Kverneland Miniair Nova Operating Manual

Miniair Nova

Operating manual

Edition 9/2011

Print 11.2011

Language EN [Original]

From machine number ACPNPxx1940

Explanation Foldable

Product number AC758881

Identification of the machine

Your dealer requires some information about your machine in order to be able to help you as quickly as possible.

Please enter the information here.

Designation

Working width

Weight

Machine number

Accessory

Address of dealer

Miniair Nova

Address of manufacturer

Kverneland Group Soest GmbH

Coesterweg 42

D-59 494 Soest

Tel: +49 (0)2921 / 974-0

Copyright by Kverneland Soest GmbH, Germany. Reproduction, transfer to other media, translation or the use of extracts or parts of this manual

without the explicit permission of Kverneland, is not permitted. All rights reserved. The content s of this operating ma nual are subject to chang e

without notice. The right to technical revision is reserved.

Table of Contents

Preliminary information..................................5

Target group for this operating manual 5

Meaning of the symbols 5

Safety................................................................6

For your safety 6

Safety stickers 6

Who is allowed to operate the machine? 11

Coupling 11

Centre of gravity 12

Road transport 14

Putting the machine into operation 14

Uncoupling the machine 16

Care and maintenance 16

Further regulations 17

Getting to know the machine .......................18

Range of application of the machine 18

Proper use 18

Definitions 18

Characteristics of the machine 19

Component designations 20

Technical specifications 25

Delivery and assembly..................................28

Check scope of supply 28

Coupling the machinery................................29

Coupling the machine 29

Connections 29

Preparing for operation.................................33

General 33

Frame 34

Track marker [+] 36

Adjust sowing units 42

Setting of the grain distance 46

Adjusting the seed coverer 51

Adjusting the intermediate press wheel [+] 53

Adjusting the clod deflector [+] 54

Adjusting double seed rows 54

Emptying the seed hopper 58

Filling seed 59

Adjusting the negative pressure and overpressure 60

Settings at the seeding heart 63

Lifting device [+] 64

Checks 65

Granule distributor [+] 66

Table of Contents

Driving on the road .......................................72

Safety 72

Prior to travel on public roads 72

Transport position of seed rows 74

Folding in the track markers [+] 74

Granule distributor [+] 76

Fold in frame 77

Lengthways transport attachment 79

Checking the machine 81

Road transport 82

Preparations in the field ...............................83

Lengthways transport attachment 83

Frame and track markers 85

Granule distributor [+] 86

Seed rows 86

Inspection tasks 86

Filling the seed hopper 87

Filling the granule distributor 87

Test drive 88

Operation .......................................................90

Before sowing 91

Sowing 91

Turning 91

Mechanical hectaremeter[+] 92

Checks during sowing 94

Cleaning and care .........................................95

Cleaning 95

Care 96

Parking and storage......................................97

Parking and securing the machine 97

Storing the machinery 98

Maintenance...................................................99

For your safety 99

General information 100

Maintenance General 106

Boom 107

Frame 107

Hydraulics 107

Seed row 108

Dust filter on the fan 110

Wheels 111

Drive 112

Track marker 113

Granule distributor [+] 115

3

Table of Contents

Accessories .................................................120

Hydraulic changeover of track markers 120

Lengthways transport attachment 120

Press wheels 121

Intermediate press wheels 122

Coverer 123

Clod deflector 124

Crumbler 124

Band sowing coulter 124

Other accessories 125

Eliminating malfunctions............................127

Frame, rigid 127

Frame,

6.00 metres PH 128

Frame

9.00 m and 12.00 m, oscillating 129

Hydraulic lengthways transport

attachment 130

Seeding technology 130

Disposal........................................................131

EU Conformity Declaration.........................132

As per EC Directive

2006/42/EC 132

Index.............................................................133

4

Preliminary information

Preliminary information

Target group for

this operating ma-

nual

Training

Meaning of the symbols

This operating manual is directed at trained farmers and individuals

who are otherwise qualified to perform agricultural activities and who

have received training in the operation of this machinery.

For your safety

Study the cont ent s of thi s operat ing manual c areful ly bef ore ass embly

or initial operation of the machine. In this way, performance and work

safety are optimised.

For the employer

All personnel are to be regularly trained in the use of the machine (at

least once a year) i n accordance wit h employers' liabi lity insurance association guidelines. Untrained or unauthorised individuals are not

permitted to use the machinery.

Your dealer will provide instruction on the operation and care of the

machine.

We have used v ari ous sy mbols to make t his manual clear and easy t o

read. They are explained below:

• A dot accompanies each item in a list

> A triangle indicates operating functions which must be performed

→ An arrow indicates a cross-refe rence to other sections of this manual

[+] A plus sign indicates an accessory that is not included in the standard version.

We have also used pictograms to help you find instructions more

quickly:

The warning triangle i ndicate s imp ort ant safe ty instruct ion s. Failur e to

observe these safety instruct ions can result in:

• Serious operational faul ts for the machinery;

• Damage to the machinery;

• Personal injury or accidents

This symbol indica tes information, tips and instruct ions about operation.

This symbol indicates tips for assembly or adjustment work.

This symbol indicates examples that help you to understand the instructions better

5

Safety

Safety

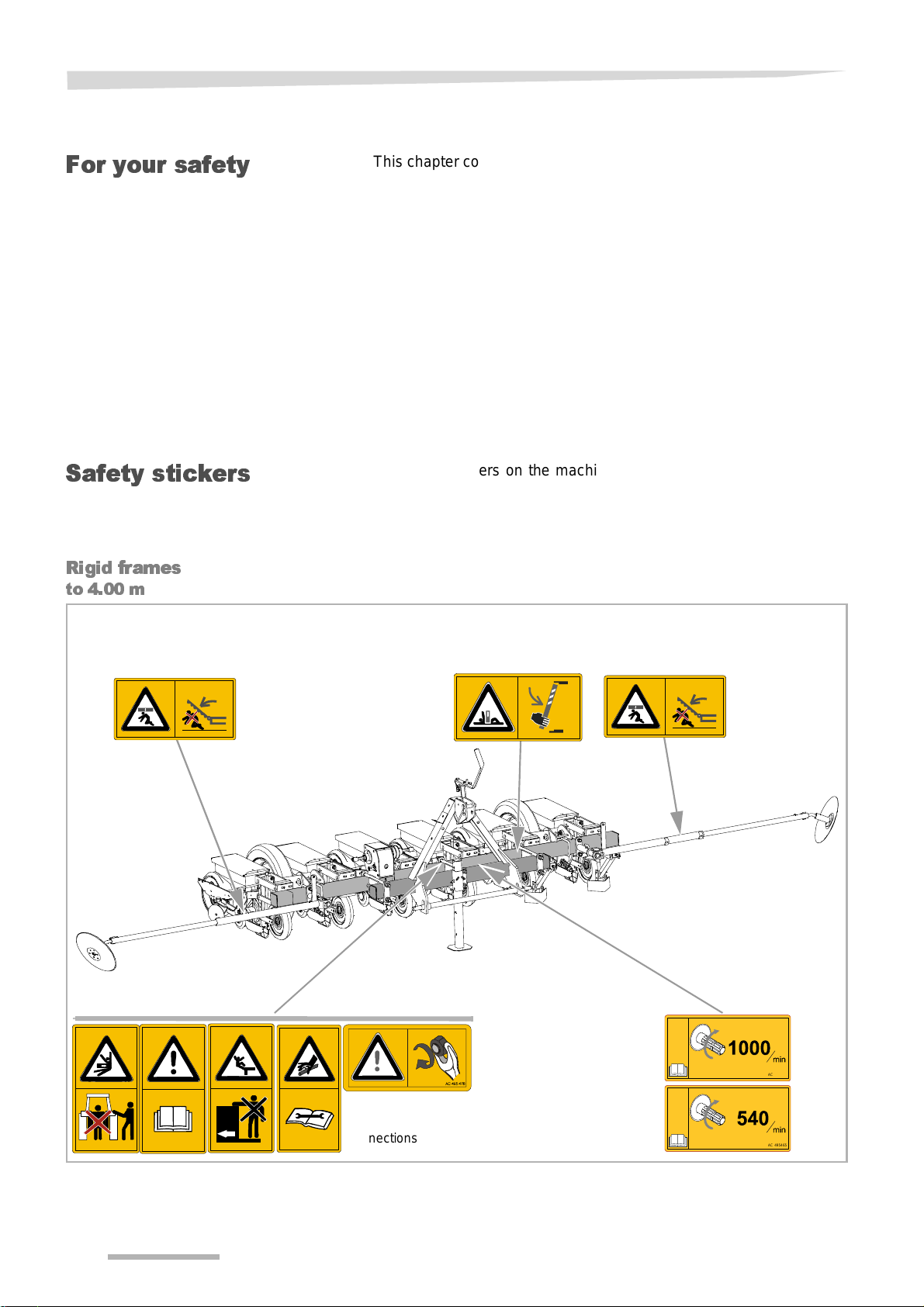

For your safety

Safety stickers

Rigid frames

to 4.00 m

This chapter contains general saf ety instruct ions. Each chapter of the

operating manual contains additional specific safety instructions

which are not described here. Observe the safety instructions:

• in the interest of your own safety,

• in the interest of the safety of others,

• to ensure the safety of the machine

Numerous risks can result from handling agricultural machines in the

wrong way . The refore , alway s work wi th sp eci al car e and never under

pressure.

The employer should:

Inform personnel working with the machine of these safety instructions at regular intervals and according to statutory regul ations.

There are stickers on the machine that serve to ensure your safety.

