KYLAND Technology SICOM2024M-4S/M-24T, SICOM2024M-2S/M-24T, SICOM2024M-24T, SICOM2024M-1S/M-24T, SICOM2024M-16T Hardware Installation Manual

SICOM2024M Industrial Ethernet Switch

Hardware Installation Manual

Kyland Technology Co., Ltd.

Publication Date: Sep. 2013

Version: V4.3

FAX: +86-10-88796678

Website: http://www.kyland.com

E-mail: support@kyland.com

SICOM2024M Industrial Ethernet Switch

Hardware Installation Manual

Disclaimer: Kyland Technology Co., Ltd. tries to keep the content of this manual as accurate and

as updated as possible. This document is not guaranteed to be error-free, and we reserve the right

to amend it without notice to users.

All rights reserved.

No part of this documentation may be excerpted, reproduced, translated, annotated or duplicated,

in any form or by any means without the prior written permission of KYLAND Corporation.

Copyright © 2013 Kyland Technology Co., Ltd.

Notice for Safety Operation

The product performs reliably as long as it is used according to the guidance. Artificial damage or

destruction of the device should be avoided. Before using the device, read this notice carefully for

personal and equipment safety. Please keep the manual for further reference. Kyland is not liable to

any personal or equipment damage caused by violation of this notice.

Do not place the device near water sources or damp areas. Keep the ambient relative humidity

within the range from 5% to 95% (non-condensing).

Do not place the device in an environment with high magnetic field, strong shock, or high

temperature. Keep the working and storage temperatures within the allowed range.

Install and place the device securely and firmly.

Please keep the device clean; if necessary, wipe it with soft cotton cloth.

Do not place any irrelevant materials on the device or cables. Ensure adequate heat dissipation

and tidy cable layout without knots.

Wear antistatic gloves or take other protective measures when operating the device.

Avoid any exposed metal wires because they may be oxidized or electrified.

Install the device in accordance with related national and local regulations.

Before power-on, make sure the power supply is within the allowed range of the device.

Overhigh voltage may damage the device.

Power connectors and other connectors should be firmly interconnected.

Do not plug in or out the power supply with wet hands. When the device is powered on, do not

touch the device or any parts with wet hands.

Before operating a device connected to a power cable, remove all jewelries (such as rings,

bracelets, watches, and necklaces) or any other metal objects, because they may cause

electric shock or burns.

Do not operate the device or connect or disconnect cables during lightning.

Use compatible connectors and cables. If you are not sure, contact our sales or technical

support personnel for confirmation.

Do not disassemble the device by yourself. When an anomaly occurs, contact our sales or

technical support personnel.

If any part is lost, contact our sales or technical support personnel to purchase the substitute.

Do not purchase parts from other channels.

Dispose of the device in accordance with relevant national provisions, preventing

environmental pollution.

In the following cases, please immediately shut down your power supply and contact your Kyland

representative:

Water gets into the equipment.

Equipment damage or shell damage.

Equipment operation or performance has abnormally changed.

The equipment emits odor, smoke or abnormal noise.

I

Contents

1 Product Overview .................................................................................................................... 1

2 Structure and Interface ............................................................................................................ 2

2.1 Front Panel ....................................................................................................................................... 2

2.2 Rear Panel ....................................................................................................................................... 3

3 Mounting .................................................................................................................................. 8

3.1 Dimension Drawing .......................................................................................................................... 8

3.2 Mounting Modes and Steps .............................................................................................................. 8

4 Connection ............................................................................................................................. 11

4.1 10/100Base-T(X) Ethernet Port ...................................................................................................... 11

4.2 100Base-FX Ethernet Port .............................................................................................................. 12

4.3 Console Port ................................................................................................................................... 13

4.4 Grounding....................................................................................................................................... 13

4.5 Power Terminal Block ..................................................................................................................... 14

4.6 Alarm Terminal Block ..................................................................................................................... 16

5 LEDs ...................................................................................................................................... 18

6 Switch Access ........................................................................................................................ 20

6.1 Access through Console Port ......................................................................................................... 20

6.2 Access through Telnet .................................................................................................................... 22

6.3 Access through Web ...................................................................................................................... 22

7 Basic Features and Specifications ......................................................................................... 24

Product Overview

1

1 Product Overview

SICOM2024M includes a series of high-performance industrial Ethernet switches developed by

Kyland particularly for industrial applications. SICOM2024M is applicable to harsh and hazardous

industrial environments due to its high-performance switching engine, solid closed housing, fanless

but heat dissipation-capable single-rib shaped chassis, overcurrent, overvoltage, and EMC

protection for power input, and sound EMC protection of RJ45 ports. The redundant network and

power input support as well as power alarm functions guarantee the reliable operation of the

system.

SICOM2024M provides powerful network management functions. The device can be managed

through CLI, Telnet, Web, and SNMP-based network management software.

SICOM2024M supports 19 inch 1U rack mounting. It provides up to four 10/100Base-T(X) Ethernet

ports and four 100Base-FX Ethernet ports, as listed in the following table.

Table 1 SICOM2024M Models

Model

Port

Power Supply

100Base-FX

Ethernet port

10/100Base-T(X)

Ethernet port

SICOM2024M-4S/M-24T

4

24

220AC/DCW, 220AC/DC, 48DC, 24DC

(single and redundant power supply)

SICOM2024M-2S/M-24T

2

24

SICOM2024M-1S/M-24T

1

24

SICOM2024M-24T

--

24

SICOM2024M-16T

--

16

Note:

We reserve the right to amend the product information listed in this table without notice. To obtain the

latest information, contact our sales or technical support personnel.

Structure and Interface

2

2 Structure and Interface

Caution:

To keep ports clean and ensure switch performance, you are advised to purchase the port dustproof

shield (optional).

