Operating Instruction and

Parts Manual for

KPT 36/48

Walk Behind

Power Trowel

12010 Dairy Ashford Road, Suite 160

Sugar Land, TX 77478

281-313-2506 • 800-469-4178

TABLE OF CONTENTS

2

Contents ……………………………………………...…1

Forward …………………………………………...…… 2

Feature…………………………….......................………2

Specification ………………………….................………2

Safety precautions …………………………………...… 3

Maintenance record ……… ……………………....……4

Maintenance schedule…………................................……5

Operation elements………................................…………7

Operation (floating)…………………..........................…8

Operation (finishing)…………………………............…8

Starting & stopping procedure…………………………9

1. Before operation checks…………………………...…9

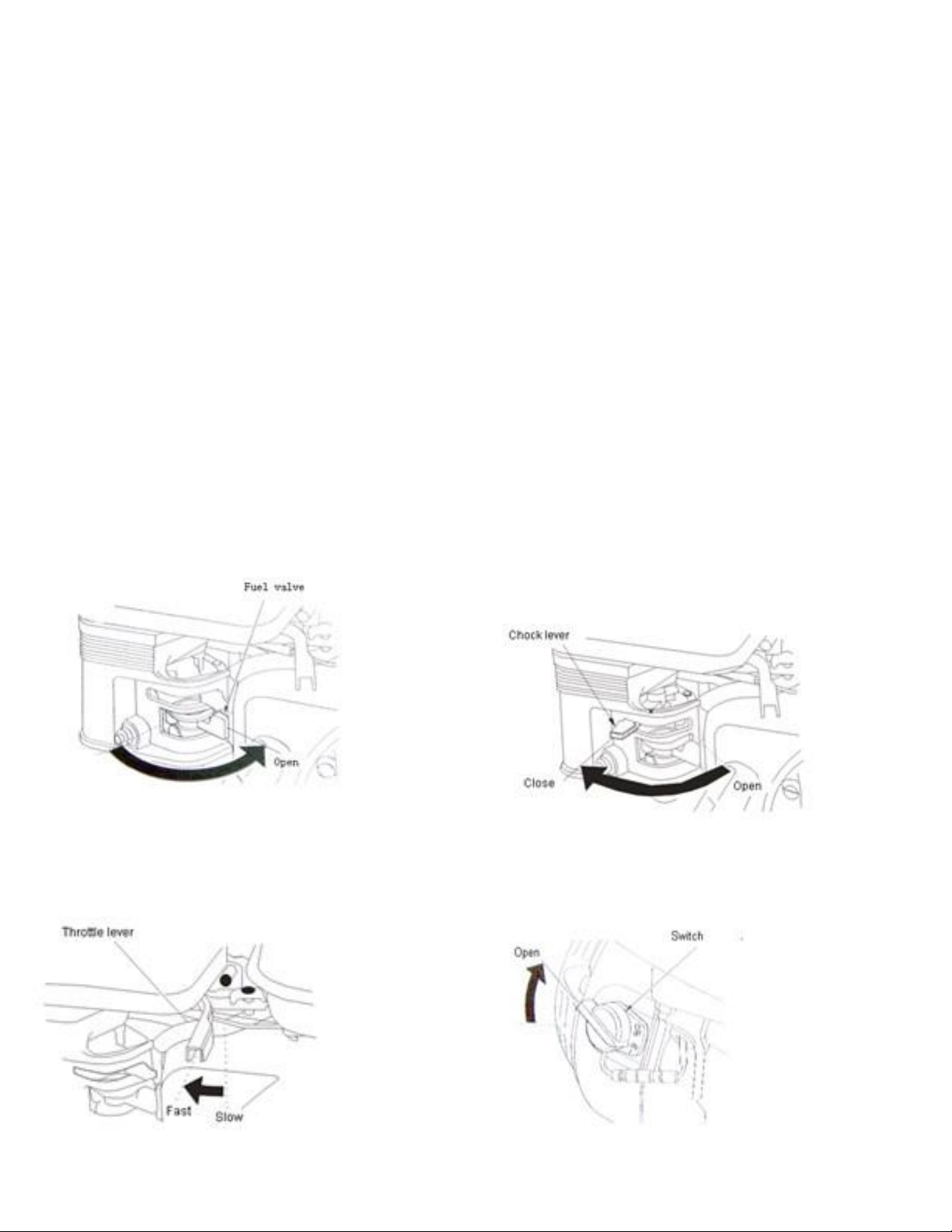

2. Starting engine

procedure……………………………9

3. Stopping engine

procedure……………………….…11

4. Setting engine speed………………………...………12

Lubrication………………………………………….…12

1. Engine oil lever check………………………………12

2. Engine oil change……………………………………13

Spark plugs…………………………………………….13

Carburetor adjustment……………………………..…14

Air filter service………………………………………..15

Storage…………………………………………………16

Troubleshooting…………………………………….…16

FOREWARD

• For your own safety and protection from bodily injuries,

carefully read, understand and follow the safety instructions

in this manual.

