KCA/KCW

Operation Manual

CEILING

MASTER

KwiKool CeilingMaster Series

KCA/KCW

Operation Manual

Table of Contents

Before installing and using your KwiKool Portable Cooling

System, read this manual carefully for instructions and

proper usage and all safeguards.

This manual should be retained for future reference.

Section I / Unit Components - Page: 3

Section II / KCA/KCW Standard Features - Page: 3

Section III /Introduction - Page: 4

Section IV / In the Package - Page: 4

Section V / Installation - Page: 4-8

Section VI / Installation Checklist - Page: 9

Section VII / Inspection & Maintenance - Page: 9

Section VIII / Troubleshooting Guide - Page: 10-11

II / KCA/KCW Standard Features

Page 3

I / Unit Components

A.

B.

Built-in high lift condensate pump

Built-in HD mounting brackets

Built-in duct collars for supply and return air, and condensate discharge air

Fire alarm / EPO (emergency power off) N/O connection

Automatic shut off with alarm signal output and audible alarm for:

C.

D.

E.

Condensate Pump

High Pressure Switch Activation

Low Pressure Switch Activation

1.

2.

3.

Legend

1. Evaporator Return

2. Schreader Port

3. Manual High Pressure Switch

4. Evaporator Supply

5. Electrical Panel Cover

6. 1/4” Condensate Pump Discharge Nipple

7. Power Entry

8. Condenser Hot Air Discharge

5

1

2

3

4

6

7

8

IV / In the Package

A.

B.

Check for damage not apparent upon delivery of unit (if damage is noted and is severe

enough to warrant a claim, call freight company immediately and file a claim).

Check to make sure that there are 3 duct collars attached to the KCA unit. 2 Duct

collars will be attached to the KCW unit.

After you have uncrated your new CeilingMaster, you should check the following:

Page 4

III / Introduction

If you are reading this, then you have made the decision to purchase the smallest most

powerful ceiling mounted unit made, KwiKool’s CeilingMaster.

The information in this manual will explain how to assemble, install and operate the

KCA/KCW ceiling mounted unit. Please read the complete manual before proceeding to try

an install the unit. If you have any questions after reading the manual, please feel free to

contact our technical support department at: 1-800-KWIKOOL (800-594-5665).

NOTE: All Electrical and Mechanical work should be completed by a licensed professional and should be completed in accordance with local building codes. Diversity

Industries, Inc. is not responsible for injuries, and/or damages for use or misuse of unit,

improper installation, or failure to follow local building codes.

V / Installation

Things you will need for installation:

B.

Before you begin installation, it is important to verify that you have sufficient clearance

for the unit in the space above the ceiling for the unit to fit. The most important

clearance items are the condenser discharge and the condenser inlets. You need a

minimum clearance of 24” for the condenser inlets and sufficient area and/or clearance

to run duct if necessary to move the heat to another area or space. The evaporator

needs no clearance accept the amount of clearance needed to attach the duct work

and the space needed for the duck work.

NOTE: The KCA model uses the space above the ceiling for the condenser supply

and return. It is mandatory that consideration be made for movement of the heat so

as not to short cycle the condenser by allowing the heat to be sucked directly into

the condenser inlet(s). If you have questions about this please call KwiKool’s

technical support at: 1-800-KWIKOOL (800-594-5665)

A.

Four (4) mounting rods (all-thread) with mounting hardware and vibration isolators

all rated to handle the load requirements.

Power cable and connector to mount unit.

1/4” Rated drain line with 2 clamps. For distance needed to reach hard pipe drain

line.

1.

2.

3.

Page 5

Standard 24 volt thermostat with thermostat wire.

Return air duct with a filter grill (minimum 24” x 24”)

Supply duct with “T” connections as necessary for proper air distribution

(dampers are suggested but not required for balancing of system)

Hot air exhaust duct (optional)

4.

5.

6.

7.

