Page 1

GCU-20

Automatic Engine Control Unit

WARNING

Disconnect all electric power to the machine before

installation.

Protection Functions

Engine fail to start

Engine tries 3 times to start

Engine Low Oil Pressure Protection

Shutdown activated after 3 seconds

Oil Pressure Switch Type NO or NC

Auxiliary Shutdown

Shutdown activated after 3 seconds delay by NO contact

Engine High Water temperature Protection

Shutdown activated after 3 seconds delay by NO contact

Engine Over-speed Protection

Shutdown activated after 3 seconds

50 Hz activated at 55 Hz – 60 Hz activated at 66 Hz

Engine Under-Speed Protection

Shutdown activated after 5 seconds

50 Hz activated at 45 Hz – 60 Hz activated at 54 Hz

No Speed Signal Present Protection

Shutdown activated after 5 seconds (MPU use only)

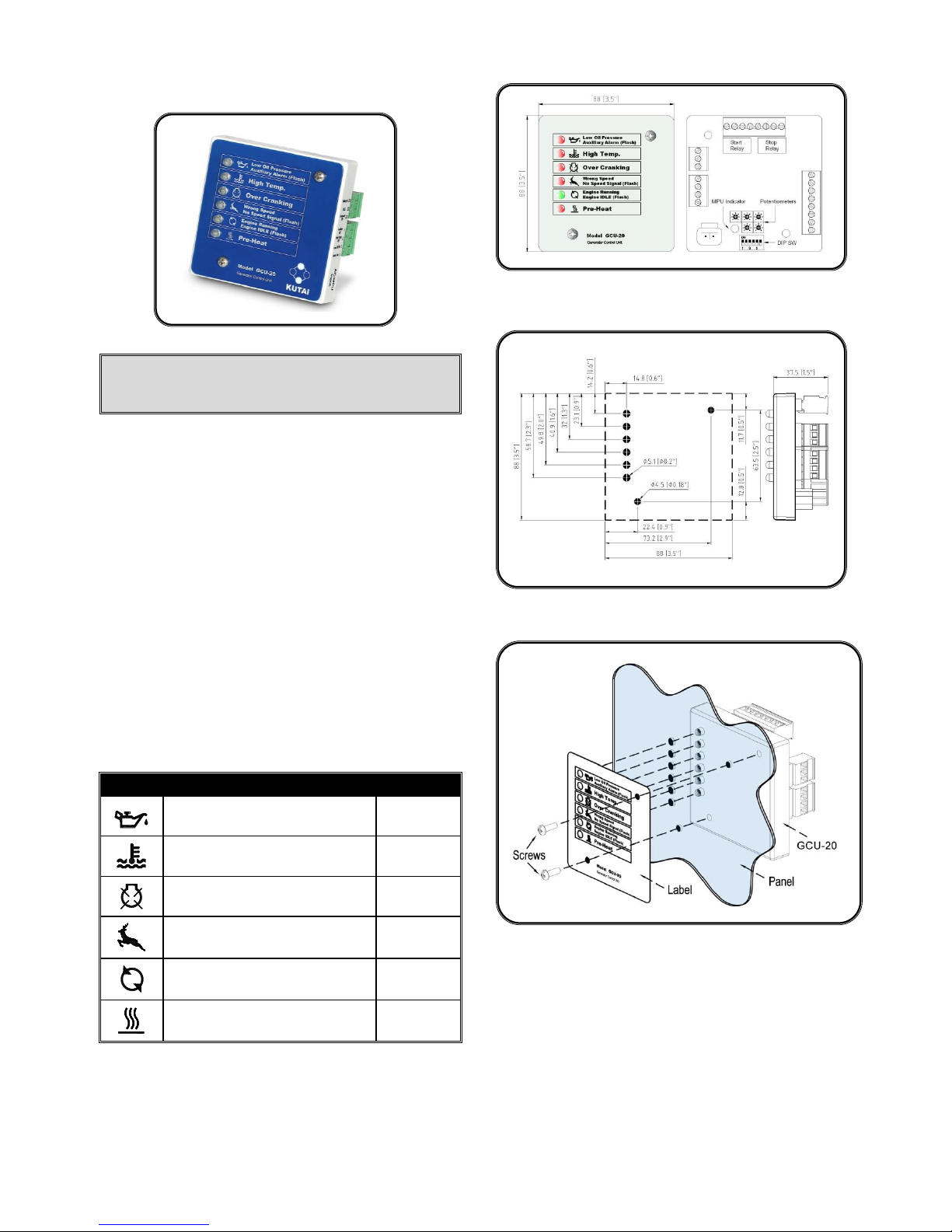

Icon Reference Table

ICON

DESCRIPTION

ACTION

Low Oil Pressure Alarm

Auxiliary Alarm (Flashing)