• Please operate and maintain your machine in accordance

with the instructions in this manual.

• Defective machine parts are to be replaced as soon as

possible.

• Keep this owner's manual handy, so you can refer to it at

any time.

• No part of this publication may be reproduced without

written permission.

• We expressly reserve the right to technical modifications-

even without express due notice - which aim at improving

our machines or their safety standards.

FEATURE

The KPT 36 and the KPT 48 Walk Behind Power Trowels can

be used in surface finishing of concrete road, terrace, boatyard,

airport and floor etc.

Deadman switch design pr ovide safe. A sophisticated system to

protect the operator from an out-of-control spinning handle.

When the operator is using a walk-behind power trowel and

let go of the safety sensor detects the motion of the handle and

stops the engine before the handle reaches a 45-degree ro tation.

The handle can be adjusted due to the stature of operator, and it

offers maximum control and comfort for the operation. The alloy

blades which have get heat treatment are worn well. Low center

of gravity provides workers with saf e and stable operation.

KPT 36

Weight: 83kg

Diameter: 980mm

Float pan diameter: 945mm

Trowel blade rev: 70r/min~140r/min

Overall diameter: 1820×945×980mm

Blades: 4

Gearbox oil: WA460

Gearbox oil capacity: 950ml

Power output: 5.5hp

Engine type: HONDA GX160

Fuel capacity (L): 3.6

Engine oil type: Recommended

SAE10W-30

Engine oil capacity (L): 0.6

SPECIFICATION

KPT 48

Weight: 119kg

Diameter: 1175mm

Float pan diameter: 1180mm

Trowel blade rev: 70r/min~140r/min

Overall diameter: 2080×1170×1020mm

Blades: 4

Gearbox oil: WA460

Gearbox oil capacity: 950ml

Power output: 9/13hp

Engine type: HONDA GX270/390

Fuel capacity (L): 6/6.5

Engine oil type: Recommended SAE10W30

Engine oil capacity (L): 1.1

SAFETY PRECAUTIONS

3

1. Before starting operation, the operator has to check that all control and safety devices function properly.

2. Always keep unauthorized, inexperienced, untrained people away from this machine.

3. Rotating and moving parts will cause injury if contacted. Make sure guards are in place. Keep hands and feet away

from moving parts.

4. The engine must always be stopped before attempting any repair or adjustments. Ignition switch should be off.

5. To avoid slipping and loss of control when starting the trowel, the operator should maintain good footing. It is

recommended that the operator wear safety shoes for added protection.

6. Be careful when working around pipes or ducts protruding from the floor or slab edges. If the trowel blades hit such

obstacles, damage to the machine or possible operator injury may result.

7. When starting the machine, do not exceed 1/3 throttle position. A higher setting may cause the Centrifugal clutch to

engage and the handle to rotate.

8. Be careful not to come in contact with the muffler when the engine is hot, serious burns may result!

9. Over time, the blades will form a sharp edge. Be careful when handling the old blades.

10. Gasoline is extremely flammable, and gasoline vapor can explode. Refuel outdoors, in a well-ventilated area, and keep

other flames and sparks away.

11. Do not fill the fuel tank completely. After refueling, tighten the fuel tank cap securely.

12. Before beginning your preoperational checks, be sure the engine is level and the engine switch is in the OFF. The max.

gradient of 20° must not be exceeded when the engine working.

13. Don’t allow children to operate the engine. Keep children and pets away from the area of operation.

14. After each use your machine should be cleaned to remove any dust and debris from the undercarriage and

surrounding components.

15. When the machine start working you should be check the clutch whether or not wear and tear. If the clutch will have

3/4 worn and torn, you must change new clutch-ring.

16. Check that all shields and covers are in place, and all nuts, bolts, and screw are tightened when the machine working.

Make sure put the cable while the machine working.

