Page 1

OPERATION GUIDE

›

PRINT

ECOSYS P6030cdn

Page 2

Page 3

iii

Contents

Legal and Safety Information

1 Machine Parts

Components at the Front of the Printer ................................... 1-2

Components at the Left of the Printer ...................................... 1-2

Internal Components .................................................................. 1-3

Components at the Rear of the Printer ................................ ..... 1-3

Operation Panel ........................................ .... ... ... ... ... .... ... ... ........ 1-4

2 Handling Paper

General Guidelines ..................................................................... 2-2

Selecting the Right Paper ........................................ .... ... ... ... .... . 2-4

Special Paper .............................................................................. 2-7

Paper Type ................................................................................ 2-13

Loading Paper ..................... ... .......................................... ... ... ... 2-14

3 Printing Operation

Changing Network Interface Parameters ................................. 3-2

Printing a Network Interface Status Page ........ ... ... .... ... ... ... .... . 3-4

Command Center RX .................................................................. 3-5

Installing the Printer Driver ..................................................... 3-14

Printing from Application Software ........................................ 3-21

Printing by AirPrint ................................................................... 3-22

Status Monitor .......................................................................... 3-23

Energy Saver Function ...................................... ... ... .... ... ... ... ... 3-27

4 Maintenance

General Information ................................................................... 4-2

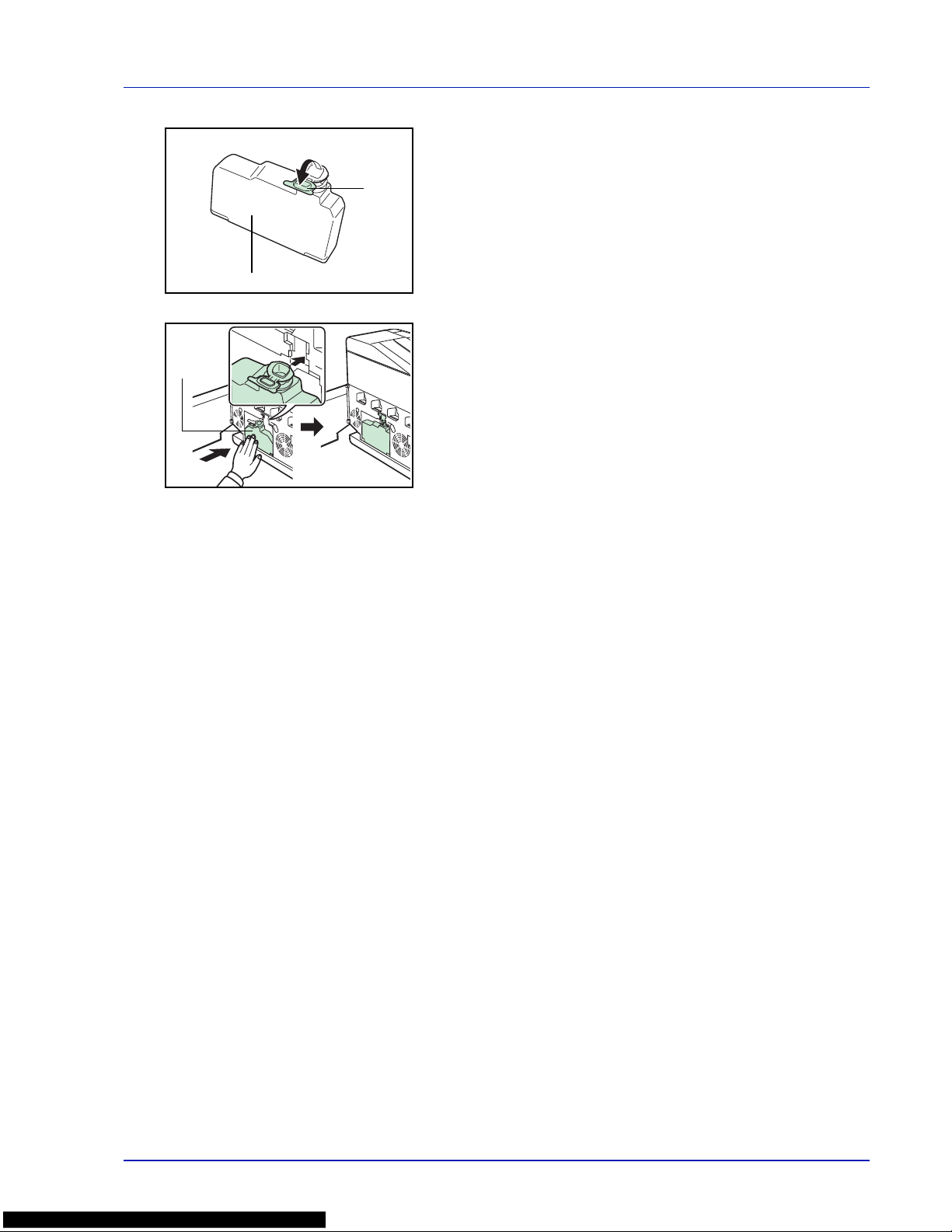

Toner Container Replacement ....................................... ... ... .... . 4-2

Replacing the Waste Toner Box ................................................ 4-6

Cleaning the Printer ................................................................... 4-8

5 Troubleshooting

General Guidelines ..................................................................... 5-2

Print Quality Problems ............................................................... 5-3

Error Messages ........................................................................... 5-6

Clearing Paper Jams ................................................................ 5-11

6 Using the Operation Panel

General Information ................................................................... 6-2

Understanding the Operation Panel ......................................... 6-3

Keys ............................................................................................. 6-6

Using the Menu Selection System ............................................ 6-8

Setting a Mode Selection Menu ............................................... 6-10

Report Print ............................... ... .... ... ... ................................... 6-11

USB Memory (USB memory selection) ................................... 6-16

Custom Box (Using a Custom Box) ..................... ................... 6-18

Job Box ..................................................................................... 6-22

Counter (Viewing the counter value) ...................................... 6-28

Paper Settings .......................................................................... 6-29

Print Settings ............................................................................ 6-37

Network (Network settings) ..................................................... 6-47

Optional Network (Optional Network settings) ...................... 6-56

Device Common (Selecting/Setting the common device) .... 6-61

Security ..................................................................................... 6-79

Job Accounting (Job Accounting selection/setting) ............ 6-87

Page 4

iv

Administrator (Administrator settings) ......................... ... .... .. 6-94

Adjust/Maintenance (Adjust/Maintenance selection/setting) 6-97

7 Options

General Information .................................................................... 7-2

Expansion Memory Modules ..................................................... 7-3

General Description of Options ................................................. 7-5

8 Computer Interface

Interface .................................. ................................................. ....8-2

USB Interface .............................................................................. 8-2

Network Interface ....................... ... ... ... ... .... ... ... ... .... ... ... ... ...........8-3

9 Specifications

Glossary

Index

Page 5

v

Legal and Safety Information

Notice on Software

SOFTWARE USED WITH THIS PRINTER MUST SUPPORT THE

PRINTER'S EMULA TION MODE. The printer is factory-set to emulate the

PCL.

Notice

The information in this guide is subject to change without notification.

Additional pages may be inserted in future editions. The user is asked to

excuse any technical inaccuracies or typographical errors in the present

edition.

No responsibility is assumed if accidents occur while the user is following

the instructions in this guide. No responsibility is assumed for defects in

the printer's firmware (contents of its read-only memory).

This guide, any copyrightable subject matter sold or provided with or in

connection with the sale of the page printer, are protected by copyright.

All rights are reserved. Copying or other reproduction of all or part of this

guide, any copyrightable subject matter without the prior written consent

of KYOCERA Document Solutions Inc. is prohibited. Any copies made of

all or part of this guide, any copyrightable subject must contain the same

copyright notice as the material from which the copying is done.

Regarding Tradenames

• PRESCRIBE and ECOSYS are registered trademark of Kyocera

Corporation.

• KPDL is a trademark of Kyocera Corporation.

• Microsoft, Windows, Windows XP, Windows Server 2003, Windows

Vista, Windows Server 2008, Windows 7, Windows Server 2012,

Windows 8 and Internet Explorer are registered trademarks or

trademarks of Microsoft Corporation in the U.S.A. and/or other

countries.

• PCL is a trademark of Hewlett-Packard Company.

• Adobe Acrobat, Adobe Reader and PostScript are trademarks of

Adobe Systems, Incorporated.

• Ethernet is a registered trademark of Xerox Corporation.

• NetWare is a registered trademark of Novell, Inc.

• IBM is a registered trademark of International Business Machines

Corporation.

• AppleTalk, Bonjour, Macintosh, and Mac OS are trademarks of Apple

Inc., registered in the U.S. and other countries.

• All European language fonts installed in this machine are used under

licensing agreement with Monotype Imaging Inc.

• Helvetica, Palatino and Times are registered trademarks of Linotype

GmbH.

CAUTION NO LIABILITY IS ASSUMED FOR ANY

DAMAGE CAUSED BY IMPROPER INSTALLATION.

Page 6

vi

• ITC Avant Garde Gothic, ITC Bookman, ITC ZapfChancery and ITC

ZapfDingbats are registered trademarks of International Typeface

Corporation.

• UFST™ MicroType® fonts by Monotype Imaging Inc. are installed in

this machine.

• AirPrint and the AirPrint logo are trademarks of Apple Inc.

• iOS is a trademark or registered trademark of Cisco in the U.S. and

other countries and is used under license by Apple Inc.

• ThinPrint is a trademark of Cortado AG in Germany and other

countries.

All other brands and product names are registered trademarks or

trademarks of their respective companies. Thedesignations ™ and ® will

not be used in this Operation Guide.

License Agreements

Typeface Trademark Acknowledgement

All resident fonts in this printer are licensed from Monotype Imaging Inc.

Helvetica, Palatino and Times are registered trademarks of Linotype-Hell

AG. ITC Avant Garde Gothic, ITC Bookman, ITC ZapfChancery and ITC

Zapf Dingbats are registered trademarks of International Typeface

Corporation.

Monotype Imaging License Agreement

1 “Software” shall mean the digitally encoded, machine readable,

scalable outline data as encoded in a special format as well as the

UFST Software.

2 You agree to accept a non-exclusive license to use the Software to

reproduce and display weights, styles and versions of letters,

numerals, characters and symbols (“Typefaces”) solely for your own

customary business or personal purposes at the address stated on

the registration card you return to Monotype Imaging. Under the

terms of this License Agreement, you have the right to use the Fonts

on up to three printers. If you need to have access to the fonts on

more than three printers, you need to acquire a multi-user license

agreement which can be obtained from Monotype Imaging.

Monotype Imaging retains all rights, title and interest to the Software

and Typefaces and no rights are granted to you other than a License

to use the Software on the terms expressly set forth in this

Agreement.

3 To protect proprietary rights of Monotype Imaging, you agree to

maintain the Software and other proprietary information concerning

the Typefaces in strict confidence and to establish reasonable

procedures regulating access to and use of the Software and

Typefaces.

4 You agree not to duplicate or copy the Software or Typefaces,

except that you may make one backup copy. You agree that any

such copy shall contain the same proprietary notices as those

appearing on the original.

5 This License shall continue until the last use of the Software and

Typefaces, unless sooner terminated. This License may be

terminated by Monotype Imaging if you fail to comply with the terms

of this License and such failure is not remedied within thirty (30)

days after notice from Monotype Imaging. When this License expires

or is terminated, you shall either return to Monotype Imaging or

Page 7

vii

destroy all copies of the Software and Typefaces and document ation

as requested.

6 You agree that you will not modify, alter, disassemble, decrypt,

reverse engineer or decompile the Software.

7 Monotype Imaging warrants that for ninety (90) days after delivery,

the Software will perform in accordance with Monotype Imagingpublished specifications, and the diskette will be free from defects in

material and workmanship. Monotype Imaging does not warrant that

the Software is free from all bugs, errors and omissions.

8 THE PARTIES AGREE THAT ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF

FITNESS FOR A PARTICULAR PURPOSE AND

MERCHANTABILITY, ARE EXCLUDED.

9 Your exclusive remedy and the sole liability of Monotype Imaging in

connection with the Software and Typefaces is rep air or replacement

of defective parts, upon their return to Monotype Imaging.

10 IN NO EVENT WILL MONOTYPE IMAGING BE LIABLE FOR LOST

PROFITS, LOST DATA, OR ANY OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES, OR ANY DAMAGES CAUSED BY

ABUSE OR MISAPPLICATION OF THE SOFTWARE AND

TYPEFACES.

11 Massachusetts U.S.A. law governs this Agreement.

12 You shall not sublicense, sell, lease, or otherwise transfer the

Software and/or Typefaces without the prior written consent of

Monotype Imaging.

