ES/LS

Operator‘s manual

Original operator‘s manual

Edition 06.2015

Date of printing 06.2015

Language EN

Machine number

Model ES/LS

Document number A133309940.EN

Machine identification

In order for your dealer to assist you as efficiently as possible, you will need to provide some information about

your machine. Please enter the details here.

Designation

Machine ID

Address of

supplier

ES/LS

Address of

manufacturer

Kverneland Group Operations Norway AS

Plogfabrikkvegen 1

4353 Klepp Stasjon

Norway

Tel. +47 5142 9000

www.kvernelandgroup.com

Copyright by Kverneland Group Operations Norway AS. Reproduction, transfer to other media, translation or the use of extracts or parts of this

manual without the explicit permission of Kverneland, is not permitted. All rights reserved. The contents of this operator’s manual are subject to

change without notice. The right to technical revision is reserved.

Table of contents

Preface ....................................................... 4

Target group for this operator‘s manual 4

Demonstration and training 4

Symbols used 4

Terminology used 5

Safety ......................................................... 6

DANGER, WARNING and CAUTION

labels 7

General safety information 10

Getting to know the plow ......................... 15

Proper use 15

Features 15

Components 16

Technical specifications 18

Cross shaft 19

Tire pressure 19

Information plate 20

Optional equipment .................................. 21

Preparation for use ................................... 27

Tractor 27

Remove paint 28

Connecting ................................................ 29

Coupling 29

Connection geometry 30

Clearance between the depth wheel/plow

and the ground 30

Clearance between the tractor and plow 30

Table of contents

Before maintenance 55

Maintenance table 56

Cleaning 56

Replace hoses 60

Replace worn parts 60

Replace Quick-fit points 61

Replace Knock-on® points 61

Tighten bolts and nuts 62

Check springs for correct length 63

Tire pressure 64

Set the bodies 64

Possible modifications ............................. 67

Reversing direction 67

Restrictor position 67

Spring release system [ES] 68

The position of the cross shaft 74

Parking and storage .................................. 75

Parking and storage 75

Plow with Eco-plowshare [+] 75

Storage 75

Troubleshooting ........................................ 76

Checklist .................................................... 77

Disposing of the plow ............................... 79

EU goods certificate .................................. 80

Index ........................................................... 1

Transport ................................................... 31

Safety 31

Before transport 32

Stabilize rotating cross shaft [+] 32

Put into transport position 33

Set into the plowing position 37

Set into the plowing position 39

Adjust the plow ......................................... 41

Working width 41

First furrow width 43

Working depth 44

Levelling 46

Disc coulter [+] 48

Skimmer [+] 50

Trash board [+] 51

Soil packer arm [+] 51

Plowing ...................................................... 53

Safety 53

Before plowing 53

Check during plowing 53

Reversing the plow 54

Care and maintenance ............................. 55

Safety 55

3

Preface

Preface

Target group for

this operator‘s

manual

This operator‘s manual is intended for personnel concerned with the

inspection, use and maintenance of the plow. It contains all the infor-

mation needed for safe handling, use and maintenance of the plow.

For your safety

Before starting to adjust and use your plow, familiarize yourself with

this operator‘s manual. Doing so will help ensure the operator‘s safety

and the safety of any persons in the immediate area. It is very impor-

tant to read this manual carefully before using the plow and to keep it

handy. In this way, you will:

•

Avoid accidents

•

Satisfy the warranty terms and conditions

•

Ensure that you have a functional plow which works as it should do

at all times

•

Understand how to operate in different conditions.

\

WARNING

Observe the warning triangle

The warning triangle indicates important safety information and

danger. Failure to observe this safety information can result in:

•

Improper use of this machine

•

Damage to the machine,

•

Personal injury or accidents.

Demonstration

and training

Symbols used

For the employer

Every employee must be given training at regular intervals on how to

use this plow (at least once a year) in accordance with the guidelines

issued by the employer's insurance company. Untrained or unauthor-

ized individuals are not permitted to use the plow.

You are personally responsible for the safe use and maintenance of

the plow. You must ensure that you and anyone else who is going to

operate, maintain or work around the plow is familiar with the operating

and maintenance procedures and related safety information contained

in this operator‘s manual.¨

This operator‘s manual uses the following symbols and expressions:

•

Lists are bulleted

> A triangle indicates points you must follow

→ An arrow indicates cross references to other sections of the man-

ual

[+] Indicates optional equipment

4

Preface

\

In addition to these symbols, the following pictograms are used to help

you find the text sections:

TIP“Tip” indicates useful tips and advice.

The warning triangle indicates that there is a risk involved with the

work of fitting or adjustment.

Shut off the engine, set the parking brake, remove the ignition key and

secure the tractor against rolling away.

Terminology used

This operator‘s manual uses the following terminology:

•

Right hand position: viewed from the rear, the first body is located

at the right side of the plow.

•

Left hand position: viewed from the rear, the first body is placed on

the left-hand side of the plow.

•

Turning with the bodies over: when reversing, the bodies turn over

the frame, with the depth wheel positioned under the frame.

•

Turning with the bodies under: when reversing, the bodies turn un-

der the frame, with the depth wheel positioned above the frame.

5

Safety

\

California Proposition 65

\

WARNING

Engine exhaust, some of its constituents, certain machine compo-

nents and fluids, contain or emit chemicals known to the State of

California to cause cancer and birth defects or other reproductive

harm.

\

SAFETY FIRST

This symbol, the industry's "Safety Alert Symbol", is used through-

out this manual and on labels on the machine itself to warn of the

possibility of personal injury. Read these instructions carefully. It is

essential that you read the instructions and safety

regulations before you attempt to assemble or use this unit.

Safety

\

DANGER

Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

\

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

\

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury.

6

\

Safety

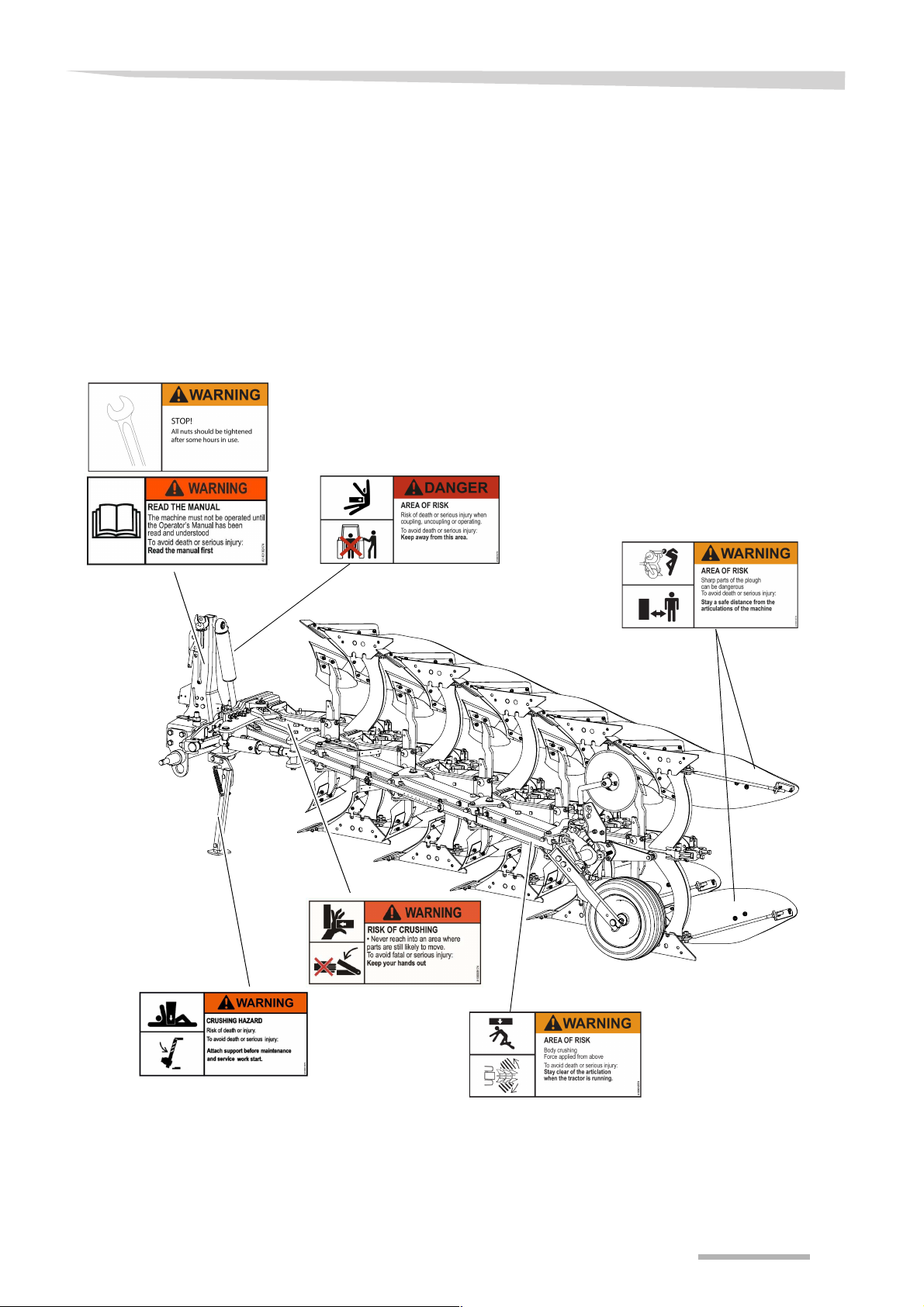

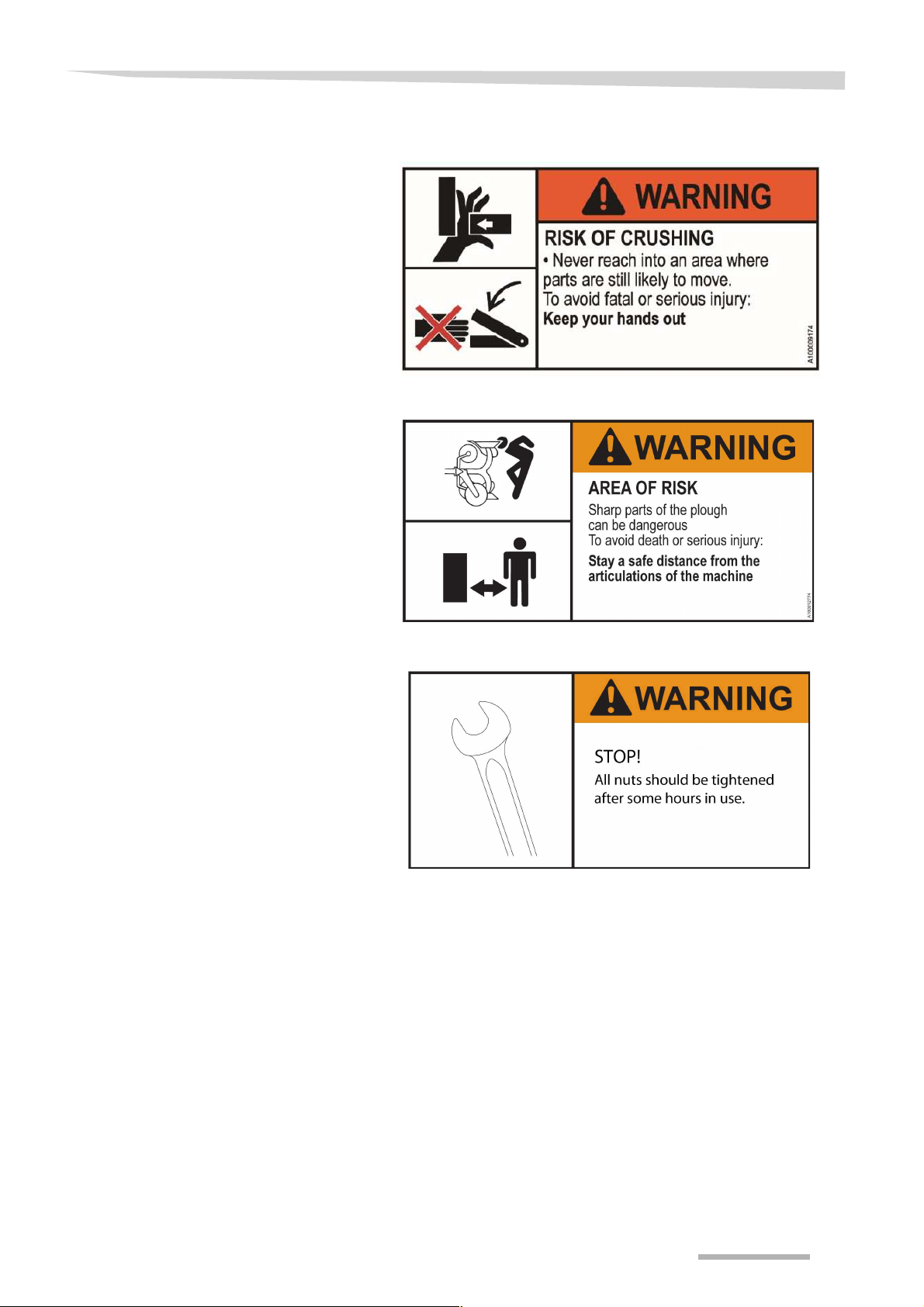

DANGER,

WARNING and

CAUTION labels

DANGER, WARNING and

CAUTION labels on the

plow

This chapter describes general safety information for this product.

