Kuzma Stabi-M130105 User Manual

KUZMA STABI M TURNTABLE (

Instruction manual

2013-1

without arm ) S/N……..

1

KUZMA LTD

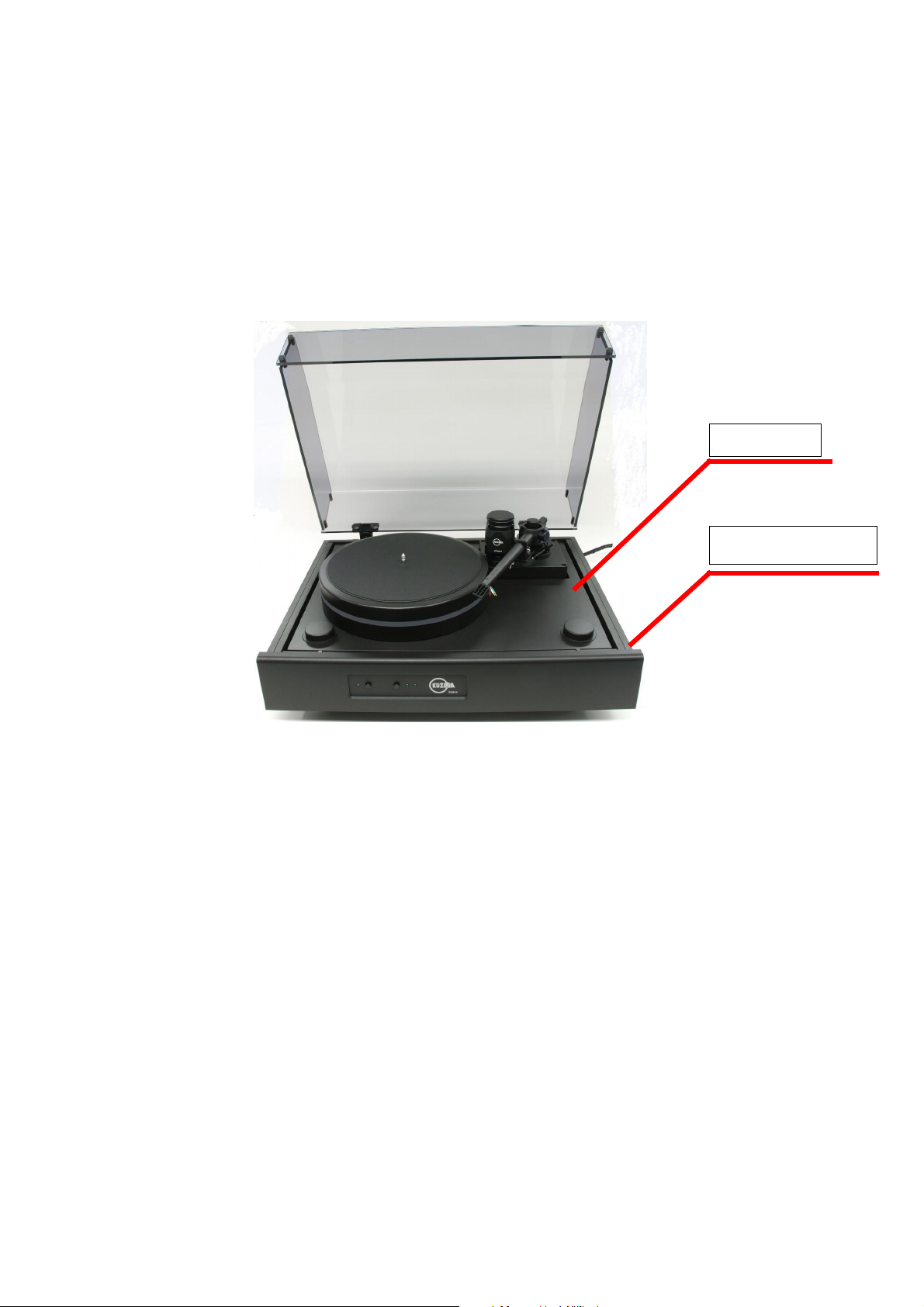

Top plate

INSTRUCTION MANUAL FOR STABI M turntable

The Stabi M turntable is a very precisely engineered piece of equipment. However the

construction is robust and requires minimal maintenance for optimal performance.

Outer main frame

CONTENTS: Page

General 3

Tech. data 4

Unpacking and assembling 5-6

Setting up turntable 7-8

Use and Adjustment 10-11

Maintenance 11

Troubleshooting 11

Transportation 12

2

General

STABI M is a modern turntable designed in a classic turntable style with the emphasis on

providing the best possible record playback.

The turntable's size allows even 12 inch tonearms to be mounted and covered with its massive

acrylic dust cover on spring hinges. The dust cover is constructed not to pick up any vibration

from loud music.

The turntable is assembled from various solid parts of aluminium, making the construction

rigid and absorbing vibration. On the outer sides of the main structure are solid aluminium

plates, which give the turntable mass and further increase structural rigidity and damping.

The covered spikes within the legs allow horizontal levelling of the whole turntable.

The top aluminium plate under the platter, has an elastically underhung main frame and

motor system below. This is insulated from the outer main turntable's structure via four big

elastic dampers, which allow for fine horizontal levelling of the platter and tonearm.

The platter is constructed from two pieces of 40mm thick aluminium with an acrylic

damping plate sandwiched between making a very inert support for records.

The bearing has an inverted shaft with a ruby ball which gives precise, low noise rotation to

a supporting subplatter.

The main frame carrying the main bearing and massive aluminium armboard, is bolted

together from solid aluminium blocks forming a unique damped rigid support.

The motor system: The DC motor itself is specially mounted inside a brass cup and

aluminium plate. This motor assembly is enclosed and suspended inside a massive brass

motor housing. Thus the main frame is doubly insulated from the motor system and yet

still maintains rigidity, allowing for max. torque momentum to be transmitted via the stiff

plastic belt to the subplatter. This gives the platter a high torque drive with the positive

properties of belt and idler drives, while minimising the negatives one.

The external power supply: This controls the DC motor with precise frequency and it has

very fine speed adjustments. The control panel on the front plate of the turntable has

start/stop and speed change functions. The full speed of platter of 33rpm is reached in just

over 3 seconds. There is also a remote control start/stop function.

3

Technical data:

Mass 60 kg

Platter mass 12 kg

Platter material aluminium& acrylic

Bearing type ruby ball- inverted

Shaft diameter 16 mm

Chassis/levelling aluminium/yes

Turntable levelling yes

Motor 1 DC ( three phase)

Belt material special

External power supply yes

Speeds 33, 45, 78 ( see page 10)

Armboard yes

No. of tonearms 1

Suspended special

Dimensions 610x500x290

Finishes black

Clamp yes

Mat yes

Lid yes

Accessories oil, Allen keys

Options: armboards

Optional: various predrilled armboards (SME, Graham, Triplanar, Ikeda, Ortofon,…)

Safety Precautions:

Electrical connection to the motor controller unit (PS DC) from the mains comes via the

cable. Please keep PS DC away from moisture and be careful not to damage the mains cable.

The same precaution applies to cables feeding the turntable motor and front panel.

Basic Setup

Note: The turntable is packed in two wooden crates.

Note: Be careful when inserting the top plate into the main frame

Note: Some parts are heavy, so be careful when handling!

Note: Choose a suitable supporting table which can hold over 60 kg without warping.

Note: While the parts are packed in plastic bags for protection, these are not intended to be

strong enough to lift or carry the contents.

Note: Allow ventilation space above the motor controller unit.

4

Loading...

Loading...