Kuzma 150217 User Manual

Kuzma RD Kit for ultrasonic record cleaning

( ULTRASONIC CLEANER BATH IS NOT SUPPLIED WITH KIT)

INSTRUCTION MANUAL FOR RD KIT

2015-02

.

Page | 1

Contents:

Page:

General information and description: 1-4

RD kit parts and assembling 4-10

Preparing records 10-11

Preparing bath 11-13

Record cleaning 13

Record drying &wiping 13-14

Notes 15

General introduction:

Ultrasonic cleaning is used in industry for cleaning the most precise and delicate parts such as bearings for

the aerospace industry or gold and silver jewellery. Ultrasonic high frequency waves ( 40 kHz ) are

transmitted through water creating a process called cavitation. This creates microscopically small bubbles

between the surface of the submerged parts and any small particles on surfaces, such as dirt. These bubbles

burst and push the dirt away from surfaces. When cleaning metal or plastic the process must be optimised to

avoid damage to surfaces. To do this it is necessary to control power, temperature and the time of the

cleaning process.

This is how all dirt in the grooves of records, even in new pressings is removed. Sonic results are beyond

expectations!

To bring the ultrasonic cleaning process to every record collector we decided to make the RD kit's

( rotating and drying kit) purchase price as low as possible, thus enabling the customer to purchase the

ultrasonic cleaner bath locally (using our guidlines).

The Rotating and Drying record rack kit ( RD kit) will allow you to submerge records in the ultrasonic

cleaning bath and position them in a suitable drying position.

It will allow you to clean 10 LPs in one hour by the ultrasonic process, giving you the cleanest records

ever, free of static charge.

Brief description of the ultrasonic cleaning process:

Records are positioned on the spindle with spacers on the stand and then submerged into the ultrasonic

cleaner warm bath for a limited time. The liquid is distilled water with a few drops of isoproply alcohol

and wetting agent added. The spindle rotates with the records, powered by a small motor while dipped into

the liquid just below the record labels. The records rotate with 0.4-0.6 rpm ( less then one revolution per

minute).

If by any chance the record label gets wet no harm is done.

After ultrasonic cleaning the spindle with records is lifted out and positioned on the stand to air dry. When

dry, any particles on the record surface are brushed with a carbon fibre brush ( records have no static

electrical charge ) and the records are inserted if you wish into new sleeves.

Description of RD kit: (kit does not include ultrasonic cleaner bath)

The RD kit compromises frame with motor , supporting legs, spindle for holding records, record spacers, a

clamp for fixing records on the spindle and a stand for drying records. In the kit small starter bottles of

isoproply alcohol and wetting agent are also included as well as a carbon fibre cleaning brush and DC

power supply for motor. Kit assembly requires only 10-15 minutes and a meduim size Philips screwdriver.

Page | 2

RD kit ( rotating and drying) 8 pcs extension legs included

RD kit:

1x main frame with motor ( DC 9V with provided mains adaptor)

1x spindle ( record holder)

1x drying stand

1x clamp ( grip lock)

8x extension legs( 40 mm- for higher size cleaners)

10x PVC spacers

1x record carbon brush

1x PVC bottle wetting liquid- as for photography ( for 5 bath fillings)

1x PVC bottle isopropyl alcohol ( for 2 bath fillings)

1x instruction manual

2x Allen keys for leg and rods fixing ( 3mm, 2,5 mm )

2x Allen keys for spindle positioners adjustment ( 2 mm, 1,5 mm)

To start cleaning your records you need to purchase :

1x ultrasonic cleaner bath

10 liters distilled water( for one filling: 300-400 LPs)

