Readers are advised to check the validity of this Certificate by either referring to the BBA’s website (www.bbacerts.co.uk) or contacting

the BBA direct (Telephone Hotline 01923 665400).

1 The Building Regulations 2000 (as amended) (England and Wales)

The Secretary of State has agreed with the British Board of Agrément

the aspects of performance to be used by the BBA in assessing the

compliance of unvented hot water storage systems with the Building

Regulations. In the opinion of the BBA, Kwikot Unvented Hot Water Storage

Systems, if used in accordance with the provisions of this Certificate, will meet

or contribute to meeting the relevant requirements.

Requirement: G3 Hot water storage

Comment:

See the tinted areas of the

Safety

section and the relevant

tinted area of the

Installation

section of the accompanying

system Detail Sheets.

Requirement: L1 Dwellings

Comment:

See the tinted areas of the

Hot water storage and supply

section of the accompanying system Detail Sheets. Systems

with a capacity of more than 150 litres that are not heated

by off-peak electricity should be fitted with a time switch.

Requirement: Regulation 7 Materials and workmanship

Comment:

The systems are acceptable.

Kwikot Limited

Aberdeen Road

P O Box 389

Benoni 1500

Republic of South Africa

Tel: 00 27 11 914 2300 Fax: 00 27 11 914 1286

e-mail: hotwater@kwikotinl.co.za

website: www.kwikot.co.za

Agrément

Certificate

No 96/3253

Third issue*

Designated by Government

to issue

European Technical

Approvals

KWIKOT UNVENTED HOT WATER STORAGE SYSTEMS

Système d’eau chaude sanitaire

Heißwasserbereiter

Product

Regulations — Detail Sheet 1

• THIS CERTIFICATE RELATES

TO KWIKOT UNVENTED HOT

WATER STORAGE SYSTEMS.

• The systems are for use in

domestic, commercial and

public buildings with domestic

hot and cold water services to

BS 6700 : 1997.

• T

he systems are for connection

to mains water supply at

pressures up to 12 bar.

• Kwikot is distributed in the

UK by A & J Gummers, Unit H,

Redfern Park Way, Tyseley,

Birmingham B11 2DN and

Stockgap Ltd, 209 Watling

Street, Dartford,

Kent DA1 6EG.

CI/SfB

(53.3) X

continued

Electronic Copy

2

2 The Building Standards (Scotland) Regulations 1990 (as amended)

In the opinion of the BBA, Kwikot Unvented Hot Water Storage Systems,

if used in accordance with the provisions of this Certificate, will satisfy or

contribute to satisfying the various Regulations and related Technical

Standards listed below.

Regulation: 10 Fitness of materials and workmanship

Standard: B2.1 Selection and use of materials, fittings, and components, and workmanship

Comment: The product can contribute to a construction meeting this

Standard. See the

Installation

part of the relevant Detail Sheet.

Standard: B2.2 Selection and use of materials, fittings, and components, and workmanship

Comment:

The product is an acceptable material.

Regulation: 22 Conservation of fuel and power

Standards: J11.2 to J11.4 Buildings in purpose groups 2 to 7 — Building services (space heating and hot

water) — Space heating controls

Comment:

The systems are fitted with a thermostat which meets the

requirements of Standard J5.2a. Systems having a capacity of

more than 150 litres, and where the water is not heated by

off-peak electricity, require a time switch that can start up and

shut off the supply of heat. See the tinted areas of the

Hot

water storage and supply

section of the accompanying system

Detail Sheets.

Standards: J11.6 and J11.7 Buildings in purpose groups 2 to 7 — Building services (space heating and hot

water) — Insulation of pipes, ducts and vessels

Comment:

The storage vessels have a heat loss of not more than

90 Wm

⫺2

and thus satisfy these Standards.

Regulation: 27 Miscellaneous hazards

Standard: P2.6 Danger from accident — Discharge of steam or hot water

Comment: The systems will satisfy the requirements of this Standard. See

section 16 of each system Detail Sheet.

Regulation: 28 Miscellaneous hazards

Standard: P3.1 Danger from malfunction of an unvented hot water storage system — Unvented

hot water storage system

Comment:

The systems are constructed to prevent the temperature of the

stored water at any time exceeding 100°C and to provide

adequate protection from malfunctions of the system. See the

tinted areas of the

Safety

section of the accompanying system

Detail Sheets.

3 The Building Regulations (Northern Ireland) 2000

In the opinion of the BBA, the position of Kwikot Unvented Hot Water

Storage Systems, if used in accordance with the provisions of this

Certificate, will satisfy or contribute to satisfying the various Building

Regulations as listed below.

Regulation: B2 Fitness of materials and workmanship

Comment:

The systems are acceptable.

Regulation: F3 Space heating, hot water supply and artificial lighting systems

Comment:

The systems are fitted with a thermostat meeting the

requirements of this Regulation. To comply with the

deemed-to-satisfy provision set out in Technical Booklet F :

1991

Conservation of fuel and power

Section 2, systems

having a capacity of more than 150 litres, and where the

water is heated by means other than off-peak electricity, must

be used in conjunction with a time switch to shut off the supply

of heat when the building is not occupied. See the tinted

areas of the

Hot water storage and supply

section of the

accompanying system Detail Sheets.

Regulation: F4 Insulation of pipes, ducts and hot water storage vessels

Comment:

The systems will satisfy the requirements of this Regulation.

Regulation: P5 Unvented hot water storage systems

Comment:

The systems incorporate suitable safety devices to meet the

requirements of this Regulation. See the tinted areas of the

Safety

section of the accompanying system Detail Sheets.

Regulation: P6 Deemed-to-satisfy provision for an unvented hot water storage system

Comment:

The systems will meet the deemed-to-satisfy provisions of

Regulation P6.

• It is essential, for reasons of

safety and performance, that

the systems are installed and

maintained in accordance with

this Certificate.

These Front sheets must be read in

conjunction with the accompanying

Detail Sheets which provide

information on components and the

different systems.

continued

Electronic Copy

4 Construction (Design and Management) Regulations 1994 (as amended)

Construction (Design and Management) Regulations (Northern Ireland)

1995 (as amended)

Information in this Certificate may assist the client, planning supervisor,

designer and contractors to address their obligations under these Regulations.

See sections:

2

Delivery and site handling

, 6

Safety

, 7

Properties in relation

to fire,

12

Maintenance

and 17

Installation procedure

of the

relevant Detail Sheets.

5 The Health and Safety at Work etc Act 1974 and the Health and Safety at

Work (Northern Ireland) Order 1978

In buildings subject to this Act and Order, regular maintenance is a

requirement. See section 12 of each system Detail Sheet.

6 Water Supply (Water Fittings) Regulations 1999 England and Wales, Water

Byelaws 2000, Scotland and the Water Regulations, Northern Ireland

England and Wales

The product satisfies the requirements of the water regulations, if used and

installed in accordance with this Certificate.

Scotland

The product satisfies the requirements of the water byelaws, if used and

installed in accordance with this Certificate.

Northern Ireland

The product satisfies the requirements of the water regulations, if used and

installed in accordance with this Certificate.

7 The Electrical Equipment (Safety) Regulations 1994 and the Electromagnetic

Compatibility Regulations 1994

These Regulations implement the Low Voltage Directive 73/23/EEC (as

amended by the CE Marking Directive 93/68/EEC) and the Electromagnetic

Compatibility Directive 89/336/EEC and require manufacturers to carry out

assessment of their products against the criteria given in the Directives.

Declarations of Conformity have been provided by Kwikot Limited. The BBA

has not assessed the product for compliance with these Directives.

3

Electronic Copy

Bibliography

BS 6700 : 1997

Specification for design,

installation, testing and maintenance of services

supplying water for domestic use within buildings

and their curtilages

Conditions of Certification

8 Conditions

8.1 This Certificate:

(a) relates only to the product that is described,

installed, used and maintained as set out in this

Certificate;

(b) is granted only to the company, firm or person

identified on the front cover — no other company,

firm or person may hold or claim any entitlement to

this Certificate;

(c) is valid only within the UK;

(d) has to be read, considered and used as a

whole document — it may be misleading and will

be incomplete to be selective;

(e) is copyright of the BBA;

(f) is subject to English law.

