Innovation, Quality & Honesty

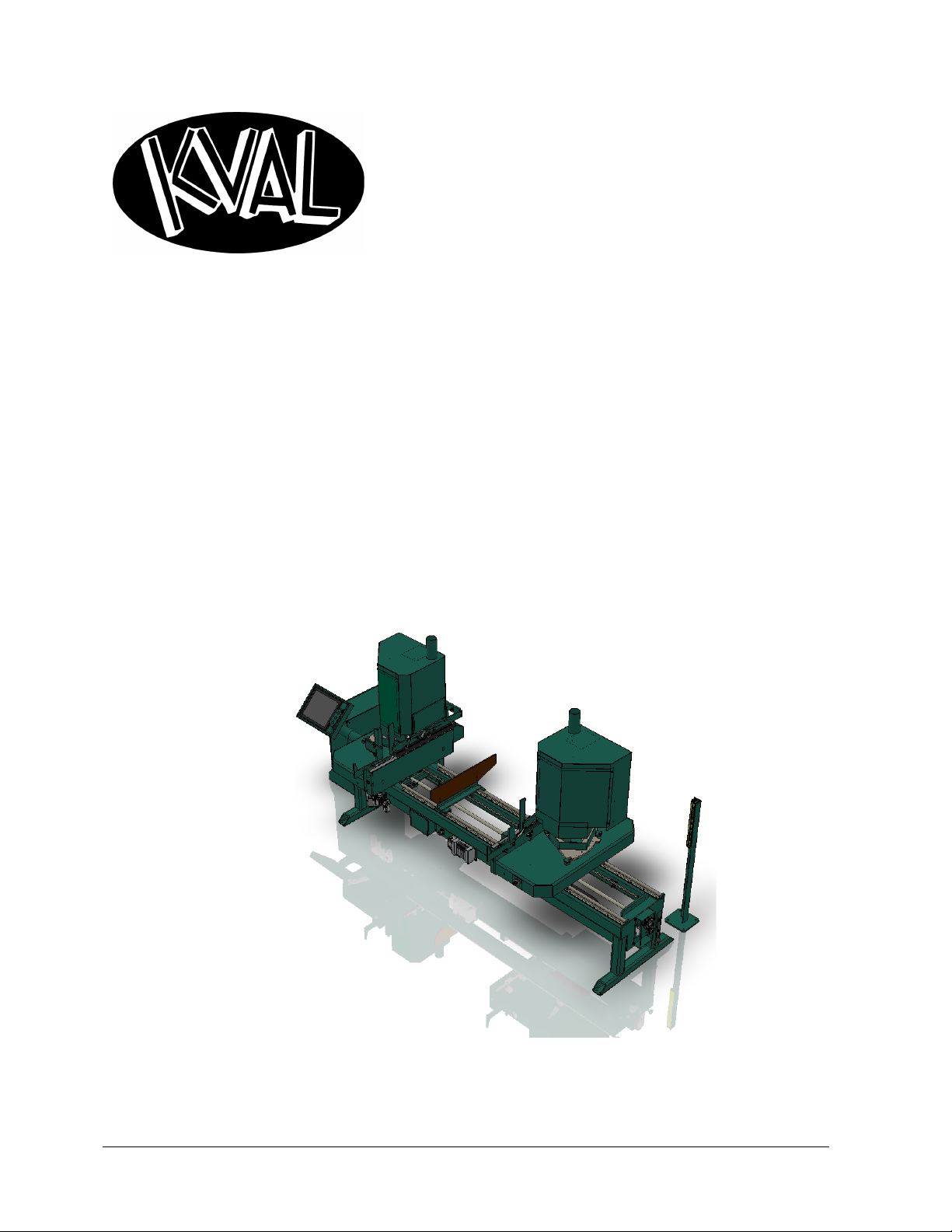

979-2 Miter Trim Saw System

Operation and Service Manual

Published 5/24/2019

979-2 Miter Trim Saw System

Proprietary Notice

This Manual is confidential and contains proprietary information and intellectual

property of KVAL Inc., and is to be used solely by Customer as an operating manual

for KVAL Inc. machines. Neither this Manual nor any of the information contained

herein may be reproduced or disclosed under any circumstances without the express

written permission of KVAL Inc. For authorization to copy this information, please

call Kval Customer Support at (800) 553-5825 or fax (707) 762-0485. Outside the

U.S. and Canada, call (707) 762-7367.

Manual Part Number: DOC-146_3-OPS

The 979-2 Miter Trim Saw System is a trademark of Kval Incorporated.

Copyright 2006 Kval Incorporated. All rights reserved.

Beckhoff® , TwinCAT 2® , and EtherCat® are registered trademarks and are licensed

by Beckhoff Automation GmbH

Windows 7® is a registered trademark of Microsoft Corporation .

All other products are trademarks or registered trademarks of their respective holders,

all rights reserved. Reference to these products is not intended to imply affiliation with

or sponsorship of Kval Incorporated.

Contacting KVAL

Customer Service: For further information about this manual or other Kval Incorporated products, contact the Customer Support Department

• Mailing address:

Customer Support Department

Kval Incorporated

825 Petaluma Boulevard South

Petaluma, CA 94952

• Phone and Fax:

In the U.S and Canada, call (800) 553-5825 or fax (707) 762-0485

Outside the U.S. and Canada, call (707) 762-7367 or fax (707) 762-0485

• Business hours:

Technical Support:

6:00 AM to 4:00 PM Pacific Standard Time, Monday through Thursday

6:30 AM to 1:30 PM Pacific Standard Time, Friday

Parts & Service Sales:

6:30 AM to 4:00 PM Pacific Standard Time, Monday through Thursday

6:30 AM to 1:30 PM Pacific Standard Time, Friday

(Other sales related inquiries: http://www.kvalinc.com)

• Email: service@kvalinc.com

KVAL 979-2 Operation/Service Manual

KVAL 979-2 Operation/Service Manual

http://www.kvalinc.com

Your Feedback is Welcome: To help us design products that make your job easier

and your business more successful, we'd like to gain your perspective about your user

experience with our product - that is, the manual, the machinery, the software, etc.

What was easy or difficult to use or to learn? If you could change something about the

design, what would it be? Please email your comments and suggestions for improvement to userexperience@kvalinc.com. (NOTE: This is not a customer support email

link. For that, please refer to the Customer Service contact information above.) Thank

you!

KVAL 979-2 Operation/Service Manual

KVAL 979-2 Operation/Service Manual

Table Of Contents

Chapter 1 Introduction to the 979-2 Miter Trim Saw System

Chapter 1 at a Glance.............................................................. 1-1

Overview of the 979-2 Miter Trim Saw System........................ 1-2

About this Manual .................................................................................1-3

Safety First!.............................................................................. 1-4

Safety Sheet Sign-Off Sheet.................................................................1-4

Safety Terminology of Labels................................................................1-4

Safety Guidelines..................................................................................1-4

Lockout-Tagout Guidelines ...................................................... 1-8

Follow the P-R-O-P-E-R lockout rule of thumb.....................................1-8

Lockout Tagout Procedure....................................................... 1-9

Pre-Steps Before Lockout Tagout .........................................................1-9

Lockout Tagout Power ..........................................................................1-9

Lockout Tagout Air Supply ..................................................................1-10

Start Maintenance...............................................................................1-10

Post Maintenance Steps .....................................................................1-10

Zero-Energy to Start-Up........................................................... 1-11

Getting Help from KVAL........................................................... 1-13

On-Line Help.......................................................................................1-13

Product Return Procedure ..................................................................1-13

Safety Sign-Off Sheet .............................................................. 1-16

A Note to the Operator........................................................................1-16

Chapter 2 Operation of the 979-2

Operator’s Tour ........................................................................ 2-2

In-Feed Section ....................................................................................2-3

Foot Pedal ............................................................................................2-3

Operators Station..................................................................................2-4

Operators Station (Small Platform Screen)...........................................2-4

The Starts Saws Button ........................................................................2-5

Out-Feed...............................................................................................2-5

About the Electrical Panels...................................................... 2-6

Main Electrical Panel with VPN ............................................................2-6

Main Electrical Panel (Before VPN)......................................................2-7

About Using the VPN............................................................... 2-8

About the Safety Curtain.......................................................... 2-9

Description of the Six Light Panel ........................................... 2-10

KVAL 979-2 Operation / Service Manual

About Sensors ....................................................................................2-11

Quick Start ............................................................................... 2-12

Powering Operations for the 979-2.......................................... 2-14

How to Power Up the 979-2................................................................2-14

Home the 979-2..................................................................................2-15

How to Power Down the 979-2 ...........................................................2-16

Emergency Shutdown and Recovery .................................................2-16

About Modes.......................................................................................2-17

Mechanical Set Up................................................................... 2-18

Description of User Interface Screens ..................................... 2-20

Screen Selection Menu Map...............................................................2-20

Screen Selection Menu Map (Small Platform Screen) .......................2-21

Machine Feed Back ............................................................................2-22

About Lock-Outs (Option) ...................................................................2-22

Main Screen........................................................................................2-23

About the Software Start Saws Button (Older Machines) ...................2-23

About the Setup Screens......................................................... 2-26

About Calibration Data........................................................................2-26

Running a Reference Cut ...................................................................2-26

About Motion of Servo Motor ..............................................................2-26

Entering Calibration Data....................................................................2-27

About the Machine Calibration Screen ...............................................2-28

About Assigning a Pre-set ..................................................................2-30

About Manual Operation and Chipout Routine ........................ 2-31

Diagnostic Screen.................................................................... 2-33

Chapter 3

System IT Administration

System IT Administration......................................................... 3-2

About the 979-2 Computer ...................................................................3-2

Connections on the PLC.......................................................................3-2

Backing up the Computer .....................................................................3-3

Chapter 4 Maintenance of the 979-2

Maintenance Schedule ............................................................ 4-2

Maintenance NO-GOES .......................................................... 4-4

Lubrication Schedule ............................................................... 4-5

Typical Lucubration Kit..........................................................................4-5

979-2 Miter Trim Saw System

Lubrication Requirements........................................................ 4-6

