KVAL INC.

INSTRUCTION MANUAL

.

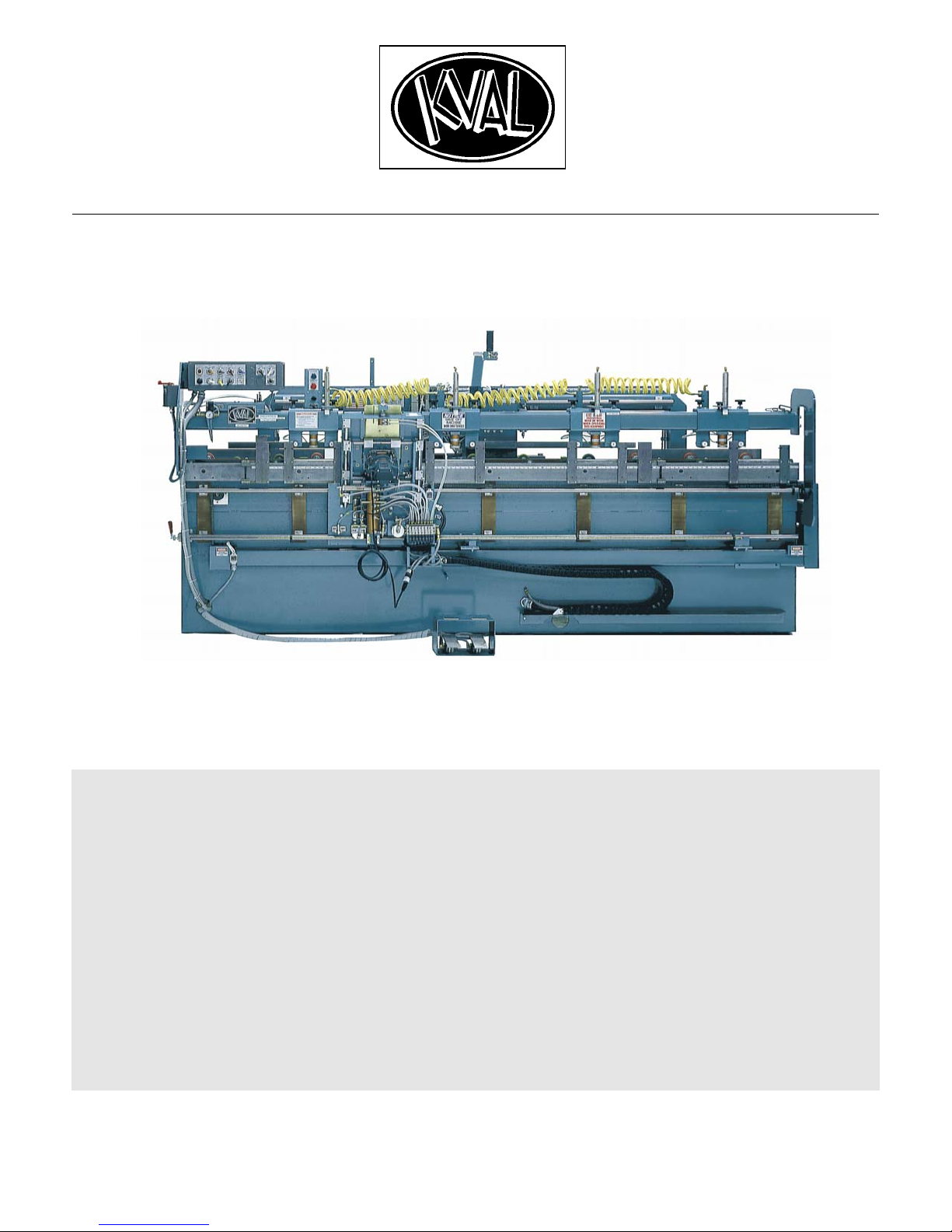

Door Pre-Hanging Machine

Commander

REV.1

1

R

CONGRA TULATIONS ON YOUR PURCHASE OF A NEW KVAL

COMMANDE

SERIAL No._____________________________________________

DATE OF PURCHASED___________________________________

This manual is designed with safety in mind. We at KVAL want to begin FAST and

SAFE production as soon as possible. It is very important that all OPERATORS

and MAINTENANCE personnel read this manual thoroughly. We have included

important safety information that will help prevent serious injury; as well as

complete maintenance, and troubleshooting instructions.

Proper operation and maintenance of your new KVAL machine will guarantee

many years of trouble-free, fast-paced production.

KVAL INC.

OPERA TOR’S & P ARTS MANU AL

For further information about this manual or other Kval Incorporated products, contact the Customer Support Department, Kval

Incorporated, 825 Petaluma Boulevard South, Petaluma, CA 94952. In the U.S and Canada, call (800) 553-5825 or fax (707) 762-

0485. Outside the U.S. and Canada, call (707) 762-7367.

Kval Incorporated welcomes your opinion regarding this document. Please send them to the Customer Support address shown

above.

Copyright 2005 Kval Incorporated. All rights reserved.

All other products are trademarks or registered trademarks of their respective holders, all rights reserved. Reference to these products

is not intended to imply affiliation with or sponsorship of Kval Incorporated.

Proprietary Notice

This document contains confidential and trade secret information, which is proprietary to Kval, Inc. (“Kval”), and is protected by

laws pertaining to such materials. This document, the information in this document, and all rights there to are the sole and exclusive

property of Kval, are intended for use by customers and employees of Kval, and are not to be copied, used, or disclosed to anyone,

in whole or in part, without the express written permission of Kval. For authorization to copy this information, please call Kval

Customer Support at

Copyright 2005 Kval Incorporated. All rights reserved.

825 Petaluma Blvd So.

Phone (707)-762-7367 • Fax (707)-762-0485

www.kvalinc.com

Table of Contents

OPERATOR’S & PARTS MANUAL........................................................................................................ III

CUSTOMER SERVICE INFORMATION..................................................................................................1

RETURNING PARTS / EQUIPMENT TO KVAL.....................................................................................2

WHEN YOU CALL:......................................................................................................................................... 2

WHEN SENDING MERCHANDISE BACK: ........................................................................................................2

GETTING STARTED....................................................................................................................................3

SAFETY FIRST DANGER!..........................................................................................................................5

PROCEDURE.................................................................................................................................................6

LOCK OUT AND TAG OUT PROCEDURE..............................................................................................7

LOCK RULES................................................................................................................................................9

SAFETY GUIDELINES ..............................................................................................................................13

ELECTRICAL.........................................................................................................................................13

COMPRESSED AIR:..............................................................................................................................13

OPERATING SAFETY: .........................................................................................................................13

COMPLIANCE WITH CODES AND REGULATIONS:...................................................................... 13

OPERATORS TRAINING:.....................................................................................................................13

OTHER HAZARD CONTROL ACTION:..............................................................................................13

SPECIFICATIONS......................................................................................................................................15

UNCRATING THE COMMANDER..........................................................................................................16

COMMANDER INSTALLATION.............................................................................................................16

REMOUNTING COMPONENTS:....................................................................................................................16

BOLTING THE OPTIONAL 555 DOOR SIZER:..............................................................................................16

LEVELING THE COMMANDER AND THE OPTIONAL 555 DOOR SIZER:.....................................................16

ELECTRICAL HOOK UP:.............................................................................................................................16

ROTATION CHECK:.....................................................................................................................................16

