Page 1

FILE: 091-60A.PMD

DATE: 07-30-09

INSTRUCTION MANUAL

REV. B

LOAD MANAGER MARK II

A START-UP AND SHUT DOWN LOAD SEQUENCER

AND AUTOMATIC LOAD SHEDDING SYSTEM

INTEGRAL RELAYS FOR 8 LOADS

WITH

MODEL #091-60A

INPUT: 12VOLTS, D.C.

OUTPUT LOAD: 30 AMPERES, MAXIMUM

3 YEAR WARRANTY

KUSSMAUL ELECTRONICS CO., INC.

170 CHERRY AVE., WEST SAYVILLE, N.Y. 11796

TEL: 631-567-0314 TOLL FREE: 800-346-0857 FAX: 631-567-5826 EMAIL: Sales@Kussmaul.com

Page 2

INTRODUCTION

The Load Manager Mark II is a device which:

1. Sequentially energizes and deenergizes relays which are mounted inside the unit at approximately

1/2 second intervals in order to reduce transients in a vehicle’s electrical system.

2. Detects when the vehicle’s electrical load is greater than the output of the alternator. When this

occurs, loads are sequentially deenergized until the alternator output is equal to the load.

The Load Manager Mark II contains the following features:

1. An electrical input which changes the Load Manager Mark II from an automatic load shedding

device to operation only as an automatic load sequencer.

2. An automatic override of the Load Manager Mark II which operates all the relays simultaneously by

connecting one input to ground.

3. An adjustable time delay from 2 to 16 seconds which prevents load shedding until the timeout

occurs. This timer starts when the Load Manager Mark II detects an overload. If the battery voltage

returns to normal before the timeout, the timer is reset and no loads are shed.

4. An indicator panel which includes a Power ON LED indicator and a Load Reduce indicator. This

provides the vehicle's driver with the information that the Load Manager Mark II is in operation and that

the loads are in the process of being shed.

5. Internally mounted relays that eliminate the need to supply separate relays in the vehicle. The loads

are wired to the relay contacts at the top of the unit using standard 1/4" quick disconnect terminals.

Each relay output is rated at 30 amperes maximum at 12 volts.

Page 3

LOAD MANAGER PROGRAMMING

Recognizing that priorities may change after an installation is made, the Load Manager Mark II is

designed so that the sequence of load removal may be easily altered.

At installation, the highest priority load is wired to relay K1 which is operated by terminal 3. The second

highest priority load is wired to relay K2, which is operated by terminal 4. A total of 8 relays, decreasing