MAINTENANCE RECORD

Due to the nature and environment of use, Walk-behind Power Trowels could be exposed to severe operating

conditions. Some general maintenance guidelines will extend the useful life of your trowel.

1. The initial service for your trowel should be performed after 25 hours of use, at which time your mechanic

(or authorized repair shop) should complete all of the recommended checks in the schedule below. The chart is handy

for keeping a record of the maintenance performed and the parts used for servicing your trowel.

2. Regular service according to the schedule below will prolong the life of the Walk-behind Power Trowel and prevent

expensive repairs.

3. Keeping your Walk-behind Power Trowel clean and free from debris is the single most important regular maintenance

operation, over and above the checks in the service schedule above, that can be performed. After each use your Walk

behind Power Trowel should be cleaned to remove any dust and debris from the undercarriage and surrounding

components. Use of a power washer will make clean up quick and easy, especially if a non-stick coating was applied

prior to use.

4. In the Service Schedule below, items that should be checked, replaced or adjusted are indicated by "o" in the

column. Not all Walk-behind Power Trowel models include the same features and options and as such not all service

operations may have to be performed. For ease of recording place a checkmark (√) through the "o" when the item is

complete. If an item is not required or not complete place an "×" through the "x" in the box.

CAUTIONS! Over time, if the blades will have 3/4 worn and torn, you must change new trowel blades.

appropriate

Routine

Service Intervals

Each use

After 1.5

Months

or 50 hrs

Each 3

Months

or 100 hrs

Each 6

Months

or 200 hrs

Each 9

Months

or 300 hrs

Each 12

Months

or 400 hrs

General Inspection:

Guards

Check

O O O O O

Warning

Stickers

Check

O O O O O

Test Run

Check Operation

O O O O

Controls:

Dead-Man

Switch Operation

Check O O O O O O

Pitch

Control Assembly

Check O O O O O O

Lubricate

O O O O O

Engine:

Engine oil

Check level

O O O O O O

Change

O

O

O

Engine Oil

Filter

Replace

O

O

Oil Cooler

Clean

O O O O

Cooling Fins

Clean

O O O O O

Air cleaner

Check-clean

O O O O O

Replace

O

Air Intake Line

Check O

Replace

2 yrs

Fan Belt

Check tightness

O

O

Valve Clearance

Replace

500 hrs

Check-Adjust

O O

Fuel filter

Check & Clean

O O O O

Replace

O O

Fuel Tank

Engine wiring

Clean

500hrs

Check

O

Drive Train:

Clutch/Pulley

Operation

Check O O O O O O

Spider plate assembly

Check O O O O O O

Lubricate

O O

V-Belt Check O O O O O O

Blades Check O O O O O O

Gearbox:

Gearbox oil

Check level

O O

Check O O O

Gearbox

Breathers

Check Operation

O

O O O

MAINTENANCE SCHEDULE

OPERATION ELEMENTS

V-

belt is driven gearbox by engine, and then transmit torque to trowel and the machine working. The trowels can be

4

adjusted due to the stature of operator through pitch control assembly. Dead man switch designs provide safe and

stable operation. Holding the deadman lever before start the engine, and loosening deadman lever the machine will

stop working.

OPERATION (Floating)

When the slab has set sufficiently firm that the operator’s footprint leaves a very slight depression on the surface of the

slab, it is ready for the floating operation.

Guiding the machine on the slab is very simple; a slight upward lift of the handle causes the machine to travel to the

left. Holding the handle in the neutral position, will slowly cause the machine to spin in one spot. Slight downward

pressure on the handle causes the machine to the travel to the right. Best results are obtained by covering

approximately 4” on each turn. In other words, let the machine move right or left, backwards or forwards,

approximately 4” with each revolution of the trowels. To fill a hole or cut down hump, move the unit back and forth

over the problem area.

Under normal operating conditions the machine should cover as much as 1000 sq. ft. in about 15 minutes. It is

recommended that a slight tension on the trowel control cable, (but not a definite tilt), during the floating operation

will cause the machine to operate much smoother. After the floated slab has set sufficiently, it is ready for the finishing

operation.

CAUTION!

operation is complete.

Do not let the machine stand in one spot on the soft cement. Lift from the slab when the floating

Model 350WSB & 350WSB With Stand Parts List

OPERATION (Finishing)

When starting the finishing operation, never set the trowels up over 1/4" pitch.

After the floating operation, the first thing to do is to remove the floating disc from the blades. Clean the blades, spider

plate and disc from cement paste collected during the floating operation. Increase the blade pitch up to a maximum of 1

cm for the first finishing operation and then continue to increase the pitch on the following finishing operations.

