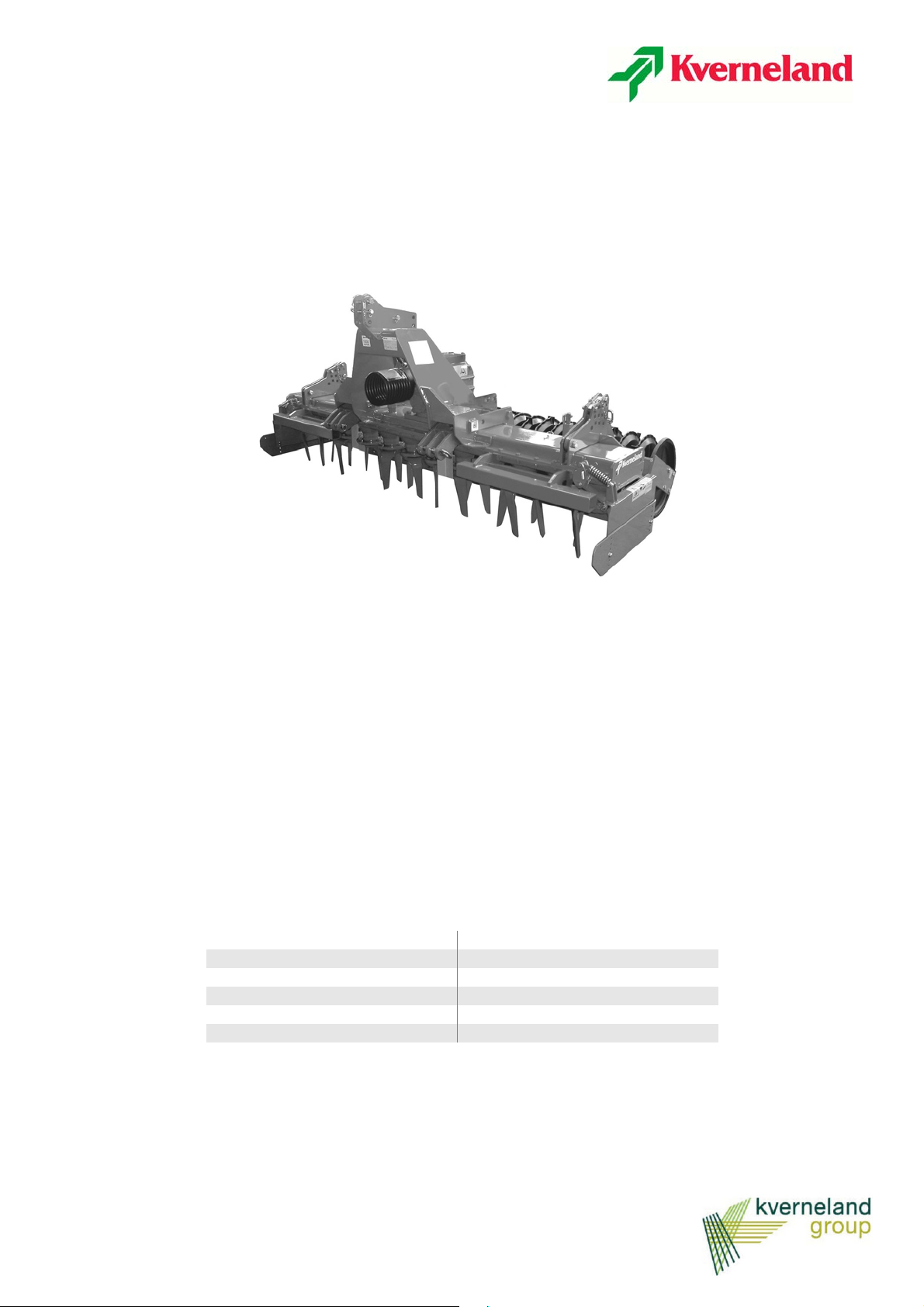

Kverneland NGH 301, NGH 401, NGH 351, NGS 401, NGS 301 Instruction Manual

...

NGH 301-351-401

NGS 301-401-451

Instruction manual

Edition

Print

Language EN

from machine number

Article code

06/2014

06/2014

MUM78EN08

Machine identification

To enable your dealer to help quickly and efficiently, you need to supply certain information about your machine. Use the spaces below to record this information.

Designation

NG............

Serial number

Accessories

Dealer's address

Manufacturer's address

Kverneland Group Modena

Strada Ponte Alto, 74

41100 Modena

ITALIA

Telefono +39 059 380 511

Copyright owned by Kvernel and Gr oup Mode na, I TALY. A ll c opying , tr anscri ption to o ther me dia, t rans latio n and use of extr acts o r par ts is prohibited without the express authorization of Kverneland. All right reserved. The contents of this instruction manual are subject to modifcation without prior notice. We reserve t he right to make technical modifcations.