Pillow Block Bearing Housings .............................................................4-6

Flange Bearing Housings .....................................................................4-7

Ball Rail Bearing ...................................................................................4-7

About Taper Bearings ...........................................................................4-8

Tapered Bearing Housings ...................................................................4-8

Ball Screw Nut ......................................................................................4-9

Ball Screw Drive Assembly...................................................................4-9

Pulley and Idler Shafts........................................................................4-10

Lubrication Points on the 979-2 ............................................... 4-11

Lubrication Points Heads...................................................................4-12

Replacing the Chipout Block.................................................... 4-13

Replacing Saw Blades............................................................. 4-14

Remove the Saw ................................................................................4-14

Description of Air Input System ............................................... 4-16

Air Input with Lubrication ...................................................................4-16

Air Line Without Lubricator .................................................................4-17

Mechanical Adjustments.......................................................... 4-18

979-2 Guard Placements and Purpose ..............................................4-18

Feed Dog Adjustment Procedure ......................................................4-20

Chapter 5 Troubleshooting the 979-2

About Motion Control ............................................................... 5-2

Basic Control Circuit .............................................................................5-2

Typical Positioning Systems .................................................................5-4

Troubleshooting Basics .......................................................... 5-7

Using Sensors to Trouble Shoot...........................................................5-7

Location of Sensors on 979-2.................................................. 5-8

Troubleshooting Electrical Problems ....................................... 5-9

If the Power Stops During Normal Operation........................................5-9

Troubleshooting with the Status Light Panel ......................................5-10

About VFD Troubleshooting ...............................................................5-15

Troubleshooting the Air Cylinders............................................ 5-16

Adjusting Cylinder Extension Speed:..................................................5-17

Adjusting Cylinder Retraction Speed: .................................................5-17

Adjusting Limit Switches.......................................................... 5-18

KVAL 979-2 Operation / Service Manual

979-2 Miter Trim Saw System

CHAPTER 1 Introduction to the 979-2 Miter Trim Saw

System

This chapter provides an overview of the KVAL 979-2 Miter Trim Saw System and important

safety information to follow when operating the machine.

Chapter 1 at a Glance

Chapter 1 at a Glance ....................................................................................... 1-1

Overview of the 979-2 Miter Trim Saw System .............................................. 1-2

About this Manual ..................................................................................... 1-3

Safety First! ...................................................................................................... 1-4

Safety Sheet Sign-Off Sheet ...................................................................... 1-4

Safety Terminology of Labels .................................................................... 1-4

Safety Guidelines ....................................................................................... 1-4

Lockout Tagout Procedure ......................................................................... 1-8

Follow the P-R-O-P-E-R lockout rule of thumb. ..................................... 1-10

Zero-Energy to Start-Up ................................................................................ 1-11

Zero-Energy State to Start-Up to Operating State ................................... 1-11

Getting Help from KVAL .............................................................................. 1-13

On-Line Help ........................................................................................... 1-13

Product Return Procedure ........................................................................ 1-13

Safety Sign-Off Sheet .................................................................................... 1-16

A Note to the Operator: ........................................................................... 1-16

1-1

Overview of the 979-2 Miter Trim Saw System

Overview of the 979-2 Miter Trim Saw System

KVAL model 979-2 Miter Trim Saw is designed to cut casing for doors and windows at rates up

to 25 pieces per minute for softwood material. Saws pivot between either 0- or 45-degree positions. The CNC index system will automatically compensate for cut length by adjusting the distance between saws.

The 979-2 saw heads cut down from above the face of the casing to eliminate any tear out on the

face.

There is also a chip-out support below the saw to prevent any deflection in thin casing as the saw

passes through it. This is especially important when cutting MDF casing, or pre-finished casing.

This design allows the scraps to drop below the machine into waste bins (Not included) without

assistance from compressed air nozzles. The air consumption of the 979-2 operating at maximum

capacity is only 8 CFM.

The 979-2 will miter side casing, with a 90 degree trim on the bottom, up to 98” long on the short

side of the miter. Head casing, mitered on both ends, can be cut as short as 12-3/8” measured on

the short side.

The feed hopper may be easily adjusted to accommodate material up to 4-1/2” wide and up to 1-1/

4” thick. The pieces of casing are fed from the hopper by a reciprocating dog system. The feed

dog systems on each carriage are tied together with a timing shaft to insure that each piece of casing is precisely positioned under the saws every time. Each cutting head is equipped with a 3 HP,

3450 RPM, TEFC, three phase motor. The saw motors have 1” diameter arbors.

Types of options available Are:

Option A: Spline Saw System

Cuts slots for kerf nail in head and leg casing miter.

Option B: Mitered ends on Door stop

Is capable of cutting mitered ends on door stop.

The Option G: Auto Calibrated Stops

Is an air operated system with calibrated stops that automatically adjust the movable carriage

when the saw heads are rotated.

Option Z: Computer Controlled Positioning

The 979-2 will be equipped with a computer driven servo motor to position the movable head.

The system will automatically compensate for the offsets when the cutting heads are switched

from 90 degrees to 45 degrees. The system will be controlled by a touch screen that will allow the

operator to simply enter the short side length of casing to cut. The finished length of the casing

will be correct for all saw head configurations.

1-2

KVAL 979-2 Operation/Service Manual

Overview of the 979-2 Miter Trim Saw System

About this Manual

This manual contains operation information and service and maintenance information.

It includes identification of machine assemblies, power-up and power-down steps, and information about using the user interface.

The Troubleshooting and Maintenance sections are directed toward qualified service

technicians

TABLE 1- 1.

Title Part Number

979-2 Operation and Service Manual

DOC-146_3-OPS

1-3

KVAL 979-2 Operation/Service Manual

Safety First!

This machine is a powerful electro-mechanical motion control

system. You should test your motion system for safety under

all potential conditions. Failure to do so can result in dam-

age to equipment and/or serious injury to personnel.

Ensure that all employees who operate this machine

are aware of and adhere to all safety precautions

posted on the machine and are trained to operate this

machine in a safe manner.

Training

Safety First!

Safety Sheet Sign-Off Sheet

At the end of this chapter, there is a safety sign-off sheet. It lists personnel and machine safety criteria to understand before operating the machine. It is highly recommended that personnel operating, working on a machine meet the criteria listed in this sheet. It is recommended the sheet be

signed and kept for records. See “Safety Sign-Off Sheet” on page 1-16.

Safety Terminology of Labels

In addition to the nameplate, KVAL machines may have other warning labels or decals that provide safety information to operators. Safety labels should be clearly visible to the operator and

must be replaced if missing, damaged, or illegible.

There are three types of warning labels or decals:

• DANGER means if the danger is not avoided, it will cause death or serious injury.

• WARNING means if the warning is not heeded, it can cause death or serious

injury.

• CAUTION means if the precaution is not taken, it may cause minor or moderate

injury.

Safety Guidelines

In addition to the caution and warning labels affixed to this machine, follow the guidelines below

to help ensure the safety of equipment and personnel.

KVAL 979-2 Operation/Service Manual

1-4

Safety First!

Never operate the machine without proper eye and

ear protection.

Protective Gear

• Never reach hands beyond safety cage. Servo

motors can unexpectedly move quickly.

• Never clear screws or hinges out of the machine

while it is running.

• Never reach into the router area to retrieve a

hinge. The router may still be running down

after shut down.

• Never perform any maintenance unless machine

is at zero state.

• Never clean the machine while it is running.

• Never walk away from the machine while it is

running.

When the Machine is ON

The compressed air system connected to this

machine should have a three-way air valve

for shut-off and pressure relief.

All cylinders on machine are under high

pressure and can be very dangerous when

activated. Before performing any maintenance or repairs on this machine turn off the

main air disconnect. Lockout and tagout

this connection.

See “Lockout Tagout Procedure” on

page 1-9.

Compressed Air

1-5

KVAL 979-2 Operation/Service Manual

Safety First!

Electrical circuitry on this

machine is protected by an

approved lockable disconnect

circuit. In addition to this equipment, you must install an

approved disconnect for the

electrical power supplying this

machine.

When opening the cabinet you must first turn off the

disconnect switch. When the cabinet door is open there

is still power on the top side of the disconnect switch.

Some machines are powered by more than one supply

located at different locations. Before performing any repairs or maintenance, lockout and tagout must be installed at all locations

All maintenance and repairs to electrical circuitry should only be performed by a qualified electrician.

Still has power

in OFF position

Electrical

Prior to performing any maintenance, repairs,

cleaning or when clearing jammed debris, you

must disconnect, tag out, or lock out the electrical

and air pressure systems. This should be done in

accordance with applicable state and/or federal

code requirements.

Before Conducting Maintenance

Laser Warnings

On some machines, laser indicators are used to set boundaries. Follow the

manufacturers safety precautions.

1-6

KVAL 979-2 Operation/Service Manual

Safety First!

KVAL advises that you request an on-site state

safety review of your installation of this

machine. This is to ensure conformance to any

additional specific safety and health regulations which apply in your geographic area.

Compliance with Codes and Regulations

Other Hazard Control Action

Report a Hazard

Before You Report an Accident

If you believe any part or operation of this machine is in

violation of any health or safety regulation, STOP production. It is your responsibility to immediately protect

your employees against any such hazard.

Additional detailed safety guidelines are included in the

operating instructions of this manual. KVAL will be

pleased to review with you any questions you may have

regarding the safe operation of this machine

Follow Your Company’s Safety Procedures

In addition to these safety guidelines. Your company

should have on-site and machine specific safety procedures to follow.