Each section of this operator‘s manual also contains its own specific

safety information.

Safety decals are placed on important parts of the plow for your own

safety. Do not remove these. If they can no longer be read or start to

fall off, replace them with new spare decals (see spare-parts cata-

logue).

7

Safety

\

Meaning of DANGER,

WARNING and CAUTION

labels

The meaning of the safety decals is explained below.

8

\

Safety

9

Safety

General safety

information

\

Please read and ensure you understand the following general safety

information. Specific safety information is pointed out in the relevant

chapters.

For your safety

Read and ensure you understand the instructions

Before starting to operate the plow, read the operator‘s manual and

follow the instructions. Failure to follow the instructions may damage

the plow or lead to injury.

Qualified users only

The plow must not be used before the user has received the proper

training and is familiar with the function and safe use of the plow. In-

correct use of the plow can result in damage to the plow or personal

injury.

Check for technical faults

Before starting to use the plow, check that the machine is in perfect

condition. If any components are faulty, contact the dealer and ar-

range for them to be replaced. Faulty components can lead to further

faults and damage to the plow or personal injury.

Keep your distance

Do not go under or close to the plow when it is in operation or when it

is being connected to the tractor. This can result in personal injury.

Support the plow

Do not go under or close to the plow if it is not properly supported. If

the plow tips, it can damage the plow or cause personal injury.

Lower the plow

Always lower the plow when the tractor is parked. Otherwise, acciden-

tal lowering of the plow can result in damage or personal injury.

Use front weights

Adjust the tractor with sufficient front weights to ensure stability and

safe control.

Check the area

Always check the immediate area before starting to move or use the

plow. There must be no personnel in the vicinity of the plow when it is

in use.

Use the parking stand

Use the parking stand when parking the plow. If the plow is not

supported properly, it can tip over. This can result in damage to the plow

or personal injury.

10

Information for the employer

Inform all persons who work with the machine about this safety

information at regular intervals and in accordance with statutory regu-

lations.

\

Coupling

Safety

No riding on the plow

Persons or objects must never be transported on the plow. Carrying

passengers, especially children, on the plow is life threatening and

prohibited. Serious or fatal injury may be caused as a result.

Safety for children

Never assume that children will remain where you last saw them.Be

alert and shut your machine down if children come into the work area.

Never allow children to play on or operate the machine.

Increased risk of injury when coupling

There is an increased risk of injury when the plow is coupled to the

tractor. Therefore:

•

Shut off the engine, set the parking brake, remove the ignition key.

•

Secure the tractor to prevent it from rolling.

•

Do not stand between the tractor and plow when coupling

•

Lift and lower the plow slowly

An unsecured tractor can create hazardous conditions.

If this requirement is ignored, the consequence may be damage

to the machine and the potential for life-threatening injuries.

Adjust and maintain

Relieve the oil pressure – accidental movements

Relieve the oil pressure both in the tractor’s and the plow’s hydraulic

systems before connecting or disconnecting the hydraulic hoses. Otherwise, oil under pressure can result in the plow starting to move ac-

cidentally. This can result in damage to the plow or personal injury.

Check the length of the hose

Check that there is sufficient slack in the length of the hose on the plow

and between the plow and tractor. If the hoses are trapped or

stretched, this can result in the hoses becoming damaged or de-

stroyed.

Ensure the hydraulic connections are correctly coupled.

Make sure you do not cross hydraulic connections when coupling

them to the tractor. If the connections are crossed, it will cause the

plow to move unexpectedly. This may damage the plow or lead to injury.

Avoid skin contact with oil and lubricants

When handling oil or lubricants, avoid contact with the skin by using

oil-resistant gloves. Oil and lubricants can damage the skin.

Relieved oil pressure – jet streams

Before replacing hydraulic parts or performing other work on them, re-

lieve the oil pressure in the system. The oil pressure can be very high.

Jet streams due to high oil pressure can result in injury. In case of in-

jury, seek medical advice immediately.

11

Safety

\

Maintain at regular intervals

Perform maintenance on the plow at regular intervals as described in

»Care and maintenance«. Also replace worn parts as described.

Plows which are not well maintained can malfunction. This can result

in damage to the plow or personal injury.

No welding

Do not weld any part of the plow. The plow is made from reinforced

steel, and welding will greatly impair the strength of the plow. Welding

can result in the plow failing.

Retighten bolts and nuts

Retighten all the bolts and nuts on the plow at regular intervals. This

is especially important after the first few hours of use. Loosening of

bolts and nuts can result in personal injury.

→ »Tighten bolts and nuts«, page 59.

Replace the cross shaft after 1000 km (621 miles)

On large mounted plows we recommend you to replace the cross

shaft after 1000 km (621 miles) of road transport. Road transport can

result in non-visible damage to the cross shaft.

Proper working condition

Ensure that the tractor and the machine are always in proper working

condition. Make sure that the tractor brakes work in synchronisation

with the machine. Also follow the instructions in your tractor's

operator’s manual.

Wear protective clothing

Wear protective clothing, e.g. gloves, when working with sharp parts

of the plow. In particular, parts which come into contact with the soil

can be very sharp. Careless handling can result in injury.

Spesified workwear

Do not wear loose fitting or other inappropriate clothing. Loose fitting

items of clothing may become caught in rotating parts. Wear the prop-

er protective clothing. Different environments may require special

clothing to preform the operation and maintenance of the plow. Seri-

ous or fatal injury may be caused if these guidelines are not followed.

12

Use original spare parts

Use only genuine Kverneland spare parts. Other products may

adversely affect the correct operation of the plow and safety. The

warranty will no longer be valid if parts not produced by Kverneland

are used.

Check the tire pressure

Regularly check that the tire pressure meets the requirements. Incor-

rect tire pressure can result in damage and poor performance.

→ »Tire pressure«, page 17.

\

Safety

Driving on the road

Be aware of the plow’s length

The plow is very long and swings out when turning. Avoid allowing the

rear of the plow to hit obstacles during sharp swings.

Stabilize the lower links

During all operations other than plowing, stabilize the tractor’s lower

links. This prevents the plow from unintentionally moving sideways.

Obey local state, and Federal laws when transporting

Obey all laws when driving with the plow on public roads. For

example

•

have all necessary lights installed and warning signs displayed.

•

do not exceed the maximum permitted weights, loads and

dimensions.

The user is responsible for ensuring that the plow complies with the

law when driving on public roads.

Additional markings are required for road transport in some U.S. states

and some Canadian provinces:

Marking for slow-moving vehicle – SMV

This SMV emblem shall be used on all slow moving machines when

operated or traveling on public roads.

•

On slow moving machines with design specifications of a maxi-

mum speed of 40 km/h (25 mph) or less, the SMV emblem shall be

used. Per ASABE S276.7

Adjust speed: max. 25 km/h (15 mph)

Always adjust the driving speed according to the road’s conditions, but

never drive faster than 25 km/h (15 mph). Excessive speeds can result

in too much stress on the tractor, plow and transport wheel. This can

result in damage or breakage.

Speed adjustment

In poor road conditions and at high speeds, significant forces can be

generated which subject the tractor and machine material to high or

excessive stresses. Adjust your driving speed to the road conditions.

A driving style which is not adapted to conditions can cause accidents.

Accidents with serious or fatal injuries may be caused as a result.

Unrestricted field of vision to the rear

After plow has been coupled, ensure that you have an unrestricted

view of the machine, in both its work and transport positions. Other-

wise, dangerous situations may not be detected in time, resulting in

accidents or damage.

13

Safety

Hydraulics

\

Hydraulic connection at zero pressure only

Only connect hydraulic hoses to the tractor hydraulic system if the

tractor and machine hydraulic system is at zero pressure. A pressurize

hydraulic system can trigger unforeseen movements on the machine

and can cause serious machine damage and personal injury. Serious

or fatal injury may be caused as a result.

High pressures in the hydraulic system

The hydraulic system is under high pressure. Regularly check all lines,

hoses, and coupled connections for leaks and externally visible damage. Do not use hands to search for suspected leaks. Only use suita-

ble equipment when looking for leaks. Rectify any damage imme-

diately. Fluid escaping under pressure can penetrate skin and may re-

sult in injuries and fires. Seek medical attention immediately if injuries

occur.

Replace hydraulic hoses every six years or earlier

Hydraulic hoses age without showing externally visible signs. Replace

hydraulic hoses every six years, or earlier if aging or degradation is

visible. Defective hydraulic lines can cause serious or fatal injuries.

Warranty

The warranty and manufacturer's liability will no longer be valid if the

instructions provided in the chapter on Safety are not observed, if

maintenance is inadequate or faulty, if the machine is used for pur-

poses other than those for which it was intended and if it is overstressed, or if impermissible modifications are made to the machine.

14

Getting to know the plow

Proper use

Features

This chapter provides information on the plow. It instructs you on the

correct use of the plow and the plow’s functions in addition to providing

technical information.

The intended use of this machine is for purposes of plowing. Any other

use of the plow, e.g. as for lifting or pulling operations, is deemed im-

proper use. The manufacturer and dealer are not liable for damage

caused by improper use.

Two types of beam

The ES plow is equipped with Kverneland’s automatic stone release

system. The singel leaf spring system cushions the plow body when a

hard object is impacted. Once the plow has passed the obstacle, the

body automatically reverts to the correct plow depth.

The LS plow is equipped with a shear bolt beam. On collision with a

stone or other object in the ground, the shear bolt is sheared, thus pro-

tecting against greater damage.

Variable working width

The parallel design of this plow provides for a steplessly variable work-

ing width, operated either hydraulically or mechanically. This ensures

an optimum combination of tractor, plow and soil consistency.

Getting to know the plow

Complete range of bodies

We supply a complete range of plow bodies to meet all needs. Kver-

neland’s plow bodies offer excellent plowing quality, are very durable

and require low tractive power.

Robust headstock

The plow’s headstock is designed with its centre of gravity close to the

tractor, enabling lift requirements to be as low as possible.

Complete range of optional equipment

The optional equipment for the plow comprises a wide range of depth

wheels, bodies, body attachments, skims and rear disc coulters. They

can be adapted to your needs depending on the type of soil and field

conditions.

Low-wear parts

All parts in direct contact with the soil have undergone heat treatment.

This makes them extremely resistant to wear, but also flexible enough

to withstand jolts.