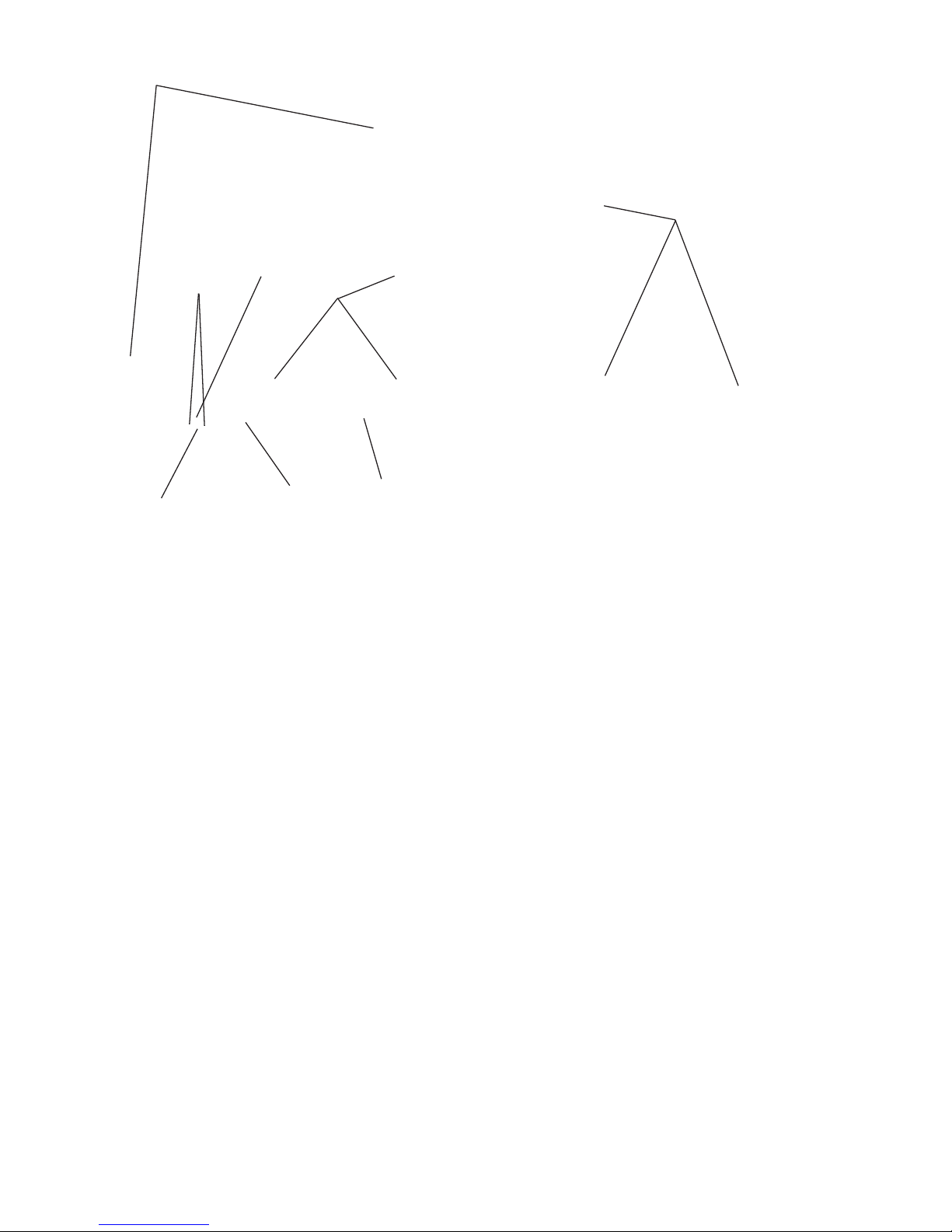

The KCA/KCW comes equipped with mounting rails. These rails are made so that the

installer has maximum flexibility is installation methods. Vibration isolation is required but

can be installed on the unit or on the attachment to the building structure. One common

installation method and one that is tried and true is shown in figures 1 and 2.

C.

All mounting hardware and vibration isolator shall be supplied by others. Make sure all

hardware can handle the loads applied. Mounting of unit could be from joists, the

concrete above or any other method provided a mechanical engineer verifies the safety

of the installation method for the individual application and location.

D.

Page 6

Electrical Requirements:

F.

It is important to make sure you use the recommended breaker size for the unit

being installed. The rating plate will give you a Maximum breaker size (MOP) and a

recommended breaker size. Make sure the wire and circuit are appropriately

sized for the breaker size and unit being installed. Always use wire that is rated

for the voltage and amperage of the unit.

To install the power follow the following guidelines:

1.

2.

Open the electrical panel by removing the screws to the cover.

Bring your circuit with flex conduit to the unit and install the conduit to the

cabinet with a conduit 1/2” or 3/4” BX connector or cable strain relief (Romex)

connector, depending on which CeilingMaster model you purchased. Leave

approximately 12” of wire past the connector and run the wire into the electrical box. Strip the ends of the wires and install the appropriate connectors to

the 3 wires for single phase units and 4 wires on the 3-phase models.