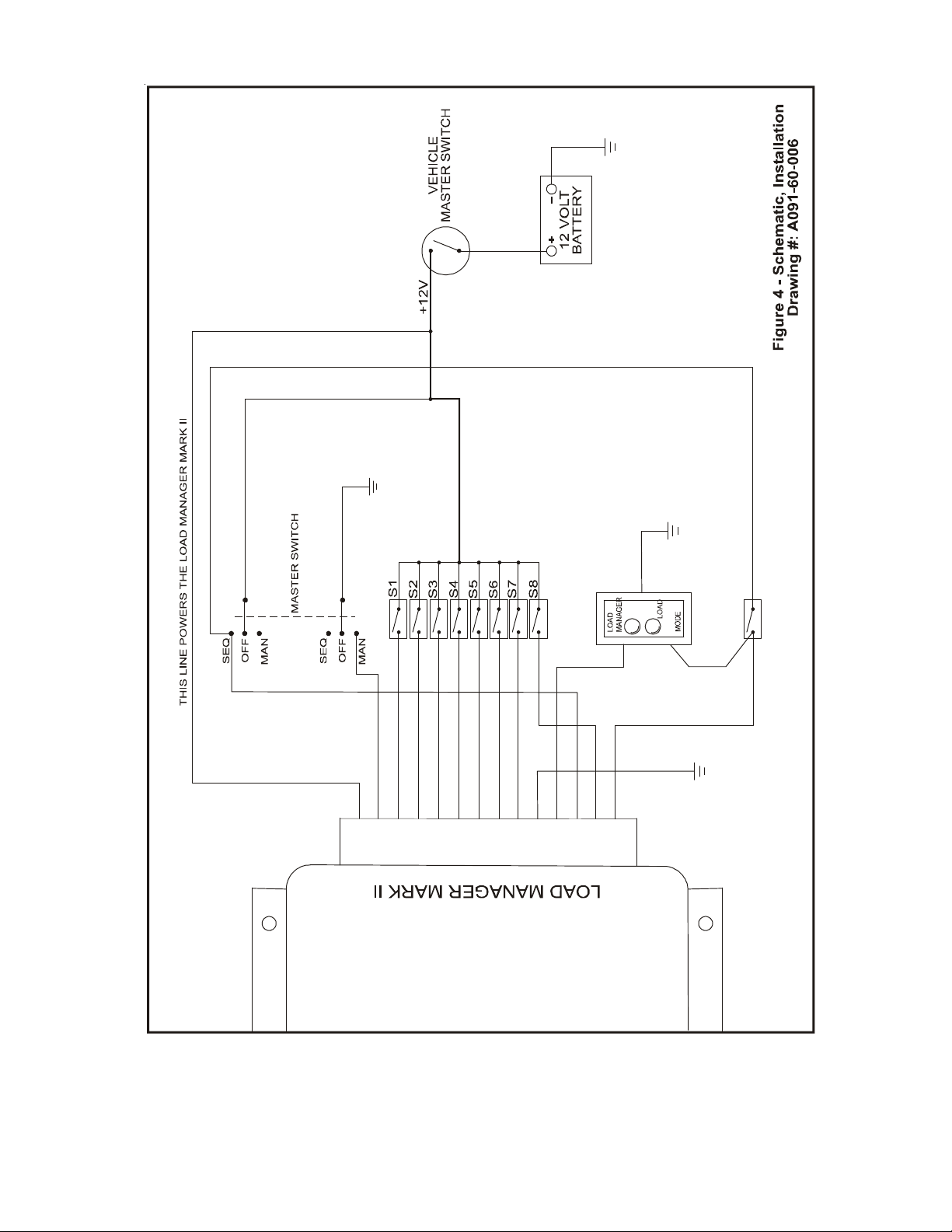

in priority are operated by terminals 5, 6, 7, 8, 9, & 13. See Figure 4 - Schematic, Installation.

Upon start-up, when the Load Manager Mark II operates as a sequential loading device, the loads are

applied in priority order with the highest priority first.

When the Load Manager feature is enabled and excessive electrical loads cause a drop in battery

voltage, the Load Manager Mark II will deenergize loads at approximately 2 second intervals starting

with the lowest priority. Loads will be removed until the voltage sensed returns to normal. The exact

interval between load removals depends on the degree of the overload and the capacity of the

batteries. With only a slight overload and large batteries the time interval is extended.

After installation the user may vary the priority by altering the switch setting from the BASIC SETTINGS

illustrated on Figure 3 - Relay Wiring Connections.

Caution: There are 5 switches, each with 5 levers. Only one lever on each switch my be in the

"ON" Position.

Each switch controls the operation of a relay. The actuation sequence of a particular relay

is controlled by the individual levers of each switch. Lever #5 is the lowest priority, while

lever #1 is the highest. It is thus possible to arrange the relay operating priority for the 5

lowest priority relays.

NOTE

The Load Manager Mark II contains the load switching relays. The

manual switches wired by the installer control the 12 volt supply to these

relays.

THE RELAY CONTACT CAPACITY IS 30 AMPS. DO NOT EXCEED.

Page 4

LOAD MANAGER SETTINGS

The standard setting on Load Manager Mark II may not be optimum for all applications. The

Configuration Switch , S6, sets the initial time delay and the initial shed voltage for the unit. On the

Configuration Switch, levers 1-3 are used for time settings. Levers 5 and 6 are for voltage

settings.

To prevent false voltage readings, the Load Manger Mark II, delays the shedding or adding of

loads. The initial delay time is factory set for four seconds. By adjusting levers 1-3 on the

Configuration Switch, the user may vary the initial time delay from 2 to 16 seconds. Figure 1 below

indicates how to alter the initial delay time.

Lever 1 Lever 2 Lever 3 Time Delay

on on on 2±.5 sec

Factory Setting

off on on 4±.5 sec

on off on 6±.5 sec

off off on 8±.5 sec

on on off 10±.5 sec

off on off 12±.5 sec

on off off 14±.5 sec

off off off 16±.5 sec

Figure 1

Configuration Switch, S6, InitialTime Delay Settings

Subsequent time delays for additional load shedding is factory set for 2 seconds and is not

adjustable.

Load Reduce will start at the Initial Shed Voltage. The Factory Setting, for the Initial Shed Voltage,

is 12.3VDC. For the first load to go off, the voltage must be 12.3 VDC or lower for the duration of

the time delay. Recovery, that is reapplication of a load will not occur until the voltage is .2 VDC

higher than the shed voltage. A time delay prevents the instantaneous operation of the output

relay. After shedding the first load the Load Manager waits 2 seconds before making a decision

to shed more loads. If the sensed voltage is .2 volts less than that at the previous shed point and

maintains this lower voltage for 2 seconds, the next load will be shed. This continues until

sufficient loads are shed so that there is no further decrease in sensed voltage. Figure 2 below

indicates the switch settings required to vary the Initial Shed Voltage. Loads are reapplied when

the voltage rises and is maintained for a suitable time.

