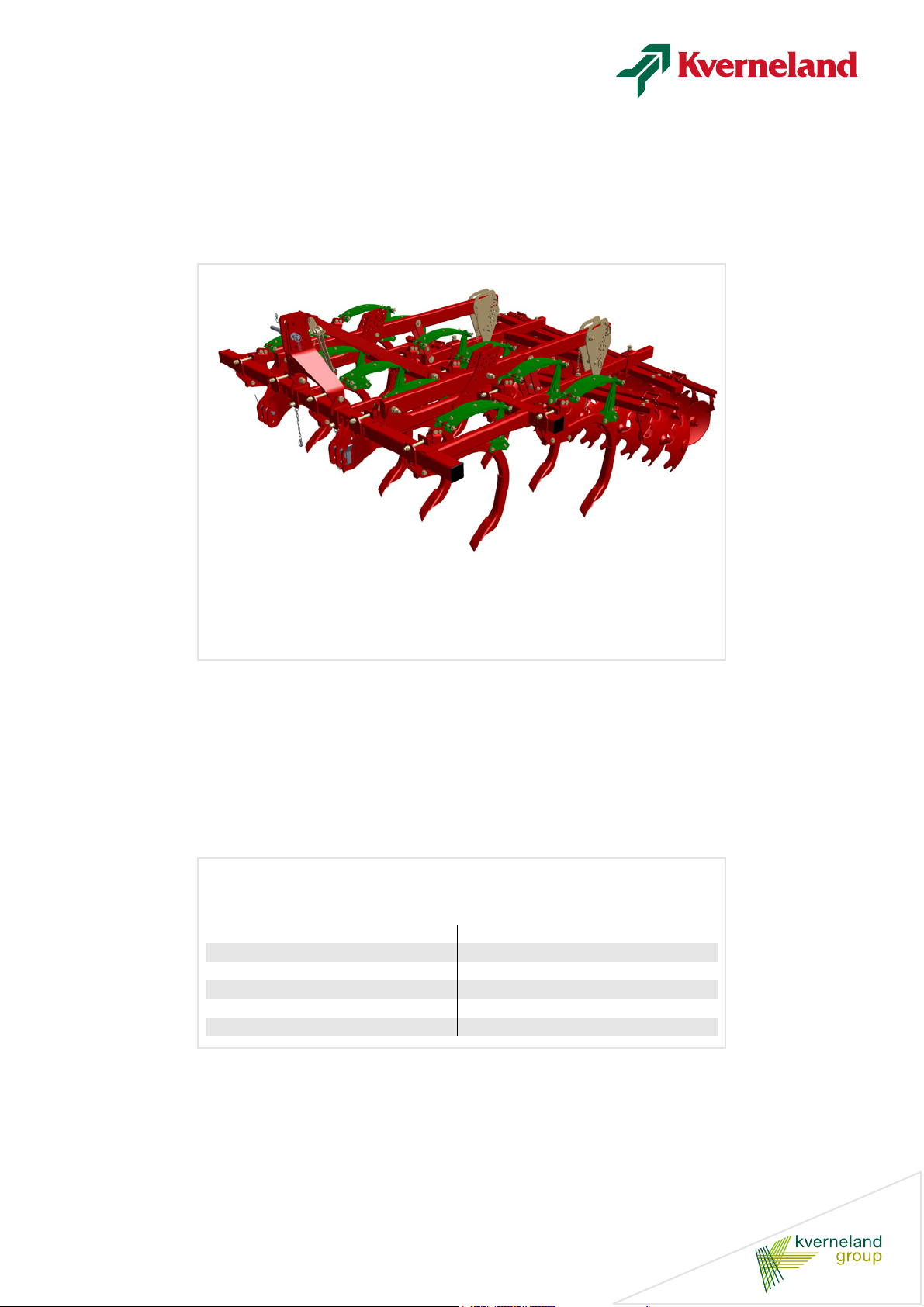

Kverneland CLC Evo, CLC PRO, CLC PRO CUT, CLC PRO CLASSIC User Manual

CLC Evo

User manual

Translation of the original document

Issue 02/2017

Printing 4.2017

Language EN

From serial no. RFCSTxx010625

Execution Rigid/Folding

Reference. A135368940

Machine identification

For your dealer to help as fast as possible. He needs some information regarding your machine.

Please provide this information below.

Description

Width of

work

Weight

Machine no.

Accessories

Retailer’s

address

CLC Evo

Manufacturer’s

address

Kverneland Group Les Landes Génusson S.A.S.

9 Rue du Poitou

F-85130 LES LANDES GENUSSON, FRANCE

Tel. +33 (0)2 51 64 13 00

Copyright and usage rights are held by the Kverneland Group Les Landes Génusson SAS, France. Copying, transfer to other media, translation

or even partial use of this text are unlawful without written authorization from Kverneland. All rights reserved. The content of these operating

instructions may be changed wit hout notice. Subject to technical changes

Table of contents

Introduction ............................................... 4

Who should read this user’s manual? 4

Meaning of symbols 4

Table of contents

Unhitching .................................................. 63

Rigid machines 63

Folding machines 63

Safety ......................................................... 5

For your safety 5

The HAZARD, WARNING

and CAUTION safety stickers 7

Safety rules 18

Other instructions 25

Presentation of the machine ................... 26

Usage clause 26

General Description 27

Technical specifications 28

Rear accessory variants 31

Roller variants 32

Depth control wheels [+] 33

Other optional equipment [+] 34

Distribution of right and left deflectors 34

Configurations 35

Safety ......................................................... 38

Unhitching 38

Hydraulic system 38

Other instructions 38

Acceptance and assembly ....................... 39

Verifications at the time of acceptance 39

Assembly of the arms 40

Fastening of the rear accessory [+] 40

Attachment of the roller [+] 40

Installing the rear struts 41

Maintenance ............................................... 66

Cleaning 66

Maintenance 66

Storage 66

Maintenance ............................................... 67

Safety instructions 67

General 69

Greasing 70

Wear rings 71

Inspection 73

Wearing of the

knife skids on Actipack and Actiring 81

Wearing of the

leveling blades on Actiflex 81

Hydraulic diagrams 81

Replacement of the

hydraulic system parts 82

Hydraulic diagrams ................................... 83

Warranty ..................................................... 84

Scrapping the machine ............................. 85

Metal parts 85

Tires 85

Hydraulic fluid 85

Index ........................................................... 86

Hitching ..................................................... 43

Rigid machines 43

Folding machines 44

Lighting ..................................................... 45

Electrical connections 45

Transport ................................................... 47

Safety 47

Before traveling on public roads 47

Switching on ............................................. 49

Adjustments - Versatility ......................... 50

Coulter range 50

Deflector range 50

Adjustments .............................................. 51

Adjustment of the working depth 52

Adjustment of the rear accessories 57

Actipack and Actiring rollers 59

Actiflex roller 61

Lighting kit for folding machine 62

3

Introduction

[+]

Introduction

Who should read this user’s manual?

Instructions

Meaning of symbols

This user’s manual is addressed to farmers and individuals trained

and certified in agricultural activities and who have received training in

the use of this machine.

Safety note for the user

Familiarize yourself with the contents of this user manual before

starting to use it or climbing on the machine. Performance and user

safety depend on it.

Note for the manager:

All personnel are to be regularly trained in the use of this mach ine. No

one without proper training or authorization may use this machine.

The dealer provides the user with instructions relating to the use and

maintenance of the machine.

Va rious symbols are used for the sake of clarity. Their meanings are

as follows:

• A dot is followed by a list.

A triangle precedes operations to be carried out.

→ An arrow refers back to other passages in the text.

Also, pictograms clearly indicate important instructions:

N

OTE

The term “Note” indicates advice and comments on use.

A key indicates advice on fitting or adjustment work.

A star indicates examples to assist with comprehension.

A plus sign in square brackets indicates optional equipment.

Proposition 65 from the State of California

\ WARNING

Exhaust gases from the motor, some of its components, some of

this machine’s components and fluids contain or emit chemical

compounds known in the State of California to be carcinogens, or

the cause of congenital deformities and other reproductive

disorders.

4

Safety

Safety

For your safety

This section contains general safe ty information. The various chapters

in this user’s manual include specific safety instructions.

Be sure to comply with all safety guidelines

• in the interest of your own safety,

• in the interest of the safety of others,

• to ensure the safety of the machine.

