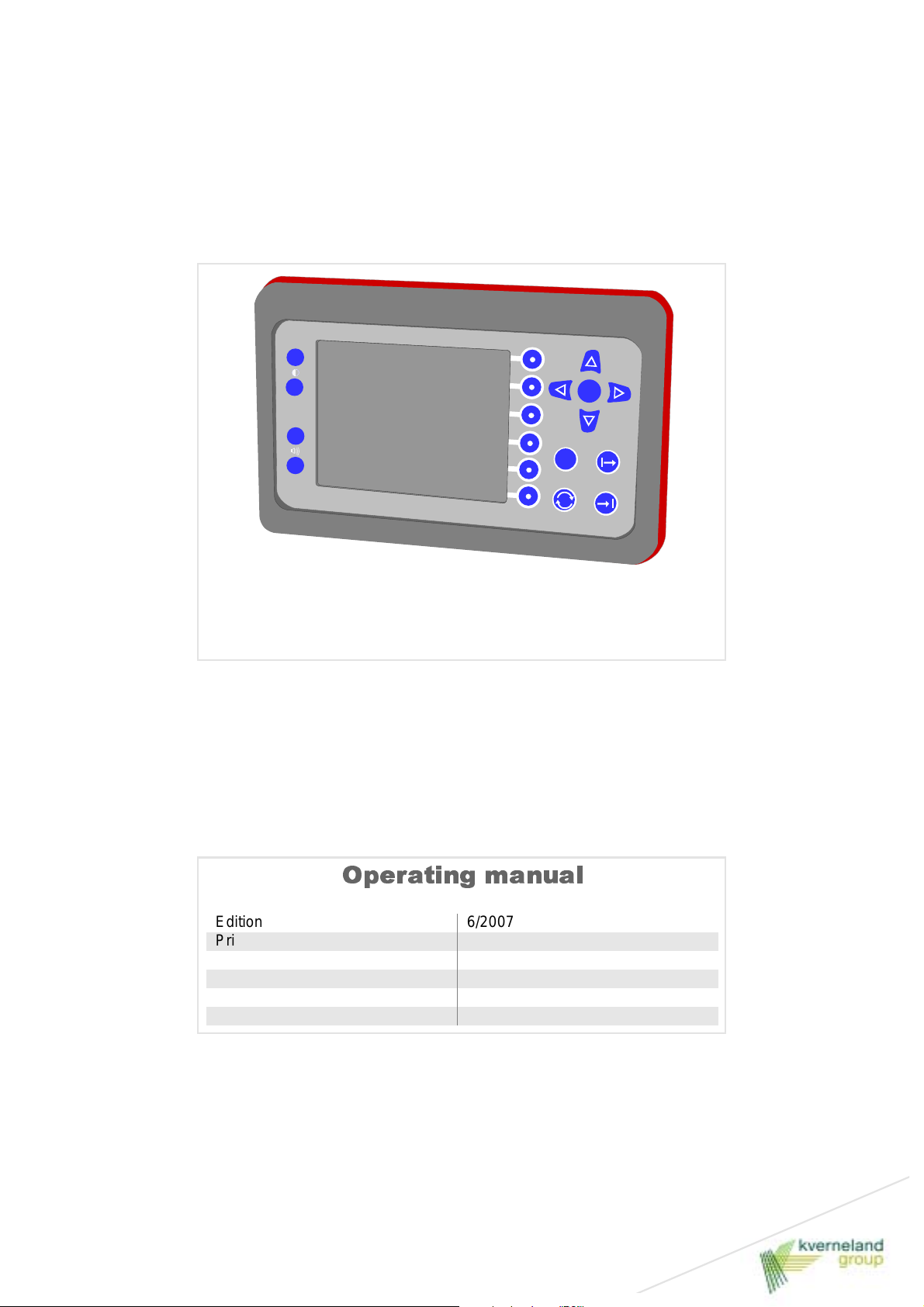

Kverneland Focus 2 Operating Manual

+

–

+

–

O

K

E

S

C

Focus 2 for

sowing machines

Operating manual

Edition 6/2007

Printing 10.2007

Language EN

For software from 1.03

For hardware version from –

Article number AC 758971

Identification of the machine

Your dealer will requi re certain information about your machine to be able to help you as quickly as possible.