KVAL 979-2 Operation/Service Manual

1-7

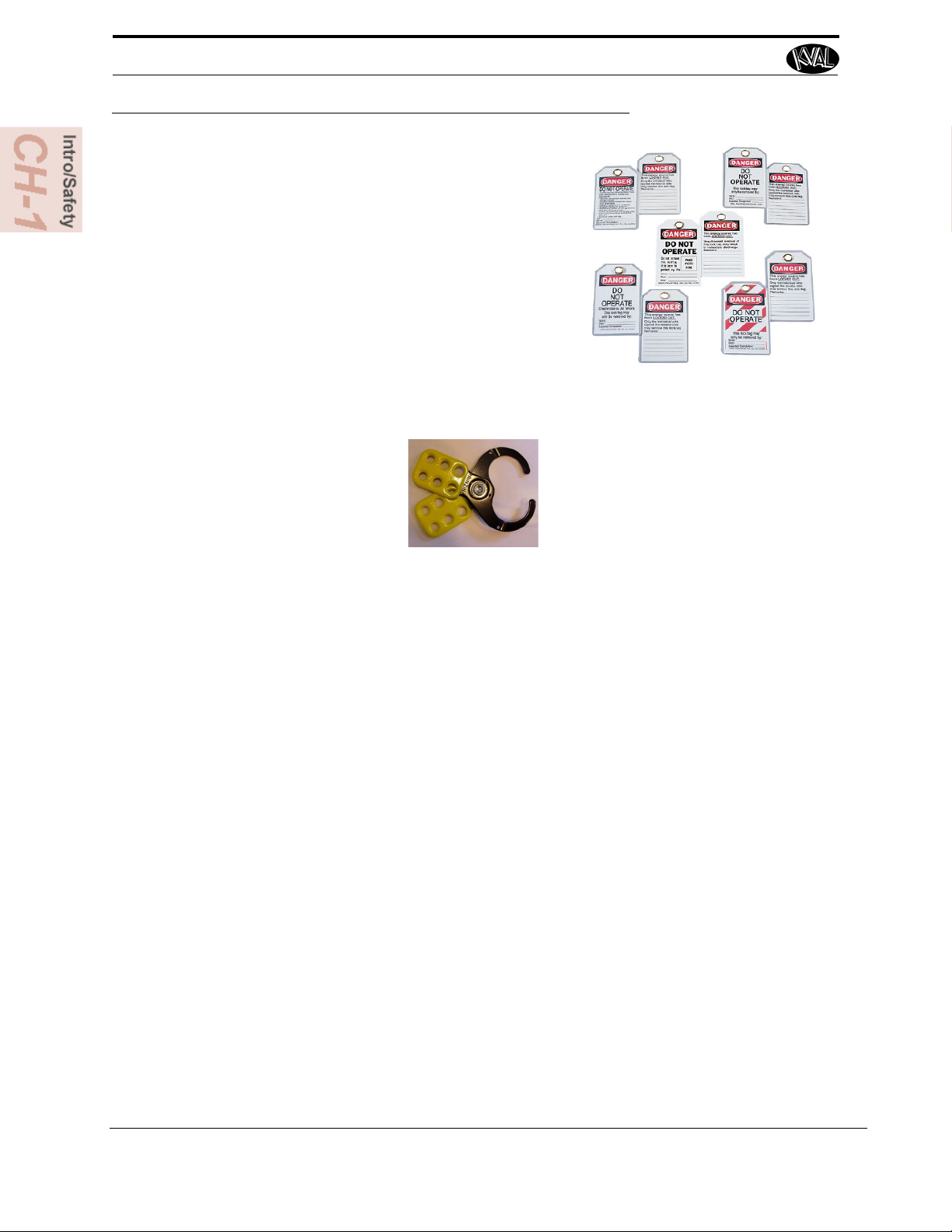

Lockout-Tagout Guidelines

Lockout-Tagout Guidelines

• Place a tag on all padlocks. On a tag, each

operator must put their own name and date.

(These locks are only to be removed by the

person who signs the tag)

• If more than one person is working on the

machine, then each additional person places a

lock and tag on each disconnect.

• Only each operator may remove their own

lock and tag.

Important: When many people are all working

on the same machine you will need a multiple

lockout device, such as the one shown here.

Follow the P-R-O-P-E-R lockout rule of thumb.

P...... Process shutdown

R ...... Recognize energy type (electrical, pneumatic, mechanical, etc.)

O...... OFF! Shut off all power sources and isolating devices

P...... Place lock and tag

E...... ENERGY: Release stored energy to a zero-energy state

R ...... Recheck controls and test to ensure they are in the “OFF” state

1-8

KVAL 979-2 Operation/Service Manual

Lockout Tagout Procedure

1. Evaluate the equipment to fully understand all energy sources (multiple electrical

supplies, air supply and pressure, spring tension, weight shifts, etc.).

2. Inform all affected personnel of the eminent shutdown, and the duration of the

shutdown.

3. Obtain locks, keys, and tags from your employer’s lockout center.

4. Turn off machine. See Chapter 2 for power down and power up procedures.

5. Turn the disconnect switches on ALL electrical and frequency panels to the OFF

position. Then push the red tab to pop it out. Place a padlock through the hole.

Place your tag on the padlock, as per the tagout guidelines below. (see illustration

below).

Power

Note: When multiple people are working on the machine, each person needs to

have a lock on the handle in the extra holes provided.

Insert Lock into hole.

Turn Switch to the

OFF position

Lock and Tag out

This policy is required by OSHA regulation 1910.147 and Cal OSHA’ S

SB198 ruling of July 1991.

Use the following lockout procedure to secure this machine while it is

powered down. During a lockout, you disconnect all power and shut

off the air supply. Be sure to use the tagout guidelines noted below.

Pre-Steps Before Lockout Tagout

Lockout Tagout Procedure

Lockout Tagout Power

1-9

KVAL 979-2 Operation/Service Manual

Lockout Tagout Procedure

6. Turn all air valves to the OFF position and place a pad-

lock through the hole (see illustration below).

NOTE: Place your tag on the padlock, as per the

tagout guidelines.

Lockout Tagout Air Supply

Start Maintenance

7. Once the locks and tags are in place and all personnel are clear, attempt to operate

the machine to ensure equipment will not operate.

8. Maintenance or repairs may started.

Post Maintenance Steps

9. After maintenance is completed, the person performing the work must ensure all

tools, spare parts, test equipment, etc., are completely removed and that all guards

and safety devices are installed.

10. Before removing the locks and tags, the person who attached them shall inspect the

equipment to ensure that the machine will not be put in an unsafe condition when

re-energized.

11. The lock and tag can now be removed (only by the person(s) who placed them),

and the machine can be re-energized.

12. The tags must be destroyed and the locks and keys returned to the lockout center.

1-10

KVAL 979-2 Operation/Service Manual

Zero-Energy to Start-Up

Zero-Energy to Start-Up

Starting the equipment properly is just as important as the lockout/tagout guidelines in terms of

safety.

Start-up Guidelines

The following guidelines below should be followed to start the equipment.

Inspect

The equipment must be inspected for proper adjustment before starting equipment.

Clean Up

All materials and debris must be cleaned up. Any combustible materials or old parts

used during repairs must be cleaned up and/or properly disposed of.

Replace Guards

Replace all equipment guards. If part of equipment cannot be properly adjusted after

start-up with guard on, contact the KVAL Service team. See “Getting Help from

KVAL” on page 1-13.

Check Controls

Confirm that all switches are in the “OFF” position. Please be advised that some components of the machine may start automatically when energy is restored.

Remove Locks

Each operator must remove his or her own lock and tag. This will ensure that all operators are in a safe place when the equipment is started.

Perform Visual Checks

If the equipment is too large to see all around it, station personnel around the area and

sound the personnel alarm before starting the equipment. If your operation is more

complex, your company’s comprehensive safety procedure may involve additional

steps. You will need to ask your supervisor about these procedures. The company’s

lockout procedure should be posted at each machine. On larger or long-term maintenance or installation projects, the company’s procedures must be explained to all new

operators and a copy of the company’s procedures should be posted on-site for the

duration of the work.

The Company’s procedures should also include provisions for safely handling shift

changes and changes in operators or new operators.Comprehensive lockout/tagout

may use a gang box or other system to ensure that locks are secure and not removed

without authorization.

1-11

KVAL 979-2 Operation/Service Manual

Zero-Energy to Start-Up

Remember, lockout/tagout procedures work because you are the only one with the key

to your lock. Proper lockout/tagout can save lives, limbs, and money. Help make your

work environment safe for you and your fellow workers. Be sure to follow the P-R-OP-E-R lockout/tagout procedures, and that those around you do also.

Close the Cage Gate

Verify all cage gates are securely closed. Ensure all safety protocols are in effect.

1-12

KVAL 979-2 Operation/Service Manual

Getting Help from KVAL

Serial Number

3 phase volts

Electrical Print

Air Print

Getting Help from KVAL

Before you seek help, first try the troubleshooting procedures. Follow the procedures below.

If you are unable to resolve the problem:

1. Locate the machine’s Specification Plate and record the serial number, 3 phase

volts, electrical print number, and air print number.

2. Contact our customer support team:

• In the U.S and Canada, call (800) 553-5825 or fax (707) 762-0485

• Outside the U.S. and Canada, call (707) 762-7367 or fax (707) 762-0485

• Email address is service@kvalinc.com

• Hours:

6:00 AM to 4:00 PM Pacific Standard Time, Monday through Thursday

6:30 AM to 1:30 PM Pacific Standard Time, Friday

On-Line Help

On machines with a Beckhoff® PLC and an internet connection, our service team are able to connect, run, and troubleshoot your machine. Ask about this procedure when calling are service team

Product Return Procedure

If you’ve contacted Kval for help and it is determined that a return is necessary, use the procedure

below to return the machine or part.

Note: Non-Warranty returns are subject to a 15% restocking charge.

Obtain the packing slip and/or invoice numbers of the defective unit, and secure a

1.

purchase order number to cover repair costs in the event the unit is determined to be

out of warranty.

2. Reason for return: Before you return the unit, have someone from your organization

with a technical understanding of the machine and its application include answers to

the following questions:

1-13

KVAL 979-2 Operation/Service Manual

Getting Help from KVAL

• What is the extent of the failure/reason for return? What are the relevant error messages or error codes?

• How long did it operate?

• Did any other items fail at the same time?

• What was happening when the unit failed (e.g., installing the unit, cycling power,

starting other equipment, etc.)?

• How was the product configured (in detail)?

• Which, if any, cables were modified and how?

• With what equipment is the unit interfaced?

• What was the application?

• What was the system environment (temperature, spacing, contaminants, etc.)?

