid inside.

5) Unstitch the conductor (3 pairs = 6 conductors) and connect them to the specified

crimping connector.

For the assignment of inserting conductor 1pin and 2pin to the connector, refer to the

following figure.

Press the connector while inserting the conductors to the far end.

Recommended connector: Press-contact connector manufactured by DDK (DDK Ltd.)

Product No: 232D-02S1B-DA2

Twisted pair line Press-contact connector

1 pin

2 pin

TXD+ 2 pin Green

TXD- 1 pin Green/spiral

RXD+ 2 pin Orange

RXD- 1 pin Orange/spiral

FS+ 2 pin Blue

FS- 1 pin Blue/spiral

Before pressing

Press connector while the conductors are inserted to the far end.

Press

fter pressing

2 pin

1 pin

2 pin

1 pin

2 pin

1 pin

(Page: 67/138)

Page 68

CONFIDENTIAL

A

A

–

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

6) Fixing the cable clamp

Position the copper shield part of the cable at the arrow marking in the following

figure and fix it with the cable clamp and fixing screw (M4).

ÆTightening torque: 1.5N⋅m

+ – + – +

FS RXD TXD

B

B

Fix the cable clamp with a fixing screw (M4).

The attachment position of a cable clamp changes by the diameter of a cable.

When the diameter of a cable is from 6 to 8mm, it attaches at A-side.

When the diameter of a cable is from 7 to 10.5mm, it attaches at B-side.

Note)

If fixing of the shield is incomplete, noise may be caused during communication or

interference may be caused on other electronic devices.

7) Tightening the dome nut

After inserting the cable packing, tighten the dome nut by hand and then retighten it

using a torque wrench.

ÆTightening torque: 2.45N⋅m

Dome nut

Fixing part of bushing

(Page: 68/138)

Page 69

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

8) Inserting the press-contact connector

Insert the press-contacted connector to the (232D) connector for the PA control in the

Lid.

9) Treatment of the PA control cable

Form the AC power supply cable along the inside of the Lid so that the Lid does not

clip the cable.

+-+-

RXD TXD

+-

FS

FS RXD TXD

– + – + – +

10) Waterproof treatment for the PA control cable

Cover the cold shrinkable tube over the root of the connector and shrink it.

Cold shrinkable tube

(Page: 69/138)

Page 70

CONFIDENTIAL

Installation Manual for Kyocera iBurst System (BS1905A-US-A) (Q05T-AI-BB001E)

3.2.3.4 Connecting the antenna cable

1) Pre-finishing the antenna cable

Put antenna cable through cold shrinkable tube.

(See the following figure for the direction.)

2) Removing the antenna connector dustproof cap

Remove the dustproof cap attached to the antenna connector of the PA unit.

3) Connecting the antenna cable to PA unit