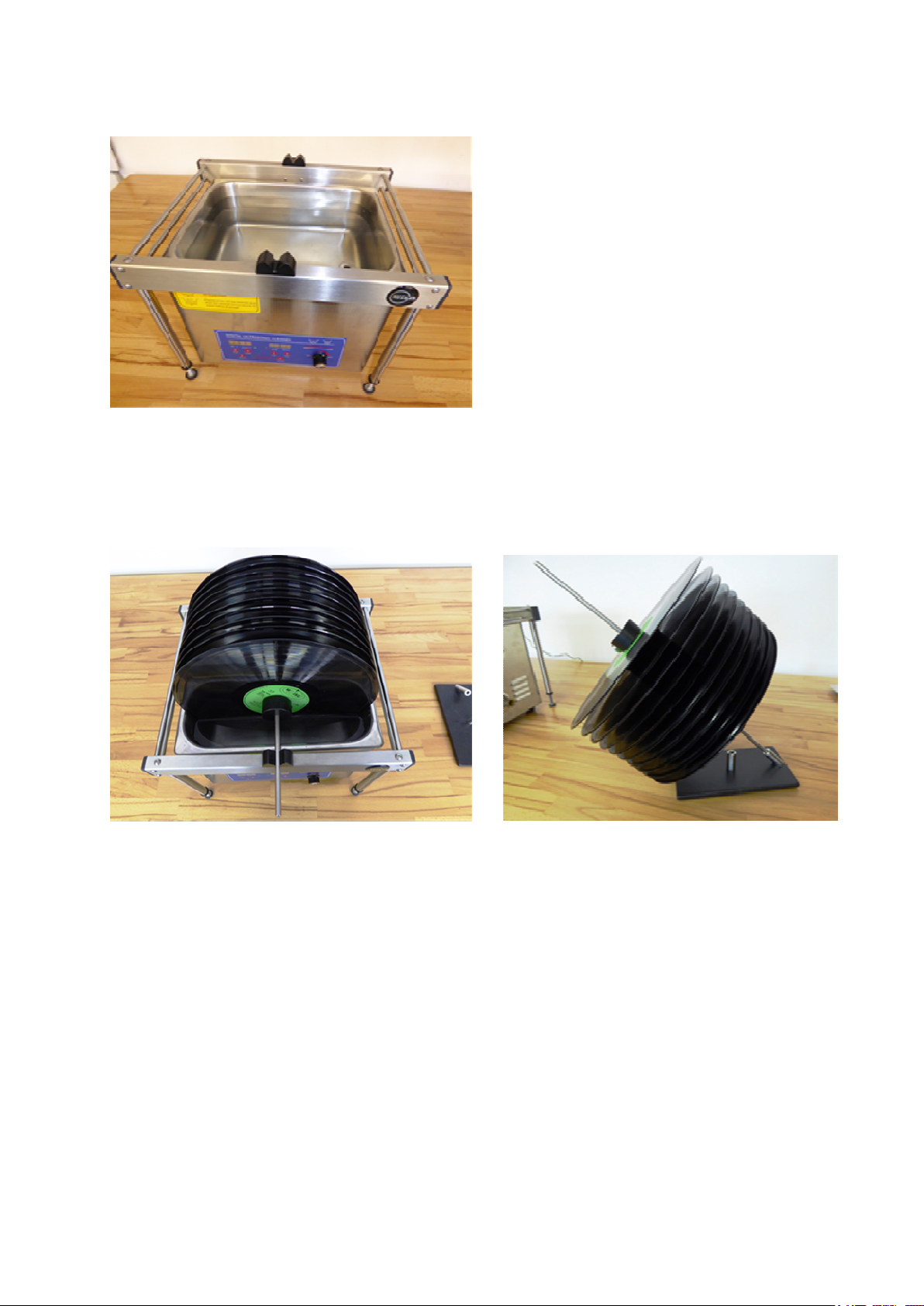

Ultrasonic cleaner bath- typical sample

Page | 3

The main frame is positioned around the ultrasonic cleaner bath. Records are placed with spacers on the

spindle fitted on the stand. The spindle holding the records is then positioned on top of the frame where the

motor slowly rotates them in the bath.

Frame is positioned over ultrasonic (US) cleaner bath

US cleaner must have time, temperature and ultrasonic power control. After aprox 10-15 minutes the

spindle with the records is lifted from the bath and positioned back onto the stand to air dry records. Once

records are dry , the top surface of the record is swept with the carbon brush to get rid of any possible dust

particles and the records put in new record sleeves. As the records are free of static charge, this process is

very easy.

Spindle with records on frame in ultrasonic bath Spindle with records in drying position

Technical requirements for ultrasonic cleaner bath:

There are various ultrasonic cleners on the market. Simply look into the technical data and if they meet the

following criteria it will clean safely.

Bath inner size: min 297 x 220 x 135 (mm: Lenght x Width x Depth )

max 305 x 240 x 150 (mm: L x W x D)

Cleaner outer size: min 325 x 265 x 270 (mm: Lenght x Width x Height )

Max 365 x 278 x 395 (mm: L x W x H )

(special size frame can be made on request)

Volume: min 8-10 lit ( depends on the bath size)

Ultrasonic frequency: 35-40 kHz

Temperature control: min 20-50 Celsius range ( suggested temperature is 30-33 C degrees)

Timer: min 5-20 minutes range (suggested cleaning time is 10-15 minutes)

Power control: 0-100% ( suggested cleaning power is 50-60 % of full power)

In case of doubt ask your dealer or us directly, sending us technical details about cleaner.

Page | 4

Ultrasonic record cleaning process with RD kit

Ultrasonic Bath:

Purchase an ultrasonic cleaner bath (to our technical requirements) following our instructions and

familiarise yourself with the instruction manual. Find adequate space and a surface, which is not sensitive to

moisture, with good light and a mains outlet. Purchase at least 10 liters of distilled water.

Position the ultrasonic cleaning bath on a solid flat surface. Level horizontally if necessary.

For more information how to prepare the liquid go to page 12. Once you get familiar with cleaning process

everything will be really simple.

RD kit assembling and preparation:

Locate the various RD kit parts. See Fig.1.0. The only tool which is not provided in kit the for assembling is

medium size Philips screw driver. You need to assemble the frame and stand.

Fig.1.0. RD kit- various parts

Fig. 1.1. Spindle with 10x spacers & clamp

Page | 5

Loading...

Loading...