ANCHORING THE MACHINE TO THE FLOOR..................................................................................19

MAINTENANCE SCHEDULE FOR COMMANDER.............................................................................21

DAILY:.......................................................................................................................................................21

WEEKLY:..................................................................................................................................................21

MAY AND DECEMBER CHECK UPS..................................................................................................21

LUBRICATION REQUIREMENTS..........................................................................................................23

Linear Bearings: .....................................................................................................................................23

Flange Bearing:......................................................................................................................................23

Lubricate special high speed bearings:...................................................................................................23

Perske High Frequency Motors:.............................................................................................................23

Approved Lubrication Products:.............................................................................................................23

Lubricator Adjustments:.........................................................................................................................23

Gear Motor Lubrication Requirements:.................................................................................................23

Mist Oil Lubrication:...............................................................................................................................24

Priming the Lubricator:..........................................................................................................................24

CONTROL PANEL OPERATIONS..........................................................................................................27

JAMB CLAMP PEDAL:................................................................................................................................. 27

DOOR CLAMP: ............................................................................................................................................27

DOOR WIDTH ADJUSTABLE:......................................................................................................................27

CONTROL TRANSFORMER:......................................................................................................................... 27

START MACHINE:.......................................................................................................................................27

BACK SECTION/ BOTH / FRONT SECTION: ................................................................................................ 27

LOCK BORE OFF / REG. / DEEP:................................................................................................................27

BOLT DRILL OFF/ ON: ............................................................................................................................... 27

FACE PLATE OFF/ REG. / EXTEND TIME:..................................................................................................28

EXTEND HINGE ROUTER TIME OFF / ON:.................................................................................................28

FRONT SECTION SKIP #2 / ALL:.................................................................................................................28

AUXILIARY CONTROL PANEL..............................................................................................................28

EMERGENCY STOP: ....................................................................................................................................28

START SEQUENCE:...................................................................................................................................... 28

DOOR STOP:................................................................................................................................................29

LOCK LOCATION (OPTIONAL):..................................................................................................................29

FEED MODE (OPTION): ...........................................................................................................................29

AUTO IN:.....................................................................................................................................................29

AUTO IN / OUT:...........................................................................................................................................29

Door Only:...............................................................................................................................................29

Door & Jamb:..........................................................................................................................................29

FEED (OPTION):.........................................................................................................................................29

JOG FWD: ..................................................................................................................................................29

JOG REV.....................................................................................................................................................29

START SEQUENCE (FRONT/BACK) (OPTION):.................................................................................29

FRONT:........................................................................................................................................................29

BACK:.......................................................................................................................................................... 29

FRONT SECTION....................................................................................................................................31

COMMANDER HINGE SECTION:..........................................................................................................31

HINGE LOCATIONS:....................................................................................................................................31

STANDARD HINGE CENTER SET UP:..........................................................................................................31

SETTING THE OFF FEED STOP: ..................................................................................................................31

HINGE SIZE:................................................................................................................................................32

HINGE BACKSET DOOR:.............................................................................................................................32

HINGE BACKSET JAMB:..............................................................................................................................32

EXTERIOR DOORS: .....................................................................................................................................32

CHANGING CHIPOUT BLOCKS: ..................................................................................................................33

MACHINING NEW HINGE CHIPOUT BLOCKS: ...........................................................................................33

SETTING THE JAMB STOPS:........................................................................................................................33

ALTERNATIVE SET UP FOR PRE HANGERS:...............................................................................................34

DOUBLE BEVELED DOORS: ........................................................................................................................34

DALTON TORQUE LIMITER OSD:..............................................................................................................35

DOOR HINGE BACKSET: BOTTOM PIN..............................................................................................35

SETTING UP FOR A CUT CONTINUED......................................................................................................... 36

COMMANDER EXTERIOR DOOR REVEAL ADJUSTMENT ...........................................................37

HIGH FREQUENCY ROUTER DEPTH ADJUSTMENT:.....................................................................38

SETTING UP THE BACK SECTION:...................................................................................................41

COMMANDER LOCK SECTION:............................................................................................................41

LOCK SECTION LOCATION: ..........................................................................................................................41

LEFT AND RIGHT SHIFT WITH MULTI-STOP FOR LOCKS SECTION (OPTIONAL):............................41

LOCK BORE...........................................................................................................................................43

LOCK BORE OFF, REG, DEEP:..........................................................................................................43

LOCK BORE DIAMETER.....................................................................................................................43

LOCK BORE BACKSET ........................................................................................................................43

MAKE SURE CHIPOUT AND DRILL ARE ALIGNED PROPERLY!................................................44

ADJUSTING BACKSET TURRET BOLTS:.........................................................................................44

TWO STAGE FACE DRILLING...........................................................................................................44

FACE PLATE SET UP:..................................................................................................................................45

PLATE LENGTH: .........................................................................................................................................45

PLATE WIDTH:............................................................................................................................................45

PLATE ROUTER DEPTH:......................................................................................................................45

SWITCHING TO BEVEL PLATES:...................................................................................................... 46

SIDE DRILL (LATCH HOLE): ..............................................................................................................46

TROUBLE SHOOTING..............................................................................................................................49

LIMIT SWITCHES ..................................................................................................................................49

PHOTO EYES........................................................................................................................................... 50

GENERAL AIR CIRCUITRY TROUBLE SHOOTING......................................................................51

To change cylinder extension speed:......................................................................................................52

To change cylinder retraction speed:......................................................................................................52

BASIC ELECTRICAL TROUBLE SHOOTING ..................................................................................53

IF THE POWER STOPS DURING NORMAL OPERATIONS: DE-ENERGIZED:..........................53

FRONT SECTION DOES NOT FUNCTION PROPERLY..................................................................55

FRONT SECTION IS NOT TURNED ON AT THE CONTROL PANEL:........................................55

THE SIX SHOOTER IS NOT MOVED FULLY TO THE RIGHT:.....................................................55

THE THROUGH BEAM LENSES ARE DIRTY:.................................................................................55

SOMETHING IS WRONG WITH THE CYLINDERS THAT MOVE THE FRONT SECTION.... 57

MOVE FRONT SECTION TO THE “IN POCKET POSITION” THEN DO THE FOLLOWING:..57

ONE OF THE CYLINDERS IS BAD:................................................................................................... 57

THE ALIGNMENT OF THE CYLINDER SHAFTS IS OFF: .................................................................57

THERE IS AND OBSTRUCTION BLOCKING THE THROUGH BEAM:........................................57

GUARDS ARE MISS-ALIGNED:..........................................................................................................57

THROUGH BEAMS ARE NOT LINED UP:........................................................................................57

ONE OR MORE THROUGH BEAMS ARE BAD:............................................................................... 58

ENVIRONMENT TOO COLD:.............................................................................................................. 58

WIDTH ADJUSTS DOESN’T FUNCTION PROPERLY ....................................................................59

UNSATISFACTORY HINGE POCKETS..............................................................................................59

FUZZY HINGE POCKETS:...................................................................................................................59

RING AROUND THE POCKET:........................................................................................................... 59

FEED SYSTEM SURGING:..................................................................................................................59

FEED SYSTEM MOVING DOORS TO FAST:.................................................................................... 59

SETTING UP BOLT PLATE LENGTH:...............................................................................................60

LOCK BORE TWO STAGE FACE DRILLING:...................................................................................60

PLANNED MAINTENANCE PROGRAM ...............................................................................................65

COMMANDER PRE-HANGING DOOR MACHINE

Chapter

1

Customer Service Information

KVAL is happy to help its customer make the most of their investment, and help solve any problems

that may occur. When you call, please have the electrical print, air print number, and the serial number

of the machine ready, so that we are able to accommodate your needs efficiently.