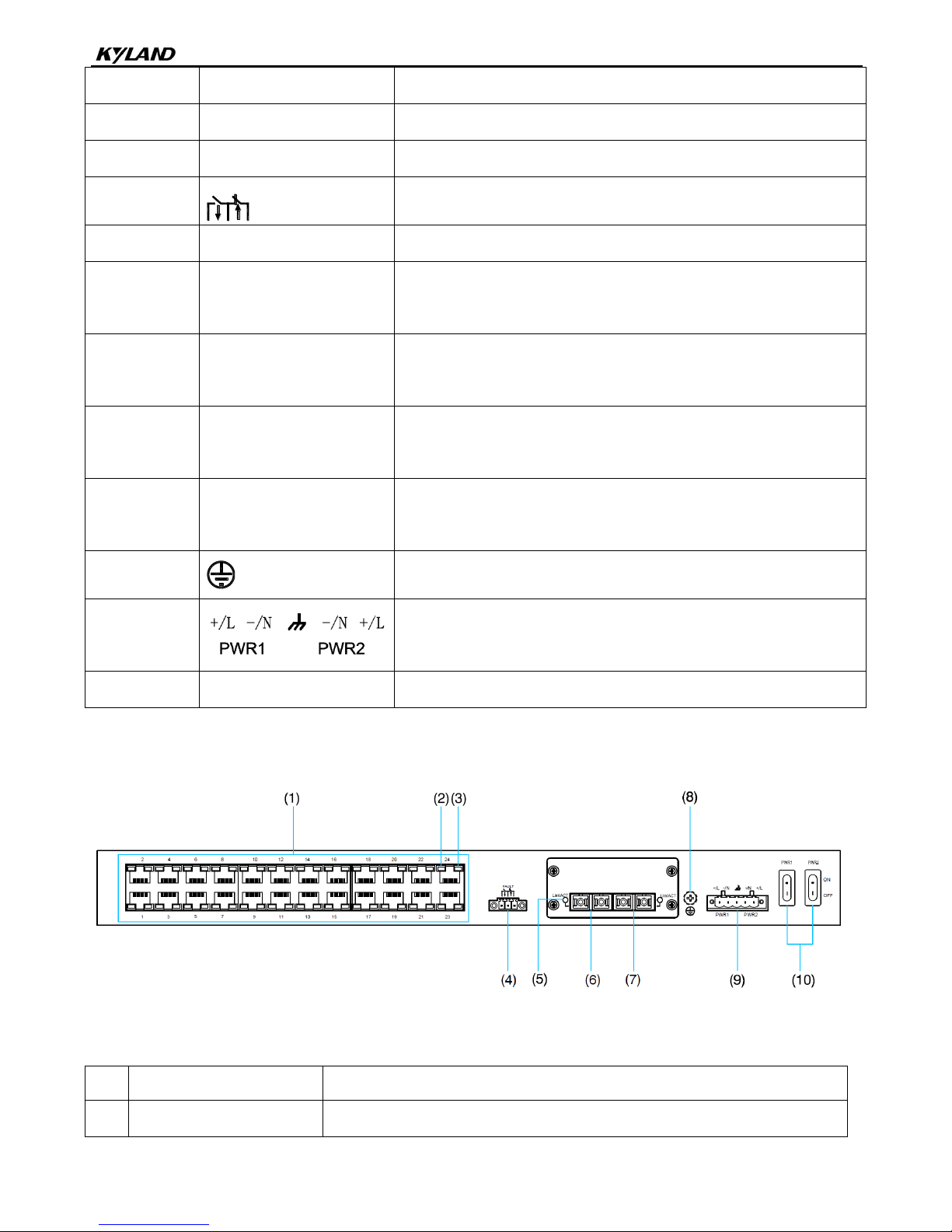

2.1 Front Panel

Front Panel (1)

Applicable to: SICOM2024M-4S/M-24T

SICOM2024M-2S/M-24T

SICOM2024M-24T

Figure 1 Front Panel (1)

Table 2 Description of Front Panel (1)

No.

Identifier

Description

(1)

ALARM

Alarm LED

(2)

RUN

Running LED

(3)

PWR1

Power 1 LED

(4)

PWR2

Power 2 LED

(5)

G1-G4: DPX

Speed LEDs for four 100Base-FX Ethernet ports

(6)

G1-G4: LINK

Connection status LEDs for four 100Base-FX Ethernet ports

(7)

1-24: LINK/ACT

Connection status LEDs for twenty-four 10/100Base-T(X) Ethernet ports

(8)

1-24: 10M/100M

Speed LEDs for twenty-four 10/100Base-T(X) Ethernet ports

(9)

CONSOLE

Console port

Front Panel (2)

Applicable to: SICOM2024M-2S/M-24T

Structure and Interface

3

SICOM2024M-1S/M-24T

SICOM2024M-24T

SICOM2024M-16T

Figure 2 Front Panel (2)

Table 3 Description of Front Panel (2)

No.

Identifier

Description

(1)

Run

Running LED

(2)

PWR1

Power 1 LED

(3)

PWR2

Power 2 LED

(4)

A-B: Speed

Speed LEDs for two 100Base-FX Ethernet ports

(5)

A-B: Link/ACT

Connection status LEDs for two 100Base-FX Ethernet ports

(6)

1-24: Link/ACT

Connection status LEDs for twenty-four 10/100Base-T(X) Ethernet ports

(7)

1-24: Speed

Speed LEDs for twenty-four 10/100Base-T(X) Ethernet ports

2.2 Rear Panel

Rear Panel of SICOM2024M-4S/M-24T

Figure 3 Rear Panel of SICOM2024M-4S/M-24T

Table 4 Description of Rear Panel of SICOM2024M-4S/M-24T

No.

Identifier

Description

Structure and Interface

4

(1)

1-24

Twenty-four 10/100Base-T(X) Ethernet ports

(2)

--

10/100Base-T(X) Ethernet port speed LED

(3)

--

10/100Base-T(X) Ethernet port connection status LED

(4)

FAULT

Alarm terminal block

(5)

LINK/ACT

100Base-FX Ethernet port connection status LED

(6)

--

100Base-FX Ethernet port (Its status is indicated by G1 on the front

panel.)

(7)

--

100Base-FX Ethernet port (Its status is indicated by G2 on the front

panel.)

(8)

--

100Base-FX Ethernet port (Its status is indicated by G3 on the front

panel.)

(9)

--

100Base-FX Ethernet port (Its status is indicated by G4 on the front

panel.)

(10)

Grounding screw

(11)

Power terminal block

(12)

PWR1&PWR2: ON/OFF

Switches for Power 1 and Power 2

Rear Panel of SICOM2024M-2S/M-24T (The model involves two types of rear panels. You can

refer to the following descriptions according to your panel type.)

Figure 4 Rear Panel of SICOM2024M-2S/M-24T

Table 5 Description of Rear Panel of SICOM2024M-2S/M-24T

No.

Identifier

Description

(1)

1-24

Twenty-four 10/100Base-T(X) Ethernet ports

Structure and Interface

5

(2)

--

10/100Base-T(X) Ethernet port speed LED

(3)

--

10/100Base-T(X) Ethernet port connection status LED

(4)

FAULT

Alarm terminal block

(5)

Link/ACT

100Base-FX Ethernet port connection status LED

(6)

--

100Base-FX Ethernet port (Its status is indicated by G1 on the front panel.)

(7)

--

100Base-FX Ethernet port (Its status is indicated by G3 on the front panel.)

(8) Grounding screw

(9) Power terminal block

(10)

PWR1&PWR2: ON/OFF

Switches for Power 1 and Power 2

Figure 5 Rear Panel of SICOM2024M-2S/M-24T and SICOM2024M-1S/M-24T

Table 6 Description of Rear Panel of SICOM2024M-2S/M-24T and SICOM2024M-1S/M-24T

No.

Identifier

Description

(1)

1-24

Twenty-four 10/100Base-T(X) Ethernet ports

(2)

--

10/100Base-T(X) Ethernet port speed LED

(3)

--

10/100Base-T(X) Ethernet port connection status LED

(4)

AT AR, BT BR

100Base-FX Ethernet ports

(5)

A, B

100Base-FX Ethernet port connection status LEDs

(6) Grounding screw

(7)

Console

Console port

(8)

Alarm terminal block

(9) Power terminal block

Structure and Interface

6

(10)

P1&P2: ON/OFF

Switches for Power 1 and Power 2

Rear Panel of SICOM2024M-24T (The model involves two types of rear panels. You can refer

to the following descriptions according to your panel type.)

