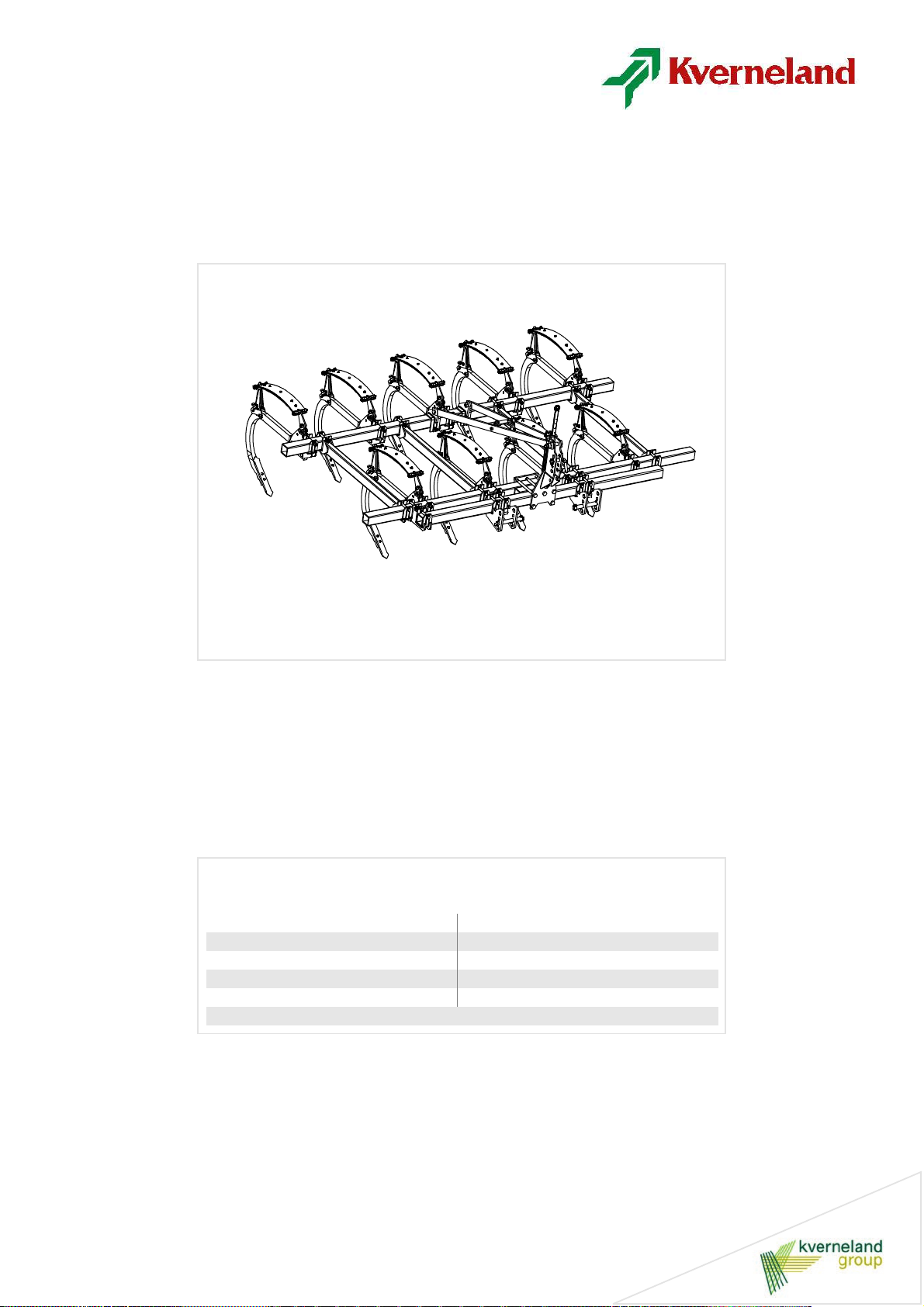

Kverneland CLG-II, CLG-II-CLC TINES Operation Manual

CLG-II

Operation manual

Issue 2/2008

Date of printing 8.2014

Language EN

From machinenumber (PSN) 728

Referencenumber A133095240

Original operation manual

Identification of the machine

To support you as soon as possible your dealer requires several details of your machine.