Continue the finishing passes until you obtain the desired floor finish. The time required between each finishing pass is

again dependent on the weather conditions and water content of the concrete etc. If some areas of the concrete

set/harden too fast you may apply a small amount of water using a hand brush as an aid to achieving the finish.

STARTING & STOPPING PROCEDURE

1. Before operation checks

a.

Check the oil level: Before beginning your preoperational checks, be sure the engine is level and the engine switch

is in the OFF. Remove the filler cap/dipstick and wipe it clean. Insert and remove the dipstick without screwing it

into the filler hole. Check the oil level shown on the dipstick. If the oil level is low, remove the oil filler cap, and fill to

the upper limit mark on the dipstick with recommended oil. Screw in the filler cap/dipstick securely.

SAE 10W-30 is recommended for general use. The engine is certified to operate on unleaded gasoline with a

research octane rating of 90 or higher. Unleaded gasoline produces fewer engine and spark plug deposits and

extends exhaust system life. Never use stale or contaminated gasoline or an oil/gasoline mixture. Avoid getting dirt

or water in the fuel tank.

b.

Check air filter: Remove the air cleaner cover and inspect the filter. Clean or replace dirty filter elements. Always

replace damaged filter elements. If equipped with an oil-bath air cleaner, also check the oil level.

Notice!

Running the engine with a low oil level can cause engine damage.

2. Start engine/Stopping engine procedure

Move the fuel valve lever to the ON position.

a.

b. Move the choke lever to the CLOSE position. If the engine is

warm or the air temperature is high, move the control lever away

from the OPEN position as soon as the engine starts.

5

c. Move the throttle lever away from the

SLOW position, about 1/3 of the way to

toward the FAST position.

d. Turn the engine switch to the ON position.

6

e. Pull the starter grip lightly until you feel resistance,

then pull briskly. Return the starter grip gently.

CAUTION!

Do not allow the starter grip to snap back

against the engine. Return it gently to prevent damage

to the starter.

