Innovation, Quality & Honesty

700-C System

Reference

Published: 3/8/18

Proprietary Notice

This document contains confidential and trade secret information, which is proprietary to Kval, Inc.

(“Kval”), and is protected by laws pertaining to such materials. This document, the information in this

document, and all rights thereto are the sole and exclusive property of Kval, are intended for use by customers and employees of Kval, and are not to be copied, used, or disclosed to anyone, in whole or in

part, without the express written permission of Kval. For authorization to copy this information, please

call Kval Customer Support at (800) 553-5825 or fax (707) 762-0485. Outside the U.S. and Canada, call

(707) 762-7367.

Copyright 2015 Kval Incorporated. All rights reserved.

KVAL 2012 and 700-C are trademarks of Kval, Incorporated.

All other products are trademarks or registered trademarks of their respective holders, all rights

reserved. Reference to these products is not intended to imply affiliation with or sponsorship of Kval

Incorporated.

Contacting KVAL

Customer Service: For further information about this manual or other Kval Incorporated products,

contact the Customer Support department

• http://www.kvalinc.com/customer_service.html (lists all the representatives, including email

addresses and phone numbers)

• Mailing address:

Customer Support department

Kval Incorporated

825 Petaluma Boulevard South

Petaluma, CA 94952

• Phone and Fax:

In the U.S and Canada, call (800) 553-5825 or fax (707) 762-0485

Outside the U.S. and Canada, call (707) 762-7367 or fax (707) 762-0485

• Business hours:

Technical Support: 4:00 AM to 4:30 PM Pacific Standard Time, Monday through Friday

Parts & Service Sales: 6:30 AM to 4:30 PM Pacific Standard Time, Monday through Friday

(Other sales related inquiries: http://www.kvalinc.com/contact_us.html)

• Email: service@kvalinc.com

Your Feedback is Welcome: To help us design products that make your job easier and your business

more successful, we'd like to gain your perspective about your user experience with our product - that

is, the manual, the machinery, the software, etc. What was easy or difficult to use or to learn? If you

could change something about the design, what would it be? Please email your comments and suggestions for improvement to userexperience@kvalinc.com. (NOTE: This is not a way to get customer support. For that, please refer to the Customer Service contact information above.) Thank you!

700-C a

b 700-C

Proprietary Notice ..................................................................................... .................... a

Contacting KVAL ....................................................................................... .................... a

CHAPTER 1

.................................................................................Introduction 1-1

Safety First!.........................................................................................................3

Lock Out Procedure.................................................................................. .................... 4

Lockout and Tagout Guidelines................................................................. .................... 5

Follow the P-R-O-P-E-R lockout rule of thumb. ....................................... .................... 5

Zero-Energy Start-Up..........................................................................................6

Zero-Energy State to Start-Up to Operating State..................................... .................... 6

Initial Set up ........................................................................................................9

Electrical Connections Overview...................... ... .... ... ... ... .... ... ... ... ... .... ... ........... ... .... ... 11

CHAPTER 2

.............................................................Operation of the 700-C 2-13

Machine Tour.......................................................................................................15

Quick Start...........................................................................................................17

Turning the 700-C On and Off.............................................................................21

Powering Up the 700-C.............................. ... ... ... .... ... ... .......................... ....... .... ... ... ... 21

Powering Down the 700-C...................................................................... .................... 21

Control Panel ......................................................................................................22

Main Control Panel.................................................................................. .................... 22

Remote Control Panel (Optional)............................................................ .................... 23

Width Adjust........................................... ....................................... ... .... ... .................... 24

Length Adjust (Option D).................. ... ... .... ... ... ... .................................... .................... 26

Touch Screen Interface.......................................................................................27

CHAPTER 3 ..............................................................................Maintenance 3-29

Maintenance Schedule........................................................................................30

Lubrication Schedule..........................................................................................31

Lubrication Requirements....................................................................... .................... 31

Grease Points ......................................................................................... .................... 33

CHAPTER 4

..................................................................Theory of Operation 4-37

I/O for Normal Operation .....................................................................................38

Clamps and Rollers (Feed System)...................................................................40

Tandem Cylinders .................................. .... ... ... ... .... ... ... ... .... ... ................ .............. ... ... 41

Wheel Assist Cylinder............................................................................. .................... 42

Operation ................................................................................................ .................... 42

Staple Guns.........................................................................................................43

Staple Gun Horizontal Positing ............................................................... .................... 44

CHAPTER 5

........................................................................ Troubleshooting 5-49

Troubleshooting the Air Cylinders.......................................................................50

KVAL 700-C Operation/Service Manual

Adjusting Cylinder Extension Speed:...................................................... .................... 51

Adjusting Cylinder Retraction Speed: ..................................................... .................... 51

Troubleshooting Electrical Problems...................................................................52

If the Power Stops During Normal Operation......................................... .................... 52

Troubleshooting with the Status Light Panel........................................... .................... 53

Troubleshooting Photo Detectors........................................................................57

Touch Screen Troubleshooting ...........................................................................59

Getting Help from Kval........................................................................................69

Product Return Procedure ...................................................................... .................... 69

Part Locations.....................................................................................................71

Control Panel .......................................................................................... .................... 77

700-C

CHAPTER 1 Introduction

The KVAL 700-C Frame Assembly Machine is generally used in-line with the Commander or 990

Series of machines.

The operation includes placing the strike jamb and header into the machine and clamping into place.

The door, with hinge jamb installed, is then moved into position, gently lowered into place, and then

securely clamped into position. A foot pedal activates the staple guns, which move vertically to attach

the jambs to the header. The door is then raised and rolled out of the machine to the next station to the

packaging station.

The 700-C is adjustable for doors from 18" to 4', wide with a standard length capacity of 6'8" or an

optional capacity for 7'0" and 8'0" doors. The 700-C can have up to four staple guns moun ted on four

corner brackets. Staple guns are not included.

SPECIFICATIONS

Footprint Size: 10' x 6'

Crated Dimensions: 120"L x 80"W x 53"H

Shipping Weight: 1,200 lbs.

{UL} Electrical panel is built according to Underwriter's Laboratories specifications and the UL label is

applied.

Prices FOB KVAL Plant in Petaluma, CA.

700-C 1

Introduction

2 700-C

Safety First!

The compressed air system connected to this machine should have a three-way air

valve for shut-off and pressure relief. The air supply line providing the pressure to this

machine also has a three-way air valve. All cylinders on the machine

are under high pressure and can be very dangerous when activated.

Before performing any maintenance or repairs on the machine, turn the

main air disconnect off. Lock-out and tag-out this connection.

Still has power

in OFF position

Safety First!

The 700-C is a powerful electro-mechanical motion control system. You should test your motion system

for safety under all potential conditions. Failure to do so can result in damage to equipment and/or serious injury to personnel.

Safety Guidelines

In addition to the caution and warning labels affixed to the 700-C system, follow the guidelines below

to help ensure the safety of equipment and personnel.

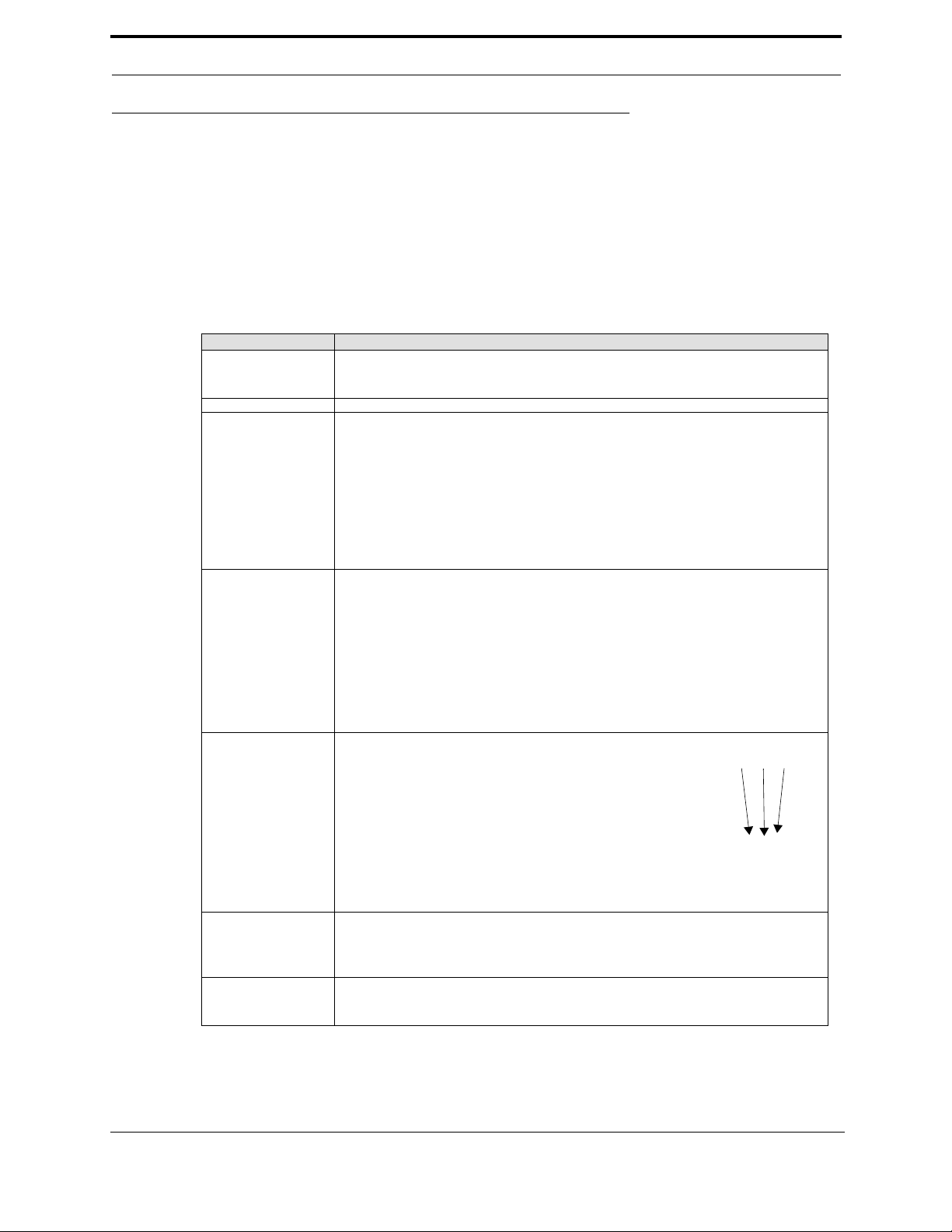

Guideline Description

Safety Training Ensure that all employees who operate this machine are aware of and adhere to all

Protective Gear Never operate the machine without proper eye and ear protection.

Entering the Safety

Cage

Compressed Air .

safety precautions posted on the machine and are trained to operate thi s ma chine in a

safe manner.

When the machine is on:

• Never reach hands beyond safety cage. If the machine has servo motors

can unexpectedly move quickly and out of control.

• Do not clear slugs out of the machine while it is running.

• Never perform any maintenance while machine is running.

• Never clean the machine while it is running.

• Never walk away from the machine while it is running.

Electrical Electrical circuitry on this machine is protected by an

approved lockable disconnect circuit. In addition to this equipment, you must install an approved disconnect for the electrical power supplying this machine.

When opening the cabinet you must first turn off the disconnect switch. When the cabinet door is open there is still power

on the top side of the disconnect switch. All maintenance and

repairs to electrical circuitry should only be performed by a

qualified electrician.

Before Conducting

Maintenance

Compliance with

Codes and Regulations

700-C 3

Prior to performing any maintenance, repairs, cleaning or when clearing jammed

debris, you must disconnect, tag-out and lock-out the electrical and air pressure systems. This should be done in accordance with the state and/or federal code requirements.

KVAL Inc. advises that you request an on-site state safety review of your installation

of this machine. This is to ensure conformance to any additional specific safety and

health regulations which apply in your geographic area.

