Kverneland a-drill Operating Manual

Pneumatic seed drill

a-drill

Operating manual

Translation of the original operating manual

Issue 04/2018

Printing 02.2018

Language EN

From serial no. RFSDCxx006315

Execution Accessories

Reference RF31913

Identification of the machine

In order that your dealer may help as fast as possible. He needs a few indications regarding your machine.

Please provide this information below.

Description

Pneumatic seed drill a-drill

Working

width

Weight

Machine no.

Accessories

Reseller

address

Manufacturer

address

Kverneland Group Les Landes Génusson S.A.S.

9 Rue du Poitou

F-85130 LES LANDES GENUSSON

Tel: +33 (0)2 51 64 13 00

The copyright and use (Copyright) are held by the Kverneland Group Les Landes Génusson SAS, France. Copying, transfer to other

media,translation or even partial use of this text are unlawful without the written authorization from Kverneland. All rights reserved. The content of

these operating instructions may be changed without notice. Subject to technical changes.

Table of contents

Preamble ................................................... 4

Target group for this operating manual 4

Meaning of symbols 4

Safety ......................................................... 5

For your safety 5

Warning symbols 6

Safety regulations 7

Table of contents

Adjustments ............................................... 90

Using the seed drill with the box 3.2 90

Adjustments ............................................... 94

Using the seed drill with the box 5.2 94

Changing the flow during

operation 103

Trouble-shooting 108

Presentation of the accessory ................ 8

Conditions of use 8

General Description 9

Type of Seed drills 10

Technical specifications 10

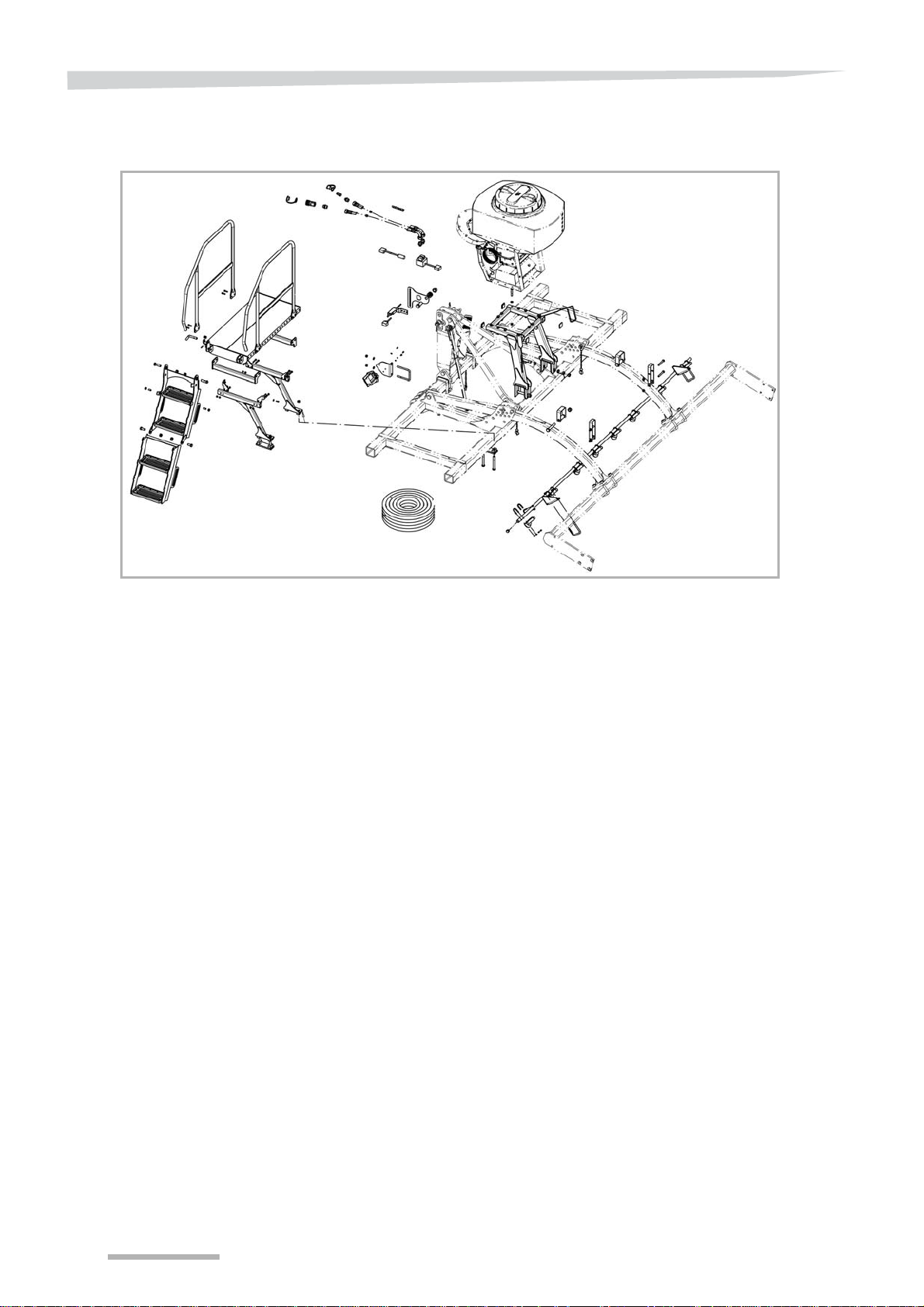

Delivery and assembly ............................. 12

Rigid CLC 12

Delivery and assembly ............................. 22

Folding CLC 22

Delivery and assembly ............................. 28

Rigid Qualidisc 28

Delivery and assembly ............................. 34

Folding Qualidisc 34

Delivery and assembly ............................. 40

Rigid Qualidisc Farmer 40

Delivery and assembly ............................. 46

Folding Qualidisc Farmer 46

Delivery and assembly ............................. 54

Equipment available on

mounted machines 54

Maintenance ............................................... 110

For your safety 110

Guarantee ................................................... 111

Disposal of the tool ................................... 112

Metal parts 112

Hydraulic oil 112

Conformity declaration ............................. 113

In accordance with directive 2006/42/EC 113

Index ........................................................... 114

Delivery and assembly ............................. 56

Qualidisc T 56

Equipment available on Qualidisc T 63

Delivery and assembly ............................. 64

CTC 64

Delivery and assembly ............................. 70

Equipment available on CTC 70

Delivery and assembly ............................. 71

Mounting kit for hopper only 71

Installing the hydraulic blower 71

Adjusting the machine ............................. 72

Lifting sensor 72

Hydraulic blower 74

Seed drill adjustment ............................... 76

Distribution 76

Filling the seedbox ................................... 88

Safety 88

Folding CLC 88

Qualidisc and Qualidisc Farmer 89

3

Preamble

[+]

Preamble

Target group for this operating manual

Training

Meaning of symbols

This operating manual is intended for trained farmers and individuals

who are otherwise qualified to perform agricultural activities,

and who have received training in the operation of this machinery.

For your safety

Study the contents of this operating manual carefully before assembly

or initial operation of this machine.

In this way, performance and work safety are optimised.

For the employer

All personnel are to be regularly trained in the use of this machine.

Untrained or unauthorised individuals are not permitted to use this

machine.

The retailer provides the user with instructions relating to the use and

maintenance of the machine.

In order to make this manual clear and easy to read, we have used

various symbols. They are explained below:

• A dot precedes each item in a list.

A triangle indicates operating functions which must be performed.

→ An arrow indicates a cross-reference to other sections of this

manual.

We have also used pictograms to help you find instructions more

quickly:

N

OTE

The term “Note” indicates tips and notes on operation.

The spanner indicates tips for assembly or adjustments.

The warning triangle indicates important safety instructions. Failure to

observe these safety instructions can result in:

• Serious operational faults of the machinery;

• Damage to the machinery;

• Personal injury or accidents.

A star indicates examples that help to better understand the instruc-

tions.

A plus sign in square brackets indicates that the equipment is optional.

4

Safety

Safety

For your safety

In this chapter, you will find the general safety instructions. The

different chapters in this operating manual include specific safety

instructions.

Please follow these safety instructions:

• in the interest of your own safety,

• in the interest of the safety of others,

• to ensure the safety of the machine.

Numerous risks can result from handling agricultural machines in the

wrong way. Therefore, always work with special care and never under

pressure.

For the employer:

Inform personnel working with the machine of these safety instructions at regular intervals and according to statutory regulations.

5

Safety

Warning symbols

Meaning of safety symbols

On this machine, you will find safety decals for user safety.

These decals must not be removed.

When these are illegible or they no longer stick, order new decals and

affix them at the corresponding locations.

Read and comply with the manual and safety instructions before

starting up or carrying out any operations on the machine.

Carrying persons on the machine while in motion (in transit or at work)

is strictly forbidden.

Risk of crushing by an articulated part of the machine. Install the safety

devices provided and/or check the working order of the automatic

safety devices before entering a hazardous area.

Risk of hands being pinched when adjusting the machine.

Please follow the adjustment instructions.

EC type plate guaranteeing the conformity of the machine according

to directive 2006/42/EC and adapted to national legislations.

6

Safety regulations

Safety

Maintenance

Hydraulic system

The brakes or vehicle immobilisation system must be engaged before

all interventions within the radius of the tractor - tool unit.

Wear safety gear (helmet, safety shoes, gloves, etc.) when changing

parts on the machine.

