Kverneland CLC Evo Wings, CLC Evo Instruction Manual

CLC Evo - CLC Evo Wings

Instructions

Edition 04/2014

Printing 1.2014

Language EN

From serial no. 009171

Execution Rigid/Folding

Reference. RF30115D

Identification of the machine

In order that your dealer may help as fast as possible, he needs a few indications regarding your machine.

Please provide this information below.

Description

Working width

Weight

Machine No.

Accessories

Dealer’s

address

CLC Evo - CLC Evo Wings

Manufacturer's

address

Kverneland Group Les Landes Génusson S.A.S.

9 rue du Poitou

F-85130 LES LANDES GENUSSON

Tel: +33 (0)2 51 64 13 00

The copyright and use (Copyright) are held by the Kverneland Group Les Landes Génusson SAS, France. Copying, transferring to other media,

translating or using even partially this text are illegal without Kverneland's written authorisation. All rights reserved. The content of these operating

instructions may be changed wit hout notice. Subject to technical changes.

Table of contents

Preamble ................................................... 4

Target group for this operating manual 4

Meaning of symbols 4

Safety ......................................................... 5

For your safety 5

Warning symbols 5

Safety rules 8

Other instructions 12

Getting to know the machine .................. 13

Scope of use of the machine 13

General description 14

Technical specifications 15

Rear accessory variants 20

Roller variants 21

Depth control wheel variants [+] 22

Option (other) [+] 22

Distribution of right and left deflectors 24

CLC Evo configurations 25

CLC Evo wings configurations 29

31

Table of contents

Control 58

Replacing the tines 61

Wear of the coulters 62

Disc wear 64

Skid wear on Actipack 65

Hydraulic diagram ..................................... 66

Guarantee ................................................... 67

Disposal of the machine ........................... 68

Metal parts 68

Tyres 68

Hydraulic oil 68

EC conformity declaration ........................ 69

In accordance with EC directive

2006/42/EC 69

In accordance with EC directive

2006/42/EC 70

Index ........................................................... 71

Delivery and assembly ............................. 32

Check on reception 32

Repositioning the tines 32

Installing the accessory or roller arms [+] 33

Attaching the rear accessory [+] 33

Attaching the roller [+] 33

Rear accessory configuration 34

Mounting the rear struts (folding machine) 36

Coupling .................................................... 38

Transport ................................................... 39

Safety 39

Commissioning ......................................... 42

Settings - Adaptability .............................. 43

Range of coulters 43

Range of deflectors 43

Settings ..................................................... 44

Step 1: working depth 44

Step 2: Adjusting the rear accessories 46

Actiflex roller 50

CLC folding lighting kit 50

Uncoupling the machine .......................... 51

Cleaning, maintenance and storage ....... 53

Cleaning 53

Maintenance 53

Storage 53

Maintenance .............................................. 54

For your safety 54

General remarks 55

Lubricating 56

3

Preamble

[+]

Preamble

Target group for this operating manual

Training

Meaning of symbols

This operating manual is intended for trained farmers and individuals

who are otherwise qualified to perform agricultural activities and who

have received training in the operation of this machinery.

For your safety

Study th e contents of this o perating manual carefully befo re assembly

or initial operation of the machine. In this way, performance and work

safety are optimised.

For the employer

All personnel are to be trained in the use of the machine regularly (at

least once a year) in accordance with employers' liability insurance

association guidelines. Untrained or unauthorised individuals are not

permitted to use this machine.

The retailer provides the user with instructions relating to the use and

maintenance of the machine.

In order to make this manual clea r and easy to read, we have u sed

various symbols. They are explained below:

• A dot precedes each item in a list.

A triangle indicates operating functions which must be performed.

→ An arrow indicates a cross-reference to other sections of this

manual.

We have also used pictograms to help you find instructions more

quickly:

N

OTE

The term “Note” indicates tips and notes on operation.

The screwdriver indicates tips for assembly or adjustments.

The warning triangle indicates importan t safety instructions. Failure to

observe these safety instructions can result in:

• Serious operational faults of the machinery;

• Damage to the machinery;

• Personal injury or accidents.

A star indicates examples that help to better understand the instruc-

tions.

A plus sign in square brackets indicates that the equipmen t is optional.

4

Safety

Safety

For your safety

Warning symbols

Meaning of symbols

In this chapter you will find the general safety instructions. Each

chapter of the operating manual contains additional specific safety

instructions, which are not described here. Please follow the safety

instructions

• in the interest of your own safety,

• in the interest of the safety of others,

• to ensure the safety of the machine.

Numerous risks can result from handling agricultural machines in the

wrong way . Therefor e, always work with special care and never under

pressure.

The employer should:

Inform personnel working with the machine of these safety instructions at regular intervals and according to statutory regulations.

On the machine you will find decals for your safety. These decals must

not be removed. When they are illegible or they no longer stick, order

new decals and affix them at the corresponding locations.