The direction of reversing can be changed

The plow can be reversed with the bodies over and under the

frame.The most common use is with the bodies above the frame. This

gives the most even reversing and must be used when the integrated

packer is fitted.

A smooth reversing of the plow is achieved when the bodies are above

the frame.

There is maximum clearance with the ground at the rear end of the

plow when the bodies are underneath the frame.

15

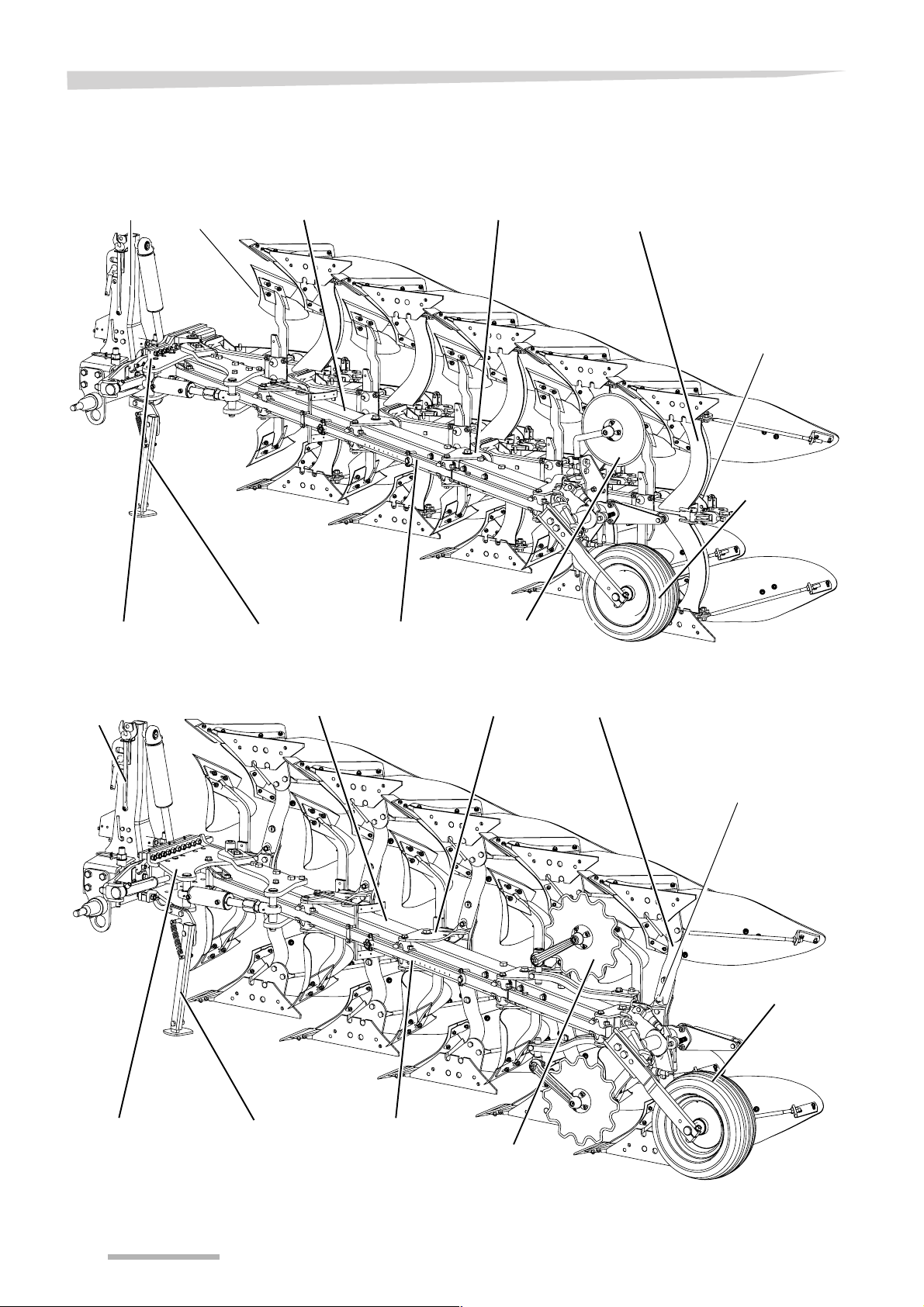

Getting to know the plow

Disc coulter

Parking stand

Main frame

Automatic beam

Front piece

Beam bracket

Parallel rod

Skimmer

Headstock

Spring

Depth

wheel

Front piece

Parking stand

Main frame

Shear bolt beam

Front piece

Beam bracket

Parallel rod

Disc coulter

Headstock

Depth wheel

Shear bolt

Components

General – ES

General – LS

16

Headstock 200

Cross shaft

Turnover cylinder

Turnover valve

Tower

Saddle

Breast piece

Mouldboard

Share

Reversible plow

(This figure shows body no. 9. Other types of body have similar components)

Landside

Stay

Getting to know the plow

Body

17

Getting to know the plow

Technical

specifications

General

ance be-

Model Head-

stock

(inches)

ES 200 85

Clear-

tween

bodies

cm

(33)

85

(33)

85

(33)

100

(39)

100

(39)

100

(39)

Beam

height

cm

(inches)

70/75

(28/30)

70/75

(28/30)

70/75

(28/30)

70/75

(28/30)

70/75

(28/30)

70/75

(28/30)

No. of

bodies

# mm

3 150x150

4 150x150

5 150x150

3 150x150

4 150x150

5 150x150

Frame Furrow

(inches)

(6x6)

(6x6)

(6x6)

(6x6)

(6x6)

(6x6)

width

cm

(inch-

es)

30–50

(12-20)

30–50

(12-20)

30–50

(12-20)

35–55

(14-22)

35–55

(14-22)

35–55

(14-22)

Recom-

mended

bhp

bhp kg

–120 1055

–160 1280

–200 1580

–120 1080

–160 1300

–200 1650

Weight1Lift req

(2326)

(2822)

(3483)

(2381)

(2866)

(3637)

(lbs)

2

kg

(lbs)

2350

(5181)

3050

(6724)

4400

(9700)

2500

(5511)

3100

(6834)

4800

(10582)

LS 200 85

(33)

85

(33)

85

(33)

100

(39)

100

(39)

100

(39)

115

(45)

115

(45)

1

Estimated net weight without equipment

2

Measured with skims, disc coulter on rear body and depth wheel

70/80

(28/32)

70/80

(28/32)

70/80

(28/32)

70/80

(28/32)

70/80

(28/32)

70/80

(28/32)

70/80

(28/32)

70/80

(28/32)

3 150x150

(6x6)

4 150x150

(6x6)

5 150x150

(6x6)

3 150x150

(6x6)

4 150x150

(6x6)

5 150x150

(6x6)

3 150x150

(6x6)

4 150x150

(6x6)

30–50

(12-20)

30–50

(12-20)

30–50

(12-20)

35–55

(14-22)

35–55

(14-22)

35–55

(14-22)

40–55

(16-22)

40–55

(16-22)

–120 930

(2050)

–160 1160

(2557)

–200 1320

(2910)

–120 950

(2094)

–160 1190

(2623)

–200 1340

(2954)

–120 980

(2160)

–160 1235

(2723)

1900

(4189)

2850

(6283)

3750

(8267)

1950

(4299)

3270

(7209)

3820

(3820)

2500

(5511)

3600

(7937)

18

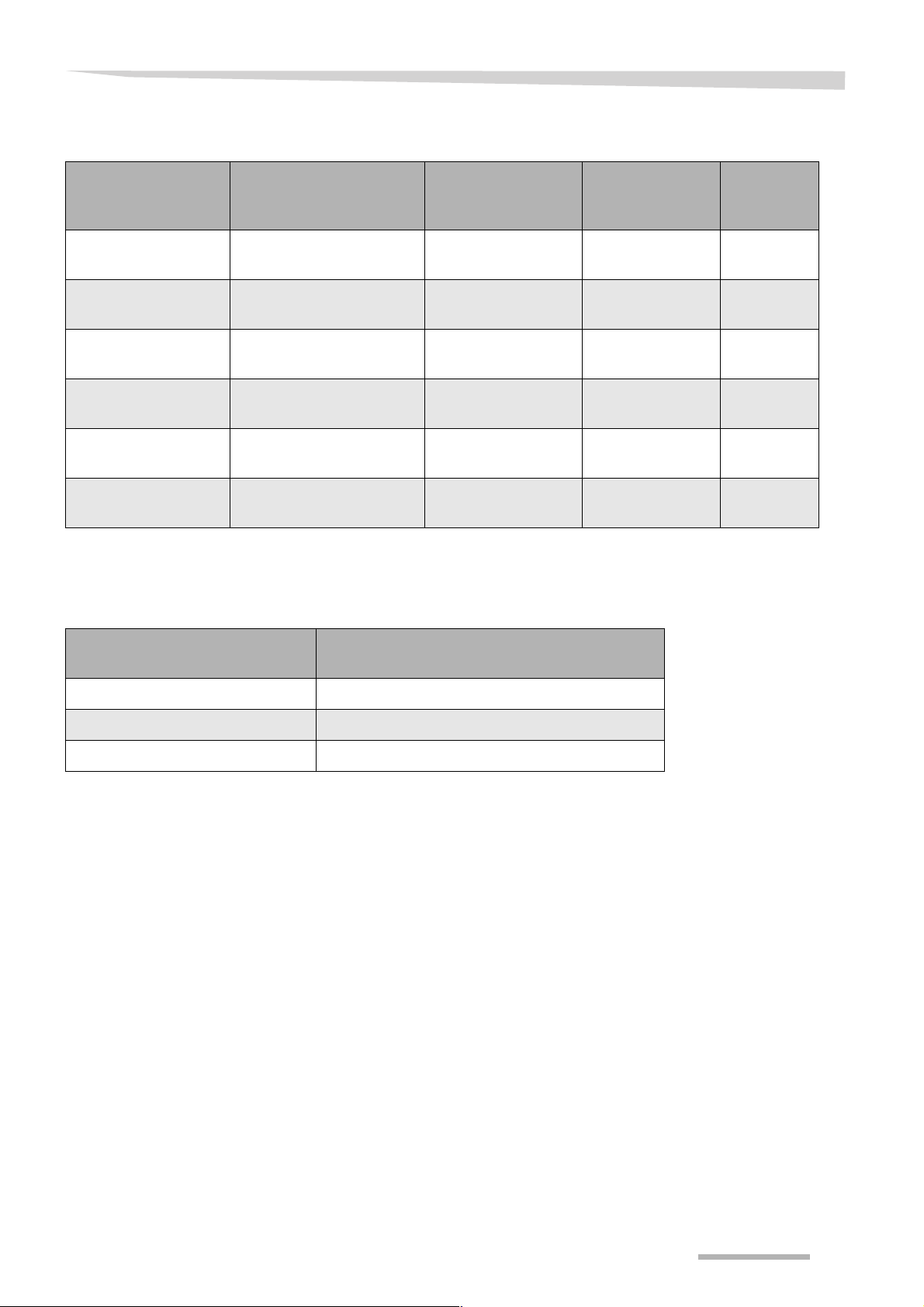

Cross shaft

Getting to know the plow

Headstock Type Category Diameter

200 fixed II 60

200 fixed III 60 / 70

200 quick coupling II 60

200 quick coupling III 60 / 70

200 turnable II 70x38

200 turnable III 70x38

Tire pressure

mm

(inches)

(2.3)

(2.3/2.7)

(2.3)

(2.3/2.7)

(2.7x1.4)

(2.7x1.4)

Length

mm

(inches)

825 (32)

935 (37)

860 (34)

965 (38)

935 (37)

860 (34)

965 (38)

825 (32)

965 (38)

Tire Recommended pressure kPa (PSI)

6.00 - 9 420 kPa (60.9 PSI)

200 - 14.5 500 kPa (72.5 PSI)

26 - 12.00 - 12 280 kPa (40.6 PSI)

19

Getting to know the plow

Model

Type

Body distance

Headstock

Plow ID

Production year

Weight (kg/lbs)

QR head

/lbs

bl

Information plate

The information plate is attached to the setting beam. When ordering

spare parts or consulting services, please state the full model code

and plow ID, to avoid any mistakes or misunderstandings.