Other Hazard Control

When multiple people are

working on the machine, each

person needs to have a lock on

the handle in the extra holes

provided.

Action

Lock Out Procedure

This policy is required by OSHA regulation 1910.147 and Cal OSHA’S SB198 ruling of July 1991.

Use the following lockout procedure to secure the 700-C while it is powered down. During a locko ut,

disconnect all power and shut off the air supply. Be sure to use the tag-out guidelines noted below.

To lock out the 700-C

1. Assess the equipment to fully understand all energy sources (multiple electrical supplies, air supply

and pressure, spring tension, weight shifts, etc.).

2. Inform all affected personnel of the eminent shutdown, and the duration of the shutdown.

3. Obtain locks, keys, and tags from your employer’s lockout center.

4. Disconnect power.

NOTE:Always lock out electrical disconnects on both electrical cabinets

a. Turn the disconnect switches on the main electrical panel to the OFF position. Then pull out

the red tab and place a padlock through the hole. Place your tag on the padlock, as per the tagout guidelines below. (see picture below).

If you believe any part or operation of this machine is in violation of any health or

safety regulation, it is your responsibility to immediately protect your employees

against any such hazard and bring the matte r to our attention for review and correction,

if deemed advisable.

Additional detailed safety guidelines are included in the operating instructions of this

manual. KVAL will be pleased to review with you any questions you may have regarding the safe operation of this machine.

b. Turn the disconnect switch on the lar ger high-frequency panel to the OFF position. Then pull

out the red tab and place a padlock through the hole. Place your tag on the padlock, as per the

tag-out guidelines below

4 700-C

Safety First!

5. Turn the main air valve to the OFF position and place a

padlock through the hole (see illustration).

NOTE: Place your tag on the padlock, as per the tag-out

guidelines below.

6. Insure the machine will not operate.

7. When maintenance or repairs are completed, the person

who performed the work must ensure all tools, spare parts,

test equipment, etc., are completely removed and that all

guards and safety devices are installed.

8. Before removing the locks and tags, the person who

attached them shall inspect the equipment to ensure that

the machine will not be put into an unsafe condition when

re-energized.

9. The lock and tag can now be removed (only by the person(s) who placed them), and the machine can

be re-energized.

10. The tags must be destroyed and the locks and keys returned to the lockout center.

Lockout and Tagout Guidelines

• Place a tag on all padlocks. On the tags, include your

name and date.

• These locks are only to be removed by the person

whose name is on the tag.

• If more than one person is working on the machine,

then each additional person places a lock and tag on

each disconnect.

• You may only remove your own lock and tag.

NOTE: When many people are working on the same

machine, a multiple lockout device is necessary.

Follow the P-R-O-P-E-R lockout rule of thumb.

P...... Process shutdown

R ...... Recognize energy type (electrical, pneumatic, mechanical, etc.)

O...... OFF! Shut off all power sources and isolating devices

P...... Place lock and tag

E...... ENERGY: Release stored energy to establish, insure and achieve a zero-energy state

R ...... Re-check controls and test to ensure they are in the “OFF” position

700-C 5

Zero-Energy Start-Up

Zero-Energy State to Start-Up to Operating State

Starting the equipment properly is just as important as the lock-out/tag-out procedure in terms of safety.

Start-up

• Inspect

• Clean up

• Replace guards

• Check controls

• Remove locks

• Perform visual checks

Inspect

When work is finished, the equipment must be inspected for proper adjustment before starting equipment.

Clean Up

All materials and debris must be cleaned up. Any combustible materials or old parts used during repairs

must be cleaned up and/or properly disposed of.

Replace Guards

Replace all equipment guards. If part of equipment cannot be properly adjusted after start-up with guard

on, leave only that guard off.

Check Controls

Confirm that all switches are in the “OFF” position. In some cases, the machine can start automatically

when energy is restored.

Remove Locks

Each person must remove his or her own lock and tag. This will ensure operators are in a safe place

when the equipment is started.

Perform Visual Checks

If the equipment is too large to see all around it, station personnel around the area and sound the personnel alarm before starting the equipment. If your operation is more complex, having many pieces of

equipment and a lot of people, a comprehensive lock-out/tag-out procedure may involve additi onal

steps. You will need to ask your supervisor about these procedures. A specific lock-out procedure may

be posted at each machine. On larger or long-term maintenance or installation projects, the procedures

should be explained to all participants and a copy of the procedures should be posted on-site for the

duration of the work. Provisions which ensure protection during shift changes when contractor or outside help is used must also comply with the lock-out/tag-out procedures. Comprehensive lock-out/tag-

6 700-C

Zero-Energy Start-Up

out may use a gang box or other system to ensure that locks are secure and not removed without authorization.

Remember, lock-out/tag-out procedures work because you are the only one with the key to your lock.

Proper lock-out/tag-out can save lives, limbs, and money. Help make your work environment safe for

yourself and your fellow workers. Be sure to follow the P-R-OP-E-R lock-out/tag-out procedures, and

that those around you do also.

YOUR LIFE MAY DEPEND ON IT.

700-C 7

8 700-C

Initial Set up

Initial Set up

Y our new Kval machine arrives at your plant crated, banded, taped, with painted set collars on all shafts,

keeping all of the precision moving parts secure during shipping.

1. To protect against damaging the machine with the forklift, move the machine as close as possible to

the area where it will be stationed before removing it from the crate

2. Use caution when removing the machine from the crate. Any time the machine is lifted to remove the

skids, there is a chance that the machine could drop suddenly, which could damage the machine or

injure people near the machine.

3. Remove all painted set collars from the shafts. Almost every shaft on the machine has set collars to

secure the moveable assembly mounted to the shafts.

4. Remove any tape securing the various buttons, switches and knobs. Level your Kval machine by put-

ting metal shims underneath the corners of the base. Leave a clear shot from the bolt holes in the foot

pads to your shop floor.

5. Once the machine is level, anchor it to the floor so that it won't move across the floor during opera-

tion. Kval recommends a ½-inch Red Head, Trubolt anchor in each of the foot pads.

700-C 9

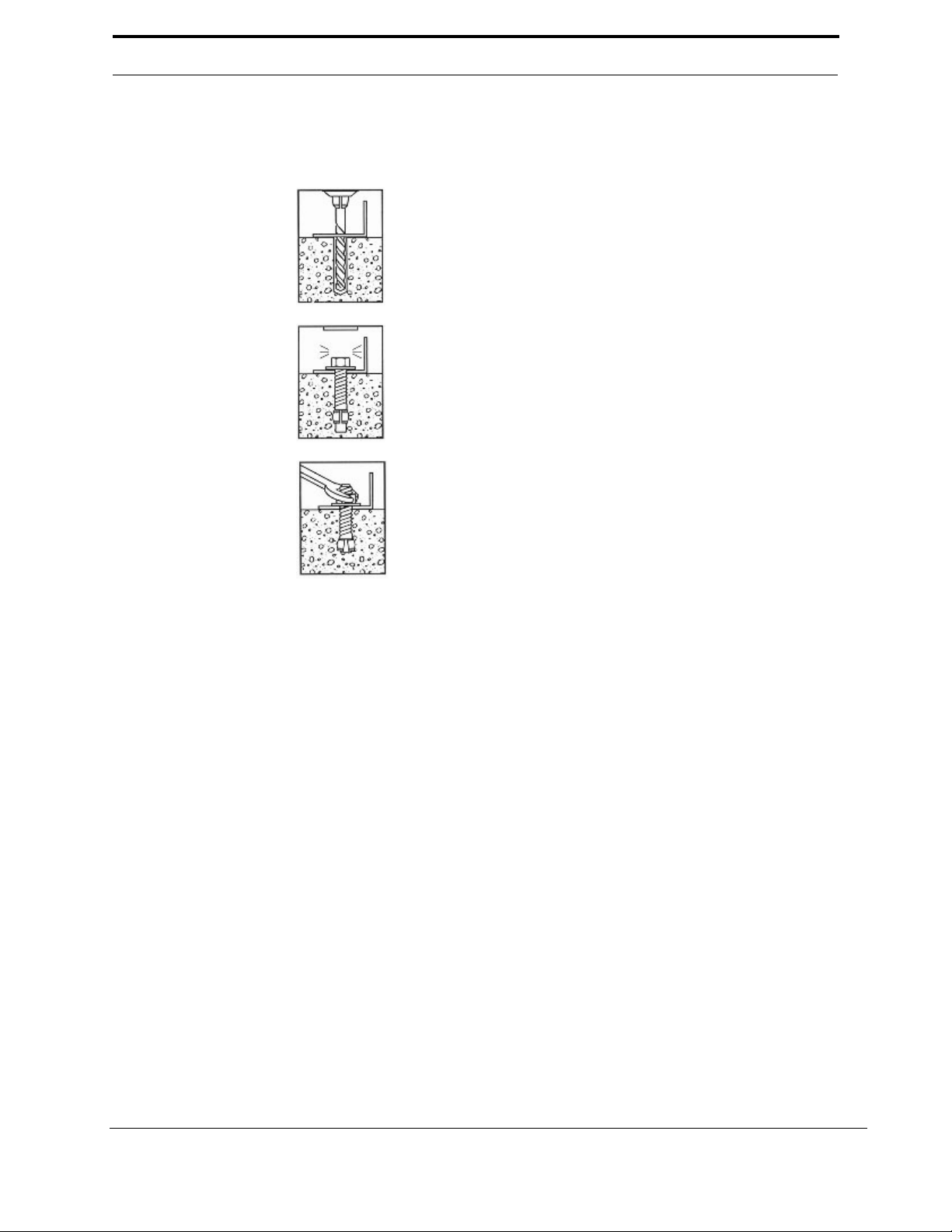

Trubolt Wedge Anchor

1.Drill a ½-inch hole, minimum of 6-inch depth. Clean hole.

NOTE: Kval recommends drilling completely through the slab. If in the

future the machine needs to be moved, remove the Red Head nut and

pound the bolt flush with the floor surface.

2.Assemble anchor with nut and washer so that the top of the nut is flush

with the top of the anchor. Drive anchor through material to be fastened so

that nut and washer are flush with surface material.

3.Expand anchor by tightening nut 3 to 5 turns (torque requirement 55 ft.

lbs. for a ½-inch Red Head Trubolt

INSTALLATION INSTRUCTIONS

10 700-C

Initial Set up

The main electrical power is connected to the disconnect,

located in the large electrical panel.

The 700-C requires 110 Volt AC. Typically this voltage is

pulled from the previous machine. Refer to the plant layout diagram from more information.