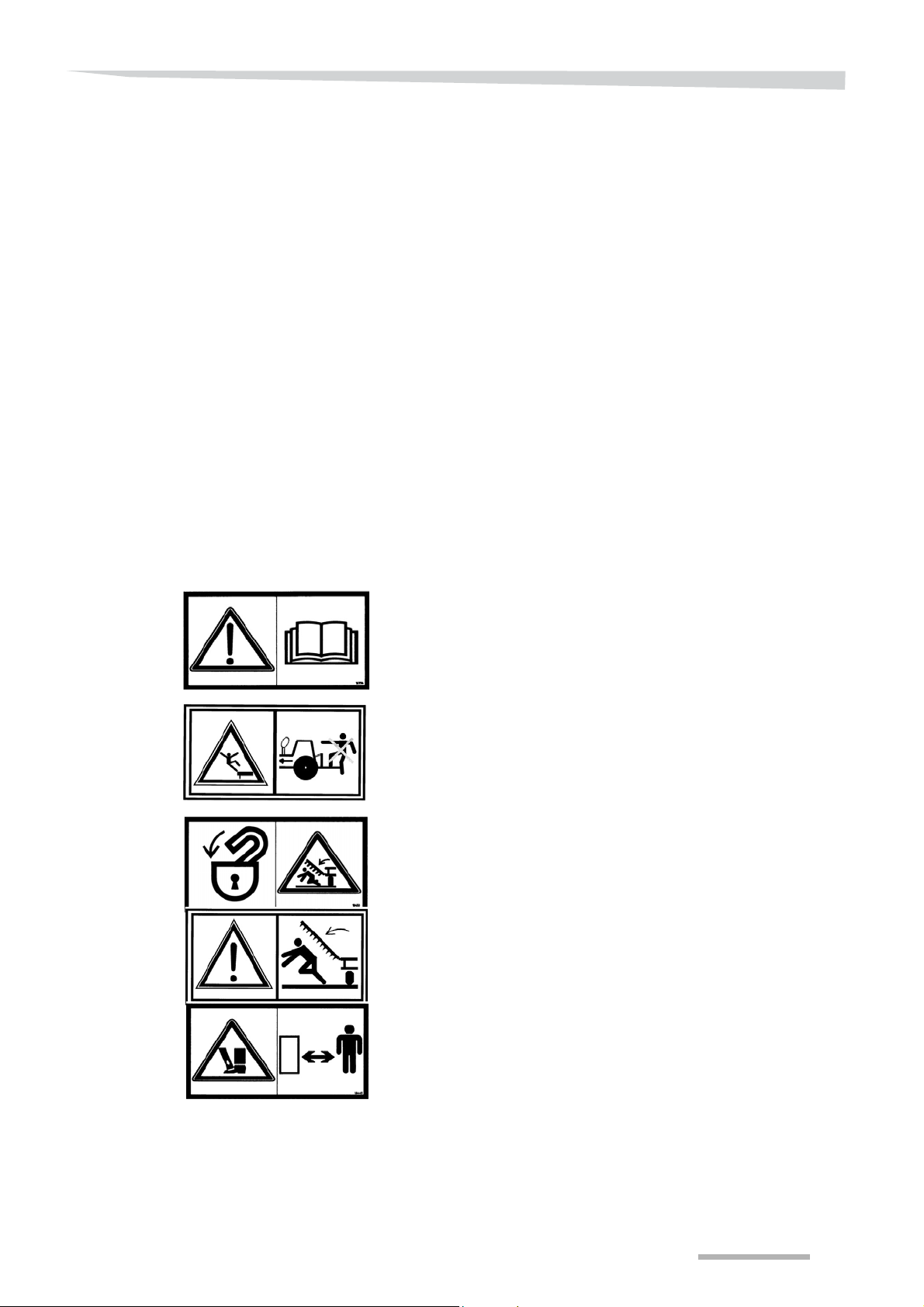

Read and comply with the manual and safety instructions before

starting up or carrying out any operations on the machine.

Carrying persons on the machine while in motion (in transit or at wo rk)

is strictly forbidden.

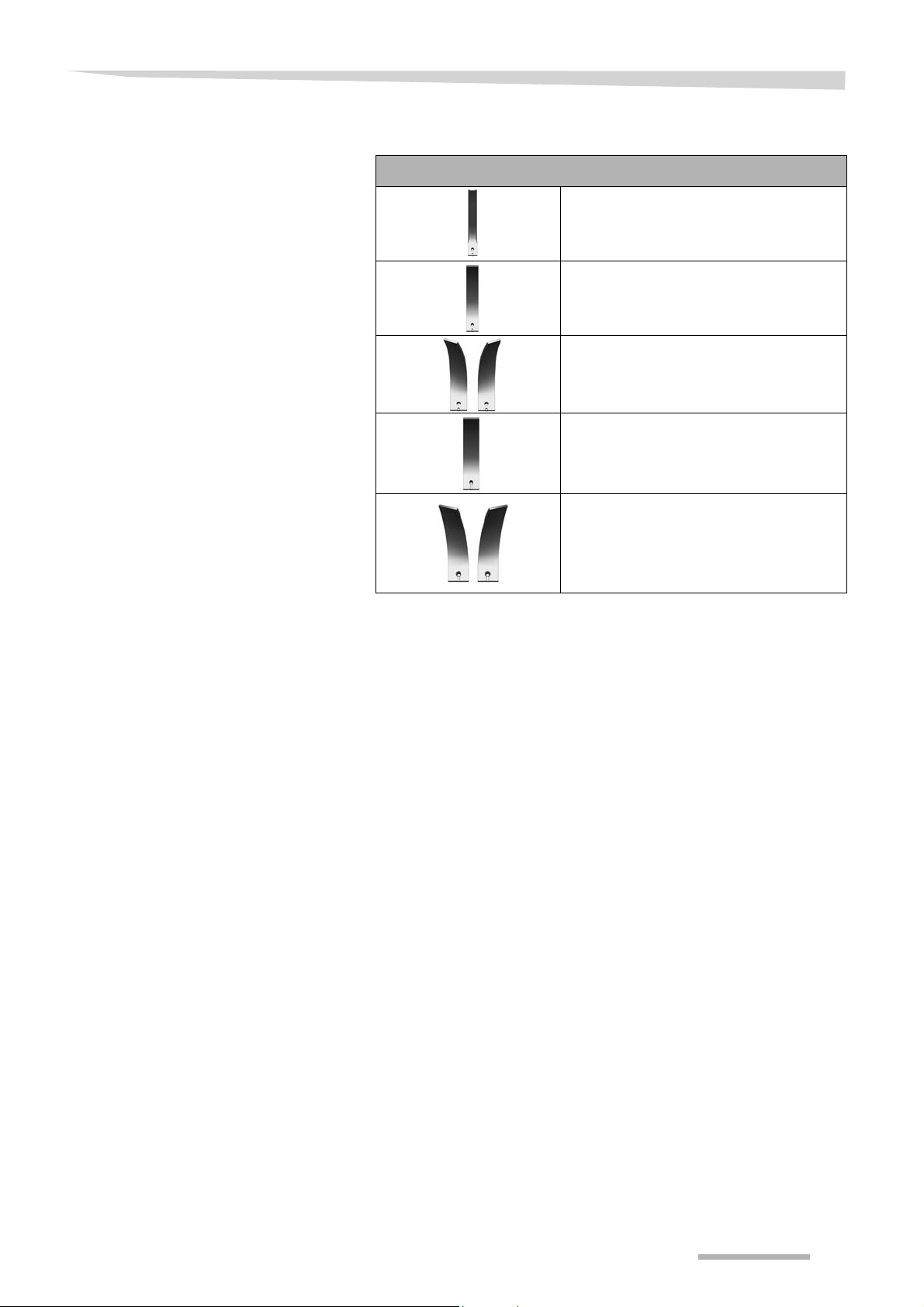

Risk of crushing by an articulated part of the machine. In stall the safety

devices provided and/or check the working order of the automatic

safety devices before entering a hazardous area.

