Kwik Lok 086AS Installation Manual

086ASP 09 08

INSTRUCTION

MANUAL

TYPE 086AS

MODEL P

BAG CLOSER

& PRINTER

for the

SEMI - AUTOMATIC

TYPE SERIAL NO.

MODEL

EXECUTIVE OFFICE P.O. BOX 9548 YAKIMA, WA. 98909

TELEPHONE: 1-800-688-5945 or (509) 248-4770

FAX: (509) 457-6531

Internet: www.kwiklok.com

CORPORATION

®

®

TYPE086AS

MODEL P CLOSER

TABLE OF CONTENTS

I SPECIFICATIONS.................................. 1.1 - 1.2

II OPERATION........................................... 2.1 - 2.3

III ADJUSTMENTS......................................3.1 - 3.14

IV TROUBLESHOOTING.............................4.1 - 4.5

V PARTS IDENTIFICATION....................... 5.1 - 5.11

VI WIRING........................................................6.1

APPENDIX..................................................A - F

SECTION HEADING PAGE

GENERAL SAFETY INFORMATION

Be sure the following safety instructions are read, understood and become a part of daily

practice when operating or maintaining the closer.

1. Do not attempt to operate the closer until you understand its function. Study the manual

carefully.

2. Keep all foreign material away from the drive system.

3. Keep fingers out of the closer and printer and away from any moving parts.

4. The printer cover must be in the closed position before applying power to and operating the

closer / printer. Electrical power should be disconnected from the closer while the printer

cover is open.

5. Disconnect the power cord before making any adjustments or maintenance. Moving the

switch to the “STOP” position does not remove power from many electrical components,

nor does it disable the motor. All adjustments, except as noted, are to be made with

power disconnected.

6. The closer is normally operated from a counter or table. While the closer is very stable

when operated from a flat a solid surface, care should be taken not use it in a way that

could cause it to tip or fall from the operating surface.

®2008 KWIK LOK CORPORATION

Kwik Lok and Striplok are trademarks of Kwik Lok Corporation ® 2008

The shape of the closure is a trademark of Kwik Lok Corporation ® 2008

086ASP 08 08

SECTION I

Specifications

P 1.1

086ASP 11 02

THE TYPE 086AS

MODEL P MACHINE

SEMIAUTOMATICALLY CLOSES

PLASTIC BAGS

WITH THE STRIPLOK® CLOSURE

AND CLOSURE LABEL.

A. The closing machine designated Type 086AS:

Model 200P uses RL and SL series closures.

Model 300P uses L series closure labels.

Model 400P uses U series closure labels.

Model 500P uses CR series closure labels.

B. The system will close a wide range of product

size variations. The Striplok closures are available

in many closure opening sizes to accommodate a

large number of variations in bag width and film

material thickness.

Upon request and upon receipt of sample bags,

the factory will gladly recommend the proper

closure opening sizes. Use the bag length formula

found in the appendix of this manual to help

determine the proper bag length needed.

C. A suggested spare parts inventory is listed in the

appendix. To save valuable time, it is recommended that an adequate supply of these parts be kept

on hand for needed repairs.

The following is a description of available printer kits, descriptions and their

respective Kwik Lok Kit numbers.

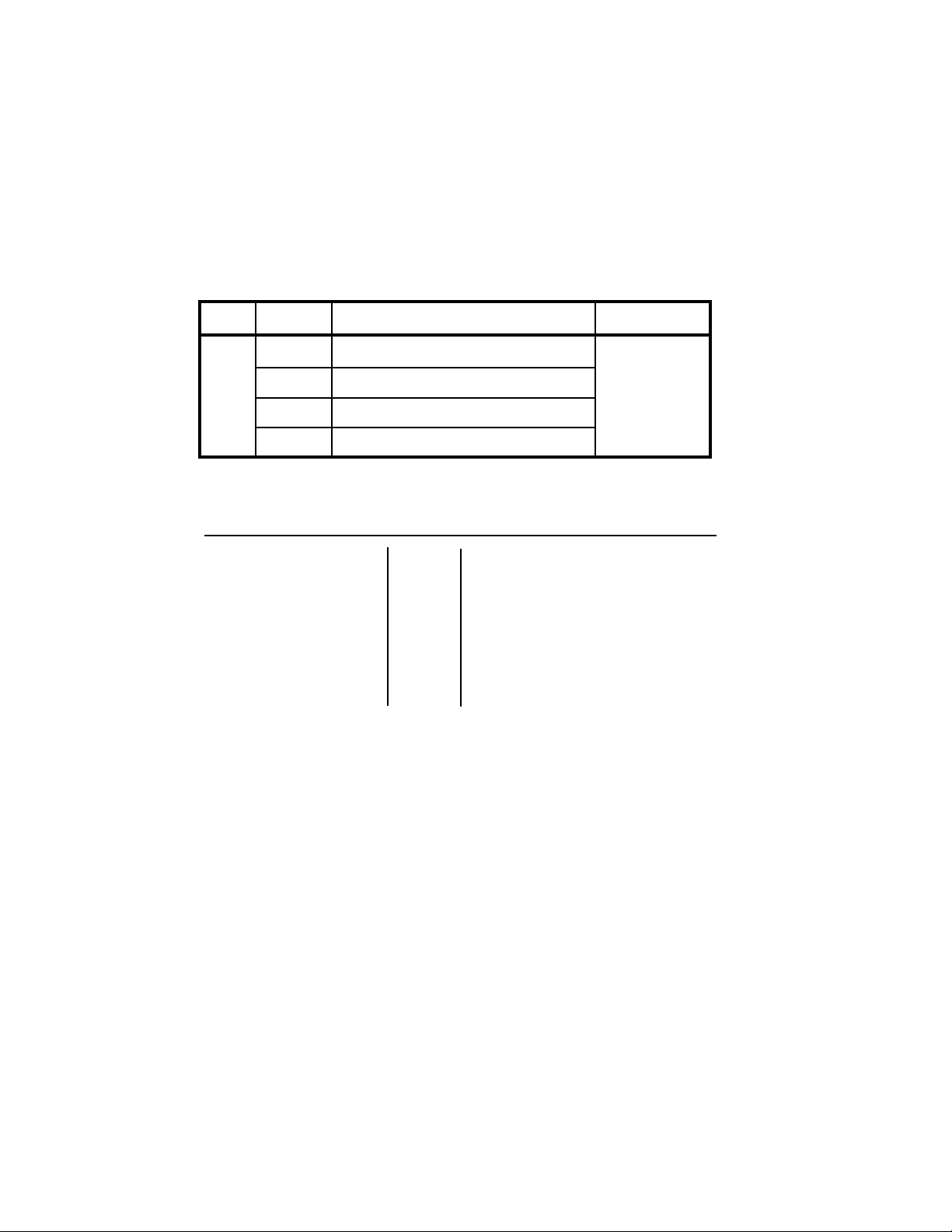

PRINTER KIT NUMBER MODEL PRINTER TYPE (DESCRIPTION)

Z0086017 PB Band printer - Non European

Z0086018 PC Band printer - European

Z0086019 PD Block printer - Non European

Z0086020 PE Block printer - European

SECTION I

Specifications

P 1.2

086AS MODEL P SEMI-AUTOMATIC BAG CLOSING

MACHINE SPECIFICATIONS

086ASP 11 02

TYPE

MODEL

CLOSURE

086AS

RL and SL (or R and S unprinted)

200P

L Labels (medium and heavy duty)

300P

U Labels (medium and heavy duty)

400P

CR Labels (medium and heavy duty)

500P

Up to

30 Bags/Min.

SPEED

1. The 086AS Model P prints on closures or closure

labels as defined in the chart above. It uses a type

band printhead or a block with grooved rubber type.