HOURS

6:30 AM to 4:30PM Pacific Standard Time – Monday thru Friday

Phone: (707) 762-7367

Fax: (707) 762-0485

www.kvalinc.com

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

1

Returning Parts / Equipment to KVAL

Before returning parts and/or equipment to Kval Inc. please call KVAL at (707) 7627367 to receive a RMA # (Return Merchandise Authorization number).

* No t e

Non-Warranty returns are subject to 15% Re-stocking Charge.

When you call:

1. Have your Packing Slip and/or invoice #’s available

2. Have reason for return available

When sending merchandise back:

1. Make sure that the Item(s) you are returning are securely packaged and well protected from

shipping damage.

2. Including Packing Slip #

3. Include your RMA # on the outside of the package so our shipping receiver will see it.

Kval tries hard to satisfy its Customers, if you have any questions concerning merchandise purchased

through KVAL, please call.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

2

Getting S tarted

Your new KVAL Machine arrives at your plant crated, banded, taped and has painted set

collars on all shafts; keeping all of the precision moving parts secure during shipping.

1. Move the machine as close to the area it will be stationed before removing the crate to

protect against damaging the machine with the forklift.

2. Remove the machine from the crate. Be careful! Anytime the machine is lifted to

remove the skids there is a chance of the machine dropping suddenly, and damaging

the machine, or injuring people near the machine.

3. Remove all painted set collars from the shafts. Just about every shaft on the machine

has set collars to secure the moveable assembly mounted to the shafts.

4. Take off any tape securing the various buttons, switches and knobs.

5. Level your KVAL machine by putting metal shims underneath the corners of the base.

Leave a clear shot from the bolt holes in the foot pads to your shop floor. Now, make

sure the machine won’t rock back and forth.

6. Once the machine is level, anchor it to the floor so that it won’t move across the floor

during operation. KVAL recommends a ½ RED HEAD, TRUE BOLT ANCHOR in

each of the foot pads. When drilling the concrete for the anch or bolts use a 5/8 bit.

Note

KVAL wants to provide the industry’s safest and highest quality wood working

machines. The following page is a quality control and safety checklist. Our technicians

have already performed an initial quality control check before shipping your machine.

Please review the checklist and return “Acknowledgment Copy” to KVAL Verifying

complete contents.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

3

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

4

Chapter

2

Safety First Danger!

This section contains important safety information. Failure to follow these safety guidelines may

subject the operator to physical hazards that may resu lt in serious bodily arm, or death.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

5

Responsibility

It is the responsibility of each employee to maintain safe working conditions in his or her area.

Failure to understand and correctly follow this procedure is direct violation of safety rules and

regulations. Violations of this policy can lead to severe injury.

PROCEDURE

To lockout or tag out a piece of equipment, the following steps must be taken:

1. Assess the equipment to fully understand all energy sources (multiple electrical supplies air

and/or hydraulic pressures, spring tension, weight shifts, etc.)

2. Inform all affected personnel of the eminent shutdown, and the duration of the shutdown.

3. Obtain lock and tags from employer.

4. Shutdown machine(s) by normal means, i.e., disconnect switch(s), air pressure relief valve(s),

on/off button, etc. NOTE: Control power switches do not serve as adequate shutdown devices.

The main source(s) of energy must be disconnected as well. Also, ensu re that all mechanically

stored energy has been released, i.e., lifting booms lowered to bottom of travel, carriages in

“HOME” position etc., No one may remove a tag or lock installed by someone else. Only the

person who attached the tag or lock is authorized to remove it.

5. Once the lock and tag is in place, the employee must try to operate the machine to ensure all

energy sources are defeated.

6. When maintenance or repairs are completed, the pe rson that did the work m ust ensu re all tools,

spare parts, test equipment, etc. are completely removed and that all guards and safety devices

are installed.

7. Before removing the lock and tag, the person who attached them shall inspect the equ ipment to

ensure that the machine will not be put in an unsafe condition when re-energized.

8. The lock and tag can now be removed (only by the person who place them), and the machine

can be re-energized.

9. The tag shall be destroyed and the lock and key returned to the lockout center.

In addition to safety concerns, this policy is required by OSHA regulation 1910.147 and Cal

OSHA’S SB198 ruling of July 1991.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

6

Lock out and Tag Out Procedure

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

7

1. P .... PROCESS SHUTDOWN

2. R .... RECOGNIZE ENERGY TYPE

3. O .... OFF - SHUT OFF ISOLATING DEVICES

4. P .... PLACE LOCK AND TAG

5. E .... ENERGY RELEASE STORED ENERGY (0 ENERGY STATE)

6. R .... RECHECK CONTROLS AND RETURN TO PROPER SETTING

ENERGY TYPES

Recognize the Types of Energy to Shut Down

1. Electrical Energy

2. Hydraulic and/or Pneumatic Energy

3. Fluids and Gases

4. Mechanical Energy

ACCIDENT SITUATIONS

• Accident Start Up

Equipment can accidentally be turned on and your hands may be in the point of operation or while you are

inside.

• Electrical Shock

You can be accidentally electrocuted if the power is still on or if it is accidentally turned on.

• Hazardous Materials

If released can go into confined areas or the work area.

• Stored Energy

You could be caught in equipment that can move due to stored energy, even with the power off.

The Solution Is Quite Simple — These Accidents Can Be

Prevented Using The P-R-O-P-E-R Lock-Out Procedures.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

8

LOCK RULES

1. Use an appropriate “Lock-Out Device”, such as Lock Tongs, or a Lock Tag. Each person must attach his or

her own lock to the Lock-Out Device.

2. Identify Locks

Each lock will be identified by a number or a name. A lock without a tag is not good enough. Additional

information that identifies the person / persons doing the work must be on the tag. Also the type of work that

is being performed should be on the tag.

3. Sign The Tag

In some instances one tag is enough, however, the tag must be signed by each worker. In some

circumstances a supervisor will also need to sign the tag.

4. One Key Per Lock

5. Never give your key to anyone else.

Recheck controls and return to proper setting

P-R-O-P-E-R ELECTRICAL LOCK-OUT

P Process Shut Down

Open disconnect before pulling the plug. Shut down process or equipment.

R Recognize Energy Type

Recognize the correct power source.

O Off! -Shut Off all Power Controls

Shut off machine and electrical energy at both machine and main power switch. There may be more than

one source of power and all must be shut off. If necessary,

electrical drawings and a supervisor may need to be involved.

P Place Lock-Out Device, Lock and Tag

Each person working on equipment needs to put his or her lock on the switches and sign the tag.

E Energy - Release Stored Energy

Bleed electrical capacitors if any.

R Recheck Controls and Return To “OFF” Setting

Recheck the start button and properly test that you have

zero energy state.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

9

P-R-O-P-E-R HYDRAULIC AND/OR PNEUMATIC

LOCK-OUT

P Process Shut Down

Shut down process using recommended procedures.

R Recognize Energy Type

Recognize all sources of energy – the electric that powers the pumps or compressors, and the air or

hydraulic valves themselves.

O Off! -Shut off all Power Controls

Shut off each energy type.

P Place Lock-Out Device, Lock and Tag

The shape or location on some valves may be difficult to lock out. If there is not a specific lock out tag out

procedure in place you should ask your supervisor.

