Kuzma 2007-6 User Manual

KUZMA AIR LINE AIR BEARING TONEARM

Instruction manual Serial Number: …..

2007-6

1

KUZMA LTD

Small ring

INSTRUCTION MANUAL FOR AIR LINE tonearm

The Air line tonearm is a very precisely engineered piece of equipment. However the

construction is robust and requires minimal maintenance for optimal performance.

CONTENTS: Page

General description 3

Unpacking 4

Basic Setup 5

Compressor 6

Dryers 8

Setting up the tonearm 9

Adjustment of tracking force 9

Adjustment of tangential geometry 10

Horizontal fine leveling 11

Adjustment of VTA 12

Adjustment of azimuth 12

Adjustment of cueing device 13

Damping 13

Mainentance 15

Problems 17

2

General description: Main outer box contains two inner boxes. One box contains the

compressor with oil and PVC drain bottle and the second box contains the tonearm with all

spare parts: Allen keys, armbase, geometry protractor and PVC tubing.

Oil lubricated electric compressors, which are the quietest on the market supply the air. The

compressor has a cylinder (head) where air is compressed and then is stored in a reservoir. On

the outlet of the reservoir is an automatic sensor system which measures the pressure inside

the reservoir. When the air pressure drops below a certain level, the system automatically

starts the compressor head and fills the reservoir to a higher pressure, at which point the

system automatically switches off. On the outlet of the reservoir there is an air filter and

pressure regulator, which keep the air pressure on the chosen level of 4.5 bar (60 psi). Due to

compression, moisture in the air is collected in the system. This is automatically drained by an

electronic device and mechanically with an automatic drain system. Water (with a little oil) is

collected into a plastic bottle from the reservoir, filter and from the automatic sensor system

(three black tubes). Red filters stand separately and they dry the air further and remove any

oil mist from the compressed air. This is automatically drained into holder stands. The

compressor is equipped with a safety valve and switches off in case of overheating. The

whole system is easily maintained and simple to use.