Neutral Hot Ground

110Volt AC

Electrical Connections Overview

700-C 11

12 700-C

CHAPTER 2 Operation of the 700-C

700-C 13

Operation of the 700-C

14 700-C

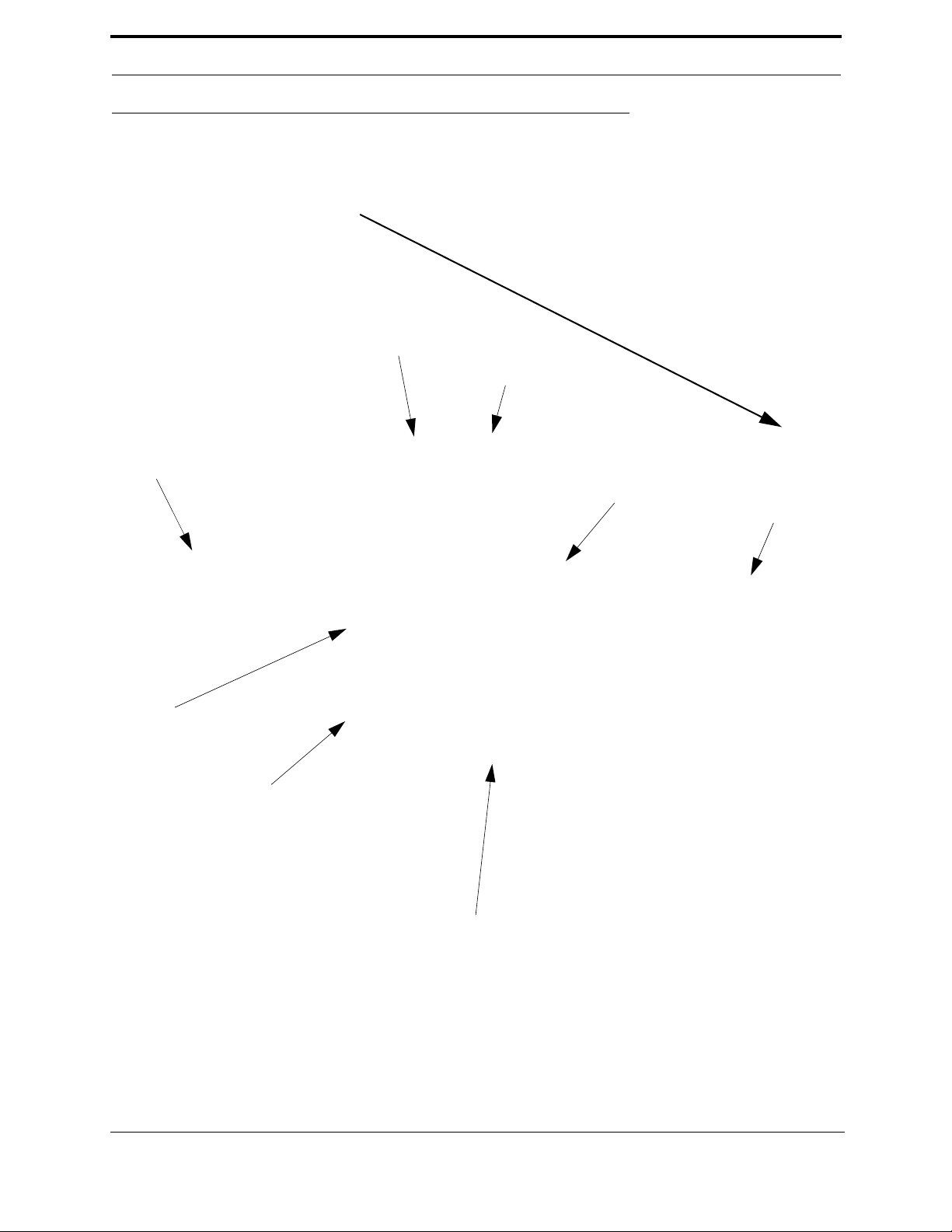

Machine Tour

Feed Direction

Infeed

End

Outfeed

End

Movable

Fence

Main

Control

Panel

Fixed

Fence

Right Hand

Movable Side

Gun

Left Hand

Movable Side

Gun

Right Hand

Fixed Side

Gun

Left Hand

Fixed Side

Gun

Touch

Screen

Machine Tour

700-C 15

16 700-C

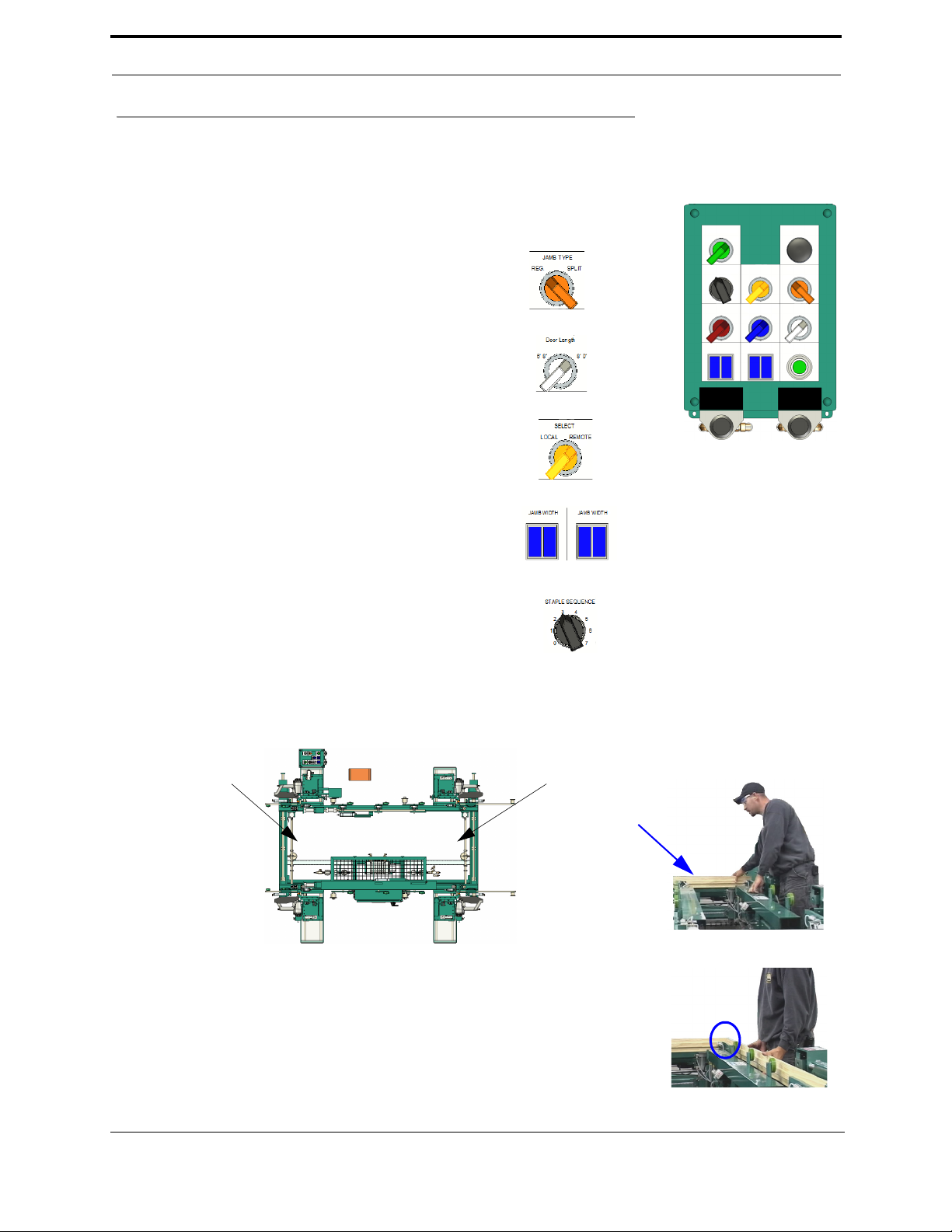

Quick Start

CONTROL CIRCUIT

OFF ON

STAPLE SEQUENCE

0

1

2

3

4

5

6

7

RESET 700-C

JAMB TYPE

REG. SPLIT

ENABLE FIXED

SIDE GUNS

OFF ON

ENABLE MOVABLE

SIDE GUNS

OFF ON

FIRE GUNS

JAMB WIDTH JAMB WIDTH

WIDTH ADJUST

PUSH

CLAMP

PULL

RELEASE

FIRE SIDE NAILER

Door Length

6’ 8”

8’ 0”

SELECT

LOCAL REMOTE

2. Select the Jamb Type. See “Main Control

Panel” on page 22.

3. Select Door Length (Optional). See “Main Con-

trol Panel” on page 22.

4. Select the Local or Remote control box

(Optional). See “Main Control Panel” on

page 22.

5. Select a Jamb Width. See “Control Panel” on

page 22.

6. Select a Staple Sequence. See “Control Panel” on

page 22.

Left hand door

Header location

Right hand door

Header location

Header Location

Left or Right Hand

10. Insert Strike Jamb and insure head and strike jamb corners meet

Quick Start

Set the door width and length before starting the process. See “Width Adjust” on page 24. See “Length Adjust

(Option D)” on page 26.

1. Power up the 700-C. See “Powering Up the 700-C” on page 21.

7. Insure the proper staple guns are enabled and staples are loaded. See “Control Panel” on page 22.

8. Adjust the machine for the desired door width. See “Width Adjust” on page 24.

9. Insert the jambs

.

700-C 17

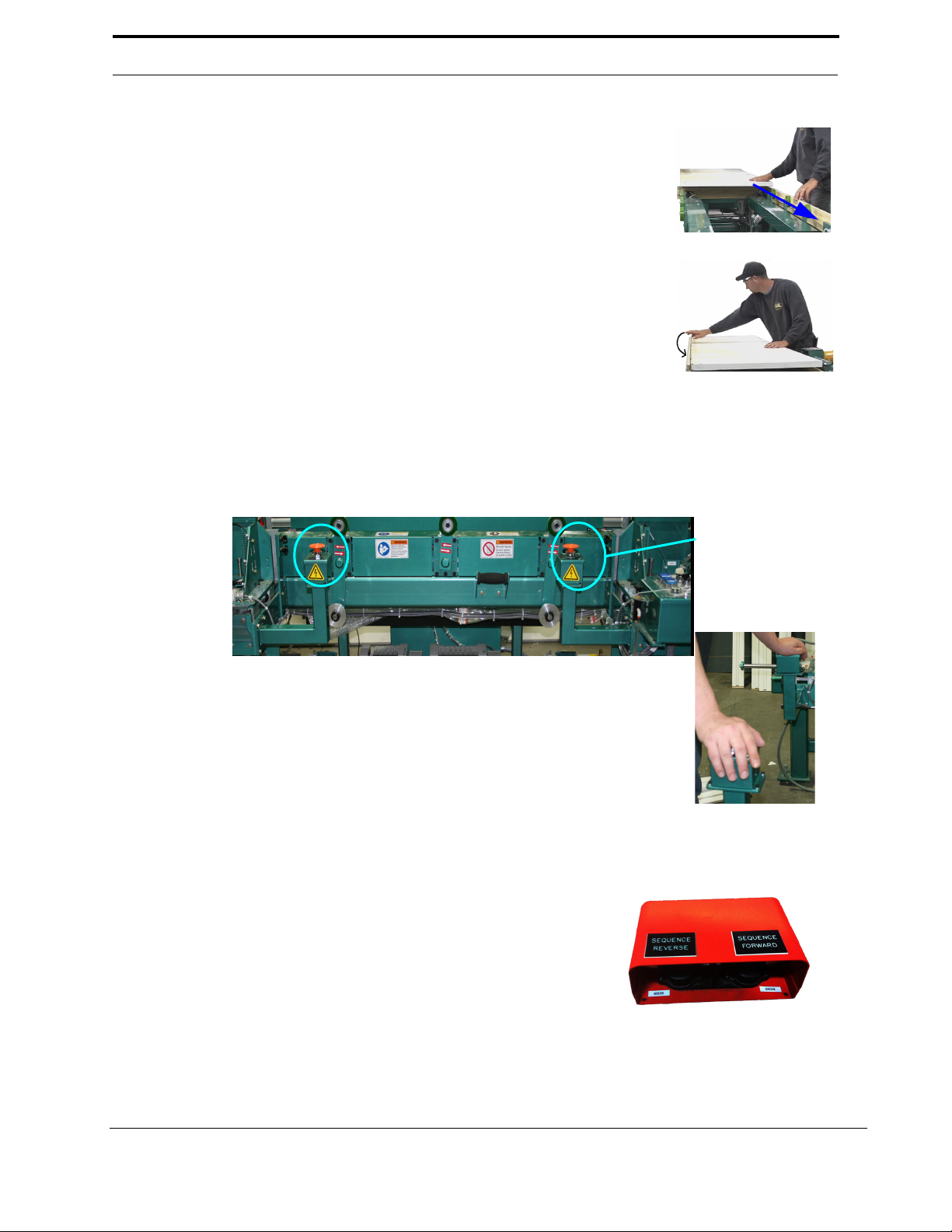

11. Pull in the door.

12. Swing the hinge jamb down.

13. Use the Foot Pedal to control the process. First Activate the Foot Pedal (Option).

14. Each press of the Sequence Forward operates the machine in a predetermined process. Press the

Sequence Reverse switch to go back 1 step to fix errors or recheck setup. Press the Sequence

Forward

to continue to where you left off.