The stickers must not be removed. If stick ers become il legible or have

peeled off, n ew stickers can be order ed and att ached in the appropri ate places

AC 495463

For machines with hydraulic

connections

6

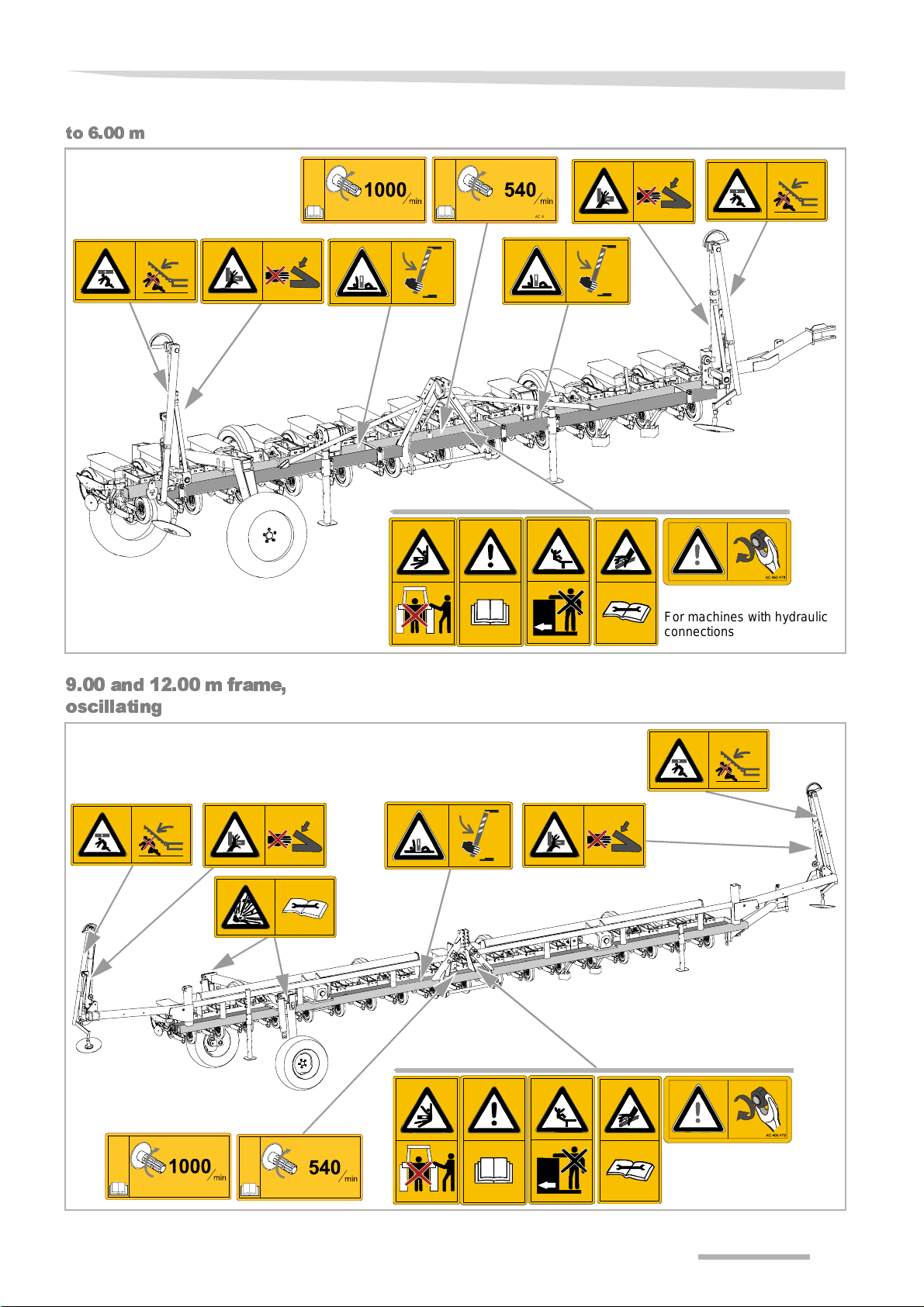

AC 495465

to 6.00 m

Safety

AC 495465AC 495463

9.00 and 12.00 m frame,

oscillating

For machines with hydraulic

connections

AC 495463

AC 495465

For machines with hydraulic

connections

7

Safety

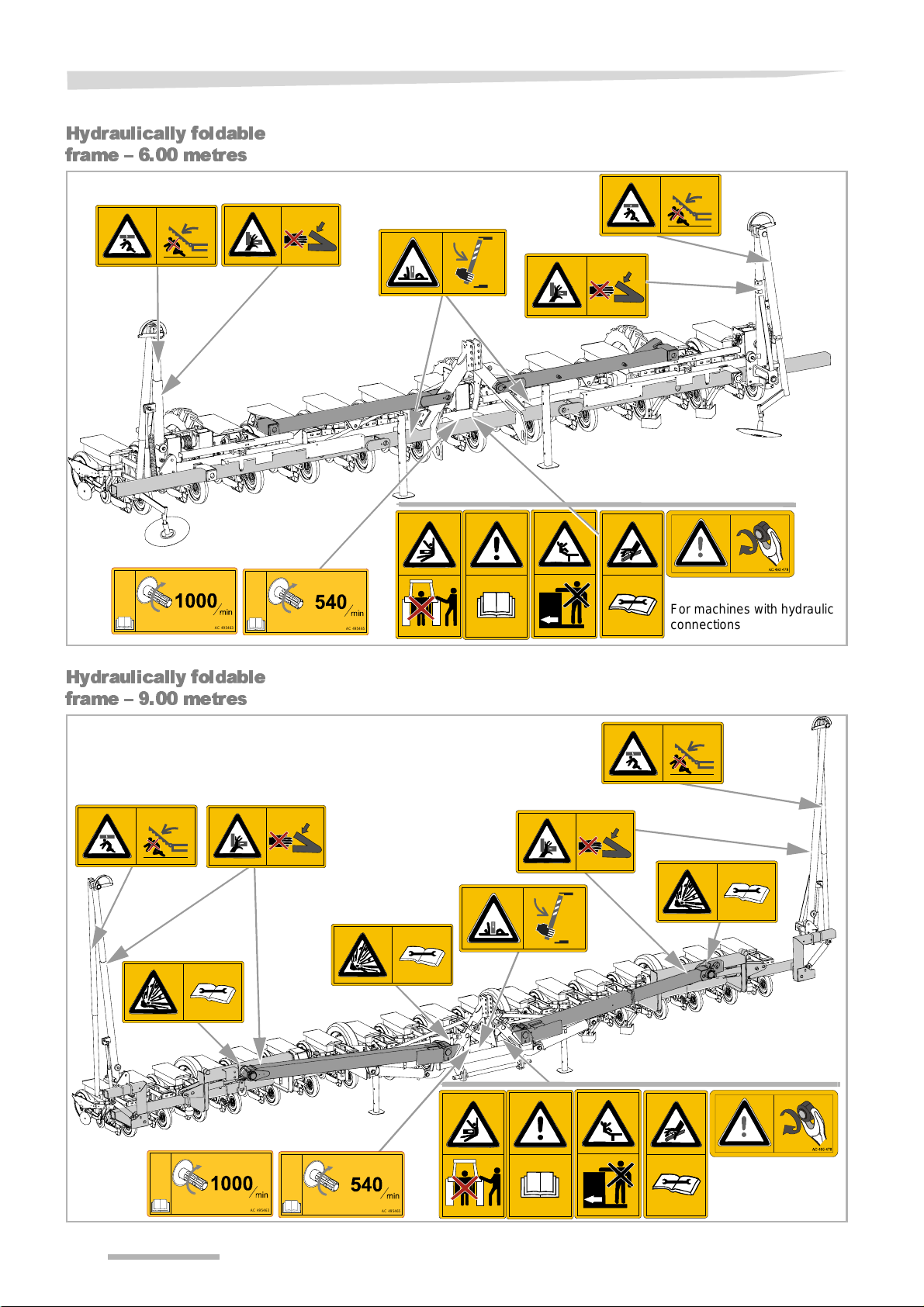

Hydraulically foldable

frame – 6.00 metres

AC 495463

Hydraulically foldable

frame – 9.00 metres

AC 495465

For machines with hydraulic

connections

AC 495463

AC 495465

8

Safety

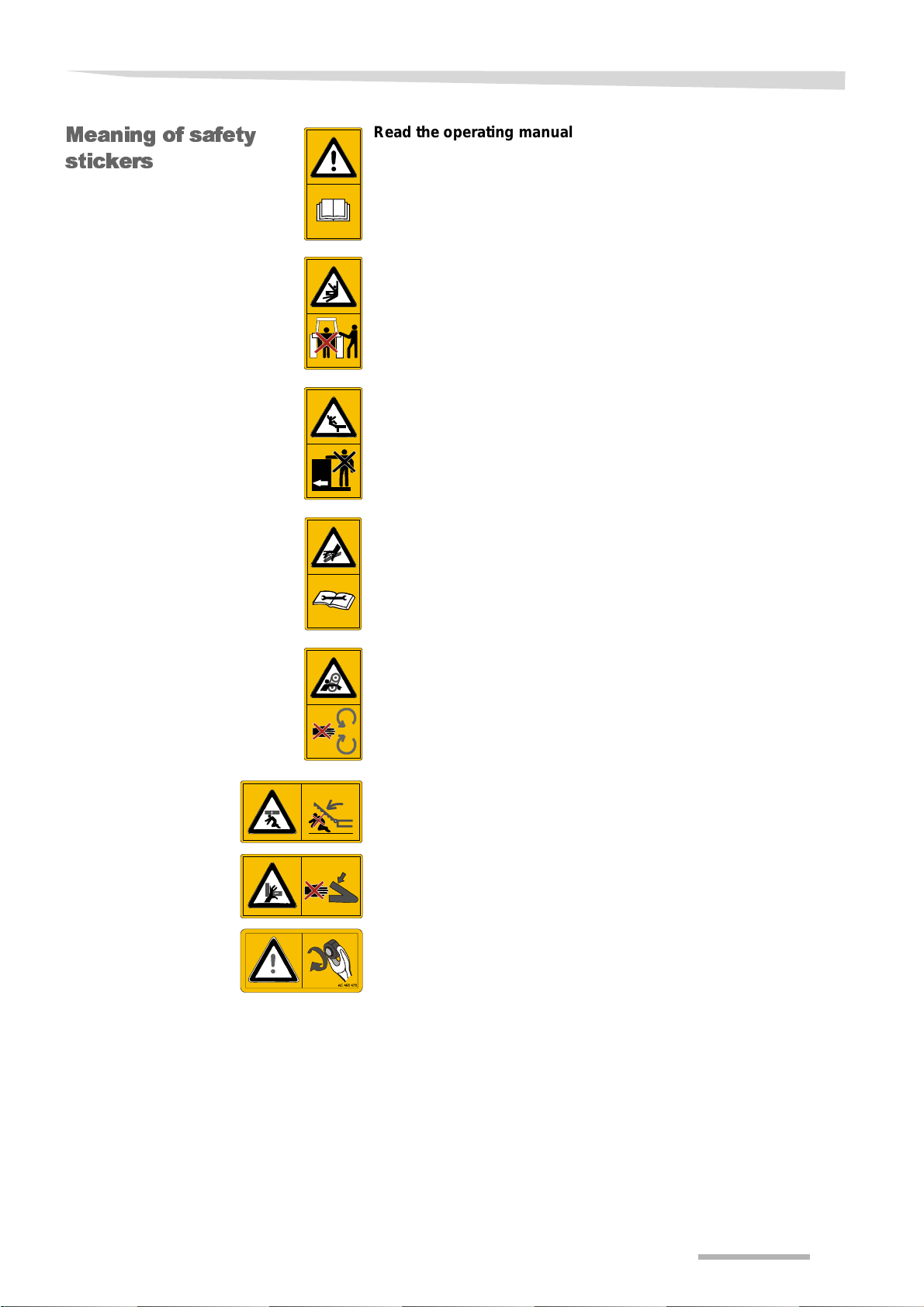

Meaning of safety

stickers

Read the operating manual carefully and follow the instructions

Initial operation of the machine must not take place before the operating manual has been read and understood. This particularly applies

to safety instructions.

Do not stand between the tractor and the machine

St anding bet ween the t ractor and the machi ne is es pecially p rohi bite d

during coupling and uncoupling and when the motor is running. The

tractor must be additionally immobili sed.

Riding on the machine is strictly prohibited

Do not transport people or objects on the machine. Riding on the machine is hazardous and strictly prohibited.

Proceed with great care in the event of leaking hydraulic fluid

Observe the corresponding safet y instruct ion s in the operating manual.

Never remove the guards

Never open or remove the guards while the engine is running. Never

operate the machine without guards.

Stay clear of the slewing range

There is an acute risk of injury in the slewing range due to swivelling

or folding machine components.

Risk of crushing

Avoid the danger area. Gaps between components may become

smaller or disappear completely.

Retighten screws

After the first opera ting hours al l scr ew must b e check ed and ret ightened, if needed. Vibrations might have loosened the screws.

9

Safety

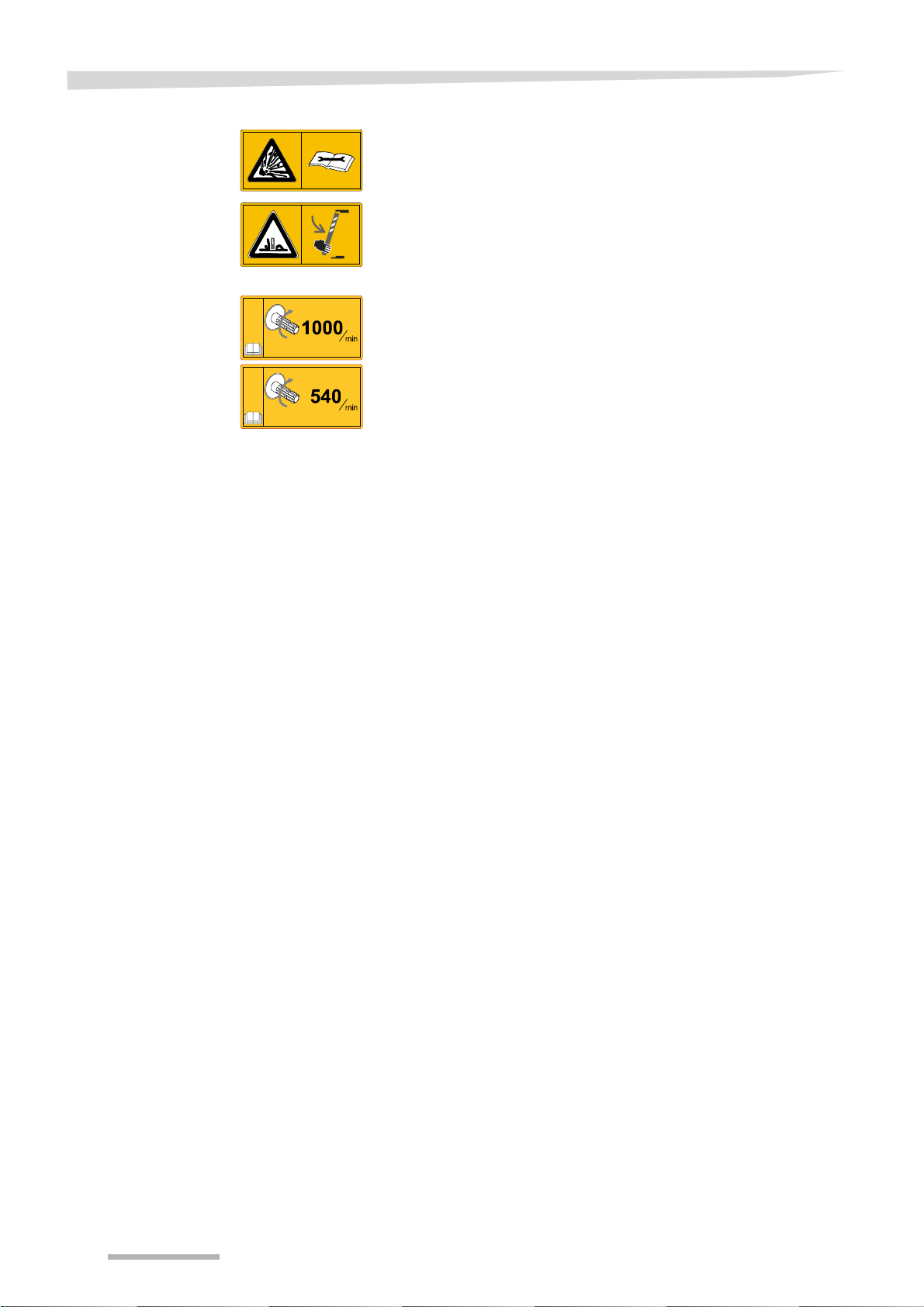

Caution, danger of explosion

The accumulator contains pressurised gas and oil. Disassembly and

repair work must only be carried out by qualified specialists.

Caution, risk of tipping