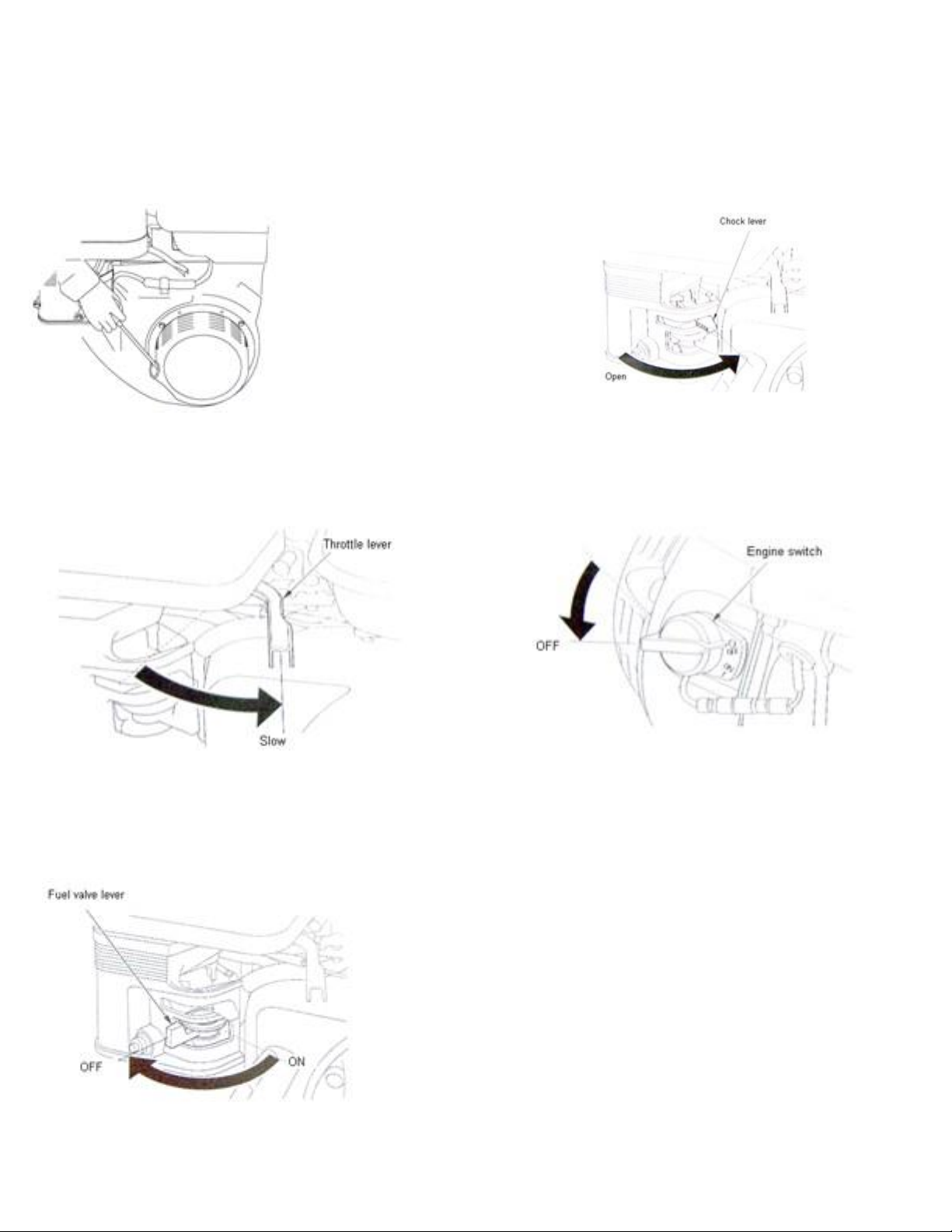

3. Stopping the engine

a.

Move the throttle lever to the SLOW position.

f. If the chock lever or chock rod (applicable types) has been

moved to the CLOSED position to start the engine,

gradually move it to the OPEN position as the engine warms

up.

b. Turn the engine switch to the OFF position.

c. Turn the fuel valve lever to the OFF position.

4. Setting engine speed

Position the throttle lever the desired engine speed.

LUBRICATION

1. Engine oil lever check

Check the engine oil level with the engine stopped and in a level position.

1. Remove the filler cap/dipstick and wipe it clean.

2. Insert and remove the dipstick without screwing it into the filler neck.

Check the oil level shown on the dipstick.

3. If the oil level is low, fill to the edge of the oil filler hole with the

recommended oil.

4. Screw in the filler cap/dipstick securely.

2. Engine oil change

Drain the used oil while the engine is warm. Warm oil drains quickly and completely.

1. Place a suitable container below the engine to catch the used oil, and then remove the filler cap/dipstick, drain plug, and

washer.

2. Allow the used oil to drain completely, then reinstall the drain plug, washer, and tighten drain plug securely.

Notice!

Please dispose of used motor oil in a manner that is compatible with the environment. We suggest you take

used oil in a sealed container to your local recycling center or service station for reclamation. Do not throw it in the

trash; pour it on the ground, or down a drain.

3. With the engine in a level position, fill to the outer edge of the oil filler hole with the recommended oil.

Notice!

Running the engine in a low oil level can cause engine damage.

4. Screw in the filler cap/dipstick securely.

SPARK PLUGS

Recommended spark plugs: BPR6ES (NGK). For good performance, the spark plug must be properly gapped and free

of deposits.

Notice!

An incorrect spark plug can cause engine damage.

1. Disconnect the spark plug cap, and remove any dirt from around the spark plug area.

2. Remove the spark plug with a 13/16-inch spark plug wrench.

3. Inspect the spark plug. Replace it if the electrodes are worn heavy carbon buildup is found, or if the insulator is

cracked or chipped.

4. Measure the spark plug electrode gap with a suitable gauge. The gap should be 0.028-0.031 in (0.70 - 0.80 mm).

Correct the gap, if necessary, by carefully bending the side electrode.

5. Check that the spark plug washer is in good condition. Install the spark plug carefully, by hand, to avoid cross-threading.

6. After the spark plug seats, tighten with a 13/16-inch spark plug wrench to compress the sealing washer.

7. When installing a new spark plug, tighten 1/2 turn after the spark plug seats to compress the washer.

8. After the spark plug seats, tighten with a 13/16-inch spark plug wrench to compress the sealing washer. If reinstalling

the used spark plug, tighten 1/8 - 1/4 turn after the spark plug seats. If installing a new spark plug, tighten 1/2

turn after the spark plug seats.

9. Attach the spark plug cap.

NOTICE!

The recommended spark plug has the correct heat range for normal engine operating temperatures. A loose

spark plug can overh eat and damage the engine. Over tightening the spark plug can damage the threads in the cylinder

head.