Switch 4 Switch 5 Initial Shed Voltage

Factory Setting

on on 12.30±.1

off on 12.15±.1

on off 12.00±.1

off off 11.85±.1

Figure 2

Configuration Switch S6, Threshold Voltage Setting

CAUTION

Changes to Configuration Switch, S6, will only take effect during power up. Remove power from

pin one of Load Manager and reapply to change the setting on the Load Manger Mark II.

Page 5

1

2

3

5

6

7

8

4

9

101112

13

14

Figure 3 - Relay Wiring Connections

K1

N.C.

K2

N.O. N.C.

COM

N.O. N.C.

COM

K3

N.O.

COM

K4

N.C.

N.O.

COM

HIGHEST PRIORITY

K5

N.C.

K7

N.O.

COM

N.O. N.C.

COM

K6

N.O. N.C.

COM

K8

N.C.

N.O.

COM

LOWEST PRIORITY

ON

ON

OFF

OFF

ON

OFF

ON

OFF

ON

OFF

Drawing #: A091-60-005

5421

3

5421

3

5421

3

542

3

1

5421

3

INCREAS ING

PRIORITY LOWEST PRIORITY

54321

VOLTAGE

HIGHEST PRIORITY

SWITCH CONTROLS

SWITCH CONTROLS

SWITCH CONTROLS

SWITCH CONTROLS

SWITCH CONTROLS

RELAY K4

RELAY K5

RELAY K6

RELAY K7

RELAY K8

TIME

Configuration Switch

Note 1. Wire COM. Terminal of each relay individually to a +12V supply using a wire size appro-

priate for the current load.

2. Relay Current is 30 Amperes Maximum

Page 6

GROUND

GROUND

GROUND

Black

REDUCE

Red

Ye ll o w

Highest Priority Relay

Lowest Priority Relay

e

r

L

e

a

M

o

n

g

a

t

a

d

Load Manager

Operate Switch

Panel

Indicator

S

i

g

n

O

o

p

t

e

a

r

l

a

GROUND

*K1

*K2

*K3

K4

K5

K6

K7

1

2

3

4

5

6

7

8

9

1011121314

K8

*Note: Relays K1, K2, and K3 will sequence "ON" and "OFF", but will not shed loads.

Page 7

6.52

14

13

12

11

10

9

8

7

6

5

4

3

2

1

M

C

O

.

.

N

N

O

.

C

.

K4

C

M

O

N

.

O

N.C.

.

K3

C

O

M

N

O

.

.

.

N

.

C

K2

C

M

O

N

N.C.

.

O

.

Highest Priority

K1

M

O

C

.

.

O

C

.

.

N

N

Lowest Priority

K8

C

M

O

.

C

N

N

.

.

.

O

K7

M

C

O

N

.

.

O

.

N

C

.

K6

C

O

M

.

O

.

.

N

N

C

.

K5

6.10

LOWEST PRIORITY

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

5.50

PRIORI TY

54321

54321

54321

54321

54321

HIGHE ST PRIO RITYINCREASING

SWITCH CONTROLS

RELAY K8

SWITCH CONTROLS

RELAY K7

SWITCH CONTROLS

RELAY K6

SWITCH CONTROLS

RELAY K5

SWITCH CONTROLS

RELAY K4

5.90

6.30

2.13

Figure 5, Outline Drawing, Load Manager Mark II

Drawing #: B091-60-008

Page 8

INSTALLATION RECORD & WARRANTY

Date Installed

Installed By

Vehicle Identification

Vehicle Owner

WARRANTY

All products of Kussmaul Electronics Company Inc. are warranted to be

free of defects of material or workmanship. Liability is limited to repairing or

replacing at our factory, without charge, any material or defects which become

apparent in normal use within 3 years from the date the equipment was shipped.

Equipment is to be returned, shipping charges prepaid and will be returned,

after repair, shipping charges paid.

Kussmaul Electronics Company, Inc. shall have no liability for damages of

any kind to associated equipment arising from the installation and /or use of the

Kussmaul Electronics Company, Inc. products. The purchaser, by the acceptance of the equipment, assumes all liability for any damages which may result

from its installation, use or misuse, by the purchaser, his or its employees or

others.

Loading...

Loading...