Kutzner + Weber RS 180, RS 180 ES, RS 180 ESP, RS 225 ES, RS 225 ESP Installation Instructions Manual

This product is in line with the requirements of the relevant EU

guidelines. The declaration of conformity can be obtained at the address

given on the back

Test certificate BAY 16 Prüf-Nr. P-BAY09-031

I n n o v a t i o n — E n v i r o n m e n t — P e o p l e

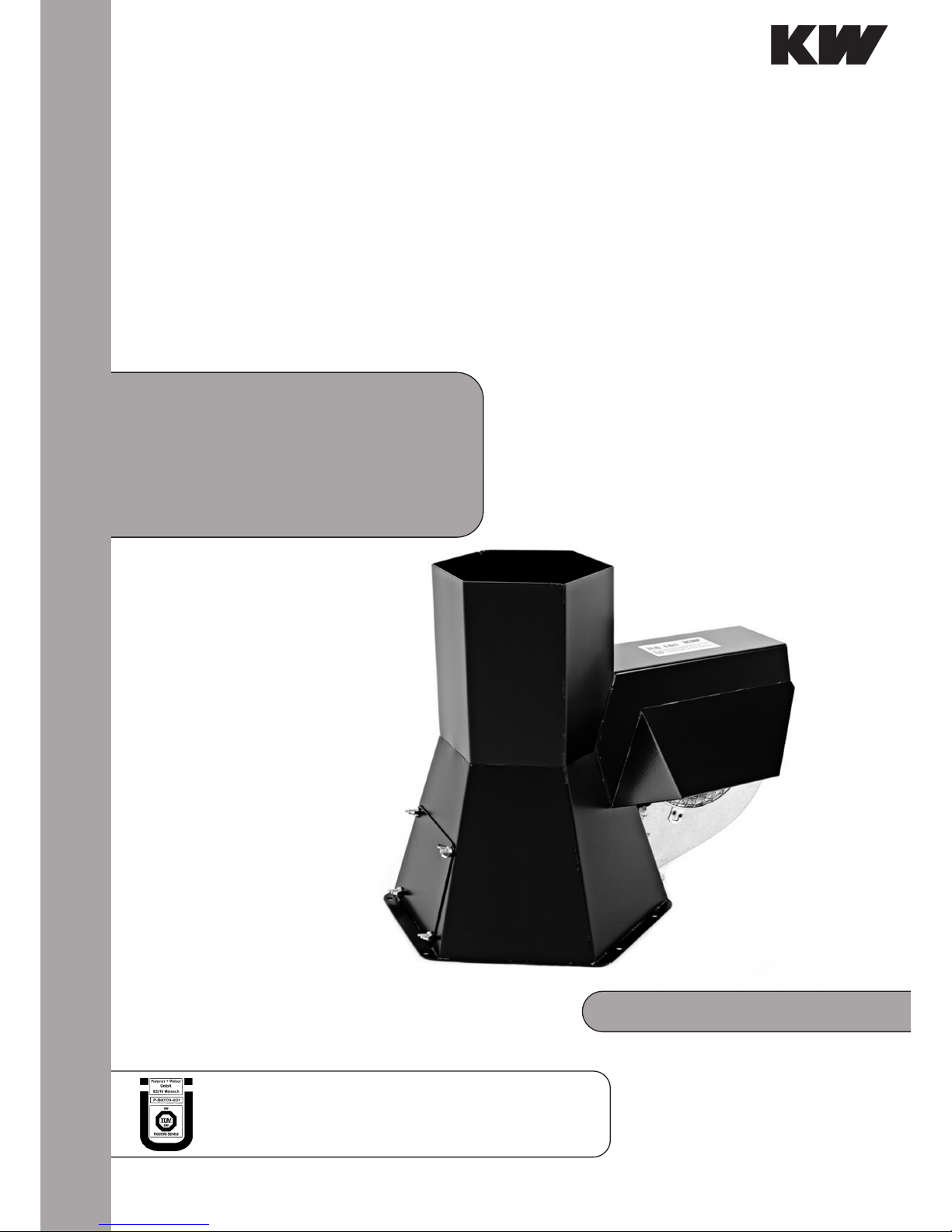

RS 180 (stainless steel black powder-coated)

RS 180 ES (stainless steel bare metal)

RS 180 ESP (stainless steel electro-polished)

RS 225 ES (stainless steel bare metal)

RS 225 ESP (stainless steel electro-polished)

K

UTZNER + WEBER

INSTALLATION INSTRUCTIONS

Kutzner + Weber is certified in accordance with DIN EN ISO 9001:2000

The Chimney Fans "Injekt"

• RS 180 usable up to NW 200 or cross-section 200x200

(needs to be certified according to EN 13384)

• RS 225 usable up to NW 250 or cross-section 250x250

(needs to be certified according to EN 1338

• If the cross-section is larger, use an conversion

adapter.

•

Place the chimney fan centrically on the opening of the

chimney's inner pipe and mark dowel drills.