• Push the

Sequence Forward foot switch (brings in movable

side staplers).

• Push the

Sequence Forward foot switch again (drops door to

lower position).

• Ensure the hinge jamb is in the correct position in relation to

the head jamb.

• Push the

Sequence Forward foot switch a third time (brings in the fixed side staple guns).

• Push the

Sequence Forward foot switch a fourth time (clamps the door).

NOTE:

Some 700-C machines have dual switches that must be activated to use the

Foot Pedals. The

switches are located next to the

Control Panel. If these switches are not installed bypass these

instructions and go to step 14

Press both switches to activate the Foot Pedal. Both switches must me

maintained to operate the Foot Pedal. If one or both switches are not

pressed, the foot pedal will not operate.

If a hand is taken of the switch during process, there is a 2 second delay

before the process can be resumed.

With both switches maintained, go to step 14 to continue using the Foot

Pedal

Dual Switches

18 700-C

Quick Start

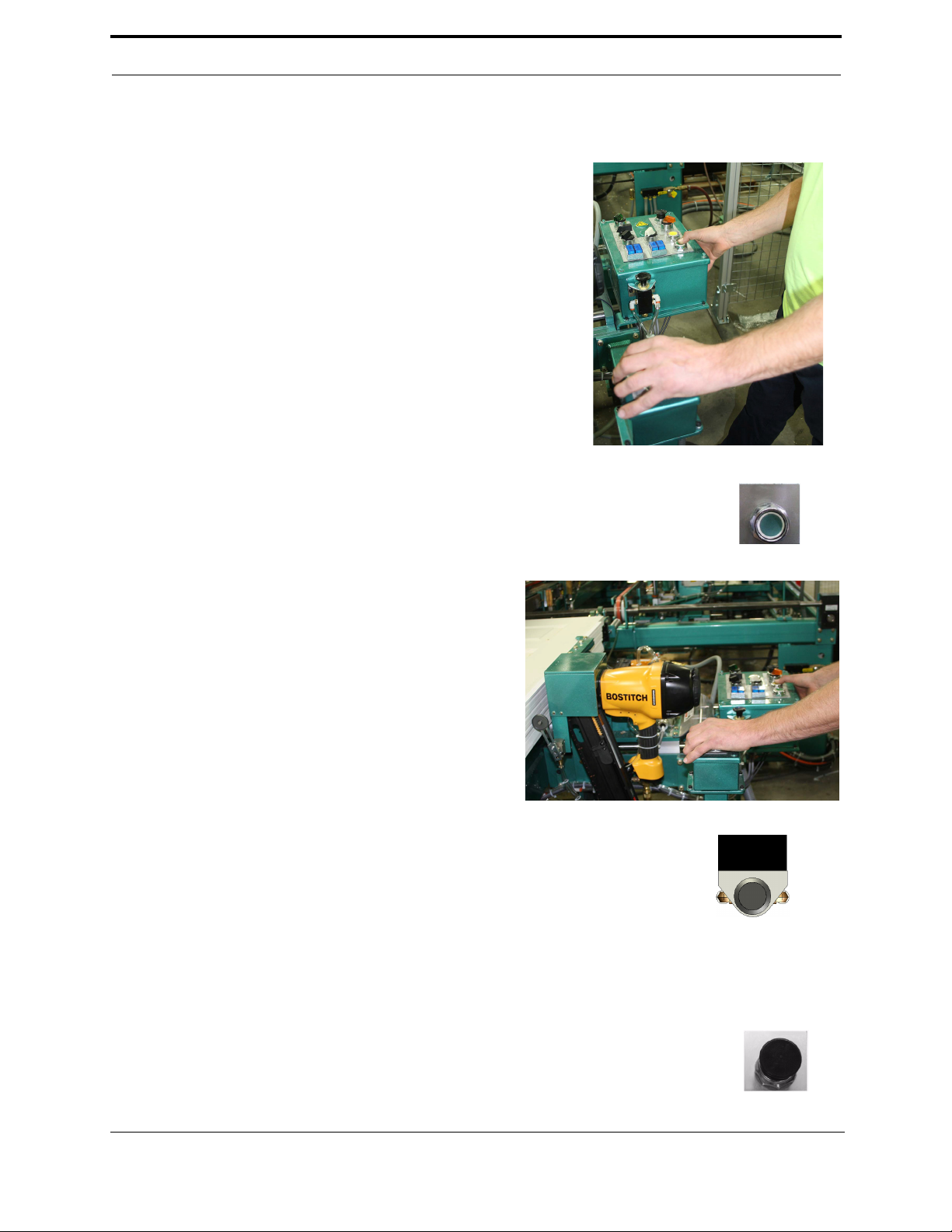

15. For 700-C machines that have dual switches, simultane-

ously hold the switch located next to the

Control Panel

and Press Fire Guns

Note: If a hand is taken of the switch during process, there is

a 2 second delay before the process can be resumed.

If these switches are not installed, bypass these instructions

and go to step 16

FIRE GUNS

16. Press Fire Guns (See “Control Panel” on page 22.)

Fire Side Nailer

17. For 700-C machines that have dual switches,

simultaneously hold the switch located next to

the

Control Panel and Fire Side Nailer

Note: If a hand is taken of the switch during pro-

cess, there is a 2 second delay before the process

can be resumed.

If these switches are not installed, bypass these

instructions and go to step 18

18. Press Fire Side Nailer (Optional) (See “Control Panel” on page 22.)

RESET

21. Press Reset. (Returns machine to start position) (See “Control Panel” on page 22.)

Firing Staple Guns and Nailer

19. Push the Sequence Forward foot switch (un-clamps door).

20. Outfeed door.

700-C 19

20 700-C

Turning the 700-C On and Off

POWER

RELAY

E-STOP

STOP

START

Turning the 700-C On and Off

Use the procedures below for powering up and powering down the 700-C.

Powering Up the 700-C

Powering up the system includes:

• Applying power to the entire system

• Starting the Control Circuit

To Power Up the 700-c

1. Make sure the electrical disconnect the electrical cabinet is turned to the ON position.

2. Turn the CONTROL TRANSFORMER switch located on the main control panel to the ON position.

It should light up.

3. All lights on the status light panel on the electrical box should be illuminated.

CONTROL

OVERLOAD

24VDC

Powering Down the 700-C

Powering down the system includes:

• Shutting down the control power

• Removing power from the entire system

To Power Down the 700-C

1. Turn the CONTROL TRANSFORMER switch to the OFF position. This kills power to the machine.

All status lights should be off.

2. Kval also recommends that you turn the disconnect switch on the electrical cabinet to OFF; this helps

reduce possible damage resulting from power surges from electrical storms.

700-C 21

CONTROL CIRCUIT

OFF ON

STAPLE SEQUENCE

0

1

2

3

4

5

6

7

RESET 700-C

JAMB TYPE

REG. SPLIT

ENABLE FIXED

SIDE GUNS

OFF ON

ENABLE MOVABLE

SIDE GUNS

OFF ON

FIRE GUNS

JAMB WIDTH JAMB WIDTH

WIDTH ADJUST

PUSH

CLAMP

FIRE SIDE NAILER

Door Length

6’ 8”

8’ 0”

SELECT

LOCAL REMOTE

PULL

RELEASE

Control Panel

Main Control Panel

Note: If the machine has the optional remote control panel, both the main and remote panel Movable

Side Gun switches must be in enable to enable the movable side staple guns.

• Door Length: Sets the machine up for 6’8” door length or a 8’0” length door.

• Jamb Width buttons: These four buttons set the machine up for the jamb width indicated on each button.

Note: Jamb width MUST be select for the machine to function.

• Fire Guns: Fires the enabled staple guns.

Note: Staple guns are enabled by the Enable Fixed Side Guns switch, the Enable Movable Side Guns

switch, the LS-14 and LS-15 limit switches (See “Fixed Fence - Inside view” on page 74. for limit

switch locations).

• Fire Side Nailer (Optional): Fires the side nailer guns.

• Width Adjust: Pulling this button releases the movable fence to adjust the fence for the disired door

width. See “Width Adjust” on page 24. for width adjust information.

• Control Circuit: Turns power on and off tho the

machine.

• Reset 700-C: Returns the machine to the first

sequence of operation.

• Staple Sequence: Selects one of seven user-programmed staple patterns. See “Programming” on

page 28. for staple programming instructions

Note: If Staple Sequence 0 is selected no staples will

be fired.

• Select (Optional): This switch between the Main and

Remote control panels. (See “Remote Control Panel

(Optional)” on page 23.)

• Jamb type: Sets the machine up for regular or split

jamb.

• Enable Fixed Side Gun: Enables the staple guns on

the fixed fence side of the machine.

Note: If the machine has the optional remote control

panel, both the main and remote panel Enable Fixed

Side Gun switches must be in enable to enable the

fixed side staple guns.

• Enable Movable side Guns: Enables the staple guns

on the movable fence side of the machine.

22 700-C

Control Panel

STAPLE SEQUENCE

0

1

2

3

4

5

6

7

RESET 700-C

ENABLE FIXED

GUSIDE GUNS

OFF ON

ENABLE MOVABLE

SIDE GUNS

OFF ON

FIRE GUNS

JAMB WIDTH JAMB WIDTH

WIDTH ADJUST

PUSH

CLAMP

PULL

RELEASE

FIRE SIDE NAILER

Remote Control Panel (Optional)

machine up for the jamb width indicated on each button.

Note: Jamb width MUST be select for the machine to function.

• Fire Guns: Fires the enabled staple guns.

Note: Staple guns are enabled by the Enable Fixed Side Guns switch, the Enable Movable Side Guns

switch, the LS-14 and LS-15 limit switches (See “Fixed Fence - Inside view” on page 74. for limit

switch locations).

• Width Adjust: Pulling this button releases the movable fence to adjust the fence for the desired door

width. See “Width Adjust” on page 24. for width adjust information.

• Fire Side Nailer (Optional): Fires the optional side nailer guns.

• Staple Sequence: Selects one of seven user-pro-

grammed staple patterns. See “Programming” on

page 28. for staple programming instructions

Note: If Staple Sequence 0 is selected no staples will

be fired.

• Reset 700-C: R3eturns the machine to the first

sequence of operation.

• Enable Fixed Side Gun: Enables the staple guns on

the fixed fence side of the machine.

Note: Both the main and remote panel Enable Fixed

Side Gun switches must be in enable to enable the

fixed side staple guns.

• Enable Movable side Guns: Enables the staple guns

on the movable fence side of the machine.

Note: Both the main and remote panel Movable Side

Gun switches must be in enable to enable the movable

side staple guns.

• Jamb Width buttons: These four buttons set the

700-C 23

Width Adjust

Collar

Bars

“Pickle”

Fork locations

Width Adjust

button

Measuring

Tape

Location

Movable

Fence

Thick Jamb

Spacer 1

Thick Jamb

Spacer 2

T-Handle

Inner Collar

Thick Jamb

Spacer

Collar bar

Bracket

Collar Bar

Travel

Outer Collar

Thick Jamb Thin Jamb

The following describes adjusting the 700-C to accommodate different door widths. The picture below

shows the location of the width adjust system components.

To adjust the width of the 700-C:

1. If necessary set the Thick Jamb spacers 1 and 2.

To adjust the Thick Jamb spacers:

a. Use the T-handle to loosen the inner collars for

Thick spacer.

b. Slide the outer collar up agents the collar bar

bracket for a narrow jamb. Or away from the collar

bar bracket to allow for the Thick Jamb spacer.

Thick Jamb spacer positions:

24 700-C

c. Put the Thick Jamb spacer in the disired position.

d. Push the inner collar up agents the collar bar

bracket and tighten the T-handle, securing the collar bar.