When handling agricultural machines, failure to follow instructions can

result in multiple hazards. Therefore, always work with special care

and never under pressure.

5

Safety

Note for the manager:

As required by law, you should regularly inform those working on the

machine of the existence of safety instruction s.

\ SAFETY PRIORITY

The “Safety priority” symbol is used in this manual and on the

pictograms placed on the machine in order to warn the user of th e

presence of a risk of bodily injury. Read these instructions closely.

It is essential that you read these instructions and the safety

guidelines before assembling or using the machine.

\ HAZARD

The warning term HAZARD warning indicates an extremely

hazardous situation, which if not avoided will lead to death or

serious injury.

\ WARNING

The warning term WARNING indicates a potentially hazardous

situation, which if not avoided could lead to death or serious injury .

The hazards identified by the term WARNING present a lower risk

of death or injury than those associat ed wit h the te rm HAZA R D .

\ CAUTION

The warning term CAUTION indicates a potentially hazardous

situation, which if not avoided could lead to more minor or

moderate injuries. The term CAUTION may also be used as a

means of notification against hazardous practices, which in cert ain

situations can cause injury.

NOTE

This symbol indicates the presence of technical and operational

information regarding personal safety around the machine.

6

Safety

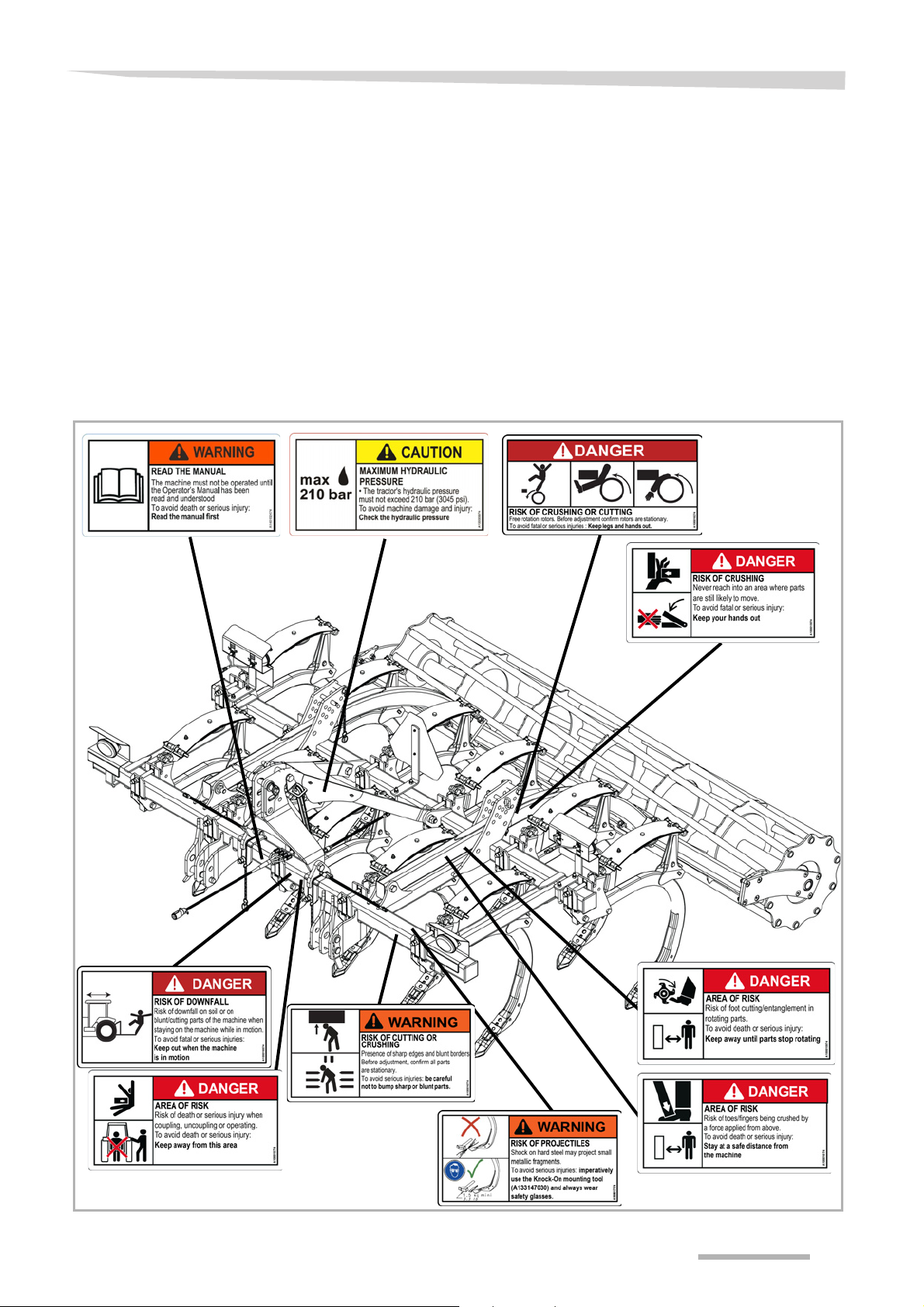

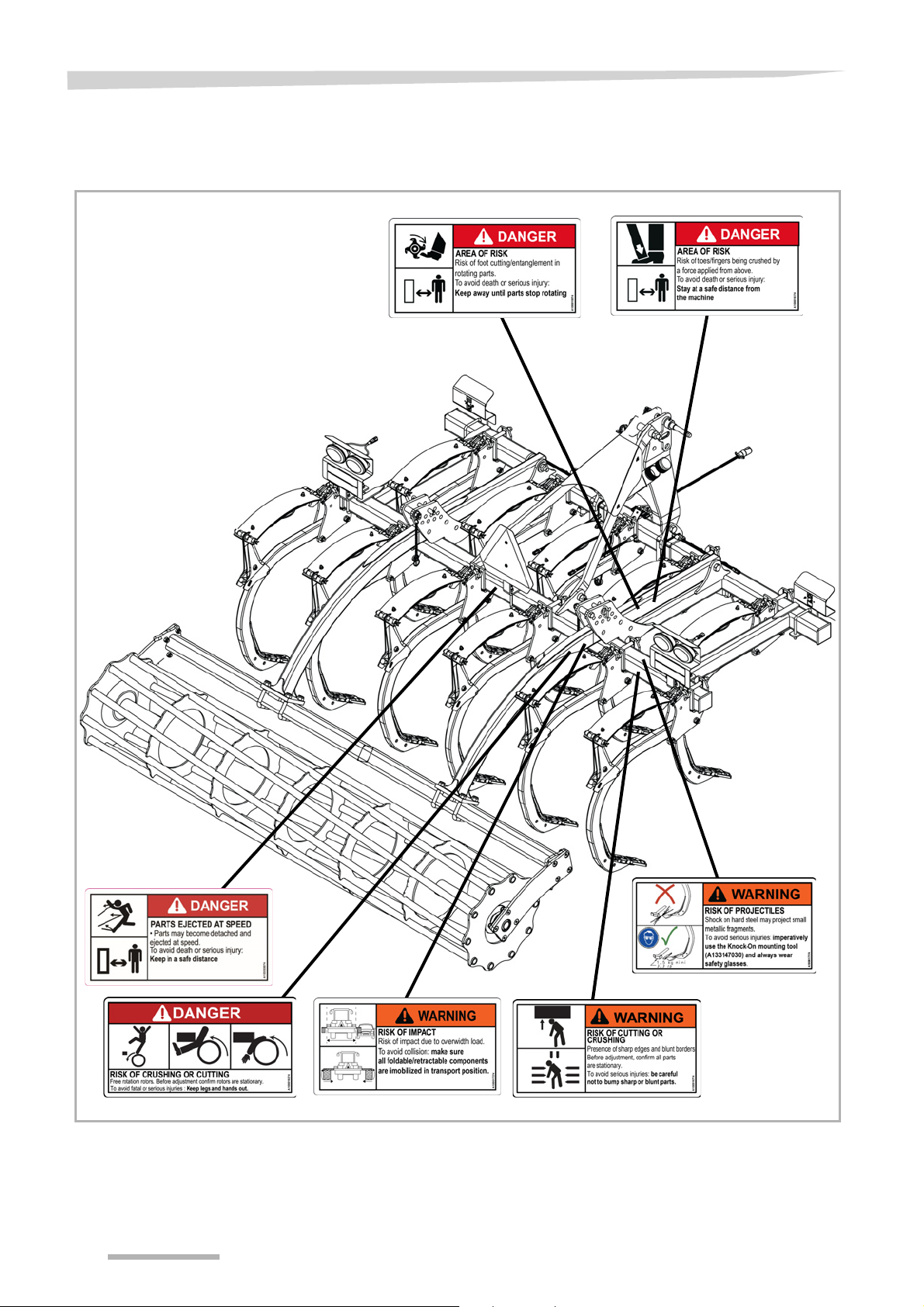

Rigid machines

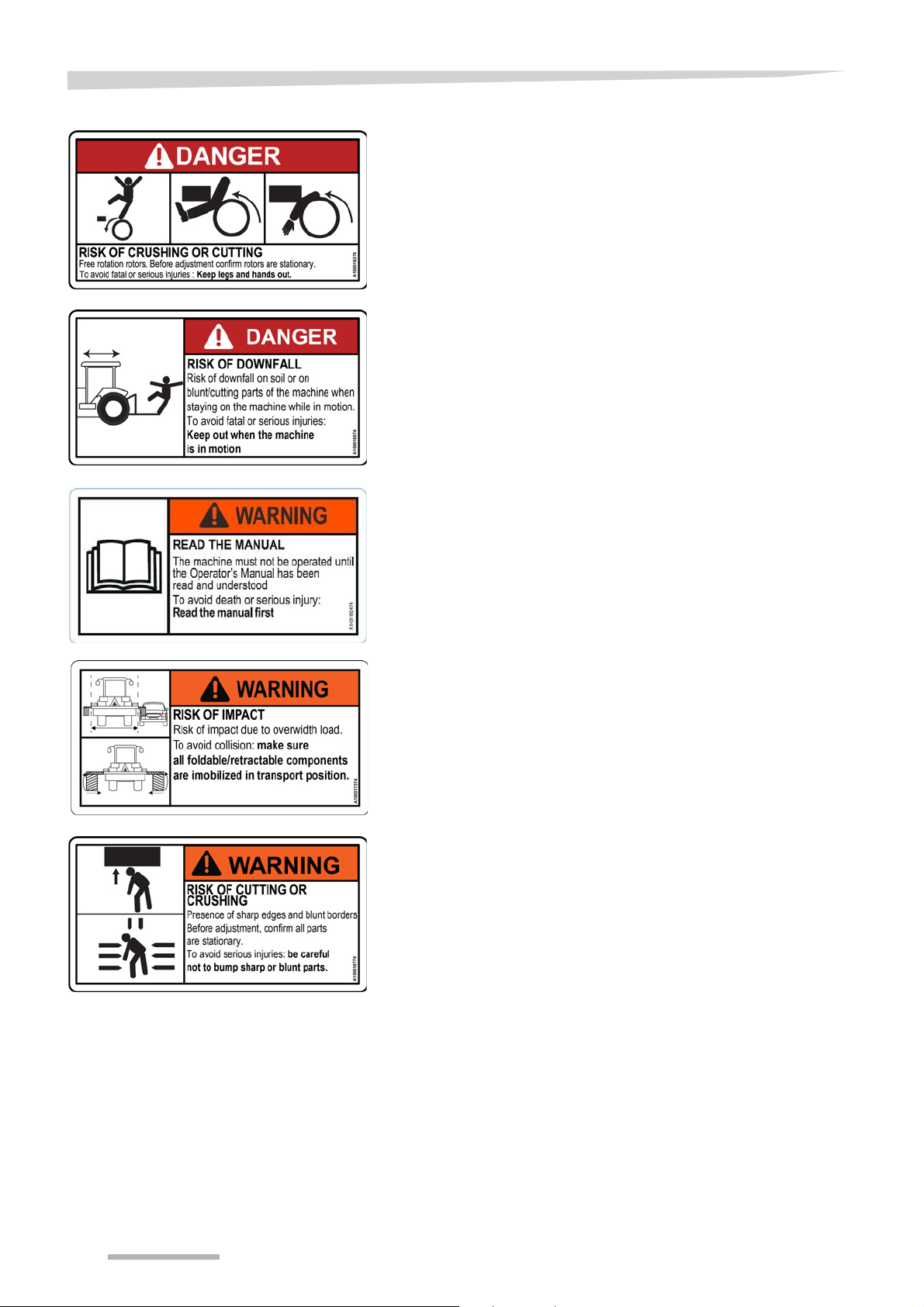

The HAZARD, WARNING and CAUTION safety stickers

Safety pictograms on the

machine

To ensure user safety, stickers are placed on the machine. Do not

remove these stickers.

When the stickers become illegible or when they lose their adhesion,

order new ones and place them in the corresponding places.

