Kuzma STOGI-90923 User Manual

Instruction manual

KUZMA STOGI TONEARM (on Stabi S)

2009-9

1

Serial Number: ……

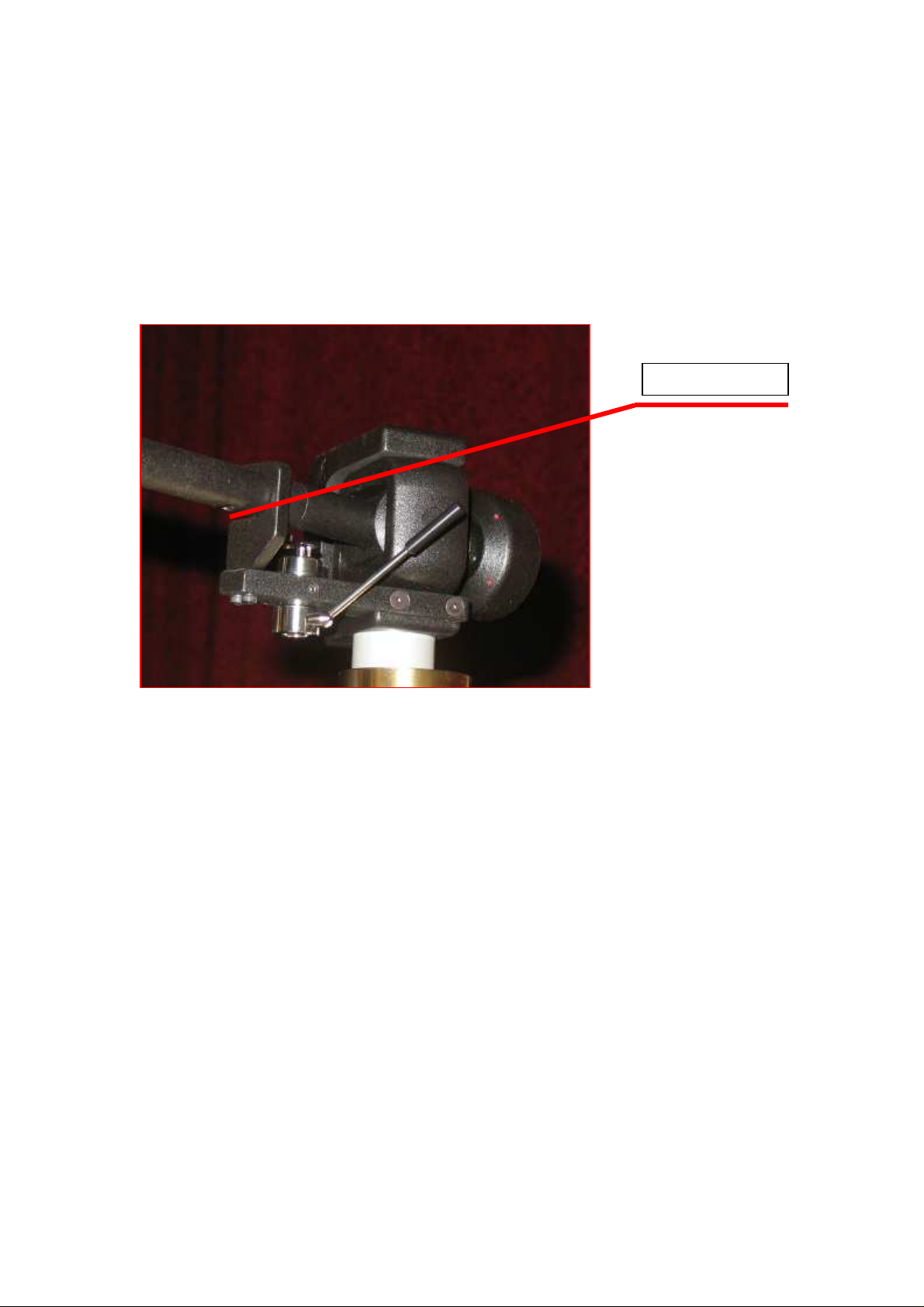

Azimuth fixing

KUZMA LTD

INSTRUCTION MANUAL FOR STOGI

TONEARM

The Stogi tonearm is very precisely engineered pieces of audio equipment. However

the construction is robust and requires minimal maintenance for optimal performance.