Use the above process for both Thick Jamb spacer

1 and Tick Jamb spacer 2.

Control Panel

Measuring Tape

Pickle Fork

(Shown in the retracted position)

Pickle Fork

(Shown in the extended position)

18” 20” 22” 24” 26” 28” 30” 32” 34” 36”

48”

Spares

42”

2. Pull up the width adjust button located on the main control panel or

the (optional) remote control panel. This will retract the pickle forks

freeing the movable fence for positing.

3. Slide the movable fence to the disired location indicated by the

measuring tape located on the main frame of the machine. This will

retract the pickle forks.

4. Push down the width adjust button. This will cause the pickle forks

to extend capturing a collar and locking the position of the movable

fence.

Note: The “pickle fork” must capture a collar for proper operation.

The Collar bar

The collar bar has factory positioned collars set for door widths of 18”, 20” 22”, 24”, 26”, 28”, 30”, 32”,

34”, 36”, 42”and 48”. There are two additional collars for user settable positions.

700-C 25

Length Adjust (Option D)

End Clamp set at 6’8”

Adjustment Pin

7’0” 8’0”

There are 2 adjustment end clamps at each end of

the machine. Adjust all 4 end clamps.

T o adjust the end clamps for 6’8”, 7’0”, or 8’0”

doors, pull the pins and move clamps to the appropriate length. Secure pin in the adjustment hole.

See the figure below.

The following describes adjusting the 700-C to accommodate different door lengths.

FIGURE 1. Adjustment End Clamps

26 700-C

Touch Screen Interface

Maintenance

See “Maintenance

Screen” on page 59.

Programing screens

See See “Programming”

on page 28. (below)

Touch Screen Interface

The following is an overview of the touchscreen functions for basic machine operation.

Main Screen

700-C 27

Programming

Program

Number

Programing

Buttons

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

3/4”

1”

1 1/4”

1 1/2”

1 3/4”

2”

2 1/4”

2 1/2”

2 3/4”

3”

3 1/4”

3 1/2”

3 3/4”

4”

4 1/4”

4 1/2”

4 3/4”

5”

5 1/2”

5 1/2”

5 3/4”

6”

6 1/4”

6 1/2”

6 3/4”

7”

7 1/4”

6

11

Programming Buttons

The programming buttons determine where staples will be fired into the jamb. For all programs a staple is fired approximately 1/2” below the top of the jamb in reference to how

the jamb is oriented in the 700-C. The programming buttons are used to toggle other staple

locations.

For example:

If staples where desired at 1/2”, 2” and 3 1/4”, programming buttons 6 and 11 would be

pushed.

• 1/2: A staple is always fired at this location.

• 2”: This location requires button 6 pressed.

• 3 1/4”: This location requires Button 11 pressed.

Note: All programming button locations have a tolerance of +/- 1/4”

28 700-C

CHAPTER 3 Maintenance

This chapter describes how to maintain the 700-C system. This chapter contains the following information:

• Maintenance schedule.......................page 30

• Lubrication requirements...................page 31

700-C 29

Maintenance

Maintenance Schedule

KVAL recommends the following maintenance schedule to ensure that the machine operates

properly. Refer to this section for steps to perform maintenance.

Daily Preventive Maintenance

Op Operation Description

Clean

Check

Clean

Check

Clean

Check

Check

Blow off dust from the entire machine.Wipe down the outside of the machine with a

clean dry cloth.

Check tooling for wear.

Wipe of f the photo eyes with a clean dry cloth, and check to ensure that all fastening nuts

are snug.

Check the air pressure to make sure it is set at 80 psi to100 psi.

Empty any Dust Collection Units.

Check for obstructed flow when excessive sawdust appears.

Check the air filter water trap. Empty if full.

Weekly Preventive Maintenance

Op Operation Description

Check

Clean

Check

LUBE

Check the machine for smooth motion through a complete door cycle

Clean linear bearings and the chrome shaft with a clean dry cloth, then lubricate.

Check all air lines & electrical wiring for kinks or rubbing.

Refill lubricator with an ISO 32 standard hydraulic oil (KVAL part# SYSLUBG)

Six Month Preventive Maintenance

Op Operation Description

Clean

LUBE

Clean

Tighten

Back-up

LUBE

Wash filter and lubricator bowls with soapy water.

Grease all bearings and tighten all bolts. Access to some grease fittings is difficult and

will require a special needle point grease tip (supplied with your system).

Clean and lubricate all slides and cylinder rods with dry silicone spray.

Tighten all bolts.

Backup computer software.

Lubricate linear bearings and chrome shafts with silicone.

30 700-C

Lubrication Schedule

Lubrication Schedule

KVAL recommends the following lubrication schedule to ensure that the machine operates properly.

TABLE 3-1. Recommended Lubrication Schedule

Type of Assembly Recommended Schedule Recommended Lubrication Type

Linear Bearing

Every 250 Hours of Machine Operation Dura-Lith Grease (KVAL P/N Lube EP-2)Pillow Block Bearing

Flange Block Bearing

Ball Screw Every 80 Hours of Machine Operation

Air Line Lubricator One drop of oil every 2 or 3 cycles

Check the lines every week to two weeks

Gear Box 2000 Hours of Machine Operation or six months

of operation

Either lubricant listed below is approved

to use.

• KVAL P/N SYSLUBG

• Chevron AW Hydraulic Oil 32

• G-C lubricants light AW R&O

• Mobile DTE 24

• Shell Tellus32

• Gulf Harmony 32

• AGMA #8 gear lube

• MOBILUBE HD 80 W-90

• or equivalent

Lubrication Requirements

This section describes the parts of the machine that require periodic lubrication, and specifies the lubricants. In addition, it explains how to maintain the lubrication systems on the machine.

Linear Bearings

If the bearing is equipped with a grease fitting, it

should receive 1 Gram (one pump from grease gun)

of Dura-Lith Grease (KVAL P/N Lube EP-2) every

30 days. Bearings without grease fittings have been

pre-lubricated at the factory and do not require further lubrication.

Flange Bearing and Pillow Blocks

Use Dura-Lith grease: 1 gram every 60 days.

Approved Lubrication Products for

Lubricators

Chevron A W Hydraulic Oil 32 – or KVAL P/N SYSLUBG or G-C lubricants light A W R&O or Mobile

DTE 24 or Shell Tellus32 or Gulf Harmony 32.

700-C 31

Maintenance

(Sight glass). Drop will form at

end of cane shaped tube visible inside glass.

(Adjustment knob). When the oiler has run

dry, open the knob all the way until flow

begins. Once you have a steady flow,

tighten knob back down until you have one

drop per every other cycle.

Lubricator

Regulator

Filter

Set bottom valve to 90 psi

Set top valve to 100psi

Sight Glass. Check

rate: 1 drop for ever

two door cycles.

Adjustment Knob

Gear Motor Lubrication Requirements

Oil change is recommended after 2000 hours or six months of operation. Use AGMA #8 gear lube or

MOBILUBE HD 80 W-90 or equivalent

Adjusting the Air Line Lubricator (not available on all machines)

Using the knob on the top of the lubricator, adjust until one drop per every other cycle is used (as

observed through sight glass.)

Priming the Air Line Lubricator

New and used machinery run out of oil from time to time. It is a good practice to check your machine

lubricator to insure that it is putting the proper dose of oil in the air lines. Usually 1 drop of oil every

other cycle is a good rule of thumb.

T o prime the lubricator, find an air line on the carriage section of the machine that is energized, and disconnect it, allowing the air stream to bleed air pressure away from any persons. Direct the air stream at

the machine so you can see when there is an oily film blowing out of the air hose. Repeat this same procedure for the back section and other trouble areas.

Check the lines every week to two weeks.

32 700-C

NOTE: The Lubricator is not installed on all machines.

Lubrication Schedule

Grease Points

Top View

700-C 33

Maintenance

Heads

34 700-C

Lubrication Schedule

700-C 35

Maintenance

36 700-C

CHAPTER 4 Theory of Operation

700-C 37

Theory of Operation

I/O for Normal Operation

The following describes the I/O of the 700-C during normal operation:

1. Insert head jamb - No I/O activity.

2. .Insert strike jamb - No I/O activity.

3. Insure head and strike jamb corners meet.

4. Manually pull in door - No I/O activity.

5. Swing hinge jamb down.- No I/O activity.

6. Push Sequence Forward foot switch - PLC input I004.

a. Brings in movable side guns and strike jamb clamps - PLC output Q000

b. Header clamps extend - PLC output Q016.

c. PLC checks header sense switches: to find the header. Input I014 for right hand door (LS-14),

input I015 for left hand door (LS-15). See “Fixed Fence - Inside view” on page 74. for limit

switch locations.

7. Appropriate staple guns and clamps are raised into position.

• If Right hand door: PLC output Q006.

• If Left hand door: PLC output Q007.

8. Push Sequence Forward foot switch - PLC input I004.

a. Lowers in feed wheels dropping door into proper alignment with head and strike jamb - PLC

output Q001

9. Insure hinge jamb overlaps head jamb - No I/O activity.

10. Push Sequence Forward foot switch - PLC input I004.

a. PLC output Q003 goes high which Brings in fixed (hinge) side guns/clamps.

b. PLC output Q17 goes high which the activates the Fixed side in close cylinder.

c. When fixed side guns and clamps move to the proper position limit switch LS-17 activates

causing PLC input I017 to go high.

11. Push Sequence Forward foot switch - PLC input I004.

a. PLC output Q005 goes high causing the end clamps to push both the strike and hinge jamb

into the header which reference to the corner reference. This should square the jambs and

header.

b. PLC output Q010 goes high which raises the outfeed wheels raising the door assemble into

stapling position.

c. PLC output Q004 goes high causing the bottom jamb clamps raise, push frame up from the

bottom.

d. Fixed side in close cylinder is retracted, extended then retracted again. This tightens, loosens

and tightens the fixed side clamps, a process called burping. This burping action aligns and

squares the head, strike, and hinge jamb against the reference stops.

12. Insure door, head jamb and strike jamb are clamped square - No I/O activity.

13. Press Fire Guns PLC input Q002 goes high causing the staple guns to fire.

a. For Right Movable gun PLC output Q012 goes high firing the gun.

b. For Left Movable gun PLC output Q013 goes high firing the gun.

c. For Right Fixed gun PLC output Q014 goes high firing the gun.

d. For Left Fixed gun PLC output Q015 goes high firing the gun.

14. Staple guns start to drop (De-energize Raise Left or Right Staple Guns)

38 700-C

I/O for Normal Operation

15. As the Staple guns drop the through beam is counting slots, when the slot (the slots are ¼” apart)

counts equals a preset value a staple is fired (PLC outputs Q012 trough Q015).

16. Press Fire Side nailer (Optional). Air single only - No I/O activity.

17. Push Sequence Forward foot switch - PLC input I004.

4.Right OR Left hand door de-energized

• If Right hand door PLC output Q006 goes low.

• If Left Hand door PLC output Q007 goes low.

6.Press Reset - PLC input I001

18. .Manually feed door to next process - No I/O activity.

a. PLC output Q006 goes low causing the Right Staple Guns to drop.

b. PLC output Q007 goes low causing the Left Staple Guns to drop.

a. PLC output Q000 goes low causing Nailers, staple guns and clamps move away from door.

b. PLC output Q016 goes low causing header clamps to release.

a. PLC output Q010 goes high causing the Out feed Wheels to move up causing the door to

move to the position for outfeed.