CARBURETOR AD J U S TM E N T

1. Start the engine outdoors, and allow it to warm up to operating temperature.

2. Move the throttle lever to its slowest position.

3. Turn the throttle stop screw to obtain the standard idle speed.

Standard idle speed: 1440r/min

7

8

AIR FILTER SERVICE

A dirty air filter will restrict air flow to the carburetor, reducing engine performance. If you operate the engine in very

dust areas, clean the air filter more often than specified in the MAINTENANCE SCHEDULE.

WARNING!

could result.

NOTICE!

enter the engine, causing rapid engine wear.

1. Remove the wing nut from the air cleaner cover, and remove the cover.

2. Remove the wing nut from the air filter, and remove the filter.

3. Remove the foam air filter element from the paper filter.

4. Inspect both air filter elements, and replace them if they are damage.

Never use gasoline or low flammable point solvents for cleaning the air cleaner element. A fire or explosion

Operating the engine without an air filter element, or with a damaged air filter element, will allow dirt to

5. Paper air filter element: Tap the filter element lightly several times on a hard surface to remove excess dirt, or blow

compressed air through the filter element from the inside out. Never try to brush the dirt off; brushing will force dirt

into the fibers.

6. Foam air filter element: Clean in warm soapy water, rinse, and allow to drying thoroughly. Or clean in nonflammable

solvent and allow to drying. Dip the filter element in clean engine oil, and then squeeze out all excess oil. The engine

will smoke when started if too much oil is left in the foam.

STORAGE

The following steps should be taken to prepare your Walk-behind Power Trowel for extended storage.

1. Close fuel shut off valve.

2. Siphon excess gasoline from tank.

3. Start engine until it stops from lack of fuel. This will use up all the fuel in the carburetor and prevent formation of

deposits due to evaporation of fuel.

4. Remove spark plug and pour 2 oz. of SAE-30 or SAE-40 motor oil into the cylinder. Slowly crank the engine 2 or 3

times to distribute the oil throughout the cylinder. This will help prevent rust during storage. Replace spark plug.

5. Store the unit in an upright position in a cool, dry, well-ventilated area.

TROUBLESHOOTING

1. WON'T START

• Throttle fully open

• Hand lever wire broken

• No gas

• Dirty gas

• No oil

2. STARTS BUT NO HIGH SPEED

• Engine problems • Throttle lever and connectors loose or out of adjustment

• Throttle cable broken or seized • Clutch shoes worn

3. STARTS AT HIGH SPEED, WON'T SLOW DOWN

• Same as above

4. ENGINE WON'T STOP

• Safety switch, wire or connectors not making good contact •Micro-switch burnt out

5. ENGINE STARTS BUT WON'T TURN TROWELS AT ANY SPEED

• Clutch seized

• No weights in clutch

• Wrong belt

• Gas filter plugged

• Gas line plugged

• Hole in gas line

• Gas supply valve turned off

• Safety switch wire or connectors

not making good contact

• Other engine problems (Refer to

engine manual)

• Dead-man safety switch is off

• Gearbox seized

• Broken or missing key

— Clutch seized

— Pulley

— Worm gear (countershaft)

— Main gear

— Spider plate

6. TROWELS TURN, ENGINE AT IDLE

• Idle too fast

• Belt too tight

7. TROWELS BLADES WEARING UNEVENLY

• Spider plate seized

• Arms bent

8. MACHINE JUMPS ON FLOOR

• Concrete hardened on bottom of spider plate

• Trowels unevenly worn/bent

• Spider plate seized

• Spider plate loose

9. PITCH CONTROLS WILL NOT OPERATE BLADES

• Cable broken or out of adjustment

• Pressure plate assembly contaminated with concrete debris

• Slot screw missing (under-side of handle)

10. BELT WEARING RAPIDLY

• Belt is too tight

• Pulley out of alignment

11. OIL LEAKS

a.

Top of gearbox

• Gearbox seal warn

• Wrong belt/defective belt

• Clutch sticking

• Engine leaks

• Too much oil in gearbox

• Clutch seized

• Pulley out of alignment

• Adjusting screws (carriage bolts) incorrectly set

• Floating disc not evenly attached to the blades

b. At main shaft or countershaft

• Shaft and/or seal worn

• Retaining screw(s) loose

• Trowel arms bent

• Adjusting screws (carriage bolts) incorrectly set

• Main shaft bent

• Spider plate seized

• Pressure plate and/or yoke arm broken or badly worn

• Hand crank adjuster malfunctioning

• Gearbox seizing

12. TROWEL BLADES WILL NOT TURN

• Yoke arm broken • Key sheared • Gearbox malfunction

9

Diagram - 36

1. Walk-behind power trowel assembly

10

Item Part No.