3. Call Kval customer support for a Return Material Authorization (RMA). When you

call:

• Have the packing slip or invoice numbers available.

• Have the documented reason for return available.

4. Send the merchandise back to Kval.

• Make sure the item(s) you are returning are securely packaged and well protected

from shipping damage

• Include the packing slip or invoice numbers.

• Include the documented reason for return.

• Include the RMA number with the parts package.

1-14

KVAL 979-2 Operation/Service Manual

Getting Help from KVAL

Page Intentionally Left Blank

1-15

KVAL 979-2 Operation/Service Manual

Safety Sign-Off Sheet

Safety Sign-Off Sheet

Machine Model Number:_____________________________

A Note to the Operator

This machine can help you be highly productive only if you understand how to use it properly and

follow the safe operating practices described in this document and the machine’s manual. If you

do not understand the machine’s proper operation or ignore the safe operating practices, this

machine can hurt or kill you. It’s in your best interest to safely and properly operate this machine.

Personnel Safety Concerns:

• I have been properly trained in the operation of this machine.

• I will always wear ear protection when operating this machine.

• I will always wear eye protection when operating this machine.

• I will never wear loose clothing or gloves when operating this machine.

• I will watch out for other people. Make sure everyone is clear of this machine

before operation.

• I will always follow my company’s safety procedures. I have read and understand

these guidelines.

Machine Safety Concerns:

• I have been given a tour of the machine and understand all the safety labels, E-

Stops and the actions to take in case of an emergency.

• I will make sure all guards are in place before operation

• I will turn off the compressed air, before loading hardware (staples, screws, etc)

• I will turn off the electrical power, for setup

• If the machine should operate in an unexpected manner stop production I will

immediately and notify a manager, a supervisor, or a qualified service technician.

I have read and understand this document and agree to operate this machine in a safe manner as described above.

Employee

Name (print):___________________ Signature: __________________ Date:____/____/____

Supervisor/Safety Officer/Trainer

Name (print):__________________Signature: __________________ Date:____/____/___

Note: It is recommended you make a copy of this sheet for new operators. If a copy is needed, you may

download a PDF at the KVAL website (http://www.kvalinc.com). You may also contact our Service Department at (800) 553-5825 or email at service@kvalinc.com.

1-16

KVAL 979-2 Operation/Service Manual

Safety Sign-Off Sheet

1-17

KVAL 979-2 Operation/Service Manual

CHAPTER 2 Operation of the 979-2

This chapter describes components, assemblies, and the user interface of the KVAL 979-2 Miter

Trim Saw System. The content is geared to help operators understand the basic operation of the

979-2.

Chapter 2 at a Glance

Operator’s Tour ............................................................................................... 2-2

In-Feed Section .......................................................................................... 2-3

Foot Pedal .................................................................................................. 2-3

Operators Station ....................................................................................... 2-4

Operators Station (Small Platform Screen) ................................................ 2-4

Out-Feed .................................................................................................... 2-5

About the Electrical Panels ........................................................................ 2-6

About the Safety Curtain ........................................................................... 2-7

Description of the Six Light Panel ............................................................ 2-8

About Sensors ............................................................................................ 2-9

Quick Start ..................................................................................................... 2-10

Powering Operations for the 979-2 ................................................................ 2-12

How to Power Up the 979-2 .................................................................... 2-12

Home the 979-2 ....................................................................................... 2-13

How to Power Down the 979-2 ............................................................... 2-14

Emergency Shutdown and Recovery ....................................................... 2-14

About Modes ............................................................................................ 2-15

Mechanical Set Up ......................................................................................... 2-16

Description of User Interface Screens ........................................................... 2-18

Screen Selection Menu Map .................................................................... 2-18

Screen Selection Menu Map (Small Platform Screen) ............................ 2-19

Machine Feed Back ................................................................................. 2-20

About Lock-Outs (Option) ....................................................................... 2-20

Main Screen ............................................................................................. 2-21

About the Setup Screens ................................................................................ 2-24

About Calibration Data ............................................................................ 2-24

Running a Reference Cut ......................................................................... 2-24

About Motion of Servo Motor ................................................................. 2-24

Entering Calibration Data ........................................................................ 2-25

About the Machine Calibration Screen .................................................... 2-26

About Assigning a Pre-set ....................................................................... 2-28