20

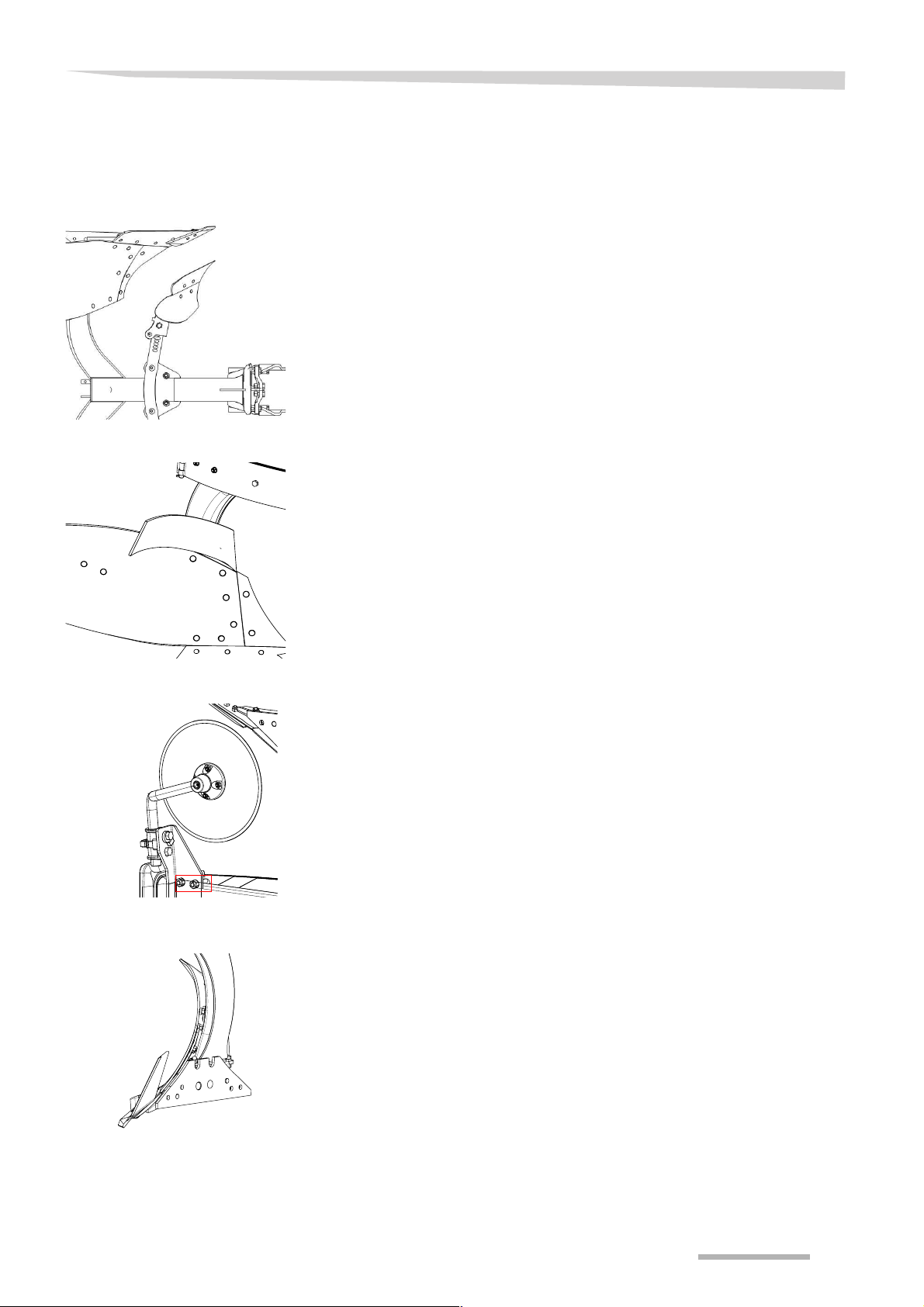

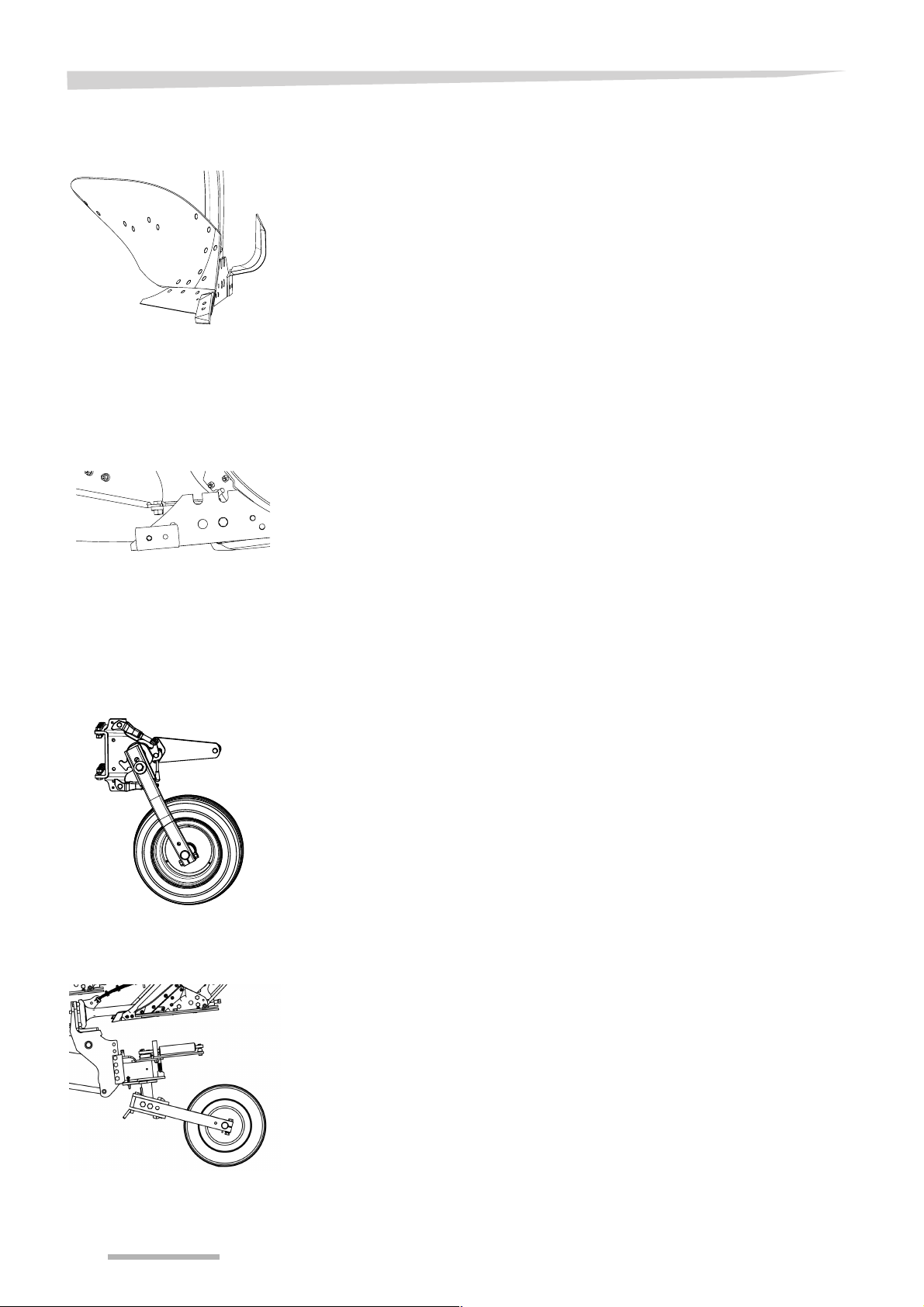

Optional equipment

Skimmer

Trash board

This chapter provides an overview of optional equipment for the ES/

LS plow. Restrictions apply. Contact your Kverneland dealer for more

information.

Recommended for effective down-plowing of grass and stubble. Two

types of skimmer are available: the standard skimmer and the maize

skimmer. Both can be fitted with either a long share (for more effective

down-plowing of plant remains) or short share (for working more deep-

ly with the skimmer).

Available with skimmer extensions.

Particularly useful when large quantities of plant waste (manure,

straw, etc.) are present. Using a trash board gives more free space be-

tween the bodies, compared to using a skimmer.

Optional equipmen t

Disc coulter

Share knife

Disc coulters are available in sizes of 45 and 50 cm (18 and 20 inches)

in diameter, plain or cut-away for positive contact with soil to aid rota-

tion. They are fitted to single arms and are easily adjusted to suit all

conditions.

An alternative to disc coulters, when a reduction in weight may be nec-

essary or when blockage from trash or stones is likely to occur. It can

only be used on plows with fitted reversible points.

21

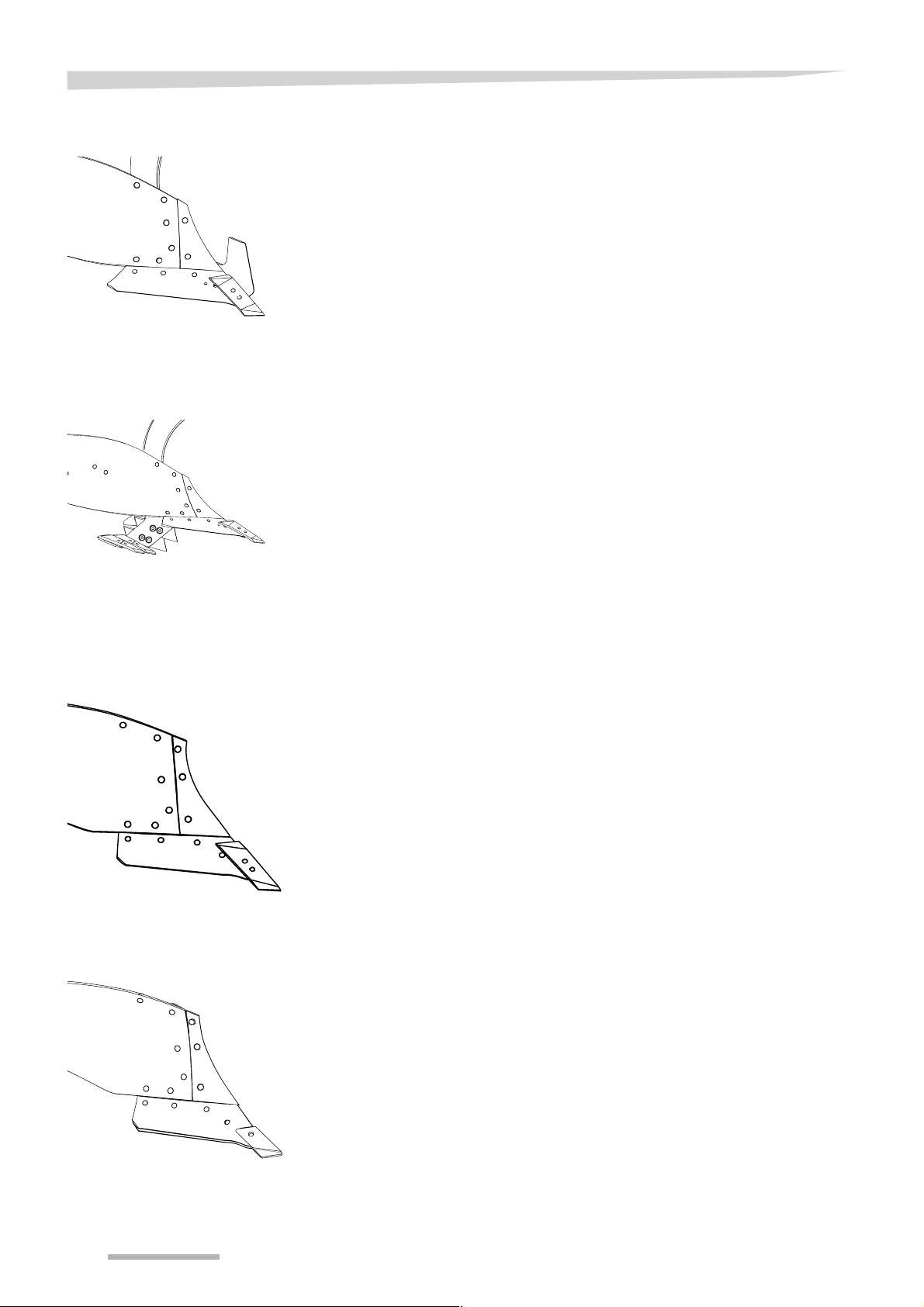

Optional equipment

Landside knife

Eco-plowshare

Can be used together with all types of share. An alternative to the disc

coulter, when the weight needs to be reduced or when there is a

strong likelihood of a lot of waste or stones. Ideal for combining with

skims and suitable for all types of share.