Contents

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 4

About this manual 4

Meaning of symbols 4

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

For your safety 5

Other regulations to be observed 5

Safety symbols 5

Meanings of the safety symbols 5

Positions of the safety warning labels 7

Sound pressure levels 7

Lifting 8

Getting to know your machine . . . . . . . . . . 9

Intended use 9

Key to parts 9

Technical specifications 10

Delivery and preparation of the

machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Checking the machine 11

Preparation 11

Universal seed drill attachment 32

Hydraulic seed drill attachment 34

Accord seed drill triangular mounting

frame 36

Troubleshooting . . . . . . . . . . . . . . . . . . . . . 37

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Guide to warranty conditions 38

Service information 38

Disposal of the machine . . . . . . . . . . . . . . . 39

EC Declaration of Conformity . . . . . . . . . . 40

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Hitching the machine . . . . . . . . . . . . . . . . . 13

Preparation for work . . . . . . . . . . . . . . . . . 16

Checking the oil levels 16

Working speed 17

Speed selection 18

Transporting the implement on

the road . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Preparations in the field . . . . . . . . . . . . . . . 21

Lateral stone guards 21

Adjusting the working depth 21

Adjustment of the levelling bar 22

Positioning the track eradicator 23

Cleaning, care and storage . . . . . . . . . . . . 24

Safe storage 24

Winter storage 24

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 25

Changing the oil 25

Comparative classification of viscosity 27

Replacing the tines of the harrow 28

Packer roller 29

Disc rollers 30

Accessories . . . . . . . . . . . . . . . . . . . . . . . . 32

3

Introduction

Introduction

Introduction

About this manual

Training

This Instruction Manual is addressed to qualified users or experienced

agricultural operatives who have received suit able tra ining on the use

of the machine.

For your safety

Before hitching up or operating the machine, please familiarise

yourself with the contents of this Instruction Manual. This will ensure

that you achieve optimum results and work in conditions of safe ty.

The manufacturer accepts no liability for any damage or operating

problems caused by failure to adhere to the instructions given in this

manual.

For the employer

All personnel must receive proper training in the use of the machine

(at least once a year) in accordance with the guidelines on safety at

work.

Unauthorized and untrained persons are prohibited from using the

machine.

Your dealer will provide instructions on the operation and care of the

machine.

Meaning of

symbols

NOTE

The following symbols are used in this manual as an aid to

comprehension:

• a bullet point denotes the individual items in a list

> a triangle indicates the operations to be carried out

-->an arrow refers the reader to informa tion in other sections of the

manual

Furthermore, other graphic symbols are used to help the reade r to find

the relative instructions more quickly:

The term "Note" is used to indicate suggestions and notes on use of

the machine.

The wrench symbol denotes suggestions for attachment or

adjustment of the machine.

The warning triangle is used to highlight important safety warnings.

Failure to observe these warnings may result in:

• Serious malfunction of the machine

• Damage to the machine

• Personal injury or accidents

An asterisk indicates examples provided to aid comprehension of the

instructions in the text.

44

Safety

Safety

Safety

For your safety

Other regulations

to be observed

This section contains general safety warnings. The individual sections

of manual contain additional specific safety warnings which are not

included in this section. Take particular care to observe the safety

warnings

• for your own personal safety

• for the safety of other persons and

• to prevent damage to the machine.

Improper use of the machine and other agricultural equipment can

create serious hazards. Always work with maxium care and attention

and never in haste.

The employer should:

At regular intervals and in accordance with legal requirements, ensur e

that all persons working with the machine are informed of these safety

warnings.

Respect regulations

In addition to these warnings, you must also observe:

• accident prevention regulations

• technical rules for safety, occupational health and the highway

code

• the warnings contained in this Instruction Manual

• the instructions for use, maintenance and repair.