Risk of crushing by an articulated part of the machine. In stall the safety

devices provided and/or check the working order of the automatic

safety devices before entering a hazardous area.

Risk of feet being crushed during machine adjustment. Keep a safe

distance from this part of the machine.

5

Safety

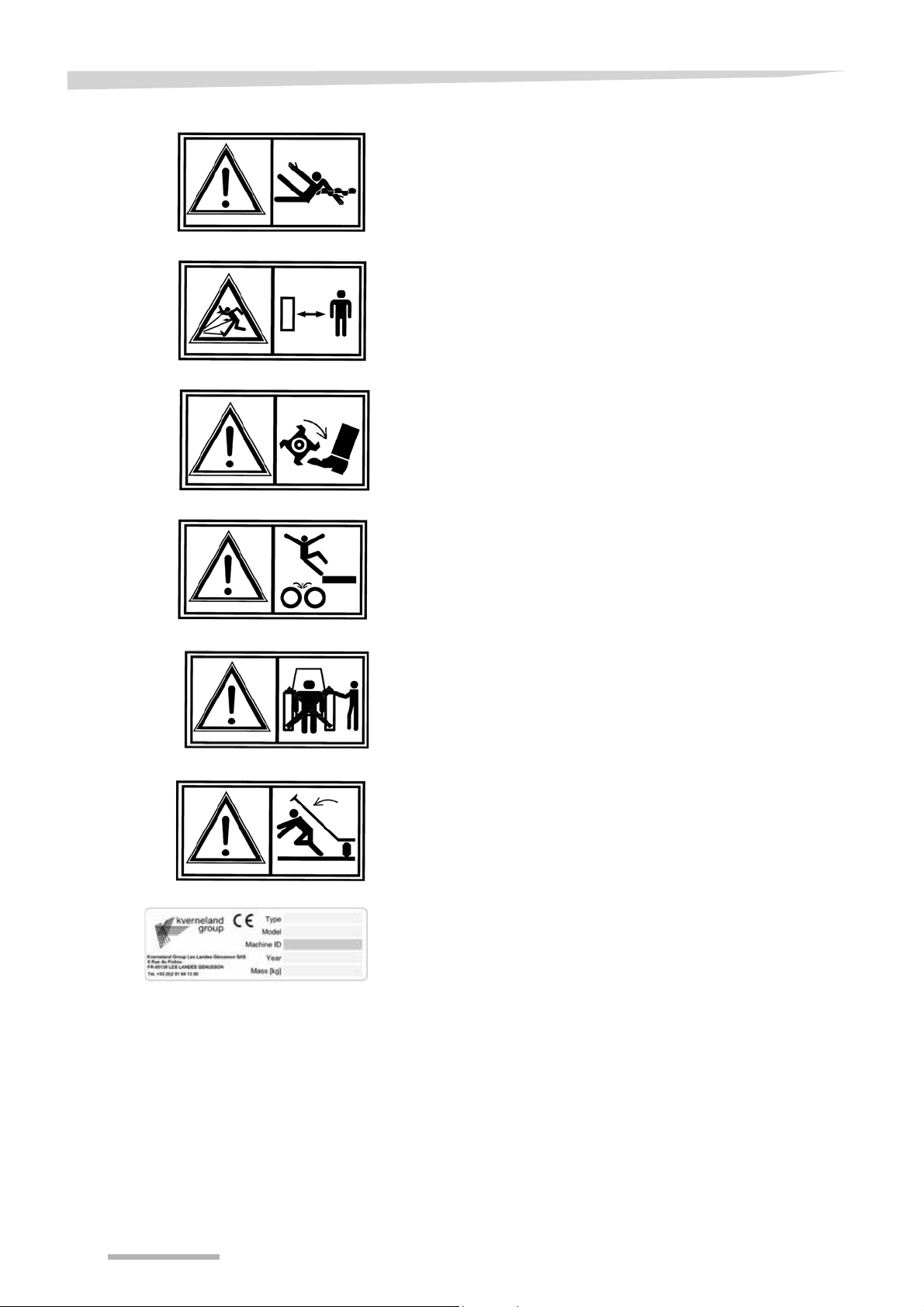

Risk of being caught by a rotating part of the machine (PTO shaft, for

example).

Risk of projection of stones and other materials. Keep a safe distance

from this part of the machine.

Risk of foot being severed by a rotating cutting implement. Keep a

safe distance from this part of the machine.

Risk of falling onto rotating roller implements. Keep a safe distance

from this part of the machine.

Risk of being crushed by the lower tractor lifting arms during hitching/

unhitching operations. Keep a safe distance from this part of the

machine.

Danger of being crushed by an articulated marker arm of the machine.

Install the safety devices provided and/or check the working order of

the automatic safety devices before entering a hazardous area.

EC type plate guaranteeing the conformity of the machine according

to directive 2006/42/EC and adapted to national legislations.