You are advised to be careful with all parts with sharp edges or

corners.

Before welding, disconnect the electric units and disconnect the

tractor alternator and battery.

Never direct the jet of high pressure cleaners directly onto the

bearings, the hydraulic hoses, electric units or other sensitive

components on the machine (risk of damage).

The jet may bounce back off some surfaces.

The hydraulic system is pressurised.

Before any intervention on the hydraulic system:

Block the folding extensions in their rest position.

Block the hydraulically controlled accessories in their rest

position.

Reduce the pressure.

Stop the tractor engine.

Identify the connectors using a colour code, as indicated in the user

manual, when intervening on the hydraulic system.

Incorrect connections and the reversal of functions could cause

serious injuries.

7

Presentation of the accessory

Presentation of the accessory

Conditions of use

This chapter contains general information about your tool as well as

information concerning the following points:

• Scope of use.

• Characteristics.

• The description of groups and technical data.

This tool has been designed solely for normal agricultural use, i.e. for

cultivating farmland. Any other use or misuse, for example,

transportation, clearing or transmission of forces to another machine

is considered to be non compliant with the intended use.

The manufacturer and the specialised retailer decline all liability for

damage resulting from use that does not comply with the intended

use. The user is responsible for all risks.

Compliance with the conditions of use includes compliance with the

manufacturer's operating instructions.

The safety instructions (specified below) as well as the general safety,

occupational health and road traffic regulations.

Modifications to the tool made by the client or the use of spare parts

or accessories that are not from KVERNELAND will cancel the

manufacturer's liability for all damages resulting from the modification.

The company will not be held liable for damage resulting from

erroneous settings, choice of equipment, seed, fertilizer, treatments or

farming strategy or for any other damage not directly related to the

machine.

8

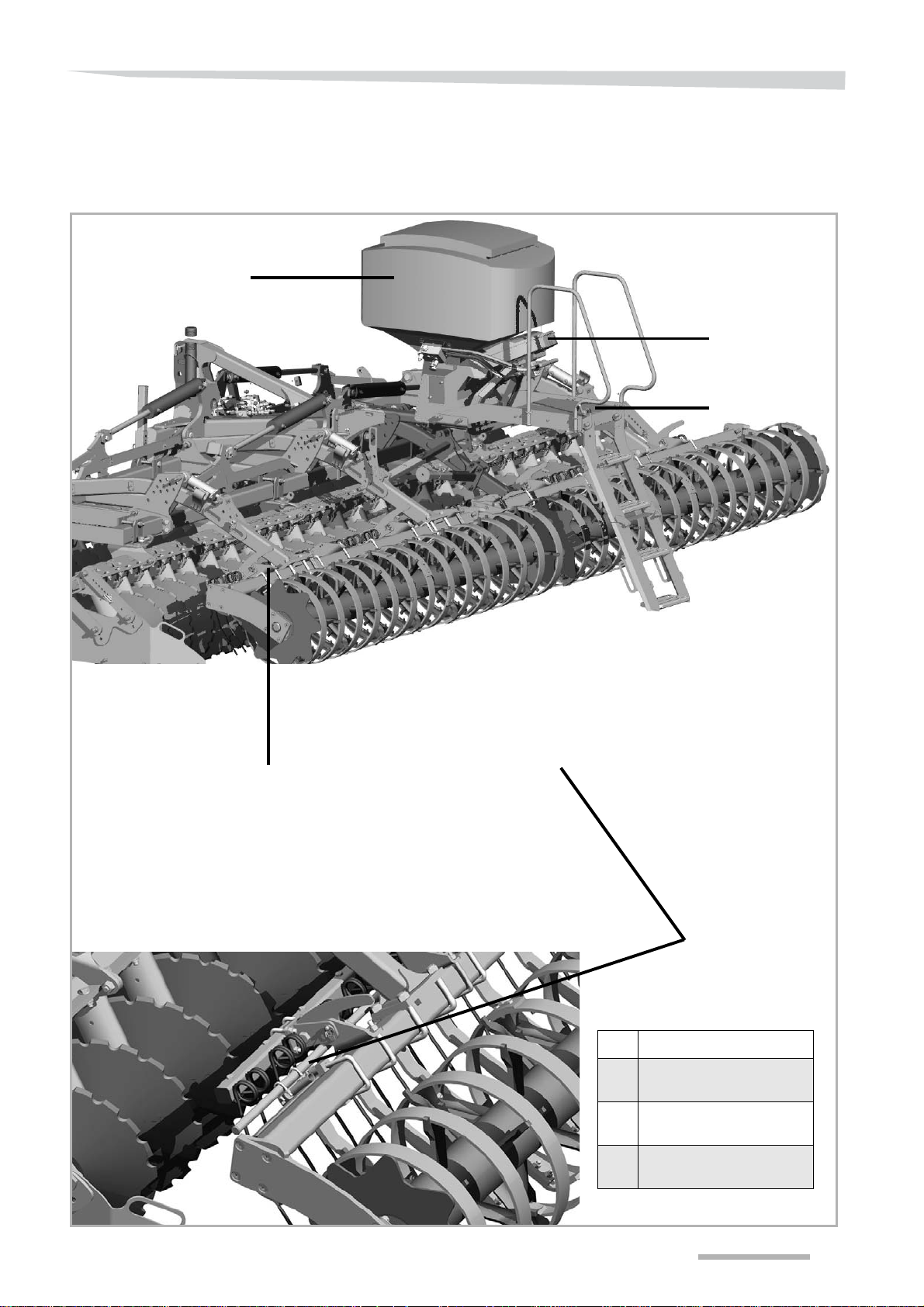

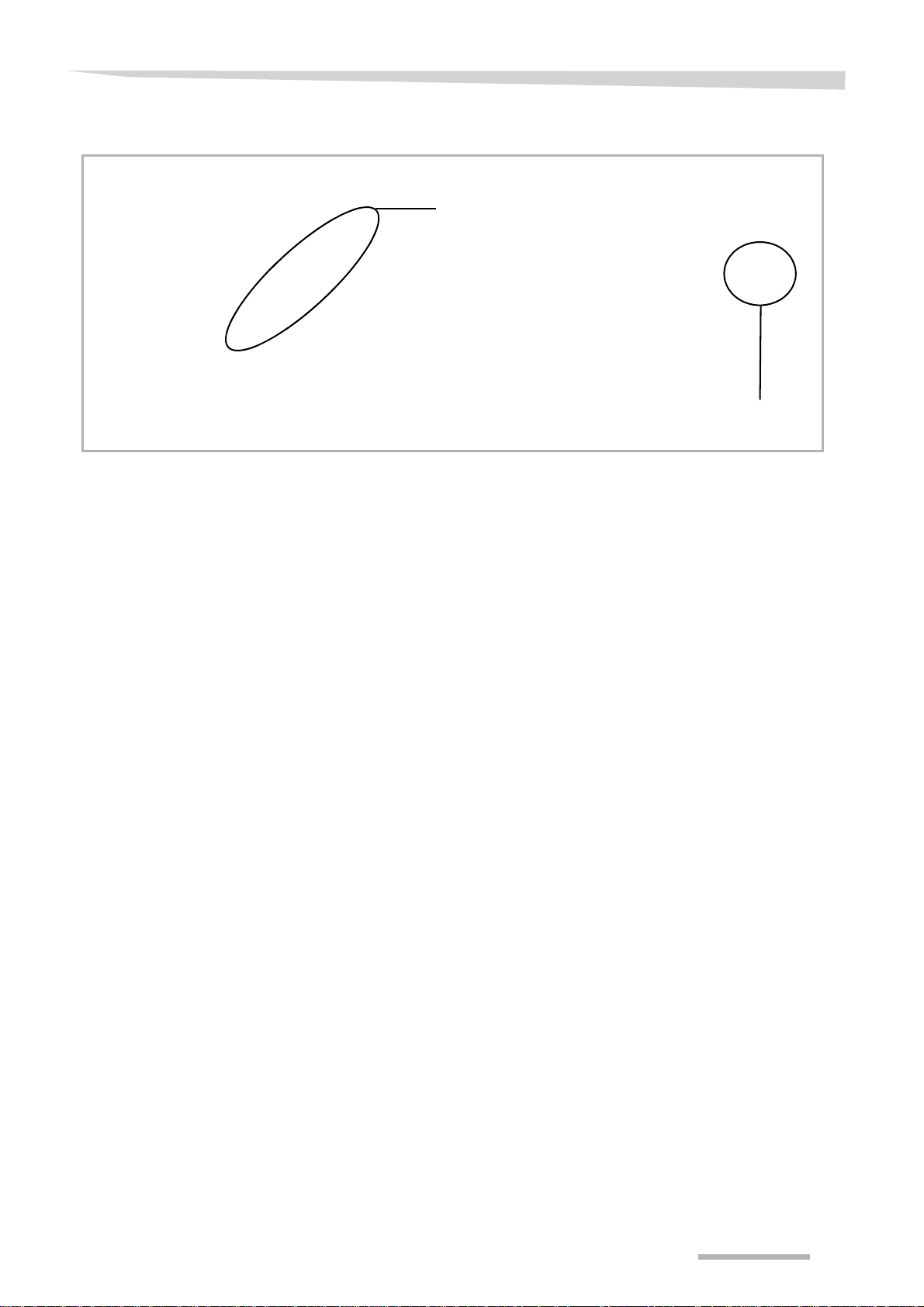

General

A

B

C

D

Description

Presentation of the accessory

A Hopper (200 or 500 l)

B Walkway (access filling and

settings)

C Blower (electrical or

hydraulic)

D Spreader rail (in front of the

roller)

9

Presentation of the accessory

Type of Seed drills

The a-drill pneumatic seed drills are distribution seed drills by fixed

grooved rotors.

s

The seed drill does not contain sowing element

carried out by 8 spreaders.