2-1

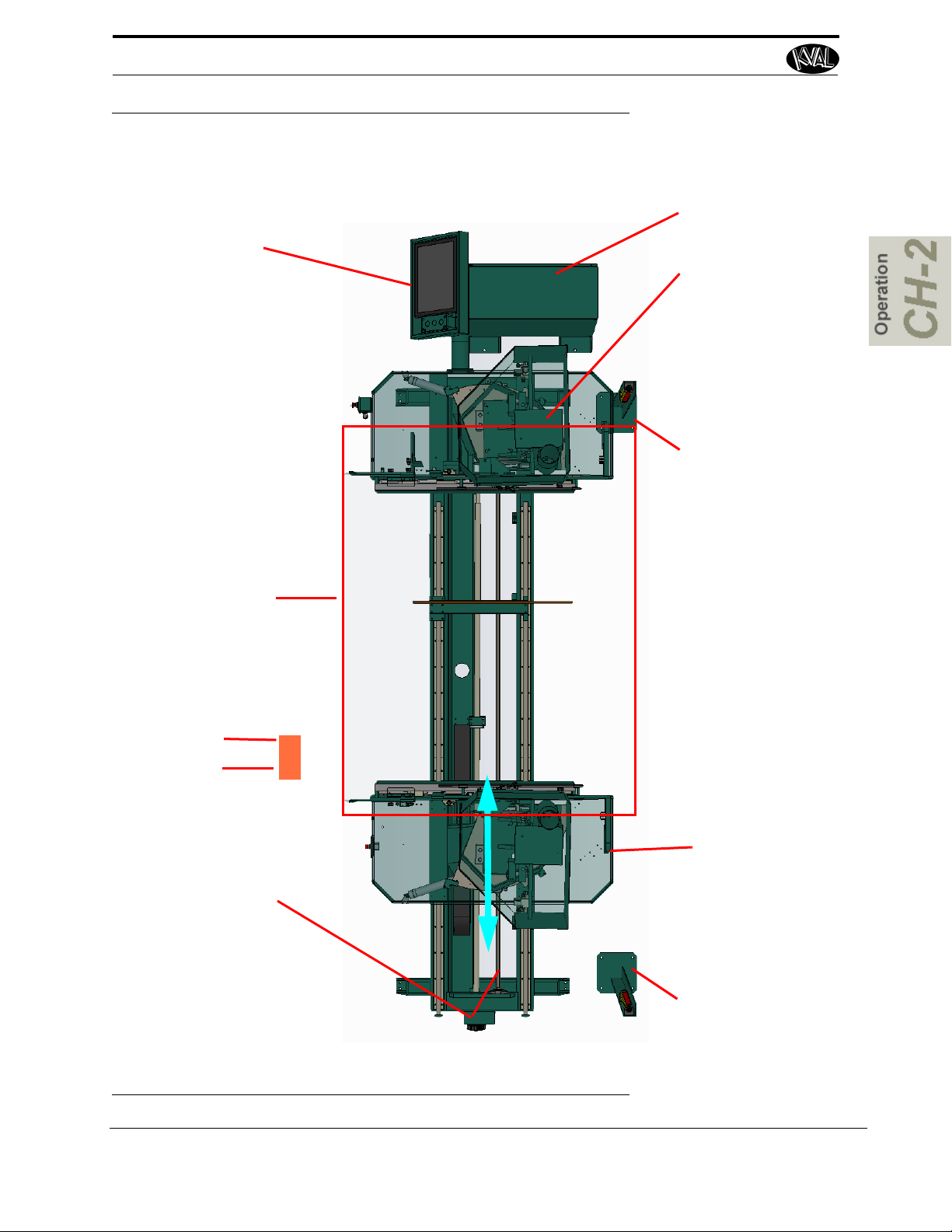

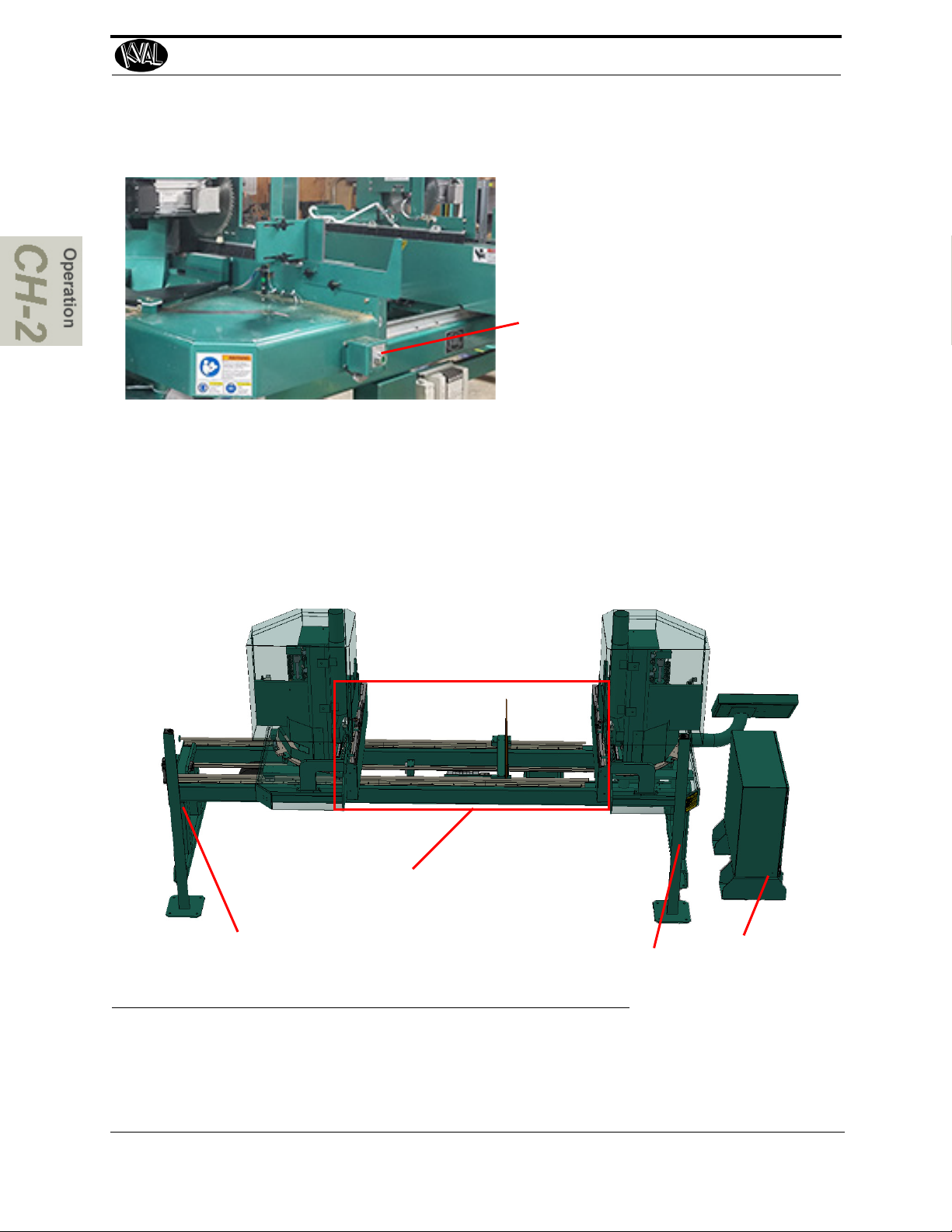

Operator’s Tour

In-Feed

Operator’s Station

Safety Curtain

Servo Motor and

Ball Screw

Out-Feed

Right or Movable

Head

Left or Fixed Head

Safety Curtain

Hopper, Staging

area, and Feed-In

Electrical Panel

Foot Pedal:

Stop

Feed

Operator’s Tour

This section takes you on a tour of the 979-2 Miter Trim Saw System machine.

FIGURE 2- 1. Identification of Key Assemblies of 979-2

2-2

KVAL 979-2 Operation/Service Manual

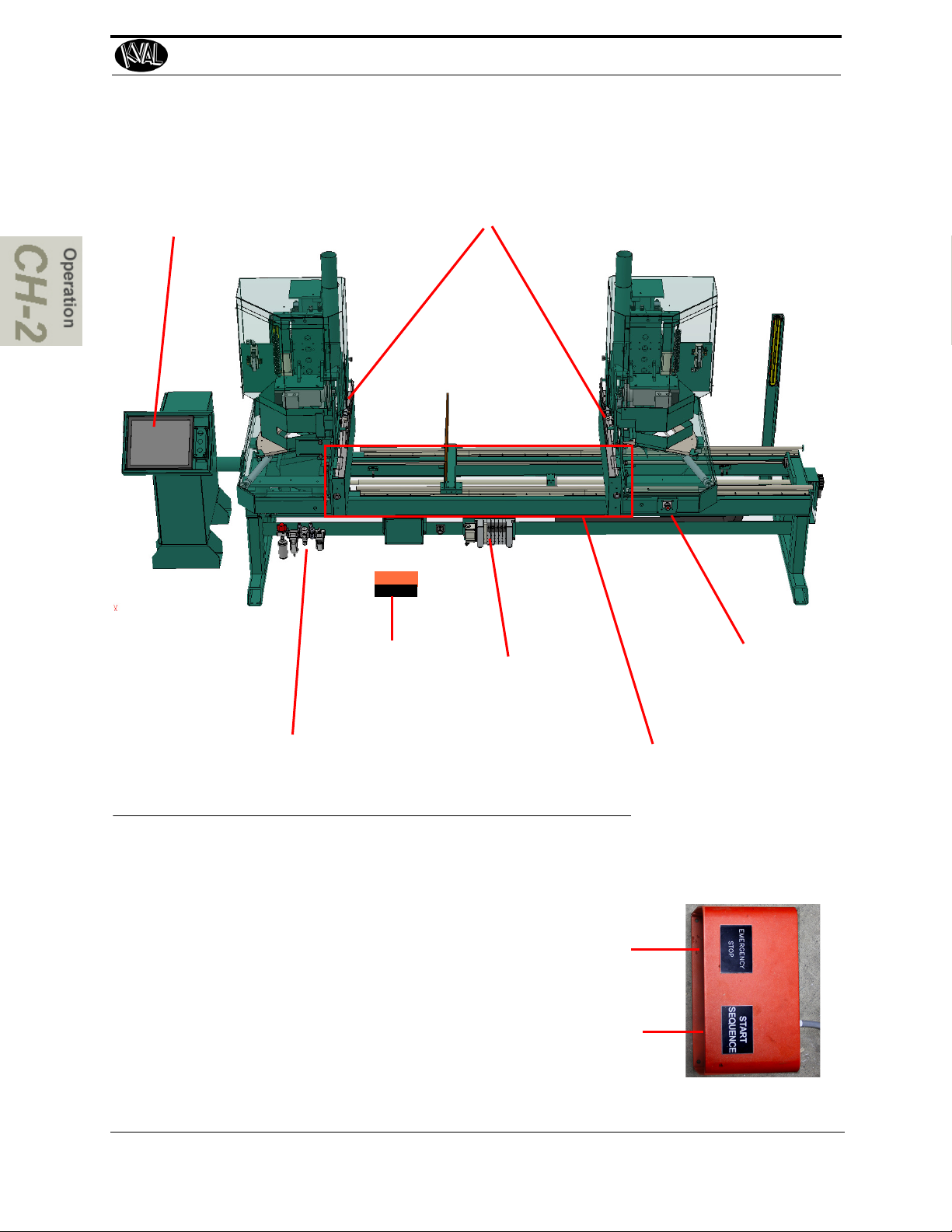

In-Feed Section

Dog Feed: Moves product

through machine

E-Stop:

Push to

shutdown machine

in an emergency.

Valve Bank: Air

Output to cylinders

Air Input System: Air Filter, PSI

Adjust, and lubricator

Operator Station

Hopper and Staging Area

Foot Pedal

The foot pedal controls the flow of the board through the

machine.

• Press the right pedals to feed the product

through the machine. If the hopper is stacked

the product will feed through automatically.(Or

the quantity set on the main screen)

• Press the left pedal to stop the machine. This

acts like an E-Stop.

E-Stop

Start

Sequence

Operator’s Tour

FIGURE 2- 2. Key Assemblies on the In-Feed Section

Foot Pedal

KVAL 979-2 Operation/Service Manual

2-3

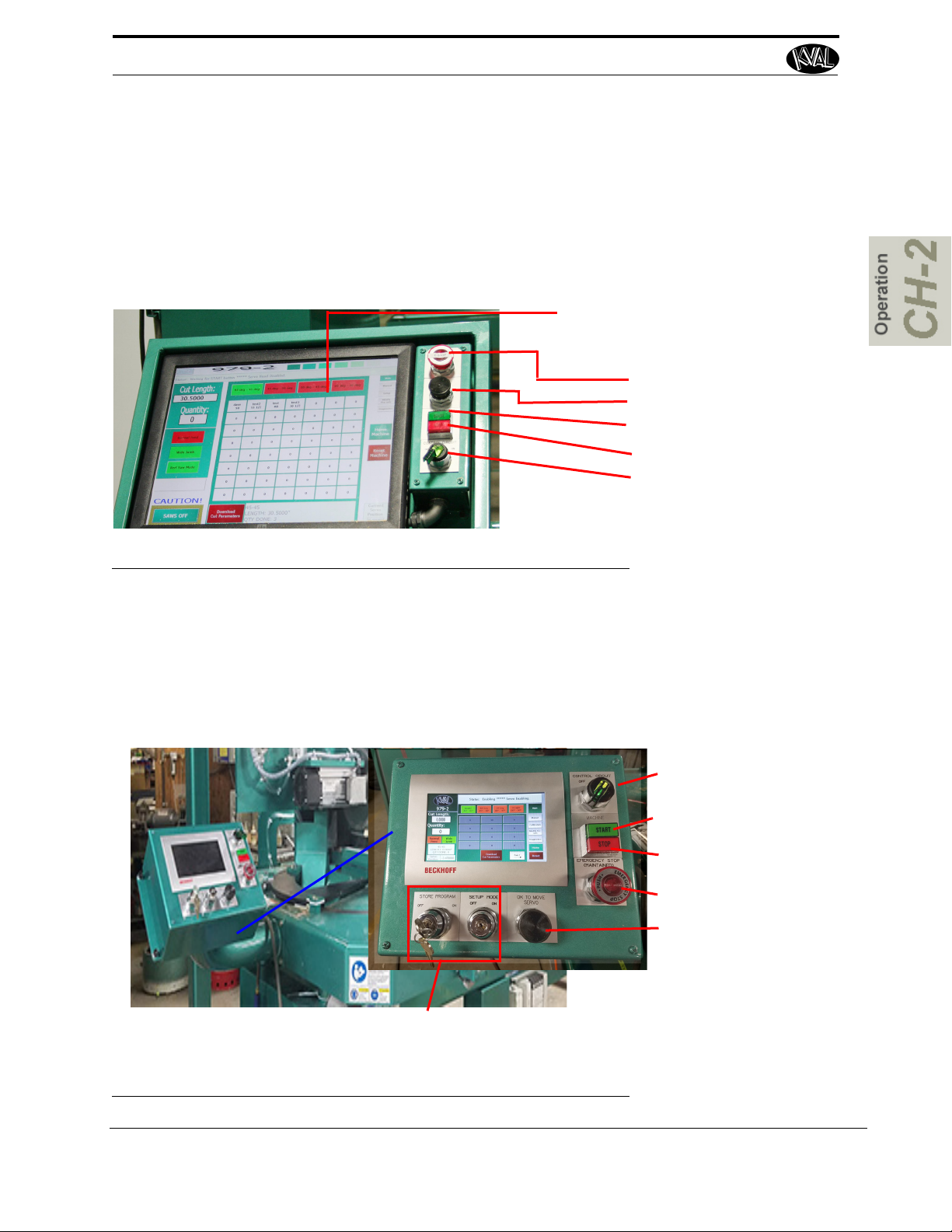

Operator’s Tour

Touch Screen Interface

Controls:

•

Emergency Stop

• Move Head

• Start “boot-up”

• Stop

• Turn ON or OFF Control

Transformer

Turn ON or OFF

Control Transformer

Start “boot-up”

Stop

Emergency Stop

OK to Move Head

Lock-Outs (See “About Lock-Outs

(Option)” on page 2-22.)

