Kwikee 2000, 2010, 3000, 3010 Installation Instructions Manual

LEVEL BEST

CONTROL REPLACEMENT

Systems 2000, 2010, 3000, 3010

Installation

Instructions

Kit 906915110

© 04/03 Kwikee Products Co., Inc.

Kwikee #1422271

Before beginning any work, read

these instructions.

Disconnect the chassis battery

before beginning any work on the

Level Best System.

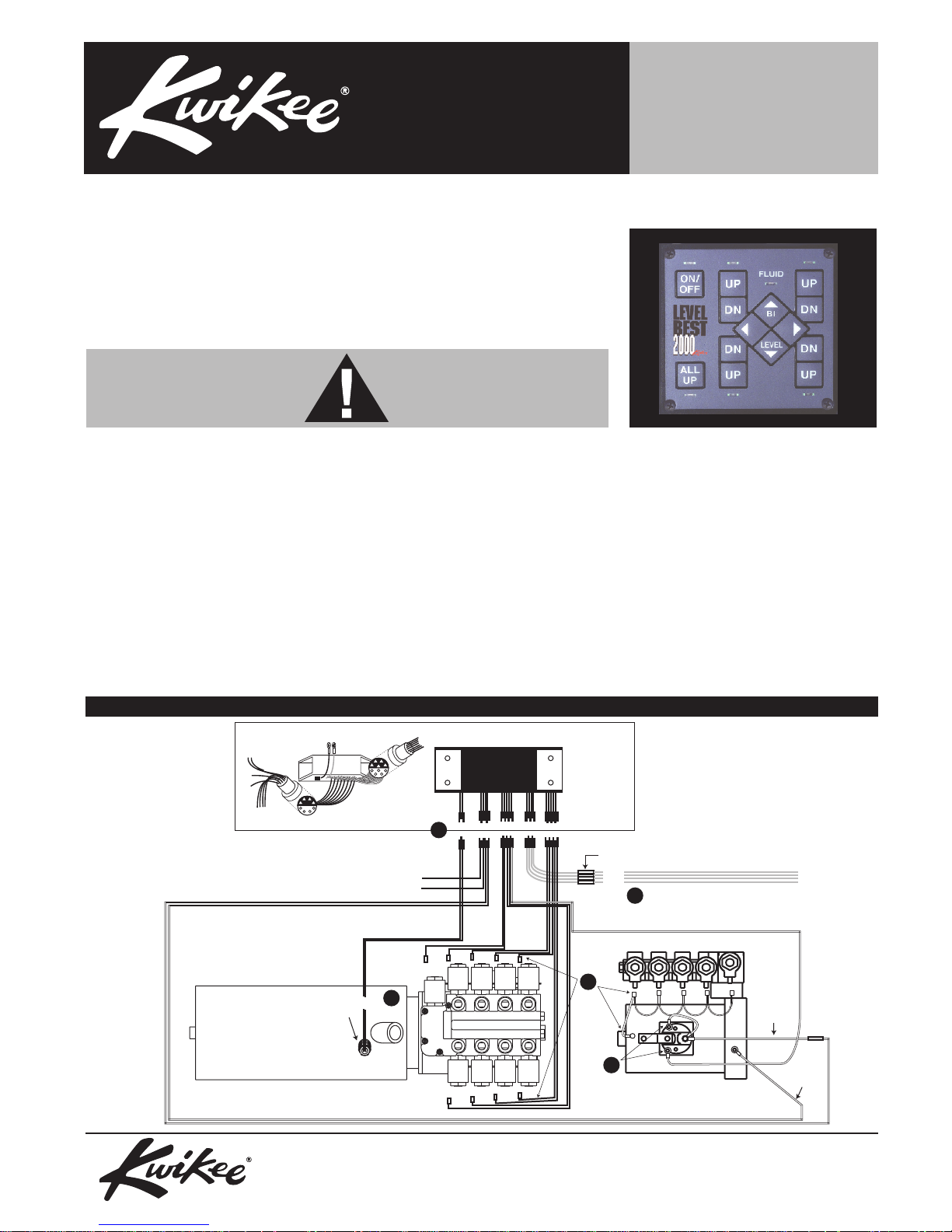

Removing the old control and wiring (Refer to Figure 1 for Steps 1 through 5.)