The flow adjustment is by variation in the gr

rotors are available. A support blower ensures the transportation of

seeds from the distributor to the spreaders.

pneumatic seed drills are available

The

in several versions :

, broadcast sowing is

oo

ved rotor speed, 8

• Hopper volume 200 l or 500 l

• Control box :

• Version 3.2 (manual flow adjustment)

• Version 5.2 (flow proportional to progression)

• Electrical or hydraulic blower on mounted machine, hydraulic on

trailed machine.

The box 5.2 provides the following additional services :

• End of field sensor (automatic stop and restart)

• EFPP (Electronic flow proportional to progression) by radar sensor

or ISO 7 terminal connector.

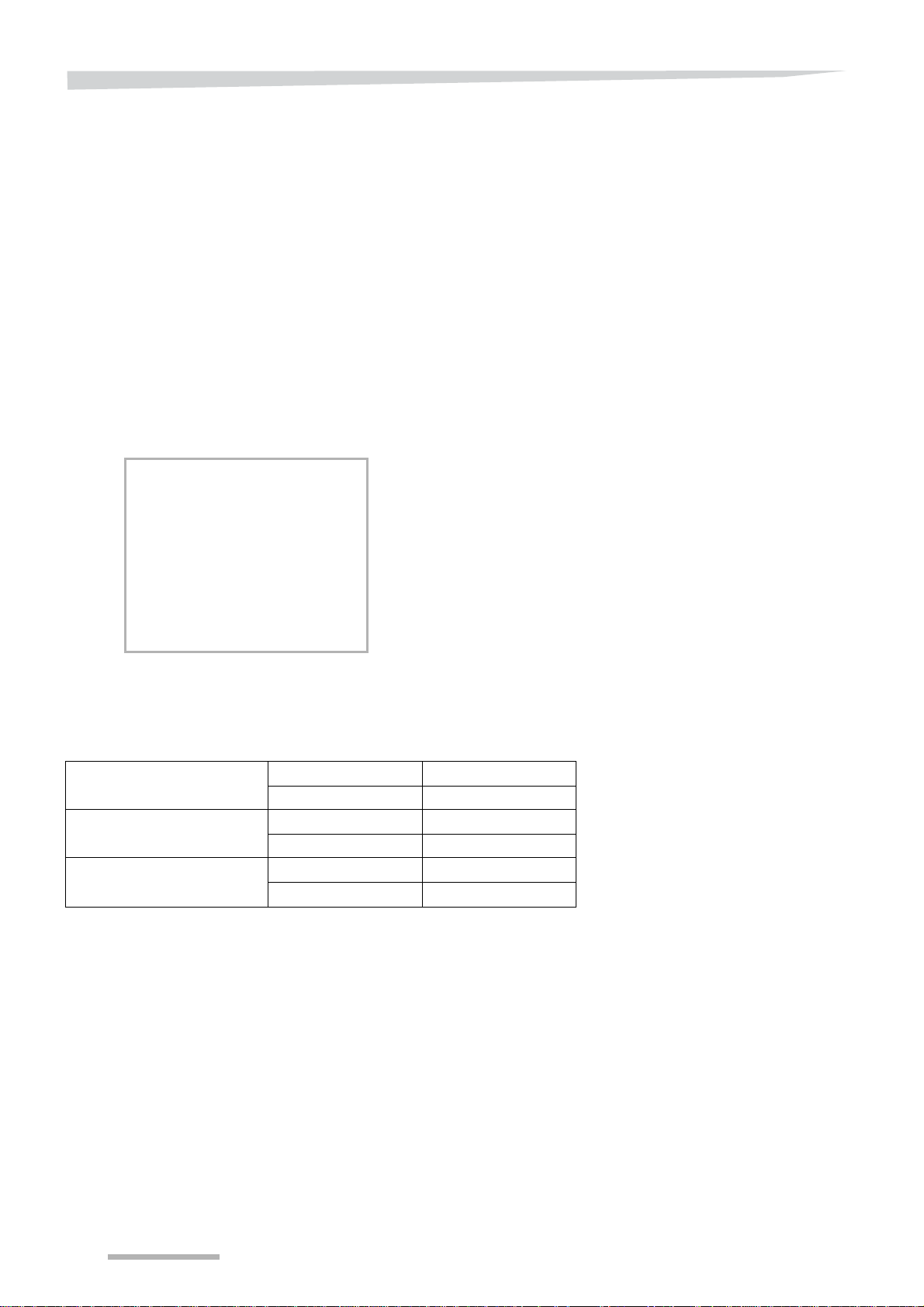

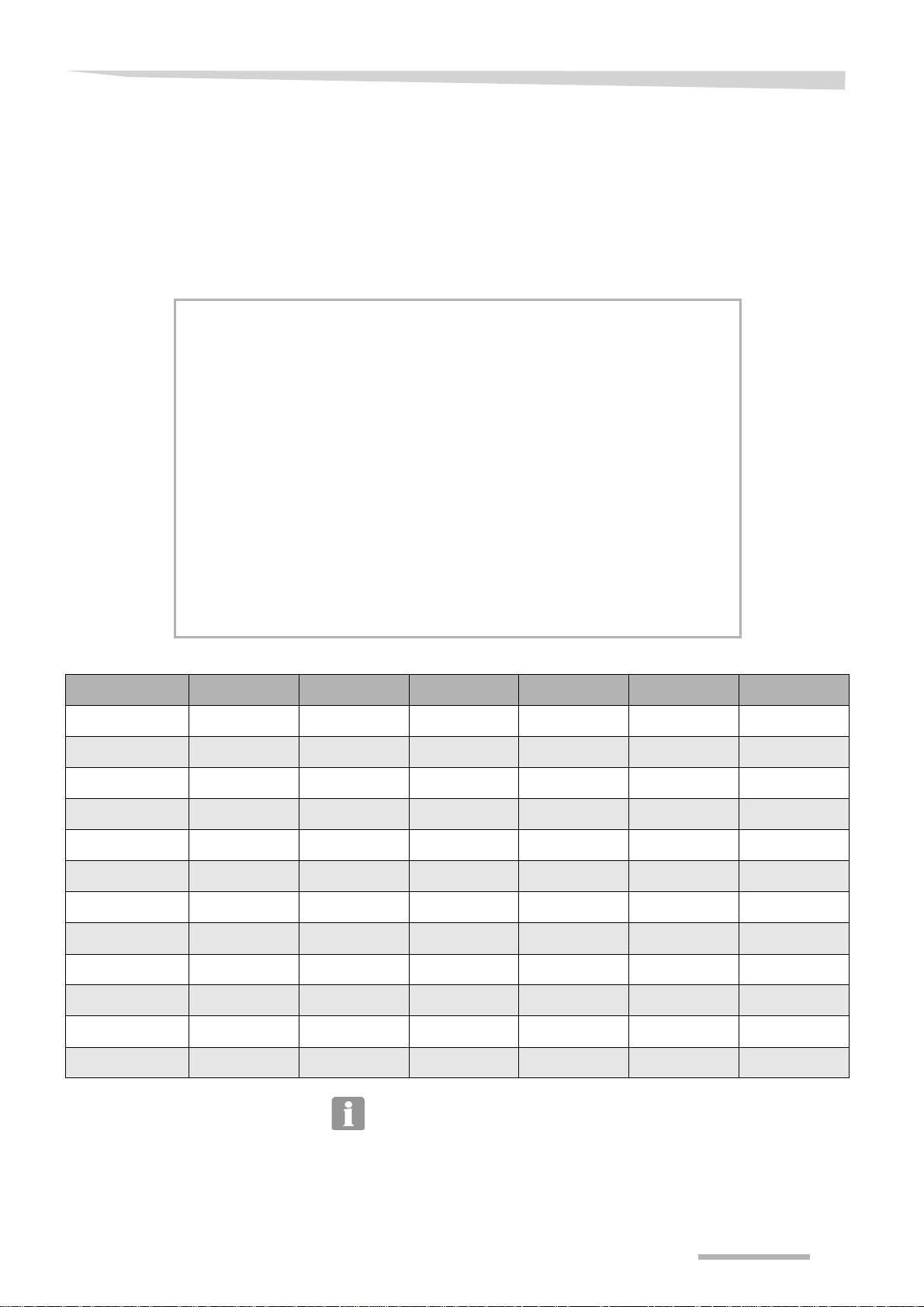

Technical specifications

Model

Weight of seed drill only

Dimensions (L x D x H)

Electrical supply

70 x 88 x 100 cm 80 x 122 x 117 cm

271/2” x 345/8” x 395/8” 311/2” x 48” x 46”

To have these two functions simultaneously, the box 5.2 is equipped

with a branch cable, that provides 2 x 12 terminal connectors.