Contact your distributor or Kwik Lok Corporation for

printing supplies.

2. The 086AS Model P semiautomatic closer comes

standard with mounted rubber feet. Optional suction

cup feet are available.

3. The 086AS Model P is available for use with the

following electrical power:

115VAC, 60 Hz, 1 amp, single phase

220 - 240VAC, 50 Hz, 0.38 amp, single phase

SECTION II

Operation

P 2.1

086ASP 09 08

A. OPERATING SEQUENCE:

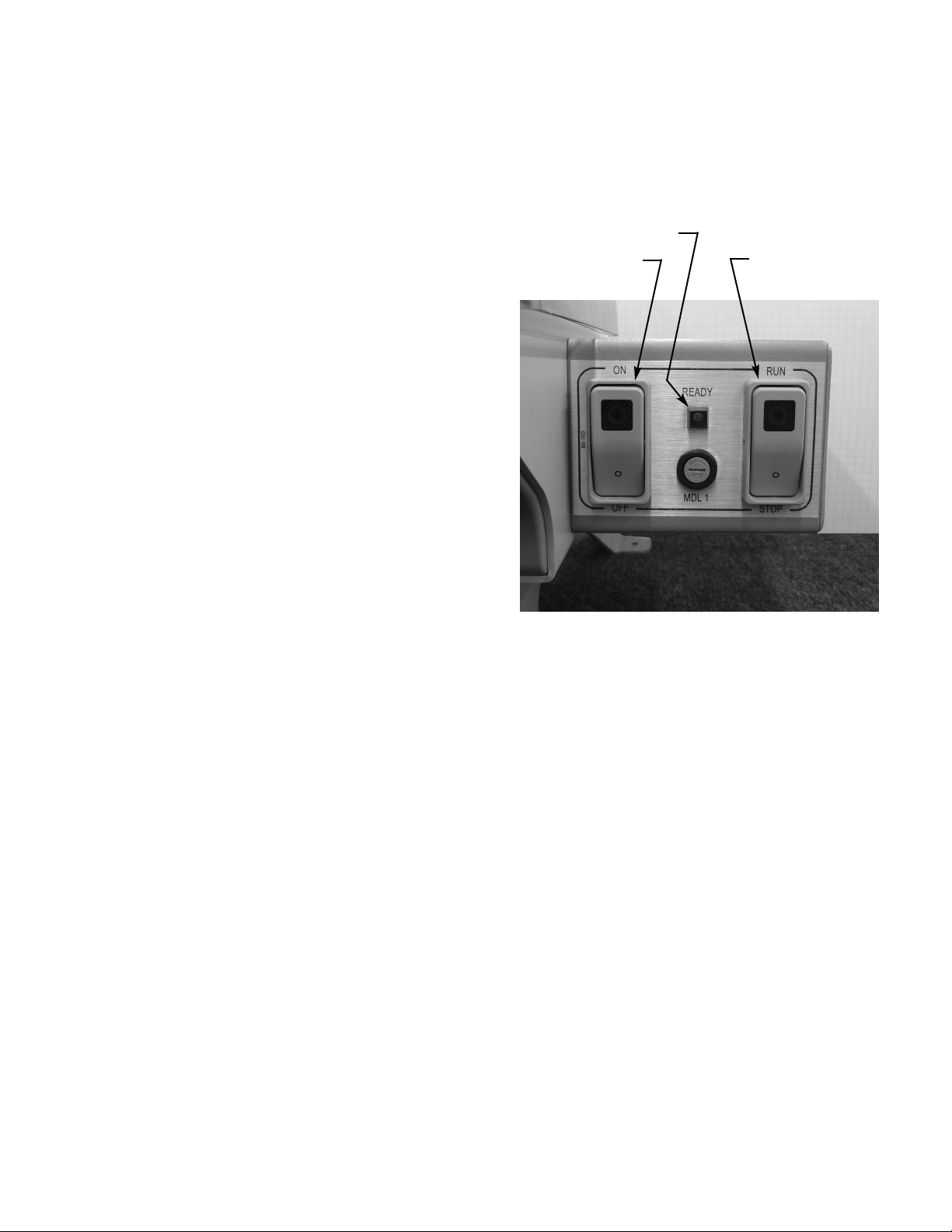

(Figure 2.1)

The closer is ready to run when the closure is in

closing position, the power switch is in the ”ON”

position, and the ”READY” light is on. When the

closed bag and closure are removed from the

closure track, the machine completes the closing

cycle placing the next closure in closing position.

The machine is again ready for the next bag.

During the completion of the closing cycle the

”READY” light will go off momentarily.

If no closure is available to move into the closing

position, the machine will continue to cycle and the

”READY light will flash repeatedly until the run

switch is turned to the ”STOP” position.

THE PRINTER COVER MUST ALWAYS BE IN THE

CLOSED POSITION WHEN OPERATING THE

CLOSER.

The power switch and light must be off to cut

off power to the two sensor switches. Utilizing

the power switch instead of the run switch may

result in the machine not stopping in the neutral

position as required for loading the closure

strip. Use the power switch when clearing the

machine of debris or preforming minor service

work.

1. Plug in the closer.

2. Press the power switch to ”ON”.

3. Slide the closure strip into the closure track until

the strip stops (refer to part B in this section).

4. Press the run switch to ”RUN”. A closure will

move into the closing position, if one is not

already there, and the ”READY” light goes on

indicating the the closer is ready to close.

5. Close the bag and remove it from the closer

(refer to part E in this section).

6. The closer cycles to print a closure and position

a new closure into the closing position, ready

for the next bag. The ”READY” light will go off

momentarily as the closure is loading.

7. If no closure is available to move into the

closing position, the machine will cycle and the

”READY” light will flash on and off repeatedly

until the run switch is pressed to ”STOP”. The

machine will then cycle back to neutral and

stop. The machine at this point is again ready

to close.

Figure 2.1

Power switch

Ready light

Run switch

SECTION II

Operation

P 2.2

B. LOADING A ROLL OF CLOSURES:

1. Cycle the closer until the closures stop

advancing. Avoid cycling the closer more than

necessary when there is no closure in the

closing position. This will avoid a buildup of ink

residue on the closure track.

2. Move the run switch to “STOP” so the

mechanism is properly positioned.

3. When closing with closures, insert the closure

hub into a new roll of closures. Be certain the

closures feed forward from the bottom of the

roll.

When closing with labels, insert the closure

hub so that the label of the closure is right

side up when the closure strip is in the closure

track.

4. Install the hub and roll.

5. Open the printer cover and check to see if there

is any ink residue on the bottom of the closure

track within the printing area. Use a soft cloth

or tissure to wipe any ink off the closure track

so the ink will not smear on the underside of

the closure.

6. Remove the masking tape and feed the end of

the strip into the closure track until the first

closure has passed the check and is against

the stop. Close the printer cover.