13 Use, duplication or disclosure by the Government is subject to

restrictions as set forth in the Rights in Technical Data and Computer

Software clause at FAR 252-227-7013, subdivision (b)(3)(ii) or

subparagraph (c)(1)(ii), as appropriate. Further use, duplication or

disclosure is subject to restrictions applicable to restricted rights

software as set forth in FAR 52.227-19 (c)(2).

14 YOU ACKNOWLEDGE THAT YOU HAVE READ THIS

AGREEMENT, UNDERSTAND IT, AND AGREE TO BE BOUND BY

ITS TERMS AND CONDITIONS. NEITHER PARTY SHALL BE

BOUND BY ANY STATEMENT OR REPRESENTATION NOT

CONTAINED IN THIS AGREEMENT. NO CHANGE IN THIS

AGREEMENT IS EFFECTIVE UNLESS WRITTEN AND SIGNED

BY PROPERLY AUTHORIZED REPRESENTATIVES OF EACH

PARTY. BY OPENING THIS D ISKETTE PACKAGE, YOU AGREE

TO ACCEPT THE TERMS AND CONDITIONS OF THIS

AGREEMENT.

GPL/LGPL

This product contains GPL (http://www.gnu.org/licenses/gpl.html) and/or

LGPL (http://www.gnu.org/licenses/lgpl.html) software as part of its

firmware. You can get the source code, and you are permitted to copy,

redistribute and modify it under the terms of GPL/LGPL. For further

information including availability of the source code,

visit http://www.kyoceradocumentsolutions.com/gpl/.

OpenSSL License

Copyright © 1998-2006 The OpenSSL Project. All rights reserved.

Redistribution and use in source and binary forms, with or without

modification, are permitted provided that the following conditions are met:

Page 8

viii

1 Redistributions of source code must retain the above copyright

notice, this list of conditions and the following disclaimer.

2 Redistributions in binary form must reproduce the above copyright

notice, this list of conditions and the following disclaimer in the

documentation and/or other materials provided with the distribution.

3 All advertising materials mentioning features or use of this software

must display the following acknowledgment:

"This product includes software developed by the OpenSSL Project

for use in the OpenSSL Toolkit. (http://www.openssl.org/)"

4 The names "OpenSSL Toolkit" and "OpenSSL Project" must not be

used to endorse or promote products derived from this software

without prior written permission.

For written permission, please contact openssl-core@openssl.org.

5 Products derived from this software may not be called "OpenSSL"

nor may "OpenSSL" appear in their names without prior written

permission of the OpenSSL Project.

6 Redistributions of any form whatsoever must retain the following

acknowledgment: "This product includes software developed by the

OpenSSL Project for use in the OpenSSL Toolkit (http://

www.openssl.org/)"

THIS SOFTWARE IS PROVIDED BY THE OpenSSL PROJECT "AS IS"

AND ANY EXPRESSED OR IMPLIED WARRANTIES, INCLUDING , BUT

NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE DISCLAIMED. IN NO EVENT SHALL THE OpenSSL PROJECT OR

ITS CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT,

INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL

DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF

SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR

PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND

ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT

LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE)

ARISING IN ANY WA Y OUT OF THE USE OF THIS SOFTW ARE, EVEN

IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

Original SSLeay License

Copyright © 1995-1998 Eric Young (eay@cryptsoft.com) All rights

reserved.

This package is an SSL implementation written by Eric Young

(eay@cryptsoft.com). The implementation was written so as to conform

with Netscapes SSL.

This library is free for commercial and non-commercial use as long as the

following conditions are adhered to. The following conditions apply to all

code found in this distribution, be it the RC4, RSA, lhash, DES, etc., code;

not just the SSL code. The SSL documentation included with this

distribution is covered by the same copyright terms except that the holder

is Tim Hudson (tjh@cryptsoft.com).

Copyright remains Eric Y oung's, and as such any Copyright notices in the

code are not to be removed.

If this package is used in a product, Eric Y oung should be given attribution

as the author of the parts of the library used.

This can be in the form of a textual message at program startup or in

documentation (online or textual) provided with the package.

Page 9

ix

Redistribution and use in source and binary forms, with or without

modification, are permitted provided that the following conditions are met:

1 Redistributions of source code must retain the copyright notice, this

list of conditions and the following disclaimer.

2 Redistributions in binary form must reproduce the above copyright

notice, this list of conditions and the following disclaimer in the

documentation and/or other materials provided with the distribution.

3 All advertising materials mentioning features or use of this software

must display the following acknowledgement:

"This product includes cryptographic software written by Eric Young

(eay@cryptsoft.com)"

The word 'cryptographic' can be left out if the rouines from the library

being used are not cryptographic related :-).

4 If you include any Windows specific code (or a derivative thereof)

from the apps directory (application code) you must include an

acknowledgement:

"This product includes software written by Tim Hudson

(tjh@cryptsoft.com)"

THIS SOFTWARE IS PROVIDED BY ERIC YOUNG "AS IS" AND ANY

EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT

LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN

NO EVENT SHALL THE AUTHOR OR CONTRIBUTORS BE LIABLE

FOR ANY DIRECT, INDIR ECT, INCIDENTAL, SPECIAL, EXEMPLARY,

OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED

TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS

OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION)

HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY,

WHETHER IN CONTRACT , STRICT LIABILITY, OR TORT (INCLUDING

NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE

USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY

OF SUCH DAMAGE.

The licence and distribution terms for any publically available version or

derivative of this code cannot be changed. i.e. this code cannot simply be

copied and put under another distribution licence [including the GNU

Public Licence.]

Page 10

x

Compliance and Conformity

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

• The use of a non-shielded interface cable with the referenced device

is prohibited.

CAUTION

—

The changes or modifications not expressly approved by

the party responsible for compliance could void the user’s authority to

operate the equipment.

This device complies with Part 15 of FCC Rules and RSS-Gen of IC

Rules.

Operation is subject to the following two conditions; (1) this device may

not cause interference, and (2) this device must accept any interference,

including interference that may cause undesired operation of the device.

* The above warning is valid only in the United States of America.

Interface connectors

IMPORTANT Be sure to power off the printer before connecting or

disconnecting an interface cable. For protection against static

electricity discharge to the printer's internal electronics through the

interface connector(s), cover any interface connector that is not in use

with the protective cap supplied.

Note

Use shielded interface cables.

Page 11

xi

Safety Information

Laser Safety

This printer is certified as a Class 1 laser product under the U.S.

Department of Health and Human Services (DHHS) Radiation

Performance Standard according to Radiation Control for Health and

Safety Act of 1968. This means that the printer does not produce

hazardous laser radiation. Since radiation emitted inside the printer is

completely confined within protective housings and external covers, the

laser beam cannot escape from the printer during any phase of user

operation.

Laser Notice

This printer is certified in the U.S. to conform to the requirements of DHHS

21 CFR Subchapter for Class I (1) laser products, and elsewhere is

certified as a Class I laser product conforming to the requirements of

IEC/EN 60825-1:2007.

Radio Frequency Transmitter

This machine contains a transmitter module. We, the manufacturer

(KYOCERA Document Solutions) hereby declare that this equipment

(page printer), model ECOSYS P6030cdn is in compliance with the

essential requirements and other relevant provisions of Directive 1999/5/

EC.

Radio Tag Technology

In some countries, the radio tag technology used in this equipment to

identify the toner container may be subject to authorization, and the use

of this equipment may consequently be restricted.

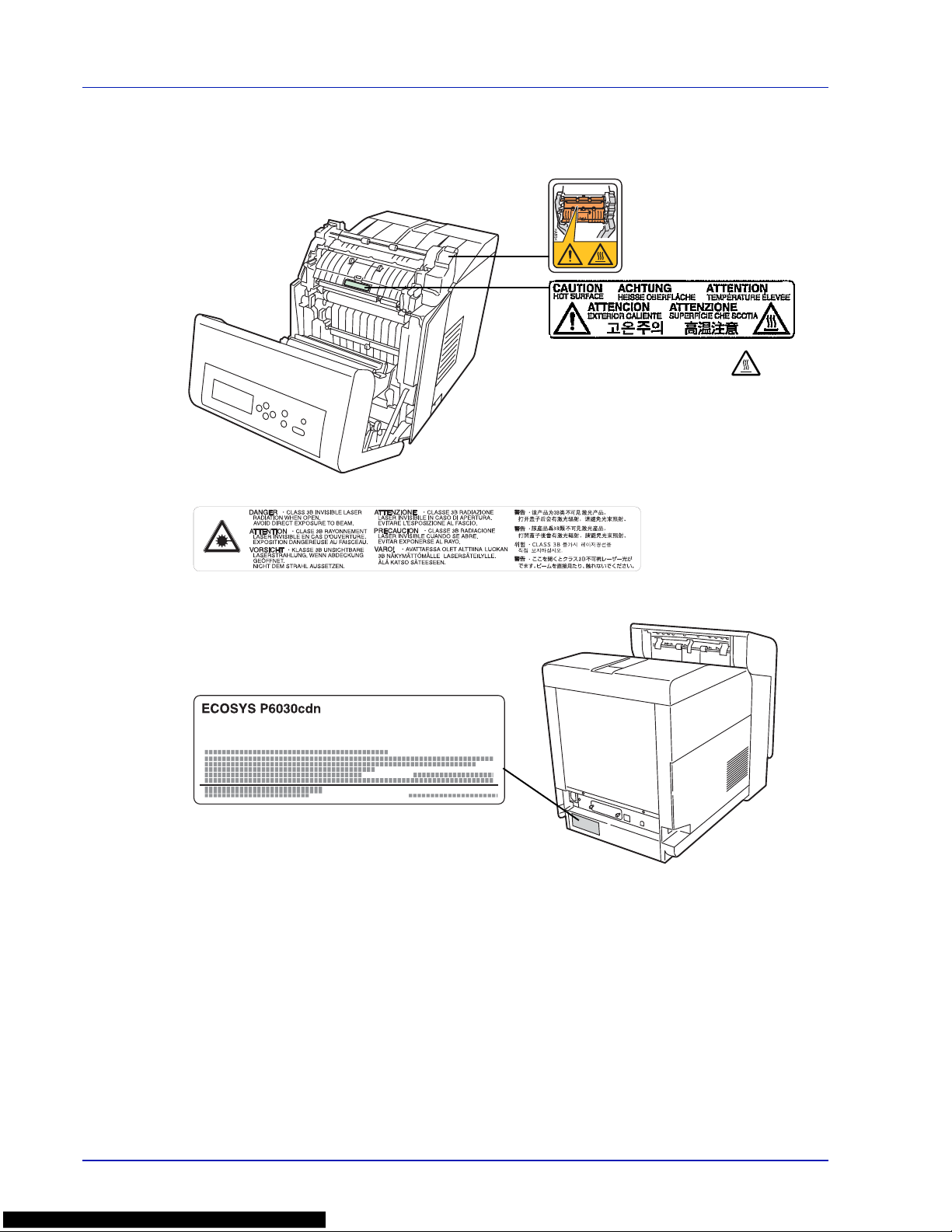

DANGER CLASS 3B INVISIBLE LASER RADIATION

WHEN OPEN. AVOID DIRECT EXPOSURE TO BEAM.

CAUTION Use of controls or adjustments or performance

of procedures other than those specified herein may result

in hazardous radiation exposure.

Page 12

xii

Cautionary Labels

The printer bears any of the following labels.

High temperature inside. Do

not touch parts in this area,

because there is a danger of

getting burned.

Label inside the printer (Laser radiation warning)

Page 13

xiii

CDRH Regulations

The Center for Devices and Radiological Health (CDRH) of the U.S. Food

and Drug Administration implemented regulations for laser products on

August 2, 1976. These regulations apply to laser products manufactured

after August 1, 1976. Compliance is mandatory for products marketed in

the United States. A label indicating compliance with the CDRH

regulations must be attached to laser products marketed in the United

States.

Ozone concentration

The printers generate ozone gas (O3) which may concentrate in the place

of installation and cause an unpleasant smell. To minimize the

concentration of ozone gas to less than 0.1 ppm, we recommend you not

to install the printer in a confined area where ventilation is blocked.

Safety Instructions Regarding the Disconnection of Power

Caution: The power plug is the main isolation device! Other switches on

the equipment are only functional switches and are not suitable for

isolating the equipment from the power source.

VORSICHT: Der Netzstecker ist die Hauptisoliervorrichtung! Die anderen

Schalter auf dem Gerät sind nur Funktionsschalter und können nicht

verwendet werden, um den Stromfluß im Gerät zu unterbrechen.

Page 14

xiv

Canadian Department of Communications Compliance

Statement

This Class B digital apparatus complies with Canadian ICES-003.