The machine or part s thereof might topp le over . Attach the safet y supports before you stand in the danger ar ea. To uncouple, use the strut s

provided and position on a firm surface.

Check the rotational speed of the PTO stub shaft

Connect the PTO shaf t to a P TO stub s haft with t he required r otati onal

speed. Always switch off the PT O st ub shaft when working on the ma-

AC 495463

chine.

AC 495465

10

Safety

Who i s a llo w e d to

operate the ma-

chine?

Couplin g

Only qualified personnel

Only qualified persons who have been informed of the dangers associated with handling the machine are permitted to operate, service or

repair the machine. As a rule, such persons are trained and experienced in agricultural work or have bee n tho roughly train ed in a si milar

fashion.

Increased risk of injury

When coupling the machine to the tractor, there is an increased risk of

injury. Therefore:

• Secure the tractor in such a way that it cannot roll for wards or back-

wards

• The tractor and machine must belong to the same category

• Never stand between the tractor and the machine during coupling

• Actuate the three-point power l if t system slowly and carefully

Nonobservance can lead to serious or fatal injury.

Only connect electric wires or cables after mounting the at tachment

The electrical supply must not be connected to t he tractor when mounting the lighting equipment. Short circuits and damage to the electronics are possible.

Only connect hydraulics at zero pressure

Only connect the hydraul ic hose s to the tr actor hy drau lic sy stem if th e

tractor and machine hydraulic system is depressurised. A hydraulic

system which is under pr essure can cause unforeseen movement s on

the machine.

High pressures in the hydraulic system

The hydraulic syst em is under hi gh pressure. Regul arly check a ll lines,

tubes and screwed connecti ons for leaks and ext erna lly visi ble damage. Only use suitable agent s when looking for leaks. Elim inat e damage immediately. Escaping fluid may result in injuries and fires. Seek

medical attention immediately if injur ies occur .

Colour-coded hydraulic hoses

To prevent operating errors, plug sockets and plugs for hydrau lic connections between the tractor and the machine must be identified by

different colours . Incorrectly connec ted hydraulic tube s can initiate unforeseen movements on the machine.