Figure 6 Rear Panel (1) of SICOM2024M-24T

Table 7 Description of Rear Panel (1) of SICOM2024M-24T

No.

Identifier

Description

(1)

1-24

Twenty-four 10/100Base-T(X) Ethernet ports

(2)

--

10/100Base-T(X) Ethernet port speed LED

(3)

--

10/100Base-T(X) Ethernet port connection status LED

(4)

FAULT

Alarm terminal block

(5) Grounding screw

(6)

Power terminal block

(7)

PWR1&PWR2: ON/OFF

Switches for Power 1 and Power 2

Figure 7 Rear Panel (2) of SICOM2024M-24T

Table 8 Description of Rear Panel (2) of SICOM2024M-24T

Structure and Interface

7

No.

Identifier

Description

(1)

1-24

Twenty-four 10/100Base-T(X) Ethernet ports

(2)

--

10/100Base-T(X) Ethernet port speed LED

(3)

--

10/100Base-T(X) Ethernet port connection status LED

(4)

Console

Console port

(5)

Alarm terminal block

(6) Grounding screw

(7) Power terminal block

(8)

P1&P2: ON/OFF

Switches for Power 1 and Power 2

Rear Panel of SICOM2024M-16T

Figure 8 Rear Panel of SICOM2024M-16T

Table 9 Description of Rear Panel of SICOM2024M-16T

No.

Identifier

Description

(1)

1-16

Sixteen 10/100Base-T(X) Ethernet ports

(2)

--

10/100Base-T(X) Ethernet port speed LED

(3)

--

10/100Base-T(X) Ethernet port connection status LED

(4)

Console

Console port

(5) Alarm terminal block

(6) Grounding screw

(7) Power terminal block

Mounting

8

(8)

P1&P2: ON/OFF

Switches for Power 1 and Power 2

3 Mounting

3.1 Dimension Drawing

Figure 9 Dimension Drawing (unit: mm)

Caution:

As part of the heat dissipation system, the switch housing becomes hot during operation. Please use

caution when coming in contact and avoid covering the switch housing when the switch is running.

The figures in this manual are only for reference.

3.2 Mounting Modes and Steps

The series switches support rack mounting by front/rear panel. The following uses mounting by

front panel as an example to describe mounting steps. The steps for mounting by rear panel are

Mounting

9

similar to those for mounting by front panel. Before installation, make sure that the following

requirements are met.

1) Environment: temperature (-40℃ to 85℃), ambient relative humidity (5% to 95%,

non-condensing)

2) Power requirement: The power input is within the voltage range of the switch.

3) Grounding resistance: <5

4) No direct sunlight, distant from heat source and areas with strong electromagnetic interference.

Installing Mounting Brackets

Figure 10 Mounting Bracket

You can select the screw holes for front or rear panel mounting to install the mounting brackets. If

there are screws inserted in the screw holes, remove the screws and keep them for future use.

As shown in the following figure, use three screws to secure two mounting brackets to the switch

respectively.

Figure 11 Installing Mounting Brackets

Mounting

Step 1: Select the mounting position for the switch and guarantee adequate space and heat

Mounting

10

dissipation for it (dimensions: 440mm×44mm×245mm).

Step 2: Move the switch in direction 1 until the screw holes for securing the mounting brackets to

rack posts are in alignment with the corresponding holes in the rack posts. Then use four

screws and supporting captive nuts to secure the mounting brackets to the rack posts.

Figure 12 Mounting

Dismounting

Step 1: Remove the four screws and supporting captive nuts securing the mounting brackets to the

rack posts.

Step 2: Remove the switch from the rack posts. Then unscrew the mounting brackets to complete

dismounting.

Connection

11

4 Connection

4.1 10/100Base-T(X) Ethernet Port

10/100Base-T(X) Ethernet port is equipped with RJ45 connector. The port is self-adaptive. It can

automatically configure itself to work in 10M or 100M state, full or half duplex mode. The port can

also adapt to MDI or MDI-X connection automatically. You can connect the port to a terminal or

network device with a straight-through or cross-over cable.

Pin Definition

The following figure shows the pin numbers of the RJ45 port.

8 7 6 5 4 3 2 1

Figure 13 RJ45 Port

The following table lists the pin definitions of the 10/100Base-T(X) RJ45 port.

Table 10 Pin Definitions of 10/100Base-T(X) RJ45 Port

Pin

MDI-X Signal

MDI Signal

1

Receive Data+ (RD+)

Transmit Data+ (TD+)

2

Receive Data- (RD-)

Transmit Data- (TD-)

3

Transmit Data+ (TD+)

Receive Data+ (RD+)

6

Transmit Data- (TD-)

Receive Data- (RD-)

4, 5, 7, 8

Unused

Unused

Note:

"+" and "-" indicate level polarities.

Wiring Sequence

Connection

12

Figure 14 Connection Using Straight-through/Cross-over Cable

Note:

The color of the cable for RJ45 connector meets the 568B standard: 1-orange and white, 2-orange,

3-green and white, 4-blue, 5-blue and white, 6-green, 7-brown and white, and 8-brown.

4.2 100Base-FX Ethernet Port

100Base-FX Ethernet port is equipped with FC/ST/SC connector, and each port consists of TX

(transmit) port and RX (receive) port. To enable data transmission between Device A and Device B,

connect the TX port of Device A to the RX port of Device B, and the RX port of Device A to the TX

port of Device B. The following uses an SC port as an example. The wiring sequence of an ST/FC

port is the same with that of the SC port.

Figure 15 Connection of 100Base-FX Ethernet Port

Caution:

The device uses laser to transmit signals in fibers. The laser meets the requirements of level 1 laser

products. Routine operation is not harmful to your eyes, but do not look directly at the fiber port when the

Connection

13

device is powered on.

4.3 Console Port

Connect the 9-pin serial port of a PC to the console port of the switch with an RJ45-DB9 console

cable. Then you can configure, maintain, and manage the switch by running the Hyper Terminal in

the Windows OS of the computer.

Figure 16 Console Port

RJ45-DB9 Console Cable

One end of an RJ45-DB9 console cable is crimped RJ45 connector to be inserted into the console

port of the switch, and the other end is the DB9 connector to be inserted into the 9-pin serial port of

a PC.

