103

Multi-Speed

Combination

Brake

Lathe

Instruction Manual and Parts List

Kwik-Way Products Inc.

Copyright © 2005, All Rights Reserved

Equipment, specifications, options and accessories subject to change without notice Part #

103 Multi-Speed Brake Lathe

521 WARRANTY

Brake Lathes • Tire Changers • Wheel Balancers

KWIK-WAY

provides a limited 521 Warranty on products when purchased in a new and unused condition to be free from

defective material or workmanship from date of purchase as per the following:

Product BENCH MODEL ON-CAR-LATHES PASSENGER CAR WHEEL BALANCERS TRUCK LATHES

Category LATHES TIRE CHANGERS AND

TIRE CHANGERS

5 Years

Spindle, spindle bearing Cast iron components, Transmission Frame, welding N/A

and housing excluding guide rods construction

2 Years

All other mechanical All other mechanical Pedal controls Shaft N/A

parts parts

1 Year

Electrical motors and Electric motors and Parts, electrics and Parts, electrics and Parts, electrics and

labor labor labor labor labor

This warranty does not apply to a product that has been purchased in used condition, that has failed due to improper

installation, repairs, service or that has sustained damage caused by accident, improper use or shipment.

Kwik-Way

will repair and/or replace, free of charge (FOB factory) all such defective parts, only when returned to factory with

shipping charges prepaid. This warranty does not cover parts and supplies consumed in normal operation of the machine.

Kwik-Way

disclaims all other warranties, expressed or implied, as to the quality of any goods, including implied warranties of

MERCHANTABILITY and FITNESS FOR PARTICULAR PURPOSES. UNDER NO CIRCUMSTANCES WHATSOEVER, SHALL KWIKWAY BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON LOST GOODWILL, LOST

RESALE PROFITS, WORK STOPPAGE, IMPAIRMENT OF OTHER GOODS OR ARISING OUT OF BREACH OF ANY EXPRESS OR

IMPLIED WARRANTY, BREACH OF CONTRACT, NEGLIGENCE OR OTHERWISE, EXCEPT ONLY IN THE CASE OF PERSONAL

INJURY WHERE APPLICABLE LAW REQUIRES SUCH LIABILITY. This limited warranty gives you specific legal rights and you

may also have other rights which vary from state to state. This document contains the complete text of this warranty and may

not be modified either orally or in writing.

Because of

KWIK-WAY

’s constant program of product improvement, specifications are subject to change without notice.

Office Hours: 7:30 to 5:00 Central Time

Kwik-Way Products Inc.

500 57th Street

Marion, Iowa 52302

Toll Free

1-800-553-5953

Fax 319-377-9101

www.kwik-way.com

service@kwik-way.com

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 1

Receiving Shipment

Upon taking delivery of your machine, carefully inspect the assembly before removing the

crating and packing materials.

If evidence of damage exists, contact the shipper and Kwik-Way Products Inc.immediately.

Although Kwik-Way Products Inc.is not responsible for damage incurred during transit, you

will be provided assistance in preparation and filing of any necessary claims.

CAREFULLY READ THIS MANUAL BEFORE ATTEMPTING TO SET-UP OR OPERATE

THIS MACHINE.

Important Note:

Always have your serial number ready when communicating with Kwik-Way Products Inc

.

regarding parts or service.

Keep this manual in a safe place.

Kwik-Way Products Inc.

500 57th Street

Marion, Iowa 52302

319-377-9421

Fax 319-377-9101

Toll Free

1-800-553-5953

www.kwik-way.com

Date

Received ________________________________________

Serial Number ____________________________________

1

1

1

1

S

P

8

8

8

A

8

0

1

1

8

8

1

1

1

8

8

8

8

8

8

B

1

1

M

1

1

1

8

0

0

0

8

8

O

A

8

8

8

8

8

C

8

8

1

1

1

8

D

8

8

103 Multi-Speed Brake Lathe

Replacement Parts & Supplies - 80 0-553-5953 3

103 Multi-Speed Combination Lathe

103-8680-30 115 V, 60 Hz, 1 Ph

103-8680-31 230 V, 60 Hz, 1 Ph

103-8680-32 230 V, 50 Hz, 1 Ph

S TANDARD EQUI PMENT IN CLUDED

Part No. Description

8 0 4 - 8 6 9 1 - 6 8 Twin Cu tter with Damp ener A s s y

8 0 4 - 8 6 9 1 - 7 5 Tool Bar & Bit Holder Assy f or Drums

8 0 4 - 8 6 9 1 - 7 6 Carbide Bit Package

4 Roto r Bits (3 Cutting Edges) 2 Drum Bits (2 Cutting Edg es )

Arbor Components

8 0 4 - 8 6 9 1 - 7 8 1" Arbor w/ Nut 12.00" (304.80 mm) Long

0 0 0 - 1 8 0 6 - 7 0 S p r i n g

1 0 9 - 1 0 3 2 - 0 9 S p a c e r, 1 " (2 5. 4 mm) (2 Included)

1 0 9 - 1 0 3 3 - 0 6 S p a c e r, 2 " (5 0. 8 mm)

8 0 4 - 8 6 6 3 - 9 0 Draw Bar

8 0 4 - 8 6 6 5 - 0 0 Tapere d Cone Set for 1" A r b o r

1 0 1 - 0 2 4 3 - 0 0 Cone, 1.70 x 2.3 5 (43. 18 x 59.69 mm)

1 0 1 - 0 2 3 6 - 0 5 Cone, 1.98 x 3.4 4 (50. 29 x 87.38 mm)

1 0 1 - 0 2 3 7 - 0 2 Cone, 3.35 x 4.0 0 (85. 09 x 101.60 m m)

8 0 4 - 8 6 5 8 - 2 2 Double Ended C on e Se t fo r 1" A r b o r

8 0 4 - 8 6 5 8 - 2 3 Cone, 1.32 x 1.6 7 (33. 53 x 42.42 mm)

8 0 4 - 8 6 5 8 - 2 4 Cone, 1.36 x 1.7 1 (34. 54 x 43.43 mm)

8 0 4 - 8 6 5 8 - 2 5 Cone, 1.71 x 2.0 7 (43. 43 x 52.58 mm)

8 0 4 - 8 6 5 8 - 2 6 Cone, 2.07 x 2.4 4 (52. 58 x 61.98 mm)

8 0 4 - 8 6 5 8 - 2 7 Cone, 2.44 x 2.8 9 (61. 98 x 73.40 mm)

Bell Clamps

1 0 9 - 1 0 11 - 0 9 4.25" O.D. (107.95 mm) (2 Inclu ded)

1 0 1 - 0 2 3 5 - 4 0 5.75" O.D. ( 146.05 m m) (2 In cl uded)

M i s c e l l a n e o u s

1 0 8 - 1 0 6 1 - 0 0 Vented Silencer-Ro to r

1 0 9 - 1 0 3 2 - 0 9 S p a c e r, 1 x 1.5 x 1. 5

1 0 1 - 0 2 3 0 - 1 0 Automotiv e Drum Silencer

8 0 4 - 8 6 6 5 - 4 1 Solid Rotor Silencer Magnetic Band

0 0 0 - 0 6 0 0 - 7 0 Hex Key, .187" (4.7 5 mm )

0 0 0 - 0 6 0 0 - 5 4 Hex Key, .125" (3.1 8 mm )

0 0 0 - 0 6 0 0 - 2 0 Hex Key, .312" (7.9 3 mm )

8 0 4 - 8 6 6 4 - 4 3 Wrench, Draw Bolt

8 0 4 - 7 8 0 3 - 3 5 Wrench, Arbo r Nut

O P T I O N A L A C C E S S O R I E S

A d a p t e r s

8 0 4 - 8 6 9 1 - 8 5 11/16” Arbor with Nut, Cone & Wa s h e r, B or e .875-11.25” (22.23-3 1. 75 mm),7.375 ” (198.3 3m m)long

8 0 4 - 8 6 9 1 - 7 8 1” Arbor with Nut & Wa s h e r, 9.75” (246.65mm) long

8 0 4 - 8 6 9 1 - 8 8 Extended 1” Arbor with Nut & Was he r (2” longer) 12” (304.8 ) long

8 0 4 - 8 6 9 1 - 9 1 2” Arbor with Nut & Wa s h e r, 15.75 ” (400.0 5mm) long)

8 0 4 - 8 6 9 1 - 9 2 Extended 2” Arbor with Nut & Wa s h e r, 19.88” (504.95mm) l ong

Centering Cones

8 0 4 - 8 6 6 4 - 6 5 Cpme Set fpr 1” A r b o r

8 0 4 - 8 6 6 4 - 4 5 Cone, 1.15x1.80 (29.21x45 .7 2 mm )

1 0 1 - 0 2 4 3 - 0 0 Cone, 1.70 x 2.3 5 (43. 18 x 59.69 mm)

1 0 1 - 0 2 3 6 - 0 5 Cone, 1.98 x 3.4 4 (50. 29 x 87.38 mm)

1 0 1 - 0 2 3 6 - 0 2 Cone, 3.35 x 4.0 0 (85. 09 x 101.60 m m)