• Drill holes for approved dowels 8 mm Ø and place

dowels.

• Attach an elastic ground (e.g. temperature-resistant [at

least 200 °C] silicone) to the base plate of the chimney

fan.

• The chimney fan has to be connected tightly with inner

flue gas pipe (in case of a multi-shell flue gas system).

•

The linear extension of the flue gas system has to be

considered. Please see the documentation of the

manufacturer. If necessary, extra measures need to be

taken based on its requirements and the conditions

on-site. Due of the great variety of flue gas systems it

is not possible to give universal solutions here.

• If the flue gas system has a rear ventilation, its outlet

has to remain unblocked. Measures need to be taken

depending on the conditions on-site. Because of the

great variety of flue gas systems, it is not possible to

give universal solutions here.

• Place the chimney fan on top and fasten it with

stainless screws.

• The chimney fan does not need to be removed, except

for repairing or burning out the chimney.

• Therefore, if there is sheet metal at the chimney outlet

please use screws and not rivets.

• Please make sure that during operation the chimney

fan does not aspirate leak air from outside through its

bearing or untight spots at the base plate = power loss.

b. Fastening on a Stainless Steel Flue System

The chimney fan can also be mounted on a double-walled

stainless steel chimney with an adapter. For this you may

order (optional) the adapter RSG.../... (Ø insertion pipe of

adapter = nominal diameter - 2 mm). Fitting adapters

especially for Raab flue gas systems or separate chimney

fan base plates for attachment on-site on request. The

fastening depends on the installation criteria of the flue gas

system's manufacturer. The structural analysis has to be

done on-site.

Start-Up

Check chimney fan compressor.

Check speed actuator (minimum and maximum rotation

speed).

Check negative pressure at fireplace.

Check circuit breaker (on-site).

Check grounding.

Start up fireplace and check overall operation.

Switch on chimney fan before lighting the fire.

Cleaning / Maintenance

The chimney fan "Injekt" is mostly maintenance-free.

The pressure chamber can be made accessible if it should

become dirty. For this, remove the wing nuts from the side

of the casing facing away from the fan and remove the

inspection cover. After cleaning the pressure chamber, the

base of the inspection cover and casing should also be

cleaned. Put the inspection cover back and tighten the

wing nuts.

Warning!

Interrupt power supply before starting maintenance!

Safety Advice

After installation, chimney fans are an integral part of the

flue gas system of the fireplace (such as boilers, tiled

stoves, wood-burning stoves and individual stoves) and

affect these directly. Therefore, you should inform your

responsible building control before installing them.

T

he chimney fan supports the operation of the flue gas

system and the design of the flue gas system has to

comply with EN 13384 T 1 / T 2.

A smooth operation is only guaranteed if the following

instructions are followed.

EN DIN 18 160 T 1

(construction standards for flue gas systems)

E

N 13384 T 1 (formerly DIN 4705 T 1)

Calculation of flue gas systems

EN 13384 T 2 (formerly DIN 4705 T 3)

Calculation of flue gas systems with multi-configuration

(only for oil and gas fireplaces with certified control

systems)

Current laws, guidelines and standards have to be

followed for installation.

The chimney fan “Injekt” is exclusively made for

installation on top of the outlet of the flue gas system

above the roof or on the outlet of a stainless steel

chimney. Structural requirements have to be considered

and a safe fastening ensured.

When burning out the chimney (Warning: In some

countries - for example the UK – it is not allowed to burn

out the chimney, please contact your authorities to find

out if you allowed to do so).

The chimney fan has to be removed before burning out

the chimney.

Range of Use

Mainly for solid fuels (heaters, tiled stoves, open

fireplaces etc.) single and multi-configuration.

Single, multi and mixed configuration for oil and gas

stoves only with control system.

Technical Data RS 180 RS 225

Max. delivery pressure* approx. 50 Pa approx. 80 Pa

Max. output* approx. 750 m

3

/h approx. 1000 m3/h

Fan capacity 170 W 270 W

Current drain 0,75 A 1,3 A

Bearings dimensions

(hexagonal) see Page 4

Height see Page 4

Weight (total) ca. 8,0 kg ca. 12,0 kg

Material stainless steel 1.4404 or 1.4571

* Please note characteristic line on page 4

Installation

a. Fastening to the Chimney Cowl

The chimney fan is fastened to the chimney cover with

the base plate.

A soft, tight layer has to be put between the base plate

and the chimney cover (e.g. temperature-resistant

silicone, ceramic fibre, etc.) to:

• ensure an even positioning

• keep out precipitation

• prevent vacuum exhaust of leak air.

The fastening has to be stable enough to withstand wind.

The chimney cover has to be attached firmly to the

chimney or have enough net weight to hold the chimney

fan safely (if necessary, attach the cover to the chimney

separately).

Mounting the Chimney Fan on the Cowl

• Make sure that the foundation (e.g. base plate) is intact

and statically stable to ensure a safe installation of the

chimney fan. It has to withstand wind.

Loading...

Loading...