Figure 17 Wiring Sequence of DB9-RJ45 Console Cable

Table 11 Pin Definitions of DB9-RJ45 Console Cable

DB9 Pin

RJ45 Pin

Signal

Description

2 3 RXD

Receive data

3 2 TXD

Transmit data

5 5 GND

Grounding

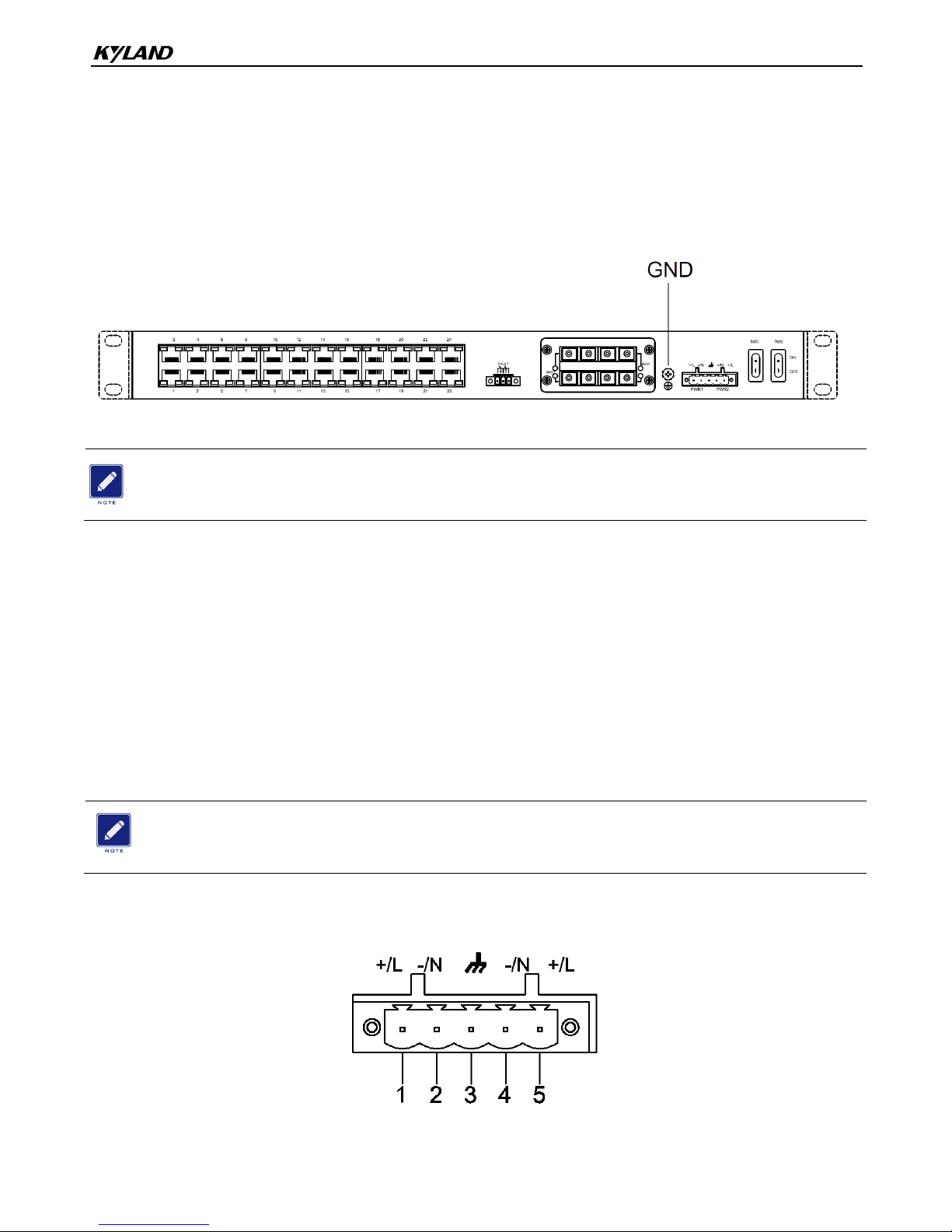

4.4 Grounding

Grounding protects the switch from lightning and interference. Therefore, you must ground the

Connection

14

switch properly. You need to ground the switch before it is powered on and disconnect the

grounding cable after the switch is powered off.

The switch provides a grounding screw on the rear panel for chassis grounding. After crimping one

end of the grounding cable to a cold pressed terminal, secure the end to the grounding screw and

connect the other end to the earth firmly.

Figure 18 Grounding

Note:

Cross-sectional area of the chassis grounding cable>2.5mm2; grounding resistance<5.

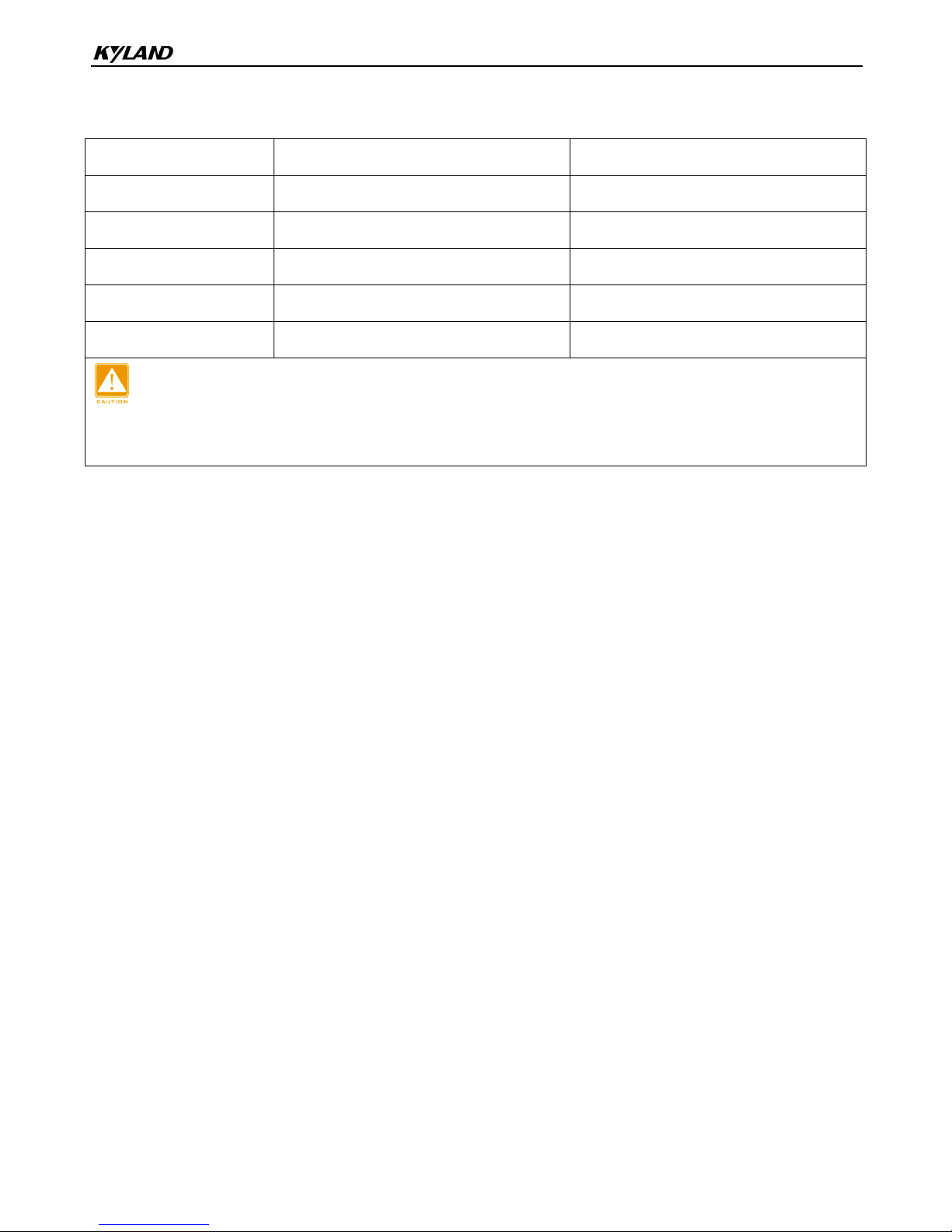

4.5 Power Terminal Block

There is a power terminal block on the rear panel of the device. You need to connect the power