8 0 4 - 8 6 6 4 - 5 0 Cone, 3.90x4.55 (99.06x115.50 mm)

Double Ended Con es for la rger hubbed drums & r o t o r s

8 0 4 - 8 6 6 5 - 1 5 Cone, 2.82x3.18 (73.41x82 .8 0 mm )

8 0 4 - 8 6 6 5 - 1 6 Cone, 3.20x3.56 (82.80x91 .9 5 mm )

STANDARD & OPTIONAL EQUIPMENT

4 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

Part # Description

804-8691-95 Hubless Adapter Set, Small Size for 1" Arbor, Bore Range 1.87"-3.00" (47.50 76.20 mm)

804-8691-93 Rotor Locator-RH

804-8659-61 Cone, 1.88x3.13 (47.63x79.38 mm)

804-8659-62 Spacer

804-8691-94 Locator Nut-RH

804-1251-10 Wrench, Spanner

804-8691-98 Hubless Adapter Set, Std Size for 1" Arbor, Bore Range 2.03"-3.93" (51.56-99.82 mm)

804-8691-96 Rotor Locator-RH

804-4151-85 Cone, 2.12x4.00 (53.85x101.60 mm)

804-4151-86 Spacer

804-8691-97 Locator Nut-RH

804-1251-10 Wrench, Spanner

804-8692-01 Hubless Adapter Set, Large Size for 1" Arbor, Bore Range 4.00"-5.75" (101.60- 146.05 mm)

804-8691-99 Rotor Locator-RH

804-4161-85 Cone, 3.68x5.93 (93.47x150.62 mm)

804-4161-86 Spacer

804-8692-00 Locator Nut-RH

804-1168-49 Wrench, Spanner

804-8692-02 Hubless/Composite Rotor Adapter Kit of 1” Arbor

804-8691-98 Hubless Adapter set, Std Size

804-8631-85 Backing Plate for 804-8631-87, 804-8657-12, 804-8656-98

804-8631-87 Adapter Plate, GM "W-Body"/Lincoln

804-8631-88 Backing Plate, Chevy 1500 (for 804-8631-89)

804-8631-89 Adapter Plate, Chevy 1500

Composite Rotor Backing Plates for 804-8691-98

804-8656-98 Adapter Plate, Jeep Cherokee

804-8657-12 Adapter Plate , Eagle Premier

804-8692-05 Hubless Adapter Set, Large Size for 2" Arbor, Bore Range 4.00-5.75" (101.60-146.05 mm)

804-8692-04 Rotor Locator-RH

804-4161-85 Cone, 3.68x5.93 (93.47x150.62 mm)

804-4161-86 Spacer

804-8692-00 Locator Nut-RH

804-1168-49 Wrench, Spanner

804-8664-66 Medium Truck Set for 2" Arbor, Bore Range 2.15"-6.10" (54.61-154.94mm) for HublessDrums/Discs

804-8664-53 Cone, 2.15x2.80 (54.61x71.12 mm)

804-8664-54 Cone, 2.70x3.35 (68.58x85.09 mm)

804-8664-55 Cone, 3.25x3.90 (82.55x99.06 mm)

804-8664-56 Cone, 3.80x4.45 (96.52x113.03 mm)

804-8664-57 Cone, 4.35x5.00 (110.49x127.00 mm)

804-8664-58 Cone, 4.90x5.55 (124.46x140.97 mm)

804-8664-59 Cone, 5.45x6.10 (138.43x154.94 mm)

101-0638-01 Spring

804-8662-02 Clamp Bell, 7.75" (2 Included)

804-7803-05 Spacer, 2" (50.80 mm)

804-7803-01 Spacer, 3" (76.20 mm)

804-8664-67 Heavy Truck Set for 2" Arbor, Bore Range 5.45"-8.30" (138.40-210.80 mm) for hubless

Drums/Discs

804-8664-59 Cone, 5.45x6.10 (138.43x154.94 mm)

804-8664-60 Cone, 6.00x6.65 (152.4x168.90 mm)

804-8664-61 Cone, 6.55x7.20 (166.30x182.80 mm)

804-8664-62 Cone, 7.10x7.75 (180.30x196.80 mm)

804-8664-63 Cone, 7.65x8.30 (194.30x210.80 mm)

101-0638-01 Spring

804-3000-84 Clamp Bell, 9.25" (2 Included)

804-7803-05 Spacer, 2" (50.80 mm)

804-7803-01 Spacer, 3" (76.20 mm)

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 5

Part # Description

804-8665-47 Basic Bench, Heavy Gauge 22"Wx38"x26"L, (558.80x965.20 x 660.0mm) w/Lower Tool Board,

Chip Tray, and Adapter Hooks

804-8410-33 341 Deluxe Bench, Heavy Gauge 22"Wx38"Lx71"H (558.80x965.20x1803.40mm)

w/ 2 Tool Boards, Chip Tray, Adapter Hooks, and Arbor Rack

804-8674-93 Bench Conversion Assembly

Converts Basic Bench to Deluxe Bench

Flywheel Accessories

804-8692-10 Small Hole Flywheel Adapter Kit

804-8692-09 Small Hole Flywheel Adapter

804-8692-08 Arbor

804-8692-07 Tapered Bolt

804-8692-11 Tool Holder

804-8682-05 Insert (3)

804-8682-06 Slotted Screw (3)

804-8682-69 1.25" ID Lock Collar

804-8690-92 1.00" ID Pillow Block Bearing

Miscellaneous

804-8665-64 Rotor Bits - Pkg/10, (3 Cutting Edges) + Rake with Holes

804-8665-61 Rotor Bits - Pkg/10, (3 cutting edges) 1/64” (.4mm) Radius

804-8692-06 Drum Bits - Pkg/10 (2 Cutting Edges)

804-8665-42 Truck Drum Silencer 2.75" (69.85 mm) Wide

804-8665-43 Brake Drum Wear Limit Gage

804-8665-44 Rotor Micrometer Range .30"-1.30" (7.62-33.02mm)

804-2049-60 Drum Grinder, 115v,50/60hz,1ph

804-8668-08 Disc Rotor Swirl Finisher

804-8668-09 Replacement Pads 25 Count, 80 Grit

804-8668-10 Replacement Pads 25 Count, 120 Grit

804-2049-69 T-Bar Holder

804-8665-45 Safety Shield

804-8685-12 Extra Large Bell & Cone Set for 2"

Arbor, Bore Range 8.06"-9.95" (204.8 -252.8 mm) for Hubless Drums/Discs

804-8685-10 Cone, 8.06x9.95"

804-8685-09 Clamp Bell, 12" (2 Included)