8.2 References in this Certificate to any Act of

Parliament, Regulation made thereunder, Directive

or Regulation of the European Union, Statutory

Instrument, Code of Practice, British Standard,

manufacturers’ instructions or similar publication,

are references to such publication in the form in

which it was current at the date of this Certificate.

8.3 This Certificate will remain valid for an

unlimited period provided that the product and the

manufacture and/or fabrication including all

related and relevant processes thereof:

(a) are maintained at or above the levels which

have been assessed and found to be satisfactory

by the BBA;

(b) continue to be checked as and when deemed

appropriate by the BBA under arrangements that it

will determine; and

(c) are reviewed by the BBA as and when it

considers appropriate.

8.4 In granting this Certificate, the BBA is not

responsible for:

(a) the presence or absence of any patent,

intellectual property or similar rights subsisting in the

product or any other product;

(b) the right of the Certificate holder to market,

supply, install or maintain the product; and

(c) the actual works in which the product is

installed, used and maintained, including the

nature, design, methods and workmanship of such

works.

8.5 Any recommendations relating to the use or

installation of this product which are contained or

referred to in this Certificate are the minimum

standards required to be met when the product is

used. They do not purport in any way to restate the

requirements of the Health & Safety at Work etc

Act 1974, or of any other statutory, common law

or other duty which may exist at the date of this

Certificate or in the future; nor is conformity with

such recommendations to be taken as satisfying the

requirements of the 1974 Act or of any present or

future statutory, common law or other duty of care.

In granting this Certificate, the BBA does not

accept responsibility to any person or body for any

loss or damage, including personal injury, arising

as a direct or indirect result of the installation and

use of this product.

In the opinion of the British Board of Agrément, Kwikot Unvented Hot Water Storage Systems

are fit for their intended use provided they are installed, used and maintained as set out in this

Certificate. Certificate No 96/3253 is accordingly awarded to Kwikot Limited.

On behalf of the British Board of Agrément

Date of Third issue: 10th September 2004 Chief Executive

*Original Front Sheets issued 23rd September 1996. This amended version includes change of product name, and

reference to the revised national Building Regulations, Water Supply Regulations, Construction (Design and

Management) Regulations, and new

Conditions of Certification

.

British Board of Agrément

P O Box No 195, Bucknalls Lane

Garston, Watford, Herts WD25 9BA

Fax: 01923 665301

©2004

For technical or additional information,

contact the Certificate holder (see

front page).

For information about the Agrément

Certificate, including validity and

scope, tel: Hotline

01923 665400

,

or check the BBA website.

e-mail: mail@bba.star.co.uk

website: www.bbacerts.co.uk

Electronic Copy

Readers are advised to check the validity of this Detail Sheet by either referring to the BBA’s website (www.bbacerts.co.uk) or contacting

the BBA direct (Telephone Hotline 01923 665400).

• THIS DETAIL SHEET LISTS THE COMPONENTS APPROVED FOR USE ON KWIKOT UNVENTED HOT

WATER STORAGE SYSTEMS.

• Each product Detail Sheet lists the components that are required to be factory fitted and others which are

supplied separately for fitting by the installer.

• The BBA has assessed each of the components as suitable for purpose.

This Detail Sheet must be read in conjunction with the Front Sheets and the relevant Detail Sheets.

Component Manufacturer/supplier Setting Size

and component number

Line strainer Reliance Water — ¾”

Controls LS75

Pressure reducing valve Reliance 312 3 bar ¾”

Watts Redupress 3 bar ¾”

Combined check valve Reliance 2014 5 bar ½”

and expansion valve

Combined temperature and Reliance Water 90°C/7 bar ½”

pressure relief valve Controls HT55 EVR

Watts SFR 52550UK 90°C/6 bar ¾”

Expansion vessel Altechnic Zilmet 3 bar 16 litres

Tundish Reliance Water Controls — 22 mm to 28 mm

Immersion heater Redring LU11TC 35° to 75°C 2¼”

Thermtec AFSTA-327 35° to 70°C 2¼”

Thermostat non-self-resetting Integral part of 80°C

thermal cut-out immersion heater

Indirect thermostat IMIT LSC2 35° to 80°C

Indirect non-self-resetting IMIT LSC1-T80 85°C

thermal cut-out

Motorised valve

(1)

Honeywell V4043

Danfoss DMV2C

Sunvic SZV2212F

(1) It is essential on indirectly heated systems that the motorised valve supplied with the system is installed and is not substituted by any

other motorised valve which may exist and be in service at the site of installation, eg a motorised valve installed in a central heating

circuit.

Certificate No 96/3253

DETAIL SHEET 2

Second issue*

Kwikot Limited

KWIKOT UNVENTED

HOT WATER STORAGE SYSTEMS

Components

CI/SfB

(53.9) X

Electronic Copy

On behalf of the British Board of Agrément

Date of Second issue: 10th September 2004 Chief Executive

*Original Detail Sheet issued 23rd September 1996. This revised version includes change of product name and

reference to the Watts valves and Thermtec immersion heater.

British Board of Agrément

P O Box No 195, Bucknalls Lane

Garston, Watford, Herts WD25 9BA

Fax: 01923 665301

©2004

For technical or additional information,

contact the Certificate holder (see

front page).

For information about the Agrément

Certificate, including validity and

scope, tel: Hotline

01923 665400

,

or check the BBA website.

e-mail: mail@bba.star.co.uk

website: www.bbacerts.co.uk

Electronic Copy

Readers are advised to check the validity of this Detail Sheet by either referring to the BBA’s website (www.bbacerts.co.uk) or contacting

the BBA direct (Telephone Hotline 01923 665400).

Technical Specification

1 Description

1.1 The Kwikot Direct Unvented Hot Water

Storage System is for use in domestic, commercial

and public buildings for connection to domestic hot

and cold water services to BS 6700 : 1997, and

comprises the components shown in Figure 1. The

storage capacities and main dimensions are listed

in Table 1.

1.2 The system generally comprises a steel

storage cylinder, enamelled on the interior surfaces

and factory fitted with two 3 kW immersion

heaters. The models are for free-standing

installations.

1.3 The cylinder is insulated with

polyurethane (PU) hard foam and covered with a

white, epoxy-coated steel sheet.

1.4 For safety of the system, electrical control

devices and the combined temperature and

pressure relief valve are factory fitted. Other

components are supplied separately for fitting on

site by a

competent person

(see Figure 1 and

section 2.1).

1.5 Factory production control is exercised during

the manufacture and assembly of each of the

components including visual examination,

dimensional checks and performance tests.

Each storage cylinder is pressure tested and

examined for leaks during manufacture and prior

to dispatch.

2 Delivery and site handling

2.1 The system is delivered in a cardboard carton

protected internally with polystyrene supports and

wrapped in a plastic bag. The following items

(see also Detail Sheet 2) are supplied separately

with each storage cylinder for fitting on site by a

competent person

, all other components are

factory fitted:

• cold water control valves — to include a

pressure control valve (pressure limiting or

pressure reducing valve)

• check valve

• expansion valve

• line strainer

• tundish.

2.2 When the system is required to be stored, it

must be stored in a dry environment and protected

from damage.

2.3 The system must be carefully handled and

kept in the delivery crate until required for siting in

position. The weight of each system empty and full

is stated in Table 1 and on the label attached to

each system.

• THIS DETAIL SHEET RELATES TO THE KWIKOT DIRECT UNVENTED

HOT WATER STORAGE SYSTEM, WITH A RANGE OF CAPACITIES

FROM 150 TO 210 LITRES, A NOMINAL OPERATING PRESSURE OF

3.0 BAR AND FITTED WITH TWO 3 kW IMMERSION HEATERS.

• The system is for use with mains or other suitable potable water supply

pressures up to and including 12 bar.

• Satisfactory outlet flow rates can only be achieved where the flow rate

available at the entry to the system is adequate (see section 5 of this

Detail Sheet).

• It is essential, for reasons of safety and performance, that the product is

installed and maintained in accordance with the requirements of this

Detail Sheet by a

competent person

(see section 12, regarding

Maintenance

and section 15 for the definition of a

competent person

).

This Detail Sheet must be read in conjunction with the Front Sheets and Detail

Sheet 1, which give the

Conditions of Certification

and the product’s position

regarding the Building Regulations, respectively.