Shutdown

High Water Temperature Alarm

Shutdown

Over Crank Alarm

Shutdown

Wrong speed Alarm

No Speed Signal Alarm (Flashing)

Shutdown

Engine Running Indicator

Engine IDLE Indicator (Flashing)

Engine Pre-Heat Indicator

Pre-Heat

Physical Dimensions

Mounting Pattern

Installing Panel

Page 2

Auxiliary Alarm (Flash)

Pre-Heat

Wrong Speed

Engine IDLE (Flash)

Engine Running

No Speed Signal (Flash)

Over Cranking

High Temp.

Low Oil Pressure

Model GCU-20

A

B

D

C

E

MPU Indicator

Speed Sensor

Connector

MPU indicator

in Green

60

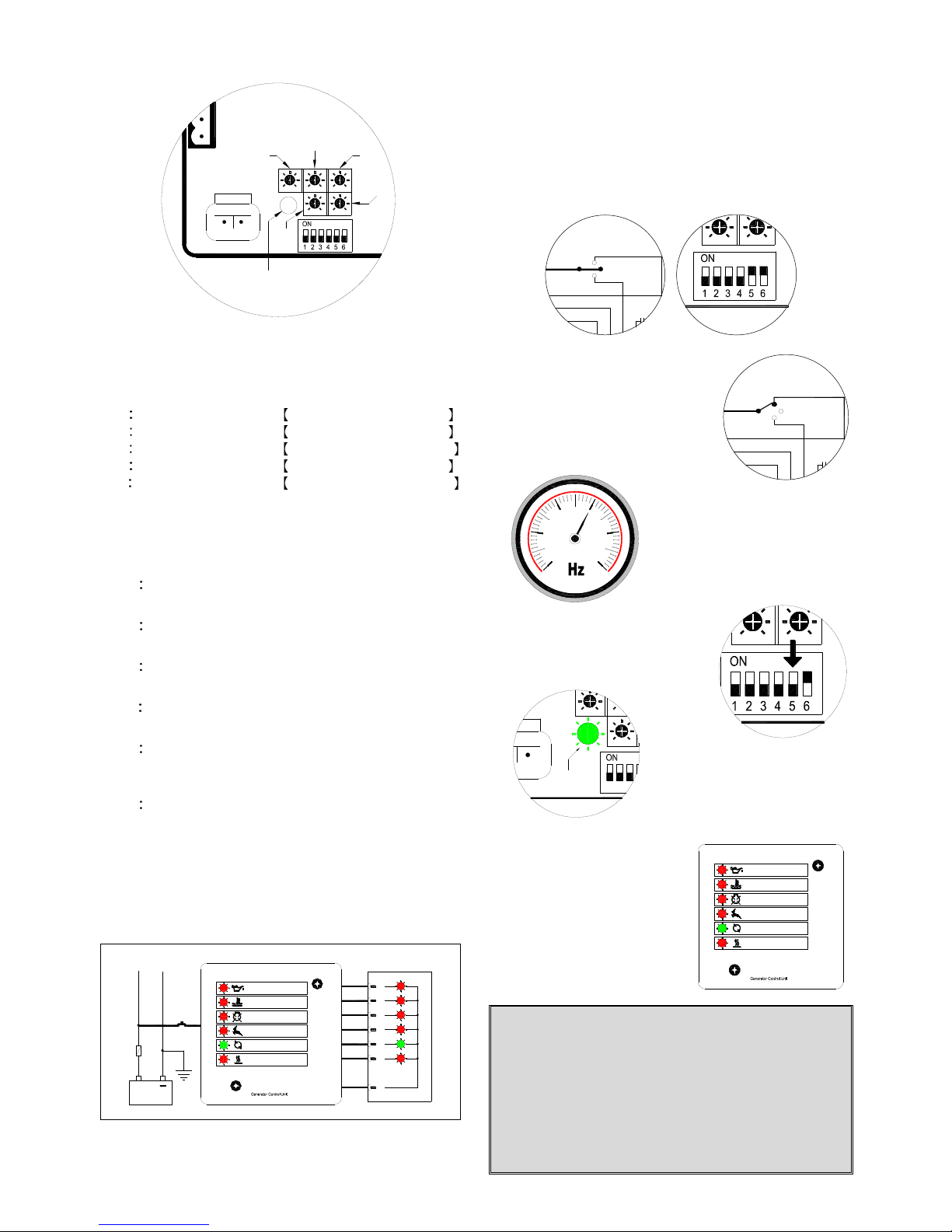

Potentiometers & DIP Switches Detail

Adjustments

On the back of the GCU-20 we have five adjustment pots that

modify time delay functions.