7. With the Power switch in the ”ON” position,

press the run switch to “RUN”. The closer will

cycle once and move a closure into the closing

position. Remove the first three unprinted

closures by hand The closer is now ready to

close bags.

C. PREPARING THE PRINTER:

1. Open the printer cover.

2. Select the print image.

a. For the band printer, rotate the top of the print-

head toward the front of the closer so the

selected type characters can be easily viewed

through the window on the top of the print head.

Slide the selector knob out to select the desired

band and rotate the knob to select the desired

character. When finished rotate the bandhead

back against the spacer (item 7, Figure 5.3).

b. For the typeholder block, remove the locking

knob (item 14, Figure 5.4) and slide the printer

block off the shaft and spring pin. Place the

selected type in the grooves that are the farthest

away from the holes in the mounting block. For

normal viewing on the closure the bottom edge

of the characters should be toward the middle of

the block. Center the type from side to side.

Replace the block on the shaft and pin so the

type is close to the ink roll arm. If the type or

typeholder block is not installed correctly, the

type will not be inked properly.

3. Unscrew the ink roll knob and position the ink

roll between the knob and the cam follower

(item 3, Figure 5.3).

4. Mate the ink roll to the end of the cam follower

and screw in the knob to secure it. Under most

conditions the ink roll can be left on the printer

until the ink is used up. The ink roll will not dry

out.

5. Close the printer cover.

6. Cycle the printer and discard the unprinted

closures.

086ASP 09 08

SECTION II

Operation

P 2.3

D. ADJUSTING THE PRINT FORCE:

DO NOT USE EXCESSIVE PRINT FORCE TO

COMPENSATE FOR PRINTING IMPERFECTIONS.

The operator can adjust the print force.

Always operate the printer with the minimum print

force that will produce acceptable printing. A quarter

turn of the knob is a large adjustment. If a

significant change in print quality is not noticed,

return to the previous setting and refer to Section III

Adjustments and Section IV Trouble Shooting to

correct any problems.

When the ink roll will no longer adequately ink the

type, replace it. Do not attempt to extend the life of

the ink roll by increasing the printing force.

To increase the print force, turn the knob (item 23,

Figure 5.3 or item 19, Figure 5.4) counterclockwise.

If the effort to turn the knob suddenly decreases, the

maximum print force has been reached.

To decrease the print force, turn the knob clockwise.

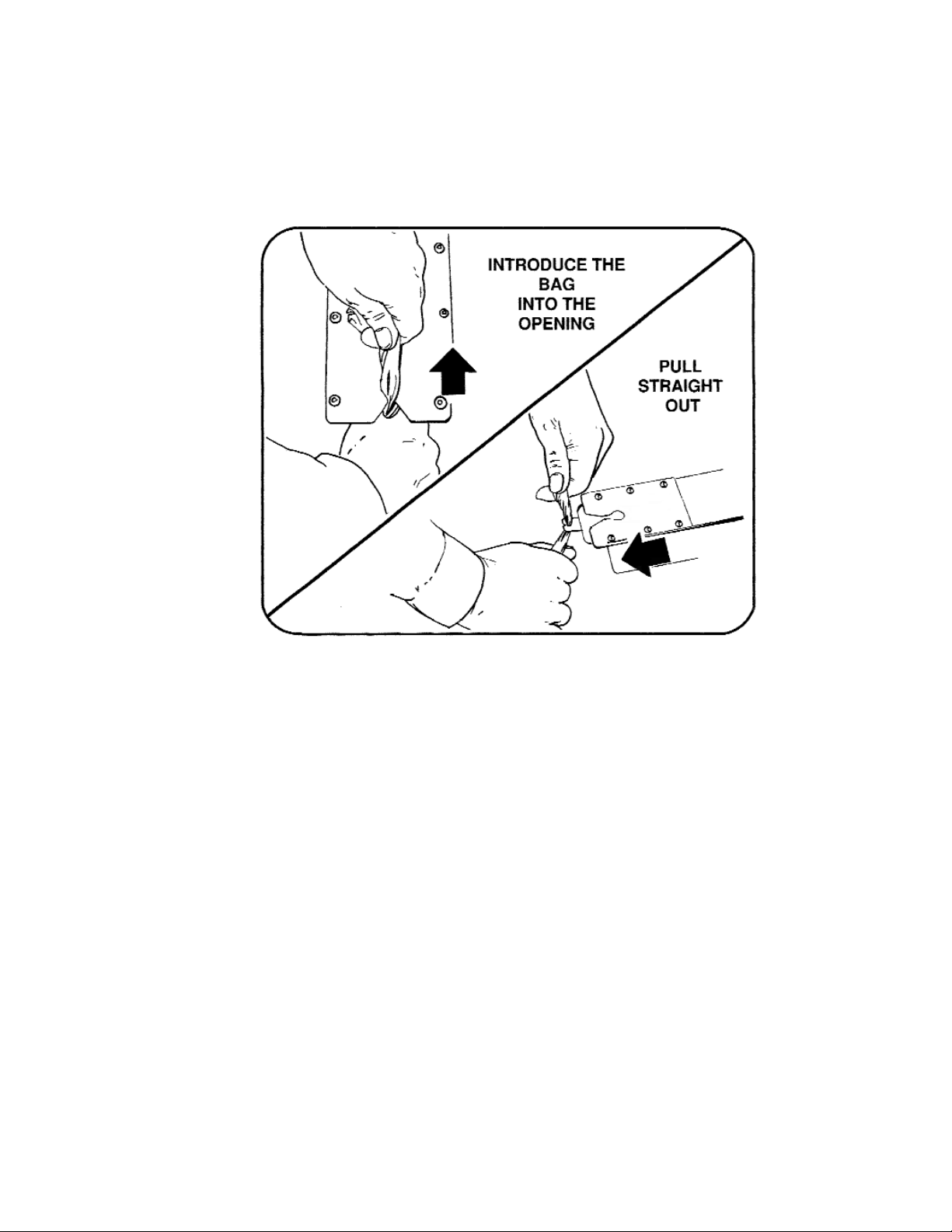

E. CLOSING BAGS:

(Figure 2.1)

1. Grasp the bag as shown. Spin the bag to twist

the bag neck. Twisting the bag helps the

material to enter the closure smoothly.

2. The lower hand should form a “V” to trap all of

the bag material. This helps to completely

insert the bag material into the closure opening.

3. Do not jam the bag material straight into the

closure opening. The top hand should lead the

bottom hand. Follow up with the lower hand

until all of the bag neck is in the closure. A tight

package is accomplished by holding the

contents of the bag snugly up against the

underside of the closure track.

4. Remove the closed bag with a horizontal

motion.

086ASP 09 08

Figure 2.2

P 3.1

SECTION III

Adjustments

086ASP 09 08

THE FOLLOWING ADJUSTMENTS ARE TO BE

PERFORMED WITH THE CLOSER ELECTRICAL

POWER DISCONNECTED.