Certificate No 96/3253

DETAIL SHEET 3

Second issue*

Kwikot Limited

KWIKOT DIRECT UNVENTED

HOT WATER STORAGE SYSTEM

Product

CI/SfB

(53.3) X

Electronic Copy

3 Labelling/marking

The system carries a label(s) bearing the

information set out in Table 2 and is supplied with

a comprehensive installation/user manual.

Figure 1 General layout

Key to Figure 1

1 Storage cylinder manufactured from 2 mm thick steel.

2 Combined temperature and pressure relief valve (see Detail Sheet 2).

Factory fitted.

3 Expansion vessel.

4 Insulation (PU foam) covered by white, epoxy-coated steel outer casing.

5 Corrosion protection magnesium alloy anode.

6 Cold water feed (¾” BSP male).

7 Hot water draw-off (¾” BSP female).

8 Drain valve to BS 2879 : 1980.

9 Immersion heater.

10 Cold water control valves (see Detail Sheet 2):

line strainer

check valve

expansion valve

pressure reducing valve.

Table 1 Storage capacities and dimensions

Manufacturer’s system

reference

150 210

Storage capacity (litres) 150 210

Cylinder size (mm)

height 1036 1382

diameter 450 450

overall height 1090 1436

overall diameter 525 525

Weight of cylinder (kg)

empty 50 67

full 200 277

Expansion vessel capacity (litres) 16 16

Connection sizes

mains water supply to control valves —

(mm) compression fitting 22 22

balanced cold water draw-off —

(mm) compression fitting 22 22

cold water inlet to storage cylinder —

(BSP inches male) ¾ ¾

hot water draw-off — (BSP inches male) ¾ ¾

expansion valve discharge —

(BSP inches male) ½ ½

temperature and pressure relief valve

discharge — (BSP inches female) ½ ½

Immersion heater

rating at 240 V (kW) 3 3

heater length (mm) 280 280

Anode length (mm) 370 480

Table 2 Labels

General

1 The BBA identification mark incorporating the number of this Certificate.

2 The system uses BEAB (British Electrical Approvals Board) approved

electrical controls.

3 UKWFBS (United Kingdom Water Fittings Byelaws Scheme) list number.

4 Manufacturer’s name.

5 Product code number.

6 Serial number.

7 The system is an unvented system.

Design

1 Maximum water supply pressure (bar).

2 Operating pressure (bar).

3 Expansion valve setting (bar).

4 Immersion heater(s) — Power/voltage — Type/BS/Length.

5 Storage capacity (litres).

6 Weight of unit — full (kg).

7 Expansion vessel charge pressure (bar).

Safety warnings/conditions

1 Installation to be carried out only by a

competent person.

2 The removal/replacement of any component to be carried out only by a

competent person

using components supplied by the Certificate holder in

accordance with their instructions.

3 Any malfunction of the system such as that resulting in discharge of water

from the expansion valve or the combined temperature and pressure relief

valve to be reported to a

competent person

after switching off the heat

source and prior to any further use of the system.

4 The installation of the system is subject to approval under the Building

Regulations, Water Byelaws and Regulations, the Health and Safety at

Work etc Act 1974 (where appropriate) and the Health and Safety at

Work (Northern Ireland) Order 1978 (where appropriate).

Installer

(1)

details

1 Space for:

(a) Name

(b) Address

(c) Telephone number

(d) Completion date

(e) Registration No ....

2 A declaration that installation has been in accordance with BBA

Certificate

No 96/3253 with space for signature of the installer

(1)

.

CE mark

1 The system complies with the Low Voltage Directive 73/23/EEC.

2 The system when installed correctly will comply with the Electromagnetic

Compatibility Directive 89/336/EEC.

3 A CE mark applied to these products by the manufacturer relates only to the

Low Voltage and Electromagnetic Compatibility Directive. In the opinion of

the BBA, the application of the CE mark does not infer compliance with the

requirements of the applicable Building Regulations.

(1) The installer must meet the definition of a

competent person

as defined in section 15.2.

2

Electronic Copy

Table 4 Standing energy losses

System ref Heat loss Energy loss

(1)

maximum daily

(W) (kWh)

D 150 100 2.40

D 210 113 2.71

(1) These figures relate to a 45°C differential between the stored water and

ambient temperature.

Design Data

4 General

4.1 The Kwikot Direct Unvented Hot Water

Storage System (see Figure 2) has been assessed

in accordance with MOAT No 38 : 1986. When

used in accordance with this Detail Sheet the

system will perform in a safe and satisfactory

manner.

4.2 The hot water system capacity should be

selected in accordance with the recommendations

of BS 6700 : 1997, to meet the demands

required from the installation.

4.3 The pressure and flow available from the

water mains should be obtained from the local

water undertaker or by testing existing supplies to

establish the likely performance of the system at

peak periods.

4.4 It is essential, for reasons of safety and

performance, that installation of the system is

undertaken only by a

competent person

working in

accordance with this Detail Sheet.

4.5 The data shown in Tables 3 and 4 represent

the analysis of tests carried out by the BBA.

5 Hot water storage and supply

Hot water storage

5.1 The capacities of the system range are

comparable with conventional systems (see

Table 1). When heated to 60°C the system can

supply 70% of the storage capacity at the mean

temperature given in Table 3.

Flow rates

5.2 The flow rates achieved at the hot water

draw-off point will depend on all the normal factors

including the layout of the pipework from the tap to

3

Figure 2 Schematic layout — direct

Table 3 Heating, re-heating and water draw-off temperature

ABCDEF

System Heat source Heat-up Percentage of the capacity Mean Reheating Upper Quantity

ref immersion time and amount drawn off within draw-off time immersion available

heater 10°C of set temperature temperature heat-up above

time 40°C

(kW) (minutes) (%) (litres) (°C) (minutes) (minutes) (litres)

D 150 3 187 90 135 60 152 54 51

D 210 3 250 93 195 60 177 60 56

Electronic Copy

the cylinder, the cold water supply pressure and the

flow rate available at the supply to the system.