804-8685-11 Spring, Heavy Duty

804-8692-14 Outboard Support Kit

804-8691-92 Extended 2" Arbor w/ Nut & Washer 19.88" (504.95mm) Long

804-8682-66 Outboard Support Base Weldment

804-8682-67 Bearing Support Weldment

804-8682-69 1.25” ID Lock Collar

804-8690-92 1.00” ID Pillow Block Bearing

6 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

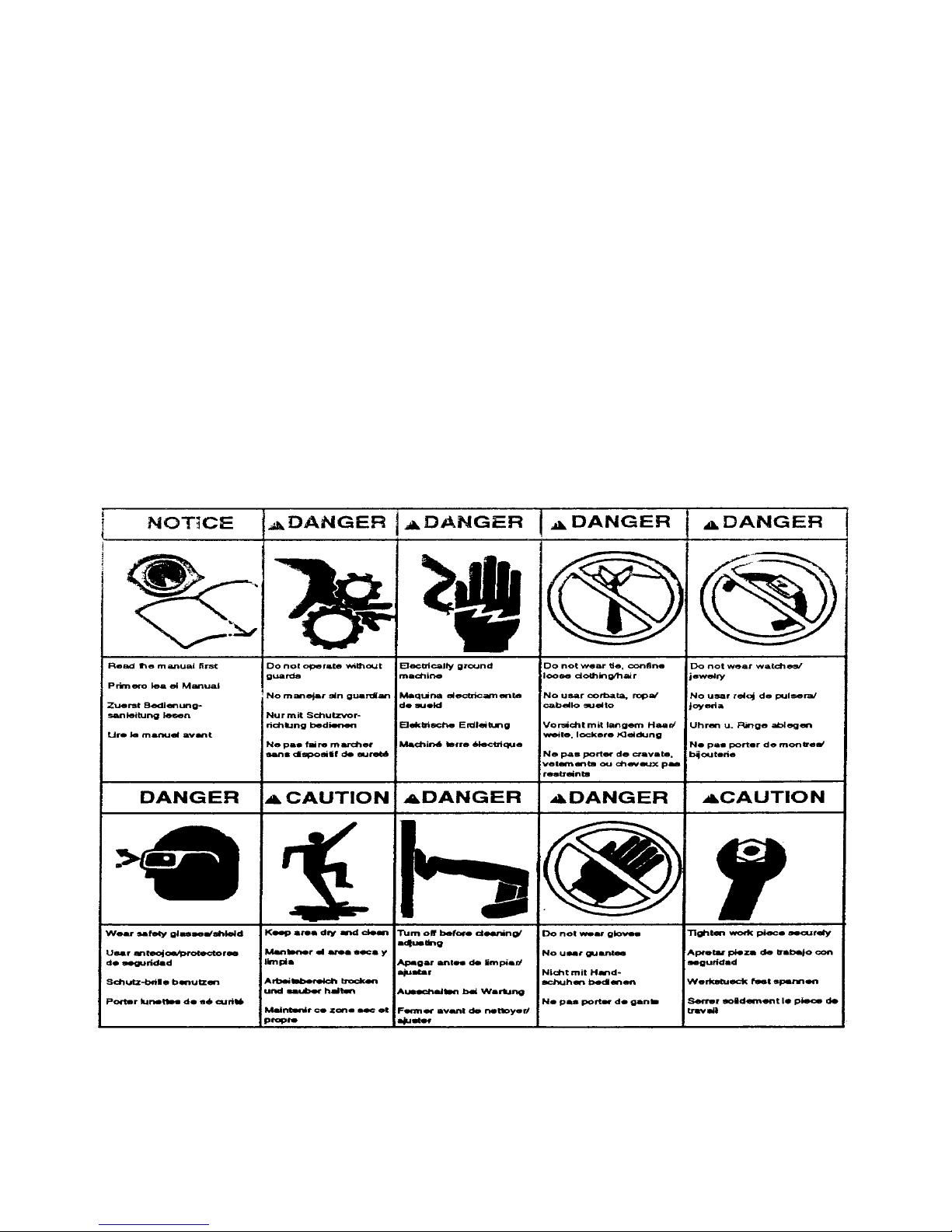

SAFETY FIRST

This manual has been prepared for the owner and those responsible for the maintenance of this machine.

It’s purpose aside from proper maintenance and operations is to promote safety through the use of

accepted practice. READ THE SAFETY AND OPERATING INSTRUCTIONS THOROUGHLY BEFORE

OPERATING THE MACHINE.

In order to obtain maximum life and efficiency from your machine; follow all the instructions in the

operating manuals carefully.

The specifications put forth in this manual were in effect at the time of publication. However, owing to

Kwik-Way Products’

policy of continuous improvement, changes to these specifications may be made at

any time without obligation.

SAFETY INSTRUCTIONS

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 7

1. Read, understand and follow the safety and operating instructions found in this manual. Know

the limitations and hazards associated with operating the machine.

2. Eye Safety: Wear an approved safety face shield, goggles or safety glasses to protect eyes

when operating the machine.

3. Grounding the Machine: Machines equipped with three prong grounding plugs are so equipped

for your protection against shock hazards and should be plugged directly into a properly

grounded three-prong receptacle in accordance with national electrical codes and local codes

and ordinances. A grounding adapter may be used. If one is used, the green lead should be

securely connected to a suitable electrical ground such as a ground wire system. Do not cut

off the grounding prong or use an adapter with the grounding prong removed.

4. Work Area: Keep the floor around the machine clean and free of tools, tooling, stock scrap and

other foreign material and oil, grease or coolant to minimize the danger of tripping or slipping.

Kwik-Way recommends the use of anti-skid floor strips on the floor area where the operator

normally stands and that each machine's work area be marked off. Make certain the work area

is well lighted and ventilated. Provide for adequate workspace around the machine.

5. Guards: Keep all machine guards in place at all times when machine is in use.

6. Do Not Overreach: Maintain a balanced stance and keep your body under control at all times.

7. Hand Safety: NEVER wear gloves while operating this machine.

8. Machine Capacity: Do not attempt to use the machine beyond its stated capacity or operations.

This type use will reduce the productive life of the machine and could cause the breakage of

parts, which could result in personal injury.

9. Avoid Accidental Starting: Make certain the main switch is in the OFF position before

connecting power to the machine.

10. Careless Acts: Give the work you are doing your undivided attention. Looking around, carrying

on a conversation and horseplay are careless acts that can result in serious injury.

11. Job Completion: If the operation is complete, the machine should be emptied and the work

area cleaned.

12. Disconnect All Power and Air to Machine before performing any service or maintenance.

13. Replacement Parts: Use only Kwik-Way replacement parts and accessories; otherwise,

warranty will be null and void.

14. Misuse: Do not use the machine for other than its intended use. If used for other purposes,

Kwik-Way Products Inc.

disclaims any real or implied warranty and holds itself harmless for

any injury or loss that may result from such use.

8 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

E L E C T R I C A L R E Q U I R E M E N T S

1. The 103 is available in three electrical configurations: 115V, 60 Hz, 1 Ph; 230V, 60 Hz, 1 Ph; and electricals of 230V, 50 Hz, 1 Ph.

IMPORTANT: Before connecting the lathe to a power source (receptacle, outlet, etc.), be sure the power

switch is in the “Off” position and the voltage source available is the same as that specified on the Serial

plate of the lathe. A power source with voltage greater than that specified for the machine can result in

SERIOUS INJURY to the user -- as well as damage to the lathe.

2. The machine is equipped with a standard 3 conductor cord with a 3 prong grounding type plug that fits

into the standard grounding type receptacle. Never do anything to defeat the grounding terminal on this

machine. Replace only with the same style plug. If an extension cord is required, use a heavy duty type

with a 3 prong grounding type plug. An under-sized cord will cause a drop in line voltage, resulting in

loss of power and over-heating.

NOTE: The 115V machines include a standard 3 prong grounded plug.

The 230V machines will not have a plug. Only the power cord will be

provided -- contact an electrical professional for the proper plug.

3. One of the following fused service lines is required for this machine —

check the serial no. plate located at rear of your machine:

115V, 60 Hz, 1 Ph: 20 amp, 12 gage wire

230V, 60 Hz, 1 Ph: 15 amp, 14 gage wire

230V, 50 Hz, 1 Ph: 15 amp, 14 gage wire

4. The 103 has two separate fuses located under the electrical control box.

Access these fuses from the rear of the machine (Figure 1). The 1/2 Amp fuse protects the 2 - DC drive

feed motors. The 1 Amp fuse protects the electrical control box circuitry.

5. The 1 HP motor is protected by a thermal overload limit switch that must be manually reset if an overload

occurs.

115V

1/2 Amp

Fuse

1 Amp

Fuse

Figure 1

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 9

MOUNTING ON BENCH

1. If the optional 103 Deluxe Bench Part # 804-8665-

29 or Basic Bench Part #804-8665-47 was

purchased, assemble per instructions included

with bench. Otherwise, select a bench that is

about 30 inches tall and capable of supporting an

operating brake lathe with it’s dynamic forces

assume 425 lbs. static weight.

2. Remove the 4 bolts holding the lathe to the

shipping pallet. Lift the lathe using the eye bolt

provided (Figure 2). Do not lift the machine by

the spindle, belt pulley cover, or either of the disc

or drum cross slides. This could damage the lathe

and would void the warranty on the unit.

3. Place the four rubber pads on the bench and

mount lathe to the bench using the four bolts

provided thru the four feet of the lathe. Secure

with washers and nuts from the bottom side of the

bench.

4. Remove eye bolt and replace with the 1/2-13 setscrew provided. Turn until flush with surface.

5. Install handwheel handles and motor bracket

handle.

POSITION MOTOR DRIVE BELT AND

TENSION PROPERLY BEFORE USE

1. The 103 is shipped with all belts pro p e r l y

tensioned with the exception of the motor drive 4

Groove Poly-V belt. The 103 was shipped with

the motor drive belt off the motor drive pulley so

the belt would not be stretched during shipment

of your machine. Refer to belt tensioning

instructions, page 7, Figures 7 thru Figure 10 to

assure proper tension of the motor drive belt

before operating machine.

PREPARING FOR USE

1. Remove the rust-preventative on the machine

ways with an approved commercial solvent. The

dove tail ways should be kept dry and should

always be free from grease, oils, etc.

2. Unwrap all adapters and accessories. Clean with

an approved commercial solvent. Check for any

damage during shipment such as burrs, nicks,

scratches, etc. Remove minor niches and

scratches with a fine file or sharpening stone.

Apply a protective coat of very light oil to prevent

parts from rusting.

3. Hang adapters on a tool board to protect from

damage while not in use.

4. Unpack work light. Mount on top of spindle

housing (Figure 4). Plug into outlet provided on

rear of electrical control box.

5. Plug machine into appropriate electrical outlet.

Refer to the Electrical Requirement Section if

t h e r e is any doubt re g a r ding the corre c t

procedure. To turn on the lathe, pull the POWER

switch (Figure 4). The spindle should turn

counterclockwise when viewing the taper end.

INSTALLATION

Figure 4

Figure 2

Eye

Bolt

Work Light Mount

1 0 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

7

8

9

10

11

14

15

13

1

12

2

3

4 5

16

22

24

20

21

17

23

19

COMPONENT & CONTROL

IDENTIFICATION

6

16

17

18

Figure 3

1. Disc Slide Handwheel (cross feed)

2. Spindle

3. Main Power Switch & Emergency Stop

4. Function Switch — selects the drum

or disc slides

5. Feed Rate Control for both drum and disc

6. Work Light Mount

7. Drum Slide Gib Adjustment Screws and Lock

(behind slide)

8. Limit Switches — one for the drum slide and

one for the disc slide to prevent overtravel

during power feed operation.