A share which reaches 10 cm (4 inches) deeper than the plow’s nor-

mal share and loosens the plowed soil. Does not need to be fitted to

all bodies. Also an alternative for up to 10 cm (4 inches) shallower

plowing.

Plowshare with

reversible point

Share with flush fit point

An effective cutting system for plowing hard and abrasive soil and in

generally difficult conditions.

For plowing in sticky soil. The point is attached using a single bolt and

can therefore be replaced easily.

22

Share with Quick-Fit

point

Share with Knock-on

point®

Optional equipment

Reduces the down time in replacing the points. Can be fitted to all plow

bodies. Very good ground penetration.

Reduces the down time in replacing the points. Can be fitted to all plow

bodies. Very good ground penetration.

Furrow splitter

Mouldboard extension

Developed for fitting to any part of the mouldboard and cutting through

hard soil, making it easier for subsequent operations. The splitter is at-

tached by a bolt in an existing hole in the mouldboard.

Mouldboard extensions can be fitted for better packing of the heaps in

firm soil and uphill

23

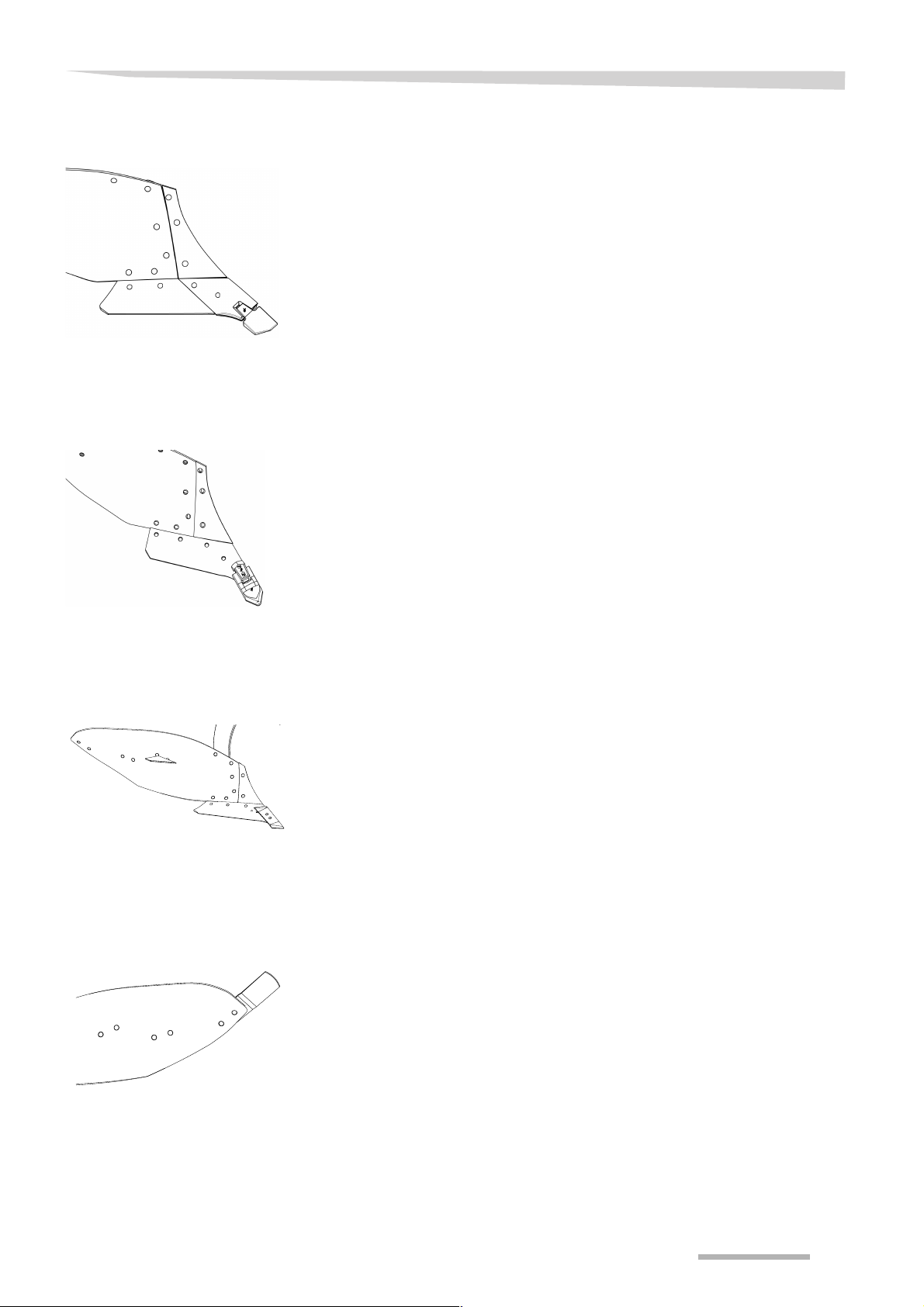

Optional equipment

Furrow opener

Used on the rear body to increase the width of the base of the furrow,

to accommodate tractors with wider tires.

Wear plate

Depth wheel

Can be fitted to landsides to reduce wear to the landsides. Fitted to the

landsides’ rear end as a replaceable high-wear part.

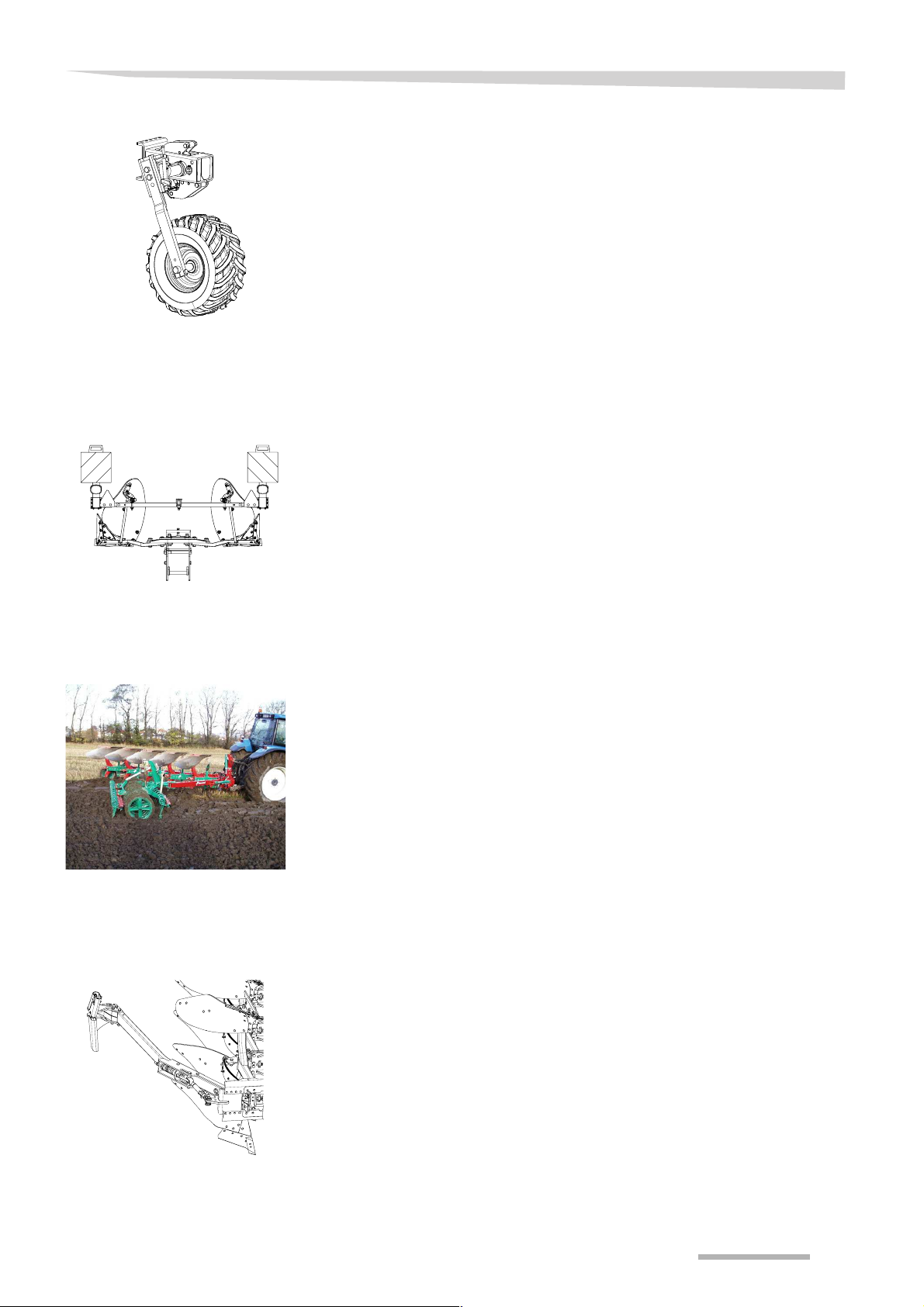

Using a depth wheel on all plows is strongly recommended. A wide

range of depth wheels are available for the plow.

Depth wheel made from steel or rubber

A sturdy depth wheel made from rubber or steel. Depth wheels are

available in two widths and diameters. The wheel’s function can be

purely mechanical or it can be equipped with different damping sys-

tems. Available as frame-mounted and rear-mounted variants.

24

Depth/transport wheel

A sturdy rubber wheel which can be used as a depth wheel during

plowing. Can be converted into a transport wheel for road use in a few

simple steps. Available as frame-mounted and rear-mounted variants.

Rear-mounted is the simplest and commonest use (see photo). The

frame-mounted variant is used to get closer to edges (hedges, fences,

etc.) towards the end of plowing.

Optional equipment

Hydraulic depth/transport wheel

A depth/transport wheel, allowing the plow depth to be set hydraulical-

ly during plowing. This cylinder function can also be used at the end

of each furrow for a more even plowing on long plows.

Lighting for transport

Packomat

Attachable/detachable lighting is available for road transport, in com-

pliance with local regulations. Several configurations are available for

the different markets. Available for transport both in plowing setting

and semi-rotated setting.

Kverneland Packomat is a soil packer which is integrated into the plow

and which ensures optimum combination of both. Kverneland’s inte-

grated soil packer harrows and packs the soil once it is in an easily

workable state, and in some cases (lightweight soil) saves all harrow-

ing, and in all cases some harrowing.

Can be supplied with a single roller or double roller section.

Soil packer arm

Available for use with the soil packer. A hydraulic cylinder releases the

soil packer on the headland.

25

Optional equipment

Hydraulic Auto-Reset

As an alternative to the leaf spring design, a hydraulic release, com-

prising a single-acting cylinder, is available [ES].