wires to the terminal block to provide power for the device. The device supports both single and

redundant power supply with 5-pin 5.08mm-spacing plug-in terminal block. When the redundant

power supply is used and one power input is faulty, the device can continue operating properly,

thereby improving network reliability.

Note:

0.75mm2<Cross-sectional area of the power wire<2.5mm2; grounding resistance<5.

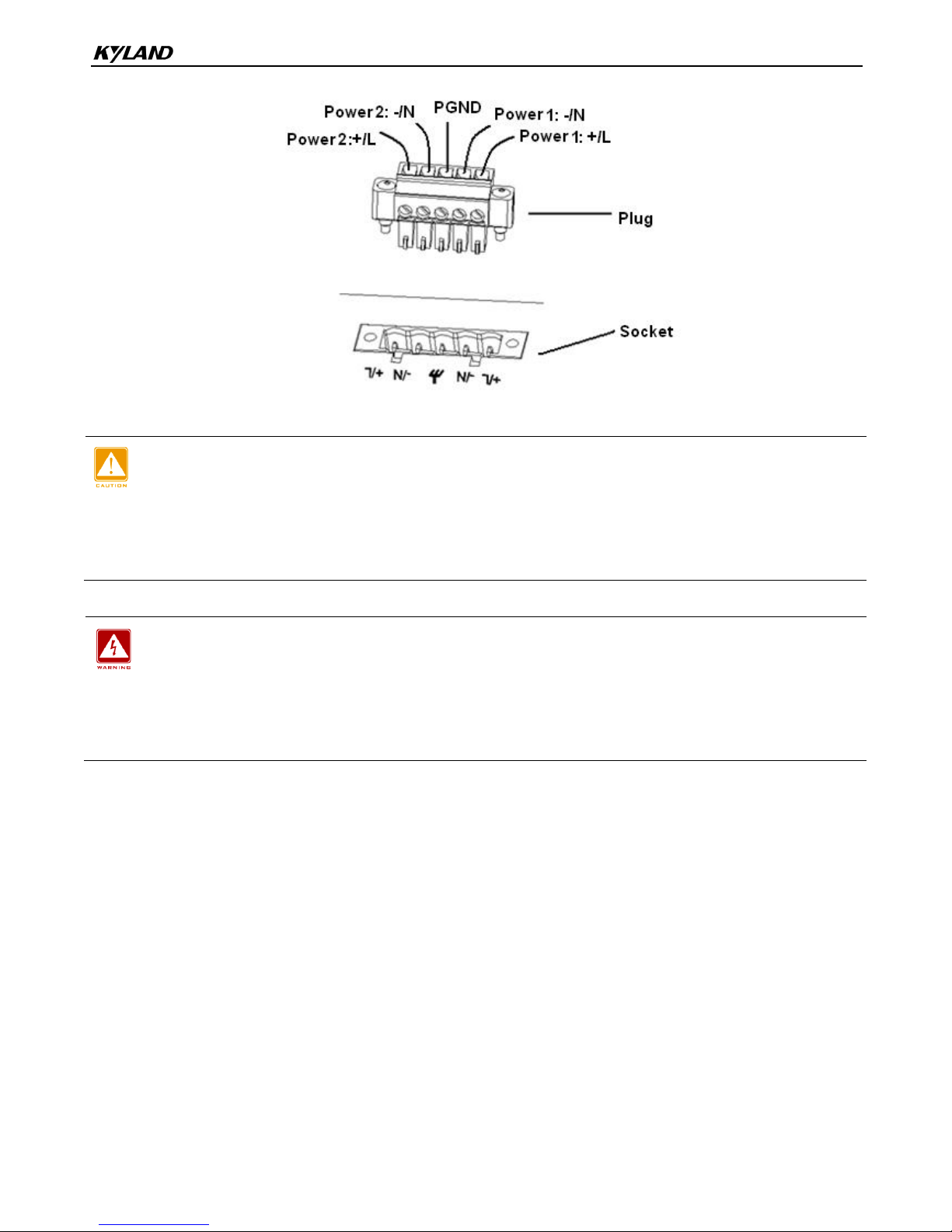

5-Pin 5.08mm-Spacing Plug-in Terminal Block

The following figure shows the 5-pin 5.08mm-spacing plug-in terminal block.

Figure 19 5-Pin 5.08mm-Spacing Plug-in Terminal Block (socket)

Connection

15

The following table lists the pin definitions of the 5-pin 5.08mm-spacing plug-in terminal block.

Table 12 Pin Definitions of 5-Pin 5.08mm-Spacing Plug-in Terminal Block

No.

DC Definition

AC Definition

1

Power 1: +

Power 1: L

2

Power 1: -

Power 1: N

3

PGND

PGND

4

Power 2: -

Power 2: N

5

Power 2: +

Power 2: L

Caution:

For single power supply, only pins 1, 2, and 3 of the terminal block can be connected. Do not use pins 4

and 5.

Wiring and Mounting

Step 1: Ground the device properly according to section 4.4.

Step 2: Remove the power terminal block from the device.

Step 3: Insert the power wires into the power terminal block according to Table 12 and secure the

wires.

Step 4: Insert the terminal block with the connected wires into the terminal block socket on the

device.

Step 5: Connect the other end of the power wires to the external power supply system according to

the power supply requirements of the device. Turn on the switch for the connected power

(power 1, power 2, or both). View the status of the power LEDs on the front panel. If the

LEDs are on, the power is connected properly.

Connection

16

Figure 20 Connection of 5-Pin 5.08mm-Spacing Plug-in Terminal Block

Caution:

The switch supports 220AC/DCW, 220AC/DC, 48DC, and 24DC power input. Before connecting the

device to power supply, make sure that the power input meets the power requirement. If connected to an

incorrect power input, the device may be damaged.

Warning:

Do not touch any exposed conducting wire, terminal, or component with a voltage warning sign,

because it may cause damage to humans.

Do not remove any part or plug in or out any connector when the device is powered on.