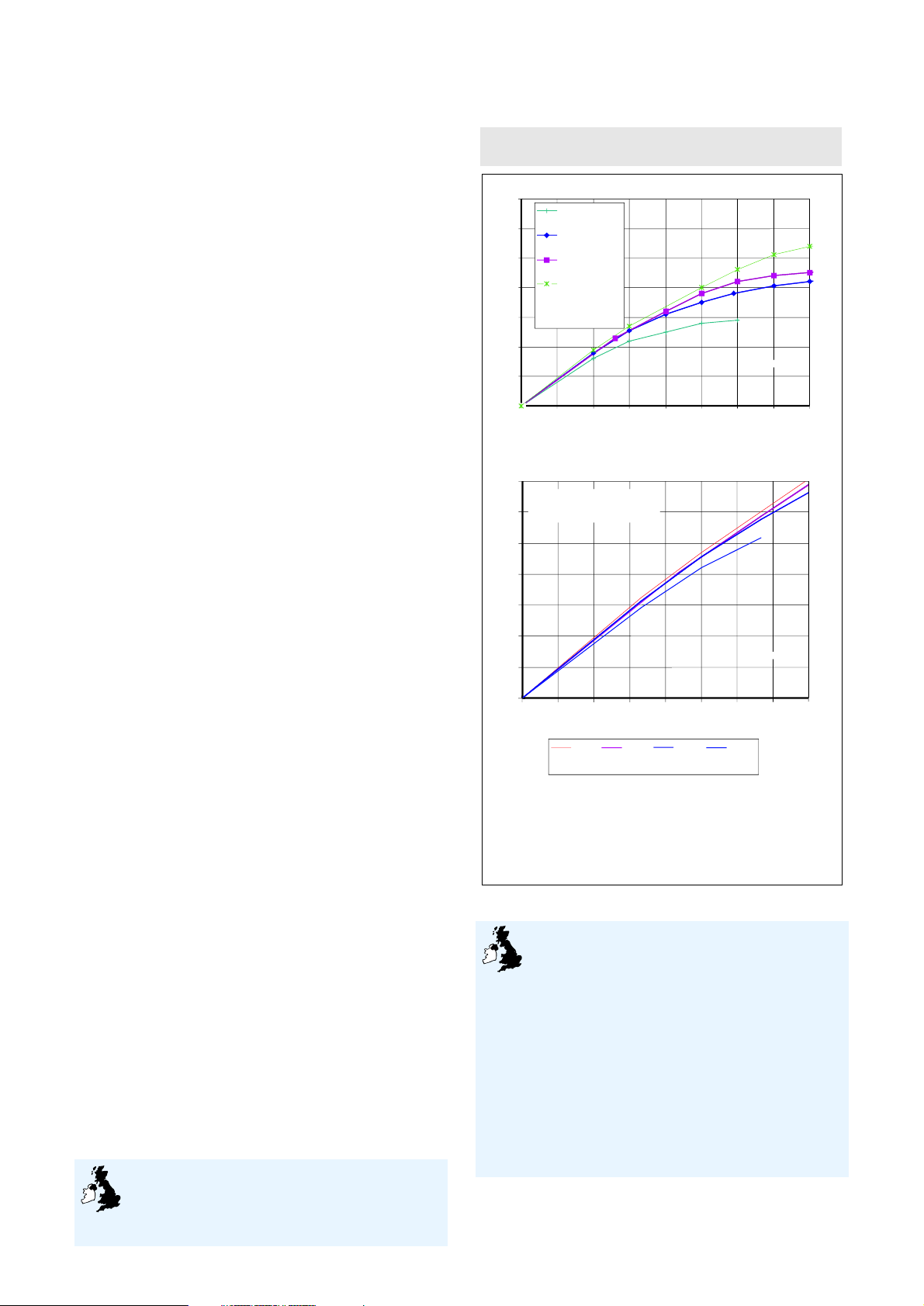

5.3 For design purposes the graphs in Figure 3

show the relationship between:

• flow available

• mains supply pressure, and

• the maximum hot water flow rate out of the

system

(1)

.

(1) Flow characteristics shown in the graphs reflect the worst

combination of cold water control components that may

be installed (see Detail Sheet 2).

5.4 The hot/cold mixed flows are for draw-off

temperatures of 40°C (assume 60% at 60°C and

40% at 10°C).

Heat-up, re-heating and hot water draw-off

temperature

5.5 The heat-up and re-heat times are comparable

with conventional systems of a similar size

supplying hot water.

5.6 The immersion heater will heat the stored

water from 15°C to 60°C in the time listed in

column A of Table 3.

5.7 The amount of water that can be drawn off

within 10°C of the set temperature is listed in

column B of Table 3, the mean temperature of 70%

of the water drawn off immediately after reaching

60°C in column C, and the time taken to re-heat

the stored water to 60°C in column D.

Temperature control

5.8 The thermostat wired to the immersion

heater is satisfactory for controlling the

temperature of the stored water.

Pressure control

5.9 The pressure control valve is satisfactory for

controlling the pressure of the water supplied from

the water mains or other suitable potable supply.

Insulation

5.10 The system is provided with adequate

insulation to satisfactorily limit the energy loss

from the stored water and meets the

requirements described in the national Building

Regulations:

England and Wales

Approved Document L1

Scotland

Regulation 22, Standard J3.4

Northern Ireland

Technical Booklet F, Paragraph 3.3.

5.11 The heat loss of each system while

maintaining the temperature of the stored water at

65°C is shown in Table 4.

Figure 3 Flow rates

Connections

5.12 The system is designed to be connected to

copper tube to BS EN 1057 : 1996, using

conventional plumbing fittings (see Table 1 for

details of connection sizes and threads). The

connections are of adequate size.

6 Safety

Excessive temperature — Prevention of explosion

— Safe discharge of hot water

6.1 The safety devices provided to ensure

that the temperature of the stored water will

not exceed 100°C, and safeguard the

operation of the system, are:

• the combined temperature and pressure relief

valve, and

• the non-self-resetting thermal cut-out fitted to the

system and wired to the immersion heater.

6.2 The system has a safety warning label

attached to the storage cylinder, bearing an

explanation of the action to be taken in the case of

0

10

20

30

40

50

60

70

0

10

20 30 40 50 60

70

80

2 bar

3 bar

4 bar

8 bar

Static supply pressures

of incoming water

supply

flow available (lmin ) at entry to system

–1

flow out (lmin ) of the system

–1

hot only

¾" valves

0

10

20

30

40

50

60

70

01020304050

60 70 80

flow available at entry to the system(lmin )

–1

8 bar 4 bar 3 bar 2 bar

Static supply pressures of incoming water supply

flow out (lmin ) of the system

–1

• Flow rates shown apply to situations where the supply is capable of supplying an

adequate dynamic pressure.

• The graph represents the results of tests carried out by the BBA.

• Where static water supplies are less than 1 bar, consult Kwikot Limited or the BBA.

• Flow rates shown for mixed hot/cold water assume that the cold supply is not

taken from the balanced connection of the pressure reducing valve

Notes

hot/cold mixed

mixed water at 40ºC, mixed from

60% hot water at 60ºC and

40% cold water at 10ºC

¾" valves

4

Electronic Copy

any malfunction of the system. It is essential that the

instructions are followed.

6.3 The system has adequate provision for safe

disposal of discharges from the expansion valve

and the combined temperature and pressure relief

valve [see also sections 16(2) and (3)].

Physical contact

6.4 The surfaces of the storage cylinder are

protected by the insulation. In normal use the

temperatures of the surfaces of the various parts of

the system are comparable with those in a

conventional, vented, hot water storage system.

Strength and stability

6.5 The system has adequate resistance to internal

pressures and does not visibly deform when

subjected to a vacuum of 0.1 bar absolute.

6.6 The system’s pressure control devices will

ensure that the operating pressure will be controlled

to a nominal 3 bar and that the design pressure of

5 bar is not exceeded. Each storage cylinder has

been satisfactorily pressure tested to 1.5 times the

design pressure, ie 7.5 bar.

6.7 The weight of the system is stated on the

label attached (see also Table 1); the support

arrangements appropriate to a conventional system

apply.

6.8 Care must be taken to avoid damage to the

system during handling and installation.

Electrical safety

6.9 The thermostat and non-self-resetting thermal

cut-out are approved by the BEAB to BS 3955 :

1986. The immersion heater is approved by the

BEAB to BS EN 60335-2.73 : 2003. To ensure

safety it is essential that the electrical wiring is

carried out in accordance with the

IEE Wiring

Regulations — Regulations for Electrical

Installations, Sixteenth Edition 1991.

7 Properties in relation to fire

7.1 The expanded polyurethane foam insulant is

covered with a steel outer casing and only a small

area of the insulant will be exposed at connection

bosses. In the presence of a source of ignition,

such as a plumber’s blowlamp, the foam will flame

locally and emit toxic fumes. Flaming and fume

emission will stop when the source of ignition is

removed.

7.2 In service, the steel outer casing encloses the

foam and risk of ignition will be minimal. During

installation care should be exercised when using a

blowlamp to make soldered joints on pipework

adjacent to the cylinder. Installation does not require

soldered joints to be made direct to the system.

8 Effect on water quality and prevention of

waste of water

The system is listed by the UKWFBS.

9 Watertightness

The storage cylinder remains watertight at

pressures

in excess of 1.5 times the design pressure,

ie 7.5 bar.

10 Noise

The system is quiet in normal operation, the flow of

water being via conventional water pipe fittings,

and compares favourably with a vented, hot water

storage system.

11 Physiological effects

The insulation is a conventional material. It will not

encourage vermin or bacteria and is not

susceptible to damage from moisture.

12 Maintenance

12.1 It is recommended that, annually, a

competent person

:

• inspects and cleans the line strainer, and

• measures the pressure in the expansion vessel

and recharges as necessary.

12.2 The replacement or servicing of components

must be carried out by a competent person, using

the

Kwikot Technical Information and Installers

Instructions

, or by the Certificate holder under their

responsibility as the product manufacturer,

including that required by their warranty, using

components supplied by the Certificate holder.

12.3 The system may be drained using the drain

valve.

12.4 When the system is used in buildings subject

to the Health and Safety at Work etc Act 1974,

an inspection of the system must be carried out

every six months.

13 Site checks

On site the following should be checked:

By the Client

(1) The installer is a

competent person

— by

reference to his/her identity card.

(2) The system being installed is BBA Certificated

— by reference to the label.

(3) That the installation complies with the BBA

Certificate — by reference to the installer’s

signature on the label attached to the cylinder.

By the Building Control Officer or Approved

Inspector

(1) 1, 2 and 3 as above.