7

Safety

8

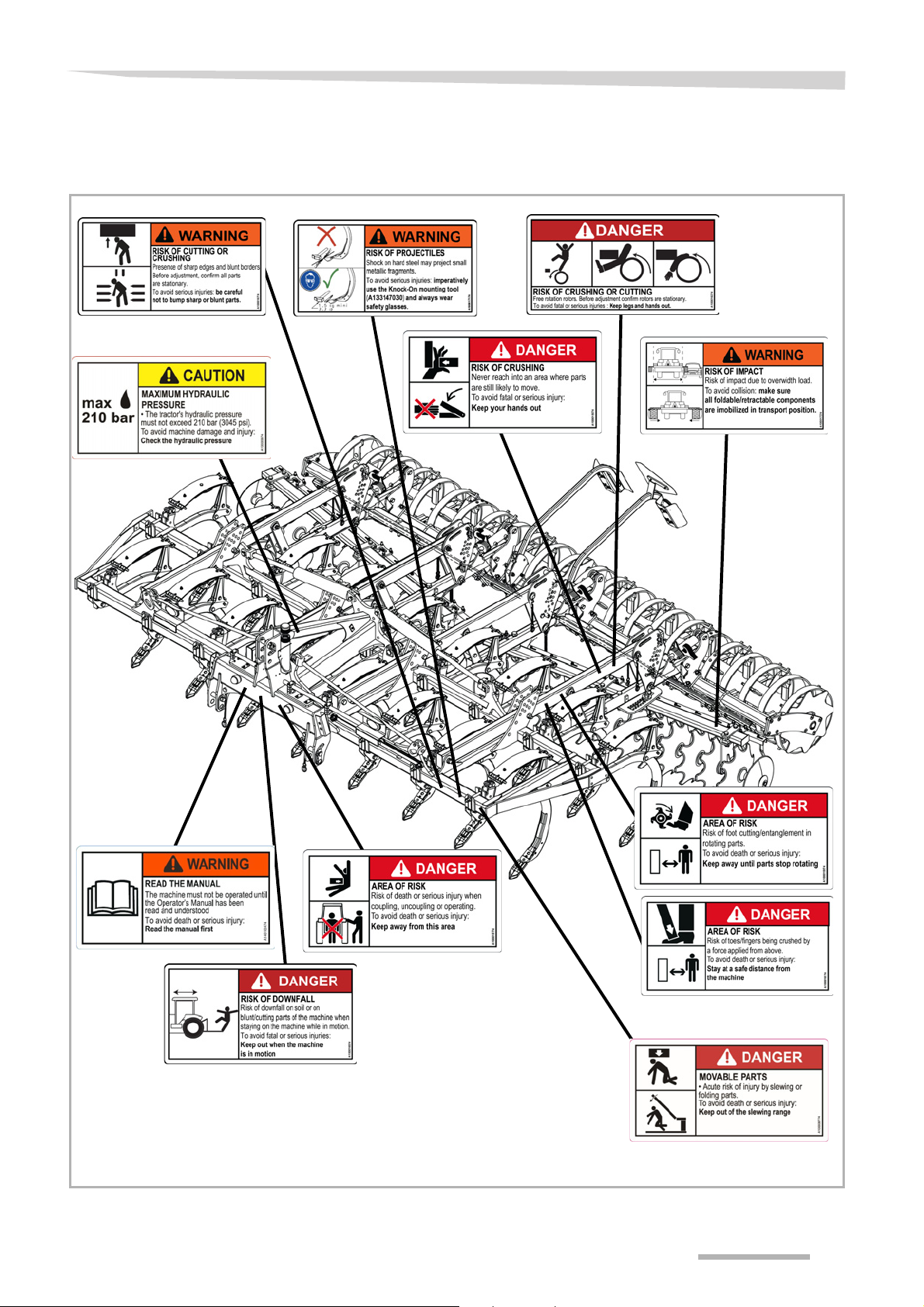

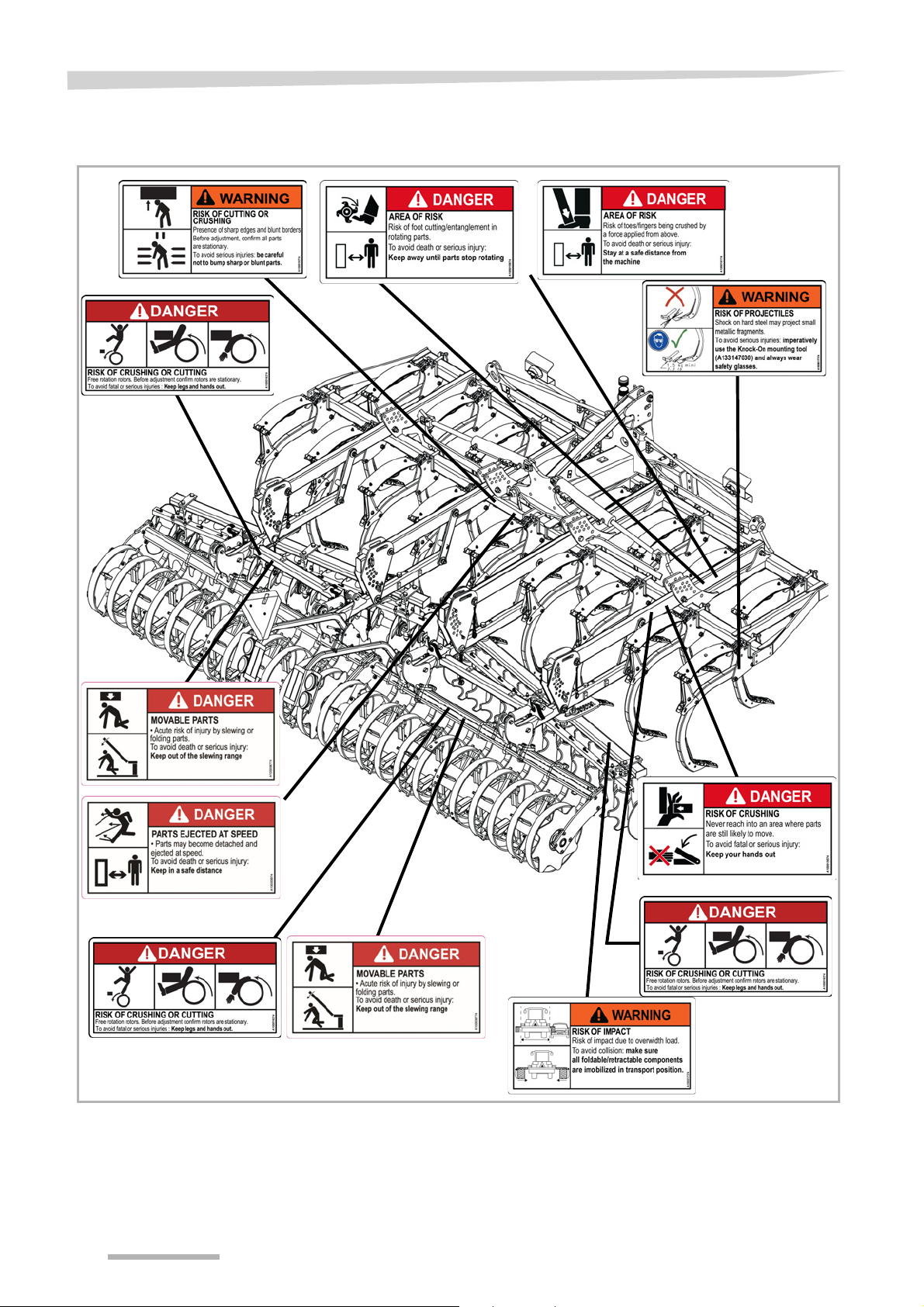

Folding machines

Safety

9

Safety

10

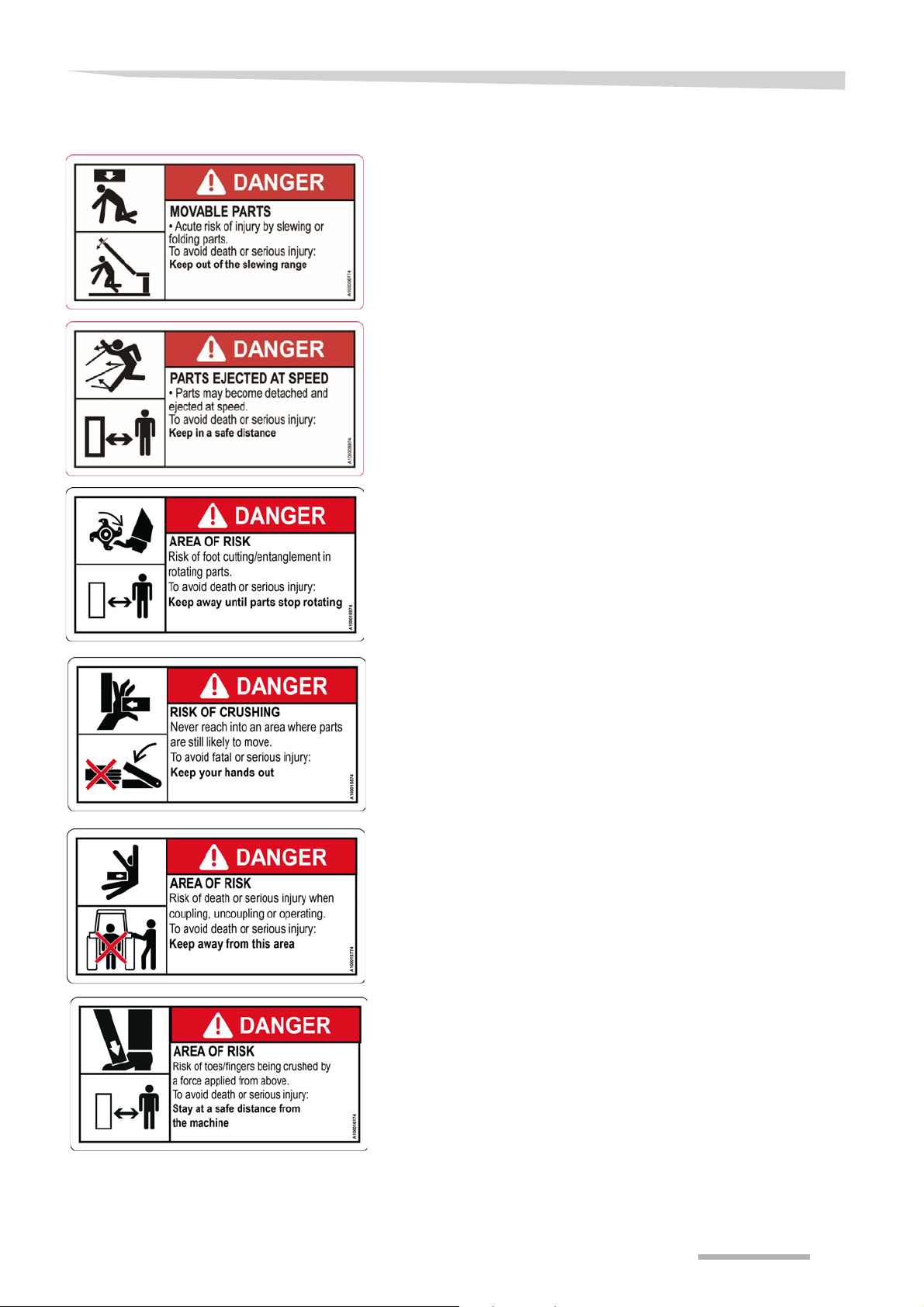

Meaning of safety symbols

Safety

HAZARD:

Pivoting or folding moving parts may cause serious injuries or death.

Stand away from the range of movement of all pivoting parts.

HAZARD:

Rotating parts can cause serious injuries or death.

Stand away from the range of movement of all rotating parts.