Fig 1.

CONTENTS: Page

1.0. General description 3

2.0. Unpacking 4

3.0. Tonearm Setup 4-7

4.0. Tonearm adjustment 7-10

4.1. Adjustment of tracking force 7

4.2. Adjustment of tangential geometry 7- 9

4.3. Adjustment of VTA 10

4.4. Adjustment of azimuth 10

4.5. Bias adjustment 11

4.6. Adjustment of cueing device 11

5.0. Maintenance 12

6.0. Transport 13

7.0. Troubleshooting 13-14

Appendix 1-3 15-20

2

1.0. General description:

The Stogi tonearm shares the same construction with the Stogi Ref arm. The main

difference is that Stogi has a cylindrical and Stogi Ref a conical tube.

The Stogi has simple azimuth adjustment mechanism.

The main structure and headshell are machined from solid aluminum blocks.

The quality ball bearings are carefully selected and individually checked and tested

before assembly. They can each support 20 Kg and are mounted free of play with

minimal friction in all planes.

Stogi arms incorporate features such as an adjustable height cueing device, precisely

calibrated counterweight and simply adjustable bias.

The arm is wired throughout with high quality Cardas wires and comes equipped with

its own full accessories kit. It will accept all cartridges and can be fitted on most

quality turntables.

Technical data:

Mass: 800 gr

Effective length : 230 mm (9 inch)

Mounting distance: 212 mm

Offset angle: 24 degrees

Effective mass: 12.5 g

VTA adjustment: yes

Azimuth adjustment: yes

Bias adjustment: yes

Cables: single ( optional silver)

Arm mount: Kuzma & Stogi

3

2.0.0. Unpacking:

2.1.0. Packing list:

Tonearm with fingerlift; counterweight; armbase; instruction manual; two protractors,

one for mounting tonearm on turntable and the other for cartridge geometry

adjustment and a bag.

Bag:

Sets of 3 socket head screws M6x16 mm, M6x20 mm, M6x25 (for Stabi Ref), M6x

30 mm, three washers, three spring washers (wooden armboards) for fixing base.

Allen keys: 5 mm for attaching armbase to armboard, 3mm for height adjustment

(VTA), 2mm for cartridge and azimuth, 1,5mm for fixing counterweight, bias and

cueing device adjustment.

Small bag containing 2 headsocket screws M2.5 x 5mm, M2.5x8 mm, M2.5x 12mm

and nuts for fixing cartridge plus Allen key 0.7mm for removing fingerlift.

Open the box carefully and remove the top cover. Ensure that the armboard on the

turntable has the correct cut-out (main central hole must be 30- 40mm in diameter).

Remove the armbase and prepare it for fixing onto the turntable.

Holding the pillar not the tube, lift the tonearm out. Observe bias and thread while so

doing.

The tonearm can be rested upside down on C shape.

Remove all other parts.

3.0.0. Tonearm Setup:

3.1.0. Armbase Setup:

3.1.1. Armboard cutout:

Take the tonearm mounting protractor and place on spindle of turntable. The Stogi

cut-out is similar to the standard Linn cut-out. You can also make a Kuzma cutout.

Mark position of holes on the tonearm mounting board as indicated on protractor.

Ensure that there is adequate space in front for tube and headshell and behind for

counterweight, in order to avoid problems of lid closure. Check also that screw

positions will be over cut-out on subchassis, unless screws are to be sunk. It is wise

before cutting to hold tonearm in position over marks and judge if position of

tonearm on board will be correct, bearing in mind these criteria. Otherwise the

precise position of tonearm is unimportant providing it lies on the protractor arc.