700-C 39

Theory of Operation

Outfeed Wheels (silver)

Tandem

Cylinders

Wheel Assist

Cylinders

Infeed Wheels

(green)

Rack

&

Pinion

Outfeed Wheels (silver)

Infeed Wheels

Wheel assist

Rack and Pinion

Outfeed Wheels Tandem Cylinders

Clamps and Rollers (Feed System)

The door transport subsystem provides a mechanism for in and out feed of the door and assists in

clamping. There are two sections, one a mirror image of the other. One section is located on the fixed

side of the 700-C, the other on the movable side. Each section consists of a set of tandem pneumatic cylinders for the main drive, a pneumatic cylinder for wheel assist, a rack and pinion, three levers, three in

feed wheels and two out feed wheels. The tandem cylinders are connected to the rack, which turns the

pinions, which turns the levers, which change the elevation of the wheels (see illustration below).

40 700-C

Clamps and Rollers (Feed System)

B

A

B

A

PLC output Q011

PLC output Q010

1.5” Cylinder

2.5” Cylinder

Common Shaft

PLC output Q002

PLC output Q001

Main Air

Supply

Dual Activated

Control Valves

(Retract)

(Extend)

(Retract)

(Extend)

Tandem Cylinders

The tandem cylinders consist of two pneumatic cylinders which share a common piston rod (see Illustration below). One cylinder has 1.5” travel, the other a 2.5” travel. This arrangement allows for four

different stroke lengths of 0”, 1.5 ” , 2.5” and 4” (see Table 1:). Each cylinder is activated by a dual activation control valve. The dual activating control valves are located in the main valve bank.

Tandem Cylinder Stroke length

TABLE 4.

Stroke

Position Visual

Length

1 0” Retracted Retracted Q011, Q002

2 1.5” Extended Retracted Q010,Q002

3 2.5” Retracted Extended Q011, Q001

4 4” Extended Extended Q010, Q001

* The dual activated control valves are latching. A control voltage pulse of approximately 0.5 seconds

to input of the control valve will cause the valve to change state and latch in that state until another control voltage pulse is received.

1.5”

Cylinder

Cylinder

2.5”

PLC

Outputs*

700-C 41

Theory of Operation

Wheels assist

cylinder

0”

1.5”

2.5”

3.7”

3.7”

Extended

Wheel Assist Cylinder

The wheel assists cylinder's function is to provide extra lift

for the out-feed wheels. The wheel assist is a pneumatic

cylinder that when activated pushes a bracket mounted on

the rack. This cylinder is activated by a control valve

located in the main valve bank. The wheels assist control

valve is activated by PLC output Q20.

Operation

TABLE 5.

Position Visual Description

1 Both cylinders deactivated Q011

2 1.5” cylinder activated Q010

PLC

Outputs*

Q002

Q002

3 2.5” cylinder activated Q011

Q001

4 Both 1.5” and 2.2” cylinders

activated

5 1.5”, 2.2” plus wheels assist

cylinders activated

Q010

Q001

Q010

Q001

Q020

42 700-C

Staple Guns

Right Hand

Movable Side

Left Hand

Movable Side

Right Hand

Left Hand

Fixed Side

Fixed Side

Trigger

Bar

Through

Beam

Control

Valve

Staple

Gun

Air

Cylinder

Staple Gun

Air Input

Air over Oil

cylinder

Fire Guns

Control

Valve

Drop Guns

Staple Guns

The staple guns inserts staples into the desired locations in the door frame. There are four staple guns.

T wo on the fixed side and two on the movable side of the 700-C labeled Right Hand-Movable Side, Left

Hand-Movable Side, Right Hand-Fixed Side, Left Hand-Fixed Side (see illustration above). Each staple

gun assembly consists of a staple gun, a control valve, an air cylinder coupled to an air over oil cylinder

and a through beam with a trigger bar. (see illustration below).

700-C 43

Theory of Operation

Air over Oil

Canister

Control

Valve

“Drop Guns”

Oil Flow

Regulators

Oil Line

Horizontal

Cylinders

To Air

Exhaust

From Main

Air Supply

BA

TABLE 6. PLC Raise Guns Outputs

Location PLC Output

Fixed Fence side Q006

Movable Fence side Q007

From

PLC

Staple Gun Horizontal Positing

The horizontal staple gun positioning subsystem consists of a two control valves, two oil canisters and

four transport cylinders and four oil flow regulators, The two control valves are located in the main

valve bank. The two oil canisters are located on the lower frame rail, one at each end of the 700-C. The

staple gun transport cylinders and oil flow regulators are located under the four staple gun carriages.

Both right hand-movable and right hand-fixed staple guns share a common control valve and oil canister, as do both left hand-movable and left hand-fixed staple guns

Staple Gun Transport Operation

A +24 volt signal from the PLC activates the control valve which pushes compressed air into the top of

the oil canister which pushes oil into the lower section of the horizontal cylinder causing the staple gun

to raise into the firing position. When the PLC removes the +24 volt signal from the control valve the air

in the top of the oil canister is coupled to the exhaust port and compressed air is forced into the upper

portion of the transport valve allowing the staple guns to drop. The drop rate is controlled by the oil

flow regulator. Each of the two control valves is controlled by a dedicated PLC output as shown in the

table above.

44 700-C

Staple Guns

From Main

Air Supply

To other

Staple Guns

Control Valve

Input

Output

Staple Gun

Trigger

PLC Outputs for firing Staple Guns

Staple Gun PLC Output

Right Hand Movable Q012

Left hand Movable Q013

Right Hand Fixed Q014

Left Hand Fixed Q015

To PLC

Output

Air

Tee

+24 Volts (Brown wire)

-24 Volts (Blue wire)

Single - To PLC (Black wire)

Through Beam

Tri gg er Bar

Firing the Staple Guns.

Each of the four staple guns is connected

to the main air supply through an air T ee.

One output of the air Tee is sent to the

staple drive input of the staple gun, the

other to a control valve. The output of the

control valve is connected to the staple

gun trigger (see illustration at right). A

+24 volt single from the PLC activates

the control valve which allows air to flow

to the staple gun trigger causing the staple gun to fire. Each of the four staple

guns is controlled by a dedicated PLC

output.

Through Beam Circuit

The through beam sub-system is

an incremental linear optical

encoder. Its function is to measure

mechanical motion. There is a

through beam circuit for each of

the four staple gun carriage. Each

through beam circuit consists of

an emitter, a receiver and a trigger

bar all of which are mounted to

the staple gun carriages See illustration at right.

700-C 45

Theory of Operation

TABLE 7.

Through Beam

Output PLC Input

Right Hand Movable I006

Left Hand Movable I006

Right Hand Fixed I010

Left Hand Fixed I011

+24 Volts

-24 Volts

+24 Volts

-24 Volts

To PLC input

(O Volts)

+24 Volts

-24 Volts

+24 Volts

-24 Volts

To PLC input

(+24 Volts)

Beam Sensed Beam Blocked

Emitter

And Receiver

Trigger

Bar

Through Beams

The emitter is a visible light source. The receiver is a light sensor. The receiver is aimed at the emitter.

When the receiver senses the light from the emitter, the receiver will output a Low (0 Volt). If the emitter beam is blocked, the receiver will output a High (+24 volts). See illustration below. Each of the four

through beam outputs is connected to a dedicated PLC input.

Tr igger Bar

The trigger bar is a plate with 1/8” slots at ¼” increments

and is mounted to the main frame. The trigger bar passes

between the through beam’s emitter and receiver. As the

receiver and emitter move down the trigger bar the light

sensor outputs a Low for every slot in the trigger bar. The

“Lows” are counted by the PLC. See the illustration at

right.

46 700-C

Staple Guns

Staple Fired

Slot 1 3/4”

Slot 2 1”

Slot 3 1 1/4”

Slot 4 1 1/2”

Slot 5 1 3/4”

Slot 6 2”

Slot 7 2 1/4”

Slot 8 2 1/2”

Slot 9 2 3/4”

Slot 10 3”

Slot 11 3 1/4”

Slot 12 3 1/2”

Slot 13 3 3/4”

Slot 14 4”

Slot 15 4 1/4”

Slot 16 4 1/2”

Slot 17 4 3/4”

Slot 18 5”

Slot 19 5 1/4”

Slot 20 5 1/2”

Slot 21 5 3/4”

Slot 22 6”

Slot 23 6 1/4”

Slot 24 6 1/2”

Slot 25 6 3/4”

Slot 26 7”

Slot 27 7 1/4”

1/2”

Here

Staple Fired

Here

Staple Fired

Here

Staple Gun and Through Beam Operation

At the start of the Staple sequence, the staple gun is approximately 1/2” from the top of the jamb. When

the Fire Guns button is pressed, the staple gun fires a staple. The staple gun transport cylinder is deactivated which causes the staple gun carriage to drop. As it drops the through beam sub-system counts the

slots in the trigger bar. Whenever the trigger bar slot count equals a number in the staple pattern, a staple

is fired.

Example:

For this example let’s say the selected staple gun pattern

contains slot numbers 7 and 12. When the “Fire Guns”

button is pressed, the staple gun fires, and this puts a staple approximately 1/2” from the top of the jamb. The

Staple gun carriage drops and the computer counts trigger bar slots. When the trigger bar slot count reaches 7 a

staple is fired. Then when the trigger bar slot count

equals 12 the staple gun would fire. The result would be

3 staples in the jamb at 1/2”, 2 1/4” and 3 1/2”. See the

illustration at right.

700-C 47

Theory of Operation

48 700-C

CHAPTER 5 T roubleshooting

700-C 49

Troubleshooting

Manual override button

CAUTION: Once activated, The valve will allow full

pressure to cylinder. Make sure you are clear of all moving

parts.

Troubleshooting the Air Cylinders

Most cylinders have an extend and retract port. To adjust the extend motion of a cylinder you must

adjust the flow control on the retract port; this regulates the air flow exhausting from the cylinder and

the opposite is true for the retract motion.

1. Check the air pressure to the machine.

2. Check the flow controls to see that they are adjusted correctly and to the proper specifications.

3. Check for any obstructions to the cylinders such as screws or a mis-

placed tool etc. FOLLOW ALL SAFETY GUIDELINES AND

SIGNS DURING THIS PROCESS.

4. Check the solenoid air valves:

a. The solenoid valves can be manually operated by pushing

the red manual override button on the end of the valve.

b. If the valve seems to be leaking, the seals may be dry or contaminated with water or it maybe

that the cylinder “O” rings are damaged and air is passing from one side to the other side of the

cylinder which means the air is exhausting through the solenoid valve. It maybe is necessary to

purchase a rebuild kit or a new cylinder.

c. If the valve is not receiving an electrical signal, for instructions. It might be necessary to call

in a specialist or check with KVAL customer service at 1-800-553-5825.

5. If an Air Leak is coming from an exhaust port on the solenoid air bank:

50 700-C

Troubleshooting the Air Cylinders

a. Check the solenoid for the manual override. If the solenoid has a manual override you can

push each of the buttons one at a time. When the air leak stops or weakens it usually means that

one or more of the cylinders that the solenoid is operating are faulty.

Adjusting Cylinder Extension Speed:

Adjusting Cylinder Retraction Speed:

700-C 51

Troubleshooting

THE FOLLOWING SHOULD ONLY BE ATTEMPTED BY TRAINED

ELECTRICAL PERSONNEL.

Troubleshooting Electrical Problems

The electrical component systems are designed to expedite the troubleshooting process and mini mize

“down time”. In general, component systems have the input or feed functions at the top. Output or load

functions are positioned at the bottom. Most two-voltage electrical panels are designed with the LOW

VOLTAGES on the LEFT, and the HIGH VOLTAGES on the RIGHT. The majority of the system components are labeled with numbers that correspond with the electrical prints included in the electrical box

door.

Computer controlled machines have signals on the computer that light up when the input or output functions are energized, respectively. Computer controlled as well as non-computer controlled machines

have white 120V control power terminal strips. This will indicate power supply from the respective circuits.

Idec controllers also have lights on them for the input and output functions. You can easily find out

which circuits are failing by watching the lights turn on or off. Compare the lights on the IDEC controller to the electrical print to determine what systems are being affected.