Leaf springs are replaced by a hydraulic cylinder which is connected

to an accumulator, the pressure of which can be regulated to obtain an

appropriate release force for different soil conditions.

26

Preparation for use

110–160 cm

(43-63 inches)

0–10 cm (0-4 inches) wider than the rear

This chapter details how to prepare the plow and tractor before putting

the plow into operation.

Tractor

Hydraulic connections

Hydraulic functions Single-acting Double-acting

Turnover 1

Hydraulic furrow width [+] 1

Hydraulic first furrow width [+] 1

Hydraulic depth wheel [+] 1

Hydraulic release system [+] 1

The following table shows the tractor’s required connections.

We recommend the tractor's hydraulic output flow is 25-35 l/min.

(6.6- 9.2 gpm)

Preparation for use

Depth control

Plow size Depth control of the plow

2–3 furrows |----------------------------------X------------|

4–6 furrows |----------------------X------------------------|

Track

We recommend setting the tractor’s depth control as shown in the following table. The soil and field conditions determine the precise set-

tings.

Initial settings

Tractive-power-regulated depth control

Position control<------------> Drag control

•

To use the plow, the tractor’s internal rear track (the distance be-

tween the internal edges of the rear wheels) must be 110–160 cm

(43-63 inches).

•

The internal front track (between the front wheels) must be 0 to 10

cm (0-4 inches) wider.

•

The rotating mechanism can be mounted in two ways on the plow,

depending on the distance between the rear wheels.

27

Preparation for use

T

IP

Be mindful when ordering the plow so that the slide can be fitted cor-

rectly.

Tire pressure

Front weights

Lower links

Remove paint

To prevent uneven furrows, the air pressure must be the same in both

the tractor’s rear wheels.

> Fit sufficient weights at the front to ensure safe driving.

> Adjust both the lower links to an equal height. This ensures equal

levelling of the plow in both directions.

> Remove paint from all surfaces which are in contact with the

ground. Use a scraper and paint remover.

28

Connecting

Large

plows

Small

plows

Safety

This chapter explains how to connect the plow to the tractor.

\

WARNING

Increased risk of injury when coupling

There is an increased risk of injury when the plow is coupled to the

tractor. Therefore:

•

Shut off the engine, set the parking brake, remove the ignition

key.

•

Secure the tractor to prevent it from rolling.

•

Do not stand between the tractor and plow when coupling

•

Lift and lower the plow slowly

An unsecured tractor can create hazardous conditions.

If this requirement is ignored, the consequence may be

damage to the machine and the potential for life-threatening

injuries.

Connecting

Coupling

Check the length of the hose

Check that the hose between the plow and the tractor is slack enough.

If the hoses are trapped or stretched, they can become damaged or

get torn off.

To couple the plow to the tractor

> Connect the lower link arms on the tractor to the cross shaft on the

plow

> Connect the top link on the tractor to the plow’s headstock/tower

> Relieve all hydraulic pressure from the tractor and the implement.

> Connect the hydraulic hoses to the tractor.

> Raise the plow carefully

> Stow the parking stand

> Check the connection geometry (see below)

> Reverse the plow to check the clearance with the ground and with

the tractor (see below)

TIPTop link connection

•

Use the slotted holes with 4-furrow plows and larger. Then the plow

can follow the contours of the field.

•

Use the fixed holes on 2- and 3-furrow plows. This prevents the

plow from tipping up in heavy or stony soil.

•

Make sure that the top link slopes slightly towards the tractor from

the plow.

29

Connecting

wrong

right

Connection geometry

To obtain a stable first furrow width, the intended pulling point between

the lower link arms must be 1/3 of the axle distance behind the front

axle. If this is not the case, use a cross shaft with a different length.

→ »Cross shaft« page 16.

Clearance

between the depth

wheel/plow and

the ground

Clearance

between the

tractor and plow

Reversing with the bodies above the frame

Once the plow is connected to the tractor, first make sure that the

depth wheel has sufficient clearance from the ground during revers-

ing. If there is not sufficient clearance, do one of the following:

•

Connect the top link to a higher hole on the plow

•

Connect the top link to a lower hole on the tractor

•

Position the cross shaft in a lower hole

→ »The position of the cross shaft«, page 74

If there is not sufficient clearance between the tractor and plow, rotate

the cross shaft’s attachment plates to the headstock

→ »The position of the cross shaft«, page 74

30

Transport

Safety

This chapter explains how to drive safely on the road.

When you use a Kverneland Packomat together with the plow, other

instructions apply. Read the operator‘s manual for Kverneland Packo-

mat.

\

WARNING

Stabilize the lower links

During transport, stabilize the tractor's lower links. This will pre-

vent the plow from accidentally moving sideways.

Use the transport wheel

If the plow is equipped with a depth/transport wheel, use it when driv-

ing on the road. If you do not use the depth/transport wheel, this can

result in an extreme load on both the tractor and the plow and they

may be damaged.

Disconnect the top link

When you use a depth/transport wheel, the top link should be discon-

nected. Otherwise, the contours of the road could result in extreme

forces on the plow and it could be damaged.

Transport

Adjust speed: max. 25 km/h (15 mph)

Always adjust the driving speed according to the road or field condi-

tions, but never drive faster than 25 km/h (15 mph). Driving at too high

speed leads to extreme loads on both the tractor and the plow and

they may be severely damaged.

Be aware of the plow’s length

The plow is very long and swings out when turning. Avoid allowing the

rear of the plow to hit obstacles during sharp swings.

31

Transport

Close valve

Bolt

Forward

Parking place

for bolts dur-

ing plowing

Before transport

Before transport

> Remove dirt and soil from the plow

> Raise the plow carefully

> Stabilize the lower links

> Adjust the plow to the narrowest working width

> Close the valve on the working-width cylinder [+]

> Put the plow into the transport position (see below)

> Stabilize a rotating cross shaft [+] (see below)

> Fit lights [+]

→ Assembly instructions for lightweight equipment

Stabilize rotating

cross shaft [+]

To stabilize the rotating cross shaft

> Lift the plow. This makes the plow slide forward.

> Locate the bolts in the holes on both sides of the headstock.

32

Put into transport

Transport position

Lift up

Rotate

Hole Y

Hole Z

Turn the wheel

position

Transport

Without transport wheel

Transport wheel for

butterfly position

If the plow is not equipped with a transport wheel, it should be trans-

ported as shown.

> Lift the plow 10 cm (4 inches) above the ground

> Lift up the upper depth stop

> Rotate the locking pin in order to lock the depth stop’s position. The

wheel will then be able to rotate freely

> Repeat the process for the lower depth stop.

> Remove the bolt from hole Y

> Turn the depth/transport wheel to the transport position

> Insert the bolt into hole Z

33

Transport

Turn the spring-

loaded stop

Handle

Unlock

Transport position

> Turn the spring-loaded stop. The wheel will then be able to rotate

freely through 360°.

\

WARNING

> Activate the transport lock on the headstock so that the locking

pin (spring-loaded) pops out.

> Turn the plow carefully into butterfly position. Ensure that the trans-

port lock locks.

> Lower the plow until it rests on the transport wheel.

> Disconnect the top link from the headstock.

34

Transport wheel for

2

1

Transport position

transport in plowing position

Transport

> Put the plow onto the ground (right body)

> Remove the locking piece and turn it through 180º

> Fasten it in the same place, it having been rotated through 180º

> Lift the plow.

> Remove the bolt from position 2

> Put the bolt into the hole to fasten the wheel arm (position 1)

> Lower the plow until it rests on the transport wheel

> Disconnect the top link from the tower

35

Transport

Bolt and ring pin

Lift slightly

Hole A

Hole B

Release plate

X

Y

Hole Z

Bolt

Hole Y

Handle

Unlock

Transport position

Hydraulic depth wheel

To change to transport position

> Lift the plow slightly

> Stabilize the lower links

> Adjust the plow to it's narrowest working width

> Lift the wheel slightly. This eases removing of the bolt.

> Remove bolt from hole B. This enables free rotation of the wheel.

> Move the release plate into position X.

> Insert bolt in hole A.

> Remove the bolt from hole Y

> Turn the wheel arm to the transport position

> Insert the bolt into hole Z

\

WARNING

> Activate the transport lock on the headstock so that the locking

pin (spring-loaded) pops out.

36

> Turn the plow carefully into butterfly position. Ensure that the trans-

port lock locks.

> Lower the plow until it rests on the transport wheel

> Disconnect the top link from the tower

Transport

Transport position

Lock

Unlock

Handle

Hole Y

Hole Z

Turn the wheel

Turn the spring-

loaded stop

Set into the plowing position

Transport wheel for

butterfly position

After transport, set the plow back to the working position.

> Connect the top link to the tower

> Lift the plow right up.

> Deactivate the transport lock on the headstock, i.e. press in the

locking pin

> Carefully turn the plow to the plowing position.

> Remove the bolt from hole Z

> Turn the depth/transport wheel to the working position

> Insert the bolt into hole Y

> Turn the spring-loaded stop at the same time as slightly lifting the

wheel arm so that the wheel points backwards

37

Transport

Rotate

> Release the locking hooks for the upper and lower depth stops so

that these can move freely.

38

Set into the plow-

2

1

ing position

Transport wheel for

plowing position

Transport

> Connect the top link

> Lift the plow

> Remove the bolt from position 1

> Put the bolt into the hole to fasten the wheel arm (position 2)

> Lower the plow to the ground

> Remove the locking pin and turn the stop plate through 180º

> Fasten it in the same place in the rotated position

39

Transport

Transport position

Handle

Unlock

Lock

Hole Z

Bolt

Hole Y

Bolt and ring pin

Lift slightly

Hole A

Hole B

Release plate

X

Y

Hydraulic depth wheel

To change to plowing position

> Connect the top link to the tower

> Lift the plow right up.

> Deactivate the transport lock on the headstock(pull the locking pin

back)

> Turn the plow into plowing position

> Remove the bolt from hole Z

> Turn the wheel arm to the plowing position

> Insert the bolt into hole Y

> Remove the bolt from hole A

> Move the release plate to position Y.

> Lift the wheel into working position

> Insert bolt in hole B

40

Adjust the plow

Safety

This chapter explains how to adjust the plow in order to achieve the

desired plowing result.

The adjustments can be made either before or during plowing.

Recommended procedure

We recommend that you use the following procedure, in this order,

when adjusting the plow in the field

> Working width

> First furrow width

> Working depth with depth wheel, depth control and top link

> Sideways levelling

> Disc coulter, skims and leaf spring

If one function is adjusted, this will affect the others. Therefore, these

adjustments must be made repeatedly.

Instructions for adjusting Packomat can be found in the Packomat op-

erator‘s manual.

Adjust the plow

Working width

\

WARNING

Use protective clothing

Use protective clothing, e.g. gloves, when working with sharp

parts of the plow. Parts that come into contact with the soil can be

very sharp. Failure to handle these carefully may lead to injury.

Do not wear loose fitting or other inappropriate clothing. Loose

fitting items of clothing may become caught in parts of the plow.

Wear the proper protective clothing. Different environments may

require special clothing to preform the operation and maintenance

of the plow. Serious or fatal injury may be caused if these guidelines

are not followed.

Adjusting the working with takes two steps

> Adjust the frame angle as described below

> Adjust the first furrow width (see next page)

T

IP

The scale indicates the working width for each body, in inches and

centimetres

41

Adjust the plow

This diagram shows hydraulic working-width

adjustment

Working width

Stop nut

Working width

Mechanically

> Adjust the working width on the turnbuckle. Use the spanner which

is supplied.

Hydraulically [plows without alignment cylinder]

> Adjust the working-width cylinder using the tractor’s hydraulic out-

let

Hydraulically [plows with sequence valve]

> Swing the plow slightly inwards by starting the rotating sequence

with the tractor’s spool valve

> Adjust the stop nut on the alignment cylinder

> Swing the plow out by activating the tractor’s spool valve in the op-

posite direction.