200 L 500 L

52.83 gallons 132.10 gallons

60 Kg 100 Kg

132.30 lbs 220.5 lbs

12 V, 25 A

Hydraulic supply

10

Maximum pressure : 200 bar (2900.76 psi)

Maximum flow: 80 L/min (21.13 gallons/min)

Dimensions (L x D x H): 400 x 460 x 270 mm (15

3/4” x 18” x 105/8”)

Presentation of the accessory

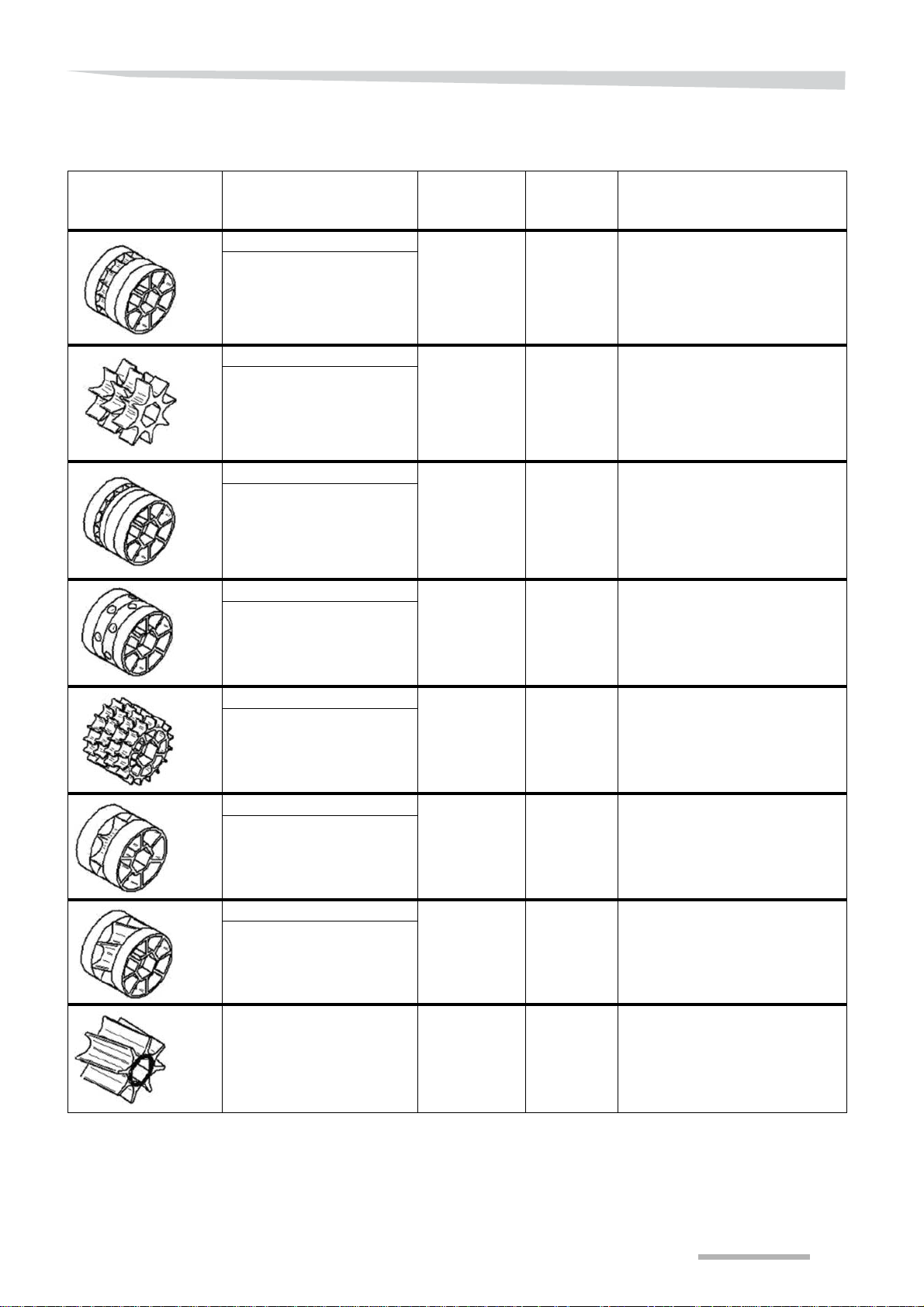

8 grooved distribution rotors are available :

Rotor Type of rotor Reference

fb-f-fb-fb

fine dummy

fine

fine dummy

fine dummy

GGG

Coarse

Coarse

Coarse

fb-ef-eb-fb-fb

fine dummy

extra fine

extra fine dummy

fine dummy

fine dummy

fb-efv-efv-fb

fine dummy

extra fine honeycomb

extra fine honeycomb

fine dummy

ffff

fine

fine

fine

fine

GB-G-GB

Coarse dummy

Coarse

Coarse dummy

RF32066

RF32061

RF32067

RF32209

A135122830

A135132030

Series /

option

Standard

equipment

Standard

equipment

Optional

equipment

Optional

equipment

Optional

equipment

Optional

equipment

Application

Fine grooves:

Sowing of small seeds or small

quantities.

Eg: mustard, rapeseed, clover,

phacelia, slug pellets, etc.

Large grooves:

Sowing of cereals.

Eg: mix of grasses, rye, barley,

wheat, oats, etc.

Very fine grooves:

Sowing of very small seeds or

very small quantities.

Eg: clover, poppy, rapeseed,

mustard, etc.

Fine honeycomb grooves:

Sowing of small seeds or small

quantities.

Eg: radish, mustard, etc.

Fine grooves:

Sowing of small seeds or small

quantities.

Eg: grass, wheat, barley, radish,

etc,

Coarse grooves:

Sowing of large seeds or large

quantities.

Eg: mix of grasses, rye, barley,

wheat, oats, etc.

fb-Flex20-fb

fine dummy

Flex20

fine dummy

Flex40 RF31432

A135002130

Optional

equipment

Optional

equipment

Flexible distribution wheel:

Sowing of very large seeds and

fertilizer.

G: fertilizer, peas and vetches.

E

Flexible distribution wheel:

Sowing of very large seeds and

fertilizer.

G: fertilizer, peas and vetches.