E Energy - Release Stored Energy

Bleed the stored energy by bleeding the air line and draining the compressor, or by using other prescribed

methods. Keep in mind that when bleeding stored energy

it could cause some parts of the equipment to move, as it is being held by the stored energy.

R Recheck Controls and Return To “OFF” Setting

Return controls to proper settings.

P-R-O-P-E-R FLUIDS AND GASES LOCK-OUT

P Process Shut Down

Shut down process using recommended procedures.

R Recognize Energy Type

Recognize the material and its hazards. If material is hazardous, use the proper protective equipment. Even

water can become a hazardous fluid under high

pressure.

O Off! -Shut Off all Isolating Valves

If a job requires breaking in to a line close off isolating device, blanking if necessary. Some valves may be

difficult to lock out. A locking bar or chains may be

needed. Check with supervisor.

P Place Lock-Out Device, Lock and Tag

Sign tag.

E Energy - Release Stored Energy

Release pressure and drain to achieve zero energy state.

R Recheck Controls and Return “OFF” Setting

Recheck line and test properly and make sure you have zero energy state.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

10

P-R-O-P-E-R MECHANICAL ENERGY LOCK-OUT

Mechanical Energy may be released at the point of operation, or where two or more

points of operation come together. This is where you might get caught. In most cases

blocking mechanical energy is done in addition to shutting off the primary source, such as

electrical, hydraulic and pneumatic. Some examples include inserting restraining pins or

bars in the point of operation or block under a lift. In cases where these blocks to

mechanical energy are not locked in place, they should not be the primary means of

shutting off energy. Mechanical energy can also be stored.

1 Gravity

Things that are up can fall of their own weight. Pins or blocking may be required.

2 Springs

BOING! can spell DEATH. Release tension or compressed springs by using methods

prescribed by the equipment manufacturer.

3 Tensions

Things under tension can spring in. Release tension by using prescribed method by

equipment manufacturer.

P Process Shut Down

Shut down the process.

R Recognize Energy Type

Recognize all forms of energy – Need to be shut off, such as electrical and mechanical.

Mechanical is usually a secondary energy source closest to point of operation.

O Off! -Shut Off all Power Controls

Such as switches, valves and other isolating devices.

P Place Lock-Out Device, Lock and Tag

Place lock on the isolating device and sign tag.

E Energy - Release Stored Energy

Release, spring or tension to achieve, zero energy state.

R Recheck Controls and Return To “OFF” Setting

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

11

ZERO ENERGY START UP

Zero Energy State to Start-up to Operating State

Starting the equipment is just as important as Lock-Out/Tag-Out in terms of safety.

Start-up

• Inspection

• Clean up

• Replace guards

• Check controls

• Remove locks

• Visual checks

Inspect

When work is finished the equipment must be inspected for proper adjustment before starting equipment.

Clean Up

All materials and debris must be cleaned up. Any combustible materials and old parts used during repairs

must be cleaned up.

Replace Guards

Replace all guards to the equipment. If adjustments can not be made with the guard on after start-up, leave

off only the ones to be adjusted after start-up.

Check Controls

Make sure all switches are in the off position. In some cases the machine can start automatically when

energy is restored.

Remove Locks

Each person must remove his or her own lock or tag. This will ensure you are in a safe place when the

equipment is started.

Visual Checks

If the equipment is too large to see all around it, station personnel around the area and sound the personnel

alarm before starting the equipment. If your operation is more complex, having many pieces of equipment

and a lot of people, a comprehensive Lock-Out/Tag-Out procedure may involve additional steps. You will

need to ask your supervisor about these procedures. A specific lock out procedure may be posted at each

machine. On larger or long term maintenance projects or installation projects, the procedures should be

explained to all participants and a copy of the procedures posted on site for the duration of the work.

Provisions which ensure protection during shift changes when contractor or outside help is used also need to

follow the Lock-0ut/Tag-Out Procedures. Comprehensive Lock-0ut/Tag-Out may use a gang box or other

system to ensure that locks are secure and not removed without authorization.

Remember Lock-Out Tag-Out procedures work because you are the only one with the key to your lock.

Proper Lock-0ut/Tag-Out can save lives, limbs and money. Help make your work environment safe for

yourself and your fellow employees. Make sure you follow the P-R-OP-E-R Lock-0ut/Tag-Out procedures,

and that those around you do also.

YOUR LIFE MAY DEPEND ON IT.

© 2004 American Concrete Pipe Association (ACPA). All Rights Reserved.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

http://www.concrete-pipe.org/sab.htm

12

Safety Guidelines

ELECTRICAL

Electrical circuitry on this machine is protected by an approved lockable disconnect circuit. In

addition to this equipment, you must install an approved disconnect for the electrical power

supplying this machine

COMPRESSED AIR:

The compressed air system connected to this machine should have a three-way air valve for

shut-off and pressure relief. The air supply providing the pressure to this machine also has a

three-way air valve for the supply line.

OPERATING SAFETY:

Prior to changing any cutters or doing any maintenance work, you must disconnect, tag out, or

lock out the electrical, air pressure and hydraulic systems. This should be done in accordance

with the State and/or Federal code requirements.

COMPLIANCE WITH CODES AND REGULATIONS:

It is advised that you request an on-site State safety review of your installation of this machine.

This is to ensure conformance to any additional specific safety and health regulations which

apply in your area.

OPERATORS TRAINING:

You must ensure that all operators of this machine be tra ined to know the potential electrical

hazards, pressure pinch points, rotating cutters, and other similar hazards. It is also your

responsibility to train the operators, or potential operators on how to operate the m achine

safely.

OTHER HAZARD CONTROL ACTION:

If you believe that any part or operation of this machine is in violation of any health or safety

regulation, it is your responsibility to immediately protect your employees against any such

hazard and bring the matter to our attention for review and correction, if deemed advisable.

You will not that additional detailed safety guidelines are in cluded in th e operatin g instructio ns

of this manual. We will be pleased to review with you any questio ns you may have regarding

the safe operations of this machine.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

13

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

14

Chapter

3

SPECIFICATIONS

The Commander is KVAL’s best-selling and most flexible door machine. It automatically machines

up to four hinges and also machines for cylindrical lock or dead bolt. Since the Commander can

simultaneously route hinge jambs, it is ideal for distributors of architectural doors and residential prehangers.

The Commander is designed to route and bore for lock and hinges in flush or stile and rail doors up to

2-1/4” thick by 4’ wide and 9’ long and wit a minimum width of 18”. It also accommodates raised

panels or molding up to ¾” thick. The jamb clamping system compensates for jam b thickn ess and will

accept flat, split and rabbeted jambs up to 1-1/2” thick with a 5/8” stop, or 1-7/8” thick overall. There

is no limitation on jamb width.

Hinge Routing: Automatic hinge-routing unit accommodates both ¼” and 5/8” radius hinges up to 51/2” utilizing turret-stop adjustments. Hinge centers are adjusted by positioning collars on a removable

plug-in shaft below the router and sliding jamb clamping fixtures into position. Extra shafts may be set

up and “plugged in” for rapid hinge center adjustments. During the routing sequence the router

automatically travels along the removable shaft to each collar and dapps the pocket. Full hinges up to

4” X 4” can be attached to the doors and jambs.