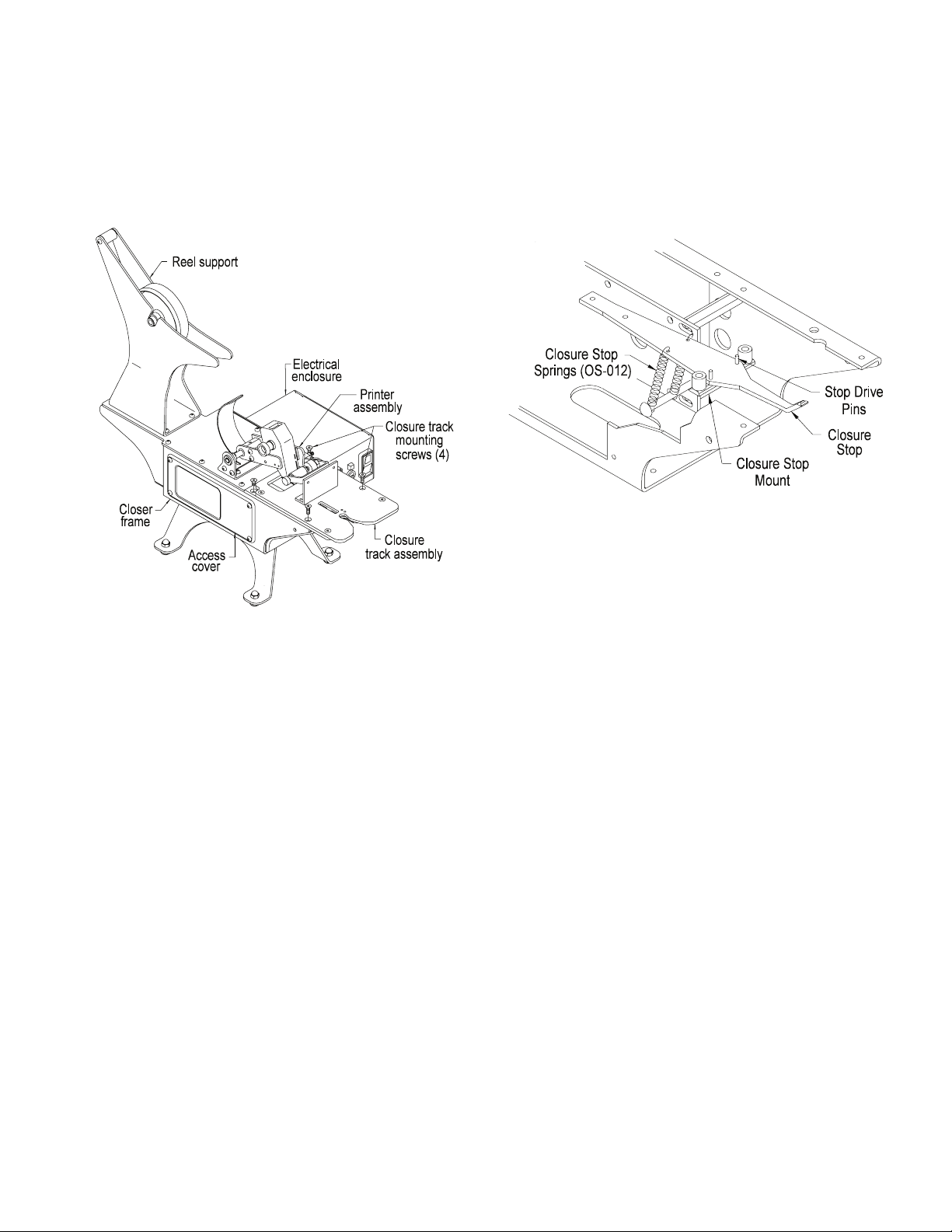

A. CLOSURE TRACK ASSEMBLY REMOVAL:

Some of the adjustments described in this section

require removal of the closure track assembly.

1. Remove the side access cover (Figure 3.1).

2. Disconnect the two gold colored closure stop

springs (OS-012) from the lower spring anchor

screw (Figure 3.2). When the springs are

reattached be careful not to stretch them.

3. Disconnect the silver colored spring (0S-006)

from the ink roll arm (items 2, and 20, Figure

5.3).

4. Disconnect the printer link (item 5, Figure 5.5)

from the printer assembly at the pivot mount

(item 35, Figure 5.4)

5. Remove the four flat head mounting screws

which attach the closure track assembly to the

closer main frame. Note that the closure track

assembly can be removed from the closer with

out removing the ink roll assembly or the printer

cover from the closure track.

When remounting the track assembly, tighten

the four mounting screws evenly.

6. Lift the closure track assembly slightly and

depress the tip of the pick to disengage it from

the closure track.

7. Raise the closure track assembly slightly off the

frame and disconnect the two wire leads from

the sensor lever limit switch.

To remount the closure track assembly, reverse the

above procedure. Before closing the access cover,

check to see that there are no pinched wires or

wires routed close to moving parts.