Safety symbols

Meanings of the

safety symbols

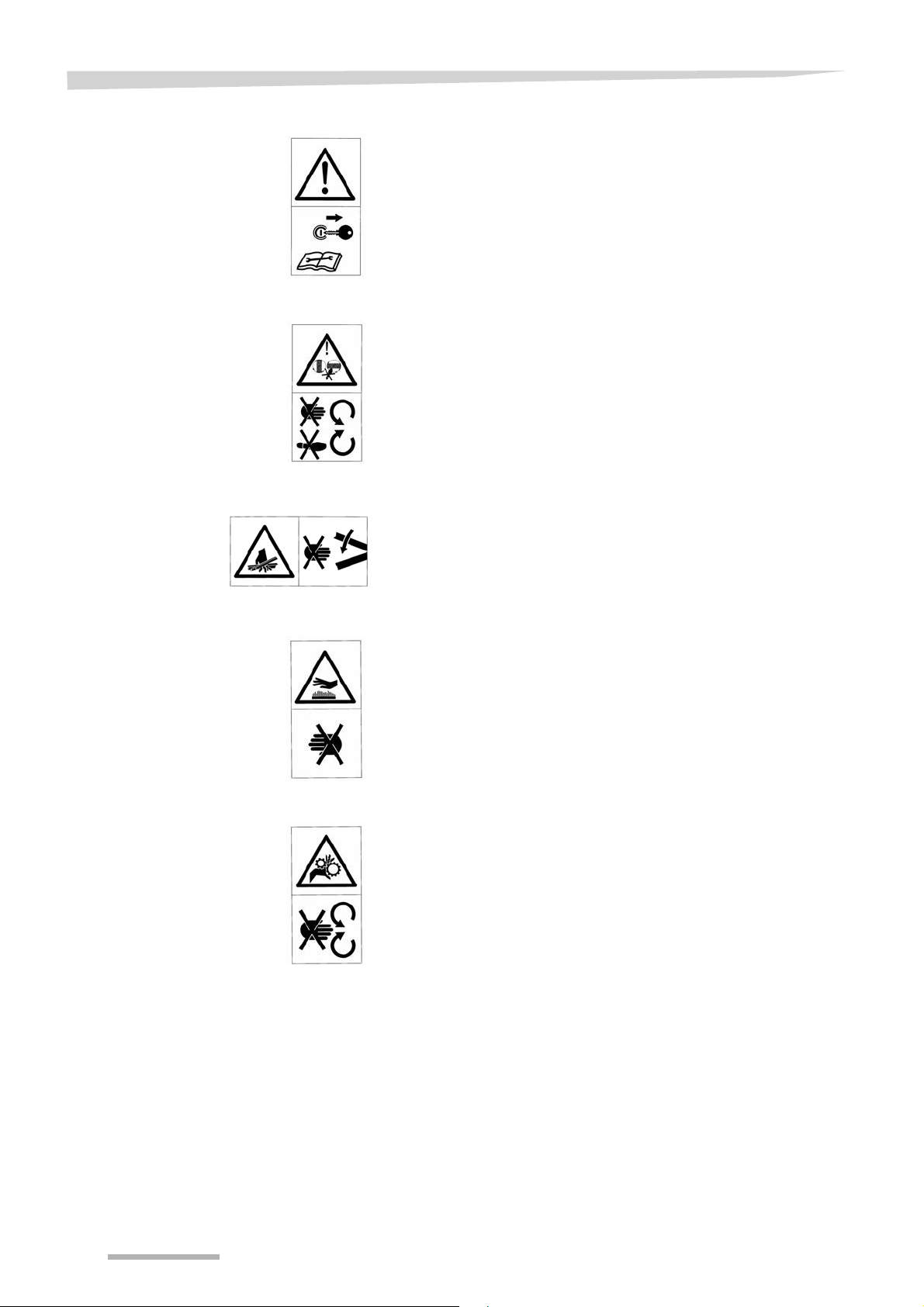

Adhesive labels bearing safety symbols are affixed to the machine to

warn the operator of potential hazards.

Observe the safety warnings!

Always:

• Keep the safety warning labels clean and legible

• Replace any damaged or missing labels

Read the instructions

Read the Instruction Manual and the safety warnings carefully before

putting the machine into service. Keep this manual in a safe place.

Adhesive label code: ZD75500710

55

Safety

Safety

Switch off the engine and remove the starter key

Before proceeding with any maintenance or repair operations, first

switch off the engine and remove the key fr om the st a rter switch, then

consult the instruction manual

Adhesive label code: ZD75500711

Keep clear of moving parts

Rotating parts hazard.

Keep hands and feet clear

Adhesive label code: ZD75500713

Keep clear of moving parts

Crushing hazard.

Keep hands clear of the danger zone.

Wait until all moving parts have come to a complete stop

Adhesive label code: ZD75500703

Keep clear of hot surfaces

Keep a safe distance from hot surfaces

Adhesive label code: ZD75500706

Moving parts

Do not lean over the moving parts of the transmission.