11

Safety

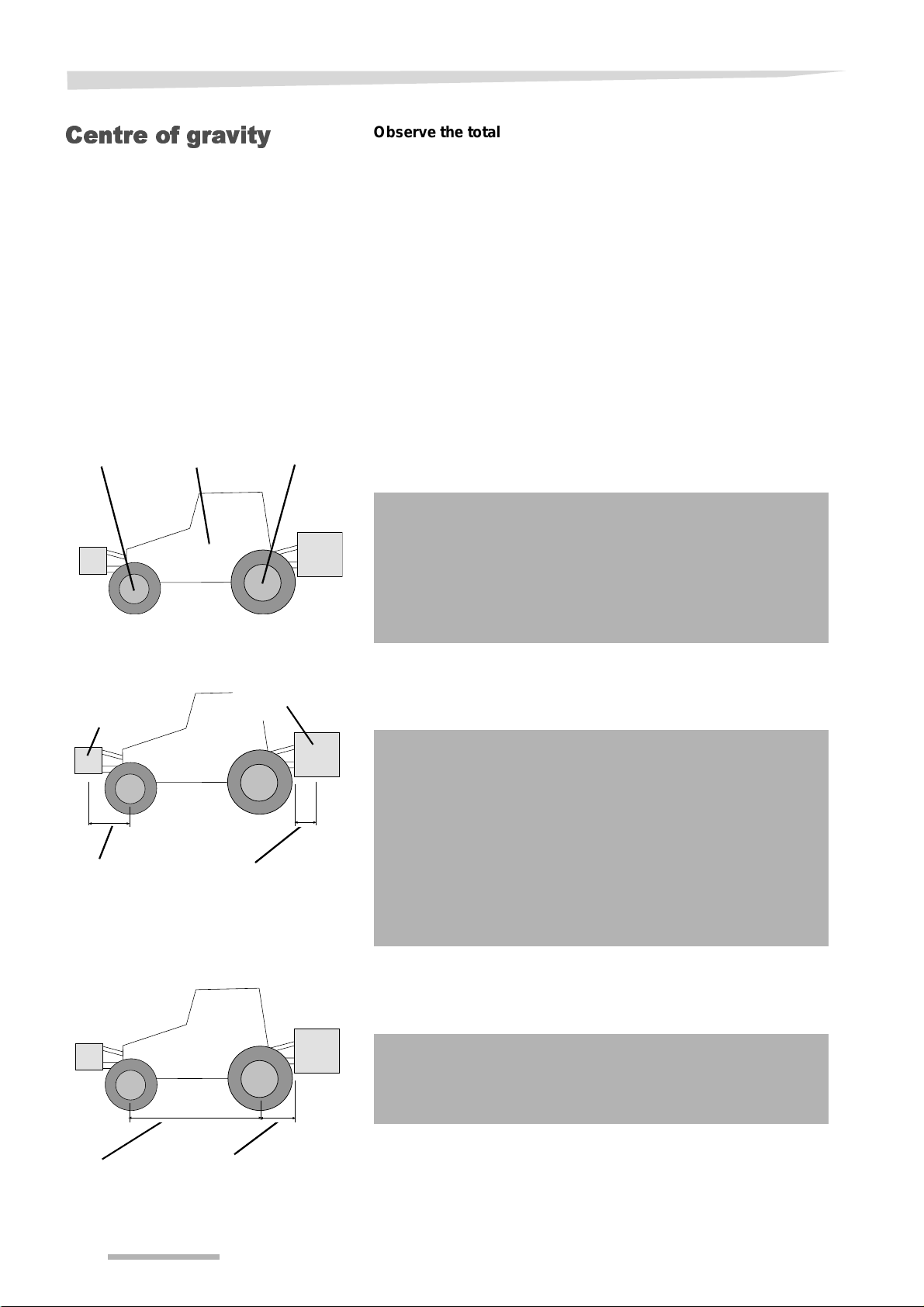

Centre of gravity

(B)

Front axle

load

(A)

Empty

weight

(C)

Rear axle

load

Observe the total weight, axle loads, tyre load-bearing capacity

and minimum ballast specifications

The front or rear at tachment of machines must not cause the tractor's

permissible total weight, its permissible axle load or its tyre load-bearing capacity to be exceeded. In order for steering capability to be

maintained, the front axle must bear at least 20 % of the t ractor's empty weight.

By investing some effort in making t he calculations i t is possible to determine the:

• Gross weight

• Axle load

• Tyre load-bearing capacity and

• Minimum ballast

The following data is required to make this cal culation:

Data from the tractor's operating manual:

• (A) Empty weight

• (B) Front axle load

• (C) Rear axle load

(E)

Total weight of

front attachment

(F)

Distance:

between centre of

gravity of front attachment and

middl e of f ro nt ax le

(D)

Total weight

rear attachment

(G)

Distance:

between lower link ball

midpoint and centre of gravity of rear attachment

Please take into consideration, for example, the weight of water in

the tyres, accessories, etc.

Data from this operating manual:

• (D) Total weight of the machine (rear attachment); the suppor-

ting load with the equipment attached

• (E) Total weight of the machine (front attac hme nt)

• (F) Distance between the machine's centre of gravity (front at-

tachment) and the centre of the front axle

• (G) Distance bet ween lower link b all midpoint and the machine's

centre of gravity (rear attachment). With machines attached,

G=0.

Data which you can determine through measurement:

• (H) The tractor's wheel base

(H)

Wheel base

12

• (I) Distance between the rear axl e midpoi nt and the lower link

ball midpoint

(I)

Distance:

between middle of rear

axle and lower link ball

midpoint

Safety

Calculation

Front ballast

Rear ballast

Front axle load

Gross weight

Rear axle load

The measured values can now be inserted into the formulae.

Calculation of front ballast

for machines attached at rear.

DIG

Front ballast in kg =

Calculation of rear ballast

for machines attached at front.

Rear ballast in kg =

Calculation of the actual front axle load

Front axle load in kg =

Calculation of act u a l to tal weight

Total weight =

Calculation of the actual rear axle load

Rear axle load in kg = actual total weight - actual front axle load

-------------------------------------------------------------------------------------------

EF×

------------------------------------------------------------------------------------

EFH) BH) DIG)+(×–×(++(×

-------------------------------------------------------------------------------------- -

EAD++

)+(× BH) 02 A H)××,(+×(–

FH+

) C( H) 045 A H)××,(+×–

HIG++

H

Tyre lo ad rating

Summary

Information about the tyre load-bearing capacity of the front and rear

wheels can be found in the tyre manufacturer's details.

• The front tyre load- bearing capacity for t wo wheels is equal to t wice

the permissible tyre load-bearing capacity of a single front wheel.

• The rear tyre load-bear ing capacity for two wheel s is equal to twice

the permissible tyre load-bearing capacity of a single rear wheel.

Check if the following conditions are met:

• The actual values for the rear axle load must be less than the per-

missible values given in the tract or's operating manual.

• The tyre load-bearing capaci ty must be great er than the values for

the rear axle load given in the operating manual.

• The actual total weight must be less than the permissi ble total

weight given in the tractor's operating manual.

If these conditions are not met, the machine must not be attached to

this tractor.

If you have a sufficiently large weigh-br idge, you can determine the total weight and the rear axle load by weighing.

13

Safety

Road transport

Make sure that the condition of the machine conforms to traffic

regulations

The machine must conform to current traffic regulations if you intend

to drive it on public roads. These include, f o r example:

• Lights, warning equipment and protective equipment are installed

• The permissible transport width and wei ght, axle loads, tyre load-

bearing capacity and total weights are observed

The driver and owner of the vehicle are liable if traffic regulations are

not observed.

Close the ball valves

If there are ball valves on the hydraulic lines or chassis cylinders, you

must close them prior to road transport. The accidental actuation of

control valves o n the tractor might otherwi se cause movements on the

machine. This can result in damage to the machine or accidents.

Check remote cord for the quick release coupling

Remote cords must hang loose and must not, when in their lowered

position, release the coup lings of their own accord. Coup led machines

might otherwise come loose from the three-point linkage of their own

accord.

Riding on the machine is strictly prohibited

Do not transport people or objects on the machine. Riding on the machine is hazardous and strictly prohibited.

Putting the ma-

chine into opera-

tion

Note the altered driving and braking performance

Driving and braking performance are altered when the machine is attached to the tractor. Take the width and balancing weight of the machine into consideration, especially when cornering. A driving style

which not adjusted to the road conditions can l ead to acci dents.

Moderate your speed

Always adjust your driving speed to the road conditions. If conditions

are poor and your speed is too high, extremely high forces can arise

that place a major load on the tractor and machine and might overstress them. T ravelling at an inappropriate speed can result in machine damage and accidents.

Initial operation after briefing

The machine must not be put into operation until the user has been

given proper initial instruction by an employee of the dealer, a factory

representative, or an employee of the manufacturer. Commissioning

without instruction can lead to damage to the machine due to false

operation or accidents can happen.

Ensure that the machine is in perfect working condition

Do not operate the machine unless it is in perfect working condition.

Check all important components and replace any defective components before starting the machine. Defect components can cause damage to equipment and injury to persons.

14

Safety

Do not remove the protective equipment

Protective equipment must not be removed or by-passed. Check all

protective equipment before start ing the machine. Unprotected machine components can cause severe or fatal accidents.

Checking tyre pressures

Check tyre pressure regularly. If the tyre pressure is too high or too

low, this can reduce the service life of the tyre and result in undesirable work results. Accidents might occur during road transport.

Riding on the machine is strictly prohibited

Do not transport people or objects on the machine. Riding on the machine is hazardous and strictly prohibited.