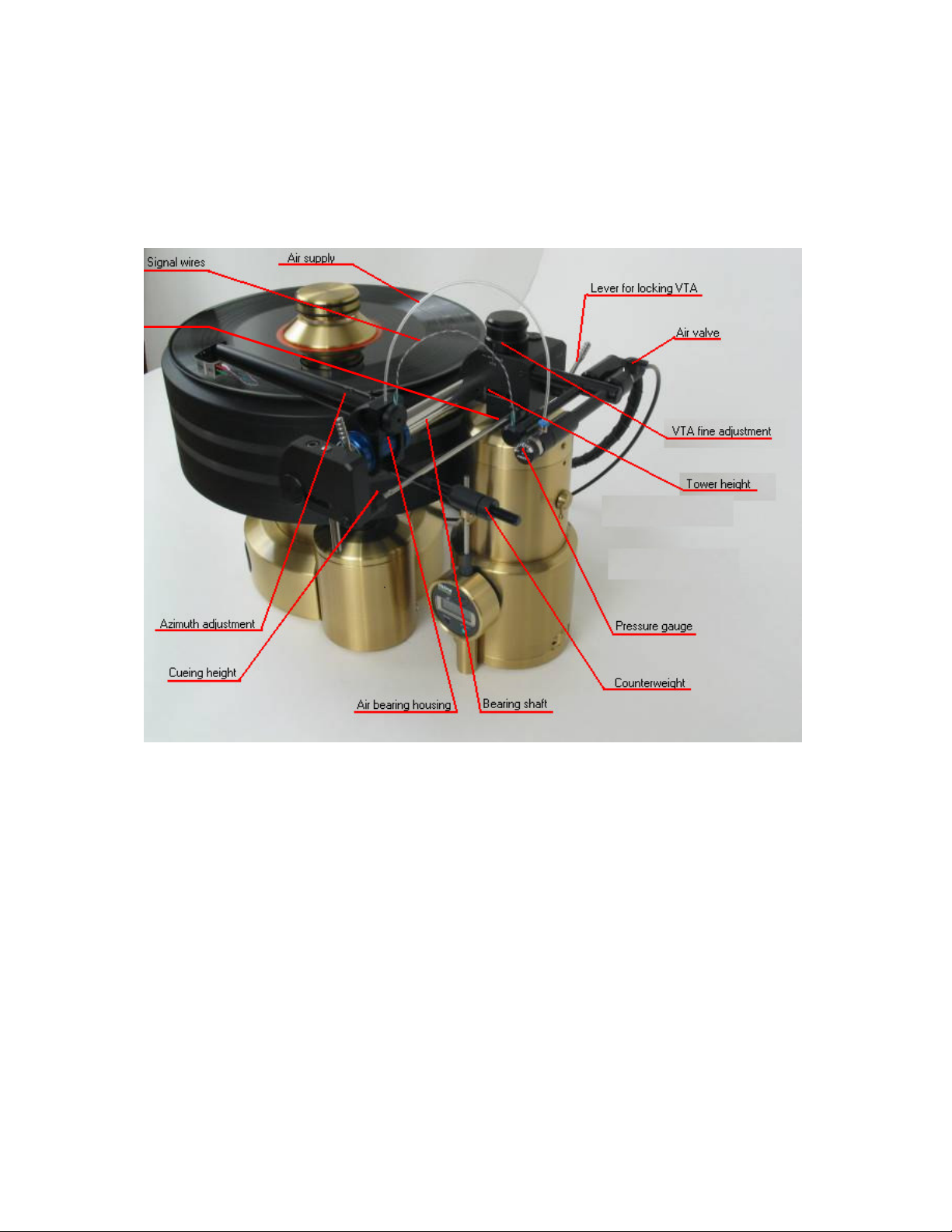

KUZMA AIR LINE-Linear tracking air bearing tonearm:

Effective length 184 mm

Fixing distance 212 mm-Kuzma cutout

Effective mass 13 gr vertical

Recommended cartridge compliance Below 25 cu

Minimum clearance below platter 30 mm

Height adjustment Yes

VTA fine adjustment 10 mm

Azimuth fine adjustment Yes

Air bearing Diameter 20mm x 50 mm

Load axial or radial 30 N (aprox 3 kg)

Air pressure 4 bar ( 60 psi )

Air consumption 4 L/min

Mass 2 Kg

Saftey Precautions:

Electrical connection to the mains comes from the compressor via the cable. Please keep the

compressor away from moisture and be careful not to damage the mains cable.

Important Note:

Turntable or turntable support must be capable of very fine horizontal levelling to allow Air

Line desired horizontal level.

3

1. Unpacking:

Compressor with drain bottle

Compressor box:

Open the box and lift up the compressor by the handle. It is a heavy item. Remove the

plastic bag. Inside the box is the instruction manual for the compressor, bottle with oil,

and plastic drainage bottle. In a small bag inside the compressor housing are the air filter

and black PVC nozzle for filling oil into the compressor. Remove the two pieces of

cardboard wedged between compressor head and housing during transport. The

compressor should not be transported with oil inside unless you can guarantee that it will

be in a vertical position at all times. Position the compressor on a hard surface with plenty

of air for ventilation. Do not position it in the sun or in temperatures below freezing. The

compressor will be connected to the mains voltage.

Tonearm box:

On top of the box you will find this instruction manual. After lifting the top cover and

second layer of foam, remove the black armbase, two red filter items with supporting

stands, set of Allen keys and PVC tubing. Lift filters out carefully because the filter

stands are not fixed onto the filters and they can slide down. Do not remove tonearm until

you have fixed the armbase onto the turntable.

4

Basic setup:

Mount the armbase onto armboard. The dimension and position is the same as for Stogi

tonearms but the main cutout hole is bigger. Diameter is 40 mm. The Air line tonearm

also fits existing armbases for the Stogi tonearm. Three screws will fix the armbase from

the top through the armboard into the black metal ring.