Lock: Face bore is adjustable from 2-3/8” to a 5” backset. The faceplate is adjustable for square or

bevel up to 3-1/2 degrees from 1” X 2-1/4” up to 1-1/4” X 12”. Self-Centering clamp system ensures

accurate latch and faceplate machining regardless of door thickness. Both drill motors feature Accuflex collet chucks so standard straight shank tooling may be used.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

15

Uncrating the Commander

Commander Installation

Remounting Components:

Slide the routers back into their bases and plug them in. While testing the machine, remove all router

bits. This includes drill bits for the lock. Remount the main electrical box to the commander’s rear leg

on the in-feed end.

Bolting the Optional 555 Door Sizer:

Rest the off-feed end of the 555 on the leveling brackets welded to the commander’s frame. Screw in

the mounting bolts from the 555 into the commander finger tight. Align and drive in the roll pins from

the inside of the commander’s frame. Tighten the bolts and fasten the 555 electrical junction box back

in place. An electrician or the Kval tech rep will reconnect the wires disconnected fro shipping.

Leveling the Commander and the Optional 555 Door Sizer:

Set a level on the Commander’s hard board (Ryertex) runner, below the jamb clamps and insert sheet

metal shims under the low leg. Level width wise by place a level on the 1 ½” shafts supporting the

lock machining carriage, again using sheet metal shim s to bring up the low le g.

Electrical Hook Up:

We recommend using a licensed electrical contractor to hook the machine into your buildings electrical

system. Code approved circuit interruption equipment and lockable wall mounted disconnects are

necessary for both the single and three phase services; otherwise, the service wires connected to the

main panel on the backside of the Commander will not shut off for maintenance or repair work.

Amperage varies depending on the optional equipment; check the stamped amperage rating on the

specification plate. Once the wall disconnects are wired; tag and lock them out. The single phases

connect at the labeled block inside the panel. These connector blocks allow either 110V service with a

jumper between “hot” terminals or 220V split phase with as single common. Three phase wires are

connected to the panel disconnect switch—remove the shield at the right of the fuse block to make

connections. Be sure to connect an appropriately sized grounding wire to the ground lug.

Rotation Check:

Close the panel door and switch on the power disconnect. Pull on the control transformer control

panel. Turn off all the selector switches except the lock bore drill, and press the master start button

followed by the emergency stop button. If the rotation of the lock drill is wrong, lock out both the

single and three phase wall disconnects, then switch two of the tree phase leads connected to the

commander’s main panel disconnect switch.

Air Service:

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

16

The standard Commander is rated at 8 CFM. Check the spec plate if the optional H-1000 or 555 was

ordered with your Commander. Air should be supplied inside the left rear leg to the Filter/ Regulator /

Lubricator module. Once the machine is up and running, sight through the glass on top of the

lubricator, and turn the adjustment screw so one drop every two cycles is fed to the system. Check the

filter bow daily and empty if its more than half full of water.

Finally, if your plant is located in a humid area we recommend a air dryer on your compressed air

system.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

17

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

18

ANCHORING THE MACHINE TO THE FLOOR

When you have set-up and test run your machine to ensure that it is feeding the material properly KVAL

recommends anchoring the machine to the floor with ½ Red head, True Bolt Anchors in each of the foot pads. An

alternative way to bolting the machine, you may want to use Epoxy and hardened threaded rods to prevent the bolts

from vibrating loose. KVAL doesn’t require the use of epoxy though its added fastening strength is significant.

Standard Anchoring Instructions:

* With machine in place and leveled, drill 3”

deep holes in the concrete using a 5/8” dia.

masonry bit, using the mounting hole as a guide.

* Clean out holes with an air compressor to

ensure that the anchor heads get a firm bite on

the walls of the holes.

* Insert anchors through the mounting holes in

the foot pads and into the holes you have drilled

into the concrete. If an anchor’s expansion

sleeve binds inside the hole, simply tap the bolt

head with a hammer until the binding stops.

* Tighten bolts until they are snug. Avoid over

tightening the bolt as this may cause the head of

the bolt to break.

Anchoring Instructions using Epoxy:

* With machine in place and leveled, drill 3”

deep holes in the concrete using a 9/16” dia.

masonry bit, using the mounting hole as a

guide.

* Clean out holes with a air compressor.

Complete hole preparation with use of a nylo n

brush (do not use wire brush).

* When starting a fresh cartridge of anchoring

epoxy, epoxy must be an evenly blended light

gray color. Insert nozzle into the bottom of the

hole. Fill hole to ½ the hole depth.

* Insert 1/2”, (hardened) threaded rod into the

bottom of the hole using a slow twisting

motion. This insures the epoxy fills voids and

crevices. Hardening begins in 7 minutes @

room temperature.

* After recommended cure time, bolt in place.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

19

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

20

Maintenance Schedule

Maintenance Schedule

KVAL recommends the following maintenance schedule to ensure that the machine operates

properly. Refer to this section for steps to perform maintenance.

Daily, Monthly, Six Month Maintenance

Daily Preventive Maintenance

Op Operation Description

Clean

Check

Clean

Check

Clean

Check

Check

Blow off dust from the entire machine.Wipe down the outside of the machine with a

clean dry cloth.

Check tooling for wear.

Wipe of f the photo eyes with a clean dry cloth, and check to ensure that all fastening nuts

are snug.

Check the air pressure to make sure it is set at 80 psi to100 psi.

Empty any Dust Collection Units.

Check for obstructed flow when excessive sawdust appears.

Check the air filter water trap. Empty if full.

Weekly Preventive Maintenance

Op Operation Description

Check

Clean

Check

Check the machine for smooth motion through a complete door cycle

Clean linear bearings and the chrome shaft with a clean dry cloth, then lubricate.

Check all air lines & electrical wiring for kinks or rubbing.

LUBE

Refill lubricator with an ISO 32 standard hydraulic oil (KVAL part# SYSLUBG)

Six Month Preventive Maintenance

Op Operation Description

Clean

LUBE

Clean

Tighten

Back-up

LUBE

Wa sh filter and lubricator bowls with soapy water.

Grease all bearings and tighten all bolts. Access to some grease fittings is difficult and

will require a special needle point grease tip (supplied with your system).

Clean and lubricate all slides and cylinder rods with dry silicone spray.

Tighten all bolts.

Backup computer software.

Lubricate linear bearings and chrome shafts with silicone.

Maintenance Schedule

Lubrication Schedule

KVAL recommends the following lubrication schedule to ensure that the machine operates properly.

TABLE 3-1. Recommended Lubrication Schedule

Type of Assembly Recommended Schedule Recommended Lubrication Type

Linear Bearing

Every 250 Hours of Machine Operation Dura-Lith Grease (KVAL P/N Lube EP-2)Pillow Block Bearing

Flange Block Bearing

Ball Screw Every 80 Hours of Machine Operation

Air Line Lubricator One drop of oil every 2 or 3 cycles

Check the lines every week to two weeks

Gear Box 2000 Hours of Machine Operation or six months

of operation

Either lubricant listed below is approved

to use.

• KVAL P/N SYSLUBG

• Chevron AW Hydraulic Oil 32

• G-C lubricants light AW R&O

• Mobile DTE 24

• Shell Tellus32

• Gulf Harmony 32

• AGMA #8 gear lube

• MOBILUBE HD 80 W-90

• or equivalent

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

22

LUBRICA TION REQUIREMENTS

Linear Bearings:

If bearing is equipped with a grease fitting, it should receive 1

Gram (one pump from grease gun) of Dura-Lith Grease (KVAL

P/N Lube EP-2) grease every 30 days. Bearings without grease

fittings have been pre-lubricated at the factory and do not require

further lubrication.