Disconnect the positive cable from

the battery before beginning any

work.

1. Cut the wires going to the Fluid

Level Sensor approximately 1 to 2

inches from the sensor.

2. Remove the wires attached to the

two small posts on the motor

control solenoid. Leave the battery

cables in place.

FIGURE 1

The control is wired to the pump using one of these two styles of connectors

3. Remove all the spade connectors

from the valve solenoids. One of

the wires forms a daisy chain

connecting each valve together.

Trace this wire back to its

connection point and remove it.

4. Unscrew the hose clamps

connecting the jack motor control

unit to the motor. Pull the control

unit and all of the wires away from

the pump unit.

Level Best

Control Unit

5. Cut the yellow wires that go to

each jack leg from the control unit.

Discard the control unit unless this

is a warranty repair, in which case

you will need to ship it back with

the warranty claim RMA.

To Ignition Activated Circuit (+)

To Park Brake Switch

Fluid level

Sensor

Pump, Reservoir, Manifold

Assembly (top view)

"

1

4

Butt connect to yellow leg reed switch wires

"

5

3

To power

2

Pump Motor & Solenoid

(side view)

© 04/03 Kwikee Products Co., Inc.

Kwikee #1422271

Control

ground

Level Best Constrol Replacement Page 2

Installing the new control

1. Check the condition of the pump

motor solenoid by measuring the

resistance of the primary coil. To do

this place an ohm meter across the

two small posts of the solenoid with

no other wires connected. If the

ohms of the solenoid is lower than

4.3 or higher than 14 ohms, the unit

must be replaced before installing

the new control.