Do not open or remove the safety shields when the engine is running

Adhesive label code: ZD75500708

66

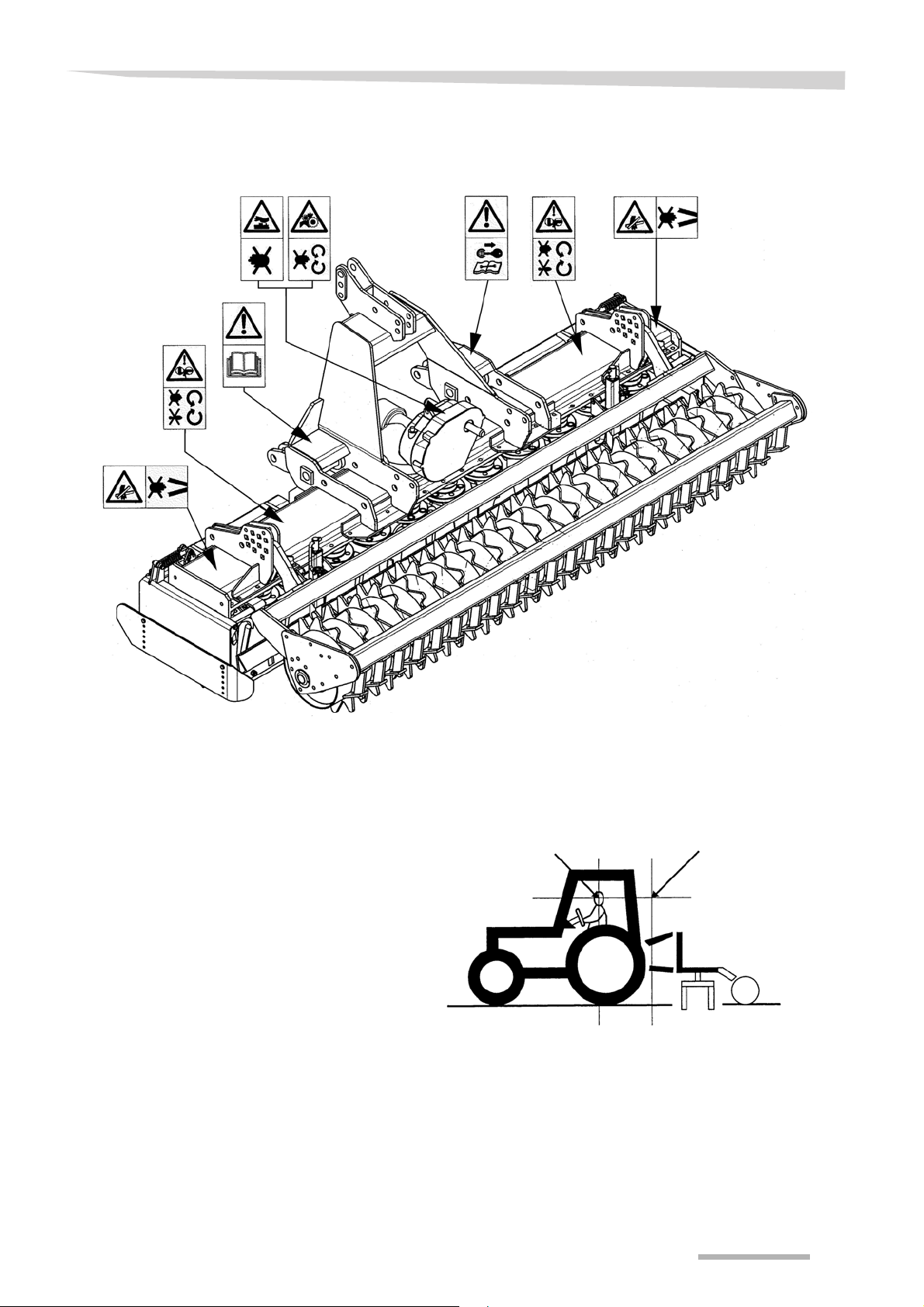

Positions of the

safety warning labels

Safety

Safety

Sound pressure

levels

Microphone1

Measured values Tractor only Tractor+implement

cab open open

Microphone 1 92 dB (A) 96 dB (A)

Microphone 2 92 dB (A) 94 dB (A)

Microphone 2

height of

measurement

77

Safety

Safety

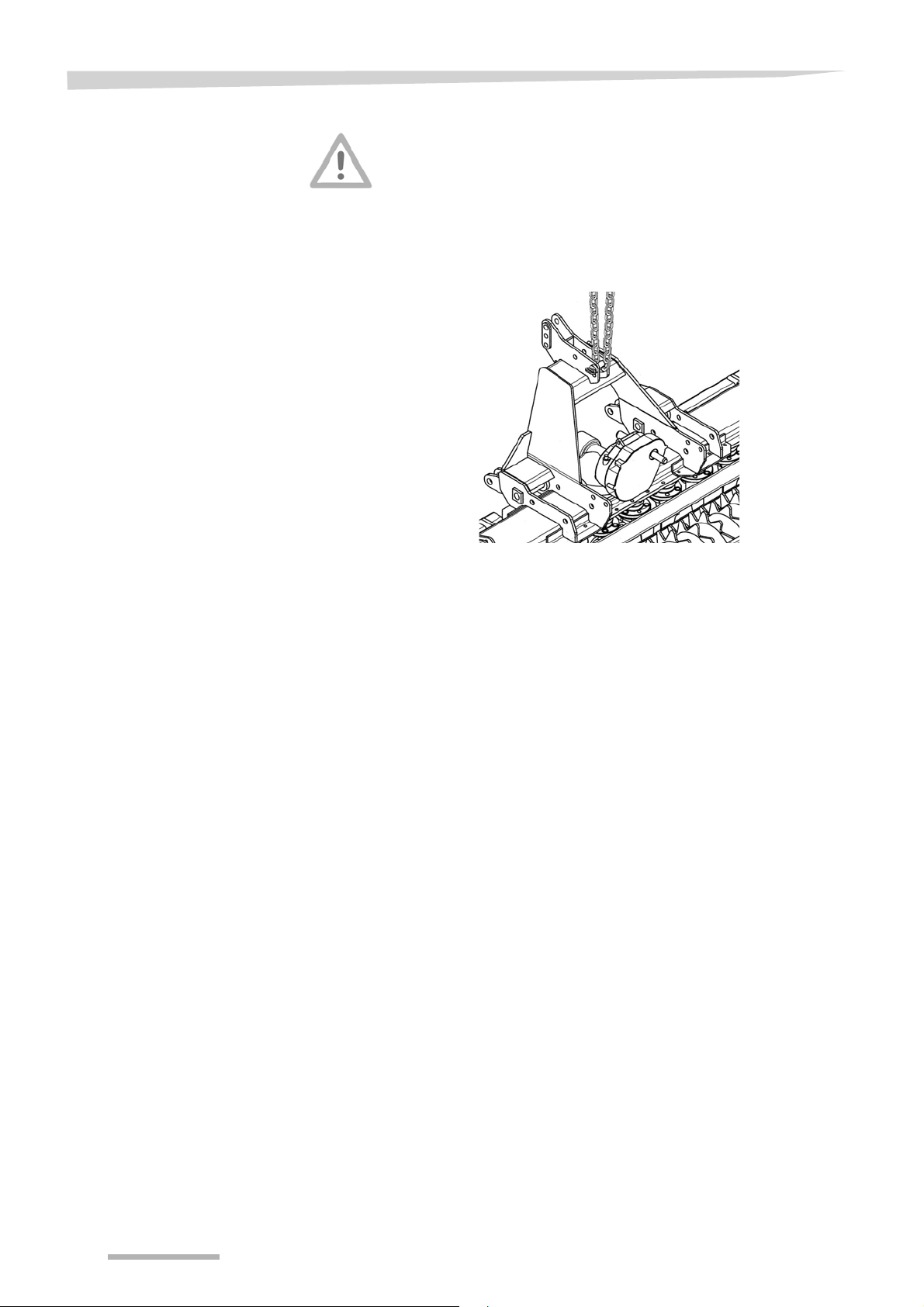

Lifting

Observe safety rules!