With the Allen key, firmly secure armbase. Position it in such way, that the hole for

fixing tonearm height is easily accessible during mounting .The usual direction is away

from the platter.

Do not slide the tonearm bearing unnecessarily without compressed air!

Do not tilt the compressor while it contains oil! For transport check page 15!

Do not rotate VTA knob when the lever is in the lock position!

Lift the tonearm from box, taking care of wires and tube loop, as well as tonearm cable.

Then fix the tonearm gently into the armbase with Allen key 2mm. The tonearm should

be rotated in such a position that the headshell is outside of the platter, i.e. as in the rest

position off the record. The height of the tonearm in the armbase should be such, that the

centre of the main stainless steel shaft is at the approximate height of an LP. Check that

scale for VTA, in front of the main base, is in the middle position with the edge in line

with the thicker mark. This means that theactual VTA can be precisely adjusted

plus/minus 5 mm. If this is not the case, move the locking rod lever away from the lock

position, in a similar way to lowering a cueing device. Now by rotating the VTA knob

bring the position of the base to the middle part of the scale. Lock back gentle.

Unscrew the small black ring under the tonearm. It will slide down to the armbase. Fix

it gently. If you now unlock the tonearm in the armbase, this ring will hold the tonearm at

the same height but it can still be rotated horizontally. This is important when adjusting

tonearm geometry.

Choose the shorter piece of PVC tube that runs from tonearm to red filters. Position red

filters on the floor or other suitable place near the tonearm. Check the arrows for air flow,

which should be from compressor to red filters and then to tonearm. Connect PVC tube.

All connections are 'quick fit'. Simply push in the tube at filter and at the tonearm. It seals

automatically. When removing the tube, you must first push in the blue (or black) plastic

collar and at the same time pull out the tube. This is much easier done when there is no

compressed air inside the tube. Using the bigger piece of tubing and fix it into filters at

input. It is a hard flexible tube and it can be hidden behind your skirting board.

Permanent walking or placement of furniture on top of it, however, will break it. Plug it

into the 'quick fit' fitting on the compressor, at the filter output. If necessary the PVC tube

can be cut to length with a sharp knife. Position the tube on a hard surface and cut at 90

degrees down. The compressor is factory set for working pressure.