E

11

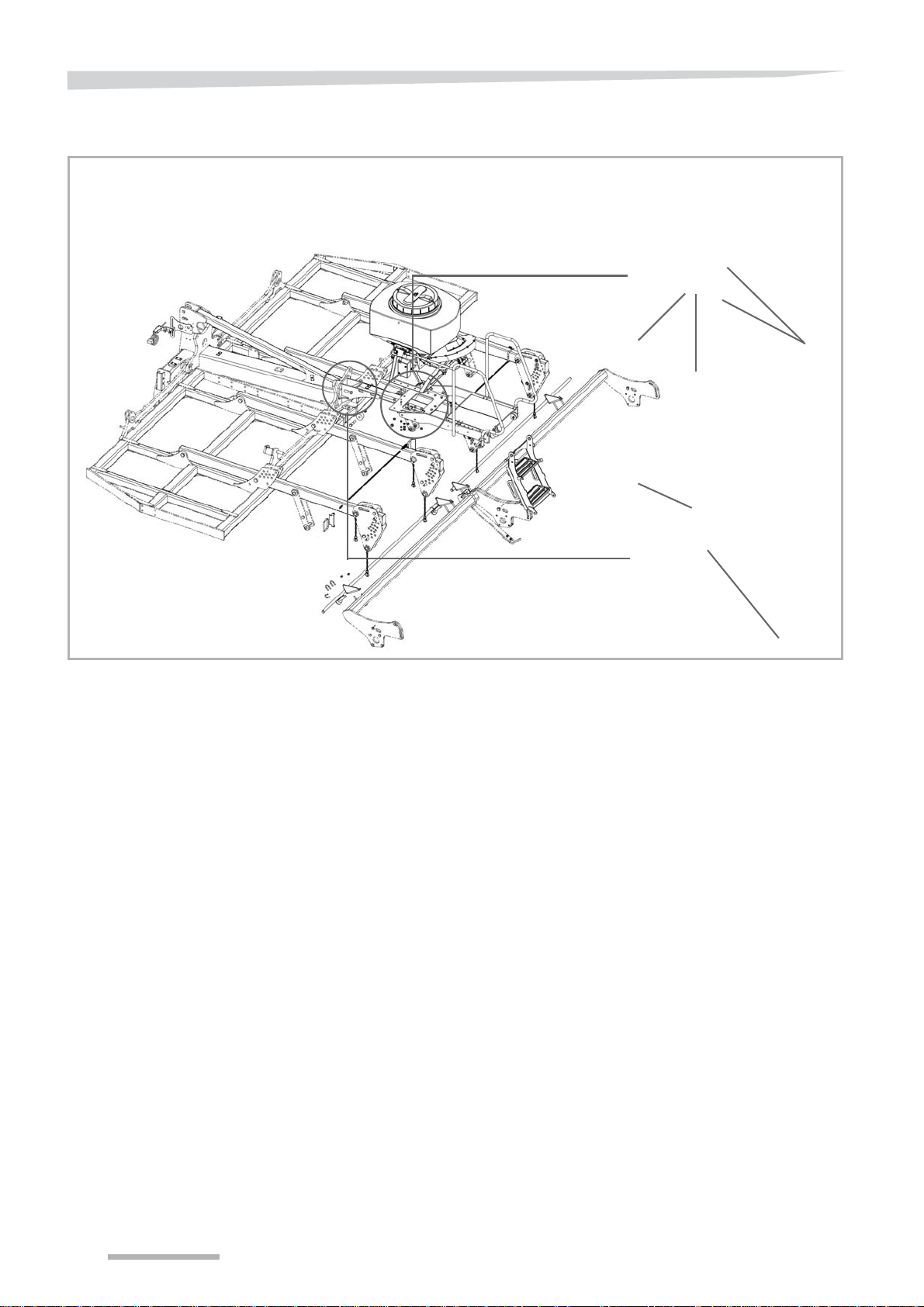

Delivery and assembly

Delivery and assembly

Rigid CLC

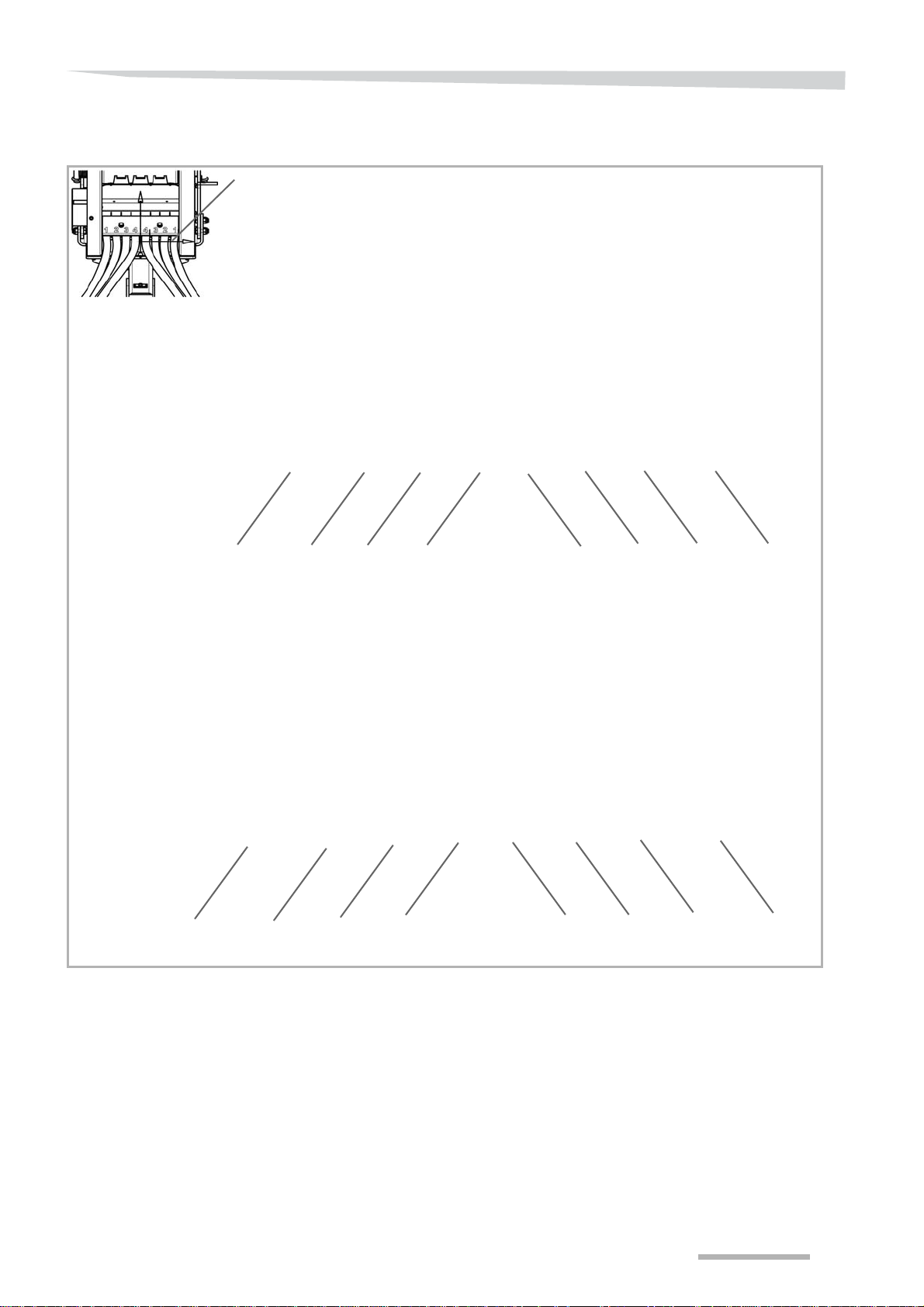

Mounting the support

and the hopper

Task description

There are two types of mountings:

• Mounting with the hopper centred compared to the machine.

• Mounting with the hopper offset compared to the machine.

During offset mounting, it is necessary to move it 14 cm to the left

(compared to the machine driving direction) on the following models:

• CLC Evo 3m00 (9’10”) - 11 tines

• CLC Evo 3m50 (11’6”) - 13 tines

• CLC Evo 4m00 (13’1”) - 15 tines

12

Procedure

A

B

CLC 2 rows 3m00 (9’10”)

CLC 2 rows 3m50 (11’6”)

345 mm

13

9/16”

140 mm

5

1/2”

345 mm

13

9/16”

A

B

Delivery and assembly

Turn the hopper so that the hoses come out from the rear of the

machine.

Using U clamps, fix the support to the second beam of the main

frame.

Use the four long fixing screws.

Insert the 14 screws (B) in the tubes to fix the hopper.

Mounting diagrams for the

platform and hopper support

APlatform

B Hopper support

13

Delivery and assembly

CLC 2 rows 4m00 (13’1”)

570 mm

22

7/16”

545 mm

21

1/2”

CLC 3 rows 3m00 (9’10”)

CLC 3 rows 3m50 (11’6”)

480 mm

18

7/8”

600 mm

23

5/8”

CLC 3 rows 4m00 (13’1”)

14

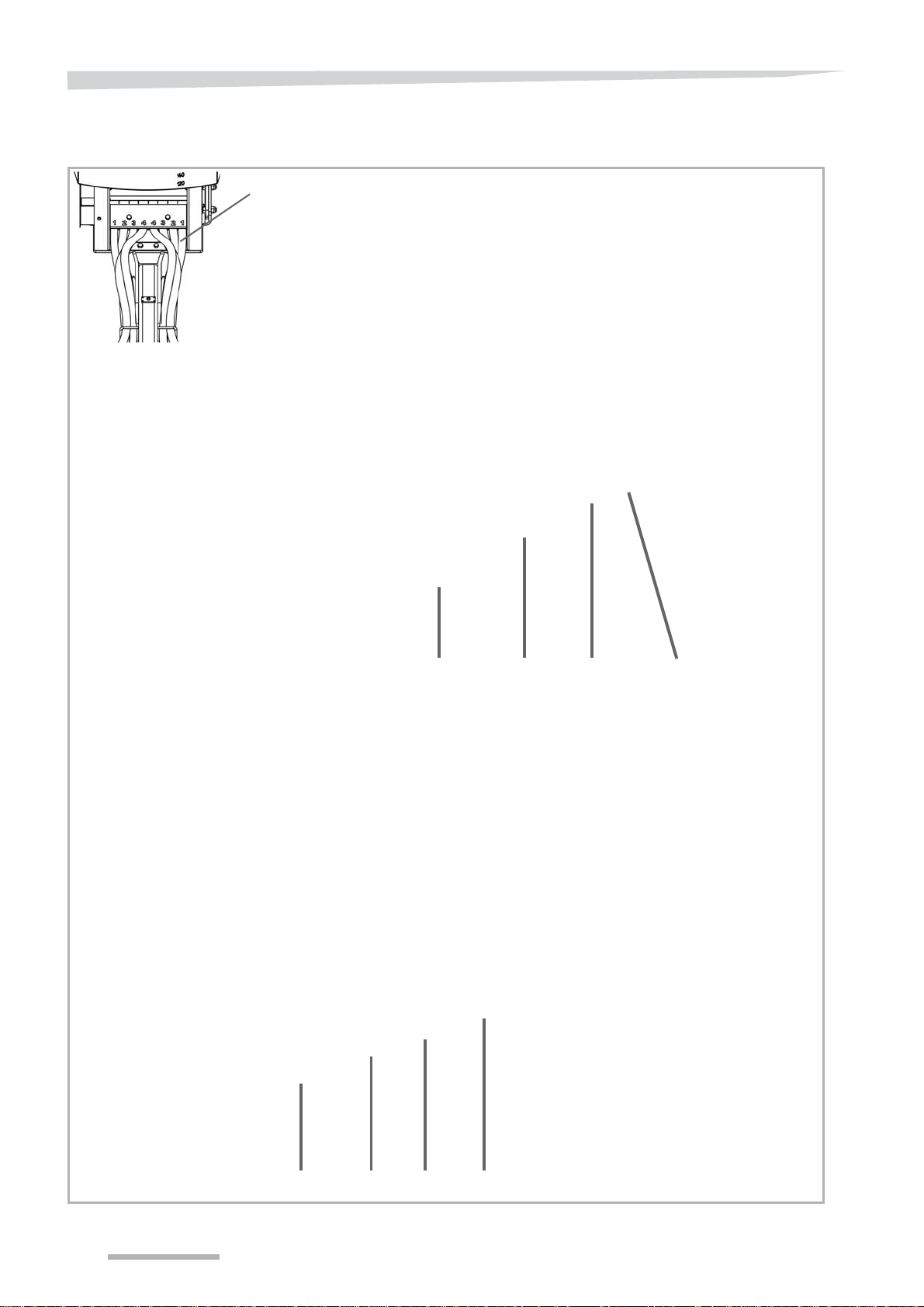

Mounting the walkway

A

B

C

D

E

F

Procedure

Delivery and assembly

A Guardrail

B Reinforcement crossbar

C Upper part of stairs

D Lower part of stairs

E Fixing brackets

F Ball screw

Position the support arms for the walkway on the frame, respecting

the dimensions indicated on the diagrams page 13.