Height of machine and overhead power lines

If a height of 4.00 m is exceeded when folding the machine in and out,

the machine must not be folded in the vicinity of conducting overhead

power lines! Danger of electrocution! Should the machine come into

contact with an overhead power line:

• Do not attempt to climb out of the tractor cabin

• Do not touch any metal parts on the tractor

• Do not create any conductive contact with the ground

• Warn all persons in the area not to app roac h the tractor or the ma-

chine

• Wait for help from professional emergency service personnel as

power in the overhead line must first be switched off

Never climb onto the machine if it is beneath con ducting overh ead power lines. The voltage can jump even if the lines are not actually touching the machine.

Make sure the immediate vicinity is clear

Before starting up, folding out the machine, and using it, check the

vicinity of the machine. Mak e sure the oper ator has an adequat e view

of the work area. Do not beg in work unt il th e immediate vicinity is cleared of any persons or objects. Any use of the machine without verification of the situation around it can lead to accidents.

Retighten all nuts, bolts and screws

Nuts, bolts and screws should be checked at regular intervals and

tightened if necessary. Screws can come loose unnoticed while operating. Damage can occur to the machine or injury to persons.

What to do in the event of a malfunction

In the event of a malfunction, shut down and secure the machine immediately. The malfunction may be eliminated immediately, or your

dealer must be assigned the task. Further operation of the machine

can lead to damage to the machine or injury to persons.

15

Safety

Uncoupling the machine

Care and m ai nte-

nance

Increased risk of injury

There is an increased risk of injury when uncoupling the

machine from the tractor. Therefore:

• Secure the tractor in such a way that it cannot roll for wards or back-

wards

• Never stand between the tractor and the machine during uncou-

pling

• Actuate the three-point power l if t system slowly and carefully

• Make sure the machine is standing on a secure and level surface

• Only disconnect the hydraulic hoses if there is no pressure in the

tractor and machine hydraulic system

Nonobservance can lead to serious or fatal injury.

Follow the care and maintenance chart

Observe prescribed interval s for maintenance chec ks and insp ections

specified in the operat ing manual . No nobservanc e of the time peri ods

can lead to damage to the machine, poor quality of work or accident s.

Only use OEM replacement parts (original equipment manufacturers)

Many components have special ch aracteris tics whic h are essent ial for

the machine's stability and correct function. Only accessories and

spare parts supplied by the manufacturer have been tested and approved. Using other pr oduct s may le ad to mal functions or impa ir safety. The use of non-OEM spare parts renders the manufacturer's guarantee null and void and frees the manufacturer from all liability.

When performing care and maintenance work:

• Switch off the tractor's power take-off shaft

• Depressurise the hydraulic system

• Whenever possible, uncouple the tractor

• Make sure the machine is standing securely. Provide additional

support as required

• Do not use parts of the machi ne as c lim bing ai ds; u se on ly spec ial

and safe means of ascent

• Secure the tractor so that it cannot rol l forwards or backwards

• Never reach into the V-belt while it is moving

It is only possible to guarantee work safety during care or maintenance work through observing these regulations.

Turn off the electrical supply

Prior to carrying out work on the electrical system, disconnect it from

the power supply . Equipment under electrical power can cause damage to equipment and injury to persons.

16

Safety

Replace hydraulic hoses

Replace hydraulic tubes every three years. Hydraulic hoses can age

without any externally vi sible damage. Defect hy drauli c lines can lead

to severe or fatal injuries.

Caution when cleaning with a high-pressure cleaner

The machine can be cleaned using either water or a steam jet. Only

use low pressure to clean bearings, fans, signal distribution boxes,

plastic part s and hydraulic tubes. Excessi vely high pressures can cause damage to these parts.

Prior to welding work, disconnect the battery and generator

Prior to carrying out electrical welding work on the attached machine,

disconnect the tractor's battery and generator. This prevents damage

to the electrical syst em .

Tighten the screw connections

All screw connections r eleased d uri ng mainte nance and rep air oper ations must now be retightened. Loo se threaded connecti ons can undo

without you noticing during your work. As a result, machine parts can

fall off. Severe injury to persons or damage to equipment can result.

Further regulati-

ons

Observe the regulations

In addition to these safety instructions, observe the following:

• Accident-prevention regulations

• Generally recognised safety regulations, occupational heal th re-

quirements and road traffic r egulations

• Instructions given in this oper ati ng manual

• Operation, maintenance, and repair regulations

17

Getting to know the machine

Range of applica-

tion of the ma-

chine

Proper u s e

This section contains general information on your machine and information on:

Getting to know the mach ine

• Range of application

• Proper use

• Definitions

• Characteristics

• Designation of the assemblies, and

• Technical specifications

The Miniair Nova is a precision seed drill for seeding after seedbed

preparation. It i s for normal use i n agriculture. V er satile equipment options allow the seeding of round, calibrated seed. The prerequisite is

always a soil condition that allows cultivation and seeding. The level

of wetness or dr yness, f or exampl e, ca n make se eding t he soil impossible with some soil types.

Any application other than or beyond this, e.g. as a means of transport, for stump pulling or to transfer power t o other objec ts i s considered improper use. The manufacturer and dealer are not liable for damage caused by improper use. The risk is borne solely by the user

Definitions

Seeding after ploug-

hing

Seeding after seed-

bed preparation

Mulch seeding

Direct seeding

There are different in terpretations and definiti ons for some agr onomic

terms. The terms used in this opera ting manual are defined as foll ows.

Seeding after completion of turning the soil with the plough.

Seeding after completion of seedbed prepar ation or secon dary prep aration after turning the soil. The purpose of seedbed preparation is to

prepare the top soil layer f or seeding. By working at a const ant depth,

clods are crushed, the soil surface levelled and the ground below the

seed deposit is recompacted due to the soil contact required.

Seeding after completion of mixing the soil. The soil must be worked

deeper than the required deposit depth.

Seeding without working the soil. Residue from the previous crop is

chaffed or in a condition that enabl es dir ect seeding.

18

Getting to know the machine

Characteristics of the machine

Perfect combination

Thanks to specially harde ned mate rial combined wi th an opt imum design and high manufacturing quality, you acquire a reliable machine

for seeding. It is easy t o handle and featur es low-maintenance mechanics.

Exact depth adjustment and guidance

All sowing units can be adjusted exact ly to the des ired depth. The deposit depth can be adjusted via the front press wheels. The pre-running press wheels allow in combination with parallelogram construction of the sowing units a precise depth guidance.

Seed spacing and seed deposit

Even without tools, the seed spacing can be adjusted easily either

electronically or using a shift gear. The optoelectronics of the machinery is responsible for the monitoring of the grain deposit (accessory). An inter mediate pre ss wheel beds the s eed in an optimum manner in the moisture-c onducting soi l layer . A seed coverer cove rs it wit h

loose earth and a press wheel firms up the ground which means that

it is better protected against mud formation.

19

Getting to know the machine

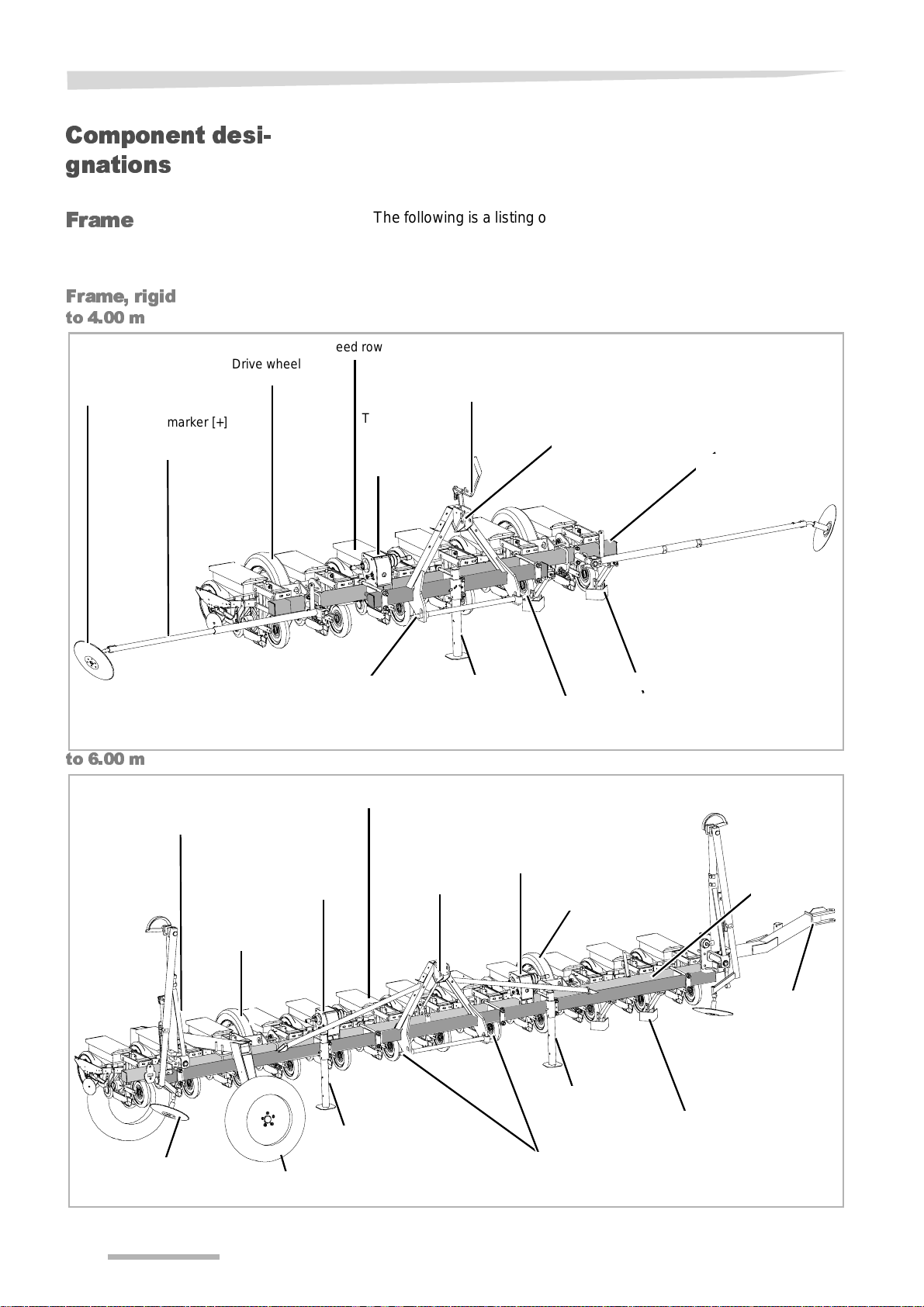

Component desi-

gnations

Frame

Frame, rigid

to 4.00 m

Track marker

disc [+]

Track marker [+]

Drive wheel

The following is a list ing of the most important assemblies in the frame

as an overview. The assemblies for the sowing units can be found

from page 23.