(2) The combined temperature and pressure relief

valve, thermostat, non-self-resetting thermal cut-out

and the immersion heater are as described in the

Certificate.

(3) The tundish and discharge pipework are

correctly located and fitted.

5

Electronic Copy

14 Durability

The system is manufactured from durable

materials and conventional plumbing components

and will have a life equal to that expected of a

vented system. It may be necessary to replace

some of the system components, eg the immersion

heater, thermostat (see section 12.2 and Detail

Sheet 2).

Installation

15 The installer

15.1 It is essential, for reasons of safety and

performance, that the installation, commissioning

and maintenance of the system is carried out by a

person with suitable training and practical

experience. However, the assessment of training

arrangements and continuing competence of

installers falls outside the scope of this Certificate.

15.2 It is the view of the Department of

the Environment, and stated in its Approved

Document G3, that, to meet the

requirements of the Building Regulations (England

and Wales) concerned with unvented hot water

storage systems, installations should be

undertaken by a

competent person

, defined as

‘one holding a current Registered Operative

Identity Card for the installation of unvented

domestic hot water storage systems, issued by the

Construction Industry Training Board (CITB), the

Institute of Plumbing, the Association of Installers of

Unvented Hot Water Systems (Scotland and

Northern Ireland), or an equivalent body’.

15.3 In Scotland, it is the requirement of

the deemed-to-satisfy provision to Technical

Standard P3.1

Unvented Hot Water

Storage System

for compliance with Regulation 28

of the Building Standards (Scotland) Regulations

that such systems be ‘in the form of a proprietary

unit or package which is: (i) the subject of a

BBA Certificate, or (ii) Kitemarked to BS 7206 :

1990’. The Standard contains no specific

requirements for installers but the Certificates

referred to state that installation must be

undertaken by a

competent person

, as defined in

section 15.2.

15.4 In Northern Ireland, it is the

requirement of Regulation P5

Unvented

Hot Water Storage Systems

that systems

with a capacity not greater than 500 litres, and

a heat input not greater than 45 kW, be certified

as meeting the relevant requirements of

Regulation P5 by a member body of EOTA

operating a Technical Approvals Scheme, eg

by the BBA under MOAT No 38 : 1986.

Agrément Certificates will refer to a need for

installation by a

competent person

, as defined in

section 15.2.

16 Conditions

The following conditions abstracted from the

Certificate holder’s instructions must be observed:

(1) The system must be connected to a water

supply with a pressure not exceeding 12 bar and

of a quality supplied by a water undertaker under

the Water Byelaws and Water Regulations, as

appropriate.

(2) The combined temperature and pressure relief

valve tundish must be in a clearly visible position

within 500 mm of the cylinder and in the same

compartment as the cylinder. The discharge pipe to

and from the tundish must be of metal and laid to

fall. It must terminate at a visible safe place, such

as a gully, where there is no risk of contact with the

hot water by persons in or about the building.

Further details are given in BBA Information

No 33 : 1989

Unvented Hot Water Storage

Systems — Hot Water Discharges from Safety

Devices. BBA Requirements and Guidance.

(3) The discharge pipe from the expansion valve

should be laid with a continuous fall to terminate in

a suitable location. The details applying to

discharge pipes given in BBA Information No 33 :

1989 are generally recommended.

(4) The system is installed in locations similar to

those for storage cylinders used in a conventional

vented system or in other locations advantageous

to the building designer (see Table 1 for load

weight of the system when ‘full’). It is important to

ensure there is adequate clearance for the removal

of the immersion heater and the corrosion

protection anode (see Table 1).

(5) Electrical wiring must be carried out in

accordance with the IEE Wiring Regulations. The

immersion heater circuit must be protected by a

suitably-rated fuse and an isolating switch with

double pole disconnection.

17 Procedure

Summary of installation procedure

17.1 The storage cylinder is located in position

(see the

Kwikot Technical Information and Installers

Instructions

and the plumbing connections made to

the inlet and outlet pipes in the same manner as for

a conventional storage cylinder, except that the

water supply pipe is taken directly from the mains

or other suitable potable supply, via the line

strainer and cold water control valves (ensuring the

arrow markings on the components are pointing

downstream) to the cold water inlet of the storage

cylinder (see Figure 2). Where balanced pressures

are required, the cold water draw-off is connected

as shown in Figure 2, using components supplied

by the Certificate holder.

17.2 The discharge pipe is connected to and

from the tundish to a safe and visible termination

point [see sections 16(2) and (3)]. The air gap at

the tundish must remain clear.

6

Electronic Copy

18 Commissioning

18.1 The system is filled with water and checked

for watertightness. The expansion vessel is

checked against the manufacturer’s stated

specification (3.5 bar). The expansion valve and

the combined temperature and pressure relief valve

are manually operated to ensure water discharge

from the valves runs freely through the tundish to the

termination point. The valves are visually checked

to ensure that they re-seat satisfactorily. Heat is

applied to the system and is allowed to reach

normal working temperature. The operation of the

thermostat is checked and an examination carried

out to ensure that no water has discharged from the

expansion valve or the combined temperature and

pressure relief valve during the heat-up.

18.2 On completion of the commissioning process

the

competent person

completes the label attached

to the system, stating that the installation complies

with the Certificate (see section 3).

Technical Investigations

The following is a summary of the technical

investigations carried out on the Kwikot Direct

Unvented Hot Water Storage System.

19 Tests and investigations

19.1 Tests were carried out in accordance with

MOAT No 38 : 1986 to determine:

• capacity of storage cylinder

• dimensional accuracy

• mean supply temperature

• outlet flow rate at various supply flow rates and

pressures

• time taken to heat to 60°

• re-heat time to 60°

• standing energy loss (adequacy of insulation)

• watertightness

• resistance of the storage cylinder and expansion

vessel to an internal hydrostatic pressure of

1.5 times the design pressure = 7.5 bar

• resistance to partial vacuum of 0.1 bar absolute

• flow capacity of the tundish and discharge

pipework.

19.2 Tests were carried out to confirm satisfactory

operation of the following components when fitted

in a system:

• cold water control valves, to include:

– pressure control valve

– expansion valve

– check valve

• combined temperature and pressure relief valve

•

immersion heater thermostat and non-self-resetting

t

hermal cut-out

• line strainer.

19.3 An examination was made of existing data

in relation to the performance requirements of the

relevant British Standards, to determine the

suitability and performance of:

• cold water control valves, to include:

– pressure control valve to BS 6283-4 : 1991

– check valve to BS 6282-1 : 1982

– expansion valve to BS 6283-1 : 1991

• combined temperature and pressure relief valve

to BS 6283-3 : 1991

• line strainer

• immersion heater to BS EN 60335-2.73 : 2003

• direct immersion heater

thermostat/non-self-resetting thermal cut-out to

BS 3955 : 1986

• expansion vessel to BS 6144 : 1990.

19.4 An examination was made of existing data

relating to:

• adequacy of installation instructions

• practicability of installation by the

competent

person

• electrical safety

• effect on water quality and prevention of waste

of water

• properties in relation to fire

• practicability and adequacy of maintenance

requirements

• durability of materials used.

20 Investigations

The manufacturing and assembly process was

examined, including the methods adopted for

quality control, and details were obtained of the

quality and composition of materials used.

7

Electronic Copy

Bibliography

BS 2879 : 1980

Specification for draining taps

(screw-down pattern)

BS 3955 : 1986

Specification for electrical

controls for household and similar general purposes

BS 6144 : 1990

Specification for expansion

vessels using an internal diaphragm, for unvented

hot water supply systems

BS 6282-1 : 1982

Devices with moving parts for

the prevention of contamination of water by

backflow — Specification for check valves of

nominal size up to and including DN 54

BS 6283-1 : 1991

Safety and control devices for

use in hot water systems — Specification for

expansion valves for pressures up to and including

10 bar

BS 6283-3 : 1991

Safety and control devices for

use in hot water systems — Specification for

combined temperature and pressure relief valves for

pressures from 1 bar to 10 bar

BS 6283-4 : 1982

Safety and control devices for

use in hot water systems — Specification for droptight pressure reducing valves of nominal size up to

and including DN 54 for supply pressures up to

and including 12 bar

BS 6700 : 1997

Specification for design,

installation, testing and maintenance of services

supplying water for domestic use within buildings

and their curtilages

BS 7206 : 1990

Specification for unvented hot

water storage units and packages

BS EN 1057 : 1996

Copper and copper alloys.