Install the walkway on the support arms using the fixing brackets

(E).

Using the same screws, fix the guardrail and reinforcement

crossbars.

Fix the upper part of the stairs to the extremity of the walkway.

Adjust the ball screws (F) to ensure the lower part of the stairs (D)

is maintained on the upper part (C).

15

Delivery and assembly

CLC Evo

CLC Pro

2 rows

3 rows

5 1/2”

5 1/2”

20”

13 9/16”

2 3/8”

21 7/16”

1 7/8”

10 3/8”

13 9/16”

5 9/16”

13 3/4”

18 7/8”

5

9/16”

5 9/16”

14

3/4”

22 7/16”

17 11/16” 23 5/8”

Mounting diagrams for

the platform

16

Positioning the

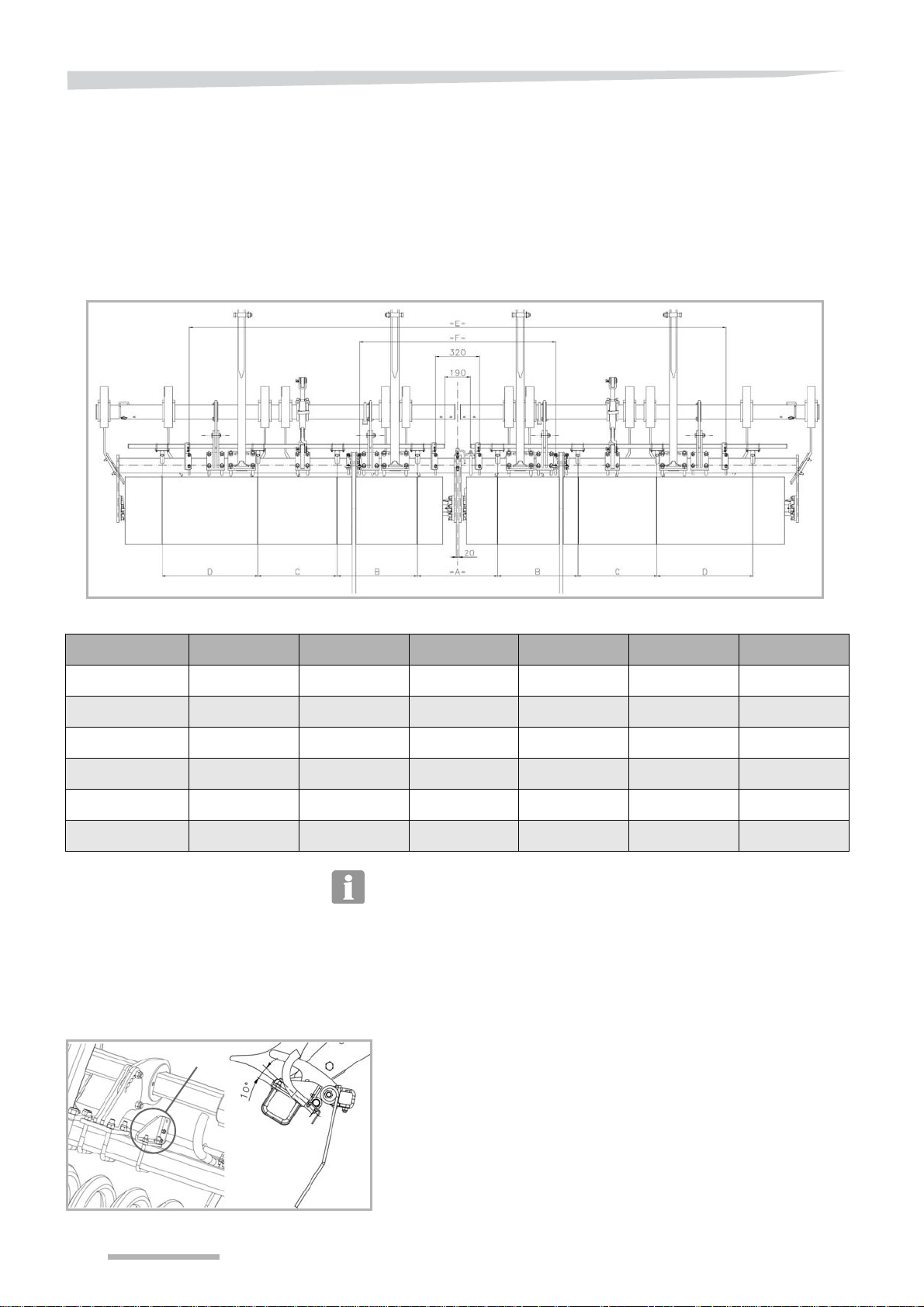

spreaders

Delivery and assembly

Task description

The spreaders must be distributed in a regular way on the machine,

although their position can be slightly offset depending on the

machines. The following table provides the mounting dimensions for

the different machines:

Machine A B C D E F

2R 3m00 arm

2R 3m00 //

2R 3m50 arm

2R 3m50 //

2R 4m00 arm

2R 4m00 //

3R 3m00 arm

3R 3m00 //

3R 3m50 arm

3R 3m50 //

3R 4m00 arm

3R 4m00 //

355 / 14” 355 / 14” 385 / 15 1/8” 385 / 15 1/8” 2257 / 89” 2605 / 103”

355 / 14” 355 / 14” 355 / 14” 355 / 14” 2257 / 89” 2605 / 103”

355 / 14” 355 / 14” 500 / 19 11/16” 500 / 19 11/16” 2757 / 109” 3065 / 121”

470 / 18 1/2” 430 / 16 15/16” 450 / 17 11/16” 450 / 17 11/16” 2757 / 109” 3130 / 123”

525 / 20 11/16” 525 / 20 11/16” 525 / 20 11/16” 425 / 16 11/16” 3057 / 120” 3500 / 138”

500 / 19 11/16” 475 / 18 11/16” 475 / 18 11/16” 550 / 21 5/8” 3057 / 120” 3500 / 138”

290 / 11 7/16” 290 / 11 7/16” 430 / 16 15/16” 430 / 16 15/16” 2257 / 89” 2590 / 102”

370 / 14 9/16” 370 / 14 9/16” 370 / 14 9/16” 370 / 14 9/16” 2257 / 89” 2590 / 102”

450 / 17 11/16” 455 / 17 15/16” 445 / 17 1/2” 440 / 17 5/16” 2757 / 109” 3130 / 123”

450 / 17 11/16” 455 / 17 15/16” 445 / 17 1/2” 440 / 17 5/16” 2757 / 109” 3130 / 123”

500 / 19 11/16” 500 / 19 11/16” 500 / 19 11/16” 500 / 19 11/16” 3057 / 120” 3500 / 138”

500 / 19 11/16” 500 / 19 11/16” 500 / 19 11/16” 500 / 19 11/16” 3057 / 120” 3500 / 138”

• “2R” corresponds to a machine with 2 rows of tines.

• “3R” corresponds to a machine with 3 rows of tines.

• "arm" corresponds to a machine whose rear tool is mounted on a

curved arm.

• “//” corresponds to a machine whose tool is mounted on a parallel-

ogram.

17

Delivery and assembly

Procedure

Levelling tines fixed to the roller beam:

Install the rail of spreaders in the lower position on the support.

18

Delivery and assembly

A

B

Adaptation on a machine equipped with levelling discs:

Fix the roller supports to the last 2 fixing holes of the parallelogram

(A).

Use and adapt the longest push bar (B) in order to keep the

working angle of the levelling discs.

Use the adapting kit for machines prior to June 2012, that do not

have a rear roller mounting position.