Attach to the 2 or 3 hot wires to the line side of the main contactor (labeled L1,

L2, etc) and attach the green ground wire to the ground screw inside the

electrical box.

On single phase units connect the neutral to the contact that has a white wire

on the load side of the contactor.

For 3-phase units this is not important, but it is important to make sure that the

fans are rotating in the correct direction. If during testing the fans rotate in the

wrong direction switch L1 and L2 and retry.

Connect the ground wire (green color) to the ground screw located in the

bottom of the electrical box below the contactor.

a.

b.

c.

d.

e.

f.

Unit must have physical clearance on all sides. The top shall have a minimum of 3”

clearance and the sides need at least 18” of air for condenser intakes. See figure 3

E.

Page 7

Drain Hose Connection - The KCA/KCW is equipped with a high lift internal conden-

sate pump. Maximum lift is 20’. Use the provided 3/8” flexible hose and connect it to

the 3/8” male connection on the unit for the evaporator coil condensate drain. The

drain line must be located so it will not be exposed to freezing temperatures. The

drain should be the full size of the drain connection. (Connect the drain hose to the

condensate drain or the janitor closet.) A 1/2” ID (5/8” OD), PVC tubing or 3/8”

copper tubing is required for the drain. Insulate the drain hose; condensation may

occur during humid conditions. (Field supplied material). Plug in the 3/8” drain hose

onto the unit and install the hose clamp. Then connect the 3/8”flexible line to the field

supplied condensate line. Make sure the hose does not leak.

NOTE: do not use more than 15’ of drain hose vertically. This is maximum head

(lift) of the condensate pump.

When securing the drain hose to the highest vertical position (no more than 15’ high)

and running the hose to the drain, run the drain hose on a downward slope at a

minimum rate of 1/4” per foot for proper drainage.

Check the following items: No kinks or bends in the drain hose; No traps in the drain

hose; The end of the drain hose should be higher than the water level at the drain;

No dripping from the drain hose at the clamping area

G.

Wall Thermostat Connection - Preparation for thermostat connection:

H.

Use with a single stage wall thermostat. (Type: standard 24 volt input system)

Set the wall thermostat to cooling system mode, since most wall thermostats are

designed for both heating and cooling.

Prepare the wire harness for connection from the unit to the thermostat. The

recommended wire size is: Wire Type: Thermostat cable / Solid Wire 16-26 AWG.

Identify the thermostat connectors labeled G, C, Y or Y1, and R

1.

2.

3.

4.

Connecting a Thermostat to Your KCA/KCW Unit

Wall Thermostat

Connector Name

R

C

Y or Y1

W

G

KCA/KCW Wiring

Label Name

R - 24V

C - Common

Y1

Not Used

G

Color

Red

White

Yellow

Not Used

Green

Function

24 VAC Power

Common

Cool ON / OFF

Heat

Fan ON / OFF

Install the wall thermostat to the proper location inside the room where it can be

conveniently accessed. Do no install the wall thermostat where unusual heating

conditions might be present ( i.e. hot pipes, direct sunlight, etc.). Install the

thermostat somewhere close to the area of the return filter grill.

Most standard thermostat devices will provide these basic functions:

Fan mode: ON / AUTO (Select the desired fan mode)

System mode: Cool / Heat

5.

WARNING: All electrical work should only be performed by qualified personnel. Installation or repair to any electrical components by non-certified personnel may result in

personal injury and/or damage to the unit.

Page 8

External Alarm Signal Connections - All KCA/KCW units are equipped with an alarm

signal output relay type (Form-C, normal open dry contacts), which can be used for

monitoring basic unit failure functions. Relay contactor (no connector) is closed when

the following condition has occurred:

I.

Condensate Tank Overflow

High Pressure Switch Closed

Low Pressure Switch Engaged

Cooling Function Fails

1.

2.

3.

4.

The output of the relay is rated at 5A at 30VDC or 5A at 250VAC (resistive load). This

can be used to connect output is compatible with various warning devises such as

alarm speakers, light indictors, etc.

Alarm contacts are labeled A1 and A2 on the external terminal block. Connect the

warning device to these terminals.

The recommended warning signal wire size is 16AWG to 26AWG for a solid or

stranded wire.

Fire Alarm Control Panel or Emergency Shut Off Connection - The KCA/KCW unit is

equipped with a normally closed circuit which can be used to shut down the unit in a fire

or emergency situation. Opening this circuit will shut the unit down and will not come

back on until the circuit is reclosed.

J.

Connecting Fire Alarm Control Panel or EPO (Emergency Power Off) to KCA/KCW -

First remove the jumper from the S1 and S2 terminals of the external terminal block.