HAZARD:

Hazardous zone

Risk of cuts/feet getting tangled in the rotating parts. In order to avoid

all serious or fatal injuries:

Maintain a safe distance between you and the machine until all

rotating parts have been immobilized.

HAZARD:

Risk of crushing

There is a danger of hands being crushed in an area where there are

likely to be moving parts. In order to avoid all serious or fatal injuries:

keep your hands away from these areas.

HAZARD:

Hazardous zone

Risk of serious or fatal injury during machine hitching, unhitching or

operations.

In order to avoid all serious or fat al injuries: Remain out side th is zone.

HAZARD:

Hazardous zone

Risk of crushed toes/fingers by a force applied from above.

In order to avoid all serious or fatal injuries: maintain a safe distance

between you and the machine.

11

Safety

HAZARD

Risk of cuts / crushing

Freely-rotating rollers Before beginning adjustments, ensure that the

rollers have been immobilized. In order to avoid all serious or fatal

injuries: keep your legs and hands outside the roller rotation zone.

HAZARD

Risk of falling

Risk of falling to the ground or onto cutting or blunt-edged parts of the

machine while it is operating.

In order to avoid all serious or fatal injuries: n ever climb onto a moving

machine.

WARNING

Read the maintenance manual

The machine must not be used prior to having read and understood

the user’s manual. To avoid serious or even fatal injuries: First read

the user’s manual.

WARNING

Risk of collision

Risk of collision due to excessive width. To avoid any collision: Make

sure that all the retractable or folding elements are blocked in

transport position.

WARNING

Risk of cuts or crushing

Presence of cutting and contusive edges. Before you start to make

any adjustments, make sure that all the parts of the machine are

immobile. In order to avoid an y ser ious injury: be care ful not to bump

against sharp or blunt edges.

12

Safety

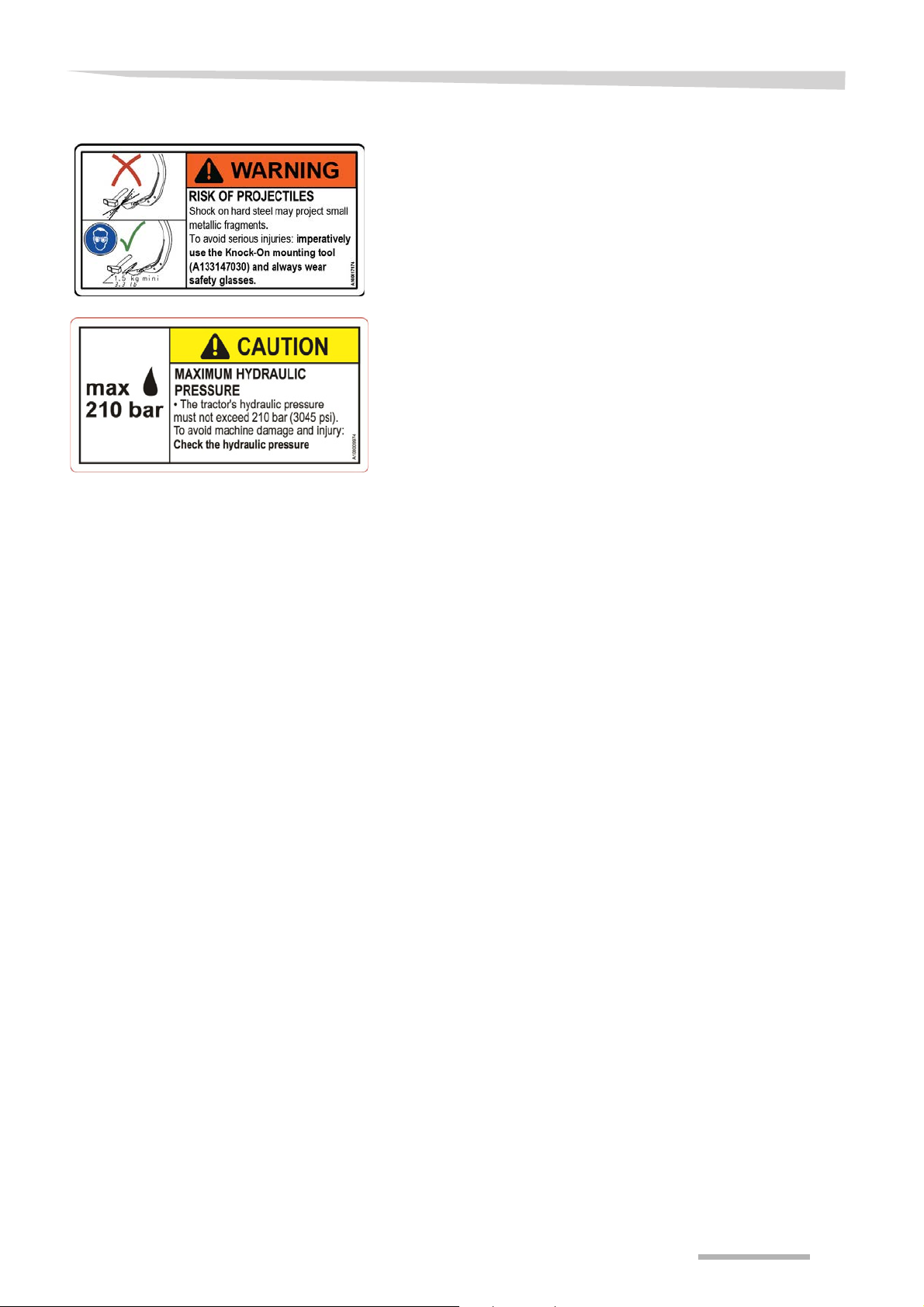

WARNING

Risk of projected debris

Metal fragments may be projected if you h it the coulters directly with a

hammer.

To avoid any serious injury: systematically use the Knock-On tool

(A133147030) and always be sure to wear protective safety glasses.

CAUTION

Maximum hydraulic pressure

The tractor’s hydraulic pressure must not exceed 210 bar (3,045 psi).

To avoid damage to the machine and injuries: check the hydraulic

pressure.