.

Seed row

Switchover lever for

the track marker

Transmission

(for mechanical

machines)

Attach m e nt po i nt

for the primary

top link

Frame

to 6.00 m

Track marker [+]

Drive wheel

Track marker

disc [+]

Attachment

point for the lower link

.

Seed row

Attachment

Transmission

(for mechanical machines)

Drawbar

pipe

Transportation wheel of the

lengthways transport attachment

point for the

primary top

link

Drawbar

pipe

Transmission

(for mechanical machines)

Attachment

point for the lower link

Attachment

point for the lower link

Drive wheel

Drawbar

pipe

Clod deflector [+]

Frame

Drawbar on

the lengthways

transport attachment

Clod deflector [+]

20

Getting to know the machine

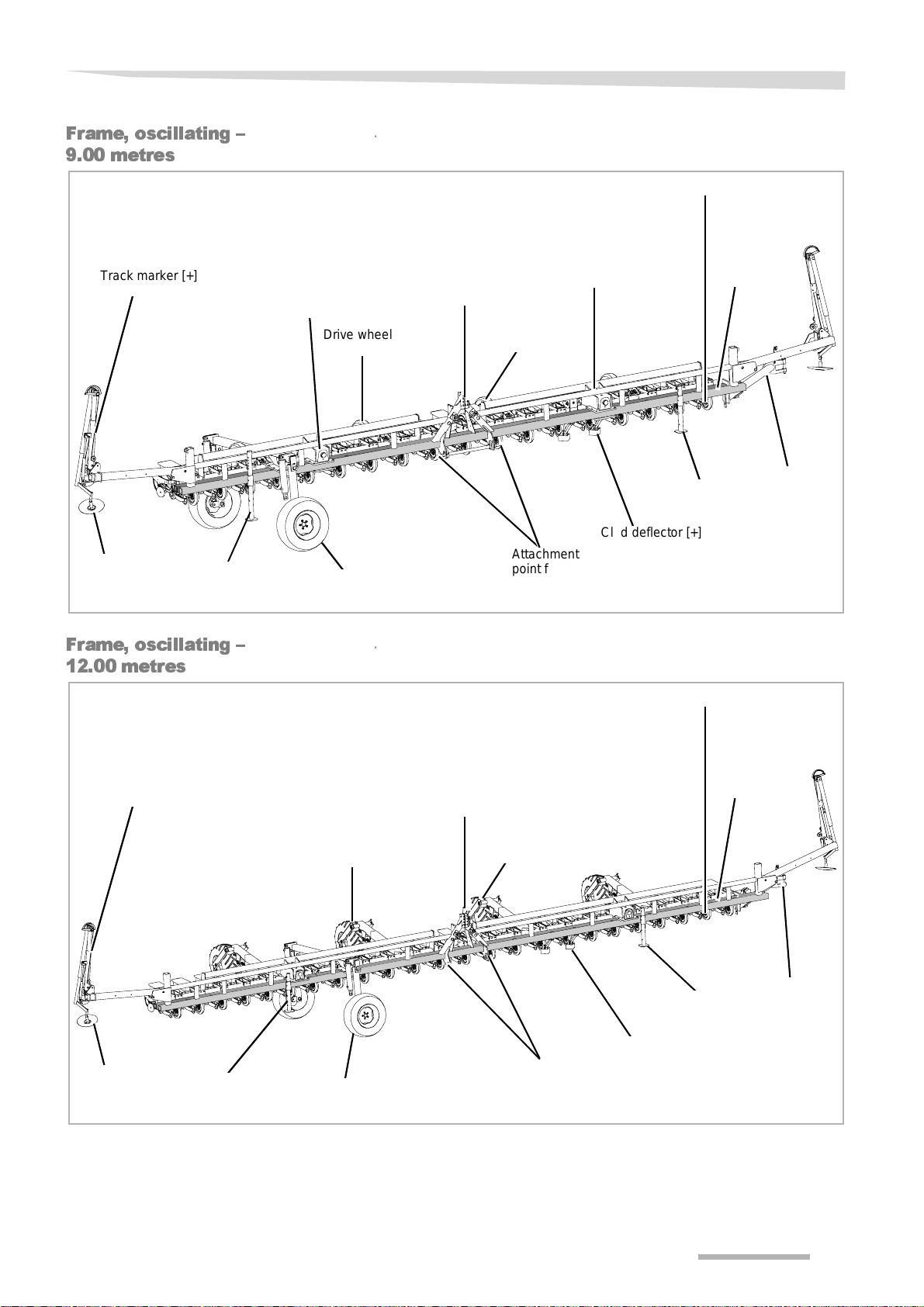

Frame, oscillating –

9.00 metres

Track marke r [+]

Track marker

disc [+]

Drawbar

pipe

.

Transmission

(for mechanical machines)

Drive wheel

Transportation wheel of the

lengthways transport attach-

Attachment point

for the primary

top link

Drive wheel

Transmission

(for mechanical machines)

Attachment

point for the lower link

Seed row

Drawbar

pipe

Clod deflector [+]

Frame

Drawbar on

the lengthways

transport at-

Frame, oscillating –

12.00 metres

Track marke r [+]

Track marker

disc [+]

Drawbar

pipe

.

Attachment point for

the primary top link

Drive wheel

Transportation wheel of the

lengthways transport attachment

Drive wheel

Attachment

point for the lower link

Seed row

Drawbar

pipe

Clod deflector [+]

Frame

Drawbar on

the lengthways

transport attachment

21

Getting to know the machine

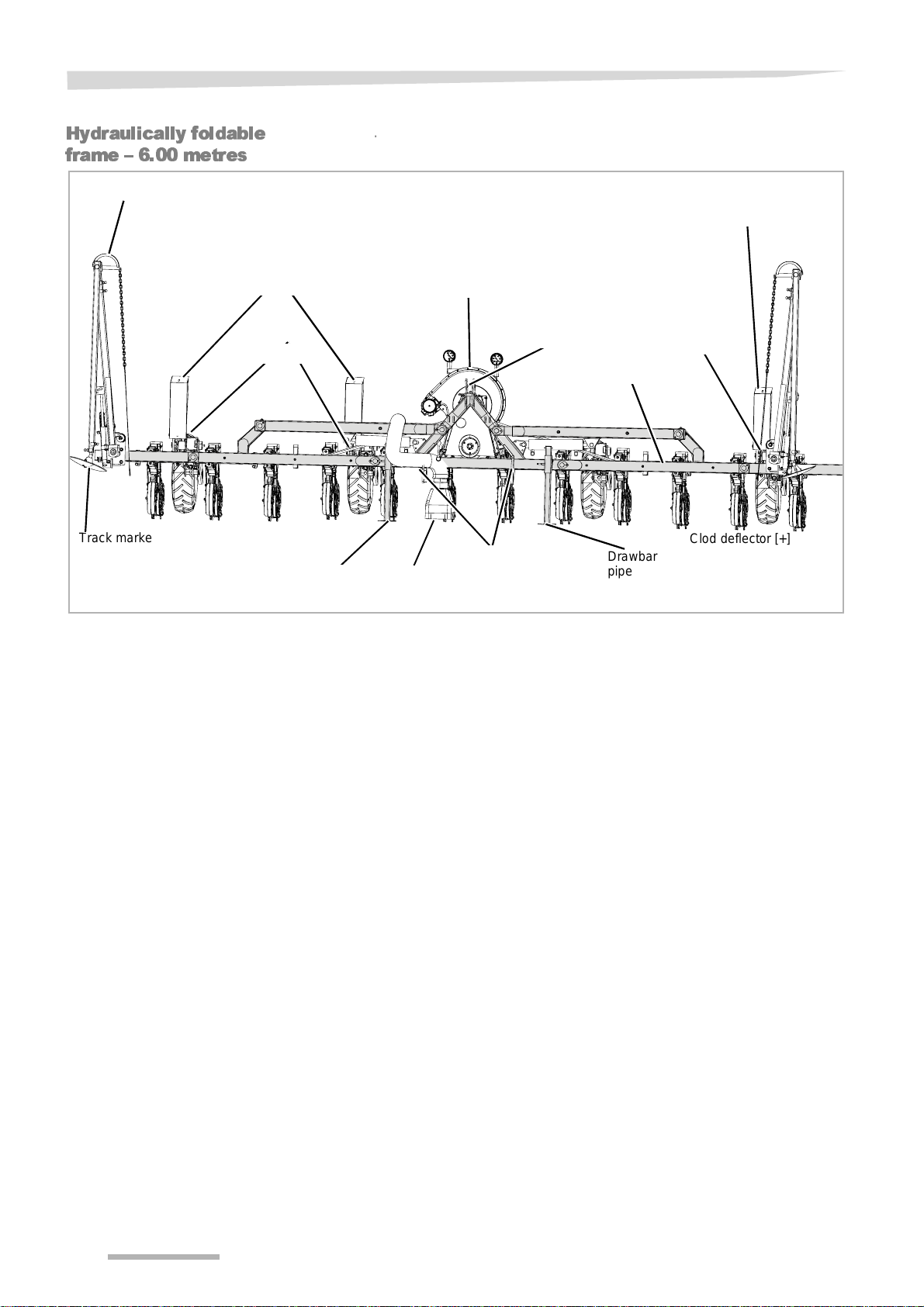

Hydraulically foldable

frame – 6.00 metres

Track marker [+]

Transmission

(for mechanical machines)

Drive wheel

Track marke r

disc [+]

Drawbar

pipe

.