6

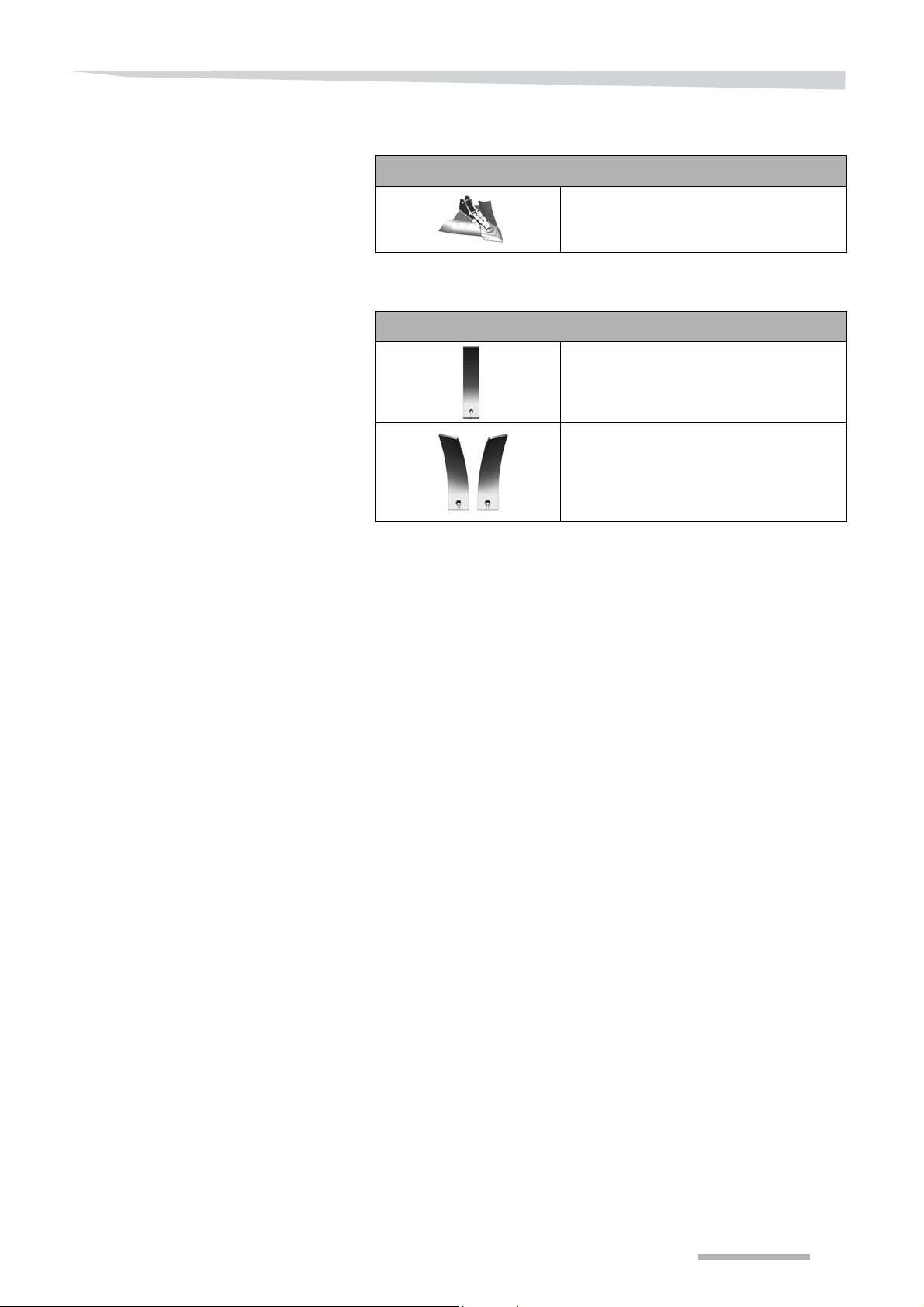

Meaning of symbols

Sticker

location on the

machine

specific to the Knock-on

accessory

Safety

Protection risk against shard in case of striking the coulters with a

hammer.

(Two copies of this sticker is sent with the accessory. These stickers

are to be placed on the front left and back right beams of your

machine, please confer to the opposite diagram).

The coulters are made from treated steel.

During assembly or disassembly operations, never hit the coulters

directly with a hammer. You risk serious injury from flying shards or

breakage of parts. As a result, in order to avoid contact between two

hard and heavy pieces, use the special Knock-on tool.

WARNING

In the interest of safety measures,

A visor must be worn (in the absence of safety goggles).

Maximum facial protection is strongly recommended.

Gloves must be worn.

Generally, wearing adapted safety equipment is highly recomme nded

(safety shoes, protective clothing, helmet, etc.).

7

Safety

Safety rules

General recommendations

Before starting up, check that the machine is not endangering any

persons and that the protection and safety devices (e.g. guards,

hoods, warning labels, etc.) are in place and functional.

Before starting work, familiarise yourself with all the parts, controls

and functions of your machine. Once you have started working, it will

be too late!

Should an incident occur, stop the machine immediately and identify

the cause. Repairs should be carried out before starting up again.

No repair operations should be carried out on the machine un le ss:

• all measures have been taken to prevent the machine starting up

again accidentally (e.g. PTO and/or hydraulic hoses uncoupled,

tractor engine switched off),

• no chocks are placed under the frame to prevent the risk of the

frame descending,

• the vehicle is immobilised by appropriate means.

Before getting off the tractor, lower the machine onto the ground.

Apply the handbrake and remove the key from the ignition.

No one should pass between the tractor and the machine unless the

vehicle is immobilised (hand brake, chocks, etc.), the engine is

switched off and the ignition key removed.

Coupling

Follow the coupling instructions carefully:

• when manoeuvring, select the tractor's lowest possible forward

gear,

• there should be no-one between the tractor and the machine when

manoeuvring the tractor or lifting,

• the category of tractor hitch must be adapted to the hitching

characteristics of the machine,

• during coupling operations, the hydraulic controls of the tractor

should be in such a position that the linkage does not move while

handling,

• the hitch must be locked and should not unhook when lowered.

The distribution of masses is modified when the machine is coupled.

The maximum vehicle axle weight (see manufacturer's instructions)

must not be exceeded. If the un-ballasting of the front end is too large,

you must place additional masses to be able to maintain the steering

control of your tractor.

When coupling or uncoupling the implement, put any support

equipment provided in place to prevent the machine from becoming

unbalanced.

8

Safety

Driving on the road

Respect the highway code when travelling on public roads.