If the Power Stops During Normal Operation

1. Check that the input power disconnect switch is not turned off.

2. Check that all of the emergency stop buttons are in the normal position.

3. Lock Out and Tag Out the main power source.

4. Turn the panel disconnect switch in the off position, open the electrical panel door.

5. Observe the disconnect switches. Look for loose or broken wires at the disconnect then at all of the

components.

6. Check for continuity of all fuses with an OHM meter.

7. Check motor overloads by pressing each white button (usually at the bottom of the panel) in

SEQUENCE,. If one is tripped there will be a slight resistance to touch and a “click” sound as it is

reset.

WARNING

The following checks require the electrical panel to be energized. These troubleshooting checks

MUST BE PERFORMED BY A QUALIFIED ELECTRICAL TECHNICIAN.

1. Remove lock and tag outs on the main power sources.

2. Manually close disconnect switches and energize the control circuit or transformer with its respective

switch. Observe that the numbers 1, 3 & 4 are lit on the white lighted terminal strip. This tells you that

there are no overloads or emergency stops tripped.

3. Most electrical problems are related to mechanical malfunction (e.g., stuck motors, jammed chain,

non tripped limit switches, etc.) The most common failure is an improperly adjusted limit switch. To

check a limit switch, manually operate the limit switch. If the computer terminal strips lights, the

switch needs to be re-adjusted. For more information on the limit switch specifications, see the manu facturer’s information. For limit switch adjustment procedures, refer to.

4. If a solenoid valve is suspected, and not cleared in the air checks section (see), it can be electrically

jumped to check operation.

52 700-C

Troubleshooting Electrical Problems

POWER

RELAY

E-STOP

T

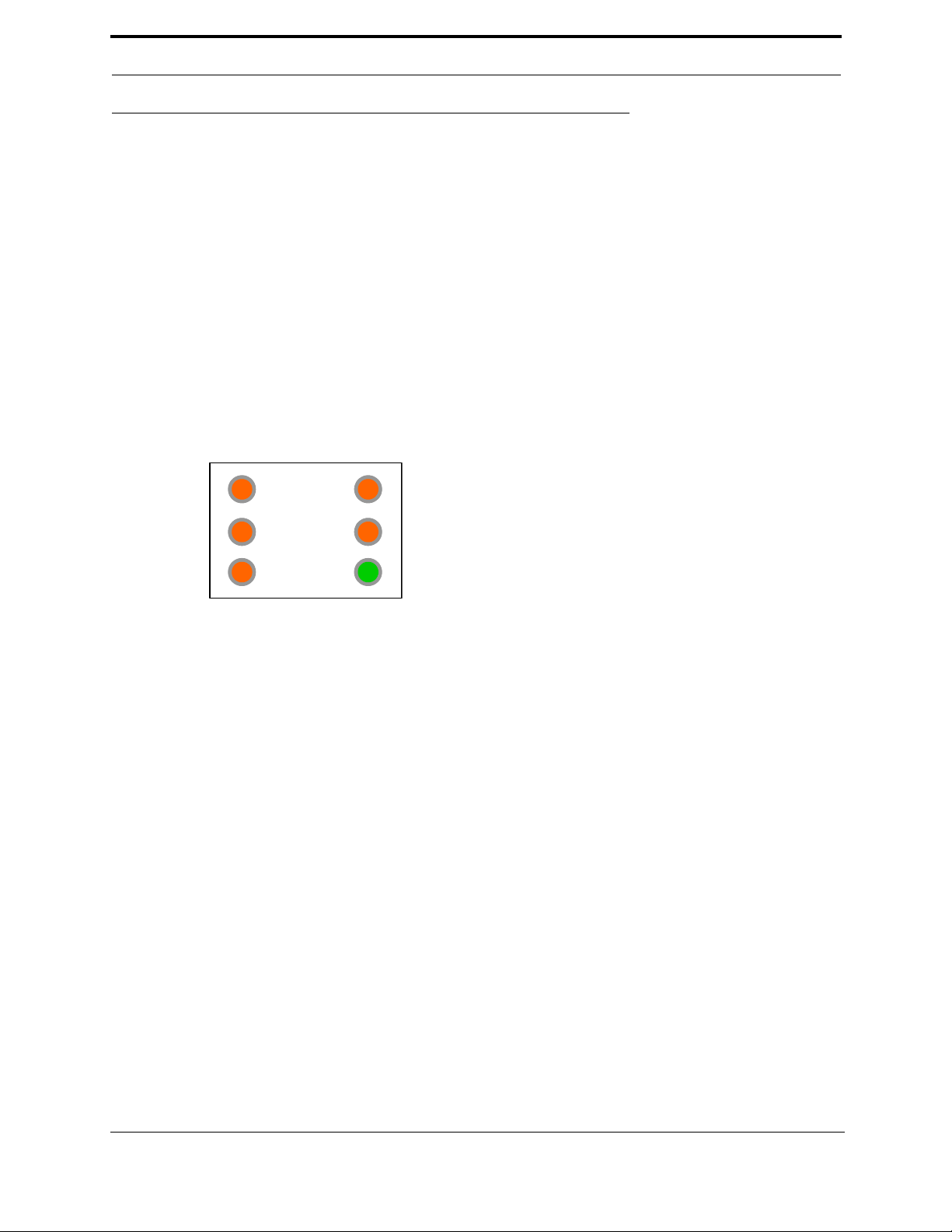

Troubleshooting with the Status Light Panel

The Status List Panel is located on the front of the Operator’s

Station, below the work surface area. It has six lights that are all

illuminated when the system is in proper working order. If one

or more lights are OFF, follow the process below to ascertain the

cause.

NOTE: Be sure to proceed down the table, starting with the

CONTROL POWER light.

CONTROL

OVERLOAD

STOP

STAR

24VDC

700-C 53

Troubleshooting

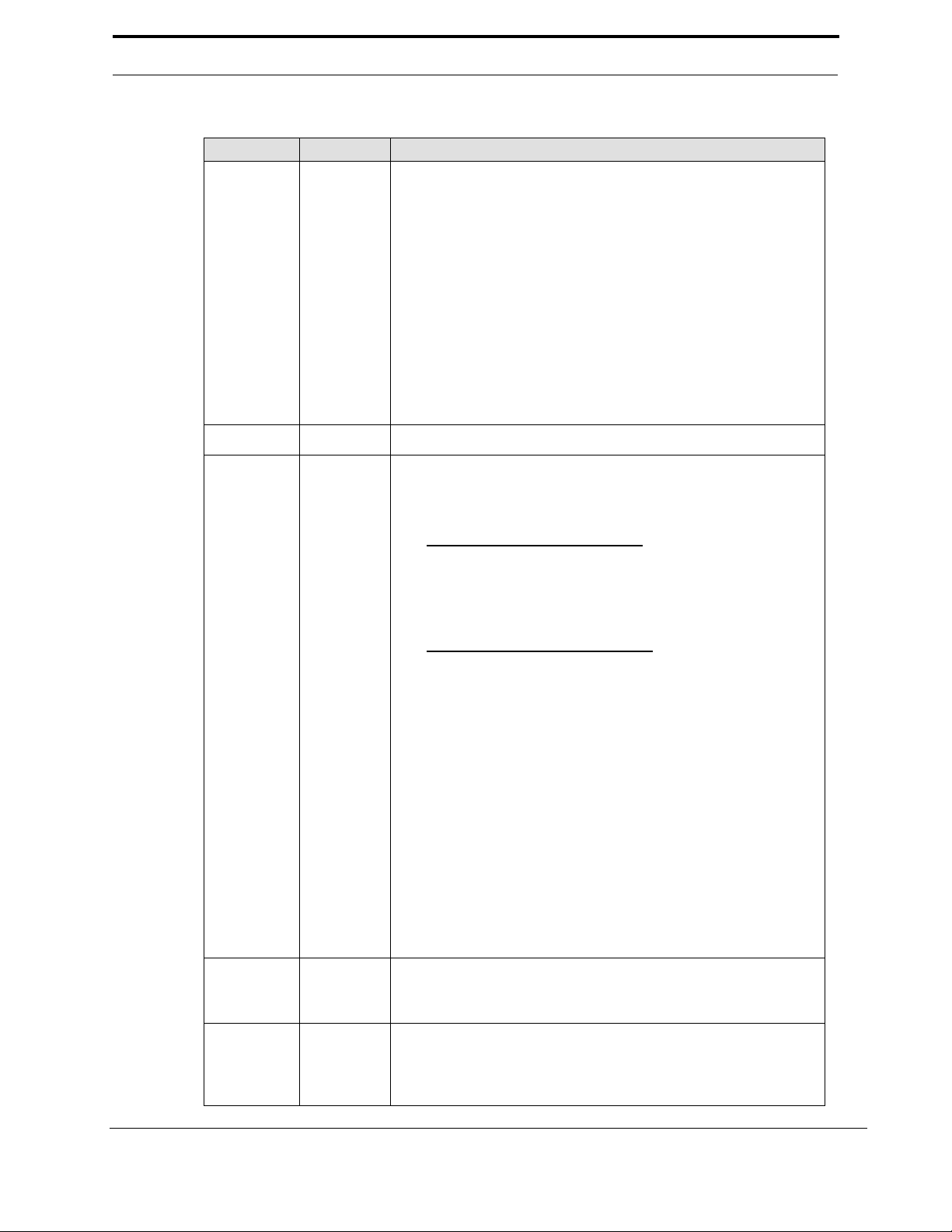

Light If ON: If OFF:

CONTROL

POWER

OVERLOAD

RELAY

E-STOP Go to STOP • Check to see the E-Stop button(s) is pulled out.

STOP Go to START • Check for 110 V AC between #2 and #6. If there is voltage, press

ST ART Go to 24VDC • Push the Start button. If the Start light remains unlit, push in the

Go to OVERLOAD

RELAY

Go to

E-STOP

• Check to see if the Control Transformer button is pulled out.

• Is the Disconnect switch on the main electrical cabinet set to

ON?

• Is there 208, 220, 440, or 575 VAC to the top side of the Control

Transformer (E3)? If not, check the fuses at the Fuse Block (E5),

and the contacts on the Control Transformer button on the switch

panel.

• Is there 110 VAC between #1 & #2 on the110 VAC Terminal

Strip? If not, check the fuse on the output side of the Control

Transformer. If fuse is good, check power coming out of Control

Transformer. If no power on the output side, and ther e is power

going into the top of the Control Transformer, replace the Control

Transformer. If there is power at the Control Transformer, check

the wiring of the black and white wire going from the Control

Transformer to the 110 VAC Terminal Strip.

• There is No over-load relay on this machine. If there is power to

the Status Light panel this light will be lit.

NOTE: Location and quantity of E-Stop buttons varies depending

on customer need. Typical locations for E-Stop buttons are near

the Rear Access Gate and near the Tool Changer Access Gate

• For Single E-Stop button machines

between #2 and #4. If no voltage, check to see if the E-Stop button is pulled out. If the E-Stop button is pulled out and E-Stop

light is OFF check the wiring. If no fault is found in the wiring turn

off the DL-NCB main power and check for continuity across the

pulled out E-S t op swi tch.

• For multiple E-Stop Button machines

on #2 check for 110 VAC on #4 through #5. If at any point no voltage is found trace the wires to find the associated E-Stop button

and check to see if that button is pulled out. If the E-Stop button

is pulled out and the E-Stop light is OFF check the wiring. If no

fault is found in the wiring turn off the DL-NCB main power and

check for continuity across the pulled out E-Stop switch.

• Check to see if the Back Gate is closed.

• Check to see if the Disconnect switch on the high-frequency

electrical cabinet is ON.

• Check for 110 VAC between #2 and #3A on the 110 VAC Terminal Strip. If there is 110VAC, go to next step: If the Disconnect

switch on the high-frequency electrical cabinet is OFF (closed)

and there is not 110 VAC between #2 and 3A, check the wiring.