●

A Engine Pre-Heat

Adjustable from 2 to 30 sec

●

B Energized to STOP

Adjustable from 1 to 15 sec

●

C Engine Cool-down

Adjustable from 0 to 300 sec

●

D Starter Cranking time

Adjustable from 1 to 15 sec

●

E Engine Idle (Governor)

Adjustable from 0 to 300 sec

Function Setting

Also In the back, the GCU-20 we have six dip / switches that

set specific working parameters.

SW 1 Oil Pressure Switch Used for Crank Disconnect

ON - Disable OFF - Enable

SW 2 Oil Pressure Switch Type

ON - Normal Open OFF - Normally Close

SW 3 Engine Stop Setting

ON - Energize to Start OFF - Energize to STOP

SW 4 Generator Frequency (Ignore if it is a Water Pump)

ON – 50 Hz OFF – 60 Hz

SW 5 MPU Setting

ON - Enable (used to Program Speed)

OFF - Disable

SW 6 Speed Signal Type

ON - Use MPU for speed sensing

OFF - Use AC generator frequency for speed sensing

Lamp Test Function

Applying battery (+) signal to terminal 1 (Lamp Test Terminal)

the GCU-20 turns on all the front panel LEDs and

annunciator lamps.

+

Battery

10A

Model GCU-20

No Speed Signal (Flash)

Engine Running

Engine IDLE (Flash)

Pre-Heat

Wrong Speed

J1 J2 J4J3

Lamp Test

Low Oil Pressure

High Temp.

Over Cranking

Auxiliary Alarm (Flash)

Remote Annunciator

J7J6J5

Using with MPU

If you use the MPU for speed sensing instead of the

generator frequency you must set (Switch 6 to ON), and

depending on flywheel size (different generators has a

different MPU frequencies). This nominal frequency MUST

be set FIRST.

It is easy, if you follow the procedure below.

Step 1:Move Switches 5 & 6 to “ON” before starting engine.

Step 2:Start engine, by moving

panel switch to “TEST”

(Manual Start)

Step 3 : Run the engine

normally at its rated

speed. (60 or 50 Hz)

or pump rated RPM

Step 4:Now quickly move

Switch 5 to “OFF”

Step 5:When MPU LED turns

GREEN setup is

complete.

MPU Setup failure

If setup fails, the control module

shuts down the engine and

immediately flashes ON all the

LEDs on the front panel.

Check MPU and wiring before

repeating this setup again.

WARNING

If the MPU signal is used for speed sensing (Switch 6

ON), but MPU frequency set up has not yet been

completed the MPU indicator will flash RED and the

engine will not run under any condition.

However, if the user tries to start the engine a “No

Speed Signal” warning LED will continue to flash

indicating that the user should repeat the set up of the

MPU frequency setting or switch to generator

frequency sensing.

Select Switch

Start

Remote

OFF

Auto

Test

Batt(-)

Select Switch

Remote

Batt(-)

Start

OFF

Test

Auto

Page 3

Specification

ITEM

SPECIFICATION

DC Supply

9 36 Vdc

Alternator Input Range

5 300 Vac

Alternator Input Frequency

50/60 Hz

MPU Signal Input Range

+/-2V to +/-70 Vac Peak

Rated MPU Frequency

100 10,000 Hz

Operating Temperature

-20 to 70 ˚C

Relative Humidity

Under 90 %

Power Consumption

Under 3W

Weight

206 g +/- 2%

Terminals Detail

PIN No.

CURRENT

MAX.

DESCRIPTION

1

10mA

Auxiliary switch input

2

10mA

Temperature switch input

3

10mA

Oil switch input

4

10mA

Lamp test input

5

10A

Start signal output

6

10A

Battery negative input

7

10mA

AUTO switch input

8 – 9

10mA

Remote start signal input

10

10mA

Test switch input

11

10A

Fuel / Stop signal output

12

300mA

Pre-heat signal output

13 – 18

300mA

Annunciator signal output

19

300mA

Warm-up signal output

20

1A

Annunciator common used only

Don’t use as main ground connection

21

1A

Accessory ON signal output

22

1A

IDLE control output

23

10A

Battery positive input

TEST Operation

To initiate a start sequence moves the external toggle switch

to the on TEST (Manual Start) position.