Part name

Qty

1

36001

Handle assembly

1 2 36002

Washer 10

4 3 36003

Stud M10×45

4 4 36004

Handle bracket

1 5 36005

Yoke arm

1 6 36006

Retaining ring

1 7 36007

Pin 1 8 36008

Screw M10×25

7 9 36009

Mounting rails I

1

10

36010

Gearbox assembly

1

11

36011

Pressure plate assembly

1

12

36012

Spider plate assembly

1

13

36013

Bolt M10x45

4

14

36014

Releaser hood

1

15

36015

Engine GX160

1

16

36016

Washer 8

4

17

36017

Lock Nut 8

4

18

36018

Hoist hook

1

19

36019

Bolt 5/16”×20

4

20

36020

Clutch A

1

21

36021

Pulley

1

22

36022

Screw M8×16

2

23

36023

Washer 10

4

24

36024

Belt-mounting plate

1

25

36025

Bolt M8×16

2

26

36026

Belt A-27

1

27

36027

Bolt M6×20

4

28

36028

Gasket 6

2

29

36029

Washer 6

2

30

36030

Belt guard

1

31

36031

Shock mount

4

33

36033

Lock NutM10

4

34

36034

Washer 10

4

35

36035

Mounting rails II

1

36

36036

Guard ring

1

37

36037

Lock NutM10

4

Item Part No.

Part name

Qty

1

36201

Pin 5×35

1 2 36202

Gasket 10

1 3 36203

Bolt M10×200

1 4 36204

Threaded rod

1 5 36205

Retaining ring 35

1 6 36206

Bearing 51203

1 7 36207

ScrewM6×8

1 8 36208

Bushing

1 9 36209

Throttle cable

1

10

36210

Lock Nut M12

2

11

36211

Washer 12

2

12

36212

Retaining ring 8

1

13

36213

Rigid handle

1

14

36214

Pin 1

15

36215

Pulley

1

16

36216

Bolt M12×80

2

17

36217

Gasket 12

2

18

36218

Carry bar

1

19

36219

Washer 5

2

20

36220

Gasket 5

2

21

36221

Screw M5×12

2

22

36222

Bolt M8×12

1

23

36223

Deadman switch

1

24

36224

Wheel I

1

25

36225

Throttle control

1

26

36226

Wheel II

1

27

36227

Handle

1

28

36228

Cable-throttle 1

Item Part No.

Part name

Qty

1

36301

Washer

1

2

36302

Washer

1

3

36303

Screw M4×30

1

4

36304

Sphere

1

5

36305

Lever

1

6

36306

Switch box

1

7

36307

Switch cover

1

8

36308

Screw M4×25

3

9

36309

Washer 4

2

10

36310

Nut M4

2

KPT 36 Power Trowel Part List Handle Part List

Deadman Switch Part List

2. Handle assembly

3. Deadman

switch assembly

11

12

Item Part No.

Part name

Qty

1

36401

Screw M8x16

8

2

36402

Large Flange

1

3

36403

Large-Flange washer

1

4

36404

Screw M12x25 LF

1

5

36405

Washer

1

6

36406

Bearing 30207

1

7

36407

Spacer

1

8

36408

Worm Gear

1

9

36409

Bearing 207

1

10

36410

Key 10x8x28

1

11

36411

Oil Seal NAK20x40x7

1

12

36412

Key 10x8x28

1

13

36413

Washer

Some

14

36414

Oil Seal NAK35x54x8

1

15

36415

Drain plugM16x1.5

1

16

36416

Washer 16(Cu)

1

17

36417

Worm Shaft

1

18

36418

Key 6x6x32

1

19

36419

Fill plug M16x1.5

1

20

36420

Washer 16(Cu)

1

21

36421

Sight Plug

1

22

36422

Screw M6x16

12

23

36423

Relief Valve

1

24

36424

Main Shaft

1

25

36425

End Cap

1

26

36426

Bearing 30304

1

27

36427

Bearing 304

1

28

36428

Flange

1

29

36429

Gearbox

1

4. Gearbox assembly

5 Spider plate assembly

Gearbox Part List

Item Part No.