19

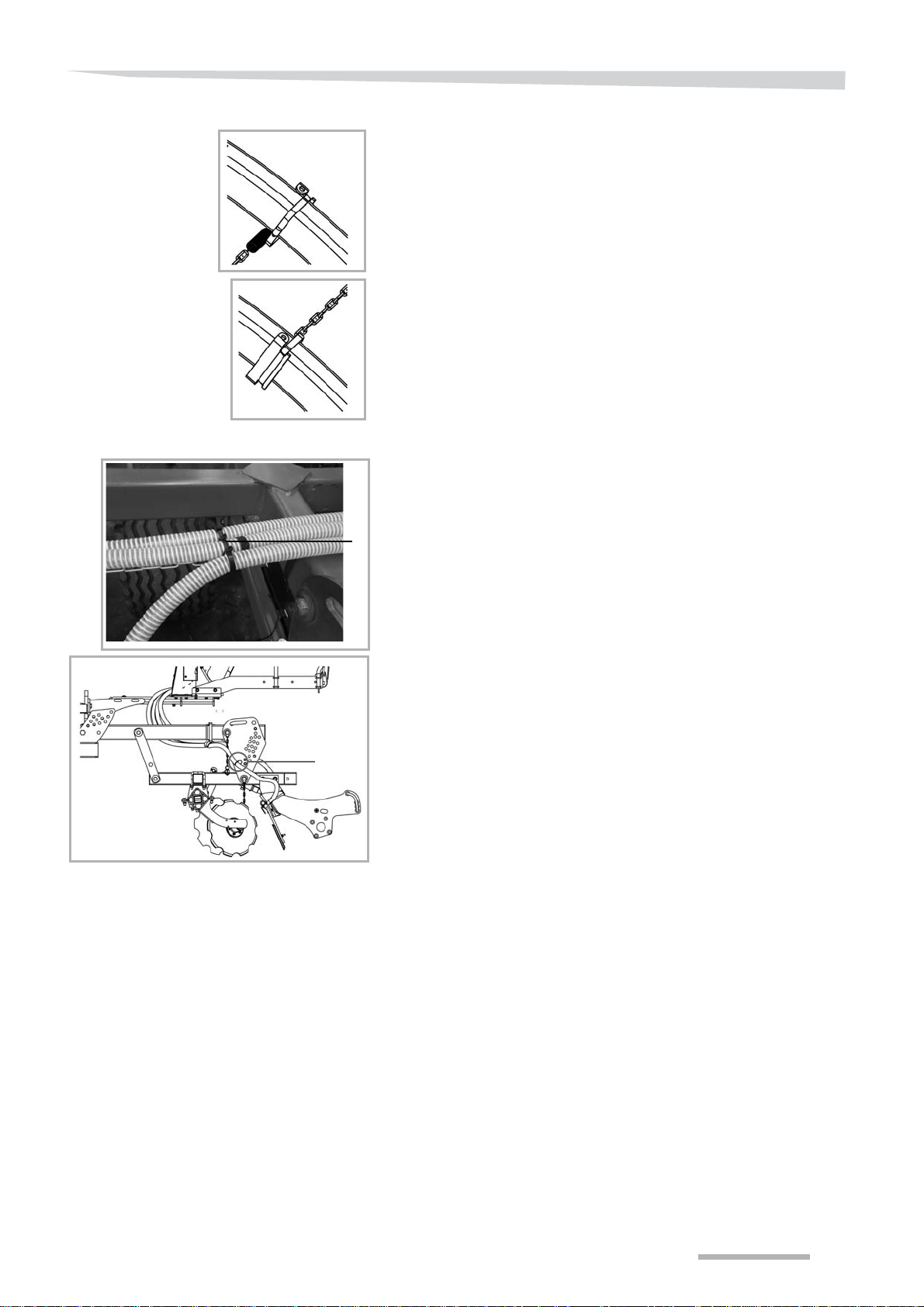

Delivery and assembly

Ensure that you respect the seed

outlet numbers compared to the spreader positions

Hose passage point

on the left side (the right side

is symmetrical).

Hose 1

Hose 2

Hose 3

Hose 4

Hose 1

Hose 2

Hose 3

Hose 4

A

Passage of hoses

Order of hose distribution for seed flow

Hose length (mm/in)

Left side / roller

Hopper N° 1 N° 2 N° 3 N° 4

CLC 2R 3m00 / 9’10” Offset 3335 /131” 3095 /122” 3075 /121” 2940 /116”

CLC 2R 3m50 / 11’6” Offset 3335 /131” 3095 /122” 3075 /121” 2940 /116”

CLC 2R 4m00 / 13’1” Offset 3550 /140” 3355 /132” 3645 /144” 3825 /151”

CLC 2R Wings 3m00 / 9’10” Centred 3195 /126” 2955 /116” 2935 /116” 2800 /110”

CLC 2R Wings 3m50 / 11’6” Centred 3195 /126” 2955 /116” 2935 /116” 2800 /110”

CLC 2R Wings 4m00 / 13’1” Centred 3410 /134” 3215 /127” 3505 /138” 3685 /145”

CLC 3R 3m00 / 9’10” Centred 3630 /143” 3260 /128” 3400 /134” 3120 /123”

CLC 3R 3m50 / 11’6” Centred 3630 /143” 3260 /128” 3400 /134” 3120 /123”

CLC 3R 4m00 / 13’1” Centred 3700 /146” 3605 /142” 3905 /154” 3975 /156”

20

Delivery and assembly

Mounting on parallelogram

Mounting on curved arm

Hose supports have been designed to allow optimal passage of hoses

on the machine.

Fix the supports above the arms.

Group the hoses and pass them in the supports.

Cross the hoses when you connect them to the rail of spreaders.

The hoses that come out of the centre of the seed drill must supply

the exterior spreaders of the machine.

N

OTE

On 3 row cultivators, a hose guide (A) is installed on the stays.

21

Delivery and assembly

A

B

C

D

E

Delivery and assembly

Folding CLC

Mounting the hopper support

Task description

Procedure

On folding cultivators, the hopper support and the access walkway are

fixed to the central frame using 4 screws.

Align the holes located at the rear extremity of the hopper support

(B) with the rear extremity of the central frame (A) of the machine.

Place the 4 hexagonal head M20x70 screws (C) in the holes.

Fix the screws using M20 nuts.

22

Mounting the hopper

Delivery and assembly

Task description

Procedure

Once the support is fixed to the machine, you now need to mount the

hopper onto it. The hopper is placed on the support and fixed using 14

screws.

Place the hopper on the support fixing plate, aligning the screw

holes.

Place the 12 screws M12x30 (D) on the sides and rear of the

hopper support.

Place the 2 screws M12x90 (E) in the holes located at the front of

the hopper support.

Fix the screws using M20 nuts.

23

Delivery and assembly

A

Positioning the

spreaders

Task description

Machine A B C D E F

The spreaders must be distributed in a regular way on the machine,

although their position can be slightly offset depending on the

machines. The following table provides the mounting dimensions for

the different machines:

4m00 //

4m00 arm

4m50 //

4m50 arm

5m00 //

5m00 arm

Procedure

490 / 19 5/16” 530 / 20 7/8” 530 / 20 7/8” 530 / 20 7/8” 3920 / 154” 1430 / 56”

530 / 20 7/8” 530 / 20 7/8” 530 / 20 7/8” 530 / 20 7/8” 3920 / 154” 1300 / 51”

490 / 19 5/16” 590 / 23 1/4” 560 / 22” 560 / 22” 3520 / 139” 1430 / 56”

560 / 22” 560 / 22” 560 / 22” 560 / 22” 2520 / 99” 1300 / 51”

490 / 19 5/16 580 / 22 13/16” 570 / 22 7/16” 700 / 27 9/16” 2785 / 110” 1660 / 65”

585 / 23” 585 / 23” 580 / 22 13/16” 700 / 27 9/16” 2785 / 110” 1300 / 51”

• Column F corresponds to the distance between signalling

supports.

• "arm" corresponds to a machine whose rear tool is mounted on a

curved arm.

• “//” corresponds to a machine whose tool is mounted on a parallel-

ogram.

Levelling tines on CLC Pro Classic

Adjust the rail to the low position (A) to position the spreaders.

24

Delivery and assembly

Hose 1

Hose 1

Hose 2Hose 3Hose 4

Hose 2 Hose 3 Hose 4

Ensure that you respect the

seed outlet numbers compared to the

spreader positions.

CLC PRO

CLC PRO Classic

Hose 1 Hose 1Hose 2Hose 3Hose 4 Hose 2 Hose 3 Hose 4

Passage of hoses

Order of distribution for seed hoses on CLC Pro

25

Delivery and assembly

Ensure that you respect the

seed outlet numbers compared to the

spreader positions.

Hose 4 Hose 3 Hose 2 Hose 1

Hose 4 Hose 2 Hose 1

Hose 3

CLC Evo equipped with a parallelogram

CLC Evo equipped with a roller arm

Order of distribution for seeds on CLC Evo

26

Delivery and assembly

A

B

D

C

Use the support containing a spring (A).

Install the spring support on the exterior arm, ensuring that the

spring is directed towards the interior of the machine.

Fix the support using a metal clamping ring.

Use the link support (B).

Install the link support on the interior arm, ensuring that the link is

directed towards the exterior of the machine.

Fix the support using a metal clamping ring.

Attach the chain to the spring.

Tighten the chain so that the weight of the hoses does not make it

bend.

Attach the chain to the link.

Cut the excess chain.

Group the hoses and fix them to the chain using plastic rings.

Fix the hoses to the extremity of the machine using a washer (D).

Check in the upper and lower positions that there are no blocking

or crushing points for the hoses.