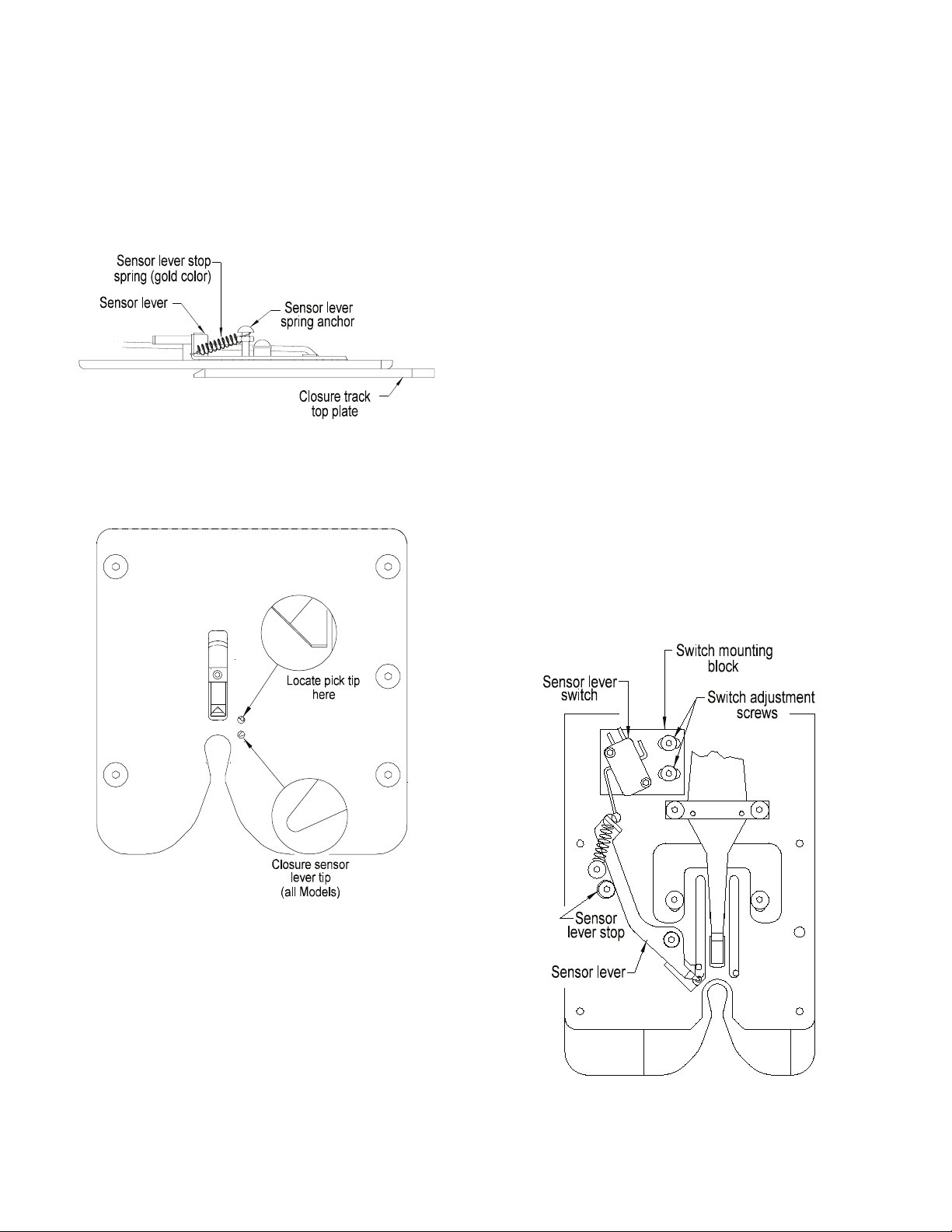

Figure 3.2

Figure 3.1

P 3.2

SECTION III

Adjustments

086ASP 09 08

B. TOP CLOSURE TRACK REMOVAL:

The top of the closure track can be removed

from the closer while the closure track assembly

remains attached to the closer mainframe. This can

be done to expose the slot that the closures move

through. The closure track can be inspected and

cleaned if needed (Figure 3.1).

1. Disconnect the 0S-006 spring (silver colored)

from the ink roll arm (items 2 & 20, Figure 5.3)

2. Remove the front six flat head screws from the

track top. Note the different screw lengths upon

removal

3. Remove the top of the closure track from the

rest of the lok track assembly.

C. REMOVE THE FRONT SHEILD:

Some of the adjustmeants described in this section

require removal of the front sheild.

DISCONNECT POWER.

1. Remove the side access cover from the closer

frame.

2. Remove the two self tapping phillips screws

(P23-00291) used to fasten the sides of the

sheild from the closer frame

3. Loosen (turn closckwise) the two sheild

mounting screws at the bottom of the closer

frame.

4. Press lightly from the inside of the closer frame

on the backside of the sheild to remove it.

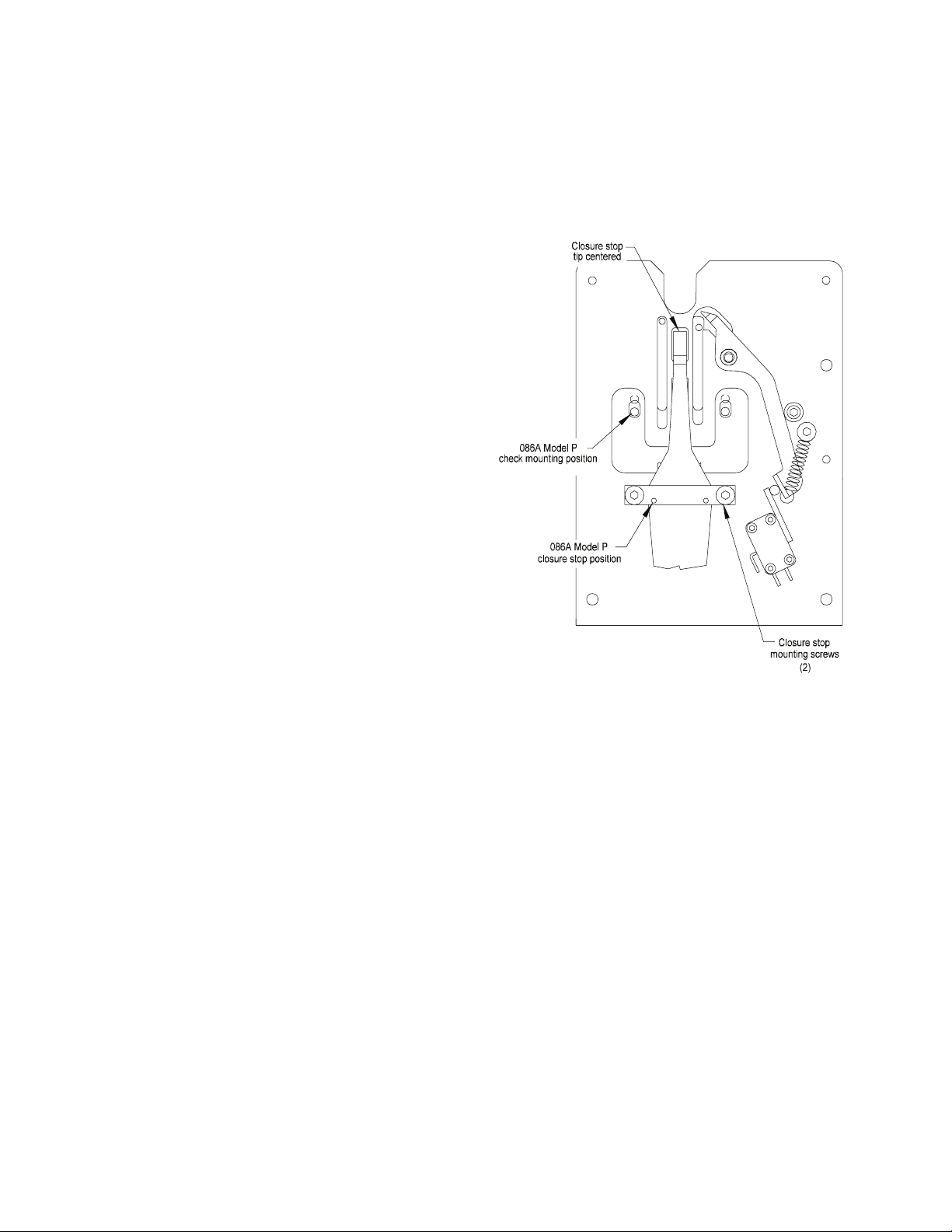

D. CHECK POSITION:

The check stops the closure strip from moving

backward while the pick retracts.

Refer to Figure 3.3 to further understand the check

mounting position. For this adjustment the closure

track must be removed from the closer.

For these models, the check is mounted in the back

mounting holes (farthest from the front of the

closure track).

1. With the check mounted in the correct holes,

and the mounting screws loose, slide the check

forward toward the front of the closure track to

the end of the mounting slots.

2. Tighten the mounting screws.

Figure 3.3

(Closure track assembly as viewed from the underside).