Please enter the information here.

Designation

Information

plate

Dealer's

address

CLG-II

Manufacturer's

address

Kverneland Group Operations Norway AS retains all copyrights and rights of usage. The contents of this operating manual are subject to change

without notice. All rights reserved. The right to technical revision is reserved.

Kverneland Group Operations Norway AS

Kverneland Klepp

N-4355 Kvernaland

Norway

Phone +47 5142 9000

www.kvernelandgroup.com

Table of contents

Preface..............................................................4

Target group of this operation manual 4

Symbols used 4

Safety................................................................5

Safety decals 5

General safety information 6

Getting to know the machine .........................9

Proper use 9

Features 9

Components 10

Technical specifications 12

Type plate 13

Optional equipment 13

Making adjustments to the machine............15

Tine distance 15

Wheel position 15

Auto-reset spring configuration 15

Working depth 17

Levelling 17

Table of contents

Working with the machine............................18

Coupling 18

Driving on the road 19

Cultivating 19

Parking and storage 20

Maintenance and care...................................21

Safety 21

Prior to maintenance 21

Maintenance chart 21

Cleaning 22

Lubrication 22

Replace wearing parts 23

Tighten bolts and nuts 23

Check Auto-reset springs 24

Tyre pressure 24

Disposal of the machine ...............................25

EC Declaration of conformity.......................26

3

Preface

Preface

Target group of

this operation

manual

This operation manual is meant for those concerned with the control,

use and maintenance of the machine. It contains all data required for

a safe handling, use and maintenance of the machine.

For your safety

Before starting to adjust and use your machine, familiarise yourself

with this operation manual. By doing so your safety and the best performance are assured. It is very important to read this manual carefully

before using the machine and to keep it handy. In this way, you will

• avoid accidents

• respect the warranty conditions and

• always have a functional machine in perfect working order

For the employer

All personnel are to be trained in the use of the machine regularly (at

least once a year) in accordance with employers’ liability insurance association guidelines. Untrained or unauthorised individuals are not

permitted to use the machinery.

You are responsible for the safe operation and maintenance of your

machine. You must ensure that you and anyone else who is going to

operate, maintain or work around the unit be familiar with the operating

and maintenance procedures and related safety information contained

in this manual.

Symbols used

In this operation manual the following symbols and terms are used:

• A bullet stands at enumerations

> A triangle stands at steps, which you must do

→ An arrow shows cross-references at other text passages

Besides these symbols, pictograms are used, which will help you with

locating of text passages:

TIPThe word “Tip“ shows tips and advices to the use.

The triangle refers to danger at assembling or (adjusting) work.