Operators Station

The Operator Station contains a touch screen that allows communication between the operator

and the machine. Through automation, the station interface replaces manual setup, thereby saving

time. Cutting parameters can be stored and retrieved by one touch.The Touch Screen logic also

includes management functions such as Daily and Lifetime Totals. See “Description of User

Interface Screens” on page 2-20 and“Quick Start” on page 2-12 for more information.

FIGURE 2- 3. Operators Station with touch Screen Interface

Operators Station (Small Platform Screen)

A reduced size screen has been added to the 979-2 (Start SN 17-146-061). The menu choices and

controls are similar but have changes in format. See “Screen Selection Menu Map (Small Plat-

form Screen)” on page 2-21.

FIGURE 2- 4. Reduced Size Screen

2-4

KVAL 979-2 Operation/Service Manual

Operator’s Tour

Safety Curtain

Safety Curtain

Out Feed Area: Fin-

ished Product is fed

out of the machine

Electrical

Panel

The Starts Saws Button

Out-Feed

The figure below shows the key parts of the out-feed of the machine. The finished product is fed

out for on the back side of the machine.

Danger: Never mechanically bypass the Safety Curtain or enter

the cutting area avoiding the Safety Curtain. Serious

injury could occur.

FIGURE 2- 5. Out-Feed Key Parts

2-5

KVAL 979-2 Operation/Service Manual

About the Electrical Panels

The Main Electrical Panel:

• Supplies voltages to the machine

• Contains the PLC (Programmable

Logic Controller)

• Contains servo drives to interact with

the servo motors (Axis and Lock Location) in the front and back sections

• VFDs (Variable Frequency Drives) to

interact with hinge and faceplate routers, width adjust motors, and feed

motors

• VPN Router added to connect with

factory intranet to internet KVAL Service (added Serial number 17-146-

061)

Note: Factory must have access to internet to use VPN.

Main Electrical Panel

PLC

110 V / 24 V Terminals

High Voltage

Section

Input / Output

Terminals

VFD Section

Servo Drive

Control Trans-

former

VPN

Thermal (Brake)

Resistor

About the Electrical Panels

Warning: High Voltage is present in this panel at the top of the Three Phase Input even with the

disconnect off. If working on the panel, follow the safety protocol as described in Chapter 1.

The 979-2 has a Main Electrical Panel. Figure 2- 7 below, is an overview of the location of assemblies in the panel

Main Electrical Panel with VPN

FIGURE 2- 6.

2-6

KVAL 979-2 Operation/Service Manual

About the Thermal (Brake) Resistor

The Thermal Resistors are 30 ohm resisters that

help the carriage stop quickly.

Main Electrical Panel

PLC

110 V / 24 V Terminals

High Voltage

Section

Input / Output

Terminals

VFD Section

Servo Drive

Control Trans-

former

Contactor

and Over-

load Circuit

Main Electrical Panel (Before VPN)

About the Electrical Panels

FIGURE 2- 7. Overview of Main Electrical Panel and High Frequency Panel

2-7

KVAL 979-2 Operation/Service Manual

About Using the VPN

To use the VPN:

1. Ensure your company has a connec-

tion to the Internet. Contact factory

IT technician.

2. Have issue organized to inform

KVAL technician.

3. Contact KVAL Service and notify

that you are using a VPN on a 979-2.

4. Tell the technician the issue.

5. When ready, push the VPN button

until the button lights up.

6. The technician can connect to the

machine and view the operation of

the program.

Call Kval Customer Support at (800) 553-5825. Outside the U.S, call (707) 762-

7367.

About Using the VPN

The VPN is an industrial remote access router that is designed to offer remote access, across the

Internet, to the 979-2.

KVAL technicians can troubleshoot machines, debug the PLC program while the operator runs

the machine. The VPN works in the background.

The factory must have access to the internet to use this feature.

2-8

KVAL 979-2 Operation/Service Manual

About the Safety Curtain

Emitter Receiver

Emitter

Receiver

Emitter

Receiver

Machine in operation

Breaking of any beam

stops the machine

Product Output:

Machine will stop if

barrier is broken.

Restart the machine to

continue

About the Safety Curtain

Danger: Never mechanically bypass the Safety Curtain or enter

the cutting area avoiding the Safety Curtain. Serious

injury could occur.

The Safety Curtain provides safety for personnel who enter the defined area when the machine is

active. If any part of an operator’s body is detected in the defined area, the machine stops the

operation.The machine must be reset from the operators station to continue machining.

The Safety Curtain is composed of an EZ-Screen emitter and receiver. The emitter has a row of

synchronized light-emitting diodes (LEDs) that send signals to the receiver. The receivers have a

a matching row of synchronized photo detectors that read the signal from the emitter. When the

signal is blocked of any beam, the machine stops. To continue machining push the Start button

Important: The EZ-Screen system is aligned at the factory. Do not move the emitter or

receiver modules. This may cause misalignment, if the system is misaligned the machine will not start

.

2-9

KVAL 979-2 Operation/Service Manual

Description of the Six Light Panel

Control Power – light

illuminates when the

Control Transformer

is pulled out and the

power is working on

secondary side-of

transformer

Overload Relay –

The overload circuit is

working when light is

on

E-Stop – The back

gate is closed and Frame E-stop is not activated when this light is on.

24VDC – light

comes on once the

ACR is latch and the

24VDC power Supply

is working

Stop – This light will

be on if Machine

Stop button is deac-

tivated.

Start – This light will

be on once the

Machine Start button

is pressed and the

ACR Relay is latched.

Description of the Six Light Panel

The six lights on this panel indicate the status of the 979-2 system.

The Sequence that the lights activate is as follows:

1. Control Power

2. Overload Relay

3. E-Stop

4. Stop

5. Start

6. 24VDC

2-10

KVAL 979-2 Operation/Service Manual

Description of the Six Light Panel

Photo Eye Detector

Emitter and Receiver

in one package

Proximity Detector

Senses metallic

objects

About Sensors

On the 979-2, sensors provide input to the PLC as part of the automation of the cutting process. It

is important to keep the sensors cleaned and aligned to keep the process running smoothly. There

are two classifications of sensors on the 979-2------Photo Electronic and Inductive Proximity Sensor.

The Photo Electronic Decor uses light as a trigger.

• Photo Eye Detectors contain both emitter and receiver. If an object is within the

Photo Eye’s sensing field light from the emitter is reflected from the object back to

the receiver. With no object is in front of the Photo Eye a constant 24VDC is sent to

the PLC. If an object is sensed by the Photo Eye, 0VDC is sent to the PLC.

• As a result, any of the photo detectors output equals 0VDC when the trim is sensed.

The Proximity Sensor detects metallic objects without touching them.

• An inductive proximity sensor consists of a coil and ferrite core arrangement, an

oscillator and detector circuit, and a solid-state output. The ferrite core and oscillator

create a field generating out the front of the sensor. When a metal object enters the

field, a loss in amplitude occurs. The detector circuit recognizes the loss of amplitude and generates 0VDC to send to the PLC. When the metal object leaves the sensing area, the sensor to returns to 24VDC and sends it to the PLC.

• As a result, if a metal object is sensed, the output of the sensor equals 0VDC.

Refer to Figure 2- 8 on page 11 for some examples of Sensors:

FIGURE 2- 8. Examples of Sensor

KVAL 979-2 Operation/Service Manual

2-11

Quick Start

1. Ensure factory air is present at the machine and the 979-2 main air

supply valve is turned on.

2. Power up the 979-2. See “How to Power Up the 979-2” on page 2-

14.

3. Home the 979-2. See “Home the 979-2” on page 2-15.

4. Set the machine up for the chosen parameters. See “Mechanical Set

Up” on page 2-18

5. Select the cut mode.

6. Select the desired preset button.

7. Select quantity of boards to cut. Enter the cut

length if different than the pre-set.

8. Select type of cut.

Note: KVAL strongly recommends using

the Wide Jamb selection on cuts.

This setting makes good cuts with

maximum efficiency.

9. Select the Load the Cut Parameters Button. The

parameters will be displayed in the box.

Preset Buttons

Quick Start

Note: Before starting production, it is recommended to perform a test cut on a board.

Follow the same steps in the Quick Start below. See “Running a Reference Cut” on

page 2-27

KVAL 979-2 Operation/Service Manual

2-12

10. Ensure area is safe. On the Operators station, push and hold

the black button to move the Heads into position.

11. Load the hopper.

12. Press the Start Saws Button to get the saws running

Note: Some machines may have a software button to activate the saws instead

of the mechanical button. If so, press and hold the Saws Off button until

the saws start. (Button displays Saws Active)

13. Start production by pressing the Start Sequence right

the foot pedal.

If finished with production and shutting the machine down, see “How to Power

Down the 979-2” on page 2-16 .

Quick Start

2-13

KVAL 979-2 Operation/Service Manual

Powering Operations for the 979-2

4. Switch the green CONTROL TRANS-

FORMER

switch to the ON position.

It should light up.

5. Push the green START MACHINE

button to “boot up” the machine.

Control Transformer

Start

6. All lights on the status light panel on the electrical

box should be illuminated. See “Description of the

Six Light Panel ” on page 2-10

Note: If a status light does not turn on during the power

up process, see “Troubleshooting with the Status

Light Panel” on page 5-10 for assistance in identifying the issue.

Powering Operations for the 979-2

This section describes how to power up and to power down the 979-2.