Do not stand under suspended loads

T ake all necessary precautions to prevent injury or damage caused by

accidental falls

When using a crane or other lifting equipment, the harrow must be

attached at the upper mounting as shown in the figure

88

Getting to know your machine

Getting to know your machine

Intended use

Key to parts

This section contains general information on the machine and

information on:

Getting to know your machine

• characteristics

• Technical specifications

The NGH and NGS harrows have been designed and built for the

usual agricultural applications. Any other use is to be considered

improper.

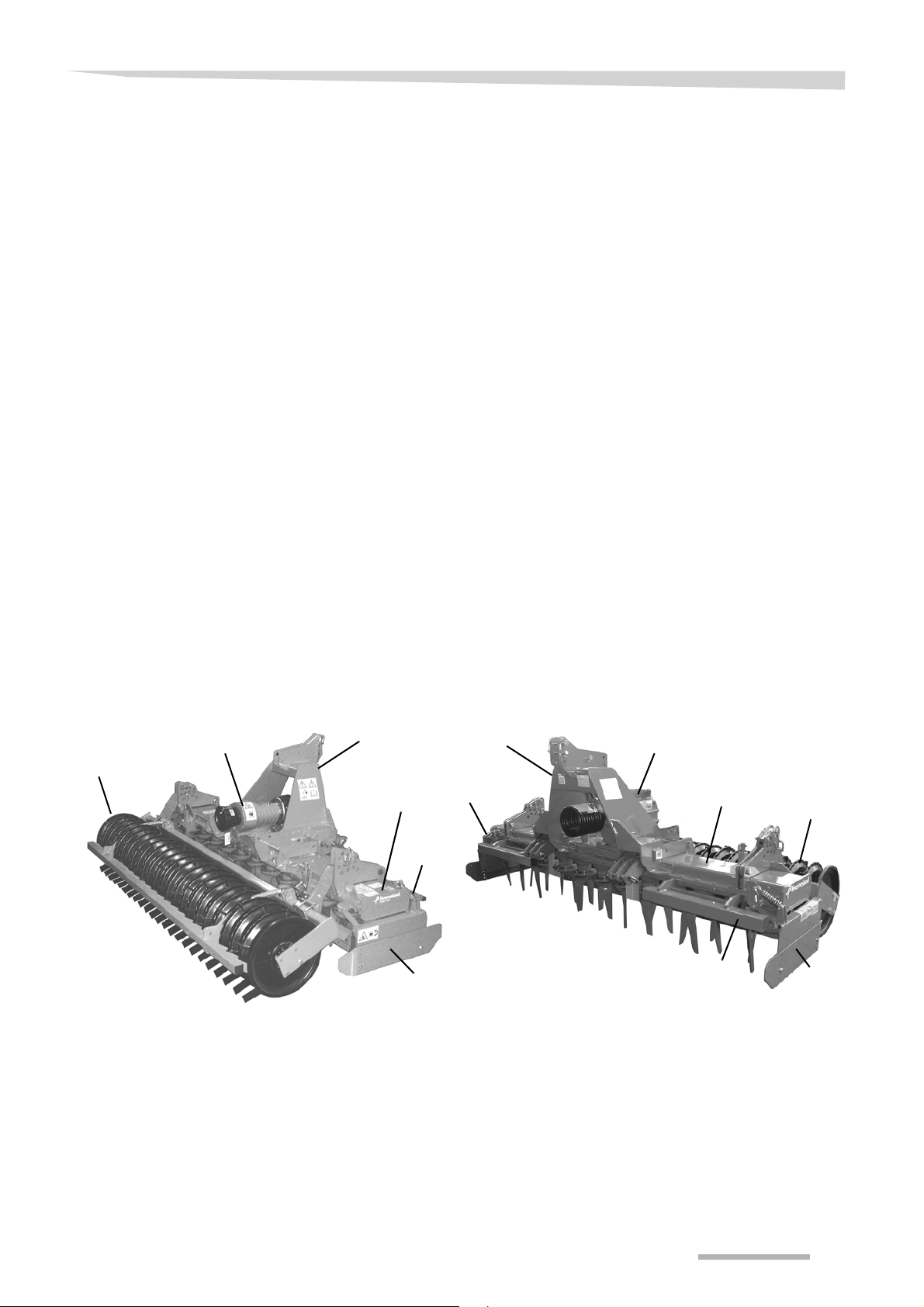

Standard machine

• Transmission casing (Ref.1):

3.0m - 12 tine holders - 24 tines (NGH 301 and NGS 301)

3.5m - 14 tine holders - 28 tines (NGH 351)

4.0m - 16 tine holders - 32 tines (NGH 401 and NGS 401)

4.5m - 18 tine holders - 36 tines (NGS 451)

• Frame for attachment to 3-point hitch of the tr actor, with floating or

fixed lower mountings (Ref.2):

Cat.II for model NGH 301

Cat.II + III for models NGH 351, NGH 401 and NGS 301 - 401 - 451.

• Gearbox with exchange speed change or lever change

(OPTIONAL) (Ref.3)

• Lateral stone guards with spring (Ref.4)

• Safety guards (Ref.5)

NGH 301-351-401 NGS 301-401-451

3

2

6

1

5

4

Accessories

The NGH and NGS harrows can be equipped with a wide range of

optional accessories, such as, for example, different drive shafts and

different rollers (Ref.6), all of which may be ordered from your dealer.