9. Way Cover

10. Drum Slide Feed Screw Lock

11. Drum Slide Handwheel (traverse feed)

12. Variable Speed DC Gear motors (behind cover)

13. Disc Slide Gib Adjustment Screws & Lock

14 Disc Slide Feed Screw Lock (behind

handwheel)

15. Disc Slide Handwheel

16. Motor Bracket Handle

17. Motor Bracket Clamp

18. Belt Access Door Latch

19. Outlet for Work Light

20. 3/8 Amp Fuse

21. 1 Amp Fuse

22. Motor

23. Power Cord

24. Reset Button

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 1 1

Specifications

Motor 1 HP

Spindle speeds .......................................................................................................................60, 120, 170 RPM

Feed speeds, infinitely variable 0 to —

Per min. ......................................................................................................................................2.10" (53 mm)

Rotor size

Maximum diameter ....................................................................................................................24" (609 mm)

Maximum thickness....................................................................................................................2.5" (63 mm)

Flywheel size

Maximum diameter ....................................................................................................................24" (609 mm)

Maximum thickness................................................................................................................7.25" (184 mm)

Drum size

Minimum diameter .......................................................................................................................6" (152 mm)

Maximum diameter.....................................................................................................................28" (711 mm)

Maximum depth............................................................................................................................9" (229 mm)

Machine Net weight .................................................................................................................415 lbs. (188 kg)

Shipping weight....................................................................................................................555 lbs. (252 kg)

Lathe Bench (optional)

Size22" x 38" x 71"

(559 x 965 x 1803 mm)

Weight .........................................................................................................................................140 lbs. (64 kg)

Kwik-Way is committed to product innovation and improvement and therefore reserves the right to change product

specifications without notice

1 2 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

.INSTALLATION OF ARBOR

1. The 1" diameter arbor is included with the 103 as standard equipment and is capable of handling work

pieces up to 150 lbs. If the work piece is heavier the 150 lbs, it will be necessary to use the optional 2" Heavy

Duty Arbor.

2. Insert arbor into spindle taper (Figure 5).

IMPORTANT: Both the arbor and the spindle taper must be clean, otherwise arbor will have run out and the

taper may be damaged. Align pin in arbor with slot in main spindle. Screw in draw bar (Figure 6) and

tighten (Figure 7). DO NOT tighten excessively. Driver pin will prevent arbor from slipping. To remove

arbor easily (arbor has a non-locking taper) loosen draw bar slightly and tap lightly on the end of the draw

bar. Hold the arbor with one hand to prevent arbor from falling while unscrewing draw bar.

3. Don’t hammer upward or downward on draw bar as damage may occur to both arbor and draw bar.

Figure 5 Figure 6

Figure 7

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 1 3

SELECTING THE SPINDLE SPEED

MAKE CERTAIN POWER SWITCH IS IN THE OFF POSITION before changing the spindle speed.

1. The 3 spindle speeds on the 103 are 60, 120, & 170 RPM’s. To select the desired speed, lift and turn the

latch handle to open the belt access door (Figure 8). Loosen the belt tensioning lock by pushing down on

the lever (Figure 9). Move the motor bracket handle forward to allow the belt to be moved to a different

pulley groove (Figure 10).

2. The outer pulley groove (high speed) is for the smaller rotors and drums,

and the inner pulley groove (low speed) is for the very large rotors and

drums. KW Products (Kwik-Way) recommends that the operator start out

in the middle pulley groove and then adjust the desired spindle speed

upward or downward from that point. Belt must be aligned in the same

upper and lower pulley groove position.

3. Reposition the motor bracket handle to the rear slightly (Figure 11). This

will apply proper tension to the belt. Re-tighten the motor bracket

clamp by moving the lever upward. DO NOT over tighten belt.

SELECTING THE FEED DIRECTION

1. The 103 function switch selects the proper feed direction (Figure 12). With

the switch setting on DISC, the machine will feed across the face of the

rotors. When the switch is set on DRUM the slide will feed left to right for

machining drums.

2. Whenever the machining operation has been completed, always move the

switch into the neutral “OFF” position.

Figure 8

Figure 10Figure 9

Figure 11

Figure 12

1 4 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

SELECTING THE FEED RAT E

1. The 103 features an infinitely variable feed on both the disc slide and the drum

slide. This will allow the operator to totally control surface finish and

machining time for drums and discs. Refer to chart below for the spindle

speed/feed rate ratio to determine the optimum feed rate.

2. The feed rate knob (Figure 13) can be adjusted from a setting of “0” (no feed)

to “10” (fast feed), or any position in between. The lower the number, the

slower the feed, and the smoother the finish -- the higher the number, the

faster the feed, and the coarser the finish.

SPINDLE SPEED/FEED CHART

APPROXIMATE INCHES/REVOLUTION AT VARIOUS RPM AND FEED DIAL SETTINGS

ENGAGING THE FEED

1. Both the disc slide and the drum slide can be manually operated in either

direction by turning the handwheel. The disc slide feed lock knob

(Figure 14) and the drum slide feed lock knob (Figure 15) however,

must be disengaged in order for the slides to be manually operated.

2. To engage the power feed on the disc or drum slide requires the operator to

engage the disc slide feed lock knob or the drum slide feed lock knob. The

power feed will not operate properly without these knobs engaged.

3. When the machining operation has been completed shut lathe off and

disengage the knob to prepare for the next job.

Figure 13

.027

.024

.020

.016

.012

.008

.004

0

60

5 10

Feed Dial Settings

120

170

Figure 14

Figure 15

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 1 5

DEPTH OF CUT DIAL

1. The drum depth-of-cut micrometer is located on the

cross slide handwheel (Figure 16). This handwheel is

used for moving the tool bit into the brake drum. The

dial has a scale to indicate amount of material to be

removed from the drum diameter.

2. The divisions on the handwheel dial are 0.002" and the

scale is direct reading. For example, if the scale is

i n c r eased .016" (8 divisions) there will be .008”

removed from each side of the drum increasing the

diameter by .016". No calculations have to be made by

the operator.

DRUM BAR TOOLING ASSEMBLY

The 103 Drum Bar, Part Number 804-8671-10, is machined at both ends. The end of the bar

with the machined slot and the two set screws is used for larger drums and flywheels. The

end of the bar that is reduced in width is for machining small drums. Two drums bits are

included with the 103, therefore is is recommended that a bit is installed in each end.

1. Insert the drum bit in the Tool Bit Holder, Part #804-3021-71 (Figure 17).

2. Assemble the bit clamp and set screw (Figure 18).

Tighten securely.

3. Place the Tool Bit Holder Assembly in the end slot of the drum bar and tighten the two

set screws (Figure 19).

4. Insert the other drum bit in the slot provided in the narrow end of the drum bar. Make

certain the bit is inserted as far as possible (Figure 20).

5. Tighten set screw

(Figure 21).

P R E PARING DRUMS FOR MACHINING

1. First, measure the diameter of the drum with a micrometer to determine that the drum will be within

maximum oversize limits after reconditioning. The drum should also be in good general condition. THE

MAXIMUM REBORING LIMIT DIMENSION IS

CAST INTO THE DRUM BY THE MANUFACTURER. NEVER

EXCEED THIS LIMIT OR THE DRUM COULD FAIL IN USE RESULTING IN BRAKE FAILURE.

IMPORTANT: To prevent galling, scratching the newly machined surface clean the drum before mounting.

Use a wire brush or a rotary wire brush in a drill to thoroughly clean all mounting surfaces. Make certain

all rust is removed from both inside and outside bolt patterns and that the inside diameter of the center bore

is absolutely clean and free from any burrs.

Figure 16

Figure 17

Figure 18

Figure 19

Figure 20 Figure 21

1 6 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

1. HUBLESS DRUMS (Fig. 22) are mounted using 2 bell clamps of the same size, a tapered cone, a spring,

and spacers. Make certain the mounting pads of the bell clamps are clean and free of nicks, burrs, etc.

Mount the drum as shown:

2. DRUMS WITH HUBS (Fig. 23) are mounted using 2 double ended cones.

3. Optional Hubless Adapter Set (Fig. 24)

MACHINING DRUMS

1. After the drum is mounted on the arbor, wrap and secure the drum silencer band

tightly around the drum (Figure 25). Cover as much of the outside of the drum as

possible.

2. Assemble and mount the drum tool bar on the slide as illustrated (Figure 26 & 27).

3. Position the tool bar by loosening the tool bar clamp nut

(Figure 28) and sliding the tool bar inward toward the

drum until the tool bit is close to the surface that is going

to be machined. The entire tool bar assembly may also

be swiveled to achieve the best cutting position.

Make certain the set screws and tool bar clamp nut are

tight before machining.

Figure 28

Wear proper eye protection

when operating machine.