Avis de conformité aux normes du ministère des

Communications du Canada

Cet appareil numérique de la classe B est conforme à la norme NMB-003

du Canada.

EN ISO 7779

Maschinenlärminformations-Verordnung 3. GPSGV, 06.01.2004: Der

höchste Schalldruckpegel beträgt 70 dB (A) oder weniger gemäß EN ISO

7779.

EK1-ITB 2000

Das Gerät ist nicht für die Benutzung im unmittelbaren Gesichtsfeld am

Bildschirmarbeitsplatz vorgesehen. Um störende Reflexionen am

Bildschirmarbeitsplatz zu vermeiden, darf dieses Produkt nicht im

unmittelbaren Gesichtsfeld platziert werden.

Disclaimer

KYOCERA Document Solutions will not be liable to customers or any

other person or entity for any loss or damage caused or alleged to be

caused directly or indirectly by equipment sold or furnished by us,

including but not limited to, any interruption of service, loss of business or

anticipatory profits, or consequential damages resulting from the use or

operation of the equipment or software.

Page 15

xv

Energy Saving Control Function

The device comes equipped with a Low Power Mode where energy

consumption is reduced after a certain amount of time elapses since the

device was last used, as well as a Sleep where printer functions remain

in a waiting state but power consumption is still reduced to a minimum

when there is no activity with the device within a set amount of time.

Low Power Mode

The device automatically enters Low Power Mode when 1 minute has

passed since the device was last used. The amount of time of no activity

that must pass before Low Power Mode is activated may be lengthened.

For more information refer to Low Power Timer (Low Power Mode timer

timeout time) section of the Advanced Operation Guide.

Sleep

The device automatically enters Sleep when 15 minutes have passed

since the device was last used. The amount of time of no activity that must

pass before Sleep is activated may be lengthened. For more information,

refer to Sleep Timer (Sleep timer timeout setting) section of the Advanced

Operation Guide.

Automatic 2-Sided Print Function

This device includes 2-sided printing as a standard function. For example,

by printing two 1-sided originals onto a single sheet of paper as a 2-sided

print, it is possible to lower the amount of paper used. For more

information refer to Duplex (Duplex Printing) section of the Advanced

Operation Guide.

Printing in duplex mode reduces paper consumption and contributes to

the conservation of forest resources. Duplex mode also reduces the

amount of paper that must be purchased, and thereby reduces cost. It is

recommended that machines capable of duplex printing be set to use

duplex mode by default.

Resource Saving - Paper

For the preservation and sustainable use of forest resources, it is

recommended that recycled as well as virgin paper certified under

environmental stewardship initiatives or carrying recognised ecolabels,

which meet EN 12281:2002

*1

or an equivalent quality standard, be used.

This machine also supports printing on 64 g/m² paper. Using such paper

containing less raw materials can lead to further saving of forest

resources.

*1: EN12281:2002 "Printing and business paper - Requirements for copy

paper for dry toner imaging processes"

Your sales or service representative can provide information about

recommended paper types.

Environmental benefits of "Power Management"

T o reduce power consumption whe n idle, this machine is equipped with a

power management function that automatically activates energy-saving

mode when the machine is idle for a certain period of time.

Although it takes the machine a slight amount of time to return to READY

mode when in energy-saving mode, a significant reduction in energy

Page 16

xvi

consumption is possible. It is recommended that the machine be used

with the activation time for energy-saving mode set to the default setting.

Energy Star (ENERGY STAR®) Program

We have determined as a participating company in the International

Energy Star Program that this product is compliant with the standards laid

out in the International Energy Star Program.

ENERGY STAR

®

is a voluntary energy efficiency program with the goal

of developing and promoting the use of products with high energy

efficiency in order to help prevent global warming. By purchasing

ENERGY STAR

®

qualified products, customers can help reduce

emissions of greenhouse gases during product use and cut energyrelated costs.

Page 17

xvii

Installation Precautions

Environment

Other Precautions

Adverse environmental conditions may affect the safe operation and

performance of the printer. Install in an air-conditioned room

(recommended room temperature: around 23 °C, humidity: around 60 %

RH) and avoid the following locations when selecting a site for the printer.

- Avoid locations near a window or with exposure to direct sunlight.

- Avoid locations with vibrations.

- Avoid locations with drastic temperature fluctuations.

- Avoid locations with direct exposure to hot or cold air.

- Avoid poorly ventilated locations.

If the flooring is of a soft material, it may be damaged by the casters when

this product is moved after installation.

CAUTION Avoid placing the printer on or in locations which

are unstable or not level. Such locations may cause the

printer to fall. This type of situation presents a danger of

personal injury or damage to the printer.

Avoid locations with humidity or dust and dirt. If dust or dirt

becomes attached to the power plug, clean the plug to avoid

the danger of fire or electrical shock.

Avoid locations near radiators, heaters, or othe r heat

sources, or locations near flammable items, to avoid the

danger of fire.

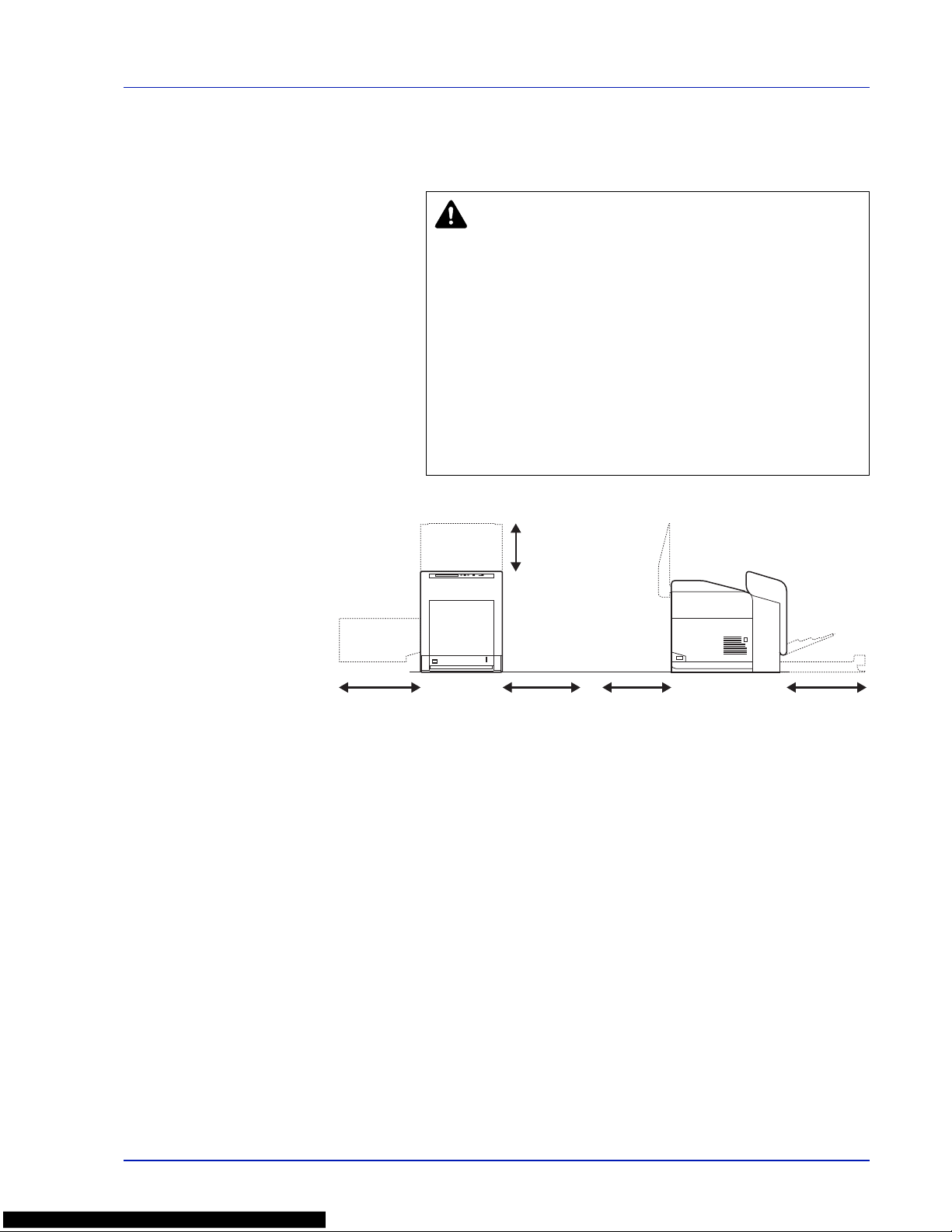

To keep the printer cool and facilitate changing of parts and

maintenance, allow access space as shown below. Leave

adequate space, especially around the side cover, to allow

air to be properly ventilated from the printer.

Left: 400 mm

(16 inches)

Right: 250 mm

(10 inches)

Rear: 200 mm

(7-7/8 inches)

Front: 600 mm

(23-5/8 inches)

Top: 400 mm

(16 inches)

Page 18

xviii

Power Supply/Grounding the Printer

Other Precautions

Connect the power plug to the closest outlet possible to the printer.

Handling of Plastic Bags

Precautions for Use

Cautions when Using the Printer

• Do not place metallic objects or containers with water (flower vases,

flower pots, cups, etc.) on or near the printer. This type of situation

presents a danger of fire or electrical shock should they fall inside.

• Do not remove any of the covers from the printer as there is a danger

of electrical shock from high voltage parts inside the printer.

• Do not damage, break or attempt to repair the power cord. Do not

place heavy objects on the cord, pull it, bend it unnecessarily or cause

any other type of damage.These types of situations present a danger

of fire or electrical shock.

• Never attempt to repair or disassemble the printer or its parts as there

is a danger of fire, electrical shock or damage to the laser. If the laser

beam escapes, there is a danger of it causing blindness.

• If the printer becomes excessively hot, smoke appears from the

printer, there is an odd smell, or any other abnormal situation occurs,

there is a danger of fire or electrical shock. Turn the power switch

OFF () immediately, remove the power plug from the outlet and

contact your service representative.

• If anything harmful (paper clips, water, other fluids, etc.) falls into the

printer, turn the power switch OFF () immediately. Next, remove the

power plug from the outlet to avoid the danger of fire or electrical

shock. Then contact your service representative.

• Do not remove or connect the power plug with wet hands, as there is

a danger of electrical shock.

• Always contact your service representative for maintenance or repair

of internal parts.

• Do not pull the power cord when removing it from the outlet. If the

power cord is pulled, the wires may become broken and there is a

WARNING Do not use a power supply with a voltage other

than that specified. Avoid multiple connections in the same

outlet. These types of situations present a danger of fire or

electrical shock.

Plug the power cord securely into the outlet. If metallic objects

come in contact with the prongs on the plug, it may cause a fire

or electric shock.

Always connect the printer to an outlet with a ground

connection to avoid the danger of fire or electrical shock in

case of an electric short. If an earth connection is not possible,

contact your service representative.

WARNING Keep the plastic bags that are used with the

printer away from children. The plastic may cling to their

nose and mouth causing suffocation.

Page 19

xix

danger of fire or electrical shock. (Always grasp the power plug when

removing the power cord from the outlet.)

• Always remove the power plug from the outlet when moving the

printer. If the power cord is damaged, there is a danger of fire or

electrical shock.

• If the printer will not be used for a short period of time (overnight, etc.),

turn the power switch OFF (). If it will not be used for an extended

period of time (vacations, etc.), remove the power plug from the outlet

for safety purposes during the time the printer is not in use.

• For safety purposes, always remove the power plug from the outlet

when performing cleaning operations.

• If dust accumulates within the printer, there is a danger of fire or other

trouble. It is therefore recommended that you consult with your

service representative in regard to cleaning of internal parts. This is

particularly effective if accomplished prior to seasons of high humidity .

Consult with your service representative in regard to the cost of

cleaning the internal parts of the printer.

Other Precautions

• Do not place heavy objects on the printer or cause other damage to

the printer.

• Do not open the top/left/rear cover, turn of f the main switch, or pull out

the power plug during printing.

• During printing, some ozone is released, but the amount does not

cause any ill effect to one's health. If, however, the printer is used over

a long period of time in a poorly ventilated room or when printing an

extremely large number of copies, the smell may become unpleasant.

T o maint ain the appropriate environment for print work, it is suggested

that the room be properly ventilated.

• Do not touch electrical parts, such as connectors or printed circuit

boards. They could be damaged by static electricity.

• Do not attempt to perform any operations not explained in this

handbook.

• If the printer will not be used for an extended period of time, remove

the paper from the cassette, return it to its original package and reseal

it.

Cautions for Toner Handling

• Do not incinerate parts which contain toner. Dangerous sparks may

cause burn.