Seamless, round copper tubes for water and gas in

sanitary and heating applications

BS EN 60335-2.73 : 2003

Household and

similar electrical appliances — Safety — Particular

requirements for fixed immersion heaters

MOAT No 38 : 1986

The assessment of unvented

hot water storage systems and the approval and

surveillance of installers

On behalf of the British Board of Agrément

Date of Second issue: 10th September 2004 Chief Executive

*Original Detail Sheet issued 23rd September 1996. This revised version includes change of product name and

reference to revised Regulations and Standards.

British Board of Agrément

P O Box No 195, Bucknalls Lane

Garston, Watford, Herts WD25 9BA

Fax: 01923 665301

©2004

For technical or additional information,

contact the Certificate holder (see

front page).

For information about the Agrément

Certificate, including validity and

scope, tel: Hotline

01923 665400

,

or check the BBA website.

e-mail: mail@bba.star.co.uk

website: www.bbacerts.co.uk

Electronic Copy

Readers are advised to check the validity of this Detail Sheet by either referring to the BBA’s website (www.bbacerts.co.uk) or contacting

the BBA direct (Telephone Hotline 01923 665400).

Technical Specification

1 Description

1.1 The Kwikot Indirect Unvented Hot Water

Storage System is for use in domestic, commercial

and public buildings for connection to domestic hot

and cold water services to BS 6700 : 1997, and

comprises the components shown in Figure 1. The

storage capacities and main dimensions are listed

in Table 1.

1.2 The system generally comprises a steel

storage cylinder enamelled on the interior surfaces

and factory fitted with an externally enamelled,

steel coil heat exchanger and a 3 kW immersion

heater for use as direct secondary back-up. The

system is for free-standing installation and connects

to a cold feed supply as indicated in Table 1.

1.3 The cylinder is insulated with polyurethane

(PU) hard foam and covered with a white, epoxycoated steel sheet.

1.4 For safety of the system, electrical control

devices and the combined temperature and

pressure relief valve are factory fitted. Other

components, including additional safety devices,

are supplied separately for fitting on site by a

competent person

(see Figure 1 and section 2.1).

1.5 Factory production control is exercised

during the manufacture and assembly of each of

the components including visual examination,

dimensional checks and performance tests.

Each storage cylinder is pressure tested and

examined for leaks during manufacture and prior

to dispatch.

2 Delivery and site handling

2.1 The system is delivered in a cardboard carton

protected internally with polystyrene supports and

wrapped in a plastic bag. The following items

(see also Detail Sheet 2) are supplied separately

with each storage cylinder for fitting on site by a

competent person

, all other components are

factory fitted:

• cold water control valves — to include a

pressure control valve (pressure limiting or

pressure reducing valve), check valve and an

expansion valve

• line strainer

• indirect thermostat

• wiring box

• motorised valve

• tundish

• expansion vessel.

• THIS DETAIL SHEET RELATES TO THE KWIKOT INDIRECT UNVENTED

HOT WATER STORAGE SYSTEM WITH A RANGE OF CAPACITIES

FROM 125 TO 210 LITRES, A NOMINAL OPERATING PRESSURE OF

3 BAR AND FITTED WITH ONE 3 kW IMMERSION HEATER FOR

DIRECT SECONDARY BACK-UP HEATING.

• The system is for use with mains or other suitable potable water supply

pressures up to and including 12 bar.

• The system is for use with gas, electric or oil fired boilers.

• The system can be used with a vented or pressurised primary with a

maximum primary pressure of 3 bar.

• Satisfactory outlet flow rates can only be achieved where the flow rate

available at the entry to the system is adequate (see section 5 of this

Detail Sheet).

• It is essential, for reasons of safety and performance, that the product is

installed and maintained in accordance with the requirements of this

Detail Sheet by a

competent person

(see section 12, regarding

Maintenance

and section 15 for the definition of a

competent person

).

This Detail Sheet must be read in conjunction with the Front Sheets and Detail

Sheet 1, which give the

Conditions of Certification

and the product’s position

regarding the Building Regulations, respectively.

Certificate No 96/3253

DETAIL SHEET 4

Second issue*

Kwikot Limited

KWIKOT INDIRECT UNVENTED

HOT WATER STORAGE SYSTEM

Product

CI/SfB

(53.3) X

Electronic Copy

2.2 When the system is required to be stored, it

must be stored in a dry environment and protected

from damage.

2.3 The system must be carefully handled and

kept in the delivery crate until required for siting in

position. The weight of each system empty and full

is stated in Table 1 and on the label attached to

each system.

3 Labelling/marking

The system carries a label(s) bearing the

information set out in Table 2 and is supplied with

a comprehensive installation/user manual.

Figure 1 General layout

Key to Figure 1

1 Storage cylinder manufactured from 2 mm thick steel.

2 Combined temperature and pressure relief valve (see Detail Sheet 2).

Factory fitted.

3 Expansion vessel.

4 Insulation (PU foam), covered by white, epoxy-coated steel outer casing.

5 Corrosion protection magnesium alloy anode.

6 Cold water feed (¾” male BSP).

7 Hot water draw-off (¾” female BSP).

8 Drain valve to BS 2879 : 1980.

9 Motorised valve to BS 3955 : 1986 (see Detail Sheet 2).

10 Primary flow, ¾” BSP male threaded connection.

11 Primary return, ¾” BSP male threaded connection.

12 Indirect cylinder thermostat to BS 3955 : 1986 (adjustable between 30°C

and 80°C) (see Detail Sheet 2).

13 Indirect cylinder non-self-resetting thermal cut-out to BS 3955 : 1986

(operates at 85°C). Factory fitted.

14 Tundish, 22 mm compression fitting inlet, 28 mm compression fitting outlet

(both to BS 864-2 : 1983).

15 Immersion heater.

16 Steel coil heat exchanger.

17 Cold water control valves (see Detail Sheet 2):

line strainer

check valve

expansion valve

pressure reducing valve.

Table 1 Storage capacities and dimensions

Manufacturer’s system reference

125 150 210

Storage capacity (litres) 125 150 210

Cylinder size (mm)

height 892 1036 1382

diameter 450 450 450

overall height 946 1090 1436

overall diameter 525 525 525

Weight of cylinder (kg)

empty 63 70 87

full 188 220 297

Expansion vessel capacity (litres) 16 16 16

Connection sizes

mains water supply to control valves —

(mm) compression fitting 22 22 22

balanced cold water draw-off

(mm) compression fitting 22 22 22

cold water inlet to storage cylinder —

(BSP inches male) ¾ ¾ ¾

hot water draw-off — (BSP inches male) ¾ ¾ ¾

expansion valve discharge (BSP inches male) ½ ½ ½

temperature and pressure relief

valve discharge (BSP inches female) ½ ½ ½

Immersion heater

rating at 240 V (kW) 3 3 3

heater length (mm) 280 280 280

Anode length (mm) 325 370 480

Primary coil

diameter (mm) 22 22 22

heating surface area (m2) 1.09 1.09 1.09

Table 2 Labels

General

1 The BBA identification mark incorporating the number of this Certificate.

2 The system uses BEAB (British Electrical Approvals Board) approved

electrical controls.

3 UKWFBS (United Kingdom Water Fittings Byelaws Scheme) list number.

4 Manufacturer’s name.

5 Product code number.

6 Serial number.

7 The system is an unvented system.

Design

1 Maximum water supply pressure (bar).

2 Operating pressure (bar).

3 Expansion valve setting (bar).

4 Immersion heater(s) — Power/voltage — Type/BS/Length.

5 Storage capacity (litres).

6 Weight of unit — full (kg).

7 Expansion vessel charge pressure (bar).

Safety warnings/conditions

1 Installation to be carried out only by a

competent person.

2 The removal/replacement of any component to be carried out only by a

competent person

using components supplied by the Certificate holder in

accordance with their instructions.

3 Any malfunction of the system such as that resulting in discharge of water

from the expansion valve or the combined temperature and pressure relief

valve to be reported to a

competent person

after switching off the heat

source and prior to any further use of the system.

4 The installation of the system is subject to approval under the Building

Regulations, Water Byelaws and Regulations, the Health and Safety at

Work etc Act 1974 (where appropriate) and the Health and Safety at

Work (Northern Ireland) Order 1978 (where appropriate).