Please enter the following data.

Designation

Operating width

Weight

Machine number

Accessories

Address of dealer

Focus 2

Manufacturer's address

Kverneland Group Soest GmbH

Coesterweg 42

D-59 494 Soest

Telephone +49 (0)2921 / 974-0

Copyright and exploitation rights for this document belong to Kverneland Soest GmbH, Germany. Copies, transfer into other m edia, tran slati ons

or the use of excerpts or parts are forbidden without express permission from Kverneland. All rights reserved. The contents of this operating manual may be changed without giving prior notice. We reserve the right to make technical changes.

Table of contents

To begin with ...................................................4

Safety................................................................5

Becoming familiar with the machine.............6

Area of use of the device 6

Features 7

An overview of the device 8

Technical data 10

functions 10

Delivery and assembly/installation..............11

Checking the scope of delivery 11

Assembly 11

Connecting up the machine .........................12

Safety 12

Connecting the Focus 2 12

Operation........................................................13

Switching on 13

Opening screen 13

Information screen 17

Table of contents

Storage...........................................................35

Removal 35

Storage 35

Removing faults.............................................36

Disposal..........................................................38

The EC Conformity Declaration ...................39

according to EC Directive

98/37/EC 39

Index...............................................................40

3

To begin with

To begin with

Target group for this

operating manual

Instruction

Meaning of the sym-

bols

This operating manual is designed for us e by tr ained a gricultu rists an d

persons who are otherwi se qualified t o work in agri culture and who have been instructed on how to use this machine.

For your safety

Please familiarise yourself with the contents of this operating manual

before commissioning or assembling the machine. You will obtain optimal operating results and will also be working more safely.

As an employer

All personnel are to be instructed on a regul ar basis , but at least onc e

a year, according to the provisions of Employer's Liability Insurance

Association Article 1. Untrained or unauthorised persons must not be

allowed to use the m achine.

You will receive instruction fr om your deal er about ho w to oper at e and

take care of the machine.

We have used various symbols in the text to make the presentation

clearer. They are described below:

• A point stands next to enumerations

> A triangle is located before activities which you should undertake

→ An arrow indicates cross- references to other texts

We also use pictograms which will aid you in findi ng text passages:

N

OTE

The word "Note“ refers to tips and guideli nes concerning operating th e

machine.

The screwdriver sym bol announces tips concerni ng assembly or setting up work.

The hazard warning triangle refers to important safety instructions.

Nonobservance of these can lead to the following consequences:

• General malfunctioning of the machine

• Damage to the machine

• Injury to persons or accidents.

0

4

A star indicates examples which serve better understanding.

Safety

Checking the cables

Check cables before connecting them up and replace damaged cables. Damaged cables can lead to damage occurring to the machine

or to uncontrolled behaviour of the electronic control system.

Observe the prescribed temperature range

The device will only oper ate reliabl y within the pr escribed t emperature

range. Higher or lower t emperatures can l ead to uncontrolled behaviour of the electronic control system.

Behaviour as a result of malfunctions

Please stop working immedi ately if a malfunction occurs and switch of f

the device. Look at the chapter "Removing faults"»Removing faults«

and remove the fault. Inform our Customer Service Department if the

fault cannot be removed. Continuing to operate a faulty machine can

lead to major damage to the machine and errors in the seed deposit.

Maintenance work

Disconnect from the power supply to the machine before conducting

maintenance work. It may prove impossible otherwise to exclude damaging the device.

Safety

5

Becoming familiar with the machine

Area of use of the device

Intended use

Mode of operati on

Notes on the ISOBUS

standard

This section contains gener al i nformation on your machine as well as

information on:

Becoming familiar with th e machine

• Area of use

• Features

• Technical data and

• functions

The device is designed for use in agriculture. It controls agricultural

machinery and devices.

The device is designed to be used in connection with agricultural machinery and devices to control and monitor their functions. Any other

use is forbidden.

A travel sensor determines the route and dis tance travelled and a job

computer calculates the current speed. The rotary speed necessary

for the drive motor on the metering devic e is deter mined from the current speed and the pres et setpoin t for the amount of seed per hectar e.

Not all of the display device f eatures are standardised in the ISOBUS

standard. It may therefore be the c ase that a termi nal made by another

manufacturer has more or fewer selection keys. Depending on the

number and arrangement of the selection keys, the symbols identifying their assignment may be in different positions. The description

here applies only to the device specified on the title page.