13

Safety

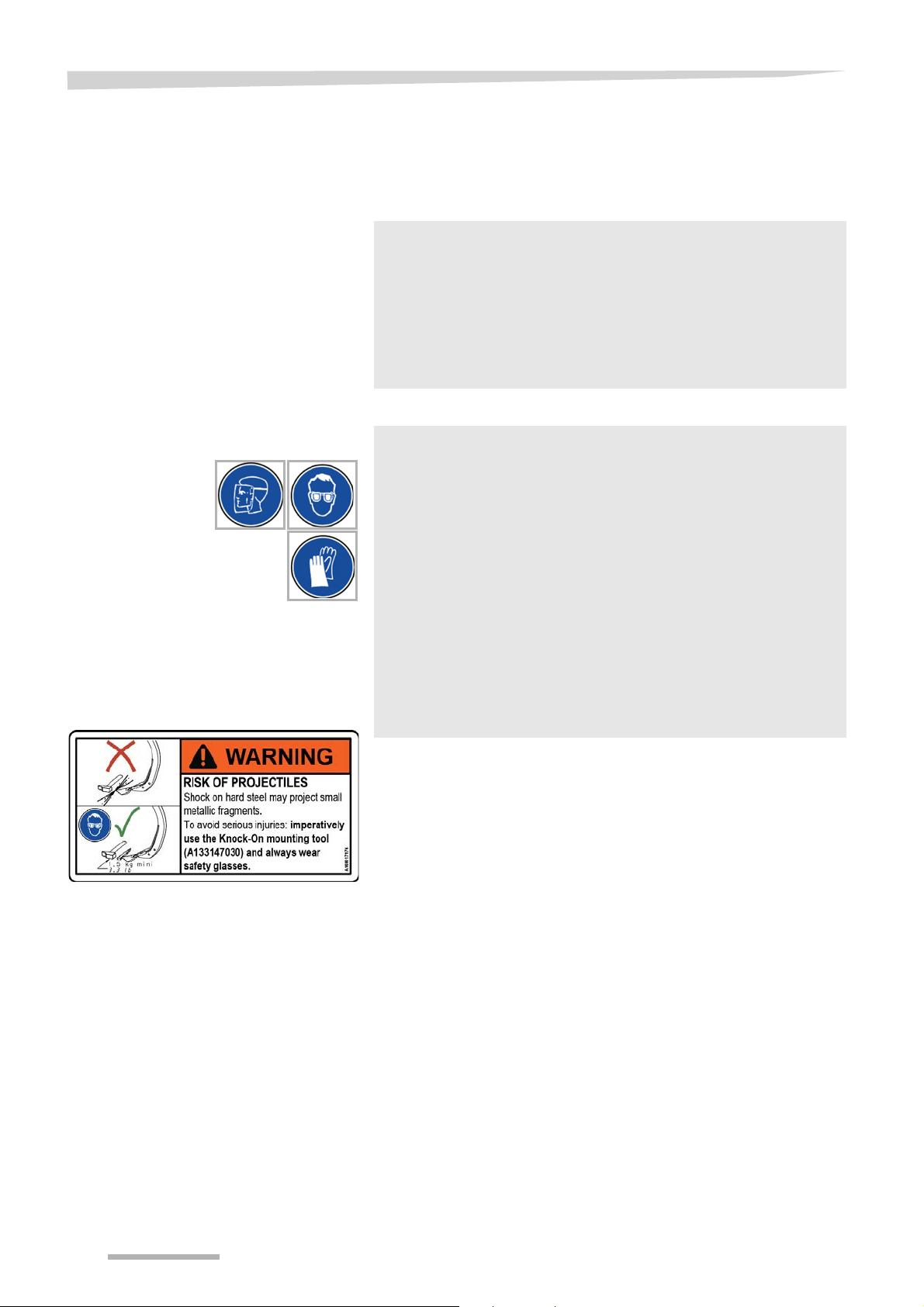

Meaning of symbols

specific to the Knock-on

accessory

\ WARNING

Never directly hit the coulters with a hammer.

The coulters are made of treated steel. During assembly or

disassembly operations, never directly hit the coulters with a

hammer. Such a hit could produce fragments, break parts and

cause serious injuries. Therefore, to avoid contact between two

hard parts, use the specific Knock-on tool.

\ IMPORTANT

Wearing a visor or safety glasses is mandatory in order to

avoid any injury.

It is compulsory to wear gloves.

The following safety equipment is highly recommended.

• Safety shoes,

• Covering clothes,

• Hard hat,

• etc.

Risk of projections in the event of hitting the coulter with a hammer.