Powering up the system includes:

• Applying power to the entire system

• Starting the Control Circuit

Powering down the system includes:

• Shutting down the control power

• Removing power from the entire system

How to Power Up the 979-2

1. Ensure factory air is applied to machine and main air supply is turned on.

2. Check to make sure all E-Stop buttons are out.

Note: A pop-up is displayed on the user screen if an E-Stop is pressed. The pop-up will

indicate which E-Stop has been activated

3. Make sure the electrical disconnect the electrical cabinet is turned to the ON posi-

tion.

.

2-14

KVAL 979-2 Operation/Service Manual

Powering Operations for the 979-2

Note: Safety Curtain Startup

Danger: Never mechanically bypass the Safety Curtain or enter

the cutting area avoiding the Safety Curtain. Serious

injury could occur.

When power is applied to the EZ Screen emitter and receiver, each sensor will conduct self-tests

to detect critical internal faults and prepare for operation.

If no faults are detected, The LED’s will be lit as follows.

1. The machine will move to the home position

2. The machine will then move to about the middle of its travel.

The 979-2 is now ready for work.

Home the 979-2

The 979-2 must go through a homing routine before any operations are performed. The homing

routine sets a zero reference from which the 979-2 measures its movement and cutting process.

If power is lost or the 979-2 is re-set, the homing routine must be performed again to reset the zero

reference

Press the Home button on the Main Screen touch screen.

2-15

KVAL 979-2 Operation/Service Manual

Powering Operations for the 979-2

1

2

3

How to Power Down the 979-2

1.

Push the Stop B

2.

Switch the green CONTROL TRANSFORMER switch to the

utton on the operator station.

OFF position.

3. KVAL also recommends that you turn the disconnect

switch on the electrical cabinet to OFF; this helps reduce

possible damage resulting from power surges from electrical storms.

Emergency Shutdown and Recovery

There are emergency shutdown (E-Stop) switch located at key points

around the machine.

The E-Stop switches are to be used when the machine is out of control

or is about to damage personnel or equipment.

When an E-Stop switch is activated, power to the machine is killed.

The machine responds, in the same way, if you press the STOP button

on the operator's station.

2-16

KVAL 979-2 Operation/Service Manual

Powering Operations for the 979-2

Right Head

Left Head

45 deg - 45 deg

Left Head

Right Head

Into machine

45 deg - 00 deg

Left Head

Right Head

Into machine

00 deg - 45 deg

Left Head

Right Head

Into machine

00 deg - 00 deg

Left Head

Right Head

Into machine

About Modes

The four different cut modes are illustrated below. See “About Adjusting Each Cut Mode” on

page 2-30 for information about selecting the dimensions for the cut.

2-17

KVAL 979-2 Operation/Service Manual

Mechanical Set Up

1. Adjust both back hopper stops for a hopper width of roughly 1/8-inch larger than

the stock.

2. Adjust both front hopper stop's height to clear the stock by roughly 1/8-inch.

Adjustment Bolts for

Height

Rear Hopper Stop

Front Hopper Stop

Note: Use a 1/2'' wrench to

Adjust the Bolts

Mechanical Set Up

After the parameters are loaded form the operator station, prepare the machine to process the

stack.

2-18

KVAL 979-2 Operation/Service Manual

3. Adjust the end stop for the cut angle. The end stop

distance is determined by the fixed head cutting

angle:

• For 45 degrees, set the end stop for the same distance

as the stock width.

• For 0 degrees, set the end stop distance for 0 inches.

Set to Stock

Width

‘0’

inches

4. Set the front edge clamp distance on each head

to the same as the stock width.

5. Set the jamb clamp width air valves. For stock less than

3 ½ inches, the valve must be slid toward the input side

of the machine. For stock greater than 3 ½ inches, the

valve must be slid toward the out-feed side of the

machine.

Mechanical Set Up

6. Load the Hopper.

7. On the Touch Screen press and hold the Start Saw button to start the saws.

8. Press the feed in foot pedal to start the machining of the product.

NOTE: Wide jamb mode has better clamping ability than narrow jamb mode; tighter

clamping produces cleaner saw cuts. Wide jamb mode can be used on narrow stock.

The disadvantage is that wide jamb mode is slower by about 3 boards per minute.

KVAL 979-2 Operation/Service Manual

2-19

Description of User Interface Screens

Below are the menu selections for the 979-2

See “About the Manual Parameter Menu” on page 2-25

See “Main Screen” on

page 2-23

See “About Calibration Data” on page 2-27

See “About Assigning a Pre-set” on page 2-31

Description of User Interface Screens

This section describes the user interface screens. The user interface allows the operator to use a

touch screen to control the trim cutting process, auto-run, manually run the trim, store trim profiles, and use diagnostics to help troubleshoot the 979-2.

Screen Selection Menu Map

..

FIGURE 2- 9. Screen Selection

KVAL 979-2 Operation/Service Manual

2-20

Screen Selection Menu Map (Small Platform Screen)

Below are the menu selections for the 979-2 using a small platform

touch screen (Start SN 17-146-061).The definitions of the buttons are

the same. Changes in menu operation is slightly changed. The main

change is there are more jump pages to utilize. The changes are

defined in the figure below. This platform is described in this chapter.

See “About the Manual Parameter

Menu” on page 2-25

See “Diagnostic

Screen” on

page 2-34

See “Main

Screen” on

page 2-23

See “About Calibration

Data” on page 2-27

See “About Assigning a Pre-

set” on page 2-31

Jump to next page of stored Preset selections. There are 4 pages

per cut type to store.(12 per page)

Jump to next page to calibrate

the Miter Stop Adjustment

Description of User Interface Screens

FIGURE 2- 10. Screen Selection (Reduced Screen)

KVAL 979-2 Operation/Service Manual

2-21

Description of User Interface Screens

Machine Feed Back

Note: Use this information to isolate issues if having problems with the machine

At the top and at the bottom right hand corner of all user screens is status feedback information.

The information generated is as follows:’

1. General Machine Status. This field lists the machine status through-out the process.

2. Current Servo Positions. This field shows the current position of the servo.

.

Store Program

To allow the operator to make changes to parameters, turn the

Set Up Lock to the On position. When this key is in the Off

position, the parameters are locked out. No changes to the

parameters may be made in the off position.

Set Up Mode

This setting allows technician to stop the saw from running if

performing calibration on the machine. The technician can feed

in a trim board with the foot pedal and check the clamps for

accuracy without cutting the boards.

In the ON position the setup mode is active the saws will be

OFF. In the OFF position the setup mode is not active and the

Saws will be ON.

These keys may be taken out in the off position.

Lock for

Software:

Lock for

Machine

Set Up:

About Lock-Outs (Option)

2-22

KVAL 979-2 Operation/Service Manual

Description of User Interface Screens

Jump Buttons

Main Screen

The Main Screen is also the startup screen for the 979-2. From this screen, all the basic user interface controls are available to run a cut on a trim board.

FIGURE 2- 11. Main Screen

About the Software Start Saws Button (Older Machines)

Some previous machines may have a software button to start the saws. This button was replaced

by a mechanical Start Saws Button. For description of the mechanical button,

2-23

KVAL 979-2 Operation/Service Manual

Description of User Interface Screens

About Home Machine Button

This button starts the home sequence on the machine, which

causes the movable fence to slowly scan to find a physical reference point on the frame. When this point is found, the position is

stored and then used to calculate the location of all moves after

this. The home sequence must be performed every time the

machine is powered up or reset.

Reset Machine Button

If a fault occurs that cannot be cleared, press the Reset Machine button. This button will

reset the machine to the start position before homing.

Press Home Machine after Reset Machine

About the Preset Selection Button Group

Pressing a preset button, calls a stored

length of the casing to be machined.

There are 56 stored presets for each cut

mode. The cut modes are:

• 45 deg- 45 deg

• 45 deg- 00 deg

• 00 deg- 45 deg

• 00 deg- 00 deg

To choose a preset:

1. Select the cut mode. The cutting

heads will move to 45 deg or 0 deg

depending on choice.

2. Select the desired preset button.

Select Page 2 Button to jump through

choices of presets.

3. Select the Download Cut Parameters Button. The parameters will be displayed in

the box.

4. Push and hold the black button to move the Right Head into position.

The machine is now primed to perform. See “Description of User Interface Screens”

on page 2-20 for full operation steps.

To assign a preset to the button:

See See “About Assigning a Pre-set” on page 2-31 for more information

KVAL 979-2 Operation/Service Manual

2-24

Description of User Interface Screens

About the Preset Selection Button Group

Pressing a preset button, calls a stored

length of the casing to be machined.

There are 56 stored presets for each cut

mode. The cut modes are:

• 45 deg- 45 deg

• 45 deg- 00 deg

• 00 deg- 45 deg

• 00 deg- 00 deg

To choose a preset:

1. Select the cut mode. The cutting

heads will move to 45 deg or 0 deg

depending on choice.

2. Select the desired preset button.

3. Select the Load the Cut Parameters

Button. The parameters will be displayed in the box.

4. Push and hold the black button to move the Right Head into position.

The machine is now primed to perform. See “Description of User Interface Screens”

on page 2-20 for full operation steps.

To assign a preset to the button:

See See “About Assigning a Pre-set” on page 2-31 for more information

About the Manual Parameter Menu

If the preference is not to use the preset buttons, manually set

the parameters.

To manually set the length and the quantity of the casings, use

this menu. The process is:

1. Enter casing length desired.

2. Set the desired quantity. The machine will stop after the

quantity is reached. (0 quantity will keep running until operator stops the machine)

3. Select the Load the Cut Parameters Button.

KVAL 979-2 Operation/Service Manual

2-25

Description of User Interface Screens

About Choosing Feed Operations.

Use this menu to set the feed speed, adjust for a wider

width casing, and apply a kerf cut (Option A).

Note: KVAL strongly recommends using the Wide Jamb

selection on cuts. This setting makes good cuts with

maximum efficiency.

About Turning on the Saw

Note: Older Machines.

After the Parameters are loaded, start the Saw.

1. Verify machine area is safe to continue machining.

2. Locate the Saws bottom on the lower left had corner

of the main scree

3. Press and hold the SAWS OFF button for 3 seconds.

4. The button will display SAWS STARTING, you will

hear the machine starting up.

Warning: The Saws are running now, DO NOT

put your hands near the saw blade.