Figure 25

Figure 26

Figure 27

Bell Clamp

Tapered Cone

Spring

Bell Clamp

Figure 22

Double

Ended

Cone

Spacer

Double

Ended

Cone

Locator

Nut

Spacer

Spacer

Rotor Locator

Cone

Figure 24

Figure 23

Spacer

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 1 7

4. On smaller drums position the tool bar and bit at the outer edge of the drum to

insure that the tool bar will not contact the spindle housing during machining.

It may be necessary to use spacers to position the drum further out on the arbor

to allow clearance for the tool bar. On 6" diameter drums the inner clamp bell

and spring should be replaced with spacers to allow room for the cutter bit.

5. Turn the lathe on and advance the tool bit until it just contacts the drum

surface and makes a scratch cut. Back the tool bit off and stop the lathe.

Loosen the arbor nut and rotate the drum one-half turn. Retighten the nut, turn

the lathe on and make a second scratch cut, stop the lathe. If the first and the

second scratch cuts are opposite each other (180° apart) remove the drum from

the arbor. Check the mounting adapters and the arbor for nicks, burrs, or chips.

Clean if necessary. If the first and second scratches are side by side, proceed

in machining the drum.

6. Turn the traverse feed handwheel (Figure 29) until the deepest worn groove of

the drum is aligned with the point of the tool bit. Advance the tool bit into the

bottom of the groove by turning the cross feed handwheel (Figure 30)

counterclockwise. Note handwheel reading then back off (clockwise) 1/2 turn.

Move cutter to inside edge of surface to be machined using the traverse feed

handwheel.

7. Reset the depth of cut by turning the cross feed handwheel to the reading

obtained in “STEP 6” above plus .003". Maximum depth of cut is .015".

Lock the cross feed slide lock (Figure 31). This will keep the slide in a fixed

position for an accurate machining job.

8. Turn on main power to start spindle. Turn drum slide feed screw lock in to

keep feed screw from turning. Set feed rate to “0” and position function switch

to DRUM. Slowly increase feed rate until desired feed is obtained.

9. After cut is complete turn function switch to “Off” and shut off main power.

Examine drum for complete clean-up. If additional cuts are required repeat

steps 7 and 8.

10. If the drum is to be finished in a single pass use a slow feed rate. If a roughing

cut is being made then a faster feed rate may be used for the first cut and a slow

feed rate for the final cut.

Figure 29

Figure 30

Figure 31

1 8 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

P R E PARING DISCS ROTORS FOR MACHINING

1. Before machining, each disc rotor should be carefully inspected for scoring, rust, ridges (at the inner and

outer circumference of the rotor) and hard spots. Any excessive wear or deformity should be noted and, if

not within acceptable limits, the rotor should be replaced.

2. Using a micrometer check the thickness of the rotor in at least three points around the circumference about

1" (2.54 cm) in from the outer diameter. If the rotor thickness varies between readings it should be

machined. However, if the thickness is less than the minimum established by the rotor manufacturer, or it

will be after resurfacing, the rotor should be replaced.

THE MINIMUM REFINISHED THICKNESS DIMENSION IS CAST INTO THE ROTOR.

NEVER MACHINE BEYOND THIS LIMIT OR THE

DISC COULD FAIL IN USE RESULTING IN

VEHICLE BRAKE FAILURE.

IMPORTANT: Clean the disc before mounting. Use

a wire brush or a rotary wire brush in a drill to

t h o rough ly clean all mounting surfaces. Make

certain all rust is removed from both inside and

outside bolt patterns and that the inside diameter of

the center bore is absolutely clean and free from any

burrs.

MOUNTING DISC/ROTORS

1. HUBLESS DISCS (Fig. 32) are mounted using 2 bell

clamps of the same size, a tapered cone, a spring,

and spacers. Make certain the mounting pads of the

bell clamps are clean and free of nicks, burrs, etc.

Disc Rotors should be mounted as close to the

spindle as possible.

THE ARBOR NUT SHOULD NOT BE OVER

TIGHTENED.

Tapered Cone

Bell Clamp

Bell Clamp

Spring

Figure 32

Spacer

Double Ended Cone

Double Ended

Cone

2. DISCS WITH HUBS (Fig. 33)

are mounted using 2 double

ended cones.

Figure 33

Cone

Spacer

Locator Nut

Rotor Locator

3. Optional Hubless

Adapter Set (Fig. 34)

Figure 34

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 1 9

MACHINING DISC/ROTORS

MOUNTING TWIN CUTTER ASSEMBLY

1. The Twin Cutter Assembly with Dampener, is shipped assembled. Position

traverse slide to the extreme left (Figure 33) and the cross slide in toward the

spindle housing.

2. Before mounting the twin cutter assembly be sure the twin cutter arms are

positioned wide enough to straddle the disc rotor. (Figure 34) Mount the twin

cutter assembly to the slide using the stud, spacer block and flange nut (Figure

35). Select the hole that allows the cutters to be just inside the smallest diameter

to finish and still be reasonably square with the slide. Tighten flange nut just

enough to hold twin cutter assembly securely.

INSTALLING TWIN CUTTER BITS

Four Rotor Bits are included with the 103. Install 2 in Twin Cutter. The rotor bits have

three cutting edges -- make certain that the narrow side of the bit is on the top. This will allow for the proper

clearance angle while machining.

3. To install the rotor bits, loosen the clamp screw located on the underside of

the toolholder arms (Figure 36).

Install insert fully into the pocket machined in the toolholder. Tighten

clamp screw securely. (when installing inserts, be sure the pocket is clear

of any chips or debris).

SCRATCH CUTS

1. Using the cross slide, position the twin cutter assembly so that the tool bits

are about in the center of the rotor surface.

2. Start spindle and bring one of the tool bits into contact with the rotor face using the traverse slide. Once

contact has been made return traverse slide to original position. (Be sure twin cutter arms are secured with

clamp knobs).

3. Loosen arbor nut and rotate disc 180° being careful not to rotate adapters. Tighten arbor nut and make

another scratch cut as in step 2 above after moving cross slide position about .100".

4. If the first and the second scratch cuts are opposite with each other (180° apart)remove the rotor from the

arbor. Check the mounting adapters and arbor for nicks, burrs, or chips. Clean if necessary remount, and

run scratch test again.

Figure 34

Figure 33

Figure 36

Wear proper eye protection

when operating machine.

Figure 35

2 0 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

MACHINING

When machining thin, non-vented or

composite rotors, use the built-in dampener

arms. When machining the thicker vented

rotors, use the silencer band. Do not use

both at the same time.

1. Manually adjust the traverse slide over until the Twin

Cutter Arms are centered over the rotor. Lock the

traverse slide using the lock knob on the back side of

the slide (Figure 37).

2. Position the Dampener arms in the Retract Position and

move the cross slide in until the rotor bits are aligned

with the thickest part of the rotor. Start the spindle motor.

3. Slightly loosen the 2 - twin cutter arm lock knobs (Figure 38). Turn each micrometer dial on the twin cutter

to adjust the individual tool bits until they just touch the rotor (Figure 39). Set the micrometer sleeves to

zero (Figure 40).

4. Move the cross slide in toward the spindle until the cutters are just clear of the machined surface.

5. Adjust micrometer dials for desired depth of cut.

(Maximum depth of cut is .015” per side) Securely

tighten cutter arm lock knobs. Engage Dampener Arms

now if machining a non vented or composite rotor and

tighten clamp bar knob (Figure 41).

6. Tighten disc slide feed screw lock (Figure 42).

7. Set feed rate to “0” and position function switch to

DISC. Slowly increase feed rate until desired feed is

obtained. After cut is complete, turn Function Switch

to “Off” and shut off main power. Examine disc for

complete clean up. If additional cuts are required,

repeat Steps 4-7.

8. After machining is complete, apply a non-directional finish to rotor.

Figure 37

Figure 41 Figure 42

Figure 39 Figure 40

Figure 38

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 2 1

FLYWHEELS

1. Mount the flywheel on the 1" arbor (Figure 43). It may be

necessary to use a smaller optional centering cone if the

pilot bore is smaller than 1.7" If the pilot bore of the

flywheel is smaller than will fit on the 1" arbor, it will be

necessary to use the optional Small Hole Flywheel Kit,

part #804-8692-10.

2. Using the handwheel for the drum slide, move the slides

to the position closest to the workpiece, then back it off

three (3) or four (4) turns. Using the handwheel for the

disc slide, turn in toward the body of the lathe as far as

possible, then back it off three (3) or four (4) turns.

3. Position the drum tool bar and mounting cradle on the

mounting surface with the tool bar and cradle facing the

workpiece (Figure 44). Select the preferred mounting

hole that will allow the tool bar to reach the innermost

s u r face to be machined while being mounted at

approximately a 45° angle to the contact surface.

4. Install the threaded stud, mounting cradle, tool bar, and

top plate. Secure using the flange nut provided. Move

the tool bar to the innermost contact surface and tighten

the nut on the cradle assembly (Figure 43).

5. At this time you should be wearing safety glasses for eye

p rot ection. Continue to wear the glasses until the

machining procedure is completed.

6. Perform a scratch test to verify the accuracy of the

mounting. With the scratch test completed, set the on/off

switch to the “on” position.