• Never open parts which contain toner.

• Do not inhale the toner.

• If you get toner on your hands, do not rub your eyes or touch your

mouth. Wash the toner from your hands.

• For the disposal of the old toner container, consult your service

technician or dispose of the toner or toner containers in accordance

with Federal, State and Local rules and regulations.

CAUTION Use of controls or adjustments or performance

of procedures other than those specified herein may result

in hazardous radiation exposure.

Page 20

xx

About the Operation Guide

This Operation Guide has the following chapters:

Chapter 1 - Machine Parts

This chapter explains the names of parts.

Chapter 2 - Handling Paper

Explains how choose, handle and load paper.

Chapter 3 - Printing Operation

This chapter explains how to print from your workstation.

Chapter 4 - Maintenance

This chapter explains how to replace the toner container and how to care

for your printer.

Chapter 5 - Troubleshooting

This chapter explains how to handle printer problems that may occur,

such as paper jams.

Chapter 6 - Using the Operation Panel

Explains how to use the operation panel to configure the printer.

Chapter 7 - Options

Shows the available options.

Chapter 8 - Computer Interface

Describes the possible connections between the printer and your

computer.

Chapter 9 - Specifications

This chapter lists the printer’s specifications.

Glossary

A Glossary of terms used is provided here.

Conventions

This manual uses the following conventions

.

Convention Description Example

Italic Typeface

Used to emphasize a key word,

phrase or reference to additional

information.

T o replace the toner container, refer to Toner

Container Replacement on page 3-2.

Bold

Used to denote buttons on the

software.

To start printing, click OK.

Braket Bold

Used to denote operation panel

keys.

Press [GO] to resume printing.

Note

Used to provide additional or useful

information about a function or

feature.

Note

Check with your network

administrator for the network address

settings.

Important

Used to provide important

information.

IMPORTANT Ensure paper is not folded,

curled, or damaged.

Page 21

xxi

Caution

Cautions are statements that

suggest mechanical damage as a

result of an action.

CAUTION Components inside the fuser

cover are hot. Do not touch it with your

hands as it may result in burn injury.

Warning

Used to alert users to the possibility

of personal injury.

WARNING High voltage is present in the

charger section.

Page 22

xxii

Page 23

Machine Parts 1-1

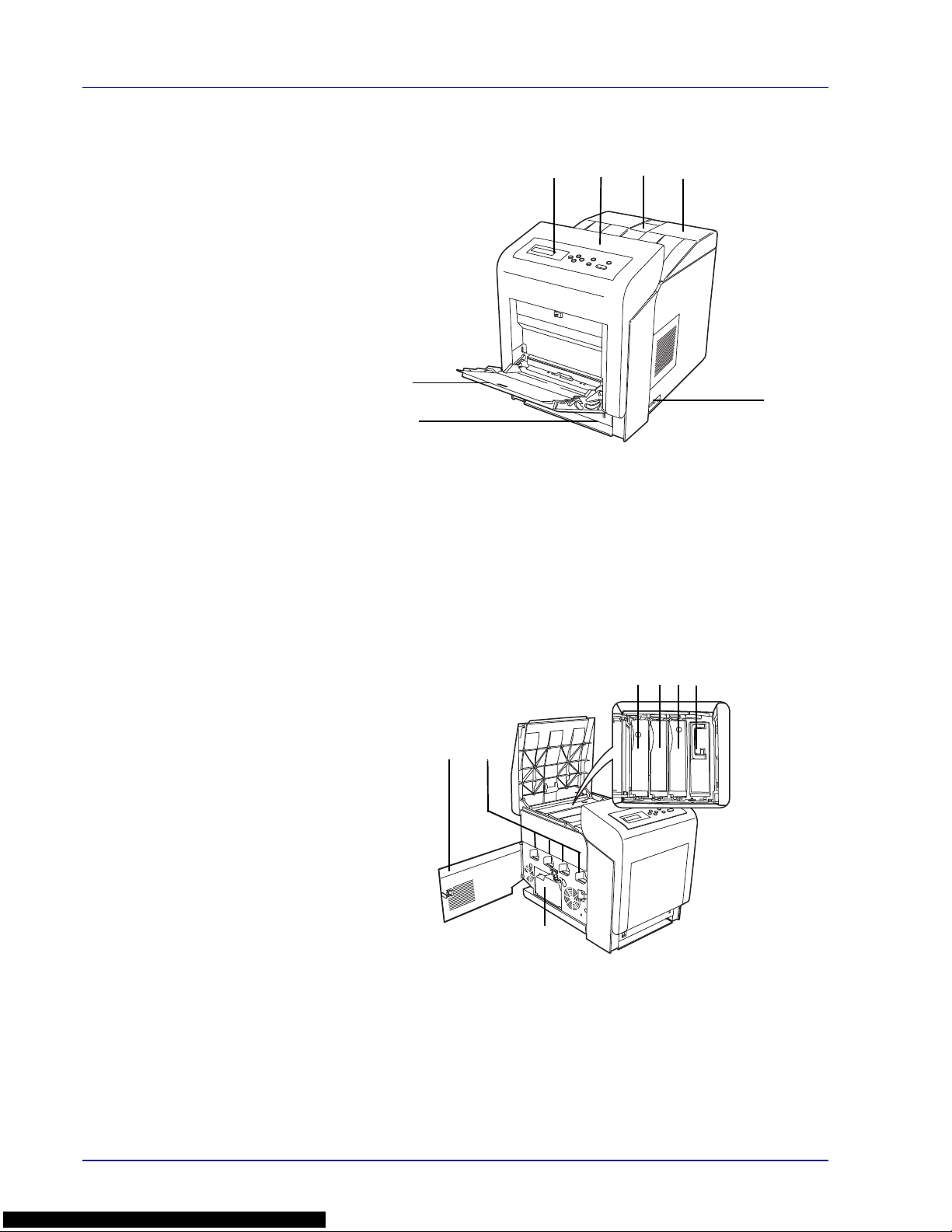

1 Machine Parts

This chapter provides explanations and illustrations for you to

determine the parts and their functions. Try to be familiar with

the names and functions of these parts for correct use and

optimal performance.

This chapter contains explanations on the following topics:

Components at the Front of the Printer 1-2

Components at the Left of the Printer 1-2

Internal Components 1-3

Components at the Rear of the Printer 1-3

Operation Panel 1-4

Page 24

1-2 Machine Parts

Components at the Front of the Printer

1 Operation Panel

2 Front Cover

3 Paper Stopper

4 Top Cover (Top Tray)

5 MP (Multi-Purpose) Tray

6 Paper Cassette

7 Power Switch

Components at the Left of the Printer

8 Left Cover

9 Waste Toner Box

10 Main Charger Units on the Drum Units

11 Magenta Toner Container (M)

12 Cyan Toner Container (C)

13 Yellow Toner Container (Y)

14 Black Toner Container (K)

2

5

6

1 3

7

4

8

9

10

11 12 13 14

Page 25

Machine Parts 1-3

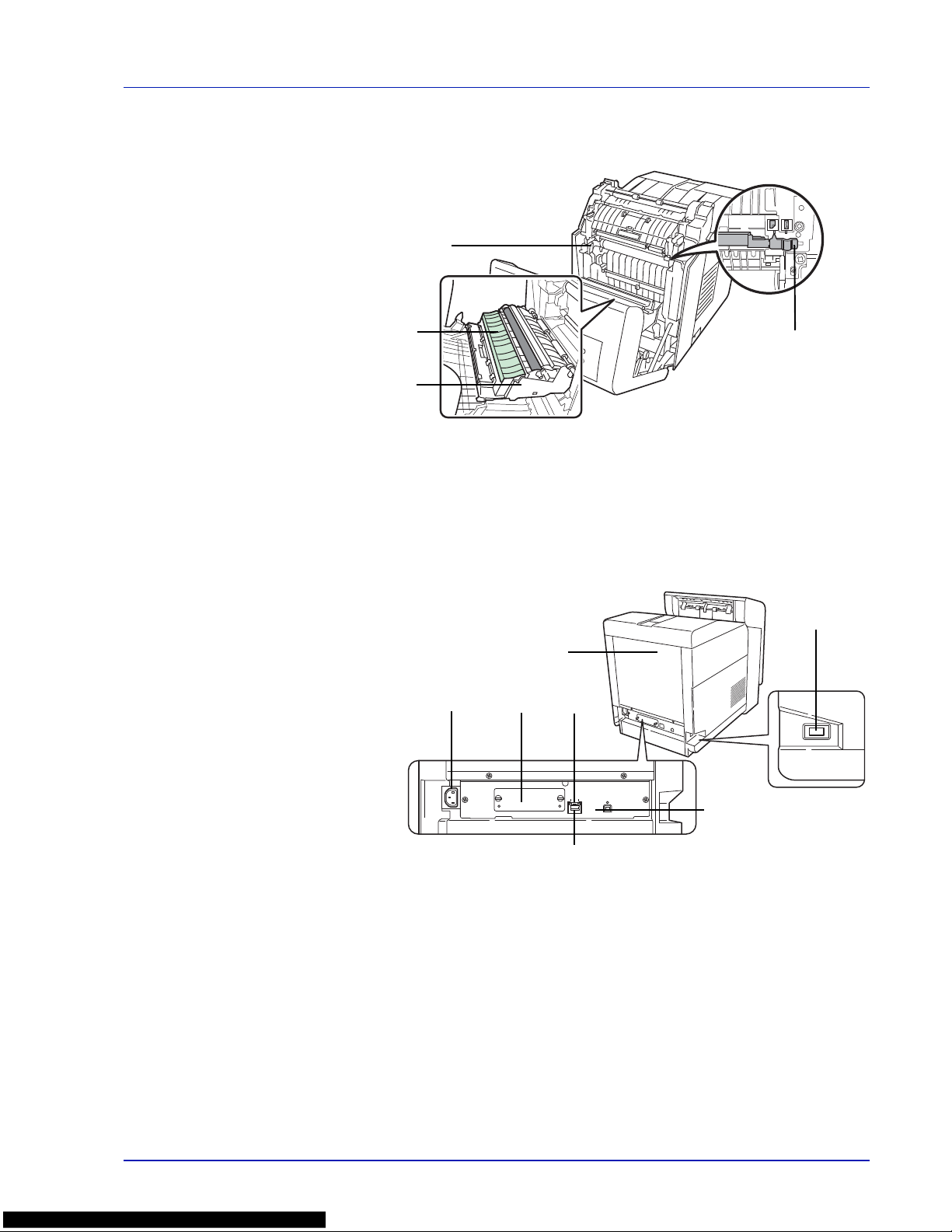

Internal Components

15 Paper Transfer Unit

16 Paper Ramp

17 Duplex Unit

18 Envelope Switch

Components at the Rear of the Printer

19 USB Memory Slot

20 Power Cord Connector

21 Option Interface Slot

22 Network Indicators

23 Network Interface Connector

24 USB Interface Connector

25 Rear Cover

18

19

20 21 22

23

24

25

15

17

16

Page 26

1-4 Machine Parts

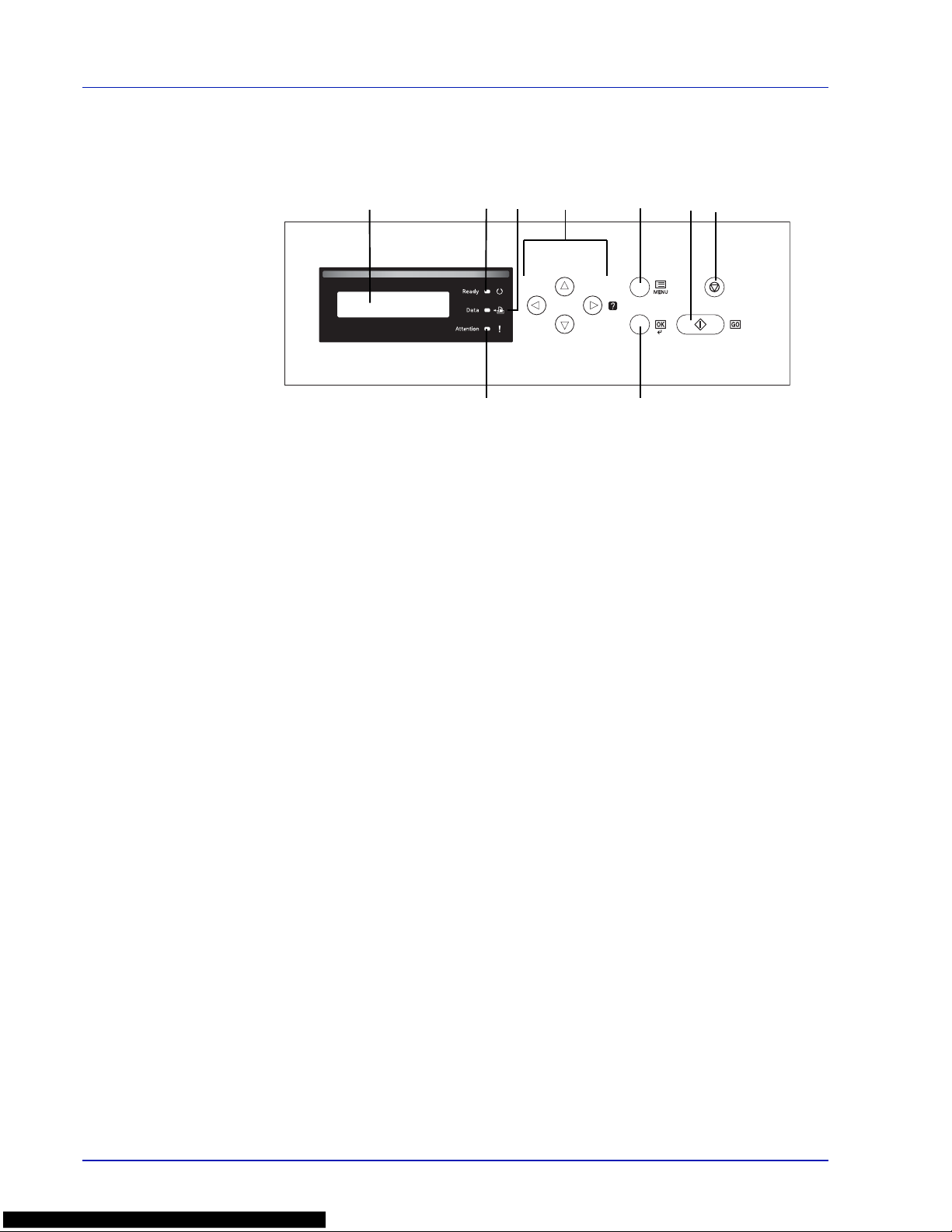

Operation Panel

26 Message Display

27 Ready Indicator

28 Data Indicator

29 Attention Indicator

30 Arrow Keys

31 [MENU] Key

32 [OK] Key

33 [GO] Key

34 [Cancel] Key

26 27 28

29

30 31

32

33 34

Page 27

Handling Paper 2-1

2 Handling Paper

This chapter contains explanations on the following topics:

General Guidelines 2-2

Selecting the Right Paper 2-4

Paper Type 2-13

Loading Paper 2-14

Page 28

2-2 Handling Paper

General Guidelines

The machine is designed to print on standard copier paper (the type used

in ordinary dry copier machines), but it can also accept a variety of other

types of paper within the limits specified below.

Selection of the right paper is important. Using the wrong paper can result

in paper jams, curling, poor print quality , and pap er waste, and in extreme

cases can damage the machine. The guidelines given below will increase

the productivity of your office by ensuring efficient, trouble-free printing

and reducing wear and tear on the machine.

Paper Availability

Most types of paper are compatible with a variety of machines. Paper

intended for xerographic copiers can also be used with the machine.

There are three general grades of paper: economy, standard, and premium. The

most significant difference between grades is the ease with which they pass

through the machine. This is affected by the smoothness, size, and moisture

content of the paper, and the way in which the p aper is cut. The higher the grade

of paper you use, the less risk there will be of paper jams and other problems, and

the higher the level of quality your printed output will reflect.

Differences between paper from different suppliers can also affect the

machine’s performance. A high-quality printer cannot produce highquality results when the wrong paper is used. Low-priced paper is not

economical in the long run if it causes printing problems.

Paper in each grade is available in a range of basis weights (defined later).

The traditional standard weights are 60 to 120 g/m² (16 to 32 pounds).

Paper Specifications

The following table summarizes the basic paper specifications. Details

are given on the following pages.

Note

The manufacturer assumes no liability for problems that

occur when paper not satisfying these requirements is used.

Item Specification

Weight Cassette, PF-500 (optional): 60 to 120 g/m²

(16 to 32 lb/ream)

MP Tray, PF-510 (optional): 60 to 220 g/m²

(16 to 59 lb/ream)

Thickness 0.086 to 0.110 mm (3.4 to 4.3 mils)

Dimensions Refer to Paper Sizes on page 2-4

Dimensional accuracy ±0.7 mm (±0.0276 inches)

Squareness of corners 90° ±0.2°

Moisture content 4 % to 6 %

Direction of grain Long grain

Pulp content 80 % or more

Page 29

Handling Paper 2-3

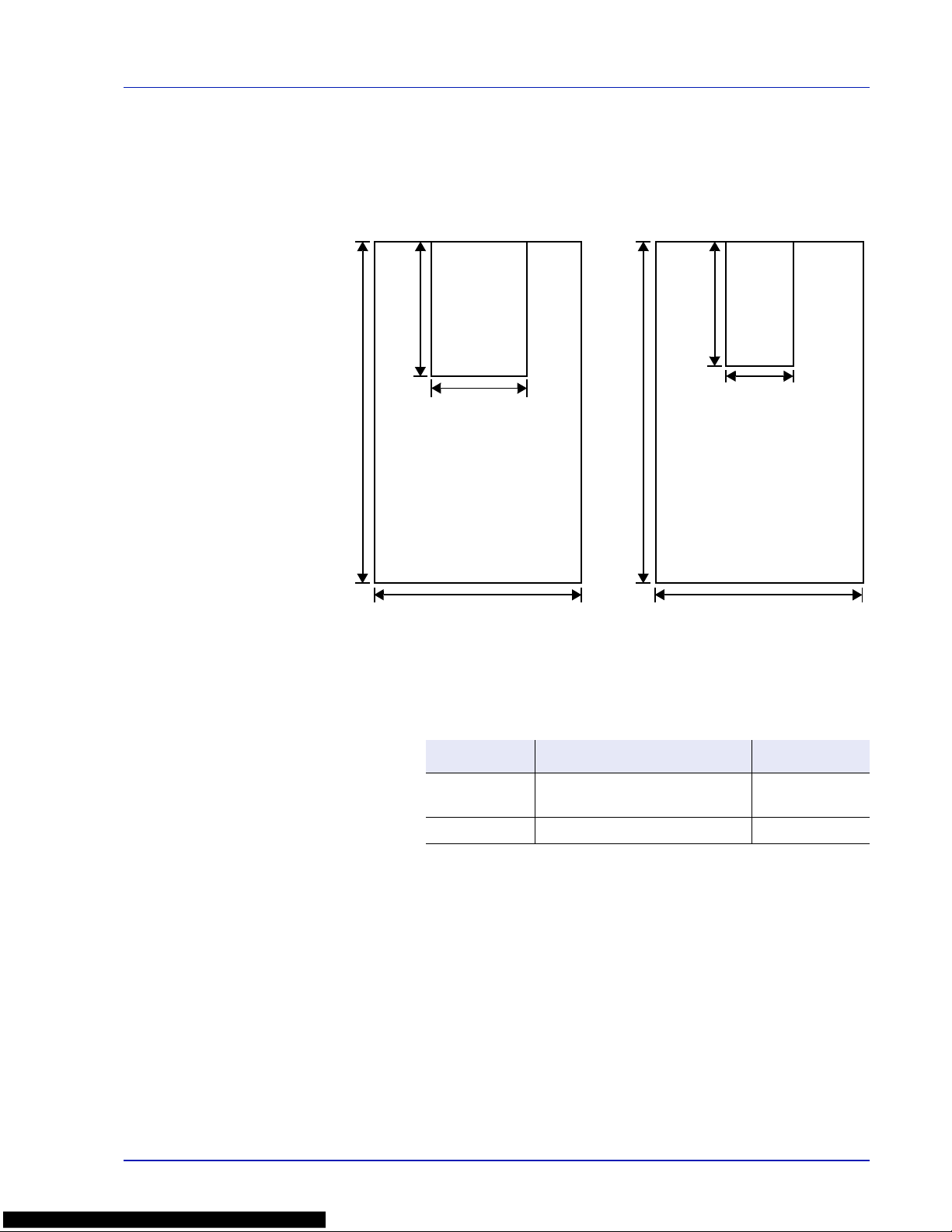

Minimum and Maximum Paper Sizes

The minimum and maximum paper sizes are as follows. For non standard

paper such as transparency, labels, vellum, cardstock, envelope, and

coated, the MP (Multi-Purpose) tray must be used.

Recommended Paper

The following products are recommended for use with the printer for

optimum performance.

105 mm

4-1/8 inches

148 mm 5-13/16 inches

216 mm

8-1/2 inches

356 mm

14 inches

Minimum

Paper Size

Maximum

Paper Size

Paper Cassette

70 mm

2-3/4 inches

138 mm

5-7/16 inches

Minimum

Paper Size

Maximum

Paper Size

MP Tray

216 mm

8-1/2 inches

356 mm

14 inches

Size Product Weight

Letter, Legal International Paper Hammermill

Tidal MP

75 g/m² (20 lb)

A4 Nautilus ReFresh TRIOTEC 80 g/m²

Page 30

2-4 Handling Paper

Selecting the Right Paper

This section describes the guidelines for selecting paper.

Condition

Avoid using paper that is bent at the edges, curled , dirty , torn, embossed,

or contaminated with lint, clay, or paper shreds.

Use of paper in these conditions can lead to illegible printing and paper

jams, and can shorten the life of the machine. In particular, avoid using

paper with a surface coating or other surface treatment. Paper should

have as smooth and even a surface as possible.

Composition

Do not use paper that has been coated or surface-treated and contains

plastic or carbon. The heat of fusing can cause such paper to give off

harmful fumes.

Bond paper should contain at least 80 % pulp. Not more than 20 % of the

total paper content should consist of cotton or other fibers.

Paper Sizes

Cassettes and the MP tray are available for the paper sizes listed in the

table below. For details, including the paper sizes for the paper feeder

(Optional paper feeder PF-500, PF-510) refer to Cassette (1 to 4) Size

(Setting the cassette paper size) on page 6-31.

The dimensional tolerances are ±0.7 mm (±0.0276 inches) for the length

and width. The angle at the corners must be 90° ±0.2°.

MP Tray Only Size

Cassette or

MP Tray

Size

Env. Monarch 3-7/8 × 7-1/2 inches Legal 8-1/2 × 14 inches

Envelope #10 4-1/8 × 9-1/2 inches Letter 8-1/2 × 11 inches

Envelope #9 3-7/8 × 8-7/8 inches ISO A4 210 × 297 mm

Envelope #6 3-5/8 × 6-1/2 inches ISO A5 148 × 210 mm

Envelope DL 110 × 220 mm ISO A6 105 × 148 mm

JIS B6 128 × 182 mm Envelope C5 162 × 229 mm

Hagaki 100 × 148 mm ISO B5 176 × 250 mm

OufukuHagaki 148 × 200 mm JIS B5 182 × 257 mm

Youkei 2 114 × 162 mm Statement 5-1/2 × 8-1/2 inches

Youkei 4 105 × 235 mm Executive 7-1/4 × 10-1/2 inches

Oficio II 8-1/2 × 13 inches

Folio 210 × 330 mm

16 kai 197 × 273 mm

216 × 340 mm 216 × 340 mm

Custom

Cassette: 105 to 216 mm × 148 to 356 mm

(4-1/8 to 8-1/2 inches × 5-13/16 to 14 inches)

MP Tray: 70 to 216 mm × 138 to 356 mm

(2-3/4 to 8-1/2 inches × 5-7/16 to 14 inches)

Page 31

Handling Paper 2-5

Smoothness

The paper should have a smooth, uncoated surface. Paper with a rough

or sandy surface can cause voids in the printed output. Paper that is too

smooth can cause multiple feeding and fogging problems. (Fogging is a

gray background effect.)

Basis Weight

Basis weight is the weight of paper expressed in grams per square meter

(g/m²). Paper that is too heavy or too light may cause feed errors or paper

jams as well as premature wear of the product. Uneven weight of paper,

namely uneven paper thickness may cause multiple-sheet feeding or

print quality problems such as blurring because of poor toner fusing.

The recommended basis weight is:

Cassette: 60 to 120 g/m

2

MP tray: 60 to 220 g/m

2

PF-500 (optional): 60 to 120 g/m

2

PF-510 (optional): 60 to 220 g/m

2

Paper Weight Equivalence Table

The paper weight is listed in pounds (lb) and metric grams per square

meter (g/m²). The shaded part indicates the standard weight.