Flange Bearing:

Dura –Lith grease; 1 gram every 60 days.

Lubricate special high speed bearings:

With optimal long time PD2 (KVAL P/N Lube PD2)

bearings must be re-lubricated once every 60 days.

Perske High Frequency Motors:

Spindle motor(s) are installed pre-lubricated. For relubrication use lithium based NLGI grade 2 grease. The only

greases currently approved for use in Perske motors are

Optimol Longtime PD2 or LDS 18 Special A (KVAL P/N

LUBE PD2). Failure to use the approved products voids

warranty.

Approved Lubrication Products:

Chevron AW Hydraulic Oil 32 – or KVAL P/N SYSLUBG or G-C lubricants light AW R&O

or Mobile DTE 24 or Shell Tellus32 or Gulf Harmony 32.

Lubricator Adjustments:

Using knob on the top of the lubricator, adjust until one drop per every other cycle is used (as

observed through sight glass.) Turn flow all the way open the reduce flow to proper

specifications.

Gear Motor Lubrication Requirements:

Oil change is recommended after 2000 hrs. or

six months of operation. Use AGMA #8 gear

lube or MOBILUBE HD 80 W-90 or

equivalent.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

23

Mist Oil Lubrication:

Spindle housing mist oilers require syslube lubricant, available through KVAL. Optimum flow

is 3 to 5 drops per minute @ 5-10 psi.

NOTE: These oils cannot be interchanged.

NOTE: On the Commander-DI front section there is about 34 bearings that have zert

fittings either use a pin fitting or a zert fitting to lubricate these bearings.

Priming the Lubricator:

New and used machinery run out of oil from time to time. It is a good practice to check your

machine lubricator to insure that it is putting the proper dose of oil in the air lines. Usually 1

drop every 3-4 cycles is a good rule of thumb.

To prime the lubricator, find an air line on the Front Section of the machine that is energized,

and disconnect it, allowing the air stream to bleed air pressure away from any persons. Direct

the air stream at the machine so you can see when there is an oily film blowing out of th e air

hose. NOTE: It might take up to 15 minutes to get a good prime. When this is

accomplished, place the air line back into its original position.

Repeat this same procedure for the back section and other trouble areas.

Check the lines every week to two weeks

Figure 1: This shows how to adjust the lubricators and show s the air lock out valves 1 dr op every 3-4 cy cles

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

24

ZERK FITTINGS

ZERK fitting

ZERK fitting

depending on the

position of the

slide.

ZERK fitting

Figure 2: This shows how to adjust the lubricators and show s the air lock out valves 1 dr op every 3-4 cy cles

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

25

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

26

CONTROL P ANEL OPERA TIONS

Jamb Clamp Pedal:

The jamb clamp pedal is used to clamp the jamb into position for routing jam b pockets.

Adjust the clamp pressure by turning the regulator knob located beneath the main

control panel. Clamp pressure has been factory set at between 45 & 55 PSI. KVAL

recommends that clamp pressure not be adjusted higher than 55 PSI, due to jamb flex,

resulting in jamb pockets being cut too deep. The bar running from the door clamp

pedal to the jamb clamp pedal, causes the jamb to unclamp when the doo r is released

WARNING:

Make sure that Hands are clear of the Clamps at all TIME!

Door Clamp:

The door clamp pedal secures the door into position for machining.

Warning: Keep yourself, and other clear of the commander while clamping –

especially the Front face clamp and jamb indexing fixtures.

Door Width Adjustable:

The door width adjustment drum switch is located on the left end of the commander.

Unclamp the machine using the Door Clamp Pedal. Turn the door width adjustment

drum switch while watching the width indicator move up or down the measurement

scale on the left end of the Commander’s frame. Release the door width adjustment

switch when the width indicator reaches the measurement of the width of your door

with in +/- ¼”

Control Transformer:

The control transformer button turns on the power within the electrical box.

Start Machine:

The start machine button turns on the Commander’s motors, and computer. The start

machine button does not start the commander’s cycle of operation.

Back Section/ Both / Front Section:

This switch allows the operator the choice of machining hinge pockets, or lock preps

independently. The BOTH command combines these functions in one machining pass.

Lock Bore Off / Reg. / Deep:

The REG. command machines bypass doors. The DEEP command machines normal

bores and different diameter cylinder and dead bolt holes without having to remove the

drill bit. Deep is used to access the second larger diameter cutter shaft.

Bolt Drill Off/ On:

The Bolt Drill selector switch controls the operation of the bolt drill. Select On for bolt

drill machining.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

27

Face Plate Off/ Reg. / Extend Time:

Small plates take less time than large plates for mortise locks. Set this switch to

EXTEND TIME for large plates or you will machine incomplete face plate routs. The

amount of time that is allowed can be adjusted with a potentiometer mounted on the

outside on electrical box. Loosen the nut and adjust the screw head counter clockwise

to decrease time, or clockwise to increase routing time.

Extend Hinge Router Time Off / On:

The selector switch increases the amount of time the router takes to complete cutting

passes. The Extend Hinge Router Time ON switch is ideal for hard woods, laminates,

and deep hinge pockets. Select off for normal machine. NOTE: When in the

EXTEND mode it is necessary to readjust the flow controls to slow cylinder operation.

If the router stalls, slow down cylinders until router cuts smoothly. These adjustments

will probably take a few test cuts to tune.

Front Section Skip #2 / All:

Skip #2 command instructs the machine to skip the routing the center hinge. “ALL”

command instructs the machine to rout all hinges.

Front Section, Override In-feed Limit:

The arrow button sends the hinge carriage to the right. The In-feed limit button

overrides the limit switch to return to a hinge pocket and m achine it again.

1. Normally the “Start” button on the auxiliary panel sends the carriage to the left, then if

the hinge router has been selected, the next press on the start button will send it to the

right, machining as it goes.

2. If the router carriage is returning to the left, pressing the In-feed limit button will stop

the carriage, and pressing the “Start” button again will cause the router carriage to

move to the right and resume cutting the next pocket tha t it comes to.

3. There are some “dead zones” caused by the set collars and proximity sensors, in which

hitting the In-feed limit button will kill the router carriage. If this happens, hit

“Emergency Stop”, then “Master Start”, the “Start”. You will quickly learn where the

“Dead Zones” are and avoid them: basically, just make sure that you bring the carriage

back past the collar for the pocket that you want to machine and you will be in

business.

Auxiliary Control Panel

Emergency Stop:

The “Emergency Stop” button instantly halts the Commander’s cycle of operation.

The motors will BEGIN to slow to a stop, cutters retract.

Start Sequence:

This button begins the Commander cycle of operation. “Start Sequence” only start the

machining that the operator has selected from the OPERATING CONTROLS.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

28

Door Stop:

Pull the “Door Stop” button to raise the out-feed stop fro LEFT HAND doors. Push to

lower the out-feed stop.

Lock Location (Optional):

Shifts the lock machining carriage left or right depending on door hand.

Feed Mode (option):

Auto In:

Door will automatically clamp in position, operator manually unclamps and exits the

door.

Auto In / Out:

Door Only:

Door & Jamb:

Feed (Option):

Automatically machines the door and out feeds the door.

Automatically machines the door and jamb 1 second after jamb is

clamped.

Jog FWD:

Manually controls the feed belts, shifting toward the out feed end of the machine.

Jog REV.