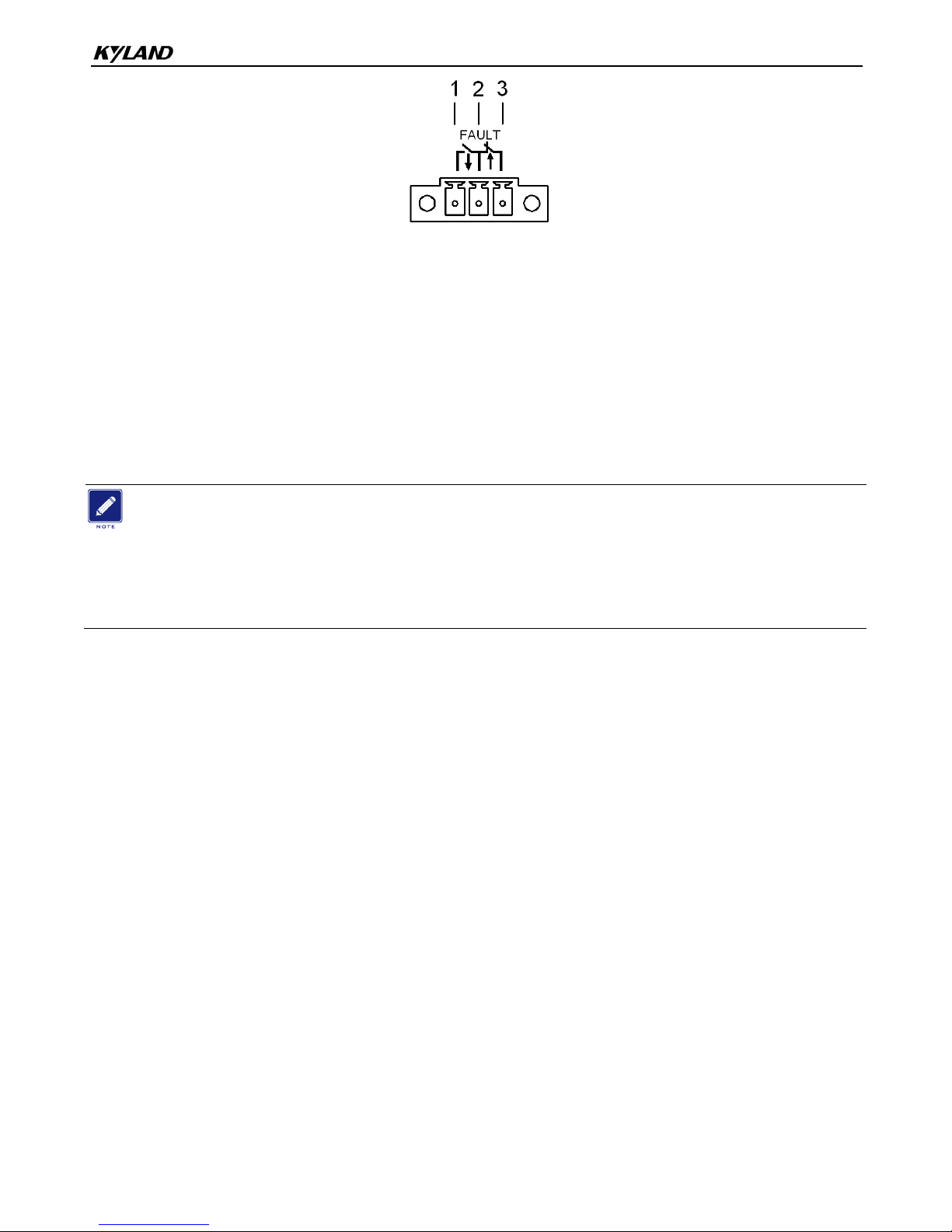

4.6 Alarm Terminal Block

The device provides an alarm terminal block on the rear panel for alarm output. When the switch

works properly, the normally-open contacts of the alarm relay are closed and the normally-closed

contacts are open; when an alarm occurs, the normally-open contacts are open and the

normally-closed contacts are closed. The alarm is outputted through a 3-pin 3.81mm-spacing

plug-in terminal block.

Connection

17

Figure 21 Alarm Terminal Block (socket)

Electrical parameters of the relay:

Max Switch Voltage: 250VAC/220VDC;

Max Switch Current: 2A

Max Switching Power: 60W

Dielectric Strength: 2KV

Note:

Pin 1 and pin 2 are normally-open contacts; pin 2 and pin 3 are normally-closed contacts. When the

switch works properly, pin 1 and pin 2 are closed, pin 2 and pin 3 are open; when an alarm occurs, pin 1

and pin 2 are open; pin 2 and pin 3 are closed.

Wiring and Mounting

Step 1: Remove the alarm terminal block from the switch.

Step 2: Secure the three wires for alarm into the alarm terminal block in the required sequence.

Step 3: Insert the alarm terminal block into its socket.