U. S. Bond Weight (lb) Europe Metric Weight (g/m²)

16 60

17 64

20 75

21

80

22 81

24 90

27

100

28 105

32 120

34 128

36 135

39 148

42 157

43 163

47 176

53 199

Page 32

2-6 Handling Paper

Thickness

The paper used with the machine should be neither extremely thick nor

extremely thin. If you are having problems with paper jams, multiple

feeds, and faint printing, the paper you are using may be too thin. If you

are having problems with paper jams and blurred printing the paper may

be too thick. The correct thickness is 0.086 to 0.110 mm (3.4 to 4.3 mils).

Moisture Content

Moisture content is defined as the percent ratio of moisture to the dry

mass of the paper. Moisture can affect the paper’s appearance, feed

ability, curl, electrostatic properties, and toner fusing characteristics.

The moisture content of the paper varies with the relative humidity in the

room. When the relative humidity is high and the paper absorbs moisture,

the paper edges expand, becoming wavy in appearance. When the

relative humidity is low and the paper loses moisture, the edges shrink

and tighten, and print contrast may suffer.

Wavy or tight edges can cause jams and alignment anomalies. The

moisture content of the paper should be 4 to 6 %.

To ensure correct moisture content, it is important to store the paper in a

controlled environment. Some tips on moisture control are:

• Store paper in a cool, dry location.

• Keep the paper in its wrapping as long as possible. Re-wrap paper

that is not in use.

• Store paper in its original carton. Place a pallet etc. under the carton

to separate it from the floor.

• After removing paper from storage, let it stand in the same room as

the machine for 48 hours before use.

• Avoid leaving paper where it is exposed to heat, sunlight, or damp.

Paper Grain

When paper is manufactured, it is cut into sheets with the grain running

parallel to the length (long grain) or parallel to the width (short grain).

Short grain paper can cause feeding problems in the machine. All paper

used in the machine should be long grain.

Other Paper Properties

Porosity: Indicates the density of paper fiber.

Stiffness: Limp paper may buckle in the machine, resulting in paper

jams.

Curl: Most paper naturally tends to curl one way if left unpacked.

Electrostatic discharge: During the printing process the paper is

electrostatically charged to attract the toner. The paper must be able to

release this charge so that printed sheets do not cling together in the

Output Tray.

Note

When using coated paper, be aware that the sheets will

stick together in a very humid environment.

Page 33

Handling Paper 2-7

Whiteness: The contrast of the printed page depends on the whiteness

of the paper. Whiter paper provides a sharper, brighter appearance.

Quality control: Uneven sheet size, corners that are not square, ragged

edges, welded (uncut) sheets, and crushed edges and corners can cause

the machine to malfunction in various ways. A quality paper supplier

should take considerable care to ensure that these problems do not

occur.

Packaging: Paper should be packed in a sturdy carton to protect it from

damage during transport. Quality paper obtained from a reputable

supplier is usually correctly packaged.

Special Paper

The following types of special paper can be used:

Use paper that is sold specifically for use with copiers or printers (heatfusing type). When using transparencies, labels, thin paper, envelopes,

postcards, or thick paper, feed the paper from the MP tray. For details,

refer to Paper Source (Selecting the paper feed source) on page 6-37.

Since the composition and quality of special paper vary considerably,

special paper is more likely than white bond paper to give trouble during

printing. No liability will be assumed if moisture and so forth given off

during printing on special paper causes harm to the machine or operator .

Note

Y ou might see the printer emitting steam in the area around

the top tray if you use damp paper, but it is safe to continue

printing.

Paper Type to be Used Paper Type to be Selected

Thin paper (60 to 64 g/m²) VELLUM

Thick paper (90 to 220 g/m²) THICK

Colored paper COLOR

Recycled paper RECYCLED

Overhead projector transparencies TRANSPARENCY

Postcards CARDSTOCK

Envelopes ENVELOPE

Label LABELS

Coated paper COATED

Note

Before purchasing any type of special paper, test a sample

on the machine and check that printing quality is satisfactory.

Page 34

2-8 Handling Paper

Transparency

Transparencies must be able to withstand the heat of fusing during the

printing process. The recommended transparency product is 3M CG3700

(Letter, A4).

The table below lists the specifications for transparency:

T o prevent printing problems,

feed transparencies into the

printer one sheet at a time

from the MP tray . Always load

the transparencies vertically

(with the long edge towards

the printer).

If the transparencies have

rough edges on the back, it

may cause a paper jam.

Remove the rough edges,

reverse the sides or feed the

sheet from the opposite edge.

When unloading transparencies (e.g., for clearing jams), hold them

carefully by the edges to avoid leaving fingerprints on them.

Item Specification

Tolerance of heat Must tolerate at least 190 °C (374 °F)

Thickness 0.100 to 0.110 mm (3.9 to 4.3 mils)

Material Polyester

Dimensional accuracy ±0.7 mm (±0.0276 inches)

Squareness of corners 90° ±0.2°

Page 35

Handling Paper 2-9

Labels

Labels must be fed from the MP tray or optional paper feeder PF-510.

The basic rule for printing on adhesive labels is that the adhesive must

never come into contact with any part of the machine. Adhesive paper

sticking to the drum or rollers will damage the machine.

Label paper has a structure

comprising of three layers, as

shown in the diagram. The top

sheet is printed on. The

adhesive layer consists of

pressure-sensitive adhesives.

The carrier sheet (also called

the linear or backing sheet)

holds the labels until used.

Due to the complexity of its

composition, adhesive-backed

label paper is particularly likely to give printing problems.

Adhesive label paper must be entirely covered by its top sheet, with no

spaces between the individual labels. Labels with spaces in between are

liable to peel off, causing serious paper jam problems.

Some label paper is manufactured with an extra margin of top sheet

around the edge. Do not remove the extra top sheet from the carrier sheet

until after printing is finished.

The table below lists the specifications for adhesive label paper.

Item Specification

Weight of top sheet 44 to 74 g/m² (12 to 20 lb/ream)

Composite weight 104 to 151 g/m² (28 to 40 lb/ream)

Thickness of top sheet 0.086 to 0.107 mm (3.9 to 4.2 mils)

Composite thickness 0.115 to 0.145 mm (4.5 to 5.7 mils)

Moisture content 4 to 6 % (composite)

Top sheet (white

bond paper)

Adhesive

Carrier sheet

Top sheet

UnacceptableAcceptable

Carrier sheet

Page 36

2-10 Handling Paper

Postcards

Fan the stack of postcards and align the edges before loading them in the

MP tray. Make sure the postcards you are going to set are not curled.

Feeding curled postcards may cause paper jams.

Some postcards have rough

edges on the back (those are

created when the paper is cut).

In this case, put the postcards

on a flat place and rub the

edges with, for example, a ruler

to smooth them.

Envelopes

Slide the envelope switch to

envelope mode and print.

IMPORTANT Envelopes

cannot be printed in paper

mode. When printing plain

paper while the envelope

mode is selected, the printing

speed and quality will lower

than in paper mode.

Envelopes should always be

fed from the MP tray, with the

print-side down. If you use

envelopes quite often, we

recommend to use optional

paper feeder PF-510.

Since the composition of an

envelope is more complex than

that of ordinary paper, it is not

always possible to ensure

consistent printing quality over

the entire envelope surface.

Normally, envelopes have a diagonal grain direction. Refer to Paper

Grain on page 2-6. This direction can easily cause wrinkles and creases

when envelopes pass through the printer. Before purchasing envelopes,

make a test print to check whether the printer accepts the envelope.

• Do not use envelopes that have an encapsulated liquid adhesive.

• Avoid a long printing session for envelopes only. Extended envelope

printing can cause premature printer wear.

• If jams occur, try setting a lesser number of envelopes on the MP tray.

• To avoid jams caused by curled envelopes, stack no more than 10

printed envelopes on the top tray.

Rough

Edge

Rough

Edge

Envelope Switch

Page 37

Handling Paper 2-11

Thick Paper

Fan the stack of paper and align the edges before loading them. Some

types of paper have rough edges on the back (those are created when the

paper is cut). In this case, put the paper on a flat place and rub the edges

once or twice with, for example, a ruler to smooth them. Feeding rough

edged paper may cause paper jams.

Colored Paper

Colored paper should satisfy the same conditions as white bond paper,

refer to Paper Specifications on page 2-2. In addition, the pigments used

in the paper must be able to withstand the heat of fusing during the

printing process (up to 200 °C or 392 °F).

Preprinted Paper

Preprinted paper should satisfy the same conditions as white bond paper ,

refer to Paper Specifications on page 2-2. The preprinted ink must be able

to withstand the heat of fusing during the printing process, and must not

be affected by silicone oil. Do not use paper with any kind of surface

treatment, such as the type of paper commonly used for calendars.

Recycled Paper

Select recycled paper that meets the same specifications as the white

bond paper except for whiteness, refer to Paper Specifications on page

2-2.

Coated Paper

Coated paper is created by treating the surface of the base paper with a

coating that provides higher printing quality than plain paper. Coated

paper is used for particularly high quality printing.

The surface of high-quality or medium-quality paper is coated with special

agents that improve ink adhesion by making the paper surface smoother.

These agents are used either to coat both sides of the paper or just one

side. The coated side appears slightly glossy.

Note

If the paper jams

even after you smooth

it out, load the paper in

the MP tray with the

leading edge raised up

a few millimeters as

shown in the

illustration.

If you use thick paper

quite often, we

recommend to use optional paper feeder PF-510.

Note

If you use colored paper quite often, we recommend to use

optional paper feeder PF-510.

Note

Before purchasing recycled paper, test a sample on the

machine and check that the printing quality is satisfactory.

Page 38

2-12 Handling Paper

IMPORTANT When printing on coated paper in very humid

environments, ensure that the paper is kept dry as moisture may

cause sheets to stick together when they are fed into the printer.

Paper Type Indicators (Optional paper feeder PF-510)

If you are going to load non

standard paper in the optional

paper feeder PF-510, cut out

the blank section of the

attached paper type indicator

sheet, fold the remaining sheet

in half and insert it into the

cassette's display folder so

that the paper type symbol is

displayed.

• Envelopes

• Thick paper

• Labels

• Coated paper

Page 39

Handling Paper 2-13

Paper Type

The printer is capable of printing under the optimum setting for the type of

paper being used.

Setting the paper type for the paper source from the printer’s operation

panel will cause the printer to automatically select the paper source and

print in the mode best suited to that type of paper.

A different paper type setting can be made for each paper source

including the MP tray. Not only can preset p aper types be selected, but it

is also possible for you to define and select customized paper types.

Refer to Type Adjust (Creating custom paper type) on page 6-34. The

following types of paper can be used.

Paper Type

Paper Source

MP Tray

Paper Cassette

Optional Paper

Feeder PF-500

Paper Weight Duplex Path

Optional Paper

Feeder PF-510

PLAIN Yes Yes Normal 2 Yes Yes

TRANSPARENCY Yes No Extra Heavy No No

PREPRINTED Yes Yes Normal 2 Yes Yes

LABELS Yes No Heavy 1 No Yes

BOND Yes Yes Normal 3 Yes Yes

RECYCLED Yes Yes Normal 2 Yes Yes

VELLUM Yes No Light No No

ROUGH Yes Yes Normal 3 Yes Yes

LETTERHEAD Yes Yes Normal 2 Yes Yes

COLOR Yes Yes Normal 2 Yes Yes

PREPUNCHED Yes Yes Normal 2 Yes Yes

ENVELOPE Yes No Heavy 2 No Yes

CARDSTOCK Yes No Heavy 1 No Yes

COATED Yes No Heavy 1 Yes Yes

THICK Yes No Heavy 2 No Yes

HIGH QUALITY Yes Yes Normal 3 Yes Yes

CUSTOM 1 (to 8)

†

Yes Yes Normal 2 Yes Yes

Yes: Can be stored No: Cannot be stored

†. This is a paper type defined and registered by the user. Up to eight types of user settings may be defined. For

details, refer toType Adjust (Creating custom paper type) on page 6-34.

Page 40

2-14 Handling Paper

Loading Paper

The following explains the procedure for loading paper in the cassette

and the MP tray.