Manually controls the feed belts, shifting toward the in feed end of the machine.

Start Sequence (FRONT/BACK) (option):

Front:

Activates the front section with out activating the back section (lock section)

Back:

Activates the back section for multi positioning for deadbolt, without activating the

front section (hinge routing).

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

29

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

30

Commander Hinge Section:

You will need a damaged door or a cull door to use when you make your initial set up. Roll

the door into the machine and pull it back against the in-feed stop. Consider this stop to be the

fixed stop. It is on the left end of your machine, calibrate all the tapes for setting hinge and

lock locations from this location. Please don’t move this stop unless you want to calibrate

every tape on the machine.

Hinge Locations:

The commander will do almost any common door size and hinge routing pattern, the versatility

comes at a price however, since door swing change-overs are slower than most straight pre

hanging machines when you switch from interior to exterior doors. There’s a simple way to

make it just as fast explained below under “Alternate Pre Hanging Set Up”

Standard Hinge Center Set Up:

Reference hinge locations from the top of the door; to the top of each hinge pocket. For

instance 7’-11” hinge centers on an 80” door requires setting the first and third collars 7” and

65-1/2”. To move a hinge location, loosen the appropriate collar on the shaft below the hinge

router. Slide it so that its left edge indicates the measurement on the tape. Notice that there’s

two center shaft supports just in case your collar lo cation ov er lap s. Be su re to set the co llars so

that the tightening screws are horizontal, or the screw heads set the ferrous proximity sensors

on the router carriage. Tighten the collars firmly.

FRONT SECTION

Instead of moving the collars for popular hinge patterns you can buy extra collar bars and the

exchange the whole bar with another that’s already set up. Three bolts secure the shaft in

place. The collars can even be roll pinned in place although a nail polish or paint slippage

mark make moving collars easy to spot.

Next, move the jamb reference blocks so they match the setting of the collars below. Use a

“T” handle Allen wrench (provided) to loosen the set screws clamping these reference blocks

in position. The white marks stamped into each block shows from which direction to read the

tape.

The door and jamb cylinder clamp fixtures that slide sideways so you can center them on the

jamb reference blocks. Loosen the four retaining knobs and line up the white plastic clamping

pads on the cylinders with the jamb clamping blocks.

Setting the Off Feed Stop:

To machine opposite swing doors, the off feed stop needs adjustment according to th e formula.

Off Feed Stop = First Hinge + Last Hinge + Hinge Size

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

31

You can now set the Off Feed Stop to the location you just calculated by loosening the socket

head bolt and sliding the stop so that its left edge indicates what you calculated on the tape.

Hinge Size:

Determine the hinge size by the turret mounted on the right side of the router, and spacer pins

for door and jamb backsets. Turn air pressure off at the router with the slide valve so you are

able to move the router easily. Don’t forget to turn it back on again before you machine doors.

Adjust hinge width by rotating the stop turret. Two stop turrets are provided for this location:

on for ¼” radius bits, and one for 5/8” radius bits. On each turret, the longest bolt gives a 3 ½”

hinge, the middle bolt is for 4” and the shortest is for 4 ½”. The Flat side of the turret exposes a

stop pin hole used for odd sized hinges, we can provide four position turrets if you determine a

need for them (like alternative pre-hanging setup.) Change this pin when the radius of the

hinge router changes.

Hinge Backset Door:

If you are using a ½” bit, the length of this pin will be the same as the backset that you desire.

Add 3/8” to the pin length for 1 ¼” router bits… in other words use a 5/8” pin for a ¼” backset.

Some machines are set up to cut completely through the stile. In this case all backset pins are

5/16” longer and no pin is used to cut through the bottom skin.

Hinge Backset Jamb:

Space stop pins limit the cutter travel up into the jamb. Notice that this pin contacts a bolt

mounted to the chip out assembly. The chipout block is spring loaded up to the contact the

jamb edge during the jamb routing sequence. The cutter is indexed off the edge of the jamb, to

compensate for bowed jambs. Select the proper pin from the pin chart for the distance that you

want to cut into the jamb.

NOTE:

If you machine jambs wider than 7 ½” turn the cylinders around so that they clamp

down on the jamb. Bowed jambs still machine correctly although hinge mounting will take a

bit more effort.

Exterior Doors:

When you wish to machine exterior doors you will probably need to change hinge sizes as

explained earlier. Two other adjustments are also necessary.

To minimize pocket tear out; the hinge router should cut less than half the bit diameter on its

first horizontal past in to the jamb; and then into the door. To make this happen you need to

adjust the routers tilt in height by adjusting the cylinder stack.

The stack needs to be raised 3/8” for exterior doors and lowered the same amount to go back to

1 3/8” doors. To adjust’ turn off the hinge section’s slide valve; loosen the bla ck ratchet h andle

that clamps the lower cylinder stack bracket in place and then turn the 4 prong black knob. The

roll pin indicator in the slot will be stationary while the slot an d scale (reference d oor th ickness )

will go up or down.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

32

If no tape is present on you machine, adjust the stack so that the center of the cutter hits the

lower edge of the jamb when the router swings into position on and interior jamb. Make a

mark next to the roll pin. Make another mark 3/8” below the first one. When you set up for

exteriors, the cylinder stack and the lower mark will rise until it aligns with the roll pin.

The second adjustment positions the chipout block so it’s centered for door thickness when the

router tilts in. Shut off the router slide valve and pull out the pin. Slide out the 3/8” thick steel

shim with the notch cut in the middle. Insert the shim under the bracket for 1 ¾” doors, and

above the bracket for 1 3/8” doors. If the jamb only needs to be raised 1/8” or ¼” Alternate

spacers are included with the machine in 1/8” and ¼” thicknesses. Use both of these spacers in

place or the 3/8” spacer, and arrange them above and below the chipout for proper height and

spring tension.

Changing Chipout Blocks:

If you are not machining jamb, it is rarely necessary to change the hinge section chipout block

because only the left edge of the cutout is likely to chip, and a block with a 5” cut in it could

work for shorter hinges as well. Notice that the same block can be used with either ¼” or 5/8”

radius cutters.

To minimize tear out in the jamb the chipout block should have a cut in it the same length as

the hinge width.

Machining New Hinge Chipout B locks:

To machine a new block, use a 1 ¼” diameter bit: It’s awkward to make multiple passes with a

½” bit. First turn off the machine, and the routers, and slide the hinge router air valve off.

Remove the pin that limits upwards router travel into the jamb, and bolt the new chipout block

in place – you will need to hold the router up manually so the bit clears the new block.

Make sure that you have the proper pins selected for the hinge length (Horizontal Travel), and

that the router setting is the proper depth of cut. With the router turned off, plug it into an

external outlet and put on a face shield and dust mask. Hold the router up so the bit clears the

right top edge of the chip out block; and cinch it on. Lower the router all the way down from

the RIGHT corner. Then push it left as far as it will go. Tilt the router into the door cutting

position to rout the bottom corners of the chipout block. When finished, plug the router back

into its own outlet, turn it on, replace the top pin and turn the slide valve back on.

Setting the Jamb Stops:

Just as the left hand stop is the fixed stop on the Commander, the left hand jamb stop is a fixed

stop. Its normally factory set for a 1/8” header clearance. Adjust the right jamb stop by

reading the tape under it against the left edge of the stop.

Thinking about the examples so far with the off feed stop set at 76” setting the jamb stop at 76

1/8” would give and 1/8” head clearance. The correct pin is a ¼” long, inserted in the jamb

stop for indexing flat jambs. Note that the pin length must be less than the depth of dado for

the jamb to set flat against the stop.