14

Safety

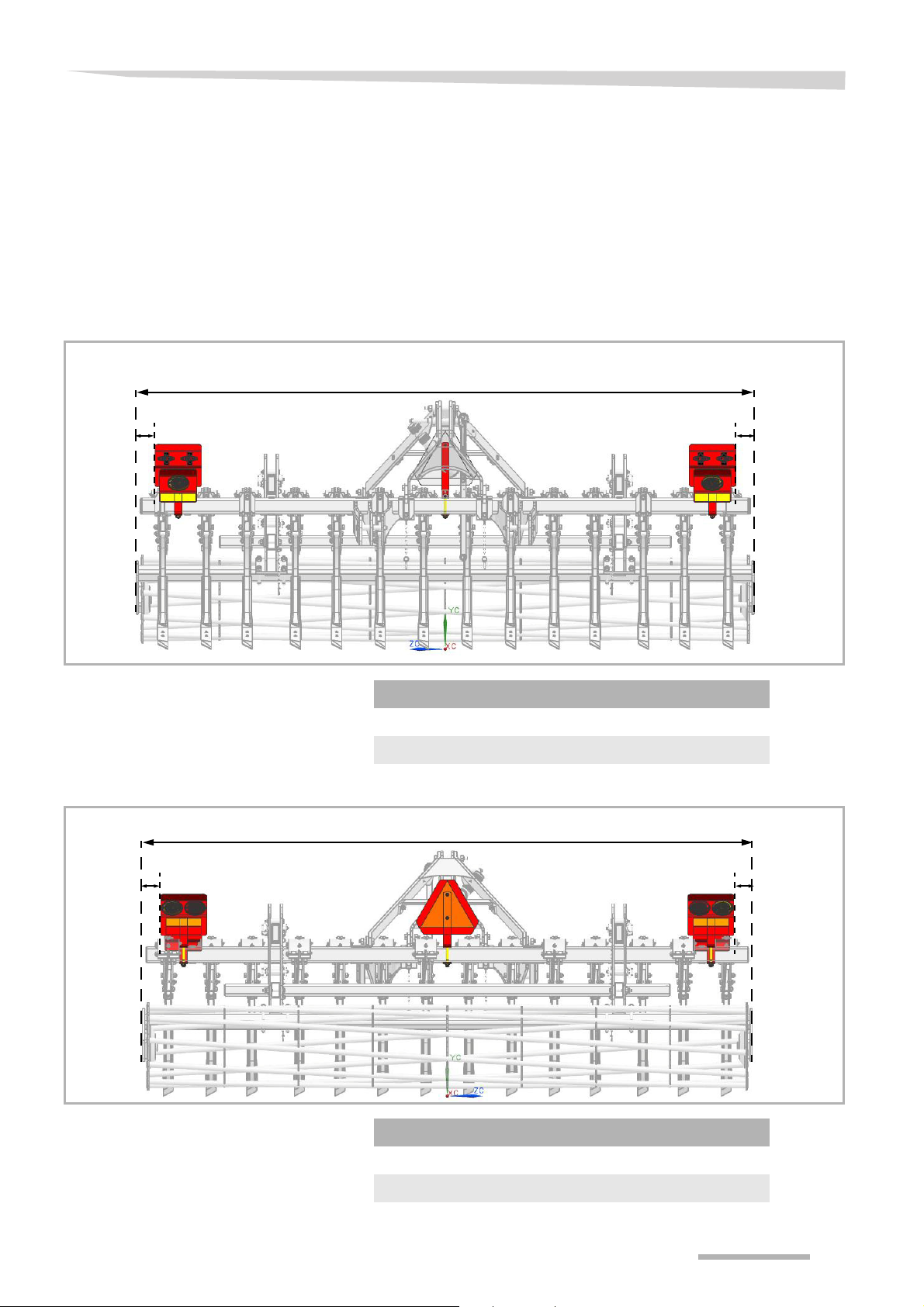

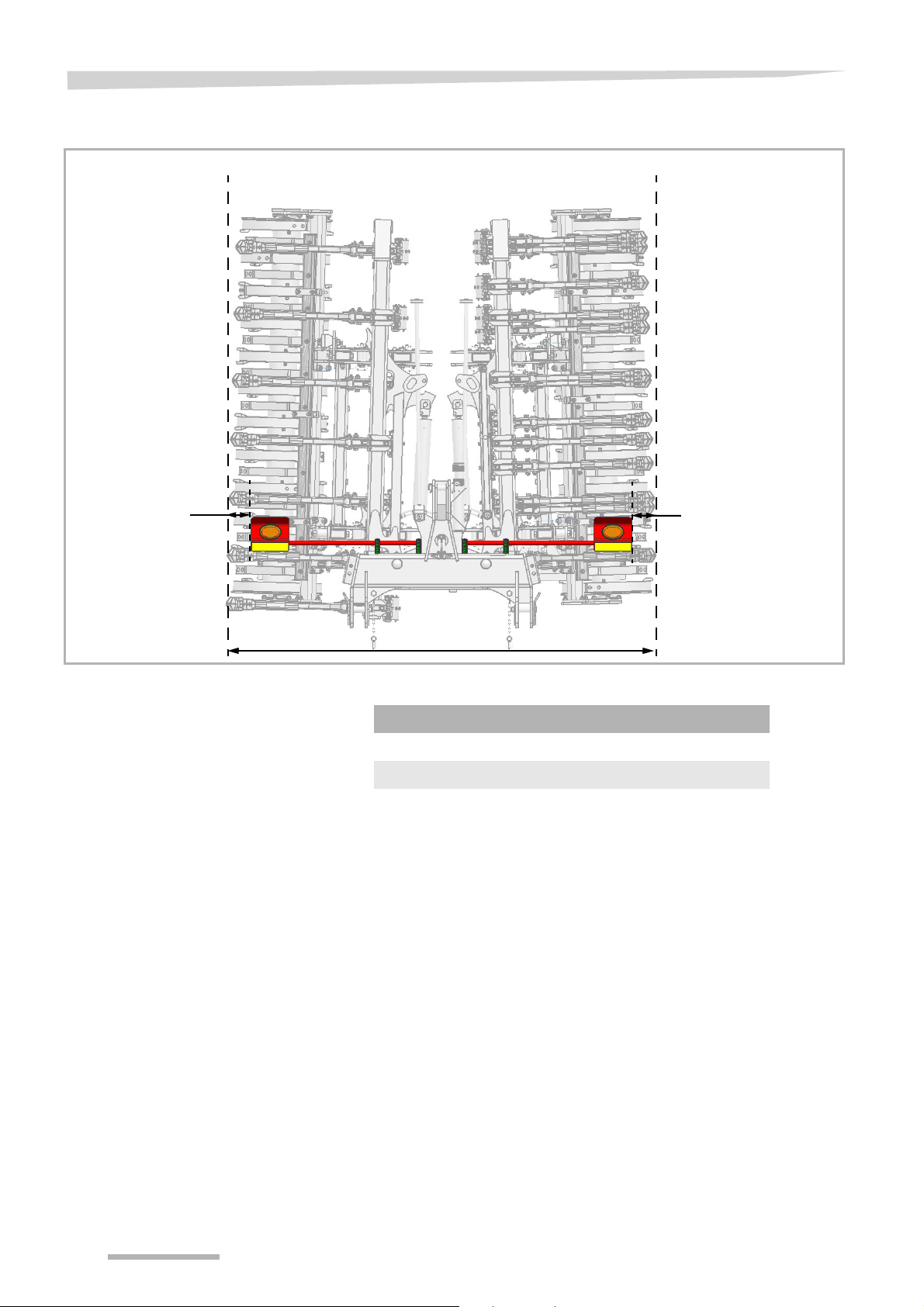

CLC Evo rigid - Front view - as an option on the 2.50-m machines (6’6”)

A

B B

CLC Evo rigid - Rear view

B

B

A

Signaling systems for North

America

Signaling systems, panels and stickers are installed o n the machine in

order to ensure complete road safety. The signaling systems must

always be functional. Under no circumstances are you to remove the

panels and stickers, but instead you must replace them if they are

missing or illegible. You can order new stickers just like a spare part

from your specialist dealer.

The user must ensure that the tractor/machine unit is compliant

with current prescriptions regarding machine transport on the

road network.

Signaling systems

Marking Dimensions

A 3.00m (9’10”) - 3.50m (11’6”) - 4.00m (13’1”)

B Max. 80 mm (approx. 3”)

Marking Dimensions

A 3.00m (9’10”) - 3.50m (11’6”) - 4.00m (13’1”)

B Max. 130 mm (approx. 5”)

15

Safety

A

B

B

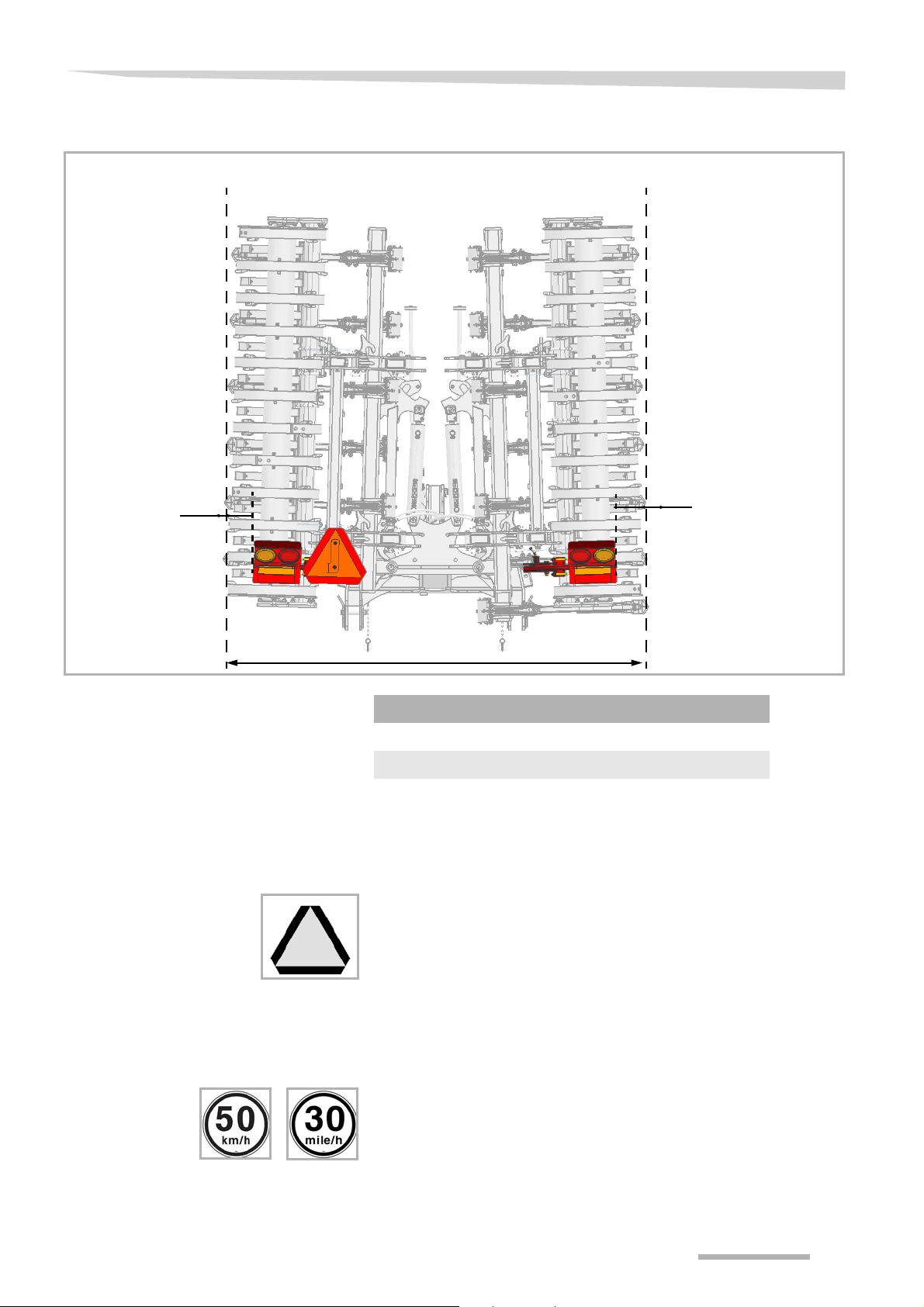

CLC Evo foldable - Front view - as an option

Marking Dimensions

A 2.75m (9’)

B Max. 80 mm (approx. 3”)

16

Safety

A

B

B

CLC Pro foldable - Rear view

Panels

Marking Dimensions

A 2.75m (9’)

B Max. 270 mm (approx. 11”)

The working depth of rollers must be set at its minimum level.

In some states of the United States and some Canadian provinces,

additional signaling is mandatory for road transport:

Slow vehicle indicator

This triangle-shaped panel is placed so as to always remain visible in

back of the machine while in the transport position. This signaling