Installer

(1)

details

1 Space for:

(a) Name

(b) Address

(c) Telephone number

(d) Completion date

(e) Registration No ....

2 A declaration that installation has been in accordance with BBA

Certificate

No 96/3253 with space for signature of the installer

(1)

.

CE mark

1 The system complies with the Low Voltage Directive 73/23/EEC.

2 The system when installed correctly will comply with the Electromagnetic

Compatibility Directive 89/336/EEC.

3 A CE mark applied to these products by the manufacturer relates only to the

Low Voltage and Electromagnetic Compatibility Directive. In the opinion of

the BBA, the application of the CE mark does not infer compliance with the

requirements of the applicable Building Regulations.

(1) The installer must meet the definition of a

competent person

as defined in section 15.2.

2

Electronic Copy

Table 4 Standing energy losses

System ref Heat loss Energy loss

(1)

maximum daily

(W) (kWh)

125 95 2.28

150 100 2.40

200 113 2.71

(1) These figures relate to a 45°C differential between the stored water and

ambient temperature.

Design Data

4 General

4.1 The Kwikot Indirect Unvented Hot Water

Storage System (see Figure 2) has been assessed

in accordance with MOAT No 38 : 1986. When

used in accordance with this Detail Sheet the

system will perform in a safe and satisfactory

manner.

4.2 The hot water system capacity, should be

selected in accordance with the recommendations

of BS 6700 : 1997, to meet the demands made

upon the installation. The primary circuit pipework

associated with indirect heating systems should be

designed in accordance with BS 6700 : 1997

and BS 5449 : 1977. Particular consideration

should be given to the inclusion of a primary circuit

by-pass to prevent excessive pressure on the

motorised valve and also safeguard against

‘nuisance tripping’ of the non-self-resetting thermal

cut-out.

4.3 The pressure and flow available from the

water mains should be obtained from the local

water undertaker or by testing existing supplies to

3

Figure 2 Schematic layout — Indirect

Table 3 Heating, re-heating and water draw-off temperature

Indirect heating

AB CD

System Primary flow Heat-up Percentage of the capacity Mean Re-heating

ref time

(1)

and amount drawn off within draw-off time

10°C of set temperature temperature

(litres per minute) (minutes) (%) (litres) (°C) (minutes)

125 15 27 89 111 60 21

150 15 34 91 136 60 26

210 15 45 93 186 60 30

(1) These heat-up times apply to a pumped system only and assume a boiler of adequate output is connected to the system. Primary flows of 15 litres per

minute normally can be attained with a standard domestic circulating pump.

Direct heating

AB CD

System Heat source Heat-up Percentage of the capacity Mean Re-heating

ref time and amount drawn off within draw-off time

10°C of set temperature temperature

(kW) (minutes) (%) (litres) (°C) (minutes)

125 3 160 89 111 60 105

150 3 187 90 135 60 152

210 3 250 93 195 60 177

M

motorised valve

primary flow

cold water

control valves

expansion

valve

tundish

discharge pipe to

safe position

[see section 16(3)

and (4)]

combined temperature

and pressure relief valve

drain valve

hot draw-off

check

valve

balanced pressure

cold draw-off

pressure

control

valve

cold feed

isolating

valve

line

strainer

expansion

vessel

anode

air bleed

valve

primary return

indirect cylinder

non-self-resetting

thermal cut-out

steel coil heat exchanger

indirect cylinder thermostat

immersion heater, direct thermostat and

non-self-resetting thermal cut-out

Electronic Copy

establish the likely performance of the system at

peak periods.

4.4 It is essential, for reasons of safety and

performance, that installation of the system is

undertaken only by a

competent person

working

in accordance with this Detail Sheet.

4.5 The data shown in Tables 3 and 4

represent the analysis of tests carried out by the

BBA.

5 Hot water storage and supply

Hot water storage

5.1 The capacities of the system range are

comparable with conventional systems (see

Table 1). When heated to 60°C the system can

supply 70% of the storage capacity at the mean

temperature given in Table 3.

Flow rates

5.2 The flow rates achieved at the hot water

draw-off point will depend on all the normal

factors including the layout of the pipework from

the tap to the cylinder, the cold water supply

pressure and the flow rate available at the supply

to the system.

5.3 For design purposes the graphs in Figure 3

show the relationship between:

• flow available

• mains supply pressure, and

•

the maximum hot water flow rate out of the

system

(1)

.

(1) Flow characteristics shown in the graphs reflect the worst

combination of cold water control components that may

be installed (see Detail Sheet 2).

5.4 The hot/cold mixed flows are for draw-off

temperatures of 40°C (assume 60% at 60°C and

40% at 10°C).

Heat-up, re-heating and hot water draw-off

temperature

5.5 The heat-up and re-heat times are comparable

with conventional systems of a similar size

supplying hot water.

5.6 The immersion heater will heat the stored

water from 15°C to 60°C in the time listed in

column A of Table 3.

5.7 The amount of water that can be drawn off

within 10°C of the set temperature is listed in

column B of Table 3, the mean temperature of

70% of the water drawn off immediately after

reaching 60°C in column C, and the time taken

to re-heat the stored water to 60°C in column D.

Temperature control

5.8 The thermostats wired to the

immersion heater and motorised valve are

satisfactory for controlling the temperature

of the stored water.

Pressure control

5.9 The pressure control valve is satisfactory for

controlling the pressure of the water supplied from

the water mains or other suitable potable supply.

Figure 3 Flow rates

Insulation

5.10 The system is provided with

adequate insulation to satisfactorily limit

the energy loss from the stored water and

meets the requirements described in the national

Building Regulations:

England and Wales

Approved Document L1

Scotland

Regulation 22, Standard J3.4

Northern Ireland

Technical Booklet F, Paragraph 3.3.

5.11 The heat loss of each system while

maintaining the temperature of the stored water at

65°C is shown in Table 4.

0

10

20

30

40

50

60

70

0

10

20 30 40 50 60

70

80

2 bar

3 bar

4 bar

8 bar

Static supply pressures

of incoming water

supply

flow available (lmin ) at entry to system

–1

flow out (lmin ) of the system

–1

hot only

¾" valves

0

10

20

30

40

50

60

70

0 1020304050

60 70 80

flow available at entry to the system(lmin )

–1

8 bar 4 bar 3 bar 2 bar

Static supply pressures of incoming water supply

flow out (lmin ) of the system

–1

• Flow rates shown apply to situations where the supply is capable of supplying an

adequate dynamic pressure.

• The graph represents the results of tests carried out by the BBA.

• Where static water supplies are less than 1 bar, consult Kwikot Limited or the BBA.

• Flow rates shown for mixed hot/cold water assume that the cold supply is not

taken from the balanced connection of the pressure reducing valve

Notes

hot/cold mixed

mixed water at 40ºC, mixed from

60% hot water at 60ºC and

40% cold water at 10ºC

¾" valves

4

Electronic Copy

Connections

5.12 The system is designed to be connected to

copper tube to BS EN 1057 : 1996, using

conventional plumbing fittings (see Table 1 for

details of connection sizes and threads). The

connections are of adequate size.

6 Safety

Excessive temperature — Prevention of explosion

— Safe discharge of hot water

6.1 The safety devices provided to ensure

that the temperature of the stored water will

not exceed 100°C, and safeguard the

operation of the system, are:

For the indirect coil heat exchanger

• the combined temperature and pressure relief

valve, and

• the indirect non-self-resetting thermal cut-out fitted

to the system and wired into the motorised

valve

(1)

.

For the direct immersion heater

• the combined temperature and pressure relief

valve, and

• the direct non-self-resetting thermal cut-out fitted

to the system and wired into the immersion

heater.

(1) The motorised valve must be fitted to the primary flow and

appropriate electrical connections made (see sections 6.9

and 16).

6.2 The system has a safety warning label

attached to the storage cylinder, bearing an

explanation of the action to be taken in the case

of any malfunction of the system. It is essential that

the instructions are followed.

6.3 The system has adequate provision for safe

disposal of discharges from the expansion valve

and the combined temperature and pressure relief

valve [see also sections 16(2) and (3)].

Physical contact

6.4 The surfaces of the storage cylinder are

protected by the insulation. In normal use the

temperatures of the surfaces of the various parts of

the system are comparable with those in a

conventional, vented, hot water storage system.