If working with a very narrow working width, you can use spacers on

the cylinder.

Hydraulically [plows with memory valve (sequence)]

> Adjust the memory cylinder with the tractor’s spool valve control.

The cylinder can be connected to a separate outlet on the tractor, or

together with the headstock hydraulic cylinder, as a sequence or

memory sequence.

42

First furrow width

Wrong adjustment

Right adjustment

This diagram shows how to adjust the first fur-

row hydraulically

First furrow cylinder

Adjust the plow

\

WARNING

Do not adjust when lifted

Do not adjust the first furrow width when the plow is lifted from the

ground. This may lead to damage or injury.

In general, the first furrow must agree with the width of the others.

Pay careful attention to the following:

•

If the tractor is fitted with wide tires, the first furrow width should be

reduced to maintain a good connection with the preceding furrows.

•

When working on an incline, the plow’s drifting downhill should be

compensated for.

•

When using a furrow opener on the last body, the first furrow width

should be 13 cm (5 inches) narrower than the width of the other fur-

rows.

Mechanically

> Adjust the first furrow width using the adjustable bolt. Use the

spanner which is supplied.

Hydraulically

> Adjust the first furrow width cylinder using the tractor’s solenoid-

valve control.

43

Adjust the plow

Wrong adjustment

Right adjustment

Depth stop

Counter nut

Both stops the same length

L

Working depth

•

The plow frame should always remain parallel to the ground.

•

The top link should be in the centre of the tractor.

•

After changing the working depth, the sideways levelling should be

checked (see next section)

Depth wheel

Changing the plowing depth

> Raise the plow carefully

> Adjust the depth wheel (see below)

> Adjust the lower link arms with the tractor’s three-point control

> Adjust the length of the top link

> Level the plow sideways

→ »Levelling«

To adjust the depth wheel, do the following with both depth stops

> Adjust the counter nut

> Adjust the depth stop

> Tighten the counter nut again

TIPA useful way to measure the working depth, both on the left and the

right

44

> Measure the depth of the last furrow

> Measure the length of both stops. Ensure that both stops are of the

same length.

Adjust the plow

Scale

Spacer cap

Bolts

Hydraulic depth wheel

[+]

Adjust the working depth more shallow than adjusted with mechanical

stops by activating the single-acting cylinder

> Activate the tractor’s spool valve.

•

Pull the cylinder back towards the stop in order to plow deeper.

•

Lengthen the cylinder in order to plow shallow

T

IP

The scale indicates the plowing depth.

Adjusting the normal plowing depth (maximum plowing depth)

To adjust the maximum plowing depth

> Pull out the cylinder in order to provide sufficient space to turn the

spacer

> Turn the spacer, by hand or with a screwdriver

Adjusting the arm length

To adjust the wheel to suit the plow and plowing depth, you can adjust

the wheel arm in 55-mm (2 inches) steps.

> Untighten the bolts

> Place the wheel arm in the desired position

> Insert the bolts and tighten them

B

TIPFor all wheels:

Adjust the arm as long as possible in order to ensure a good distance

between the stop and the axle. This ensures that the wheel will work

properly.

45

Adjust the plow

Wrong adjustment

Right adjustment

Adjustment bolts

Levelling

Seen from behind, the plow beams should be at right angles to the

ground.

Headstock 200

Levelling the plow

> Turn the plow slightly

> Turn the adjustment bolts on the headstock. Adjust both sides the

same to begin with.

> You can adjust the left and right sides unevenly.

46

Normal position

Level adjusting

stop arm

(Cross-section of

the levelling adjust-

ing bolt)

Risk of col-

lision

Frame

Adj. bolt

Level adjusting

stop arm

(Cross-section of the

levelling adjusting

bolt)

Risk of col-

lision

Frame

Adj. bolt

Adjust the plow

\

CAUTION

Extremely deep or shallow plowing

The rotating system on headstock 200 must never be in contact

with the frame of the headstock. This can occur when

•

You are plowing shallow and the bodies rotate over the frame

•

You are plowing deeply and the bodies rotate under the frame

The load should always be under pressure from the rotating system;

under no circumstances may the rotating system rest on the frame.

Alternative position

47

Adjust the plow

1/3 D

D

> 5 cm

(>2 inches)

1-4 cm

(0.4-1.6 in.)

Turning stop

Bolt T

Eccentric

Bolt U

Bolt U

Disc coulter [+]

The disc coulter is correctly adjusted

•

When the disc coulter cuts to about half the working depth in the

soil.

•

When the distance between the disc coulter and the body is at least

5 cm (2 inches). This distance is to be increased on stony ground.

•

When the rear disc coulter does not collide with the depth wheel.

•

When all the disc coulters are adjusted the same

•

When the distance between the disc coulter and the landside is be-

tween 1 and 4 cm (0.4-1.6 inches).

ES without parallel side

adjustment

Adjusting the depth

> Support the disc coulter to prevent it falling down

> Loosen the bolt (T)

> Adjust the depth

> Tighten the bolt again (T)

Adjusting the side position

> Loosen the bolts (U)

> Release the eccentric

> Tighten the bolts again (U)

Adjusting the amount of swing

> Support the disc coulter and hold it in place

> Loosen the bolt (T)

> Release the turn stop to the desired position

> Tighten the bolt again (T)

48

ES with parallel side

Arm

Bolt R

Stem

Bolt S

B

A

Bolt C

Eccentric

adjustment

Adjust the plow

Adjusting the depth

> Support the disc coulter to prevent it falling down

> Loosen the bolt (R)

> Turn the arm

> Tighten the bolt again (R)

Adjusting the side position

> Loosen the bolt (S)

> Turn the stem

> Tighten the bolt again (S)

LS

Adjusting the depth

> Support the disc coulter to prevent it falling down

> Loosen the bolt (B)

> Turn the arm

> Tighten the bolt again (B)

Adjusting the depth further, for very shallow or very deep plow-

ing

> Support the disc coulter to prevent it falling down

> Loosen the bolt (C)

> Adjust the axle position

> Tighten the bolt again (C)

Adjusting the side position

> Loosen the bolts (A)

> Release the eccentric

> Tighten the bolts again (A)

49

Adjust the plow

B

C

B

C

A

A

C

C

Y

X

Skimmer [+]

ES

The skims are correctly adjusted when

•

The skims have a working depth of approx. 3–5 cm (1.2-2 inches).

•

All the skims have been adjusted the same.

Adjusting the depth

> Support the skims to prevent them falling down

> Loosen the nut on bolt C

> Loosen bolt C, one side at a time

> Adjust the skims to the desired position, and count the markings

> Tighten the bolt again (C)

> Tighten the nut again (C)

Adjusting the forward position

> Loosen the nuts (A) at the same time

> Loosen the nuts (B) at the same time

> Adjust the skims to the desired position

> Tighten the nuts again (B)

> Tighten the nuts again (A)

LS

Adjusting the depth

> Support the skims to prevent them falling down

> Loosen the nut on bolt C

> Loosen bolt C, one side at a time

> Adjust the skims to the desired position, and count the markings

> Tighten the bolt again (C)

> Tighten the nut again (C)

Changing the forward position

> Support the skims

> Loosen and remove the nuts and conical pieces (X)

> Lift the entire skim assembly to the second position (Y)

> Fit the nuts and conical pieces and tighten

N

OTE

Be aware when mounting the skimmer of the first body on shearbolt plow. There

is a risk that the share of the skimmer can collide with the turnover

cylinder, during turning the plow, when moving the skimmer forward from

the standard position shown in the figure.

50

Adjust the plow

B

A

A

B

B

Trash board [+]

The trash board should be positioned with its front edge tight up to the

mouldboard; its back edge should be adjusted in accordance with the

plowing depth.

The bracket for the trash board has two adjustment holes, one for

deep plowing and one for more shallow plowing (A). There are also

two slots in the trash board to allow for additional adjustment (B).

TIP!

When commissioning the new plow, it is a good idea to adjust the trash

board in the upper position to strip the paint from the plow bodies when

plowing.

TIP!

It may be a good idea to adjust the height of the trash board when

changing the working width.

Soil packer arm [+]

Position of the packer

•

Place the conventional packer so that it allows at least two furrows

to remain unpacked. This allows you to check the connection be-

tween following rounds.

•

The length of the arms (B) must be adjusted so that the tractor

wheel runs clear when you are returning.

> Adjust the stay tightener (A)

51

Adjust the plow

direction of drive

15°

Protection plate

Direction of the packer

arm

•

The packer arm should always be fitted at an angle of 15° to the

direction of drive.

•

There are three possible settings. When using setting 1, a pusher

is fitted to protect the hydraulic hose.

Setting 1 Setting 2 Setting 3

52

Plowing

Plowing

Safety

Before plowing

Be careful when you reverse when driving backwards (when

turning with bodies under)

Be careful when reversing the plow while driving backwards. There is

a risk of mouldboards or the depth wheel hitting the ground. This may

result in damage.

Release the stabilizer bars

Destabilize the tractor’s stabilizer bars before plowing. If plowing is

done when the lifting bars are still stabilized, this can result in damage

to the tractor or the plow.

Plowing on a slope

Do not reverse the plow when the tractor is standing sideways on a

slope. If the plow is reversed, this can result in the tractor becoming

unstable.

Before you begin to plow

> Remove all oil and grease from parts which are in contact with the

ground.

> Release the lower link arms

> Turn the depth/transport wheel to the plowing position

→ »Set into the plowing position«Maintenance intervals, page 37

Check during

plowing

Regularly check the following during plowing.

Penetration into the ground

When plowing hard or dry ground, it is possible that the plow will not

force down well. To achieve better penetration

> Replace worn-out parts. Worn tips do not penetrate into the

ground.

> Connect the top link the fixed hole position on the headstock.. This

transfers the weight from the tractor to the plow.

> Connect the top link to the tractor and the plow as flat as possible.

Tractor wheels sliding (on two-wheel-drive tractors)

To reduce the sliding of tractor wheels

> Connect the top link to a fixed hole on the headstock and make the

top link shorter. This prevents the back end of the plow from tipping

up.

> Adjust the tractor’s depth control more in the direction of the rheo-

static regulator, or do not plow so deep.

»Checklist« page 77

53

Plowing

Reversing the

plow

Different change-over

valve systems

\

CAUTION

Complete the turning sequence

Always complete the entire turning sequence. Only then the turn-

over cylinder will be locked, and will not rotate during plowing.

The plow reverses when you apply pressure to the P side of the turn-

over valve. The turning sequence is dependent on the type of turnover

valve.

> Activate the tractor’s spool valve until the turning sequence has

been completed.

Turnover valve – only for turning the plow

•

The plow reverses completely from one side to the other side

Turnover sequence valve

•

The plow should first be set to the narrowest working width

•

The plow reverses completely from one side to the other side

•

The plow goes back to the working width which is set with the me-

chanical stop.

Soil packer arm [+]

Turnover (sequence) memory valve

•

The plow should be set to the narrowest working width

•

The plow reverses completely from one side to the other side

•

The plow goes back to the working width which is set with a sepa-

rate outlet on the tractor

When you use a packer arm for a conventional packer, you must re-

lease the soil packer just before you get to the marking furrow

> Activate the tractor’s spool valve for a short while in the opposite

direction of reversing.

54

Care and maintenance

Safety

This chapter explains necessary maintenance and care of the plow.

\

CAUTION

Use original spare parts

Only use original Kverneland spare parts. Using other products

may lead to malfunction of the machine or a reduced safety. War-

ranty is not valid if parts not produced by Kverneland are used.

\

WARNING

Wear protective clothing

Wear protective clothing, e.g. gloves, when working with sharp

parts of the plow. In particular, parts which come into contact with

the soil can be very sharp. Careless handling can result in injury.

Avoid skin contact with oil and lubricants

When handling oil or lubricants, avoid contact with the skin by using

oil-resistant gloves. Oil and lubricants can damage the skin.