27

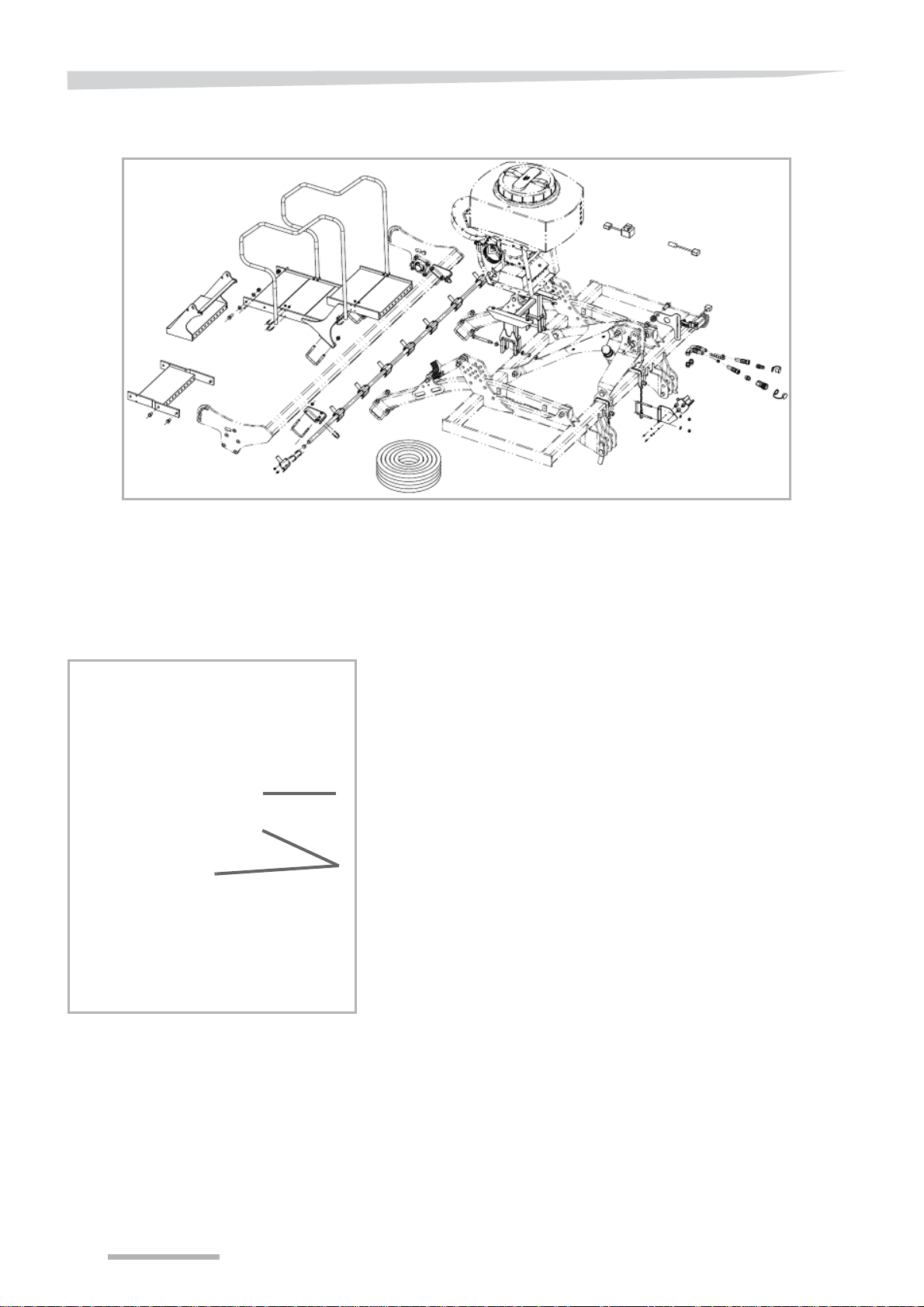

Delivery and assembly

A

B

Delivery and assembly

Rigid Qualidisc

Mounting the hopper

support and the hopper

Procedure

Turn the hopper so that the hoses come out from the rear of the

machine.

Using U clamps (A), fix the support to the second beam of the main

frame.

Insert the two screws M20x160.

Tighten the M20x160 screws to 500Nm torque.

Insert the 12 screws M12x35 (B) in the angles of the hopper

support.

Place the bolts.

28

Mounting the

A

C

D

E

B

F

walkway

Delivery and assembly

Procedure

APlatform

B Retractable step

C Walkway extension

D Guardrail

EBrackets

F Roller beam

Centre the support for the walkway on the roller beam (F).

Position the two brackets (E) on the roller beam.

Bolt the brackets.

Machines equipped with double rollers:

Attach the walkway extension (C) between the platform (A) and the

retractable step (B).

29

Delivery and assembly

3m00 / 9’10”

3m50 / 11’6”

4m00 / 13’1”

A

B

C

D

E

FG

H

I

J

KL

M

A

B

C

D

A

B

C

D

E

F

G

HI

J

KL

M

E

F

G

H

I

J

KL

M

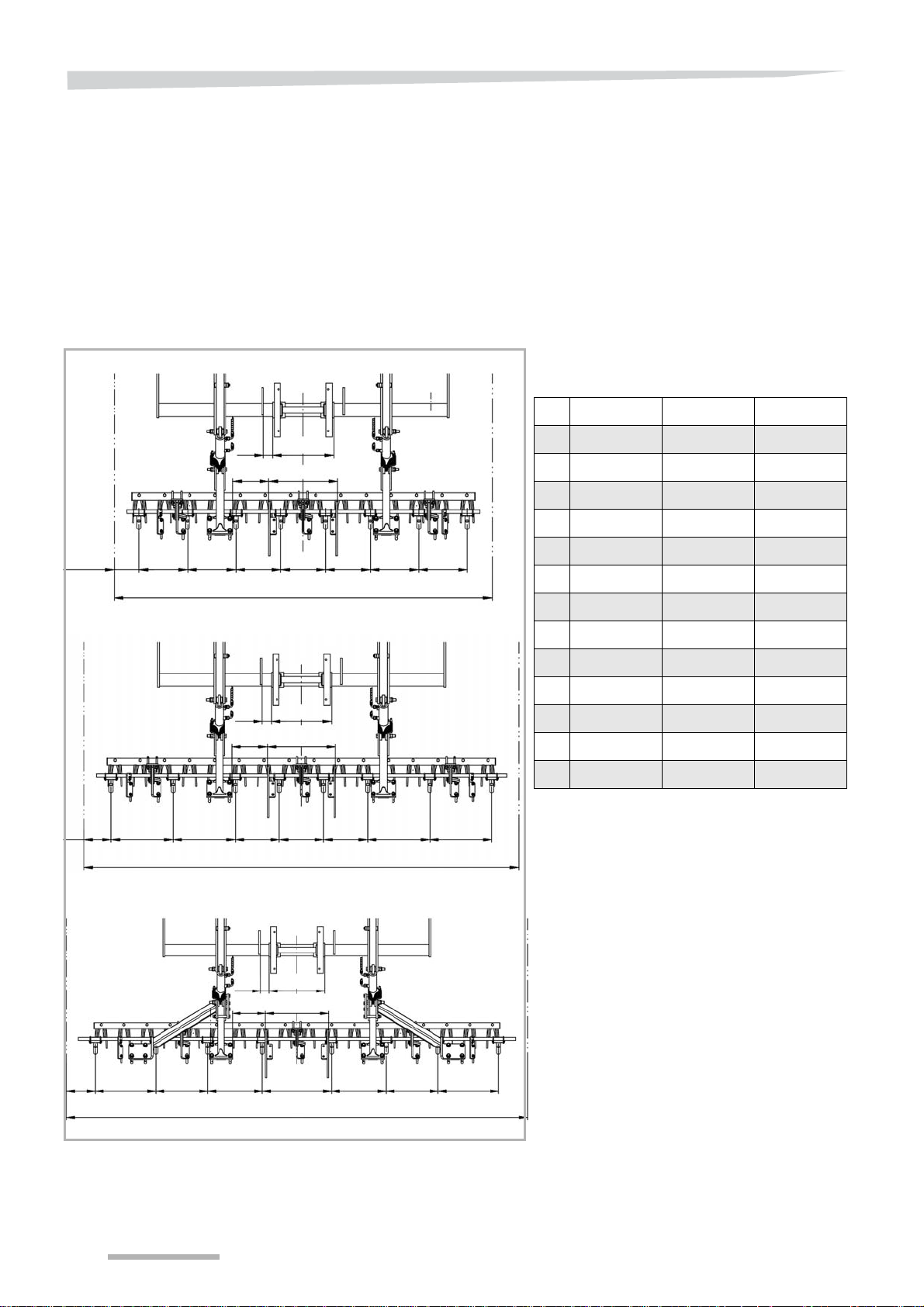

Positioning the

spreaders

Task description

Different accessories such as a comb harrow or rollers can be

mounted on disc cultivators. The tool has no effect on the mounting of

the spreader rail.

The spreaders must be distributed in a regular way on the machine,

although their position can be slightly offset depending on the

machines. The following tables specify the mounting dimensions (mm/

in) for the different machines:

3m00 (9’10”) 3m50 (11’6”) 4m00 (13’1”)

A 73 / 2 7/8” 73 / 2 7/8” 73 / 2 7/8”

B 484 / 19” 484 / 19” 484 / 19”

C 286 / 11 1/4” 286 / 11 1/4” 286 / 11 1/4”

D 548 / 21

E 197.5 / 7 3/4” 217.5 /8 9/16” 250 / 9 7/8”

F 385 / 14” 500/ 19

G 385 / 14” 500/ 19 11/16” 450 / 17 3/4”

H 355 / 15

I 355 / 15 3/16” 355 / 15 3/16” 600 / 23 5/8”

9/16” 548 / 21 9/16” 548 / 21 9/16”

11/16” 525/ 20 11/16”

3/16” 355 / 15 3/16” 475/ 18 11/16”

J 355 / 15

K 385 / 14” 500/ 19 11/16” 450 / 17 3/4”

L 385 / 14” 500/ 19

M 3000 / 118” 3500 / 138” 4000 / 157”

3/16” 355 / 15 3/16” 475/ 18 11/16”

11/16” 525/ 20 11/16”

30

Loading...

Loading...