7. Using the handwheel for the disc slide, position the tool

bar with the cutting bit at the innermost contact surface

(Figure 45). Lock the disc feed hand nut. Having

previously determined the amount of material you plan to

remove from the workpiece, use the handwheel for the

drum slide to set the desired depth of cut and tighten the

drum slide tension lock.

8. On the control panel, set the feed control knob for the

desired feed rate and set the function switch to the disc

position. If for any reason the workpiece should bind on

the cutting tool and stall the machine, perform the

following steps:

a. First, immediately set the main on/off switch to the

“off” position.

b. Back the cutting tip away from the workpiece.

c. Reset the depth of cut to a slightly smaller amount.

d. Re-start the machining process.

9. When the machining function is complete, set the

function switch to the “off” position. If additional cuts

are desired, repeat the procedure. Otherwise, set the

o n / o ff switch to the “off” position and remove the

workpiece from the arbor. Clean the adapters and tools

used.

Bell Clamp

Bell Clamp

Spring

Spacers

Tapered Cone

Figure 44

Figure 45

Figure 43

2 2 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

GearFree™ SPINDLE DRIVE

1. The GearFree™ Drive System contains 4 sets of pulleys

(Figure 46):

A 4 Groove Poly-V pulley .....Belt #804-1405-83

B 10 Groove Poly-V pulley .....Belt #804-8680-53

C 14 Groove Poly-V pulley .....Belt #804-8680-54

D Cogged timing pulley...........Belt #804-8680-52

NOTE: It is possible to adjust all belts with the sheet metal

belt assembly guard left in-place by opening the belt

access door (Figures 47 & 48).

2.

If it is necessary to replace any belts or other parts in the

G e a r F r ee™ Spindle Drive, it will be necessary to

completely remove the sheet metal belt assembly guard.

3. The GearFree™ Spindle Drive consists of the upper

(Figure 46 E) and lower (Figure 46 F) reduction shafts. To

re-adjust the tension of the three main belts:

a. Remove the motor drive belt (Figure 46 A)

b. Loosen both jam nuts on the upper (Figure 52) and

lower reduction shaft (Figure 50) with a 1 1/8"

wrench.

c. Use a 9/16" wrench and turn the hex shaft (Figure 49)

of the lower reduction shaft first (Figure 51). This

will apply tension to the upper cogged timing belt.

Tighten until snug, but, DO NOT OVER-TIGHTEN.

While holding the tension with the 9/16" wrench, retighten the jam nut (Figure 50) of the lower shaft.

d. With the 9/16" wrench turn the hex shaft of the upper

reduction shaft (Figure 49). This will apply tension

to the 10 Groove and the 14 Groove Poly-V belts.

Tighten until snug, but, DO NOT OVER-TIGHTEN.

While holding the tension with the 9/16" wrench, retighten the jam nut (Figure 52) of the upper shaft.

e. Replace the motor drive belt on the desired step of the

three-step pulley, tension properly, tighten the motor

bracket, and the lathe is ready to operate.

Figure 46

Figure 47 Figure 48

Before Adjusting Or Changing Any Belt

Or Replacing Any Parts

Unplug The Power Cord

Figure 49 Figure 50

Figure 51 Figure 52

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 2 3

MAINTENANCE AND SERV I C E

SCHEDULED MAINTENANCE

1. DAILY:

Clean all surfaces to remove chips and dirt. Use a brush or a shop vac. To prevent metal in machine bearings NEVER use compressed air to clean the 103 Brake Lathe.

1. WEEKLY

Apply dry graphite lubricant to the dovetail ways. DO NOT use grease or oil on the ways or leadscrew since

this collects chips and causes accelerated wear.

GENERAL MAINTENANCE INFORMATION

1. SPINDLE

The spindle is permanently enclosed in the housing and supported in tapered roller bearings which require

no scheduled maintenance or lubrication.

2. MOTORS

The 1 HP spindle motor and the two DC gear motors are totally enclosed and do not require maintenance.

3. DOVETAIL WAYS GIB ADJUSTMENT

If it becomes necessary to adjust the gibs on the dovetail ways it can be easily done using a 5/32" hex wrench

and a 1/2" open end wrench. Loosen the hex nuts then turn the set screws in just until there is resistance

(Figure 53). While holding the set screw from turning, tighten the hex lock nut. When all screws are properly adjusted there should be no side to side play in the slide and the handwheel should turn easily with

only light resistance. Over tightening the gibs will cause premature failure of the gearmotor, nut, and leadscrew.

4. DRIVE BELT

When drive belt becomes cracked or frayed, it should be replaced with part no. 868051

5. CARE OF ARBORS AND ADAPTERS

The arbors, adapters, and the spindle are precision made and must be cared for to assure quality brake jobs

every time. When the adapters are not in use, they should be wiped completely clean, and sprayed daily

with a light rust-preventative product like WD40.

DO NOT store any of the adapters loose in a box or container where they might become nicked or scratched.

This will cause incorrect rotor or drum alignment, resulting in inaccurate machining. Store all adapters on

the individual hooks supplied with the machine.

Figure 53

2 4 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

103

BRAKE LATHE ASSEMBLY

FRONT VIEW

Item Part No. Description Qty.

1 804-8680-39 Base (Mach) 1

2 804-8680-44 Spindle Housing Assembly 1

3 804-8681-23 Slide Assembly 1

4 804-8680-36 Control Box Assembly 1

5 804-8679-90 Outlet Box Assembly 1

6 804-8680-86 Motor Guard 1

7 804-8680-85 Pulley Guard 1

9 800-8014-71 Strain Relief 1

10 000-0595-28 BHCS #10-32 x .38 1

11 000-0168-02 SHCS .312-18 x 1.00 1

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 2 5

REAR VIEW

RIGHT SIDE VIEW

2 6 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

103 RIGHT VIEW

GearFree™ DRIVE

Item Part No. Description Qty.

1 804-1405-24 Motor 1 HP 115-207 1

2 804-8680-57 Motor Mount Plate Assembly 1

3 804-8686-72 Washer Thrust 1

4 804-8680-75 Adjustment Arm 1

5 804-8665-27 Cradle Handle 1

6 804-8030-16 Knob 1

7 804-8654-24 Kipp Elesa Handle 1

8 000-0598-50 Stripper Bolt, .500 x 1.500 1

9 000-0102-86 HHCS .312-18 x .75 4

10 804-8680-83 Motor Pivot Shaft 1

11 000-0482-91 SSS #10-32 x .25 2

12 000-1160-17 Washer, Flat .312 SAE 4

13 804-1138-92 SSS .250-20 x .75 2

14 804-8680-58 Cogged Timing Pulley 1

15 804-8680-69 Pulley, Secondary 1

16 804-8680-82 Step Bushing 1

17 804-8680-63 Upper Reduction Shaft 1

18 804-8680-62 Drive Pulley 1

19 804-8680-68 Primary Drive Pulley 1

20 804-8680-74 Sleeve 1

21 804-8680-73 Cogged Timing Pulley 1

Item Part No. Description Qty.