The Focus 2 terminal does not comply with the ISOBUS standard. It

can only be used in conjunction with machines made by the Kverneland Group.

6

Becoming familiar with the machine

Features

Terminal [+]

Switched power ca-

ble [+]

Job compute r

Control and monitori ng are possibl e using a termi nal i n connecti on with further components on the respective machine which can be matched to the type of machine being used. The overall system consists

of the components

• Terminal [+]

• Switched power cable [+]

• Job computer

• Travel sensor

• and possibly other sensor or act ors

The individual functions ar e shown graphical ly in the display. We have

dispensed with text as far as possible.

The terminal serves to enter and monitor sowing val ues.

The switched power cable is t he int erf ace between the tract or and th e

machine. Some tractors have already been fitted out with this interface

at the works. Please have the switched power cable installed on your

tractor by the dealer or a specialist workshop if this is not the case.

The job computer cr eates the connection between terminal, sensors

and actors. It is mounted on the seed sowing machine.

Travel sensor

A travel sensor determines the distance travelled.

7

Becoming familiar with the machine

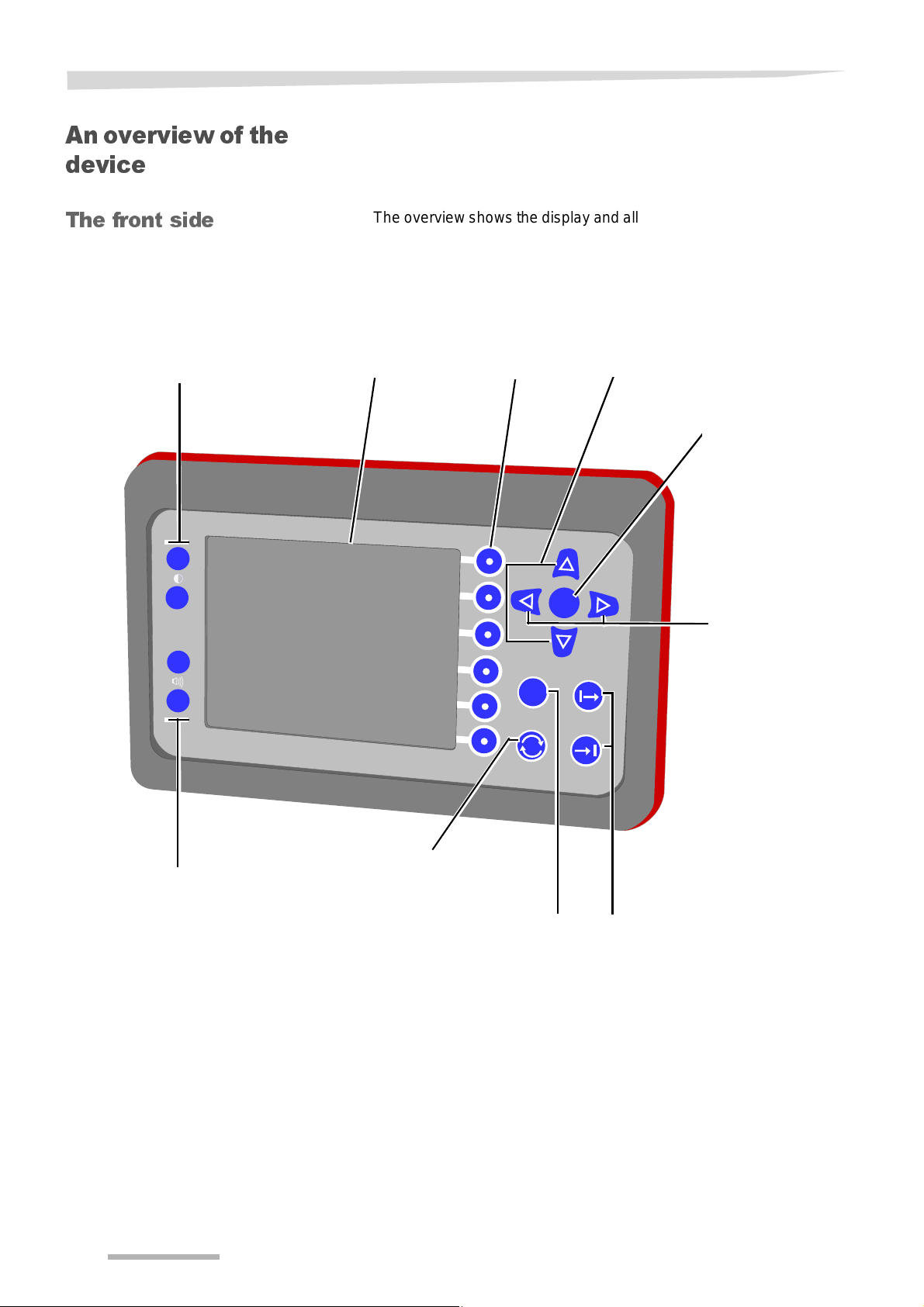

An overview of the device

The front side

Increase or reduce the contrast

+

–

+

The overview shows the display and all of key s which have each bee n

allocated a function.

Display

Selection keys

Increase or decrease

values

O

K

Confirmation of

entries

Selection of

data entry

fields

–

Increase or reduce the

volume

Switch to the previous screen or

to other connected machines

E

S

C

Resetting of

entries to their

original value

Keys without a

function

8

Becoming familiar with the machine

The rear side

Connection for the control cable from the job

computer

The overview shows all connections on the rear side.

Base for the bracket for

fixing devices

ON-OFF

switch

Connection for the

service technician

1. Connection for radar

or speed sensor on the

tractor

2. Outlet for CAN BUS

9

Becoming familiar with the machine

Technical data

Focus 2

Power supply (V) DC 12-14

Safety fus e (A)

• Switched power cable

• Central printed circuit board

• Battery cable for power supply to the te r-

minal

• Battery cable for power supply to the mo-

tors

Protective classes

• Terminal

• Control unit

Temperature range (°C) -10 to +50

25

1x 30 A; 1x 5 A

25

60

IP 54

IP 65

functions

The device possesses the following functi ons:

• Regulation of the amount of seed

• Automatic tramlining control system

• Automatic tramline marking [+]

• Determination of the processed area per task

• Determination of the overall area processed

• Indication of speed

• Determination of the operating time

• Adjustment to partial widths (of a trenc h)

10

Delivery and assembly/installation

Delivery and assembly/ installation

Checking the scope of delivery

Assembly

Terminal

+

–

+

–

K

O

S

E

C

The following items are mounted on the seed sowing machine at the

works:

• Job computer

• Travel sensor

The following can be supplied as accessories:

• Switched power cable

• Terminal

N

OTE

A claim should be made without delay to your dealer, the importer or

the manufacturer for any missing parts or parts which have been damaged during transport.

Maintain defined minimum clearances

When mounting the terminals a minimum distance of one metre must

be maintained from mobile telephones, radios or radio antennae. Unforeseen malfunctions could occu r if the distance is too small.

Ensuring a good view

The terminal must not limit the oper ator's v iew. Access to all functions

of the tractor must remain unimpaired. Accidents can arise if the operator's view is blocked or there are impairments to operating tractor

functions.

Switched power ca-

ble

> The terminal should be mounted on the tractor in such a way that

you can easily read the display and can easily reached all operating keys.

The switched power cable should only be i nstalled on the tractor by th e

dealer or a specialist workshop.

11

Connecting up the machine

Safety

Connecting the Fo-

cus 2

Prerequisites for connecti ng up the machine are:

Connecting up the mach ine

• The machine is coupled to the tractor.

• All components are installed in an orderly manner.

• All cables and plugs are in perfect condition.

Checking the cables

Check cables before connecting them up and replace damaged cables. Damaged cables can trigger unexpected malf unctions.

Observe the prescribed temperature range

The device will only oper ate reliabl y within the pr escribed t emperature

range. Higher or lower temperatures can trigger unexpected malfunctions.

It is necessary to connect up two cables to operate the Tellus.

• Cable from machine to switched power cable.

• Cable for control system to terminal

Cable from machine to switched power cable

> Remove dust cap from plug

> Connect plug to switched power cable

> Secure plug

Dust cap

Plug

Plug

Cable for control system to terminal

> Connect cable to the rear of the terminal

> Secure plug

12

Loading...

Loading...