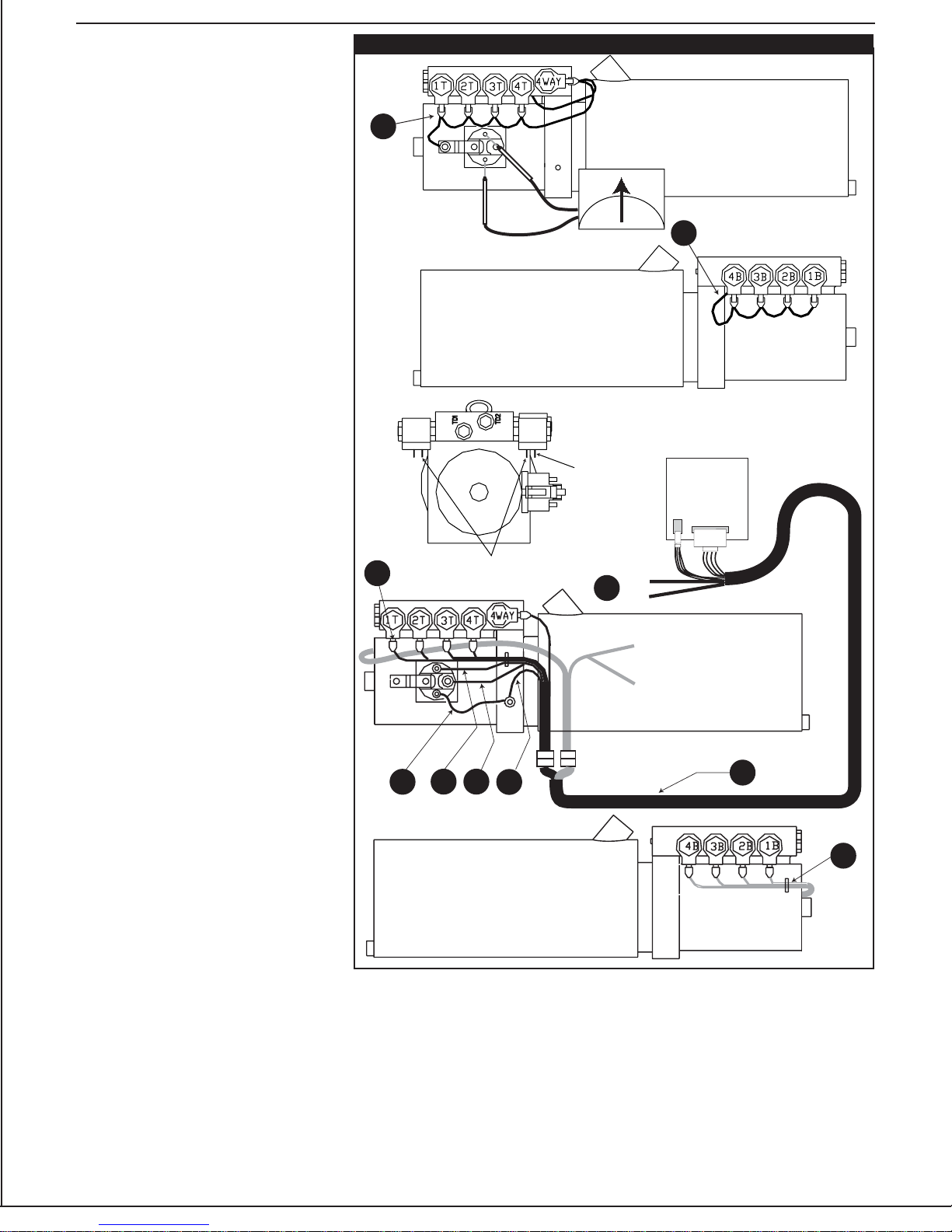

For Steps 2-6 Refer to Figure 2.

2. Install the daisy chain harness. This

harness is identified by its red color,

nine spade connectors and one ring

terminal.

2a. Attach the ring terminal to the

bolt on the motor side of the

solenoid. Then attach the spade

connectors to the inside spade on

the valve solenoids working your

way around the manifold from 1T

through 4T.

2b. Attach the next spade

connector to the 4-way valve

solenoid and pass the remaining

section of the daisy chain across to

the 4B valve solenoid. Attach the

spade connector to 4B through 1B.

3. Attach the wiring harness pigtail to

the pump by attaching the wires

corresponding to the valve markings

on the top of the manifold. Wire TD1

will not be connected at this time.

Wire TD2 is not used at all for this

installation so it can be coiled, tie

wrapped and secured at this time.

FIGURE 2

2a

3

Inside Male Spade

4.3

Outside

Male

Spade

6

14

2b

Back of

Control Unit

PKBK

IGN

TD 1 to Jack leg

position switches

TD 2

3a. Connect the black wire with the

ring lug to the ground bolt on the

side of the pump. On some pumps

this ground lug will be on the back of

the motor and have the black battery

cable connected to it.

3b. Connect the red wire with the

ring lug to the pump solenoid on the

battery cable side of the solenoid.

3c. Connect the white wire labeled

SOL + to one of the empty small

posts on the pump solenoid.

4. Connect the 12" jumper wire

included in the kit between the

remaining small posts on the

solenoid and the ground bolt on the

side of the pump.

5. Install the 16' multi-wire harness.

Route the end with the two

connectors that mate to the control

panel through the firewall and into

the dash area near the control panel

location.

4

6. At the small connector of the multi

wire harness that goes to the

control panel, are yellow, blue and

black wires. The black wire is not

used. Connect the yellow wire to an

ignition source that has 12 volts

when the engine is running.

Connect the blue wire to the park

brake wire. This connection must

show ground when the park brake

3b3c

3a

5

3

is set. In the chassis wiring harness

you will need to identify the park

brake signal wire. The park brake

switch and signal wire will usually

be found on, or near, the park brake

pedal assembly. This wire will show

ground or 12-volts positive when

the park brake is applied, the type

of signal will vary from one type

chassis to another.

Loading...

Loading...