Connect the fire alarm signal wires or EPO wires to your KCA/KCW on the S1 and S2

terminals on the external terminal block. Test functionality.

The recommended fire alarm signal wire size is 16AWG to 26AWG for a solid wire, or

16AWG to 22AWG for a stranded wire. This function is used for test purposes and

verification.

K.

Ducting for use with Typical Drop Ceiling - Ducting for both supply and return

including a filter grill with filter will need to be supplied by the installer. All ducting

should be of the insulated type to prevent condensation from forming on the duct and

dripping on or around the installation. All duct should keep an bends to a minimum and

should be the largest radius possible. Make sure that all ducts are properly secured to

maintain proper airflow and integrity of the cooling section. Avoid sharp bends and try

to make air ducts travel in a straight line for best performance.

L.

Insulated supply duct(s)

Filter return air grill with a filter for evaporator air intake

Diffuser(s) for cold air

Duct clamps

1.

2.

3.

4.

The following field supplied items are required:

CAUTION: DO NOT OPERATE UNIT WITHOUT A FILTER INSTALLED IN THE RETURN

AIR FILTER GRILL

Page 9

VI / Installation Checklist

VII / Inspection & Maintenance

Unit Installation -

A.

Check and make sure all screws are tight and unit is secured in place.

Check and make sure inlet/outlet air exhaust are clear without blockage.

Make suer that there is adequate condenser air ventilation.

Check the condensate line and make sure that the connections are secure and that

the line is properly insulated.

1.

2.

3.

4.

Wiring -

B.

Check and make sure the unit is properly connected to the dedicated circuit breaker.

Check and make sure all wiring is properly connected and secured.

Check and make sure ground wire is tightened and secured.

1.

2.

3.

Diffuser and Filter Grill Installation - Check and make sure that all devices for air

distribution and connected properly with no air leaks.

C.

Thermostat - Check and make sure that the 3rd party thermostat is connected

properly to unit and secured to the wall.

D.

Test Operation -

E.

Check operation with wall thermostat - Set wall thermostat to FAN ON or FAN ONLY

mode:

Fan should engage without compressor.

Set I thermostat to FAN AUTO or COOL mode operation. During cool mode

operation check and confirm that cooling is functional the 2 minute safety time

delay.

Abnormal Noise - Check and observe noise during Fan / Cooling operation

1.

2.

Drain - During cooling operation check and observe condensation drip through

normal drainage path.

3.

Air Leakage- Check for air leakage from duct and duct connection.

4.

a.

b.

Cleaning Air Filters - The air filter on the evaporator return grill should be checked at least

once a week for dust buildup. Clean the air filter or replace if needed. If the unit is used in a

abnormally dirty environment, more frequent inspection and/or cleaning may be required. A

dirty air filter will reduce the air output, resulting in a decrease of the cooling capacity of

your KCA / KCW.

Page 10

VIII/ KCA & KCW Troubleshooting Guide

Fault Possible Cause Possible Solution

Unit Does Not Operate

Low or No Cooling

Thermostat Has No Power Check the breaker

Power Interruption The unit has auto restart and

will automatically restart after

a 2 minute safety delay when

power is restored (some 3rd

party thermostats require a

manual reset)

Blockage of Air Duct Check ducting for any

blockages for excessive

bend radius’

EPO N/C Switch Open Check the EPO/Fire alarm

contacts for a N/C condition, install the original

factory jumper and retest

Condenser Blocked Make sure that the

condenser inlets and outlets

are not blocked. Verify that

the condenser intake air is

not overheated due to lack

of ventilation or condenser

heat

Thermostat Malfunction Test thermostat for proper

outputs

Dirty / Blocked Air Filters Clean and/or replace air filter

Excessive Duct Static Evaporator ducting should

not exceed 30’ or equivalents and bend radius should

be larger than twice that of

duct diameter.

High Pressure Switch

Actuated

1. Check condenser fan

motors for operation

2. Check for over heating of

condenser because of

inadequate ducting of

condenser heat

3. After checking 1 & 2 reset

HPS by pressing the reset

button

No Cooling Alarm Sounding

Page 11

Fault Possible Cause Possible Solution

No Cooling Alarm Sounding

Low Pressure Switch

Actuated

Potentially low on refrigerant,

Call a qualified technician

since this is not user

serviceable

Condensate Pump Overflow Check to make sure

condensate line is not kinked

or obstructed. If alarm still

sounds after checking line

for restrictions, call a

qualified technician

Revision 071916

Loading...

Loading...