device is necessary:

• at a road speed of less than 50 km/h (30 mph)

and

• if the hitched machine conceals the slow vehicle panel of the

tractor when in transport position.

Maximum speed indicator

Circular panel bearing the indication 50 km/h or 30 miles per hour.

This panel needs to be placed on the tractor when not already pr esent

and when the certified tractor speed exceeds 50 km/h (30 mph).

17

Safety

Safety rules

General recommendations

Before starting up, check that the machine is not endangering any

persons and that the protection and safety devices (e.g. guards,

hoods, warning labels, etc.) are in place and functional.

Before you start work, familiarize yourself with all the equipment,

controls and functions on your machine. Once you have started, it is

too late.

If an operating incident occurs:

Shut down the machine immediately.

Identify the cause of the incident.

Carry out repairs out before starting up the machine again.

No work should be attempted on the machine delivered unless:

• all measures have been taken to prevent unintentional start-up

(uncouple the power take-off and/or hydr au lic ho se s, tr act or

engine switched off, for example).

• chocks have been placed under the frame to prevent it falling,

• the vehicle has been immobilized using the appropriate systems.

Before leaving the tractor:

Put the machine on the ground.

Activate the hand brake.

Remove the ignition key.

No one should stand between the tractor and the machine unless the

vehicle is immobilized (hand brake, chocks, etc.), the engine is

switched off and the ignition key removed.