When cornering, beware of machine offset and weig ht transfer. Adapt

your speed.

In transit, secure the lower raising arms to prevent them from swinging

out.

The machine must not be moved outside the field or near people until

the fold-away extensions or the fold-away or tipping accessories (if

any) have been locked in the transport position.

In transit, the hydraulic hoses of the folding cylinders must be

disconnected to prevent them from unfolding accidentally.

On machines equipped with a transport carrier, secure the carrier

locking system before taking the machine onto the road.

When driving, the lift control should be positioned so as to prevent the

implement from being accidentally lowered.

Check that your hitch complies with local road safety legislation. If

necessary, you are responsible for fitting and testing transport

equipment (e.g. lighting, signals, guards, etc.) corresponding to the

characteristics of your tractor-machine assembly and the applicable

statutory requirements. Make sure that the dimensions of the machine

comply with the highway code.

Carrying persons on the working tool in transit is not allowed.

The brakes must be coupled up for all movements (no single-wheel

braking).

9

Safety

Use

Any tine that is abnormally blocked in the raised position may

suddenly return to its position and is therefore a source of serious

danger . Keep well clear and out of the return path of the tine. Once the

tine has returned to the low position, check that it is tight and does not

jam at any point.

Nobody must enter the range of movement of the folding extensions

or folding or tilting accessories (if present) if they have not been locked

by the system provided for that purpose. This system can be a chain,

pin, rigid rod or a controlled double valve.

Before starting up, make sure that the surrounding area is clear (no

children in the vicinity, etc.). Make certain that you have sufficient

visibility.

Any intervention on the machine is prohibited when the tractor is

moving. Keep a safety distance of at least 5 m from the machine in

motion (advance, movement of any part of th e machine, movement of

the tractor hitch).

For machines equipped with covering disks, edge disks, retractable

teeth, levelling boards, track erasers or any other accessory with a

vertical adjustment, it is recommended to maintain a safety distance

in case of an accidental fall of the equipment during its adjustment.

You are advised to wear safety shoes.

Serious injury and even death may result from contact with electric

power lines. T ake all precautio ns if you move or use the machine close

to power lines to avoid any contact.

When using on uneven ground, the tractor may deviate from its path

when it passing over holes, ditches or other irregularitie s in the terrain.

Only authorise a single person, the operator, on the tractor when the

tractor and machine are in operation.

10

Safety

Maintenance

No intervention must be made within the radius of the tractor - to ol unit

without the brakes or vehicle immobilisation system being engaged.

When changing parts on the machine, you are advised to be careful

with all parts with sharp edges or corners. We recommend that you

wear safety gear (helmet, safety shoes, gloves, etc.).

For machines equipped with folding extensions, make sure you follow

the instructions in this manual for assembly , disassembly and settings.

It is strictly forbidden to disassemble springs used as safety devices

for working parts. This operation must only be performed by

specialists.

Regularly check that bolts are tight, the tyre pressure and the

condition of the hydraulic circuit.

Before welding, disconnect the electric units (if there are any) and

disconnect the tractor alternator and battery if the tractor is hitched up.

Never direct the jet of high pressure cleaners directly onto the

bearings, the hydraulic pipes, electric units or other sensitive

components on the machine (risk of damage). The jet may bounce

back off some surfaces.

Power take-off

Follow the instructions of the cardan joint manufacturer.

Use only the cardan drive designed for the machine and equipped with

regulatory guards.

Start the transmission only after having ensured that there is no one

close to the machine.

The rotation speed of the power take-off must correspond to the

maximum rotation speed permissible by the machine.

11

Safety

Uncoupling the

machine

Hydraulic system

There is a higher risk of injury when uncoupling the machine from the

tractor! Therefore:

• Immobilise the tractor.

• Never stand between the tractor and the machine when coupling.

• Actuate the three-point power lift system slowly and carefully.

• Make sure that the machine is on flat and sufficiently stable

ground.

• Only disconnect hydraulic tubes if there is no pressure in the

tractor and machine hydraulic system.

The hydraulic system is pressurised.

When connecting the hydraulic system, make sure that the tractor

system and tool are not pressurised.

Connect the hydraulic system according to the instructions in the

user's handbook. Identify the connectors using a colour code to avoid

incorrect connections (the reversal of functions can cause accidents).

Before any intervention on the hydraulic system, block the folding

extensions and hydraulically controlled accessories in their rest

position, reduce the pressure and stop the tractor engine.

Other instructions

Following the instructions

In addition to the instructions listed above, always obey:

• Accident prevention regulations

• Generally recognised safety regulations, occupational health

requirements and road traffic regulations

• Remarks made in this operating manual

• instructions for use, maintenance and servicing.

12

Getting to know the machine

Getting to know the machine

Scope of use of the machine

This chapter contains general information about your machine as well

as information concerning the following points:

• Scope of use

• Features

• The description of groups and technical data

This machine has been designed solely for norm al agricultural use,

i.e. for cultivating farmland. Any other use or misuse, for example,

transportation, clearing or transmission of forces to another machine

is considered to be non compliant with the intended use.

The manufacturer and the specialised retailer decline all liability for

damage resulting from use that does not comply with the intended

use. The user is responsible for taking any ri sks.

Compliance with the conditions of use includes compliance with the

manufacturer's operating instructions.

The safety instructions (specified above) as well as the general rules

of safety, occupational health and travel on public roads must be

respected.

Modifications to the machine made by the client or the use of spare

parts or accessories that are not from KVERNELAND will cancel the

manufacturer's liability for all damages resulting from this modification.

The company will not be held liable for damage resulting from

erroneous settings, choice of equipment, seed, fertilizer, treatments or

farming strategy or for any other damage not directly related to the

machine.