5

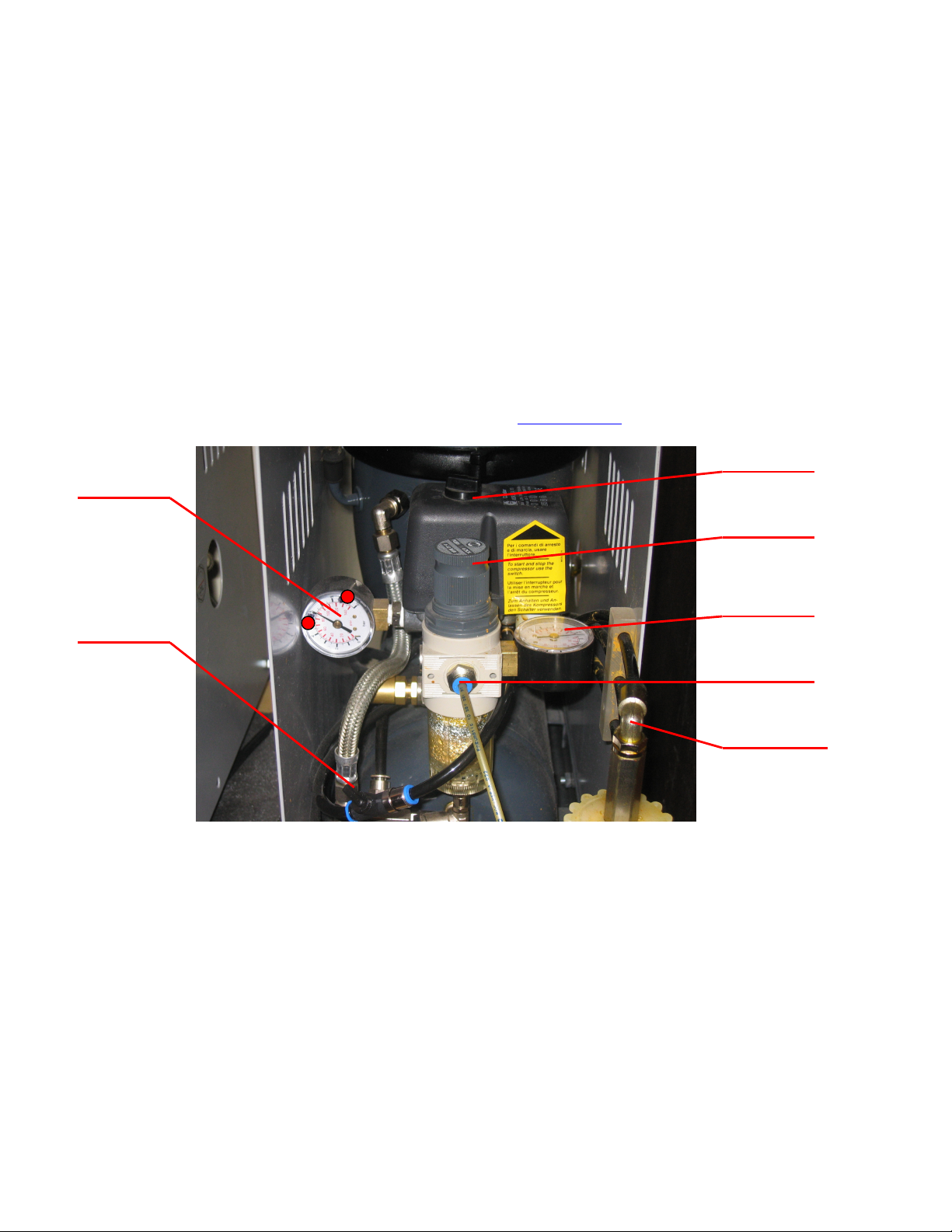

Compressor: for details see instructions with the compressor. The compressor has a

Valve

*

Mains switch

Output pressure indicator

Output tube

Drain bottle

safety valve and overheating protection!

Everything is set and checked by Kuzma Ltd. The only item missing is oil inside the

compressor and air intake filter, which must be fitted after transport. If the

compressor is in an upright position, however, it can be moved safely.

Note: The compressor is factory adjusted to a higher pressure (8 bar-120 psi) than quoted

in the Compressor Instruction Manual. (See label at the side of the cover!)

Note: Do not switch on the compressor before filling with oil and connecting the air

intake filter.

Note: Oil should last for at least 5 years of normal use and should be replaced when it is

very dark - almost black in colour.

Note: Check water condensation occasionally, 1-3 months approx.

If you have any questions just drop us an E mail: kuzma@s5.net

Compressor pressure

indicator

Pressure regulator

Compressor - front view

At one end of the compressor are filters and pressure gauge and at the other end are

main cable and input air filter. In the plastic bag inside the housing is an air intake

filter and nozzle for filling the oil. Remove the small plastic cap from the metal input

tube at the head of compressor, which is on the same side as the mains cable. Fix the

nozzle onto the oil bottle, after cutting the metal cover on the oil bottle and a 5-8 mm

of hose. Putting the nozzle into the metal tube, gently squeeze oil into the compressor.

At the side of the compressor is a glass bubble which will show the level of oil when

the compressor is not working. The whole bottle should go in. Wipe any spillage of

oil and fix on the air intake filter.

Connect the PVC tubes. It is a blue 'quick fit' fitting. Keep the valve closed at the tone

arm.

There are two pieces of PVC air supply tubing. The shorter connects the air supply

from the red filters to the tonearm and the longer connects the compressor to the red

6

Loading...

Loading...