Clean-Air

[+]

Fan

Attachment

point for the lower link

Attachment point for

the primary top link

Frame

Drawbar

pipe

Transmission

(for mechanical machines)

Drive wheel

Clod deflector [+]

22

Getting to know the machine

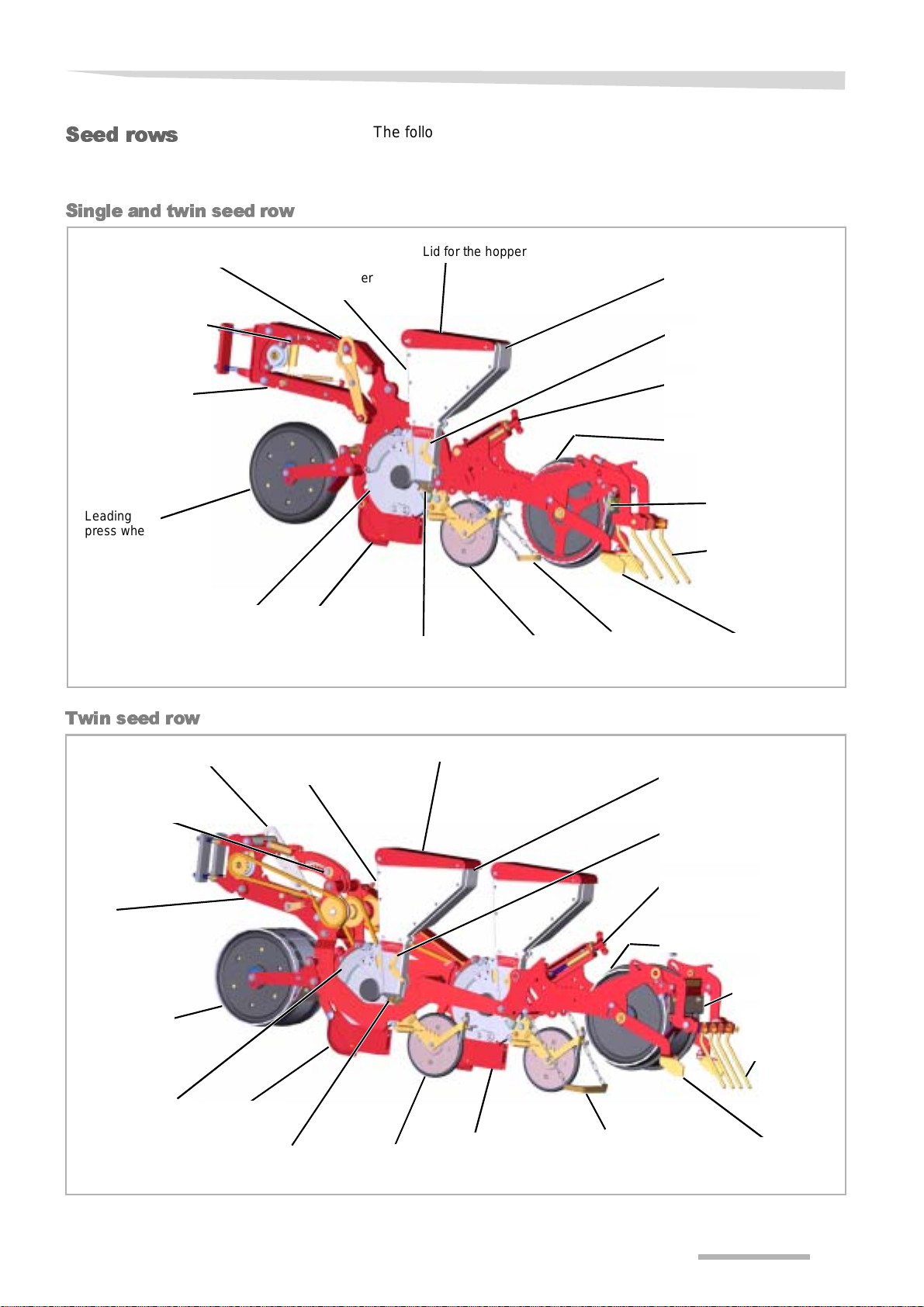

Seed rows

Single and twin seed row

Lift assembly

Adjust the load or

load-relief

Parallelogram

Leading

press wheel

Seed hopper

The following is a listing of the most important assemblies for the sowing units.

The assemblies for the frame can be found from page 20.

Lid for the hopper

Grip for opening the

seed hopper

Adjust the scraper on

the seeding heart

Adjusting working depth

Press wheel,

here the Farmflex

Scraper

Coverer,

here the finger coverer

Twin seed row

Lift assembly

Adjust the load or

load-relief

Parallelogram

Leading

press wheel

Seeding

heart

Coulter tip(s)

Seed hopper

Hopper emptying

flap

Lid for the hopper

Intermediate

press wheel [+]

Towing coverer

[+]

Grip for opening the

seed hopper

Adjust the scraper on

the seeding heart

Adjusting working depth

Press wheel,

here the Farmflex

Blade coverer [+]

Scraper

Coverer,

here the finger

coverer

Seeding

heart

Share wedge

Hopper emptying

flap

Intermediate

press wheel [+]

Second seed

row

Towing coverer

[+]

Blade coverer [+]

23

Getting to know the machine

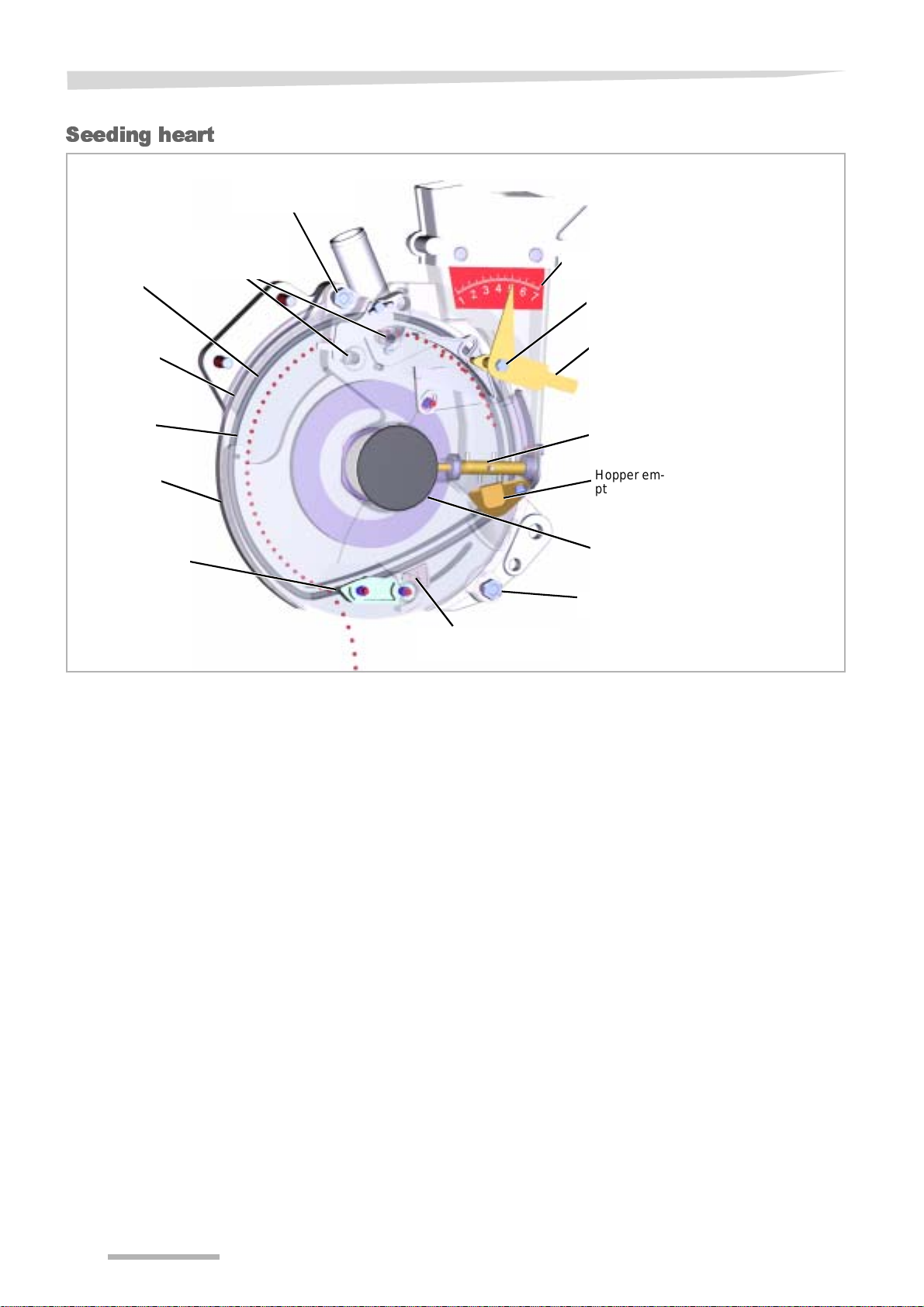

Seeding heart

Screw for the lid of

the seeding heart

Additional scraper for

O-ring

Window

special seed [+]