13

Getting to know the machine

Accessory support arm

Frame 100 mm x100 mm

(4” x 4”)

Coupling of the upper link bar

Stubble cultivator module

Rear accessories

Couplings of the lower bars

General description

14

Getting to know the machine

Technical specifications

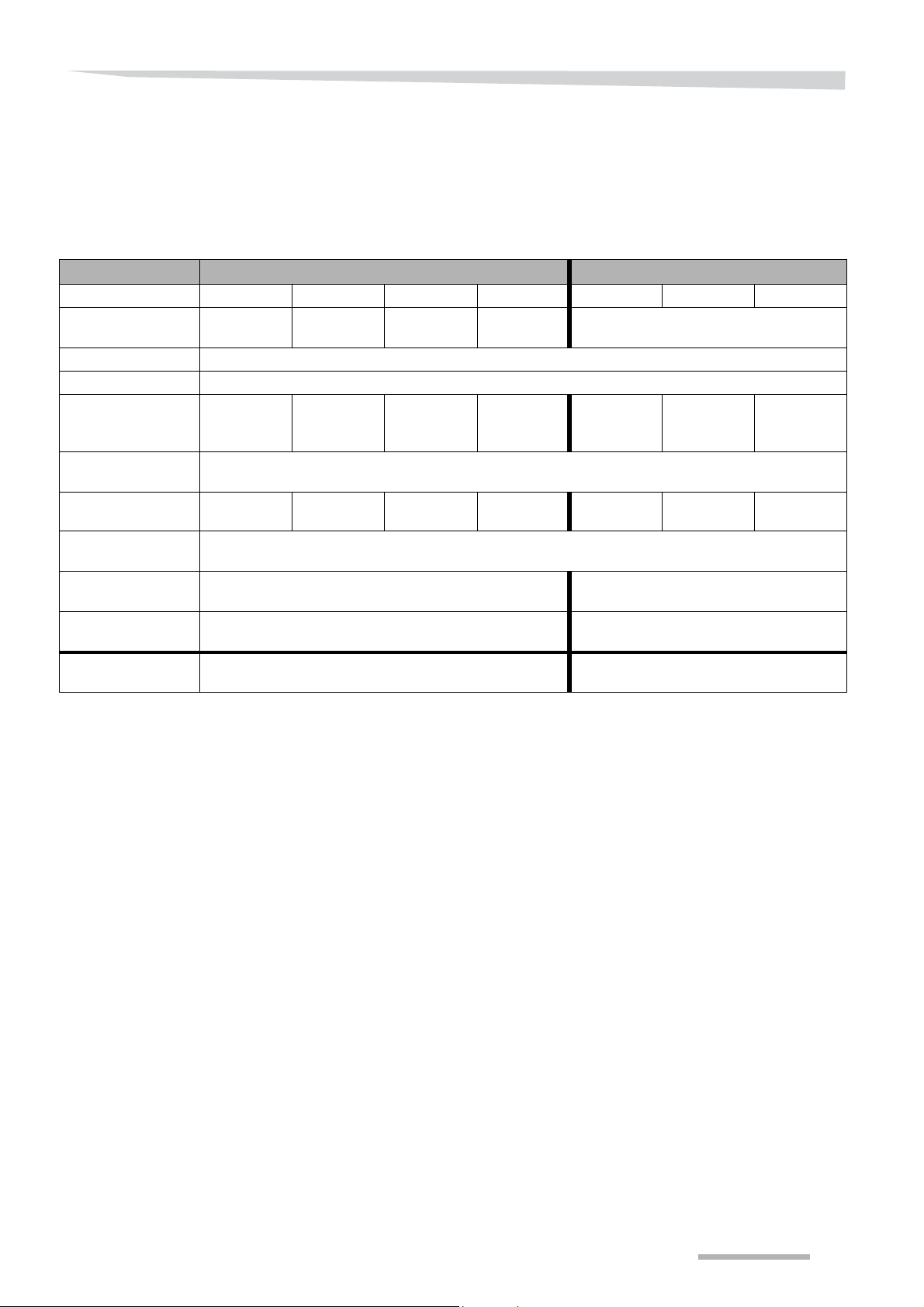

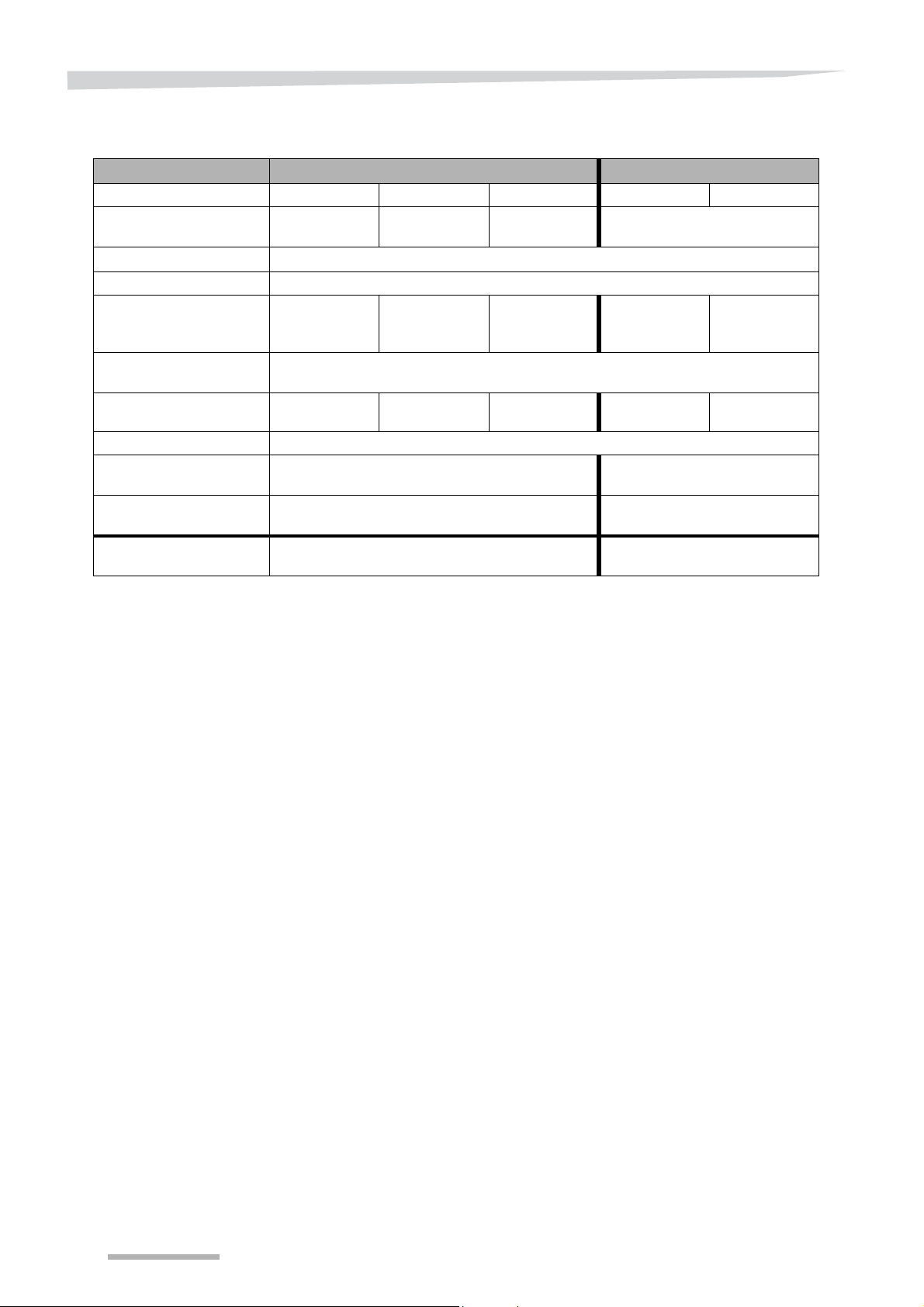

CLC EVO

Features Fixed models Folding models

Working width (m/ft) 2.50 (8’2”) 3.00 (9’10”) 3.50 (11’6”) 4.00 (13’1”) 4.00 (13’1”) 4.50 (14’9”) 5.00 (16’5”)

Transportation

width (m/ft)

Number of rows 2

Type of tines CLC with NS spring blade safety device or bolted safety device

Number of tines

Spacing/W orking

width (m)

Clearance under

the frame (mm)

Min./max. power

Lighting and

signalling kit

Coupling category

(upper link)

Coupling category

(on lifting arm)

Recommended tyre

pressure (bar)

2.50

(8’2”) 3.00 (9’10”) 3.50 (11’6”) 4.00 (13’1”) 2.85 (9’4”)

9

(265)/2.50m

(101/2”)/8’2”

65 / 210hp

48/154 kW

11

(265)/3.00m

(101/2”)/9’10”

80 / 240hp

59/177 kW

Cat II / III Cat III

Cat II / III Cat III

6 bars / 87 psi 3.9 bars / 57 psi

13

(265)/3.50m

(101/2”)/11’6”

95 / 270hp

70/199 kW

15

(265)/4.00m

(101/2”)/13’1”

870

(341/4’’’)

1 10 / 300hp

81/221 kW

Option

13

(290)/4.00m

(111/2”)/13’1”

105 / 300hp

77/221 kW

15

(290)/4.50m

(111/2”)14’9”

120 / 325hp

88/239 kW

17

(290)/5.00m

(111/2”)/16’5”

135 / 350hp

99/257 kW

Stubble cultivator

module

• Frame 100 x100 (4” x 4”)

• Clearance under the frame 870mm (341/4”)

• CLC tine

• NS safety device with spring blade or bolts

• Spacing between tines 2 rows 265-290/101/2” - 111/2”