4

Safety

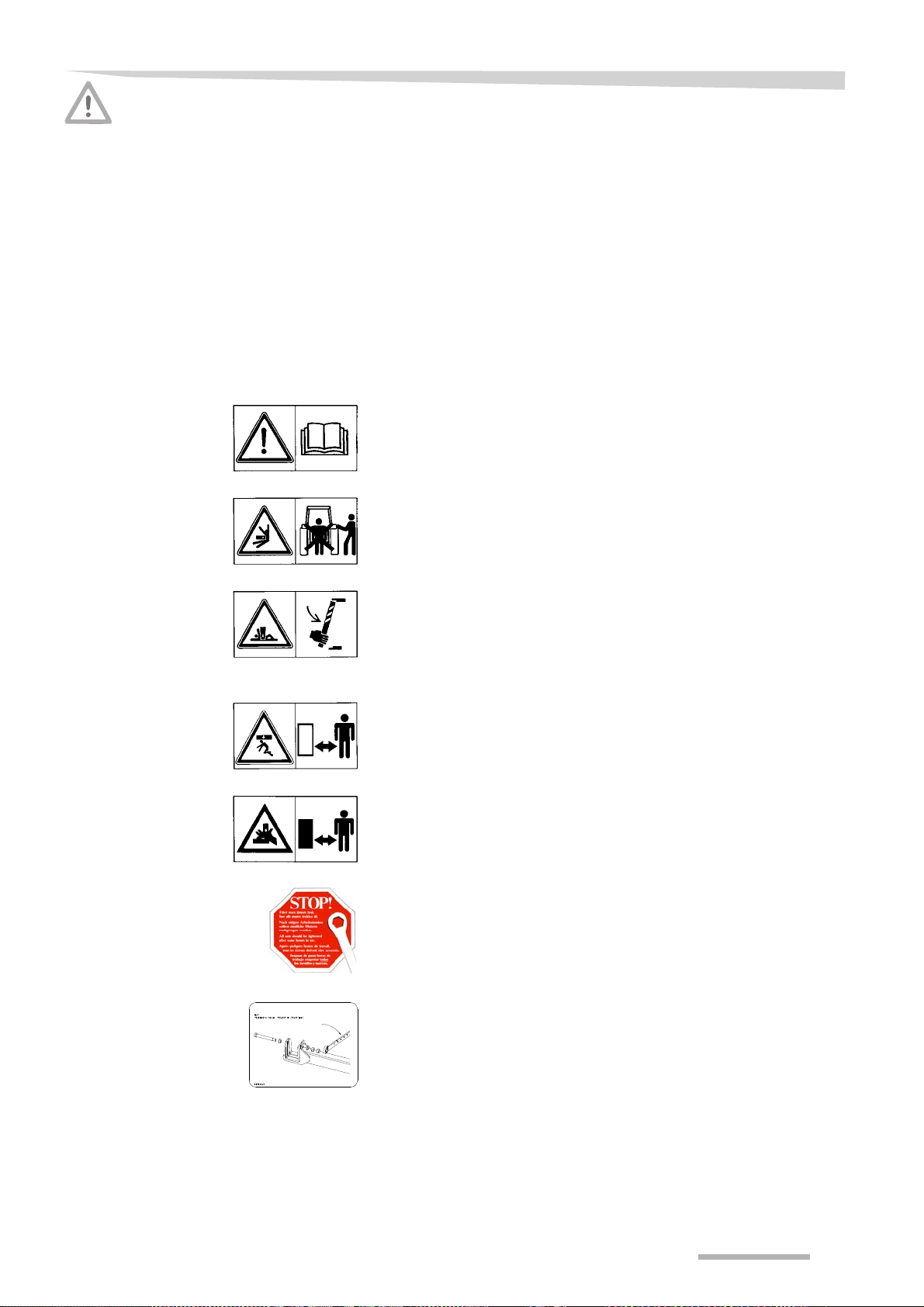

Safety decals

Meaning

This chapter describes general safety information regarding this product. Each part of this user manual will also contain its own specific

safety information.

For your safety, safety decals are placed on significant spots on the

machine. Please do not remove them. If they becom illegible or begin

to peel off, replace them with the appropriate spare stickers.

For placement of the safety decals, refer to the CLG-II assembly manual.

The meaning of the safety decals is pointed out below.

Read the operation manual and follow the instructions.

Initial operation of the machine must not take place before the operation manual has been read and understood.

Do not stand between tractor and machine.

Standing between tractor and machine increases the risk of crushing.

This complies especially when coupling the machine to the tractor.

Safety

Machine stand.

Do not stand under or near the machine unless it is properly supported. When uncoupling, use the machine stand. Tipping of the machine

may lead to damage or injury.

Crush danger

Machine parts move when the machine is being operated. Keep clear

of the danger area.

Crush danger

Operating of the machine may result in the shrinking of gaps. Beware

of crush danger. Keep clear of the danger area.