2

4

3

1

5

6

4

99

Getting to know your machine

Getting to know your machine

Technical

specifications

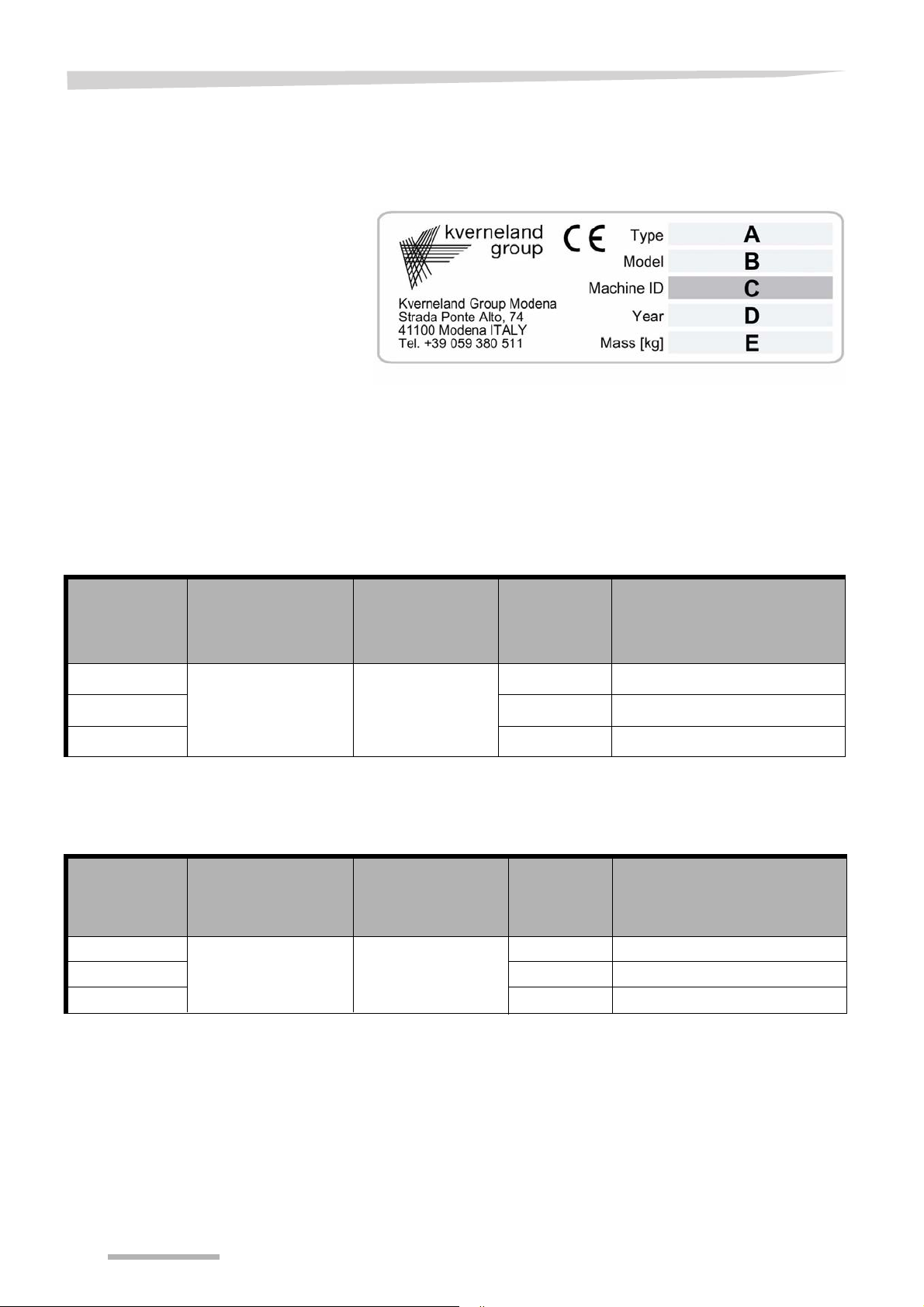

Identification plate

All machines carry an identification plate which indicates:

• the type of machine (Ref. A),

• the model (Ref. B),

• the serial number (Ref. C),

• the year of manufacture (Ref. D),

• the weight in kg (Ref. E)

General characteristics NGH

MODEL

NGH 301

NGH 351 3.50 m 1836 Kg

NGH 401 4.00 m 2046 Kg

Maximum tractor

power

131 kw/ 180 HP exchange speed

Type of gearbox

Working

width

3.00 m 1626 Kg

Machine weight with Ø500 mm

packer roller, wit

approx. values)

(

General characteristics NGS

MODEL

NGS 301

NGS 401 4.00 m 2275 Kg

NGS 451 4.50 m

Maximum tractor

power

183 kw / 250 HP exchange speed

Type of gearbox

Working

width

3.00 m 1836 Kg

Machine weight with Ø500 mm

packer roller, without drive shaft

(approx. values)

hout drive shaft

2514 Kg

1010

Delivery and preparation of the machine

Delivery and preparation of the machine

Delivery and preparation of the machine

Checking the

machine

Pre-delivery checks

On delivery, check that all parts of the machine are present and that

they have not been damaged in transit; notify your dealer, importer or

the manufacturer immediately of any defects found.

NOTE For shipping purposes, some of the components may be supplied

pre-assembled on the machine, while others may be fixed temporar ily .

The machine leaves the Manufa cturer with all parts in fully working

order. In all cases, it is the Retailer's responsibility to check the

following upon delivery to the User:

• the three-point attachment is correctly mounted,

• the grease in the transmission unit and the oil in gearbox are at

prescribed levels,

• grease injected into the greasers is present,

• all adhesive safety labels indicated in the present booklet must be

present and legible,

• screws and bolts must be securely tightened,

• EEC-compliant guards are provided,

• the machine must be free of imperfections up o n gene r al

inspection.