• Depth of up to 30cm (12”) with rear accessory or roller alone

• Depth of up to 40cm (16”) without rear accessory or with double

gang of discs

15

Getting to know the machine

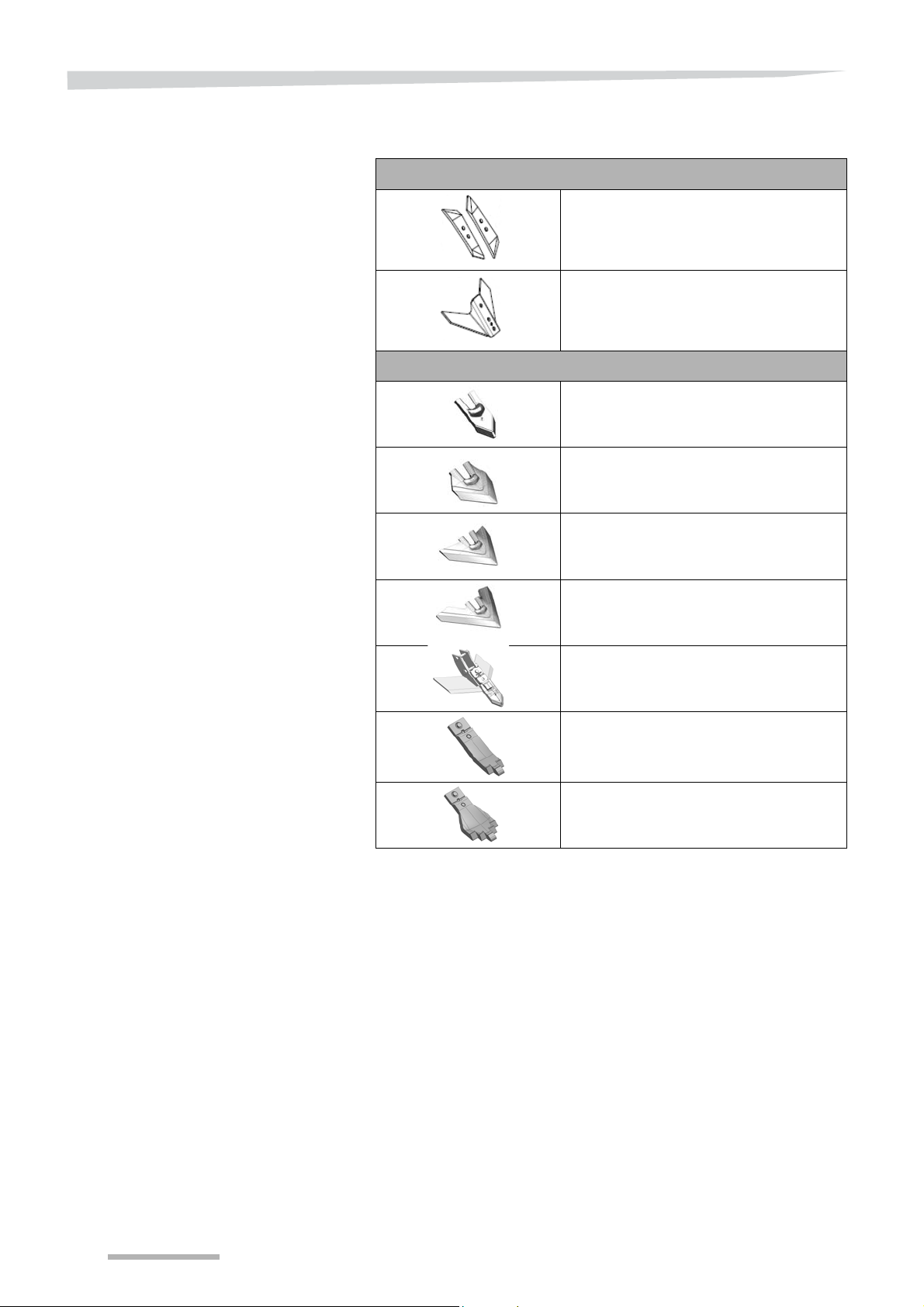

Coulter / blade

For CLC tines

Plough point 60mm (

Blade 300mm (12”)

For CLC tines (Knock-on)

Knock-on 80mm coulter (

Knock-on 150mm coulter (6”)

Knock-on 250mm coulter (10”)

Knock-on 320mm coulter (125/8”)

“Quantum”: Knock-on 80mm coulter

(

+ Blades 345mm (135/8”)

23/8”)

3”)

3”)

Carbide coulter 80mm Tiger

(3”)

Carbide coulter 150mm Tiger

(6”)

16

Tine protection /

Getting to know the machine

Deflectors

For CLC plates

65mm tine protector (2

80mm deflector

80mm twist deflector (3”)

(right and left)

100mm deflector

100mm twist deflector (4”)

(right and left)

5/8”)

(3”)

(4”)

17

Getting to know the machine

CLC EVO WINGS

Features Fixed models Folding models

Working width (m/ft) 3.00 (9’10”) 3.50 (11’6”) 4.00 (13’1”) 4.00 (13’1”) 5.00 (16’5”)

Transportation width

(m/ft)

Number of rows

Type of tines CLC with NS spring blade safety device or bolted safety device

Number of tines

Spacing/Working width

(m)

Clearance under the frame

(mm)

Min./max. power

Lighting and signalling kit Option

Coupling category (upper

link)

Coupling category (on

lifting arm)

Recommended tyre

pressure

(9’10”) 3.50 (11’6”) 4.00 (13’1”) 2.85 (9’4”)

3.00

2

7

(420)/3.00m

(165/8”)/9’10”

80 / 240 hp

59/177 kW

9

(390)/3.50m

(153/8”)/11’6”

95 / 270 hp

70/199 kW

Cat II / III Cat III

Cat II / III Cat III

6 bars / 87 psi 3.9 bars / 57 psi

11

(360)/4.00m

(14”)/13’1”

1/4”)

870(34

110 / 300 hp

81/221 kW

11

(360)/4.00m

(14”)/13’1”

105 / 300 hp

77/221 kW

13

(370)/5.00m

(145/8”)/16’5”

135 / 350 hp

99/257 kW

Stubble cultivator

module

• Frame 100 x100 (4” x 4”)

• Clearance under the frame 870mm (341/4”)

• CLC tine

• NS safety device with spring blade or bolts

• Spacing between tines 2 rows 350-420 (136/8” - 165/8”)

18

Coulter / blade

Getting to know the machine

For CLC tines (Knock-on)

Tine protection /

Deflectors

Knock-on 150mm coulter (

+ Blades 470mm (181/2”)

For CLC plates

100mm deflector (

100mm twist deflector (

(right and left)

6”)

4’’)

4’’)

19

Getting to know the machine

Rear accessory variants

CLC Evo

4 possible configurations, of which 3 are mounted on

parallelograms

Combi-disc (gang of discs + roller) [+]

• Depth control: by roller

• Levelling/ dispersal: by gang of discs

• Setting the depth of the gang of discs:

--> movement by hydraulic jack

--> depth control adjustment using plastic chocks

• Compaction: rear roller

Tandem disc (double gang of discs) [+]

• Depth control: by front wheels

• Levelling/ dispersal: by two gangs of discs

CLC Evo wings

CLC Evo + Evo wings

Hollow disc + roller [+]

• Depth control: by roller

• Levelling: by spading discs on rubber spring safety device

• Compaction: rear roller

Roller only (pivoting arm) [+]

• Depth control: by roller

• Compaction: rear roller

20

Roller variants

Getting to know the machine

Cage roller diameter 550mm (211/2”) [+]

• Compaction / light to medium soils

Flexipacker roller, diameter 58 5mm

(23”) [+]

• Compaction / light to medium soil without stones

Actipack roller diameter 560mm

(211/4”) [+]

• Compaction and dispersal / All soil types. This roller is also suited

to clayey and sticky soils

Actiring roller diameter 540mm

(211/4”) [+]

• Compaction and dispersal / All soil types (but limited by too many

stones)

Actiflex roller diameter 580mm (

Compaction and dispersal / All soil types.

Double tube roller / bar [+]

235/8”) [+]

• Dispersal, levelling and depth control / All soil types

21

Getting to know the machine

Depth control wheel variants [+]

Fixed cultivator: 6.00x9 wheel

Diameter 540 x 160 (

Folding cultivator: 10/80x12 wheel

Diameter 710 x 274 (

211/4” x 61/4”)

28” x 103/4”)

Option (other) [+]

Signalling and lighting [+]

All lights, reflectors, licence plates and signalling / warning panels

must be perfectly visible. If this is not possible, you must install lights

and a licence plate on the machine.

22

Loading...

Loading...