LEDs

18

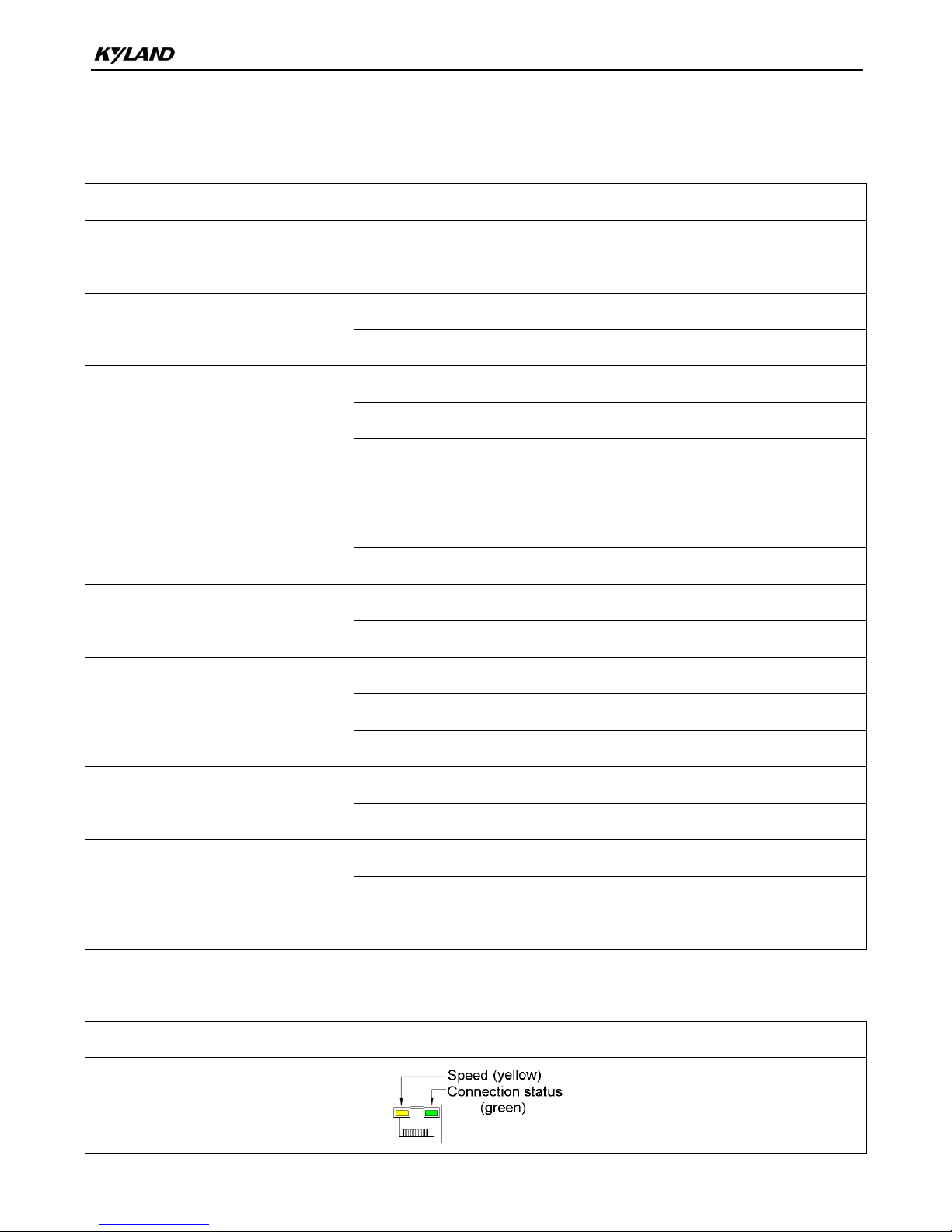

5 LEDs

Table 13 Front Panel LEDs

LED

State

Description

Power 1 LED

On

Power 1 is connected and operates properly.

Off

Power 1 is not connected or operates abnormally.

Power 2 LED

On

Power 2 is connected and operates properly.

Off

Power 2 is not connected or operates abnormally.

Running LED

Blinking

The CPU operates properly.

On

The CPU operates abnormally.

Off

The CPU operates abnormally or does not start up;

the device is starting up.

Alarm LED

On

An alarm occurs.

Off

No alarm occurs.

100Base-FX Ethernet port speed

LED

On

100M working state (100Base-FX)

Off

No connection

100Base-FX Ethernet port

connection status LED

On

Effective port connection

Blinking

Ongoing network activities

Off

No effective port connection

10/100Base-T(X) Ethernet port

speed LED

On

100M working state (100Base-TX)

Off

10M working state (10Base-T) or no connection

10/100Base-T(X) Ethernet port

connection status LED

On

Effective port connection

Blinking

Ongoing network activities

Off

No effective port connection

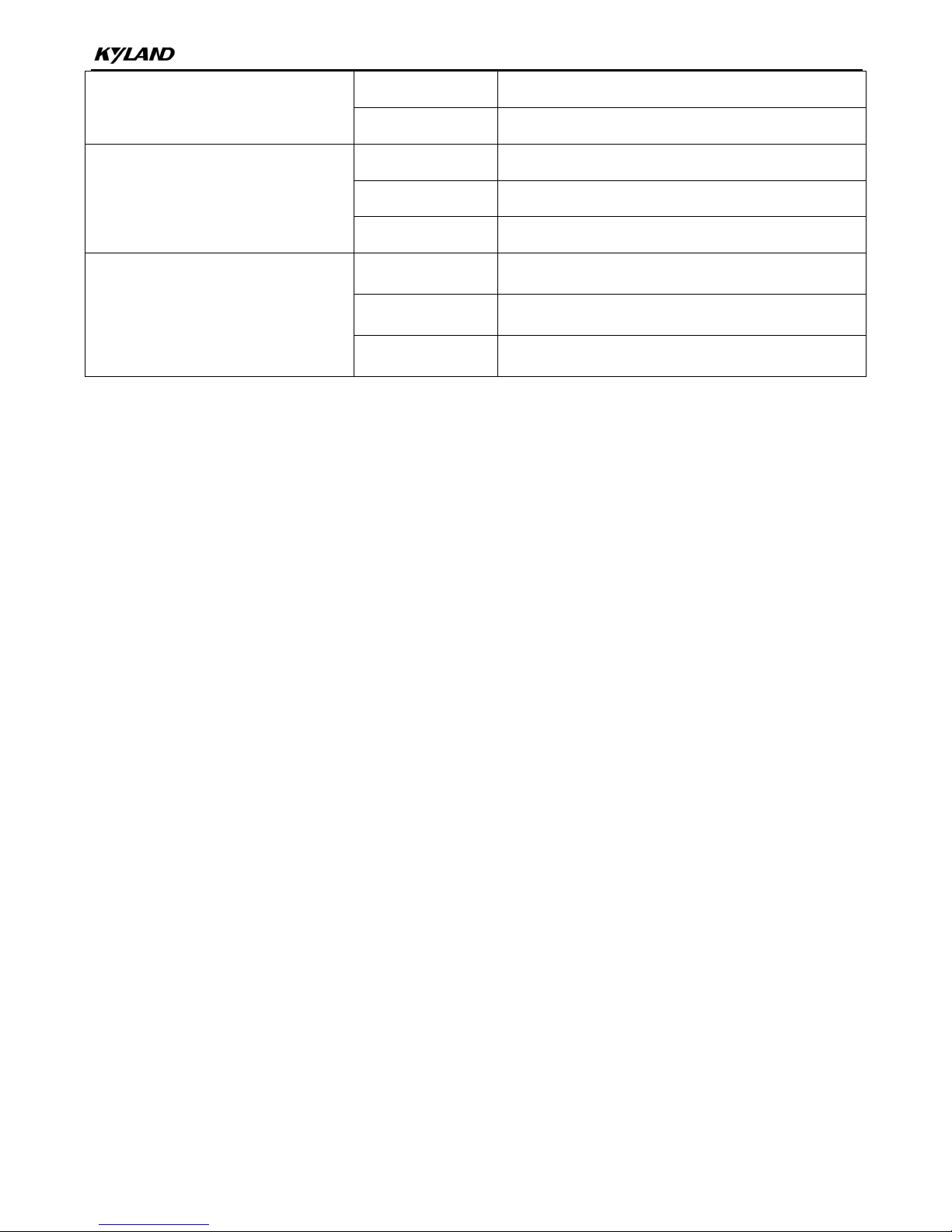

Table 14 Rear Panel LEDs

LED

State

Description

LEDs

19

10/100Base-T(X) Ethernet port

speed LED (yellow)

On

100M working state (100Base-TX)

Off

10M working state (10Base-T) or no connection

10/100Base-T(X) Ethernet port

connection status LED (green)

On

Effective port connection

Blinking

Ongoing network activities

Off

No effective port connection

100Base-FX Ethernet port

connection status LED

On

Effective port connection

Blinking

Ongoing network activities

Off

No effective port connection

Switch Access

20

6 Switch Access

You can access the switch in any of the following ways:

6.1 Access through Console Port

Step 1: Connect the console port of the switch to the 9-pin serial port of a PC with the delivered

RJ45-DB9 console cable.