Orientation scale

Sealed adjustment

screw

Scraper, adjustable to suit seed

Seed disc

Lid of the seeding heart

Fixed scraper

Cleaning jet

Agitator shaft

Hopper emptying flap

Cover cap concealing drive for agitator shaft

Nut for the lid of the seeding heart

24

Technical specifi-

cations

Frame

Getting to know the machine

Height (m) Width (m) Depth

(m)

Working

position

2.00-4.00 m 2.25-2.50 2.25-2.50 2.55-2.80 2.55-2.80 1.80 see model pla-

4.50-6.50 m 2.70-3.00 2.70-3.00 6.00 2.65-2.90 1.80 see model pla-

9.00 metres 2.40 3.20 9.00 2.70 2.70 see model pla-

12.00 metres 2. 40 3.20 12.00 2.95 2.70 see model pla-

6.00 m PH 1.80-2.20 2.90-3.20 6.10 2.80-3.20 1.70 see model pla-

Transport position

Frame, rigid

Frame, oscillating

Hydraulically foldable frame (PH)

Working

position

Transport position

Weight (kg)

te

te

te

te

te

Lengthways transport attachment, mountable

Draw bar 25

per transport wheel 40

Equal iser bar 30

Lengthways transport attachment, hydraulically foldable

Draw bar 210

per transport wheel 40

Equal iser bar 30

25

Getting to know the machine

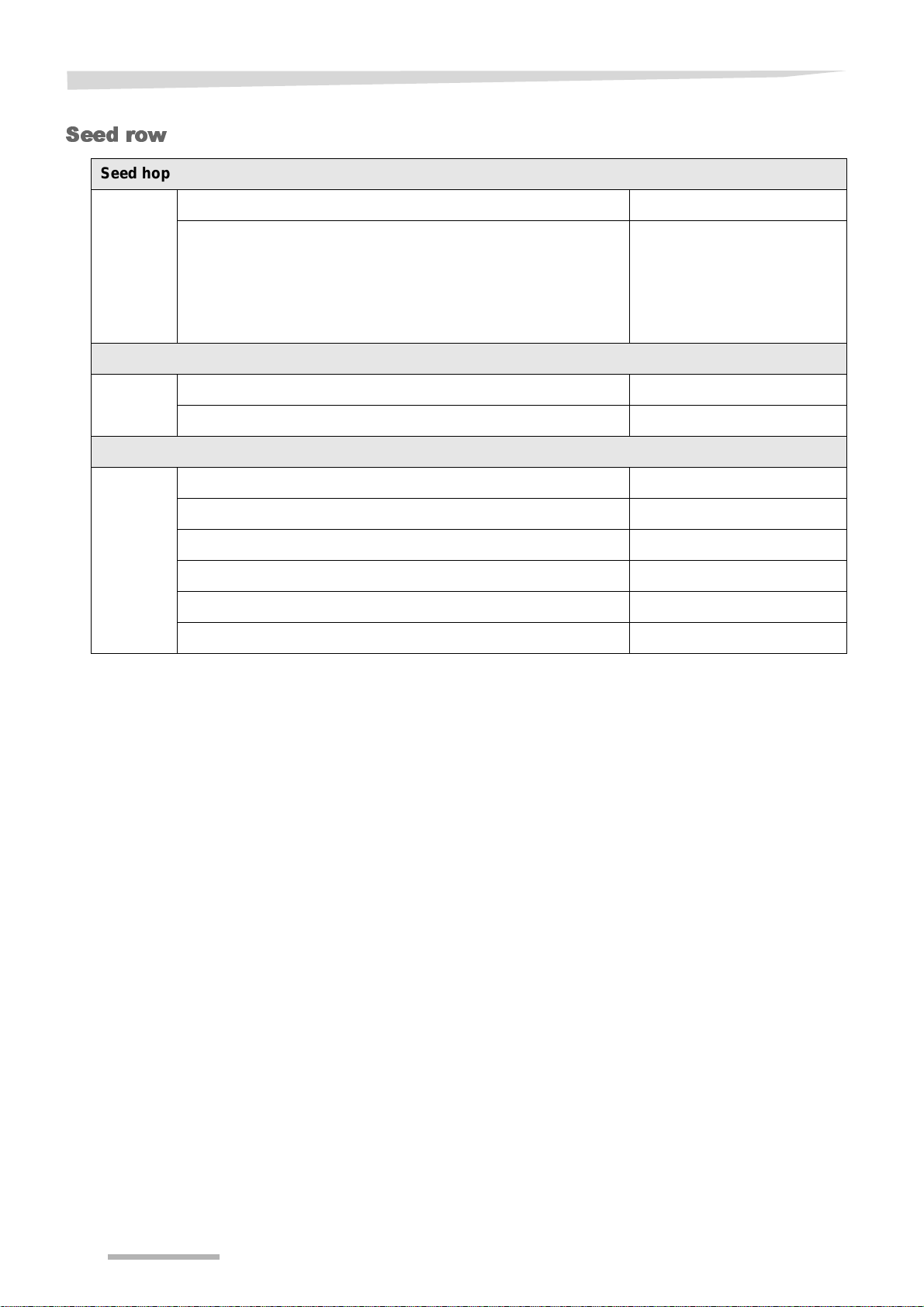

Seed row

Seed hopper

Volume (l) 4

Filling hei g ht

• minimum up to the socket

• maximum roughly 1 cm from the edge

Weights of the sowing unit (kg) without seed

Single / twin seed row 29.5 / 32.0

Twin seed row 50.0

Tool weights (kg)

Finger coverer 1.7

Adjustable coverer 1.1

of the hopper

Towing coverer 0.3

Intermediate press wheel with rubber mount 1.0

Intermediate press wheel with stainless-steel ring 1.2

Press wheel with stainless -steel ring 4.8

26

Others

Tractor

Air pressure of tyres (bar)

Getting to know the machine

Minimum tractive power (kW)

• 2.00 - 4.00 m, rigid from 30

• 4.50 - 6.50 m, rigid from 50

• 9.00 metres and 12.00 metres from 65

• 6.00 m PH from 65

Transport wheel s

• 7.00 - 12 2.0

• 10.0 / 75 - 15.3 4.0

Drive wheels

• 7.00 - 12 1.5

Granule distributor [+]

Hopper volume (l) 33

Number of overflow outlets 2 or 3

Filling height

• minimum (l) 0.3

• maximum roughly 1 cm from the edge of the

Number of sowing units 6 - 18

Control system and the electrohydraul ics

Power supply (V) 12

Fuse (A) 16

Type of protection

for all electrical systems IP 65

hopper

27

Delivery and assembly

Delivery and assembly

Check scope of supply

The machine is delivered compl etely assembled. I f part s of the machi ne have not been assembled, please contact your dealer.

Do not assemble the machine yourself

Do not do assembly work yourself since prerequisites for an orderly

condition of the machine are :

• observance of a sequence of worksteps

• observation of tolerances and torques

• safe handling of the electronics

If parts are missing or have been damaged during transportation,

please submit a complaint immediately to your dealer, importer or the

manufacturer.

28

Coupling the machinery

Couplin g the m a-

chine

Increased risk of injury

When coupling the machine to the tractor, there is an increased risk of

injury. Therefore:

Coupling the machinery

• Secure the tractor in such a way that it cannot roll for wards or back-

wards

• The tractor and machine must belong to the same category

• Never stand between the tractor and the machine during coupling

• Actuate the three-point power l if t system slowly and carefully

Nonobservance can lead to serious or fatal injury.

The machine is fact ory-equipp ed for mount ing with a three-poi nt li nkage.

> Slide suitable catch pan s on the lower link arms of the machine for

the tractor and secure with linchpins

> Couple the machine and raise slightly by means of the lower links

> Slide up support legs and secure with bolt. Secure bolt wit h cotter

pin.

> Adjust the top link so that the frame is parallel to the ground in the

working position and the three-point block is vertical

> Adjust the lower li nk so t hat the machi ne has littl e play to the left or

right

Never adjust the depth of the machine via the lower link, but rather at

each individual sowing unit.

Connections

Electrics

Increased risk of injury

When coupling the machine to the tractor, there is an increased

risk of injury. Therefore:

• Secure the tractor in such a way that it cannot roll for wards or back-

wards

• Switch off the tractor engine

After coupling, make the followi ng connections:

• Electrics

• Hydraulics

If present, connect the el ectri cal cabl es for th e foll owing to the tracto r:

• The folding of the PH frame

• The folding of the electrohydraulic track markers

• The machine's electronic control system

• The lighting equipment on the machine

> Check all connections to make sure they are working properly.

29

Coupling the machinery

Hydraulics

Hydraulic connection at zero pressure only

Only connect the hydraul ic hose s to the tr actor hy drau lic sy stem if th e

tractor and machine hydraulic system is depressurised. A hydraulic

system which is under pr essure can cause unforeseen movement s on

the machine.

Avoid mixtures of different oils

If the machine is used with different tr actors, incompatible types of oil

may become mixed. Such a mixture of incompatible oils can result in

the destruction of tractor components.

Check tubes and couplings

Check all hydraulic tubes for damage before connecting them up.

Check for firm seating of all hydraulic couplings once connected. Defect hydraulic tubes or poorly seated hydraulic couplings can initiate

unforeseen movements on the machine or lead to acci dents.

Securing the control system

Secure the control systems on the tractor in the transport position

against unintended actuation. Unintended actuation of a control system can trigger un foreseen movements on t he machine or lead t o injury to persons.

30

Loading...

Loading...