Retighten bolts and nuts

Regularly retighten all bolts and nuts on the machine. This is of special

importance after the first hours of use. Unnoticed loosening of bolts and

nuts may lead to damage or injury.

Tightening torque bolted clamps

Bolted clamps must be tightened with 589 - 638 Nm (60 - 65 kpm).

5

Safety

General safety information

General

Read and understand the following general safety information. Specific safety information is pointed out in the relevant chapters.

Read and follow the instructions

Before starting to operate the machine, read the operation manual and

follow the instructions. Not following instructions may lead to damage

or injury.

Only qualified users

Do not put the machine into use before the user has been properly

trained for operation and is familiar with the function and safe use of

the machine. False operation of the machine may lead to damage or

injury.

Check technical failure

Before starting to use the machine, check if the machine is in perfect

working condition. In case of defect components, contact your dealer

for replacement. Defect components may cause failure, leading to

damage or injury.

Keep distance

Do not stand on, under or close to the machine while it is in work or

while coupling it to the tractor.This may lead to injury.

Support the machine

Do not stand under or near the machine unless it is properly supported. Tipping of the machine may lead to damage or injury.

Lower the machine

Always lower the machine when parking the tractor. Unintended lowering of the machine may otherwise lead to damage or injury.

Use front end weights

Fit the tractor with enough front end weights for stability and secure

steering.

Check the vicinity

Always check the immidiate vicinity before starting to move or operate

the machine. No persons are allowed to stand close to the machine

when it is being operated.

Use the machine stand

Use the machine stand when parking the machine. When the machine

is not properly supported, it may tip over, which may result in damage

or injury.

6

Safety

Coupling

Adjusting and maintaining

Risk of injury when coupling

There is an increased risk of injury when coupling the machine to the

tractor. Therefore

• Secure the tractor to prevent it from rolling

• Do not stand between tractor and machine when coupling

• Lift and lower the machine slowly

Avoid skin contact with oils and lubricants

When handling oils or lubricants, avoid contact by using oil resistant

gloves. Oils and lubricants can do damage to the skin.

Maintain regularly

Maintain the machine regularly and as prescribed in »Maintenance

and care«. Also replace worn parts as prescribed. Machines that are

not well maintained can malfunction. This may result in damage or injury.

Do not weld

Do never weld on any part of the machine. The machine is made of

hardened steel, and any welding will severely decrease the machine’s

strength. Welding may lead to breakage on the machine.

Retighten bolts and nuts

Regularly retighten all bolts and nuts on the machine. This is especially important after the first hours of use. Unnoticed loosening of bolts

and nuts may lead to damage or injury. Take especially good notice of

the tightening torque for the bolted clamps.

→ »Tighten bolts and nuts«, page 23.

Use protective clothing

Use protective clothing, e.g. gloves, when working with sharp parts on

the machine. Especially soil engaging parts can be very sharp. Uncareful handling may lead to injury.

Use OEM spare parts (Original Equipment Manufacterers)

Only use original Kverneland spare parts. Using other products may

lead to malfunction of the machine or a reduced safety. Warranty is not

valid when non-Kverneland parts are used.

Check tyre pressure

Regularly check if the tyre pressure is as required. Too high or low

pressures may lead to damage and excessive wear of the tyre.

→ »Tyre pressure«, page 24.

7

Safety

Driving on the road

Beware of the machine’s size

The machine is long, and swings out in turns. In tight turns, avoid

swinging the sides of the machine into obstacles.

Obey local rules

Obey the local rules when you intend to drive with the machine on

public roads. For example

• have all necessary lights and warning decals installed.

• do not exceed the maximum permitted weights, loads and dimen-

sions.

The user is responsible for ensuring the machine complies with the

law when driving on public roads.

Adapt speed; max 25 km/h

Under all circumstances, adapt your driving speed to the road conditions, but do never drive in excess of 25 km/h. Excessively high

speeds cause excessive forces on tractor and machine. This may lead

to breakage or other damage.

8

Loading...

Loading...