Preparation

The Retailer must draw the user's attent ion to this manual and the

drive shaft manual also provided, which must both be kept by the user

throughout the machine's service life. The Retailer is also responsible

for recommending that the user reads these manuals carefully.

Risk of crushing and cuts!

During machine preparation operations, o bserve the SAFETY rules, in

particular:

• make sure that the machine is in a very stable position.

• Do not stand between the tractor and the machine during h itching

or unhitching operations. If it is necessary to work in the area

between the tractor and the machine, observe the safety rules

(tractor engine switched off, Pto disengaged, tractor parking brake

applied, key removed from starter switch, chocks placed under

wheels of the tractor)

• Before hitching or unhitching the machine to/from the tractor,

position the lift control lever in a position where it is not possible to

operate it.

• Do not stand under suspended loads

• Take all necessary precautions to prevent injury or damage

caused by accidental falls

Reposition and securely fix in working position all those parts of the

machine that were secured in temporary positions for shipment.

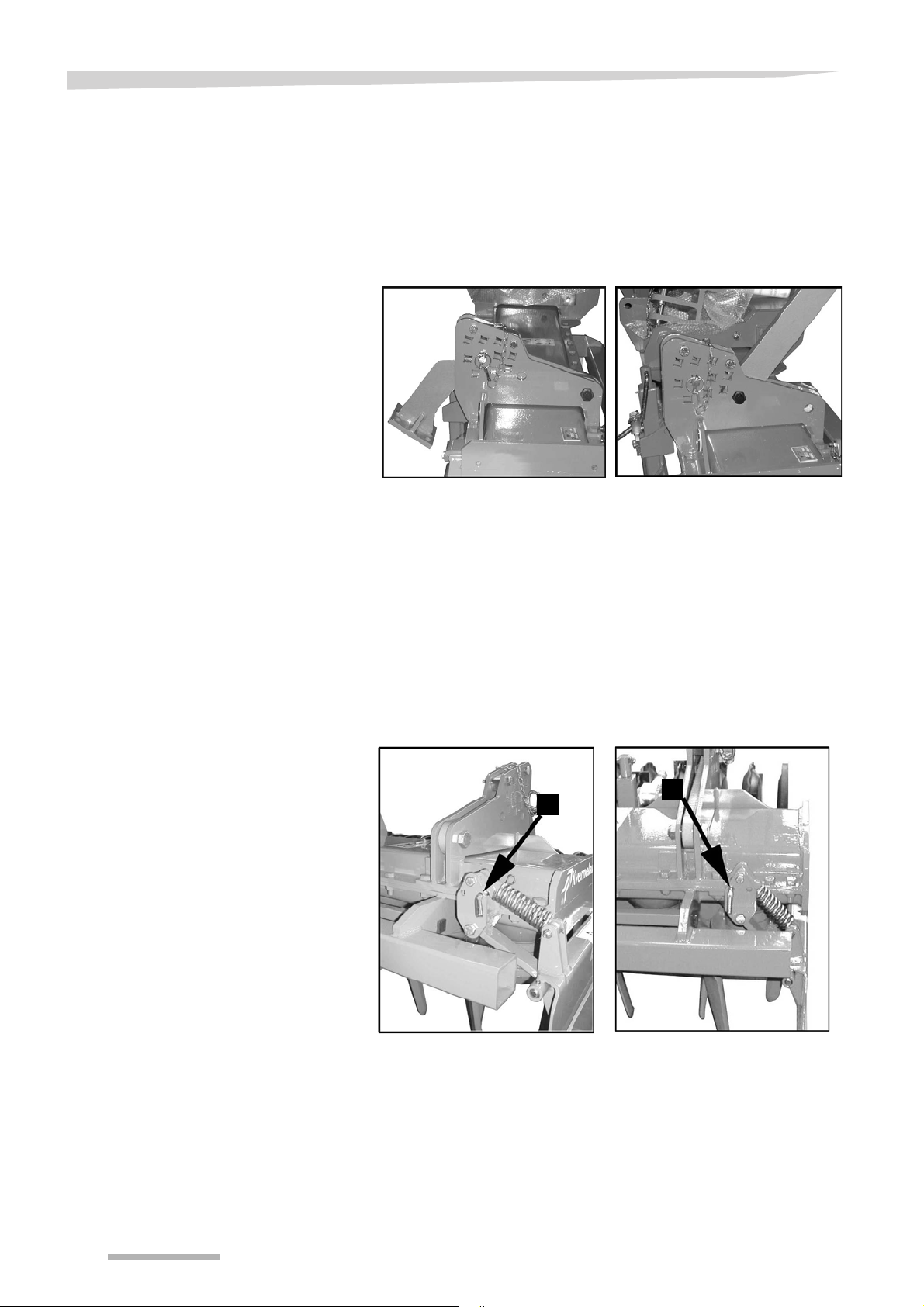

Positioning the roller

for work

When supplied with the machine, the roller is secured in transport

position; to position the roller in the correct working position, proceed

as follows:

1111

Delivery and preparation of the machine

Delivery and preparation of the machine

>

Support the roller, observing safety rules

>

Unscrew the nuts securing the arms and remove the bolts

Caution: suspended load hazard!