5. The machine is ready to start working when SAWS

ACTIVE

is displayed on the button.

6. After machining is completed, press the SAWS ACTIVE button to turn OFF the saws.

During machining it is recommended to use this button to shutdown the saws. This

will save time of booting up the machine. See “How to Power Down the 979-2” on

page 2-16 if shutting down for the night.

2-26

KVAL 979-2 Operation/Service Manual

About the Setup Screens

Red = Reverse Direction

Green = Forward Direction

X Axis Servo Motor

About the Setup Screens

Select the Setup Button on the Main Screen to open access to the Setup (Machine Calibration)

screen. Select the Modify Pre-sets button to assign values to the preset buttons on the main

screen.

About Calibration Data

In the Machine Calibration Screen, data can be entered to compensate for differences between

measured data and expected results. For example, slight changes in positioning may occur after

changing to a new tool.

Data is entered into the Offset box and combined to achieve the Actual parameter.The results are

stored in permanent memory.

Running a Reference Cut

If you notice any changes in the cut locations, run a reference cut. Run a known good profile.

After the trim is machined, measure the results:

• The Base is the start up reference.

• The differences between the template and the measured (either positive or negative)

are entered into the Offset entries.

• The Actual is the combination of the Base and the Offset entries which is the final

result.

About Motion of Servo Motor

The figure below shows the motion of the 'X' axis servo motor. Use the figure below as a reference when calibrating the machine. The reverse direction equates to a negative number and the

forward direction equates to a positive number when entering data into the calibration menus. Use

this information as a guide to help input the directional data in the calibration routines.

2-27

KVAL 979-2 Operation/Service Manual

About the Setup Screens

1. If there is a number in the Base box, Click

Combine with Offset to combine both num-

bers.

2. Click the ± to Offset to display the keypad. In

keypad, enter the positive or negative amount

to correct the length of the trim. Click the

green check button to enter the data.

a. If the board is too short, add the difference between expected

results and the measurement

b.If the board is too long, subtract the difference between

expected results and the measurement

3. If it is correct, go back to the calibration screen and click Combine

with Offset

to combine offset and base to complete the calibration.

4. Click the Clear Offset button to clear any incorrect number in the Offset box,

5. Run a second cut and recheck the result.

6. If the result is off, repeat steps 1 through 3

7. If it is correct, go back to the calibration screen and click Combine with Offset to combine

offset and base to complete the calibration.

Note: Click the Clear Offset button to clear any incorrect number in the Offset box.

Keypad

Entering Calibration Data

2-28

KVAL 979-2 Operation/Service Manual

About the Setup Screens

Miter Stop Adjustments are an Optional

choice for machines with Miter Option

About the Machine Calibration Screen

The Setup button leads to the Machine Calibration screen. In this screen, you can perform machine

calibration of the following:

• Individual parameters for each cut mode.

• System wide or all cut modes as a set.

.

FIGURE 2- 12. Setup Menu

KVAL 979-2 Operation/Service Manual

2-29

About the Setup Screens

About Adjusting Each Cut Mode

If a discrepancy noticed on one of the cut modes and not all of

them, use this menu to fine adjust the cut.

If the length on the short side is not in specification, find the

difference between the expected results and enter into the offset box. See “” on page 2-28 for more detailed instructions.

45 deg. - 45 deg.

00 deg. - 45 deg.

45 deg. - 00 deg.

00 deg. - 00 deg.

Check Length

Check Length

Check Length

Check Length

About the Miter Stop (Option)

If a discrepancy is observed on the miter stops, use this menu to

adjust stop positions.

About Adjusting System Cut Modes

If all the lengths are out of specification the same amount.

Use this menu to adjust the cutter heads.

2-30

KVAL 979-2 Operation/Service Manual

About Assigning a Pre-set

1. Select the desired Cut Mode

2. Push a preset button until it turns

green.

3. Push the Modi fy Pre -sets button to go

the Pre-set menu.

4. At the Pre-set menu, enter a title that will appear on the

main screen button.

5. Enter the length in either decimal or fractional measure-

ments.

6. Select the Save button.

7. Select the Main button to go

back to the main menu. The previously selected button will have the

title and length.

Small Platform Screen

Follow the steps below to assign a pre-set length to a button.

About the Setup Screens

2-31

KVAL 979-2 Operation/Service Manual

About Manual Operation and Chipout Routine

Press the Exit Application

button to close the user

screen and return to the Main

Screen

Enter the speed desired and

press and hold the Close or

Open Button until the Saw Carriage moves to the desired location.

About Manual Operation and Chipout Routine

From this screen, you can control certain functions of the machine in manual mode. This screen is

can be used in troubleshooting, checking cut specifications, and maintenance.

This page offers manual control of the saw carriage and running a Chipout Routine.

FIGURE 2- 13. Manual Operation Screen

2-32

KVAL 979-2 Operation/Service Manual

About Manual Operation and Chipout Routine

About the Chipout Routine

After the chipout blocks have been replaced and the machine

has been safely secured, use the Chipout Routine Button and the

Starts Saws Button to burn in the blocks.

Process to Burn in a Chipout Block

1. Perform Lockout.Tagout. See “Lockout Tagout Procedure” on page 1-9.

2. Replace the chipout blocks located under each saw. See “Replacing the Chipout

Block” on page 4-13.

3. Jump to the Manual Screen.

4. Press and hold the Chipout Routine Button to put

the machine into chipout mode.

5. While holding the Chipout Routine Button

• Press the Start Saws Button to start the saws and

bring down to the chipout block to cut it.

• Release the Start Saws Button to detract the saw

away from the chipout block.

6. After burn-in is completed, release the Start Saws

Button

and release the Chipout Routine Software

Button

7.

Reverse Lockout Tagout.

8. Home machine on start-up

Press and Hold to

start Burn-in program

Press to bring

saw down to

chipout

Release to detract

saw away from

chipout

Example of a burned-in chipout

block.

KVAL 979-2 Operation/Service Manual

2-33

Diagnostic Screen

Diagnostic Screen

The Diagnostic screen displays all the tasks the 979-2 performs. This screen can help with trouble

shooting by associating the error code to machine sections or functions. The top line will have the

most current routine that is running. If the machine issue can not be resolved, call KVAL Inc. (1800-553-5825). Have any error code that is displayed, ready to give the KVAL representative.

This will aid in troubleshooting and shorten down time.

.

FIGURE 2- 14. Diagnostic Screen

KVAL 979-2 Operation/Service Manual

2-34

Notes:

CHAPTER 3 System IT Administration

This chapter describes the KVAL 979-2 controller. The controller is an on board computer that

supplies the user interface and controls the operation of the machine. With the controller, KVAL

can remotely help troubleshoot your machine.

Chapter 3 at a Glance

System IT Administration 3-2

About the 979-2 Computer 3-2

Connections on the PLC 3-2

Backing up the Computer 3-3

About Remote Connection to KVAL Service 3-3

3-1

System IT Administration

Smart Power Supply

and EtherCat

DVI/USB Module

to User Interface

CPU Module

RJ45 to

Intranet

Compact

Flash Card

Interface to

Servos

Battery

Interface to

Frame

System IT Administration

For optimum support, the 979-2 requires internet access. With internet access, KVAL Service

Support will be able to access your machine through your company’s Intranet and help solve any

issues that may occur. Connection to the Intranet is achieved by interfacing with the 979-2 controller. The location of the Intranet connection is identified in the figure below (RJ45 to Intranet.)

About the 979-2 Computer

The 979-2 uses a Beckhoff® CPU module as a PLC (Programmable Logic Controller.) In addition

to the CPU and the chipset, the module also contains internal main memory. The computer has a

removable Compact Flash card from which it boots.The controller uses a Windows 7® operating

system with TwinCAT 2® automation software to create the PLC and Motion Control method.

Interface modules include:

• A smart power supply to connect to EtherCat® terminals. This supply contains a

LCD to display system and user messages.

• A DVI/USB module to connect to the user interface.

• An Ethernet module to connect to the servo amplifiers.

Connections on the PLC

The CPU module is located in the upper left corner of the Electrical Panel. See “About the Electrical Panels” on page 2-6. The figure blow shows a common PLC setup. For detailed information

on the PLC, see the machines electrical print.

FIGURE3- 15. Connections on the Controller

KVAL 979-2 Operation/Service Manual

3-2

System IT Administration

Backing up the Computer

Backups keep your data archived in case of a rare system crash. Click the Back-Up Icon on the

Desktop to back up your data. The data is stored in a backup folder in your Windows® directory.

It is recommended to set up a back-up schedule to save your data on a regular occurrence.

The KVAL service team would be happy to help. If any questions occur, contact our service team

at (800) 553-5825 or at www.kvalinc.com.

3-3

KVAL 979-2 Operation/Service Manual

System IT Administration

3-4

KVAL 979-2 Operation/Service Manual

CHAPTER 4 Maintenance of the 979-2

This chapter describes preventative maintenance steps for KVAL 979-2. The content is geared to

guide technicians to keep a regular maintenance schedule for your KVAL machine. Keeping your

KVAL machine maintained is an important piece for successful operation of your production process.

Chapter 4 at a Glance

Maintenance Schedule ..................................................................................... 4-2

Maintenance NO-GOES .................................................................................. 4-4

Lubrication Schedule ....................................................................................... 4-5

Typical Lucubration Kit ............................................................................. 4-5

Lubrication Requirements ................................................................................ 4-6

Pillow Block Bearing Housings ................................................................. 4-6

Flange Bearing Housings ........................................................................... 4-7

Ball Rail Bearing ....................................................................................... 4-7

About Taper Bearings ................................................................................ 4-8

Tapered Bearing Housings ......................................................................... 4-8

Ball Screw Nut ........................................................................................... 4-9

Ball Screw Drive Assembly ....................................................................... 4-9

Pulley and Idler Shafts ............................................................................. 4-10

Lubrication Points on the 979-2 ..................................................................... 4-11

Lubrication Points Heads ........................................................................ 4-12

Replacing the Chipout Block ......................................................................... 4-13

Replacing Saw Blades ................................................................................... 4-15