P 3.3

SECTION III

Adjustments

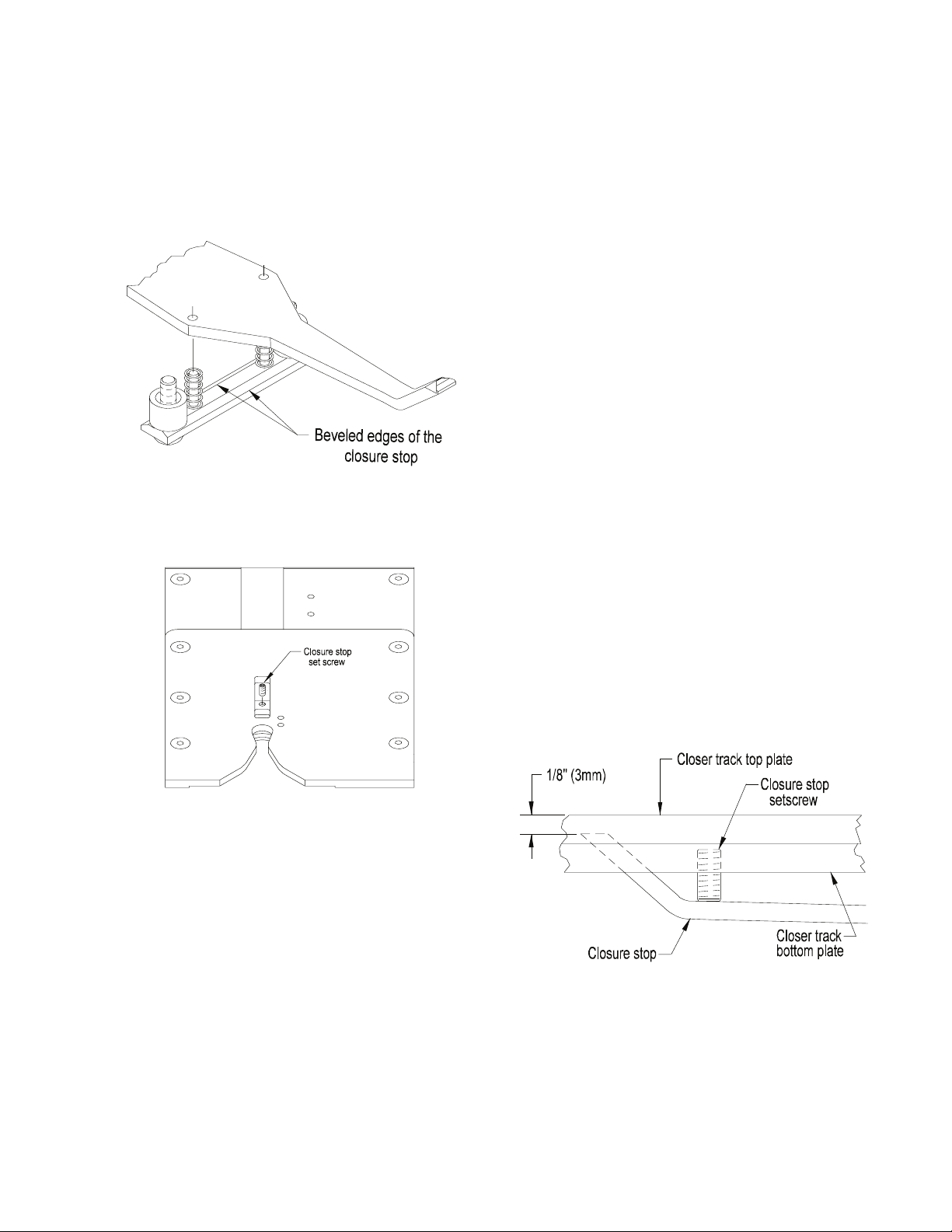

2. Be sure the beveled edges of the mount are

against the closure stop (Figure 3.4).

The closure stop tip must be centered in the slot

located in the closure track for it.

3. Slightly loosen the stop mount mounting screws.

4. Move the closure stop tip side to side until it is

centered in the slot.

5. Tighten the mounting screws.

6. Turn the closure track assembly over so it is

right side up in your hands. Again check the

position of the closure stop tip as this is the way

the closure track is oriented during operation.

Readjust if needed.

Figure 3.5

Figure 3.4

Figure 3.6

086ASP 09 08

E. CLOSURE STOP POSITION:

The end closure is separated from the closure strip

when the closure stop limits the travel of the second

closure in the strip while the pick continues to

advance the first closure.

As with the position of the check, the closure

stop mount is located in a specific way depending

on the closer model being adjusted.

1. The stop mount is mounted as shown (Figure

3.3).

P 3.4

SECTION III

Adjustments

086ASP 09 08

F. CLOSURE STOP SETSCREW ADJUSTMENT:

When properly adjusted, the closure stop set screw

sets the height of the stop. As the closure strip

advances, the second closure in the strip is stopped.

The leading closure continues to move forward and

is then seperated from the closure strip.

1. Remove any closures from the track.

2. Locate the top of the setscrew (Figure 3.5).

3. Turn the setscrew in or out to lower or raise the

tip of the stop until it is 1/8” (3mm) below the top

of the track top plate (Figure 3.6). If the tip of

the stop will not raise as the setscrew is turned

out, the stop may be bowed. If so the stop

must be removed from the machine and the part

straightened. Use thread locking compound to

secure the setscrew.

Figure 3.7

Figure 3.8

Figure 3.9

Closure track assembly as viewed from the underside.

P 3.5

SECTION III

Adjustments

G. SENSOR LEVER SPRING:

The sensor lever spring is designed to apply force

to the sensor lever tip against the side of the

closure, as well as upward against the underside of

the closure track. For the spring to operate

correctly, it must be mounted as shown in Figure

3.7.

H. SENSOR LEVER STOP ADJUSTMENT:

(Figures 3.8 & 3.9)

The sensor lever stop is a bushing which limits the

travel of the sensor lever when no closures are

present. The bushing is secured under a 10-32

button head screw. There is clearance between the

two, so the position of the bushing can vary. When

no closures are present, the sensor lever tip should

be centered below the inspection hole in the top

track (Figure 3.8).

1. Loosen the mounting screw and move the

bushing as needed.

2. Retighten the mounting screw.

I. SENSOR SWITCH ADJUSTMENT:

The sensor switch detects whether or not there is a

closure in the closing position. When a closure

moves into the closing position, the sensor switch

stops the motor at the end of the cycle. When the

closure is removed, the switch starts the motor.

The switch should turn on and off midway between

the positions of the sensor lever when it is resting

against the sensor lever stop and when it is resting

against the side of a closure.

1. Check to see if the sensor lever stop is adjusted

correctly (part H above).

2. Turn the closure track upside down.

3. Feed a short strip of closures (4 or 5) through

the track until the leading edge of the first

closure just slides past the sensor lever then

back out until the closure is free of the sensor

lever. Continue to slide the strip back and forth

while listening for an audible “click” indicating

that the switch is turning on and off. If the strip

of closures moves forward so far that it can’t

back up, push it out of the front of the track

and start over. Adjust if needed as follows.

4. Slightly loosen the two button head screws in

the switch mounting block (Figure 3.9).

5. Move the switch and mounting block toward or

away from the sensor lever. Listen for an

audible ”click” of the switch as it turns on and

off.

6. Tighten the mounting screws when the switch

actuates as described above.