Care and maintenan ce

Before

maintenance

\

WARNING

Before maintenance is carried out on the plow

> Ensure that the plow is correctly secured to prevent overturn-

ing. Use additional safety devices when required

> Depressurize the hydraulic system

> Whenever possible, uncouple the tractor

> Place all controls in neutral or park

> Set tractor parking brake

> Switch off the tractor and remove the ignition key

> Ensure the machine is standing on firm, secure and level

ground, and provide additional support, if necessary

> Secure the machine against rolling away (use wheel chocks)

> Clean the plow around the area requiring maintenance

55

Care and maintenance

Maintenance table

Check condition of the plow X X

Lubrication X X X X

Replace the hydraulic hoses X X

This maintenance table shows the maintenance interval for the vari-

ous maintenance procedures.

after the first few hours in use

daily

before the plowing season

after the plowing season

after high-pressure cleaning

annually, or after every 200 ha (500 acre)

in the event of wear or damage

After 1000 km (621miles) of transport

every 6 years

Replace worn parts X

Retighten bolts and nuts X X

Check the release-system springs X

Check the tire pressure X X

Protect parts which are in direct contact with the

ground against corrosion

Align the bodies X

Replace cross shaft X

Check the preload pressure of the hydraulic release

system

Cleaning

Thorough cleaning will help the plow to last longer.

•

The plow can be cleaned with a high-pressure cleaner, but never

aim directly at the bearings

•

Grease all grease fittings after high-pressure cleaning.

X

X X

56

Care and maintenance

Lubrication

Use appropriate grease

Only use EP (Extreme Pressure) grease. The use of inappropriate

grease will reduce the lifetime of the bearings.

Lubricate the plow

•

Daily during plowing. This prevents water and dirt from penetrating

into the bearings and moving parts.

•

After high-pressure cleaning

•

Before and after the plowing season.

> Lubricate all lubrication points until lubricant comes out of the bear-

ing.

> Remove any excess lubricant. Dust and soil will stick to excess lu-

bricant.

57

Care and maintenance

S

S

S

S

S

S

S

S

S

S

S

S

S

The diagrams below show the lubrication points (S)

Lubrication points (S)

Headstock 2000 Disc coulter

Automatic beam

In front [ES] In front [LS]

58

Care and maintenance

S

S

S

S

S

S

S

S

S

S

Lubrication points (S)

Depth/transport wheel for plowing position Depth/transport wheel for butterfly position

Depth wheel Hydraulic depth wheel [+]

Hydraulic depth wheel [+]

59

Care and maintenance

Replace hoses

\

Check the length of the hose

Check the length of the hose on the plow for sufficient slack.

Overly taut or stretched hoses can become damaged or broken.

\

Replace the hydraulic hoses

•

Immediately when they have become worn or defective.

•

Every 6 years

> Release the pressure in the hydraulic system

> Connect the hoses from the tractor

> Remove the old hose.

> Fit the new hose

> Carefully tighten all connections

WARNING

WARNING

Replace worn

parts

•

Replace all parts which go down into the ground and other parts

when they are worn out or damaged.

•

Use original Kverneland parts only.

> Remove the old part.

> Fit the new part

> Remove paint from all surfaces which are in contact with the

ground.

TIPLandsides

When rotating landsides are worn down to approx. 5 mm (0.2 inches)

at the end, they can be rotated from the bodies on the right-hand side

to the left-hand side.

TIPReversible point

When reversible points are worn out on the outermost edge, they can

be reversed.

60

Replace Quick-fit

Care and maintenance

points

\

WARNING

Wear eye protection

•

Wear eye protection when replacing Quick-fit points. Other-

wise, there is a risk that splinters from the Quick-Fit points can

cause eye damage.

Removing a worn point

> Place the gore tool

> Knock the point out with an appropriate hammer.

Fitting a new point

> Place the point in front of the share an move it backwards

> Use the gore tool as a buffer between the point and the hammer

> Knock the point into place

Replace Knockon® points

TIP!

There must be no paint on the angled surfaces

TIP!

Rotating the Quick-fit points.

When the Quick-fit points are approximately 50% worn, they can be

moved from the body on the right-hand side to the left. This gives bet-

ter penetration.

\

WARNING

Wear eye protection

•

Wear eye protection when replacing

wise, there is a risk that splinters from the

can cause eye damage.

Removing a worn point

> Place the gore tool

> Knock the point out with an appropriate hammer.

Knock-on®

Knock-on®

points. Other-

points

61

Care and maintenance

Fitting a new point

> Place the new point in front of the share and move it backwards

> Use the gore tool as a buffer between the point and the hammer

> Knock the point into place

TIP!

There must be no paint on the angled surfaces

Tighten bolts and

nuts

General

Bolt

diam.

10.9 Bolts 12.9 Bolts

kpm (ft lbs) Nm kpm (ft lbs) Nm

M12 11.5-12.5 (83-90) 113 - 122.5 14-15 (101-108) 137 - 147

M14 18.5-20 (134-145) 181.5 - 196 22-24 (159-174) 216 - 235.5

M16 28.5-31 (206-224) 279.5 - 304 34-37.5 (246-271) 333.5 - 368

M20 55.5-61 (401-441) 544.5 - 598.5 65.5-73 (474-528) 652 - 716

M24 95-105 (658-759) 932 - 1030 115.5-127 (835-919) 1133 - 1246

Tighten all bolts and nuts on the plow again.

•

After the first few hours in use

•

Whenever necessary

•

Annually, or after every 200 ha (500 acre)

The table below applies for most bolts and nuts.

Tightening torque

62

Specific tightening

M30 left-hand

side

588 Nm

60 kpm

M30 right-hand

side

588 Nm

60 kpm

shear bolt M20

545–600

Nm

55–61 kpm

M30

1500 Nm

160 kpm

M16

412 Nm

42 kpm

torque

Beam with shear bolt [LS] Headstock 200

Care and maintenance

Replace shear bolt

[LS]

Check springs for

correct length

Fit only original shear bolts

Fit only original shear bolts. Use of unoriginal shear bolts can lead to

damage of the plow.

LS is equipped with shear bolts for protection against solid objects in

the ground.

When a shear bolt shears:

> Replace it with an original shear bolt

> Retighten all bolts (see diagram)

The length of the springs from locking bolt to locking bolt must be 70

cm (28 inches). This results in maximum spring tension. Over time, the

spring adjustment can gradually be changed, and so therefore this

must be corrected.

> Check the length of the springs every year.

> Adjust the length if they are shorter or longer than 70 cm (28 inch-

es).

→ page 69

63

Care and maintenance

70 cm

(28 inches)

F

F

TIPUse the long spanner to measure the spring length. The notches on

the spanner indicate 70 cm (28 inches).

TIPCheck the spring bolts (F) for wear. Replace them if necessary.

Tire pressure

Set the bodies

Ensure that the tires are inflated to the necessary pressure.

→ »Tire pressure«Maintenance intervals, page 19

New plows are delivered with adjusted bodies. Use of the plow can

gradually change the settings. Therefore, check the setting of the bod-

ies after each plowing season

The bodies are correctly set when

•

A2 = A1

•

B2 = B1

•

A2 = B2

The maximum permitted discrepancy between A1 and A2 is 5 mm (0.2

inches). If there is a greater discrepancy, the bodies are to be adjusted

with the nuts on the braces.

> Start with the middle body.

> Loosen the counter nut

> Adjust the nut until the body is in the desired position

> Tighten all the nuts, including counter nuts

> Continue with the other bodies.

64

Also check that the bodies on the left-hand and right-hand sides are

parallel.

> Inspect the left-hand and right-hand braces above to confirm that

they are parallel

> Adjust if necessary.

Check the preload

Quick connection

slowly

suddenly

preload pressure

Care and maintenance

pressure of the

hydraulic release

system [+]

\

WARNING

Couple to the tractor and support the beams

When checking, couple the plow to the tractor and place the plow

on firm and level floor. Support the beams with a wedge under the

landsides. Releasing of the pressure may otherwise cause the

beams or the plow to drop down.

Connect/disconnect the filling hose

Due to the pressure in the hydraulic system, the filling hose cannot be

connected/disconnected directly to/from the tractor. Therefore, a special quick connection is used on the accumulator, which can be con-

nected/disconnected under pressure.

To connect the filling hose.

> first connect the hose to the tractor

> then connect the hose to the accumulator

To disconnect the filling hose.

> first disconnect the hose from the accumulator

> then disconnect the hose from the tractor

Checking the nitrogen

preload pressure

The preload pressure is nitrogen in the accumulator when the ram is

in the outermost position. The factory-set preload pressure is 90 bar

(1305.3 psi). This preload pressure may gradually fall over time.

•

Check the preload pressure before and after each plowing season.

•

Put in some nitrogen when the preload pressure falls below 80 bar

(1160.3 psi).

Before checking

> Connect the plow to the tractor

> Place the plow on a firm and level surface

> Support the beams with a wedge under all landsides.

> Remove the dust covers

> First connect the filling hose to the tractor

> Then connect the leading hose to the quick connection on the ac-

cumulator

Checking

> Observe carefully with the manometer

> Carefully open the tractor’s spool valve.The oil pressure will now

be slowly reduced

•

The pressure shown immediately before it falls suddenly is the

preload pressure

65

Care and maintenance

Hose for oil refilling to

the tractor

Quick connections

Ram

free to move

Gas valve

Do not touch

Min 100 bar (1450.4 psi)

Max 160 bar (2320.6 psi)

TIPTo check again

> Set the system under pressure to 100 bar (1450.4 psi)

> Repeat the checking procedure.

After checking

> Set the pressure of the system to 100–160 bar (1450.4- 2320.6

psi), depending on the conditions on the ground

> Disconnect the filling hose from the quick connection on the accu-

mulator

> Disconnect the filling hose from the tractor

> Refit the dust covers

Refilling

Refilling must be carried out at a special service station.

•

Refill the accumulator when the preload pressure falls below 80

bar (1160.3 psi).

•

Refill the accumulator with nitrogen to 90 bar (1305.3 psi).

66

Possible modifications

A

B

Reversing

direction

Restrictor position

This chapter explains how you can alter some of the plow’s basic con-

figurations in order to adapt it to the tractor and your requirements.

The plow can be turned with the bodies either over or under the frame.

In order to change the reversing direction, you must change

•

The hydraulics configuration

•

The (sequential) change-over valve

•

The headstock configuration

> Please contact your dealer if you want to change the reversing di-

rection

A restrictor is fitted to the turnover cylinder in order to make the reversing smoother. Always fit restrictors in accordance with the following ta-

ble.

Type of turnover Restrictor position

Headstock 200

Possible modifica tions

body over A

body under B

Packomat (integrated) B

67

Possible modifications

Pull out (A)

Pull out (F)

Insert the bolt

Press forwards

Spring release

system [ES]

Safety

This section explains how you can

•

Fit or remove an automatic beam

•

Change the automatic beams’ spring tension

•

Adjust the spring tension of automatic beams

\

WARNING

Support the beam

Support the beam firmly when disassembling it, by using appropri-

ate equipment. Dropping down of the beam may lead to damage

to the plow or personal injury.

\

WARNING

Use an even, horizontal floor

Only remove a beam when the plow is parked on a horizontal and

even floor. Otherwise, the beam could fall. This can result in dam-

age to the plow or personal injury.

Fit or remove

Fit or remove an automatic beam

•

When a beam is displaced after striking an object in the ground

•

To change the beam’s release force

•

To remove the last body to make pulling easier

•

In other unforeseen circumstances

To remove the beams

> Release the spring pressure

→ Page 70

> Pull out the spring bolt (F) if necessary

> Pull out the axle

68

To fit the beam

> Position the beam into the beam bracket

> Push the tie bar forwards

> Insert the bolt into the hole

> Apply spring pressure

→ Page 70

Possible modifications