22 804-8680-72 Flanged Pulley Adapter 1

23 000-0163-14 SHCS #10-32 x .500 8

24 804-8680-52 Cogged Belt #HPR 720-8M-30H 1

25 804-8170-33 Bearing SKF#6004-2RS 6

26 804-8632-57 Hex Nut .750-16 2

27 804-8680-77 Spacer .470 1

28 804-8680-60 Martin SDS Bushing 1 3/8" 1

29 804-8683-18 Key .312 1

30 804-8680-81 Spacer, 1.225 1

31 000-0101-20 HHCS .250 x 20 x 1.500 3

32 804-8663-56 Bearhug Locknut 1.50-16 1

33 804-8680-64 Lower Reduction Shaft 1

34 804-8680-56 Pulley Mounting Plate 1

35 000-0170-27 SHCS 3/8-16 x 1.00 4

36 804-8680-44 Housing Assembly Spindle 1

37 804-8680-61 Motor Pulley 1

38 804-1200-65 BHCS #10-32 x .250 2

39 804-8680-53 Poly-V Belt #200J10 1

40 804-8680-54 Poly-V Belt #200J14 1

41 804-1405-83 Poly-V Belt #280J4 1

42 804-8686-24 3/8 Rubber Sealing Washer 8

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 2 7

103 REAR VIEW

GearFree™ DRIVE

SECTION A-A

2 8 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

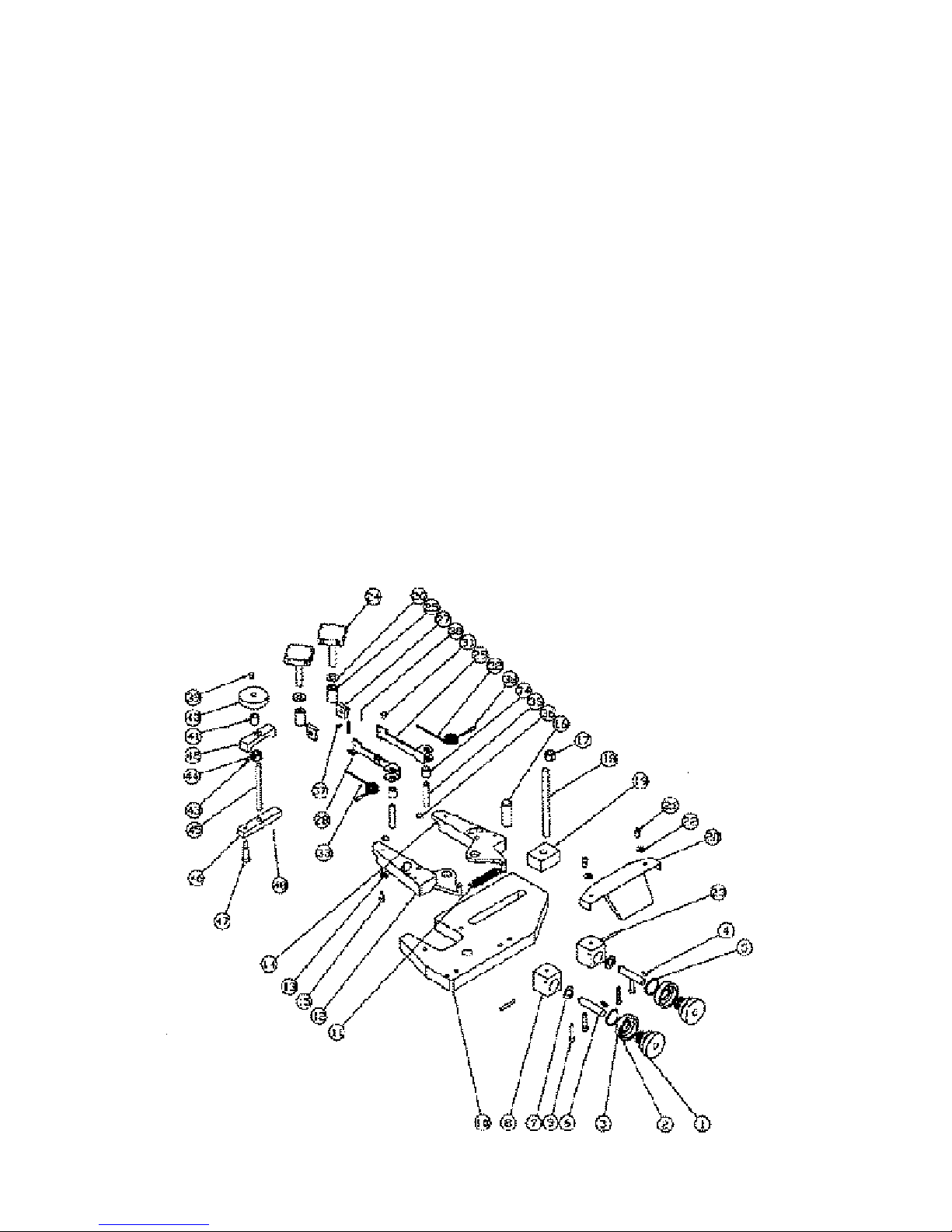

MAIN ASSEMBLY

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 2 9

Item Part No. Description Qty.

1 000-4400-10 Handle 2

2 804-8063-01 Acorn Nut, 5/16 2

3 804-8663-24 Hand Wheel 2

4 804-8679-65 Disc Slide Plate 1

5 804-8686-36 Disc Lead Screw 1

6 804-8663-17 Disc Slide 1

7 804-8679-76 Upper Gib Lock Handle Assy 1

8 000-0102-86 SHCS 5/16-18 x 3/4 1

9 804-8692-20 Disc Slide Gib Screw 4

10 804-8663-22 Gib Plate 2

11 000-0166-08 SHCS 1/4-20 x 1.00 1

12 800-8690-47 BHCS 5/16-18 x .75 2

13 804-8686-34

1

Disc Slide Lead Screw Nut Assy

1

14 804-8663-48 Drive Chain Guard 1

15 804-8671-87 Upper Lead Screw Guard 1

16 804-8680-10 Lower Gib Lock Handle Assy 1

17 804-8668-00 Chain Assembly 1

18 804-8148-06 SHCS 10-32 x 1.75 4

19 804-8663-19 Drum Slide 1

20 804-8663-36 Drive Motor Gear Assembly 1

21 804-8663-40 Gear Link Shaft Assembly 1

22 804-8680-70 Way Cover Retaining Flange 1

23 804-8665-55 Limit Switch 1

24 804-8663-35 D.C. Gear Motor 2

25 000-0595-28 BHCS 10-32 x .375 8

26 804-8663-38 Drive Sprocket 1

27 804-8663-78 Lower Lead Screw Guard 1

28

29 804-8661-62 Electric Box 1

30 804-8686-74

2

Drum Slide Lead Screw Nut Assy

2

Item Part No. Description Qty.

31 804-8681-22 Way Cover 1

32 804-8664-20 Motor Cover Guard 1

33 804-8686-37 Drum Lead Screw 1

34 804-8680-71 Way Cover Retaining Flange 1

35 804-1200-65 BHCS 10-32 x .25 10

36 804-8679-64 Drum Slide Plate 1

37 804-8680-80 Drum Slide Spacer Block 1

38 804-8679-66 Bearing 2

39 804-8689-79 Spacer 2

40 000-7204-96 Roll Pin, 1/8 x 1/2 2

41 804-8012-68 Pointer 2

42 804-8013-29 Hex Nut 1/4-20 1

43

44 804-8665-24 Disc Hand Wheel Label 1

45 804-8689-86 Rotor Feed Lock Assembly * 1

46 000-1042-64 Hex Nut 5/16-18 4

47 804-1117-26 Drum Slide Gib Screw 4

48 000-0592-20 BHCS 5/16-18 x 1.00 1

49 804-8035-96 SSS 1/4-20 x 1/4 1

50 000-0163-14 SHCS 10-32 x 1/2 12

51 000-0165-27 SHCS 1/4-20 x 5/8 4

52 000-1154-60 Flat Washer #10 1

53

54 000-0482-91 SSS 10-32 x .25 1

55 000-0594-04 BHCS 6-32 x .37 4

56 804-8665-66 Limit Switch Cover 1

57 804-8689-87 Drum Feed Lock Assembly ** 1

58 804-8665-25 Drum Hand Wheel Label 1

59 804-8622-24 SHCS 1/4-20 x 2.75 2

* See Page 26 for Detail

** See Page 27 for Detail

1 See Page 32 for Detail

2 See Page 32 for Detail

MAIN ASSEMBLY

3 0 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

ITEM 45 ON MAIN ASSEMBLY DRAWING

804-8689-86

ROTOR FEED LOCK ASSEMBLY

Item Part No. Description Qty.

1 000-0595-32 BHCS 10-32 x .500....................1

2 804-8689-80 Knob ..........................................1

3 804-8689-83 Engagement Stem (Disc) ...........1

4 804-8097-68 Roll Pin, .062 x .500 .................1

5 804-8689-85 Flat Washer, 6mm.....................1

6 804-8689-84 Spring ........................................1

7 804-8689-81 Feed Engagement Block ...........1

8 804-8690-06 Dowel Pin .125 x .625 ..............1

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 3 1

ITEM 57 ON MAIN ASSEMBLY DRAWING

804-8689-87

DRUM FEED LOCK ASSEMBLY

Item Part No. Description Qty.

1 000-0595-32 BHCS 10-32 x .500....................1

2 804-8689-80 Knob ..........................................1

3 804-8689-82 Engagement Stem (Drum).........1

4 804-8097-68 Roll Pin .062 x .500 ..................1

5 804-8689-85 Flat Washer, 6mm.....................1

6 804-8689-84 Spring ........................................1

7 804-8689-81 Feed Engagement Block ...........1

8 804-8690-06 Dowel Pin .125 x .625 ..............1

3 2 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

103 FRONT VIEW CONTROL BOX ASSEMBLY

Item Part No. Description Qty.

1 804-8680-40 Control Box 1

2 804-8607-40 Feed Rate Dial 1

3 804-8675-50 Function Switch 1

4 800-8675-49 Push/Pull Switch 1

5 800-8665-89 Fuse holder 1

6 800-8014-69 Strain Relief .230 3

7 800-8606-79 DC Controller 1

8 804-8653-31 BHCS #8-32 x .75 2

9 000-1095-17 Hex Nut #8-32 4

10 804-8668-20 Terminal Block 1

11 804-8680-87 Control Box Cover 1

12 804-8668-03 Receptacle 125V 1

13 804-8680-46 Control Box Label 1

14 804-8622-69 Fuse 1.0 Amp 1

15 804-8679-75 Fuse 1/2 Amp 1

16 800-8667-93 Lock Nut 1/2 NPT 1

17 804-8668-05 Self Tapping Screw 6

18 000-1261-01 Power Cord 1

19 804-8668-19 Terminal Jumper 3

20 800-8046-78 Work Light Mount 1

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 3 3

103 CONTROL BOX ASSEMBLY

3 4 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

804-8680-44

SPINDLE HOUSING ASSEMBLY

Item Part No. Description Qty.