Figure 3.10

086ASP 09 08

P 3.6

SECTION III

Adjustments

086ASP 09 08

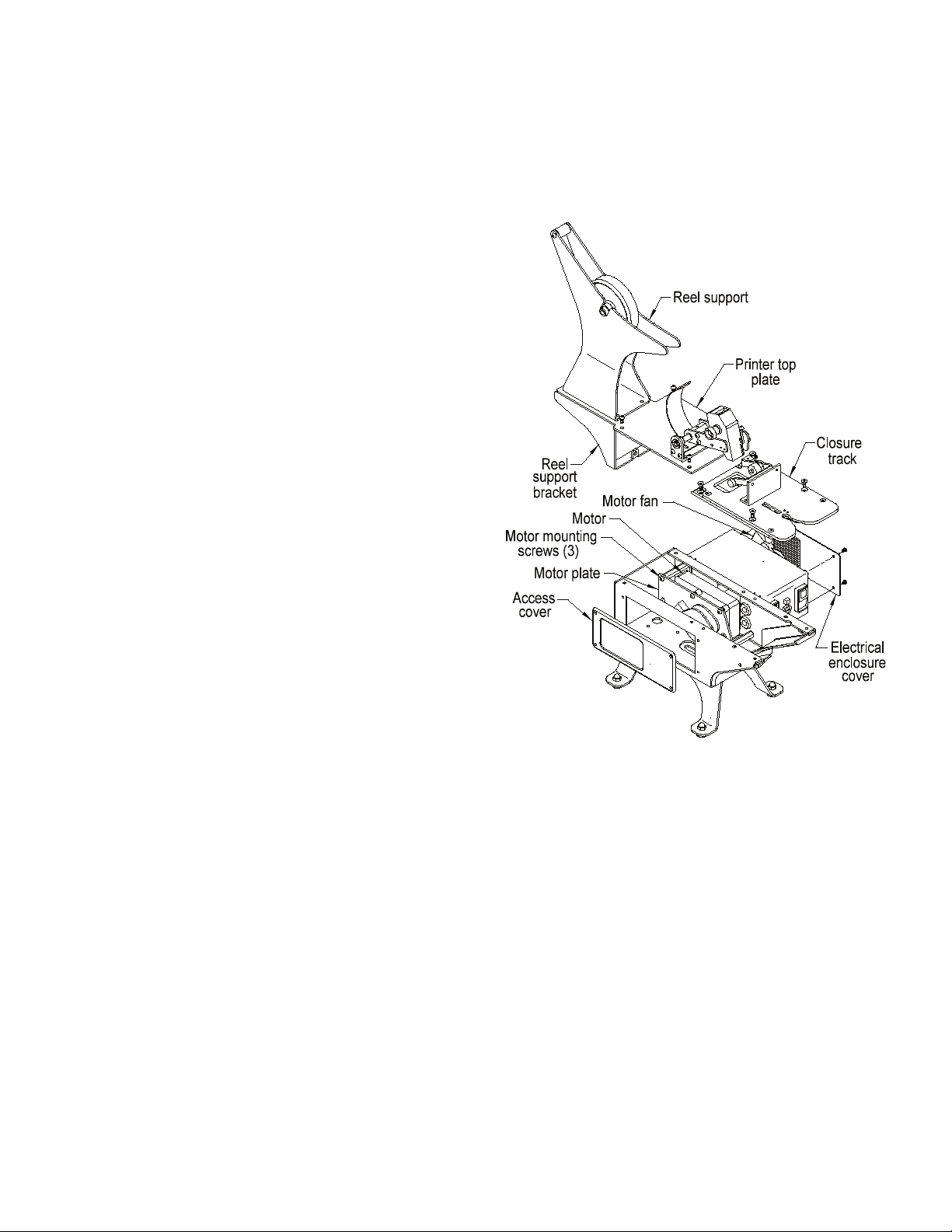

J. MOTOR REMOVAL:

(Figure 3.10)

Any time the three button head screws located in

the slots of the motor mounting plate are disturbed,

the pick position must be checked. See part K this

section.

The motor, motor mounting plate, cam assembly,

cam switch block, printer cam arm and limit switch

can be removed and reinstalled as an assembly.

Component adjustment to this assembly can be

made while the assembly is out of the frame of the

closer. Remove the motor assembly as follows:

1. Disconnect power to the closer.

2. Disconnect the 0S-006 spring (silver colored)

from the ink roll arm.

3. Remove the pivot mount from the printer link.

4. Remove the screw connecting the reel support

bracket to the back of the closer frame.

5. Remove the four mounting screws used to

fasten the printer top plate to the closer main

frame. Lift off the reel support bracket, reel

support, top plate and printer mechanism from

the mainframe.

6. Remove the side access cover.

7. Disconnect the pick spring (0S-117) from the

pick.

8. Remove the electrical enclosure cover.

9. Carefully remove the fan from the motor shaft.

Note the clamp on the inside of the fan. When

the fan is reinstalled be sure to press the fan

onto the motor shaft clamp side first. The end

of the motor shaft should extend 1/16” to 1/8”

(1.6mm-3.2mm) beyond the hub of the fan.

10. Disconnect the motor wires.

11. Disconnect the cam switch electrical leads.

12. Remove the three mounting screws from the

slotted holes in the motor mounting plate.

Refer to part K this section for readjustment of

the pick.

13. Remove the motor assembly through the top of

the closer frame.

14. To reinstall the motor assembly reverse these

steps.

Figure 3.11

P 3.7

SECTION III

Adjustments

K. PICK / CLOSURE LOCATION:

The pick advances the closure strip and locates the

leading closure in the bag closing position. To

verify whether the pick stops in the correct position,

check and adjust as follows:

1. Remove any closures from the closure track.

2. Verify that the pick is at the end of its travel. To

do this plug in the closer. Turn the rocker

switch to “RUN” and then to “STOP”. The

motor will stop with the cam and pick in their

proper ”parked” positions.

3. With the motor stopped, disconnect the power

cord.

4. The tip of the pick should be visible in half of

the inspection hole as shown (Figure 3.8).

Reposition the pick if needed as follows:

BE SURE THE POWER IS DISCONNECTED.

5. Remove the side access cover.

6. Loosen the three button head screws mounted

in the slots at the corners of the motor

mounting plate.

7. Slide the motor assembly until the pick is in the

proper position when viewed through the

inspection hole (Figure 3.8).

8. Tighten the mounting screws and again check

the pick position. Reattach the access cover.