For rabb

eted jambs, use the indexing block. A pin should be selected for the block that is ½”

longer than the thickness of the stop on your jamb. For example, if the stop is 5/16” thick, use

a 13/16” pin. The header clearance references form the position of the jamb stop on its tape.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

33

Alternative Set Up for Pre Hangers:

It’s clear at this point that adjustments for interior to exterior doors involve more than most

standard pre-hanging machines. We have a simple solution that eliminates adjustments to the

hinge centers, off feed end stops and left and right shift. Unfortunately you will need to live

with the same hinge centers for both interior and exterior doors.

For example, if you run 7-11 hinge locations with 3 ½” hinges on your interiors then your

exteriors with 4” butts will be 6 3/4” and 10 ¾” respectively.

Here’s how it works. Set the machine up normally for 3 ½” centers. We will send you a three

position turret to replace the pin on the left side of the hinge router that’s changed for ½” or 1

¼” diameter router bits. Two of the turret positions will do the same thing as the pins-set the

router for it diameter. The third position will be located ¼” back from the 1 ¼” diameter bit

position.

We will also send you a new four position turret to replace your standard 5/8” radius turret.

Three positions are standard, the fourth position is ¼” back from the 3 ½” hinge rout. When

both the special ¼” back positions are selected you will get a 4” hinge rout with the same

centers as the 3 ½” pocket.

All the settings for opposite swing doors will be the same as interiors since the pockets have

not shifted ½” towards the right. You should color code the new turret bolts for reference.

Also, when cutting 4” butts with this set up you must remember pockets will be shifted ¼”

from the collar settings on the router indexing shaft.

To machine special doors with centers different from your prehungs, we highly recommend

using the standard turret positions – with the standard hinge center set u p exp lained ea rlier. It’s

just plain confusing otherwise.

Double Beveled Doors:

Since, the router depth must be readjusted; change to a worn out chip out block, or a used block

for beveled hinge pockets. Adjust the router to the correct depth and you are ready to go. If

you need to do the jamb at the same time as the door, you will need to install beveled jamb

referencing blocks (or “H” blocks) that we can supply; other wise, if you rarely rout jambs with

bevel doors we suggest routing the jambs separately before changing the router to 3 degrees.

You can even mount half hinges and then drive in the pins with door and jamb out of the

machine.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

34

Dalton Torque Limiter OSD:

On your KVAL Commander Line’s front section there is a Dalton Torque

Limiter. This torque limiter is a safety device used by KVAL to ensure

operator safety in the front of the machine incase of accidental start up.

The torque limiter should allow the front carriage to move with a ample

amount of force almost having to use your body weight. This is different

from operator to operator. To adjust the torqu e limiters do the following .

1. Remove the plate that is covering the sprocket and torque limiter.

2. Once removed loosen the two set screws on the nut this will allow

you to make your adjustments accordingly.

3. Once you have adjusted the torque limiter to its appropriate

setting tighten the set screws down so that the bolt does not move.

NOTE: Do not get any grease or oil be tween the friction pads or the torque limit er will not work

properly especially during this adjustment.

Guard plate connected by two 10/32

socket heads removes this plate, to

access the Dayton Torque Limiter.

Door Hinge Backset: Bottom Pin

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

35

Standard Set Up

Cutter

Radius

3/16"

1/4"

5/16"

1/4" 3/16" 1/4" 5/16" 3/8"

5/8" 9/16" 5/8" 11/16" 3/4"

With Cut through the Bottom Skin Set Up

* Optional - Requires modified H Blocks

Cutter

Radius

3/16"

1/4"

5/16"

1/4" 1/2" 9/16" 5/8" 11/16"

5/8" 7/8" 15/16" 1" 1 1/16"

Jamb Backset: Top Pin

Cutter

Radius

1 1/8" Pocket

1 3/8" Pocket

1 5/8" Pocket

1/4" 2" 1 3/4" 1 1/2"

5/8" 2 3/8" 2 1/8" 1 7/8"

* 3 Degree Special Set-Up Information:

When cutting at 3 degrees you must subtract 1/32" from the Jamb

Pocket Top Pin AND Door Hinge Backset Bottom Pine.

From zero degrees to 3 degrees your overall pocket

decreases 1/16".

3/8"

3/8"

Setting Up For a Cut Continued

1 3/4" Door w/ 4" hinge 5/8" Radius

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

36

Turn off Slide valve.

Put Front section turrets to middle position.

Put 2" Jamb pin in.

Adjust router tilt in height up 3/8"

Adjust 1/4" shim on top of spring for chipout tilt-in clearance.

Install 5/32" pins for jamb height.

Turn on slide valve

1 3/8" Door 3 1/2" Hinge 5/8" Radius

Turn off slide valve.

Put front section turrets on longest bolt position.

Put Jamb pin in 2 5/16"

Adjust router tilt in height down 3/8".

Adjust 1/4" shim on top of plate for chipout tilt in clearance.

Remove 5/32" pins for jamb height.

Turn on slide valve.

Hinge

4 1/2" 1/4" 1 1/8" 5/8"

4" 1/2" 1 3/8" 7/8"

3 1/2" 3/4" 1 5/8" 1 1/8"

1/4" Radius

Left Right Left

5/8" Radius

Commander Exterior Door Reveal Adjustment

The chipout block on the router carriage serves two functions; (1) to reference off the jamb, (2)

reference off the door. When changing either the reveal measurement, or the thickness of the door, it is

necessary to adjust the position of the chip out block relative to the new thickness and reveal

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

37

measurement. The chipout adjustment shims on the top of the routing carriage need only be added or

removed; Spacer Stop pins inserted into the “H” block, and adjust the cylinder center line.

To adjust reveal for different thickness exterior doors, there are a few simple s teps to follo w:

1. Turn off electrical power and air supply.

2. Place the appropriate Spacer Stop pins into the “H” block (behind the “H” block as you face

the machine).

3. Insert or remove the chipout adjusting shims at the top of the routing carriage as necessary.

4. Loosen the handle at the base of the routing carriage (below orange pancake cylinders).

5. Turn the round knob just above the handle you have just loosened to adjust the stroke of the

cylinders (Cylinder Centerline Adjustment Knob)

6. Re-tighten the handle above the cylinder centerline adjustment knob

7. Turn on electrical power and air supply.

High Frequency Router Depth Adjustment:

The High Frequency Router has special adjustments based on a turrets and 2 set collars. Loosen the 2 set

collars and rotate the turret to the desired bolt for the proper depth that you want to rout the hinge pocket

at. See the following pictures.

Turret Bolts for the Hinge

Depth

Set Collars for Depth

adjustments.

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

38

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

39

SETTING UP THE BACK SECTION:

Commander Lock Section:

Lock Section Location:

LEFT and Right (Standard) before moving the lock section, it must be unclamped. The lock section,

positioned with an air operated clamp attachment, squeezes the upper bearing shaft on the right hand

side of the lock carriage. This clamp releases by flipping the toggle valve marked “Clamp” on the

handle bar to the “OFF” position. If the machine clamps the door and you want to move the lock

section for a second lock: flip the “index” toggle valve to the “OFF” pos ition also. This will release the

self centering chip out clamp as well as the edge clamping, while maintaining the claming on the front

side of the machine. The indicator on top of the lock section reads the distance from the fixed in-feed