First, the pre-heat timer begins by energizing terminal 12. If

Pre-Heat is not uses, simple no not use this terminal.

Second, the Engine Fuel Solenoid energizes terminal 11,

and idle terminals 22.

Third, after a 1 sec. delay, the starter motor energizes, and

the engine cranks for the duration of the crank timer.

Fourth, after the engine (start / fires), the starter motor

disengaged and locked out by using the 18-Hertz signal from

the generator or the signal from the MPU. Alternatively, the

oil pressure switch can serve as an additional back up crank

disconnect.

Fifth, after the engine fires and if the Engine Idle option is

used, the ENGINE RUNNING LED will continuous flashing in

idle indicating the status is IDLE. (If engine idle is not used set adjustment, “E” full counterclockwise).

Sixth, if the engine does not start the first time the module

will try again to start the engine 2 more times and stop after

the third try.

If the generator fail to start, move the select

switch to the OFF (Reset) position, Find out

why the engine failed to start before making

any more start attempts.

Seven, after the generator starts, the module allows Oil

Pressure, Engine Temperature and engine speed to stabilize

without triggering any faults for 20 seconds.

Moving the toggle switch to the OFF position, Stops the

engine immediately.

Automatic (Remote Start) Operation

In the “AUTO” mode, the GCU-20 control module monitors

input terminals 8 & 9 for a “REMOTE START” signal. Should

a “REMOTE START” signal be detected a start sequence

similar to previous manual start cycle is initiated.

Removing the Remote Start signal automatic activates the

Cool Down Timer and after the Cool Down ends, the Fuel

Solenoid is (de-energized or energized as the case may be)

bringing the generator or engine to a complete stop.

Should the Remote start signal be re-activated during the

cooling down period, the set will immediately return to normal

operation.

NOTE

Even if the generator is executing Engine Cool down

Timer, The Module protection system remain in operation

and if any failure occurs, the module bypasses the Engine

Cooling Timer shutting down the generator immediately.

OFF Operation

The OFF position places the module into its Stop or Reset

mode.

In RESET mode the operator must clear any fault conditions.

Selecting OFF when the engine is running automatically

STOPS the generator. The fuel supply will be removed and

engine will be brought to a standstill. Should a remote start

signal be present while operating in this mode, a remote start

will not occur.

Page 4

Wiring Diagram Using Generator AC Frequency Sensing

Wiring Diagram Using MPU Frequency Sensing

Please link to http://www.kutai.com.tw for detailed manual

17

L1

L2

L3

N

20

18

19

23

Relay

Start

2

3

4

21

1

22

15

16

14

13

Relay

Stop

65 987

L2

L3

LOAD

N

L1

RW

G

Pre-Heat Relay

RS

RF

Start Relay

Batt(-)

Select Switch

Fuel / Stop Relay

Auto

Test

OFF

Remote

Start

RP

Common(-)

Warm-up Relay

Alarm Lamp

Engine Run Lamp

Wrong Speed Lamp

Over Crank Lamp

High Temp. Lamp

Low Oil Lamp

J3

RW

J1 J2

Remote Annunciator RA-20

J4 J5 J6 J7

Battery

+

10A

RA

RI

Batt(+)

Lamp Test SW

Low Oil SW

High Temp. SW

Auxiliary SW

Acc. ON Relay

Idle Relay

Model GCU-20

Wrong Speed Lamp

High Temp. Lamp

Over Crank Lamp

Engine Run Lamp

Common(-)

Alarm Lamp

Warm-up Relay

1

Auxiliary SW

High Temp. SW

Lamp Test SW

Low Oil SW

2

4

3

Acc. ON Relay

Batt(+)

23

21

22

Start

Relay

Stop

Relay

Low Oil Lamp

Model GCU-20

Batt(-)

Remote

J5 J7J6J2 J4J3J1

19

20

17

18

16

15

13

14

Idle Relay

Start

Battery

+

10A

Start Relay

Fuel / Stop Relay

Pre-Heat Relay

Test

Auto

OFF

Select Switch

Magnetic Pick-Up

5 6 7 8 9

RA

RI

RS

RF

RP

RW

L3

L1

L2

N

L3

L2

L1

N

RW

Remote Annunciator RA-20

LOAD

G

Loading...

Loading...