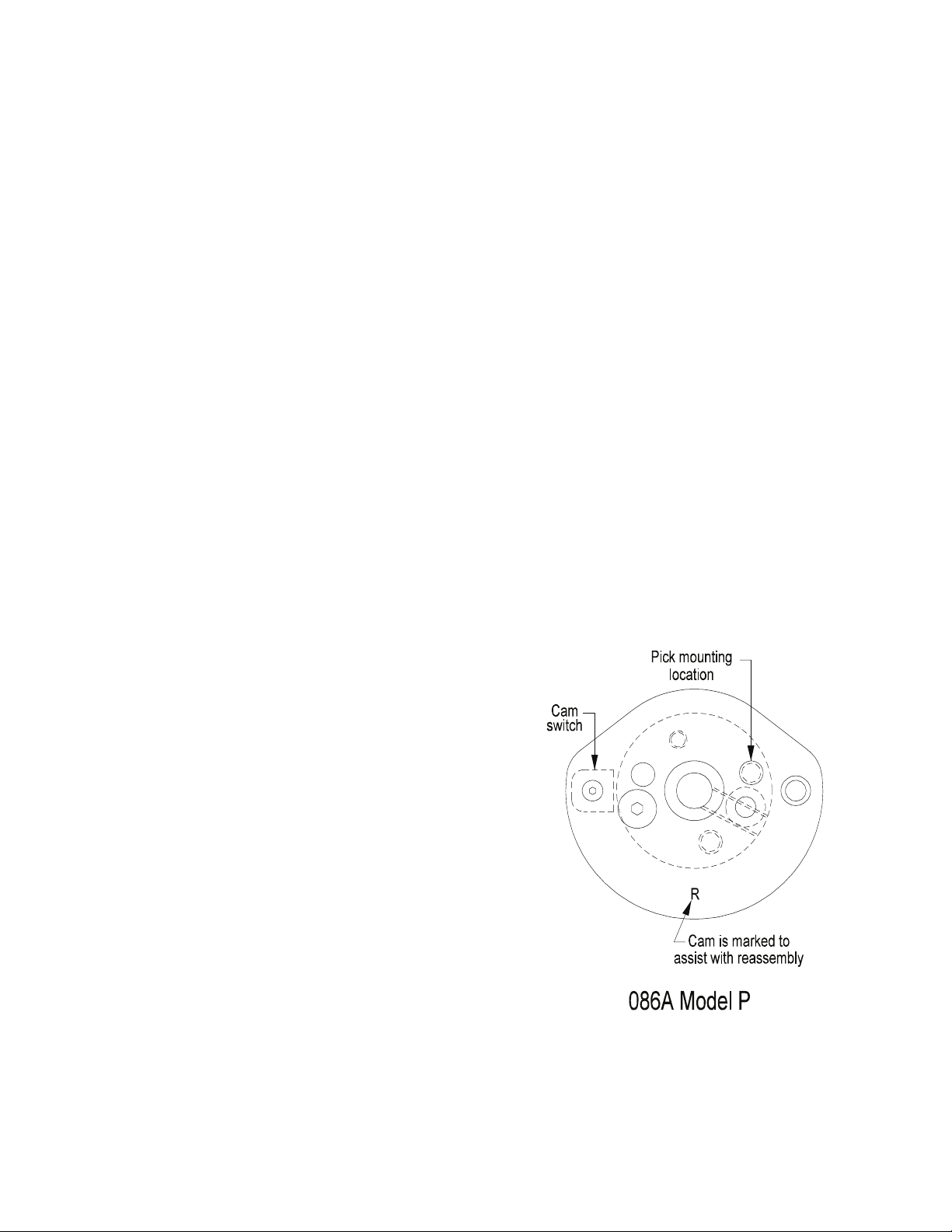

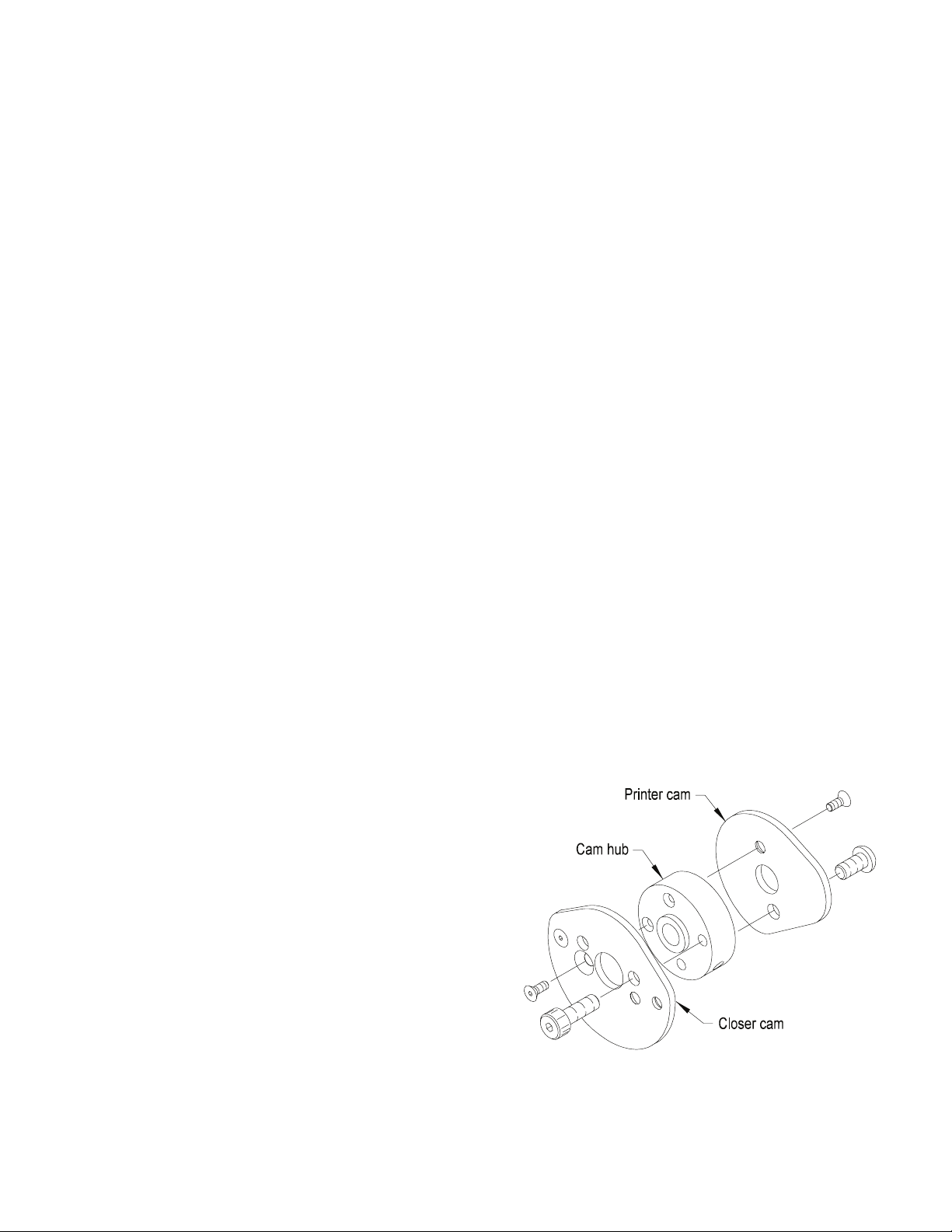

L. CAM ASSEMBLY:

The closer cam drives the pick through its cycle

and raises the closure stop at the proper time

to stop the closure strip so the leading closure

can be separated from the remaining strip. The

printer cam operates the printer mechanism. The

closer cam and the printer cam fasten to either side

of the cam hub. Additionally the switch cam

contacts the cam switch which stops the motor and

cam assembly when the pick is in the parked or

neutral position (Figure 3.13). The cam assembly

should remain on the motor shaft with no need for

adjustment. If however the cam assembly is

disassembled, the following information is helpful to

reassemble it.

The two cams and hub can only be assembled

correctly one way. It may be helpful to mark the

cams to the hub prior to removing the cams from

the hub.

The hub is designed with a shoulder on either side

at the center. One shoulder is larger than the other.

1. Turn the hub so the small shoulder is face up.

This is the printer cam side. Set the printer

cam onto the hub with the countersunk hole in

the printer cam facing up. Turn the cam on the

hub until one of the two countersunk holes in

the hub align with the countersunk hole of the

printer cam.

2. Fasten the printer cam to the hub with one 8-32

x 3/8 flathead and one 1/4 -20 x 1/2 button

head screw.

086ASP 09 08

Figure 3.12

Loading...

Loading...