18

Hitching

Safety

\ HAZARD

Never stand between the machine and the tractor during

maneuvers.

No one should stand between the tractor and the machine when

maneuvering the tractor or during lifting operations. This could

cause serious injury or even death.

Follow instructions for hitching to the letter:

• when maneuvering, select the tractor’s lowest possible forward

speed,

• the type of tractor hitch should be adapted to suit the machine’s

hitch,

• when coupling, position the tractor’s hydraulic controls such that

the hitch does not move during handling,

• the hitch must be locked and should not come detached by itself in

the lower position.

The weight distribution is altered when the machine is hitched. The

maximum load per vehicle axle (see manufacturer’s notice) should not

be exceeded. If there is insufficient loading on the front axle, extra

weights must be installed, so that control over the vehicle’s steering is

retained.

When hitching or unhitching the tool, put any support equipment

provided in place to prevent the machine from be coming unbalanced .

19

Safety

Transport

\ IMPORTANT

Machine movement

On a curved road section, beware of ma chine mo vemen t s as well

as a shifting of the load. Adjust your forward speed accordingly.

Regulations

• Respect the driving code at all times when on the road

on the road network.

• Check that your hitch meets local road safety requirements. If

necessary, you are responsible for fitting and testing transport

equipment (e.g. lighting, signals, guards, etc.) corresponding to the

characteristics of your tractor-machine assembly and the

applicable statutory requirements.

• Ensure that the machine’s dimensions are compatible with the

highway code.

Passenger transportation

Carrying passengers on the working tool or during transport is

prohibited.

Braking

For all movements, brakes must be coupled (no single wheel braking).

Trips off the farm field

No movement should be made outside an agricultural field or close to

people, until folding extensions or folding or tipping accessories

(where they exist) have been locked in the transport p osition.

Hydraulics

In transit, the hydraulic hoses of the folding jacks must be

disconnected to prevent acciden tal unfoldin g.

Lifting

• During transport, lock the lower lift arms to prevent any sideways

movement.

• During travel, the lift control must be positioned, so as to prevent

the tool from being accidentally lowered.

Axle

For machines with a transport axle, secure the locking system in place

prior to traveling on the road.

Locking of hydraulic jacks

On the machines fitted with locking devices, verify that the foldable

parts of the machine have been correctly locked and moreover that

the hydraulic safety equipment is well locked.

20

Use

Safety

\ HAZARD

Avoid all contact of the machine with electrical voltage lin es.

Any contact with electrical voltage lines can cau se serious or even

fatal injuries.

T ake all necessary precautions in order to avoid any cont act while

handling the machine adjacent to electrical voltage lines.

\ WARNING

Be mindful of the return to the initial position

of locked tine.

Any tine that is abnormally blocked in the raised position may

suddenly return to its position and is therefore a source of serious

danger.

Keep away from the tine and never stand in its return path.

Raise the machine to eliminate any blockages.

When the tine is returned to low position, check that it is fully

tightened and does not lock up.

If the tine remains locked, do not try to release it. Call a

technician.

Stay outside the zone where the machine’s foldable part s are

in motion.

No one should enter the folding extension s area or fold ing or

tipping (where present) accessories movement area, until they

have been locked by the system provided for this purpose. The

system may be chain, a pin, a rigid connecting rod or a double

control valve.

Do not take actions on a moving machine.

Any work on the machine is prohibited while the tractor is in

motion. Keep a safety distance of at least 5.00 m (

machine in motion (forward movement, movement of any part of

the machine, movement of the tractor hitch).

Verify the peripheral areas of both the machine and tractor

before starting up.

Before starting up:

Ensure that there is no one in the immediate vicinity (children,

etc.).

Ensure that you have sufficient visibility.

Wear safety shoes and maintain a safe distance when

adjusting machines fitted with discs.

For machines fitted with covering discs, border discs, folding tines,

leveling boards, track erasers or any other accessory that can be

vertically adjusted, it is advisable to respect a safety distance, as

the equipment could accidentally fall when being adjusted.

Wearing safety shoes is recommended.

16’4”) from the

21

Safety

Safety for children

\ WARNING

Do not assume that children will rema in calmly in place wh ere you

last saw them.

Remain vigilant and turn off the motor if children are present in

your work space.

Never let children play on the machine or use it.

\ IMPORTANT

Adapt your speed when the ground is sloped.

In the event of use on uneven terrain, the tra ctor can deviate from

its path if it encounters a hole, ditch or other irregularity.

To remedy this problem, be sure to always drive at a speed

adapted to the uneven ground.

Just one person is allowed on the tractor while it is running.

Only allow one person, the operator , on the tractor when it and the

tool are in operation.

22

Maintenance

Safety

\ HAZARD

Apply the brakes or immobilization system prior to any

actions taken on the tractor-tool assembly.

Be sure to always apply the brakes or the vehicle immobilization

system prior to any action taken within the radius of the tractor-tool

assembly. Failing to do so may cause serious or even fatal

injuries.

\ WARNING

Beware of sharp edges and corners.

When changing parts on the machin e, you should p ay attention to

all parts with sharp edges or corners. We recommend that you

wear safety equipment (hard hat, safety shoes, gloves, etc.) in

order to avoid any injury.

\ IMPORTANT

Beware of the return path of the high-pressure cleaning jet.

While cleaning the machine, beware of the retu rn path of th e highpressure cleaning jet on some of the surfaces. This might cause

bruises and contusions.

It is strictly forbidden to disassemble springs used as safety devices

for working parts: This operation must only be performed by

specialists.

For machines fitted with foldable extensions: Strictly follow the instructions in this user’s manual for the assembly, disassembly and

adjustment.

Before carrying out any welding works:

Disconnect the electrical boxes (if present).

Disconnect the tractor alternator and battery if it is hitched.

Regularly check that bolts are tight, tire pressure s ar e correct a nd the

hydraulic circuit is in good condition.

Be sure to never direct the high-pressure cleaning jet directly onto the

following components, so as to prevent their deterioration:

• bearings,

• hydraulic hoses,

• electrical boxes

• any sensitive machine component.

23

Safety

Unhitching

\ WARNING

Never stand between the tractor and the machine

during unhitching.

Before unhitching the machine, be sure that no one is positioned

between the machine and the tractor.

Individuals may get pinned between the tractor and machine,

thereby leading to serious or even fatal injuries.

In order to avoid any hazard during unhitching:

Immobilize the tractor,

lower the machine,

engage the parking brake,

make sure that the machine is on flat and sufficiently stable

ground.

operate the tractor’s hydraulic lift slowly and carefully,

Connect or disconnect hydraulic tubes, only if there is no pressure

in the tractor’s and machine’s hydraulic system .

24

Hydraulic installation

Safety

\ HAZARD

Any action taken on the hydraulic system must always be

performed by a trained and certified technician.

For further information, refer to Chapter "Replacement of the hydraulic

system parts" page 82.

Other instructions

Follow instructions

In addition to the instructions listed above, always follow:

• Accident prevention regulations

• generally recognized safety regulations, occupational health

requirements and road traffic regulations,

• the notes that can be found in the user manual,

• instructions for use, maintenance and servicing.

25

Presentation of the machine

Presentation of the ma chine

Field of application

Usage clause

This machine is considered to be interchangeable equipment within

the meaning of European directive 2006/42/EC and is considered to

be agricultural equipment within the meaning of directive ASABE

S390.

This chapter contains general information about your machine as well

as information concerning the following points:

• Usage clause.

• Characteristics.

• Description of machine components.

• Technical data.

This machine has been designed solely for norm al agricultural use,

i.e. for cultivating farmland. Any other use or misuse, for example,

transport, land clearing or transmission of power to another machine

is considered to be contrary to the intended use.

The manufacturer and specialist dealer decline any responsibility for

damage caused by use other than normal use. The user assumes all

risks.

Compliance with the conditions of use includes compliance with the

manufacturer’s user instr uc tio ns.

The safety instructions (detailed above) and rules regarding general

safety, occupational health and road traffic must also be followed.

Modifications to the tool made by the customer or the use of spare

parts or accessories that are not original parts will void the manufacturer’s liability for all damage resulting from the modification.

The manufacturer cannot be held liable for damage resulting from

incorrect settings, choice of equipment, seed, fertilizer, treatments or

farming strategy or for any other damage not directly related to the

machine.

26

Loading...

Loading...