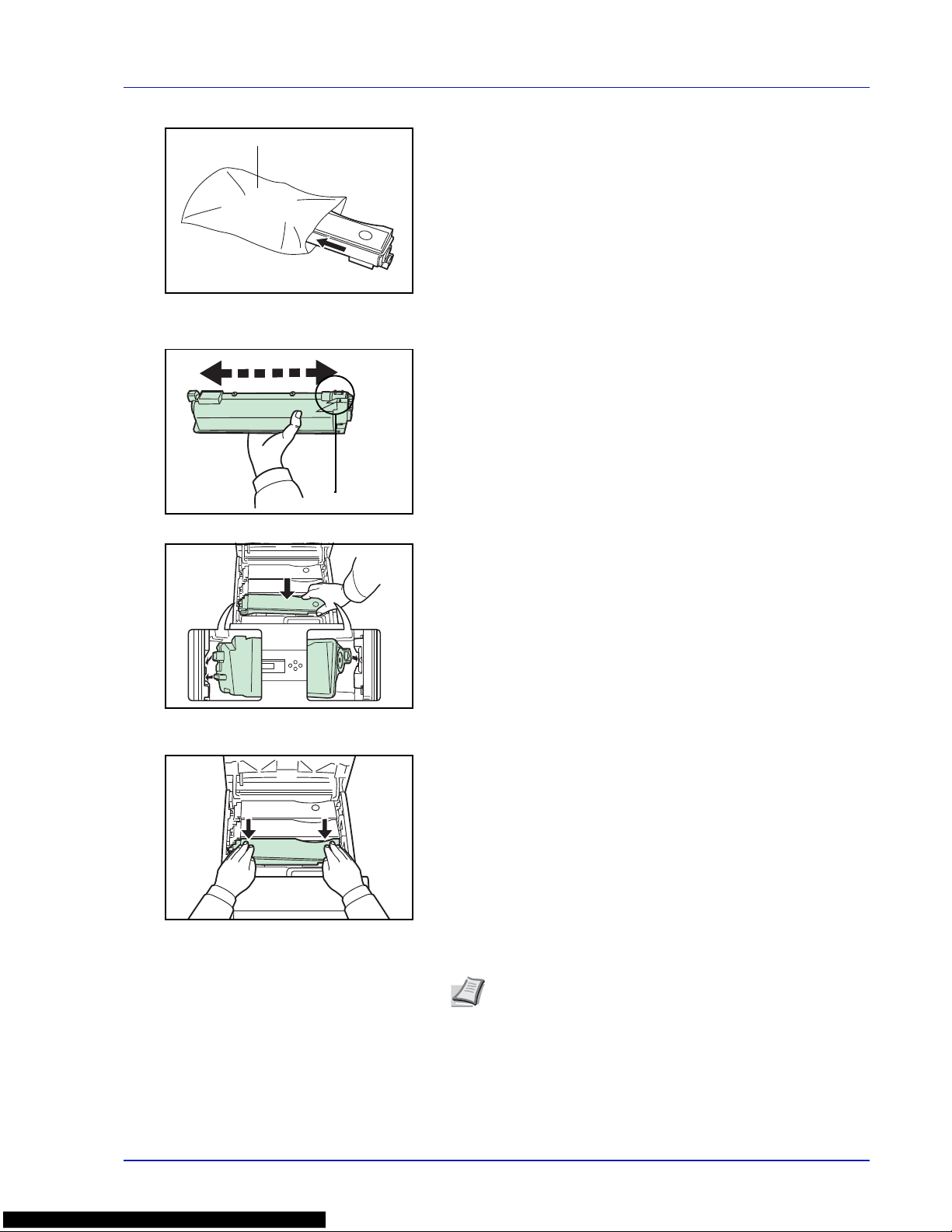

Loading Paper into the Cassette

1

Fan the media (paper/transparencies), then tap it on a level surface

to avoid media jams or skewed printing.

2

Pull the paper cassette all the way out of the printer.

3

Turn the paper size dial so that the size of the paper you are going to

use appears in the paper size window.

Note

When the paper size dial is set to Other the paper size

must be set into the printer on the operation panel. Refer to

Cassette (1 to 4) Size (Setting the cassette paper size) on

page 6-31.

Paper Cassette

A4

Paper Size Dial

Paper Size Window

Page 41

Handling Paper 2-15

4

Pull the release lever of both side guides and slide to the desired

paper size.

5

Pull the release lever and slide the paper stopper to the desired paper

size.

When using non-standard size paper, move the paper guides and

paper stopper all the way out, insert the paper , then adjust the paper

guides and paper stopper to the size of the paper. Adjust them so that

they are in light contact with the paper.

Standard pap er sizes are marked on the inside of the paper cassette.

6

Slide the paper into the paper cassette.

Note

Do not load more paper than will fit under the load limits

on the paper guides.

The paper cassette will hold approximately 500 sheets of 80

g/m² (21 lb.) paper with a thickness of 0.11 mm.

Release Lever

Paper Guides

Release Lever

Paper Stopper

Load Limit

Page 42

2-16 Handling Paper

7

Insert the paper cassette into the slot in the printer. Push it straight in

as far as it will go.

There is a paper gauge on the right side of the front of the paper

cassette to indicate the remaining paper supply. When paper is

exhausted, the pointer will go down to the level of (empty).

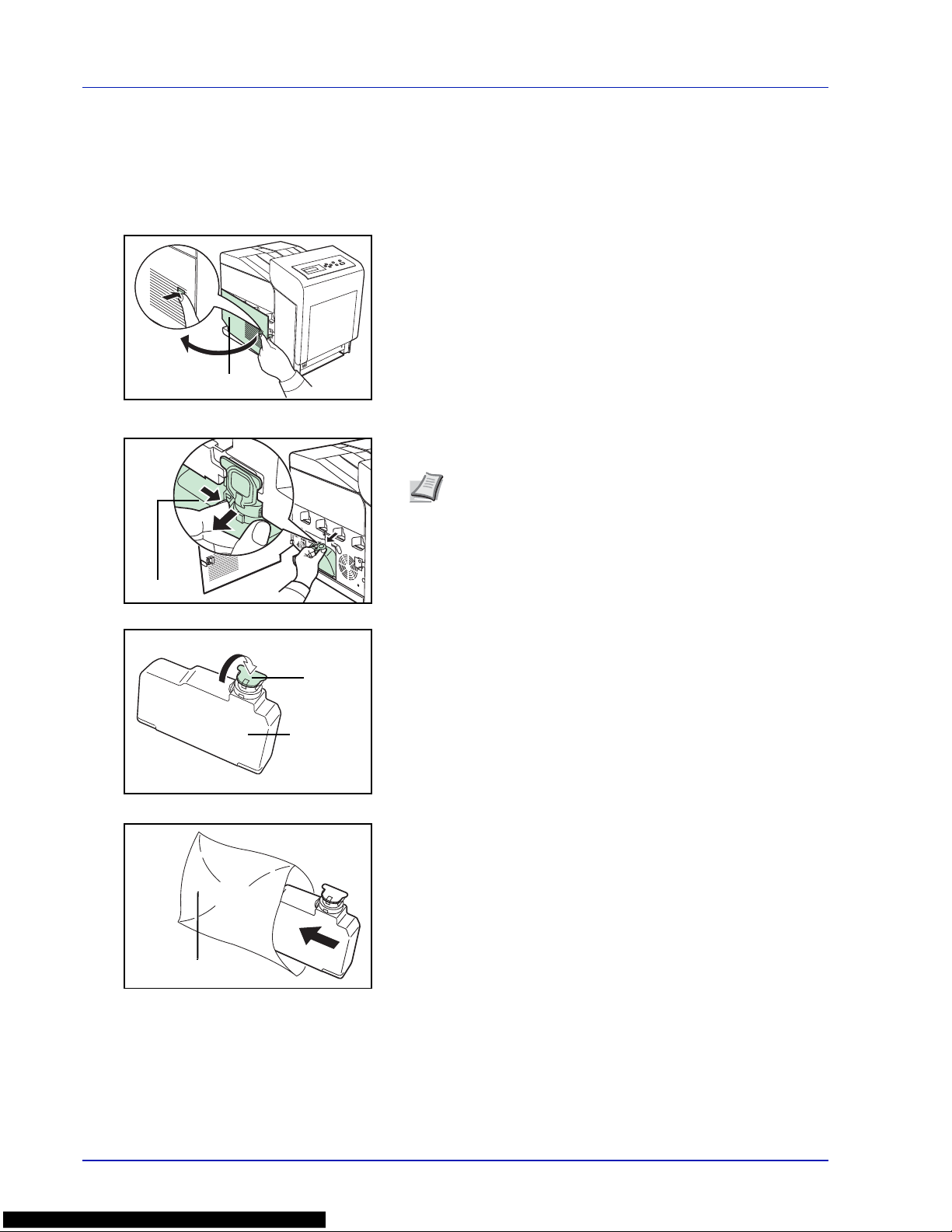

Loading Paper into the MP (Multi-Purpose) Tray

1

Fan the media (paper/transparencies), then tap it on a level surface

to avoid media jams or skewed printing.

2

Press the center of the MP tray, and pull it towards you until it stops.

3

Pull the subtray toward you until it stops, making sure there are no

gaps.

Paper Gauge

MP Tray

Subtray

Page 43

Handling Paper 2-17

4

Adjust the position of the paper guides on the MP tray. Standard

paper sizes are marked on the MP tray. For standard paper sizes,

slide the guides to the position marked correspondingly.

5

Align the paper with the paper guides and insert as far as it will go.

6

Set the MP tray paper size on the printer’s operation panel. Refer to

MP Tray Size (Setting MP tray paper size) on page 6-29.

7

Set the appropriate print mode for the paper thickness (envelopes or

plain paper). To print on envelopes, slide the envelope switch to the

right to select envelope mode. T o print on plain paper , slide the switch

to the left to select paper mode.

The print modes are imprinted on the switch. Check that the correct

mode is selected for the paper being used.

IMPORTANT Envelopes cannot be printed in p aper mode. When

printing plain paper while the envelope mode is selected, the

printing speed and quality will lower than in paper mode.

Note

Do not load more paper than will fit under the load limits

on the inside of the MP tray.

When printing on transparencies, feed the sheets into the

printer one at a time.

If the paper is considerably curled in one direction, for

example, if the paper is already printed on one side, try to roll

the paper in the opposite direction to counteract the curl.

Printed sheets will then come out flat.

Load

Limit

Load

Limit

Correct

Incorrect

Envelope Switch

Page 44

2-18 Handling Paper

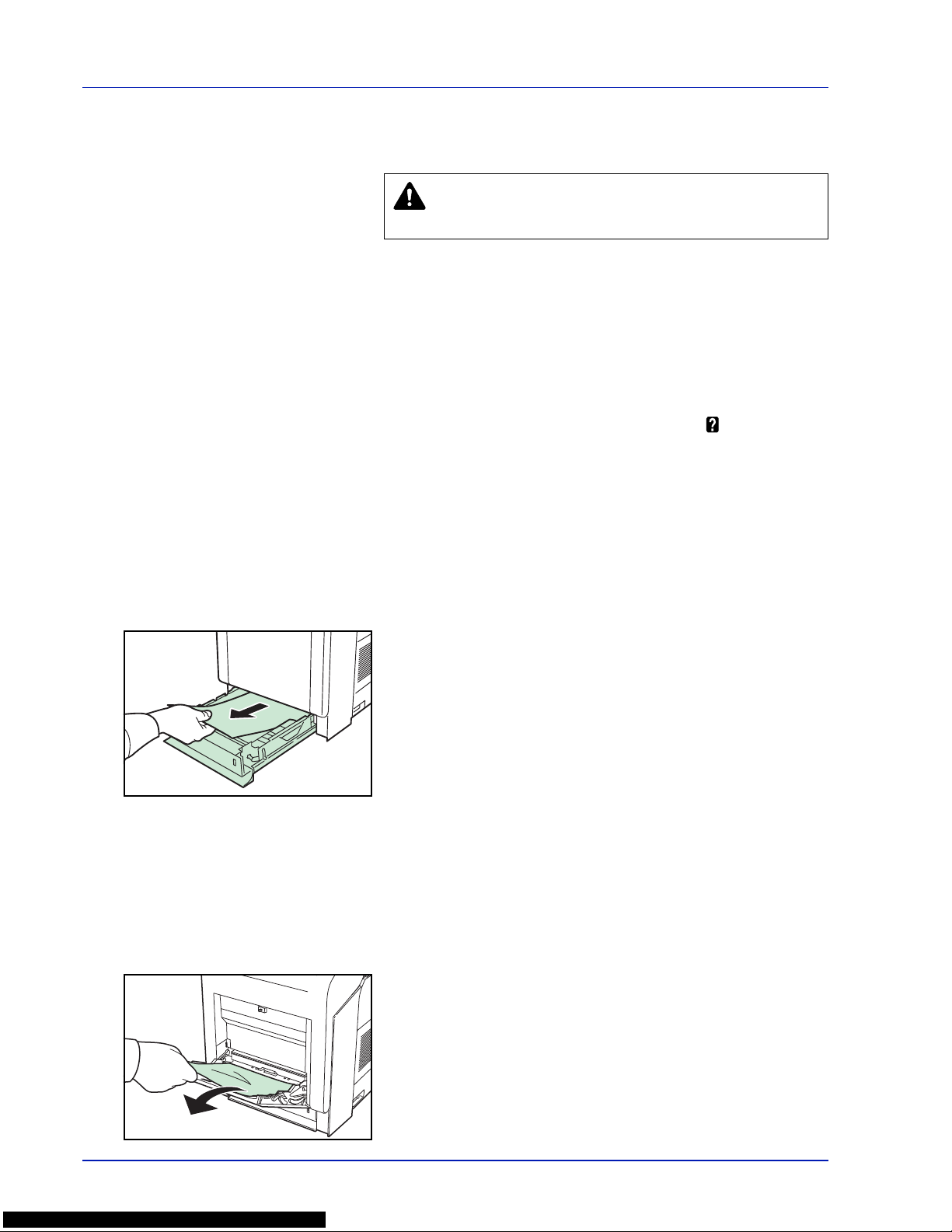

Paper stopper

Align the paper stopper to the desired paper size.