>

Move the arms and the roller into the correct position (see figure) and

replace the bolts

>

Replace the nuts and tighten

Working position Transport position

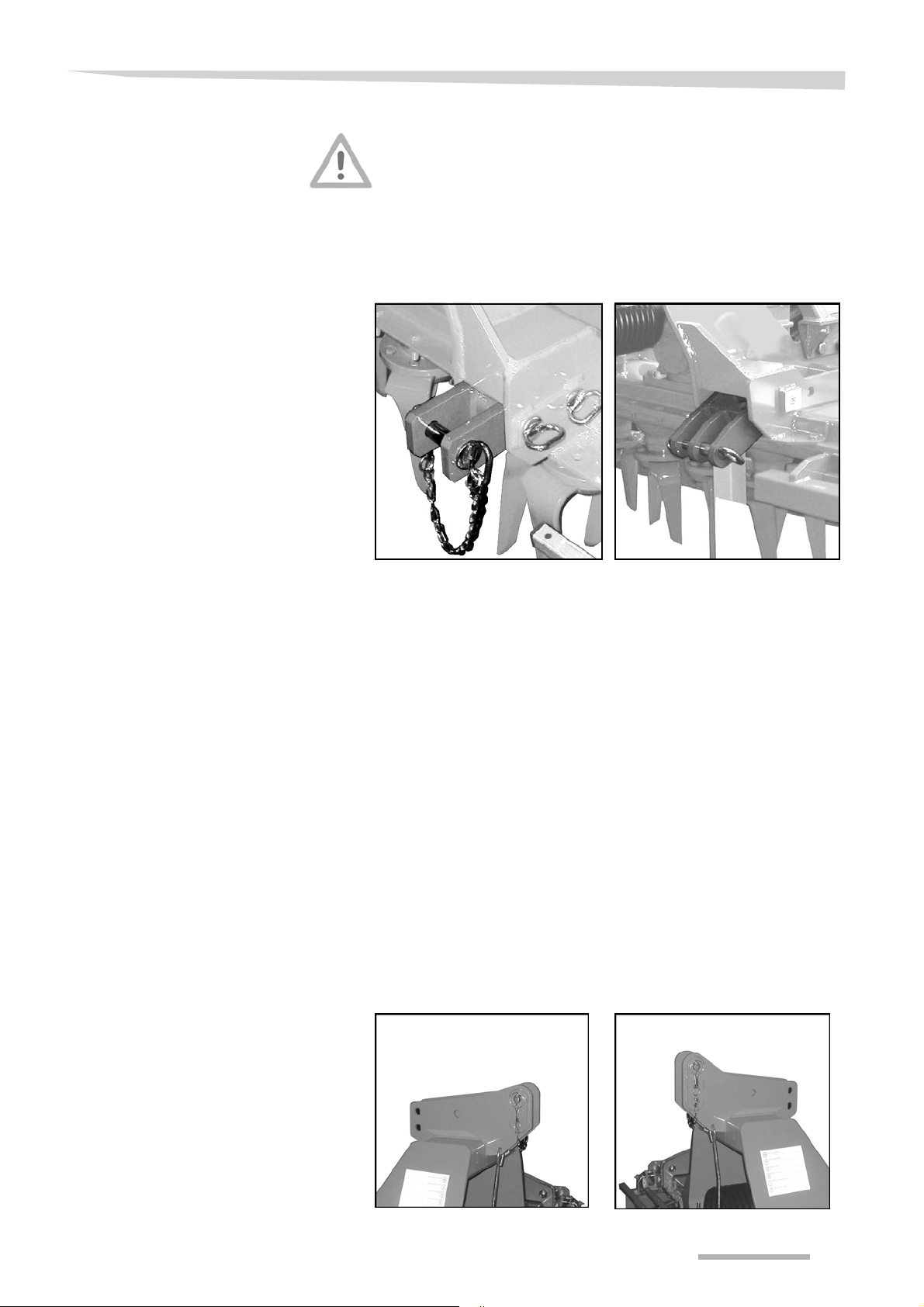

Positioning the

lateral stone guards

for work

The stone guards are secured in transport position for shipment; to

position the two stone guards in the correct working position, proceed

as follows:

Remove the locking pin from the pivot pin (7)

>

>

Remove the pivot pin (7) from the transport position hole

>

Raise the stone guard

>

Insert the pivot pin (7) in the working position hole

>

Reinsert the locking pin in the pivot pin

Working position Transport position

7

7

1212

Hitching the machine

Hitching the machine

We strongly recommend that you observe the safety warnings given

in the previous pages of this manual.

The category of the tractor 3-point linkage must match that of the

implement.

Mounting bracket

for Cat.2 linkage

Mounting bracket

for Cat.2+3 linkage

Hitching the machine

To attach the harrow to the tractor, proceed as follows:

Line up the tractor with the harrow

>

>

Insert the lower links of the tractor's hydraulic linkage in the corresponding

mounting brackets on the implement, which should both be positioned at

the same distance from the tractor.

>

Secure the lower links with the pins and locking pins provided.

NOTE Attachment is made easier if the lower link stabilisers are adjusted so

as to allow the lower links to move freely.

On completion of the hitching operation, the stabilisers should be

adjusted so as to limit oscillation (during implement transport, all

oscillation must be completely eliminated).

Insert the end of the top link of the tractor's hydraulic linkage in the upper

>

mounting bracket of the harrow and secure it with the relative pins and

locking pins.

>

Adjust the length of the top link, bearing in mind that the drive shaft

transmitting power from the tractor Pto to the harrow must be horizontal

when the implement is in operation.

NGH NGS

1313

Loading...

Loading...