Step 2: Open the Hyper Terminal in the Windows OS. On the desktop, click Start → All Programs →

Accessories → Communications → Hyper Terminal.

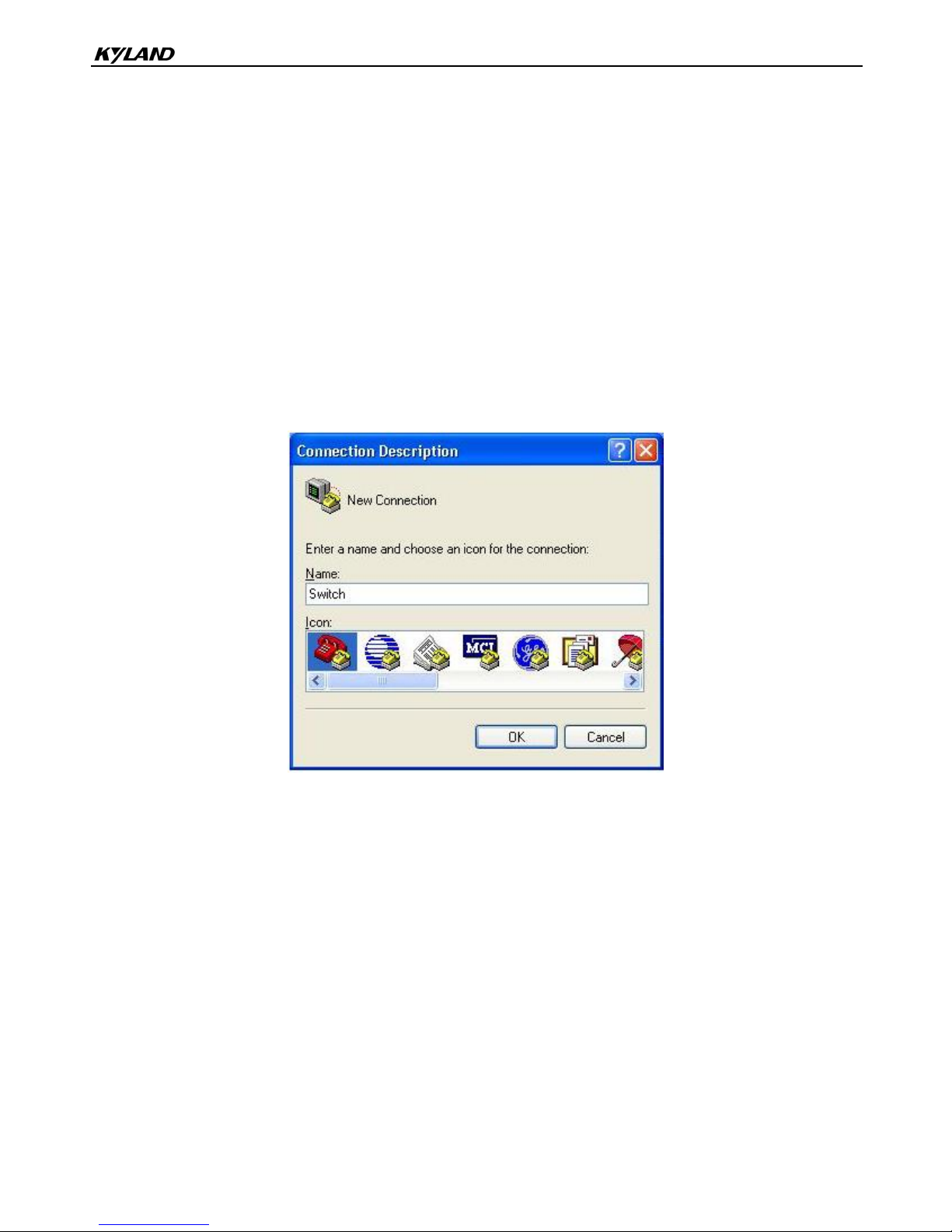

Step 3: Create a connection "Switch", as shown in the following figure.

Figure 22 Creating a Connection

Step 4: Connect the communication port in use, as shown in the following figure.

Switch Access

21

Figure 23 Selecting a Serial Port

Note:

To confirm the communication port in use, right-click [My Computer] and select [Property]. Click

[Hardware] → [Device Manager] → [Port] to view the communication port.

Step 5: Set port parameters (Bits per second: 9600, Data bits: 8, Parity: None, Stop bits: 1, and

Flow control: None), as shown in the following figure.

Switch Access

22

Figure 24 Setting Port Parameters

Step 6: Click OK to enter the switch CLI. Then you can run the following commands to perform

operations.

Table 15 CLI Commands

View

Command

Description

User view

SWITCH>enable

Enter the management view.

Management view

SWITCH#show interface

Query the current IP address of the switch.

Management view

SWITCH#show version

Query the version of the switch.

Management view

SWITCH#reboot

Restart the switch.

Management view

SWITCH#load default

Restore the factory default settings (excluding the IP

address).

Management view

SWITCH#config terminal

Enter the configuration view.

6.2 Access through Telnet

Step 1: Connect the network port of the PC to the RJ45 port of the switch with an RJ45-RJ45 cable.

Step 2: Enter "telnet IP address" in the Run dialog box. For example, if the IP address of the switch

is 192.168.0.2 (default IP address of a Kyland switch), enter "telnet 192.168.0.2" in the

dialog box.

Figure 25 Access through Telnet

Step 3: Click OK. The Telnet CLI is displayed. Then you can enter commands (as listed in Table 15)

to perform operations.

6.3 Access through Web

Step 1: Connect the network port of the PC to the RJ45 port of the switch with an RJ45-RJ45 cable.

Step 2: Enter the IP address of the switch in the address box of the browser. The user login

Switch Access

23

interface is displayed. You can log in to the Web UI by default user name "admin" and

password "123".

Note:

IE8.0 or a later version is recommended.

For details about how to access the switch and other operations, refer to the Web operation manual in

the delivered CD.

Basic Features and Specifications

24

7 Basic Features and Specifications

Power Requirements

Power Identifier

Rated Voltage Range

Maximum Voltage Range

24DC

24VDC

18-36VDC

48DC

48VDC

36-72VDC

220AC/DC

100-240VAC, 50/60Hz; 220VDC

85-264VAC/120-300VDC

220AC/DCW

100-240VAC, 50/60Hz; 110-220VDC

85-264VAC/77-300VDC

Terminal block

5-pin 5.08mm-spacing plug-in terminal block

Rated Power Consumption

Rated power consumption

<16.8W

Physical Characteristics

Housing

Metal, fanless

Installation

19 inch 1U rack mounting

Dimensions (W×H×D)

440mm×44mm×245mm

(excluding connectors and mounting brackets)

Weight

2.5Kg

Environmental Limits

Operating temperature

-40℃~+85℃

Storage temperature

-40℃~+85℃

Ambient relative humidity

5%~95% (non-condensing)

MTBF

MTBF

338,566 hours

Warranty

Warranty

5 years

For more information about KYLAND products, please visit our website: http://www.kyland.com

Loading...

Loading...