• For A4 or Letter size paper : Align with position

.

• For Legal size paper : Align with position

.

Page 45

Printing Operation 3-1

3 Printing Operation

This chapter contains explanations on the following topics:

Changing Network Interface Parameters 3-2

Printing a Network Interface Status Page 3-4

Command Center RX 3-5

Installing the Printer Driver 3-14

Printing from Application Software 3-21

Printing by AirPrint 3-22

Status Monitor 3-23

Energy Saver Function 3-27

Page 46

3-2 Printing Operation

Changing Network Interface Parameters

This printer supports TCP/IP, TCP/IP (IPv6), NetWare, AppleTalk, IPP,

SSL Server and the IPSec protocols and Security Level.

The table below shows the items required for each of the settings.

Configure the printer's network parameters as appropriate for your PC

and your network environment.

For details of the procedure, refer to the Using the Operation Panel

section of the Advanced Operation Guide.

Note

When Command Center RX is used, network

parameters and security settings can be conveniently

changed and checked from your PC. For more information,

refer to Command Center RX User Guide.

If the optional IB-50 or IB-51 is installed then NetWare and

AppleTalk settings are possible. For details, refer to Optional

Network section of the Advanced Operation Guide.

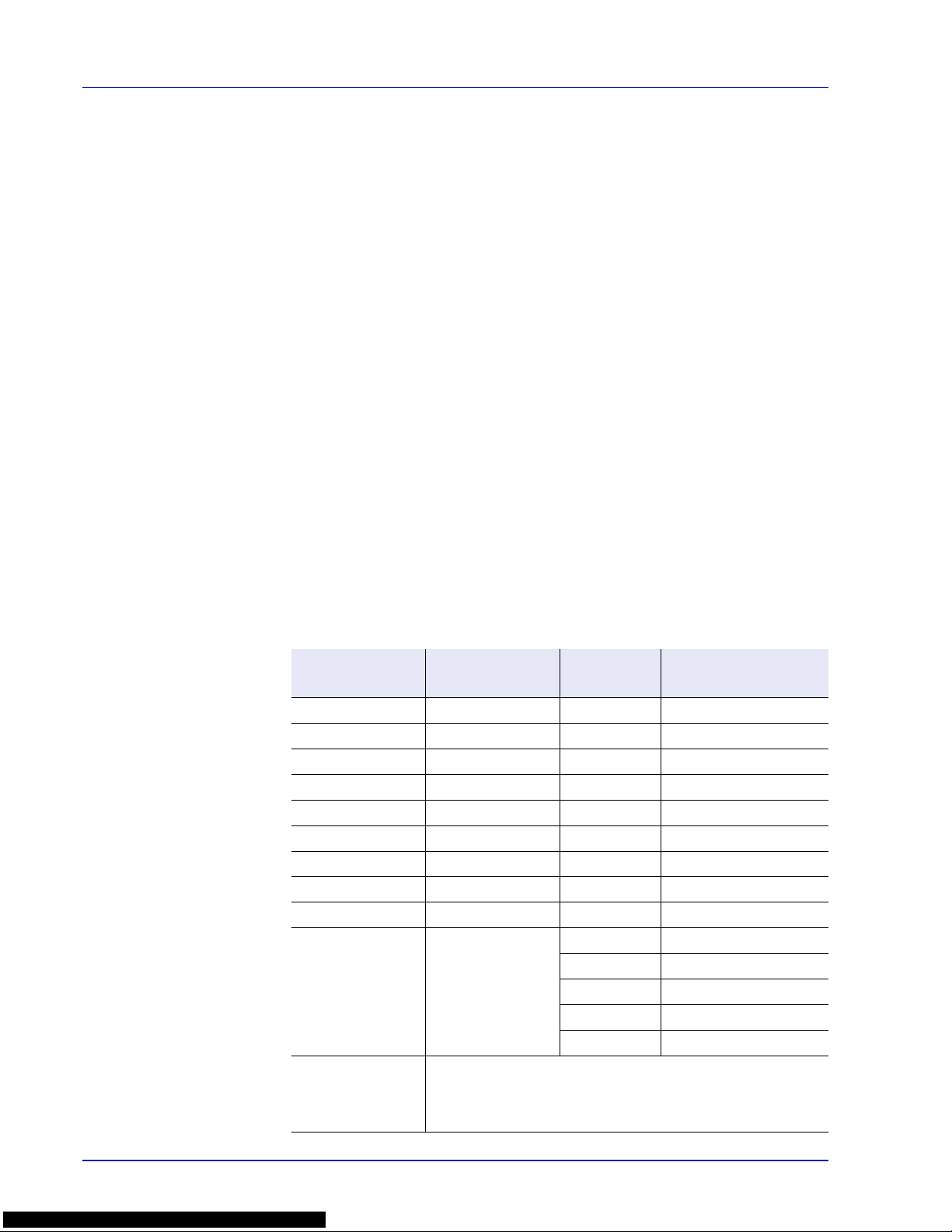

Menu Submenu Setting

Network TCP/IP On/Off

DHCP On/Off

Auto-IP On/Off

IP Address IP address

Subnet Mask IP address

Gateway IP address

Bonjour On/Off

TCP/IP (IPv6) On/Off

RA (Stateless) On/Off

DHCPv6 On/Off

Security I/F Block USB Host Block/Unblock

USB Device Block/Unblock

Option I/F Block/Unblock

USB Storage Block/Unblock

WSD-PRINT On/Off

Enhanced WSD On/Off

EnhancedWSD (SSL) On/Off

IPP On/Off

Page 47

Printing Operation 3-3

SSL Server On/Off

DES On/Off

3DES On/Off

AES On/Off

IPP over SSL On/Off

HTTPS On/Off

IPSec On/Off

LAN Interface Auto/10BASE-Half/

10BASE-Full/

100BASE-Half/

100BASE-Full/

1000BASE-T

Security Level High/Low

Note

After all network related settings have been done, turn

the machine OFF and ON again. This is mandatory to make

the settings effective!

Menu Submenu Setting

Page 48

3-4 Printing Operation

Printing a Network Interface Status Page

You can print out a status page for the network interface. The network

status page shows the network addresses, and other information under

various network protocols about the network interface.

Adjust/Maintenance

Adjust/Maintenance is used to adjust the print quality and to carry out

printer maintenance.

The options available in Adjust/Maintenance are as follows:

• Color Calibration

• Registration Normal

• Registration Details

• Restart Printer

• Service

IMPORTANT Service is primarily a menu used by service

personnel for maintenance work. There is no need for customers to

use this menu.

1

Press [MENU].

2

Press or repeatedly until Adjust/Maintenance > appears.

3

Press while Adjust/Maintenance > is displayed.

4

Press or repeatedly until >Service > appears.

5

Press .

6

Press or repeatedly until >>Print Network Status Page

appears.

7

Press [OK]. A question mark (?) appears.

8

Press [OK]. Processing appears and a status page is printed out.

9

When printing ends, the display returns to Ready.

Adjust/Maintenance >

>>Print

Network Status Page ?

Page 49

Printing Operation 3-5

Command Center RX

If the machine is connected to the network, you can configure various

settings using Command Center RX.

This section explains how to access Command Center RX, and how to

change security settings and the host name.

For details on Command Center RX, refer to the Command Center RX

User Guide.

Settings that the administrator and general users can configure in

Command Center RX are as follows.

Note

To fully access the features of the Command Center

RX pages, enter the User Name and Password and click

Login. Entering the predefined administrator password allows

the user to access all pages, including Document Box, and

Settings on the navigation menu. The factory default setting

for the default user with administrator privileges is shown

below.

* Upper case and lower case letters are distinguished

(case sensitive).

Login User Name Admin

Login Password Admin

Setting Description

Administrator

General

User

Device

Information

The machine's structure can be checked.

Configuration, Counter, About Command Center RX

Job Status Displays all device information, including print jobs and job log history.

Printing Jobs Status, Printing Job Log

Document Box Add or delete document boxes, or delete documents within a document

box.

Custom Box, Job Box Settings

Device Settings Configure the advanced settings of the machine.

Paper/Feed/Output, Energy Saver/Timer, Date/Time, System

—

Function

Settings

Configure the advanced function settings.

Common/Job Defaults, Printer, E-mail

—

Network Settings Configure the network advanced settings.

General, TCP/IP, Protocol

—

Security Settings Configure the security advanced settings.

Device Security, Network Security, Certificates

—

Management

Settings

Configure the advanced management settings.

Job Accounting, Authentication, Notification/Report,

History Settings, SNMP, Reset

—

Page 50

3-6 Printing Operation

Accessing Command Center RX

1

Launch your Web browser.

2

In the address or location bar, enter the machine's IP address or the

host name.

Examples: https://192.168.48.21/ (for IP address)

https://P001 (if the host name is "P001")

The web page displays basic information about the machine and

Command Center RX as well as their current status.

3

Select a category from the navigation bar on the left of the screen.

When you log in to the machine as an administrator, you will see

Device Settings, Function Settings, Network Settings, Security

Settings, and Management Settings.

Note

If the screen There is a problem with this website's

security certificate. is displayed, configure the certificate.

For details on Certificates, refer to the Command Center RX

User Guide.

You can also continue the operation without configuring the

certificate.

Page 51

Printing Operation 3-7

Changing Security Settings

This section explains how to change the security settings.

1

Access Command Center RX by referring to Accessing Command

Center RX on page 3-6.

2

From the Security Settings menu, select the setting you want to

configure. The configurable settings are Device Security, Network

Security, and Certificates.

Note

The configurable settings within Device Security and

Network Security can also be configured from the machine's

System Menu.

For details, refer to the Using the Operation Panel section of

the Advanced Operation Guide.

For details on settings related to certificates, refer to the

Command Center RX User Guide.

Page 52

3-8 Printing Operation

Changing Device Information

Change the device information of the machine.

1

Access Command Center RX by referring to Accessing Command

Center RX on page 3-6.

2

From the Device Settings menu, select System.

3

Enter the device information, and then click Submit.

IMPORTANT After changing the setting, restart the network or turn

the machine OFF and then ON.

To restart the network interface card, click

Reset

in the

Management

Settings

menu, and then click

Restart Network

in Restart.

Page 53

Printing Operation 3-9

E-mail settings

By configuring the SMTP settings, you can send E-mail notifications on

completed jobs.

To use this function, this machine must be connected to a mail server

using the SMTP protocol.

In addition, check the following.

• The network environment used to connect this machine to the mail

server

A full-time connection via a LAN is recommended.

• SMTP settings

Use Command Center RX to register the IP address or host name of

the SMTP server.

• If limits have been set on the size of E-mail messages, it may not be

possible to send very large E-mails.

The procedure for specifying the SMTP settings is explained below.

1

Access Command Center RX by referring to Accessing Command

Center RX on page 3-6.

2

From the Function Settings menu, click E-mail.

Page 54

3-10 Printing Operation

3

Enter the appropriate values to each field.

Setting Description

SMTP Set to send e-mail from the machine.

SMTP Protocol Set SMTP protocol. Set the SMTP (E-mail TX) setting to On on

the Protocol Settings page.

SMTP Server

Name

Enter the host name or IP address of the SMTP server.

SMTP Port

Number

Specify the port number to be used for SMTP. Use the SMTP

default port 25.

SMTP Server

Timeout

Set the amount of time to wait before time-out in seconds.

Authentication

Protocol

Set whether SMTP authentication is used. To use

authentication, enter the user information for authentication.

SMTP Security Set SMTP security.

Turn on SMTP Security in SMTP (E-mail TX) on the

Protocol Settings page.

POP before

SMTP Timeout

Specify the time in seconds until the connection to the POP

server times outs. This can be set when POP before SMTP is

selected in Authentication Protocol.

Connection Test Tests to confirm that the settings are correct.

Domain

Restriction

Set whether or not domains are restricted. Click the Domain