Strength and stability

6.5 The system has adequate resistance to internal

pressures and does not visibly deform when

subjected to a vacuum of 0.1 bar absolute.

6.6 The system’s pressure control devices will

ensure that the operating pressure will be controlled

to a nominal 3 bar and that the design pressure of

5 bar is not exceeded. Each storage cylinder has

been satisfactorily pressure tested to 1.5 times the

design pressure, ie 7.5 bar.

6.7 The weight of the system is stated on the

label attached (see also Table 1); the support

arrangements appropriate to a conventional

system apply.

6.8 Care must be taken to avoid damage to the

system during handling and installation.

Electrical safety

6.9 The indirect thermostat, non-self-resetting

thermal cut-out and motorised valve, and the

direct thermostat and non-self-resetting thermal

cut-out are approved by the BEAB to BS 3955 :

1986. The immersion heater is approved by the

BEAB to BS EN 60335-2.73 : 2003. To ensure

safety it is essential that the electrical wiring is

carried out in accordance with the

IEE Wiring

Regulations — Regulations for Electrical

Installations, Sixteenth Edition 1991

.

7 Properties in relation to fire

7.1 The expanded polyurethane foam insulant is

covered with a steel outer casing and only a small

area of the insulation will be exposed at

connection bosses. In the presence of a source of

ignition, such as a plumber’s blowlamp, the foam

will flame locally and emit toxic fumes. Flaming

and fume emission will stop when the source of

ignition is removed.

7.2 In service, the steel outer casing encloses

the foam and risk of ignition will be minimal.

During installation care should be exercised when

using a blowlamp to make soldered joints on

pipework

adjacent to the cylinder. Installation

does not require

soldered joints to be made direct

to the system.

8 Effect on water quality and prevention of

waste of water

The system is listed by the UKWFBS.

9 Watertightness

The storage cylinder remains watertight at

pressures

in excess of 1.5 times the design pressure,

ie 7.5 bar.

10 Noise

The system is quiet in normal operation, the flow

of water being via conventional water pipe fittings,

and compares favourably with a vented, hot water

storage system.

11 Physiological effects

The insulation is a conventional material. It will not

encourage vermin or bacteria and is not

susceptible to damage from moisture.

12 Maintenance

12.1 It is recommended that, annually, a

competent person:

• inspects and cleans the line strainer, and

• measures the pressure in the expansion vessel

and recharges as necessary.

5

Electronic Copy

12.2 The replacement or servicing of components

must be carried out by a competent person, using

the

Kwikot Technical Information and Installers

Instructions

, or by the Certificate holder under their

responsibility as the product manufacturer,

including that required by their warranty, using

components supplied by the Certificate holder.

12.3 The system may be drained using the drain

valve.

12.4 When the system is used in buildings subject

to the Health and Safety at Work etc Act 1974,

an inspection of the system must be carried out

every six months.

13 Site checks

On site the following should be checked:

By the Client

(1) The installer is a competent person — by

reference to his/her identity card.

(2) The system being installed is BBA Certificated

— by reference to the label.

(3) That the installation complies with the BBA

Certificate — by reference to the installer’s

signature on the label attached to the cylinder.

By the Building Control Officer or Approved

Inspector

(1) 1, 2 and 3 as above.

(2) The combined temperature and pressure relief

valve, thermostats, non-self-resetting thermal cut-outs,

motorised valve and the immersion heater are as

described in the Certificate.

(3) The tundish and discharge pipework are

correctly located and fitted.

14 Durability

The system is manufactured from durable materials

and conventional plumbing components and will

have a life equal to that expected of a vented

system. It may be necessary to replace some of the

system components, eg the immersion heater,

thermostat, (see section 12.2 and Detail Sheet 2).

Installation

15 The installer

15.1 It is essential, for reasons of safety and

performance, that the installation, commissioning

and maintenance of the system is carried out by a

person with suitable training and practical

experience. However, the assessment of training

arrangements and continuing competence of

installers falls outside the scope of this Certificate.

15.2 It is the view of the Department of the

Environment, and stated in its Approved

Document G3, that, to meet the requirements

of the Building Regulations (England and Wales)

concerned with unvented hot water storage

systems, installations should be undertaken by a

competent person

, defined as ‘one holding a

current Registered Operative Identity Card for the

installation of unvented domestic hot water storage

systems, issued by the Construction Industry

Training Board (CITB), the Institute of Plumbing, the

Association of Installers of Unvented Hot Water

Systems (Scotland and Northern Ireland), or an

equivalent body’.

15.3 In Scotland, it is the requirement of the

deemed-to-satisfy provision to Technical

Standard P3.1

Unvented Hot Water Storage

System

for compliance with Regulation 28 of the

Building Standards (Scotland) Regulations that such

systems be ‘in the form of a proprietary unit or

package which is: (i) the subject of a BBA

Certificate; or (ii) Kitemarked to BS 7206 : 1990’.

The Standard contains no specific requirements for

installers but the Certificates referred to state that

installation must be undertaken

by a competent

person, as defined in section 15.2.

15.4 In Northern Ireland, it is the

requirement of Regulation P5

Unvented Hot

Water Storage Systems

that systems with a

capacity not greater than 500 litres, and a heat

input not greater than 45 kW, be certified as

meeting the relevant requirements of Regulation P5

by a member body of EOTA operating a Technical

Approvals Scheme, eg by the BBA under MOAT

No 38 : 1986. Agrément Certificates will refer to

a need for installation by a

competent person

, as

defined in section 15.2.

16 Conditions

The following conditions abstracted from the

Certificate holder’s instructions must be observed:

(1) The system is for connection to oil, electric or

gas fired boilers.

(2) The system must be connected to a water

supply with a pressure not exceeding 12 bar and

of a quality supplied by a water undertaker under

the Water Byelaws and Water Regulations, as

appropriate.

(3) The combined temperature and pressure relief

valve tundish must be in a clearly visible position

within 500 mm of the cylinder and in the same

compartment as the cylinder. The discharge pipe to

and from the tundish must be of metal and laid to

fall. It must terminate at a visible safe place, such

as a gully, where there is no risk of contact with the

hot water by persons in or about the building.

Further details are given in BBA Information

No 33 : 1989

Unvented Hot Water Storage

Systems — Hot Water Discharges from Safety

Devices. BBA Requirements and Guidance

.

(4) The discharge pipe from the expansion valve

should be laid with a continuous fall to terminate in

a suitable location. The details applying to

6

Electronic Copy

discharge pipes given in BBA Information No 33 :

1989 are generally recommended.

(5) The system is installed in locations similar to

those for storage cylinders used in a conventional

vented system or in other locations advantageous

to the building designer (see Table 1 for load

weight of the system when ‘full’). It is important to

ensure there is adequate clearance for the removal

of the immersion heater and the corrosion

protection anode (see Table 1).

(6) Electrical wiring must be carried out in

accordance with the IEE Wiring Regulations. The

immersion heater circuit must be protected by a

suitably-rated fuse and an isolating switch with

double pole disconnection.

(7) It is essential that the motorised valve

supplied with the system is installed and is not

substituted by any other motorised valve which

may exist and be in service at the site of

installation, eg a motorised valve installed in a

central heating circuit.

17 Procedure

Summary of installation procedure

17.1 The storage cylinder is located in position

(see the

Kwikot Technical Information and Installers

Instructions

) and the plumbing connections made to

the inlet and outlet pipes in the same manner as for

a conventional storage cylinder, except that the

water supply pipe is taken directly from the mains

or other suitable potable supply, via the line

strainer and cold water control valves (ensuring the

arrow markings on the components are pointing

downstream) to the cold water inlet of the storage

cylinder (see Figure 2). Where balanced pressures

are required, the cold water draw-off is connected

as shown in Figure 2, using components supplied

by the Certificate holder.

17.2 The discharge pipe is connected to and

from the tundish to a safe and visible termination

point [see sections 16(3) and (4) of this Detail

sheet]. The air gap at the tundish must remain

clear.

18 Commissioning

18.1 The system is filled with water and checked

for watertightness. The expansion vessel is

checked against the manufacturer’s stated

specification (3.5 bar). The expansion valve and

the combined temperature and pressure relief valve

are manually operated to ensure water discharge