1 804-8663-65 Seal-Front 1

2 804-8680-45 Spindle 1

3 804-8084-14 Bearing Cone 1

4 804-8084-15 Bearing Cup 1

5 804-8680-43 Spindle Housing 1

6 804-8680-50 Bearing Cup 1

7 804-8680-49 Bearing Cone 1

8 804-8680-84 Spacer 1

9 804-8663-71 Seal-Rear 1

10 804-8663-56 Locknut BH 07 1

Item Part No. Description Qty.

1 804-8663-90 Draw Bar Assembly 1

2 804-8691-87 1.0” Extended Arbor (RH) 1

3 804-8685-14 Spherical Washer Set 1

4 804-8691-65 Arbor Nut 1

804-8691-88

ARBOR ASSEMBLY

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 3 5

TOOL BAR ASSEMBLY

Item Part No. Description Qty.

1 804-8691-73 Tool Bar 1

2 000-0505-20 SSS .375-16 x .500 2

3 804-8030-07 SS .312-24 x .375 1

4 804-8691-74 Tool Bit Holder 1

5 000-0160-14 SHCS 8-32 x .625 1

6 804-3041-67 (Package of 3) 1

7 804-3041-71 Tool Holder Assembly 1

8 804-8664-42 Flange Nut 1

9 804-2043-03 Tooling Clamp Stud 1

10 804-2040-30 Tool Holder Clamp 1

11 804-2043-01 Tool Holder 1

3 6 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

804-8686-34

DISC SLIDE LEAD SCREW NUT ASSEMBLY

Item Part No. Description Qty.

1 804-8686-35 Leadscrew Nut Sleeve 1

2 000-1624-10 Thrust Washer 2

3 000-1624-00 Needle Bearing 1

4 804-8663-26 Nut Mount, Block 1

5 804-8663-27 Leadscrew Drive Gear 1

6 804-8668-34 SSS #10-32 x .18 4

804-8686-74

DRUM SLIDE LEAD SCREW NUT ASSEMBLY

Item Part No. Description Qty.

1 804-8686-35 Leadscrew Nut Sleeve 1

2 000-1624-10 Thrust Washer 2

3 000-1624-00 Needle Bearing 1

4 804-8663-26 Block Nut Mount 1

5 804-8663-27 Leadscrew Drive Gear 1

6 804-8668-34 SSS #10-32 x .18 4

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 3 7

804-8663-40

GEAR LINK SHAFT ASSEMBLY

Item Part No. Description Qty.

1 804-8665-51 Gear Shaft Assembly 1

2 804-8663-83 Oilite Bearing 1

3 804-8663-43 Gear Link Support 1

4 804-8663-38 Drive Sprocket 1

5 000-0482-91 SSS #10-32 x .25 2

6 804-1290-02 Oilite Thrust Washer 1

3 8 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

804-8691-68 DISC CLAW ASSEMBLY

Item Part No. Description Qty.

1 804-8689-51 Micrometer Knob 2

2 804-8689-52 Zeroing Sleeve 2

3 804-8659-49 Feed Dial Label 2

4 000-7300-41 Woodruff #5 Key 2

5 804-8689-78 Spring Washer 2

6 804-2042-70 Feed Screw 2

7 804-1258-10 Finger Spring Washer 2

8 804-8690-24 Feed Dial Block 2

9 000-0166-08 SHCS, 1/4-20 x 1.25 4

10 804-8690-23 Claw Base Plate 1

11 804-1405-35 Spring 1

12 804-8678-55 Tool Holder LH 1

13 804-1292-79 Tool Bit w/Spring Clamp 2

14 804-8678-54 Tool Holder RH 1

15 000-0165-27 SHCS, 1/4-20 x .62 2

16 804-1258-12 Dowel Pin, .75 x 2.00 1

17 804-8664-42 Flange Nut 1

18 804-2043-03 Tool Clamp Stud 1

19 804-2058-49 Clamp Block 1

20 804-2043-20 Guard 1

21 000-0165-27 SHCS, 1/4-20 x 5/8 2

22 804-8684-34 Rubber Seal Washer 4

23 804-1199-25 Dowel Pin, 3/16 x 1.50 2

24 804-8693-77 Hand Lock Knob 2

Item Part No. Description Qty.

25 804-8691-28 Knob Spacer 2

26 804-1407-54 Washer 2

27 804-2052-31 Shoe 2

28 804-8691-32 Dampener Arm LH 1

29 804-8691-33 Dampener Arm RH 1

30 804-1094-24 Roll Pin, .156 x 1.00 2

31 804-8691-36 BHCS 10-32 x 1.50 4

32 804-8691-31 Dampener RH Spring 1

33 804-8691-30 Dampener LH Spring 1

34 804-8691-34 Spring Bushing 2

35 804-8035-72 Dowel Pin, .375 x 2.00 2

36 804-8012-92 O-Ring, .312 x .062 2

37 000-0593-82 BHCS 6-32 x .25 2

38 804-8691-35 Spring Grip Knob 2

39 000-0595-32 BHCS 10-32 x .50 1

40 804-8689-80 Knob 1

41 804-8691-28 Spacer 1

42 804-8691-69 Clamp Bar 1

43 804-8668-34 Socket Set Screw 1

44 804-8691-72 Machined Nut 1

45 804-8691-71 Machined Stud 1

46 804-8691-70 Lower Clamp Bar 1

47 000-0598-38 Stripper Bolt 1

48 804-1094-24 Roll Pin 1

NS

800-8083-74 Hex Nut 10-32 Std 4

103 Multi-Speed Brake Lathe

Replac ement Parts & Supplies - 800-553-5953 3 9

804-8665-29

DELUXE BENCH ASSEMBLY for 103 BRAKE LATHE

804-8665-47

BASIC BENCH

NOTE: Does not include Items

No.’s 5 & 6 as shown above.

IMPORTANT:

Inspect the shipment of your bench for evidence of damage before signing the bill of lading. A signed bill of lading indicates the shipment was received in good condition.

Contact KW Products (Kwik-Way) concerning any parts

shortages.

PARTS LIST

Item Part No. Description Qty.

1 804-8665-32 Leg 2

2 804-8665-31 Shelf 1

3 804-8665-38 Lower Tool Board 1

4 804-8665-30 Top 1

5 804-8665-40 Upright 2

6 804-8665-39 Upper Tool Board 1

7 804-8665-60 Decal (Not Pictured) 1

8 804-8665-53 Chip Tray (Not Pictured) 1

HARDWARE

000-0101-54 1/4-20 x 1.75 Machine Bolt 12

000-0100-14 1/4-20 x .50 Machine Bolt 18

000-1020-08 1/4 Hex Nut 30

000-0105-88 3/8-16 x 2.00 Machine Bolt 4

804-8033-25 3/8 Hex Nut 4

000-1150-45 3/8 Flat Washer 4

804-8665-50 Rubber Pads 4

804-8085-56 Hooks for Tool Boards 22

A S S E M B LY I N S T R U C T I O N S

(If lathe is equipped with outboard support, assemble according to

instructions on Page 36.

1. Assemble items 1 thru 6. Items are assembled in numerical

order using 1/4-20 x .50 bolts and nuts for all parts except 5 and

6 which use the 1/4-20 x 1.75 bolts and nuts. Leave all fasteners

loose until all parts are assembled.

2. Tighten all fasteners securely.

3. Place the four rubber pads in line with the four holes in the top

of the bench. Using proper lifting equipment place the 103

Brake Lathe on top of the pads.

4. Fasten the lathe to the bench using the four 3/8-16 x 2.00 bolts,

nuts and washers. Set the Chip Tray to the left of the lathe.

5. Arrange the hooks on the upper and lower tool board as desired.

A

5

6

4

3

1

1

2

A

NOTE:

A - use 1/4-20 x 1.75 Machine Bolt with Nut

1 thru 6 - use

1/4-20 x .50

Machine Bolt with Nut

4 0 Replac em ent Parts & Supplies - 800-553-5953

103 Multi-Speed Brake Lathe

804-8692-14

OUTBOARD SUPPORT ASSEMBLY

Item Part No. Description Qty.

1 000-0105-53 HHCS 3/8-16 x 1.25 2

2 804-8030-61 Lock Washer - 3/16” 2

3 804-8690-92 Pillow Block Bearing 1

4 804-8682-67 Support Bearing Slide 1

5 804-8682-69 Locking Collar 1

6 804-8682-66 Base Weldment Stand 1

7 000-1035-35 Nut 1/2-13 4

8 000-1150-53 Washer - 1/2” 4

9 804-8690-93 Leveling Pad Screw 4

10 000-1150-45 Washer 2

804-8691-92 Arbor Assembly

1 804-4041-74 Washer 1

2 804-1244-05 Groove Pin 1

3 804-8691-90 Nut LH 2" Arbor 1

4 804-8691-86 Arbor 2" Extended 1

804-8691-92

Kwik-Way Products Inc.

500 57th Street, Marion, IA 52302 USA

319-377-9421

319-377-9101 (FAX)

800-553-5953

www.kwik-way.com

service@kwik-way.com

Copyright © Kwik-Way Products Inc. 2005 All Rights Reserved

Loading...

Loading...