• Check for 110 V AC between #2 and #3B. If there is 1 10 VAC, go

to next step: If the contact on the Rear Access Gate is closed and

there is no power between #2 and #3B, check for wiring problems.

the Start button. If no voltage, check the S top button to make sure

it is all the way out and not stuck in, then check the contact to

make sure it is closed. If still no voltage, check the wiring.

Start button and hold it in while a second person checks for voltage between #2 and #7. If there is 110 VAC, replace the ACR

relay. If there is no voltage while the button is held in, check the

wiring.

: Check for 110 VAC

: With on side of the meter

54 700-C

Troubleshooting Electrical Problems

24VDC Home the

700-C (see)

Check between DC+ and DC- for 24VDC. If no DC voltage, disconnect the

+ Brown/Red and - Blue/Black wires from the 24VDC power supply and

check for DC voltage where those wires were disconnected.

If no voltage:

• Check the input side for 110 VAC. If no 110 VAC, check the

fuse. If there is 110 VAC and no 24VDC, replace the 24VDC

Power Supply.

If there is 24VDC:

• Reconnect the + Brown/Red and - Blue/Black wires to the

24VDC power supply.

• Trace the + Brown/Red wire to the DC terminal block.

• Disconnect all brown wires from the + DC from the DC terminal

block except the + Brown/Red wire form the + 24VDC power supply.

• Check for +24VDC at between any –DC and +DC terminal on

the DC Terminal block.

• Reinstall the + brown wires one by one checking for +24VDC

after installing each + brown wire. If at any point no voltage is

found trace the last reinstalled wire and check for shorts.

Adjusting Limit Switches

If a machine suddenly stops in mid cycle, check the limit switches. A worn limit

switch arm or a misadjusted limit switch is more than likely the cause. (Another

potential cause is faulty photo eyes – for details.)

Depending on the model of limit switch on your machine, the pre-travel (amount

of movement from the limit switch arm’s resting position to the position at which

the switch actuates – with a “click”) is either 5 or 20 degrees. The DL-NCB has

700-C 55

Troubleshooting

five limit switches that have 5 degrees of pre-travel (3 on the X axis and 2 on the Y axis), and two

switches that have 20 degrees of pre-travel (on the Cutter head).

If the arm is moved to the full extent of its travel and you do not hear the limit switch “click”, the switch

needs to be adjusted. Use the set screw on the limit switch arm and adjust the arm to activate at the

desired degree of rotation (see illustrations

below).

Examples of Limit Switches:

56 700-C

Troubleshooting Photo Detectors

Troubleshooting Photo Detectors

Another cause of improper machine operation is a faulty or dirty photo detector.

There are two types of photo detectors, Through Beams and Photo Eyes.

• Through Beam Detectors consist of an emitter and detector. The emitter sends a light beam that is

sensed by the detector. The detector then sends 0VDC to the PLC. If the beam is broken the detector

sends 24VDC to the PLC.

• Photo Eye Detectors contain both emitter and receiver. If an object is within the Photo Eye’s sensing

field light from the emitter is reflected from the object back to the receiver. The Photo Eye then sends

24VDC to PLC. If no object is sensed the Photo Eye sends a 0VDC to the PLC.

If the photo detector is dirty, it will falsely sense the presence of a door, or other ob st ruction, and stop

the machine operation. If a suspected Photo Detector is clean check for the proper DC Voltage.

700-C 57

Troubleshooting

58 700-C

Touch Screen Troubleshooting

Moves to screen PLC

output screens. See

“PLC Output 00-17”

on page 65.

Moves to screen PLC

output input screens.

See “PLC Input 0017” on page 61.

Touch Screen Troubleshooting

Maintenance Screen

TABLE 8.

Title Notes

Reg/Split Shows status of Jamb type switch (SW00):

• Reg. = OFF

• Split = ON

See “Control Panel” on page 77. for switch location.

Reset Shows status of Reset switch (PB01 & (OPTIONAL) PB01A):

See “Control Panel” on page 77. for switch location.

Fire Shows status of Fire Guns switch (PB02 & (OPTIONAL) PB02A):

See “Control Panel” on page 77. for switch location.

Forward Shows status of Forward foot switch. (FS1)

See “Fixed and Movable Fence” on page 71. for location

Reverse Shows status of Seq. Reverse foot switch (FS2).

See “Fixed and Movable Fence” on page 71. for location

Enable movable Shows status of Enable Movable Guns switch (SW12 & (OPTIONAL) SW12B):.

See “Control Panel” on page 77. for switch location.

Enable fixed Shows status of Enable Fixed Guns switch (SW13 & (OPTIONAL) SW13A):

See “Control Panel” on page 77. for switch location.

Right header Shows status of Infeed head in place in place limit swi tch (L S14).

See “Moveably Fence - Inside view” on page 75.

700-C 59

TABLE 8.

TABLE 9. Staple sequence switch truth table

Program

Location

1

Program

Location

2

Program

Location

3

Staple

Sequence

OFF OFF OFF 0

ON OFF OFF 1

OFF ON OFF 2

ON ON OFF 3

OFF OFF ON 4

ON OFF ON 5

OFF ON ON 6

ON ON ON 7

Title Notes

Left header Shows status of Outfeed head in place limit switch (LS15).

See “Moveably Fence - Inside view” on page 75.

Guns in Shows status of Guns In limit switch (LS-17).

See “Fixed Fence - Inside view” on page 74.

Program Local 1

Program Local 2

Program Local 4

Program Local 8

. Shows status of Staple

Sequence switch

(SW30,SW31,SW32,SW33)

See “Main Control Panel” on

page 77. for location. The S ta-

ple Sequence switch converts

the decimal Staple Sequence

number to it’s binary equiv-

lant. See the truth table at

right.

Note: At present Program

Local 8 is not used.

Program Remote 1

Program Remote 2

Program Remote 4

Program Remote 8

Jamb Width A Shows status of the Jamb Width A switch (SW34 & (Optional) SW34A). See “Main Con-

Jamb Width B Shows status of the Jamb Width B switch (SW35 & (Optional) SW35A). See “Main Con-

Jamb Width C Shows status of the Jamb Width C switch (SW36 & (Optional) SW36A). See “Main Con-

Jamb Width D Shows status of the Jamb Width D switch (SW37 & (Optional) SW37A). See “Main Con-

60 700-C

Shows status of Staple Sequence switch (SW20,SW21,SW22,SW23) See “Remote Control

Panel (Optional)” on page 78. The Staple Sequence switch converts the decimal Staple

Sequence number to it’s binary equivalent. See “Staple sequence switch truth table” above

trol Panel” on page 77.

trol Panel” on page 77.

trol Panel” on page 77.

trol Panel” on page 77.

Touch Screen Troubleshooting

PLC Input 00-17

TABLE 10.

Title Notes

SS-00 Split-jamb Shows status of Jamb type switch (SW00):

• Reg. = OFF

• Split = ON

See “Control Panel” on page 77. for switch location.

PB-01 Reset Shows status of Reset switch (PB01 & (OPTIONAL) PB01A):

See “Control Panel” on page 77. for switch location.

PB-02 Fire guns Shows status of Fire Guns switch (PB02 & (OPTIONAL) PB02A):

See “Control Panel” on page 77. for switch location.

SS-03 RH/LH Not used.

FS-04 Seq. FWD Shows status of Forward foot switch. (FS1)

See “Fixed and Movable Fence” on page 71. for location

FS-05 Seq. REV Shows status of Seq. Reverse foot switch (FS2).

See “Fixed and Movable Fence” on page 71. for location

PE-06 Movable right Shows status of Movable right through beam (THRU06)

See “Heads” on page 73. for location.

PE-07 Movable left Shows status of Movable left through beam (THRU07)

See “Heads” on page 73. for location.

PE-10 Fixed right Shows status of Fixed right through beam (THRU010)

See “Heads” on page 73. for location.

PE-11 Fixed left Shows status of Fixed left through beam (THRU011)

See “Heads” on page 73. for location.

SS-12 Enable movable guns Shows status of Enable Movable Guns switch (SW12 & (OPTIONAL) SW12B):.

See “Control Panel” on page 77. for switch location.

700-C 61

TABLE 10.

Title Notes

SS-13 Enable fixed guns Shows status of Enable Fixed Guns switch (SW13 & (OPTIONAL) SW13A):

See “Control Panel” on page 77. for switch location.

LS-14 Infeed head in place Shows status of Infeed head in place in place limit switch (LS14).

See “Moveably Fence - Inside view” on page 75.

LS-15 Outfeed head in place Shows status of Outfeed head in place limit switch (LS15).

See “Moveably Fence - Inside view” on page 75.

PE-16 Door in machine Shows status of Door in Machine photo eye (PE16).

See “Fixed and Movable Fence” on page 71. for location.

LS-17 Guns in Shows status of Guns In limit switch (LS17).

See “Fixed Fence - Inside view” on page 74.

62 700-C

Touch Screen Troubleshooting

PLC Input 20-37

TABLE 1 1.

Title Notes

SS-20 Remote Sel-1

SS-21 Remote Sel-2

SS-22 Remote Sel-4

SS-23 Remote Not-8

SS-25 Metal Sill Not used

SS-26 Manual / Auto Shows status of 6’8”/8’0 switch

CR-27 Remote hand info Not used

Shows status of Staple Sequenc e switch (SW30, SW31,SW32,S W33) See “Remo te Control

Panel (Optional)” on page 78. for location. The Staple Sequence switch converts the deci-

mal Staple Sequence number to it’ s binary equivalent. See the tr uth table Figure 12, “Staple

sequence switch truth table,” on page 64

Note: At present Program Local 8 is not used.

See “Main Control Panel” on page 77. for location.

700-C 63

TABLE 1 1.

TABLE 12. Staple sequence switch truth table

Program

Location

1

Program

Location

2

Program

Location

3

Staple

Sequence

OFF OFF OFF 0

ON OFF OFF 1

OFF ON OFF 2

ON ON OFF 3

OFF OFF ON 4

ON OFF ON 5

OFF ON ON 6

ON ON ON 7

Title Notes

SS-30 Local Sel-1

SS-30 Local Sel-2

SS-30 Local Sel-4

SS-30 Local Not-8

. Shows status of Staple

Sequence switch

(SW30,SW31,SW32,SW33)

See “Main Control Panel” on

page 77. for location. The Sta-

ple Sequence switch converts

the decimal Staple Sequence

number to it’s binary equiva-

lent. See the truth table at

right.

Note: At present Program

Local 8 is not used.

SS-34 Jamb size A

SS-34 Jamb size B

SS-34 Jamb size C

SS-34 Jamb size D

Shows status of Staple Sequenc e switch (SW20, SW21,SW22,S W23) See “Remo te Control

Panel (Optional)” on page 78. The Staple Sequence switch converts the decimal Staple

Sequence number to it’s binary equivalent. See “Staple sequence switch truth table” above

64 700-C

Touch Screen Troubleshooting

PLC Output 00-17

TABLE 13.

Title Notes

SV-00 Move side clamp Shows status of control valve SV-00 (See “Control Valves” on page 76.)

which controls PC32 and PC35 (See “Heads” on page 73.)

SV-01 Infeed wheels up Shows status of control valve SV-01 (See “Control Valves” on page 76.)

which controls PC6 and PC26 (See “Infeed and Outfeed Wheels” on page 72.)

SV-02 Infeed wheels down Shows status of control valve SV-02 (See “Control Valves” on page 76.)

which controls PC6 and PC26 (See “Infeed and Outfeed Wheels” on page 72.)

SV-03 Fixed side clamp Shows status of control valve SV-03 (See “Control Valves” on page 76.) which controls

PC39 and PC36 ((See “Heads” on page 73.)

SV-04 Bot. Jamb clamp Shows status of control valve SV-04 (See “Control Valves” on page 76.) which controls

PC13, PC23 (See “Fixed Fence - Inside view” on page 74.) and PC14, PC24 (See “Move-

ably Fence - Inside view” on page 75.)