The height of tonearm with cartridge mounted is 55mm above record.

Remove tonearm board from turntable and check that thickness of board is between 6

mm and 22 mm, if so make cuts as marked.

4

3.1.2. Armbase mounting:

To fix armbase to armboard you will need the correct length of three socket head

screws, washers and Alley key 5mm. Fit washers on screws and insert into underside

of tonearm board and up into tonearm base. Position base so that height adjustment

(VTA adjustment) screw is at top right position, i. e. 2 o’clock and tighten screws

using Allen key.

Remember that the screws are of harder material than the armbase (aluminum) so do

not over tighten as this could damage base.

Note: if armboard is thicker then 22 mm:

Either obtains screws of a length that will go through the armboard and into the base

to a depth of approximately 5mm, or sink the screw heads by first drilling a large hole

of about 9mm with drill and then drilling a hole of smaller dimension through this.

Put tonearm board back on turntable.

3.2. Tonearm mounting:

Note: Be sure that the tonearm is not too low.

Insert tonearm cable through hole in armbase, then the pillar and fix it at a suitable

height using Allen key 3mm at height adjustment screw in base.

Screw on counterweight so that the thread is covered.

It may now be necessary to adjust the suspension on the turntable due to the added

weight of the tonearm.

Fix tonearm cable onto turntable ensuring that there is adequate cable to allow for

height adjustment. If the turntable has a suspended subchassis, position cable in such

a way that subchassis has freedom of movement.

The phono plugs are marked in the standard way: left - white, right - red, and

should be inserted into phono inputs. The connector at the end of the grounding

wire should be connected to GND on preamplifier.

Check that bias and thread are correctly positioned (it may have tangled during

handling).

For optimum performance you may wish to forego the convenience of the finger lift.

If so, this should now be removed using Allen key 0.7mm, loosening screw

and easing out lift. Replace screw in hole.

Remove wire securing arm tube.

5

3.3. Setting up the tonearm:

3.3.1. Connecting tonearm:

Check the horizontal movement of the tube to ensure that the headshell will reach the

inner grooves.

Due to the high tonearm mass, turntable leveling and suspension should be checked

and adjusted according to the turntable manual.

3.3.2. Cartridge mounting:

You will need Allen key 2mm plus the two screws and nuts M 2.5 (some cartridges

has already threads, nuts will not be need it).

Mount the cartridge with the appropriate set of 2.5mm screws and check its travel

above the record with the cueing device in the “up” position! Starting overhang is

achieved, if the needle is in line with the front edge of the headshell.

Keeping the stylus guard on cartridge, insert screws from underneath the cartridge

through the slots in the headshell. Screw on the two nuts manually. The tip of the

cantilever should be level with the end of the headshell (viewed from side).

Fix by slightly tightening screws using Allen key. Ensure that nuts have fitted into the

ledge around the slots.

Note: It may be found easier to remove tube from armrest to give a little

more room below headshell.

Using tweezers push the pin connectors into cartridge according to code

Red - right

Green - right ground

White - left

Blue - left ground

The connectors will slip snugly onto pins of the majority of cartridges, but:

Pins too fat: with tweezers firmly push connector onto pin. Connector will

open slightly. Do be careful, however, that tweezers do not slip and damage

cantilever.

Pins too thin: connectors should be squeezed with tweezers to make hole

slightly smaller. First squeeze as in A then as at B then slip connectors onto pins.

Put cueing device into ‘play’ position, ie. down, release tube from armrest and

adjust counterweight until tube is balanced ie. floats in a horizontal position slowly

back towards the armrest. Prior to final balancing remove stylus guard.

3.3.3. Balancing of the tonearm:

Balance the tonearm to zero tracking force by rotating counterweight along the thread.

The instructions with your cartridge will recommend suitable tracking force. We

recommend you choose the highest force given and set arm to that amount. A higher

tracking force causes less damage to the record as the stylus maintains more stable

contact with the sides of the grooves.

6

Loading...

Loading...