Part name

Qty

1

36601

Clutch-ring

4

2

36602

Spring

1

3

36603

Cover

1

4

36604

Screw M8×16

2

5

36605

Bushing

1

6

36606

Spacer

1

7

36607

Gasket 8

1

8

36608

Bolt 5/16”×40

1

9

36609

Friction Wheel A

1

10

36610

Lubrication bearing

1

11

36611

Bearing

1

12

36612

Friction Wheel A

1

Item Part No.

Part name

Qty

1

36501

Spider plate

1

2

36502

O-ring 30×2.4

4

3

36503

Nut M8

4

4

36504

Carriage bolt

4

5

36505

Lift lever

4

6

36506

Bolt M8×16

4

7

36507

Trowel arm

4

8

36508

Bolt M8×40

4

9

36509

Bolt M8×50

4

10

36510

Gasket 8

8

11

36511

Bushing

4

12

36512

Trowel blade assembly

4

13

36513

Grease fitting M8x1

4

14

36514

Retainer

1

15

36515

Screw M12×25

1

16

36516

Cap plug

1

17

36517

Pressure plate cap

1

18

36518

Bearing 51209

1

19

36519

Bushing

1

20

36520

Pressure plate

1

Spider Plate Part List

Clutch Part List

13

6 Clutch assembly

14

Diagram - 48

1. Walk-behind power trowel assembly

2. Handle assembly

Item Part No.

Part name

Qty

1

46001

Handle bracket

1

2

46002

Lock Nut M10

4 3 46003

Washer 10

4 4 46004

Stud M10×45

4 5 46005

Yoke arm

1 6 46006

Retaining ring

1 7 46007

Pin 1 8 46008

Gearbox assembly

1 9 46009

Handle assembly

1

10

46010

Pressure plate assembly

1

11

46011

Spider plate assembly

1

12

46012

Bolt M10×35

4

13

46013

Releaser hood

1

14

46014

Belt-mounting plate

1

15

46015

Engine GX270

1

16

46016

Washer 10

4

17

46017

Lock Nut M10

4

18

46018

Hoist hook

1

19

46019

Bolt 5/16 ×20

4

20

46020

Clutch B

1

21

46021

Pulley

1

22

46022

Screw M8×16

2

23

46023

Belt B28

1

24

46024

Washer 8

2

25

46025

Gasket 8

2

26

46026

Bolt M8×16

2

27

46027

Belt guard

1

28

46028

Bolt M8×16

2

29

46029

Washer 10

4

30

46030

rubber mat

4

31

46031

Screw M10×20

8

32

46032

Lock Nut M10

4

33

46033

Washer 10

4

34

46034

Guard ring

1

35

46035

Mounting rails

1

37

46037

Mounting rails

1

Item Part No.

Part name

Qty

1

46301

Pin 5×35

1

2

46302

Gasket 10

1 3 46303

Bolt M10×200

1 4 46304

Threaded rod

1 5 46305

Retaining ring 35

1 6 46306

Bearing 51203

1 7 46307

ScrewM6×8

1 8 46308

Bushing

1 9 46309

Throttle cable

1

10

46310

Lock Nut M12

2

11

46311

Washer 12

2

12

46312

Retaining ring 8

1

13

46313

Rigid handle

1

14

46314

Pin 1

15

46315

Pulley

1

16

46316

Bolt M12×80

2

17

46317

Gasket 12

2

18

46318

Carry bar

1

19

46319

Washer 5

2

20

46320

Gasket 5

2

21

46321

Screw M5×12

2

22

46322

Bolt M8×12

1

23

46323

Deadman switch

1

24

46324

Wheel I

1

25

46325

Throttle control

1

26

46326

Wheel II

1

27

46327

Handle

1

28

46328

Cable-throttle 1

Item Part No.

Part name

Qty

1

46401

Washer

1

2

46402

Washer

1

3

46403

Screw M4×30

1

4

46404

Sphere

1

5

46405

Lever

1

6

46406

Switch box

1

7

46407

Switch cover

1

8

46408

Screw M4×25

3

9

46409

Washer 4

2

10

46410

Nut M4

2

15

KPT 48 Power Trowel Part List

Handle Part List

Deadman Switch Part List

3. Deadman

switch assembly

5 Spider plate assembly

4.

Gearbox

assembly

Pressure Plate

16

Item Part No.

Part name

Qty

1

46201

Screw M8x16

8

2

46202

Large Flange

1

3

46203

Large-Flange washer

1

4

46204

Screw M12x25 LF

1 5 46205

Washer

1

6

46206

Bearing 30207

1

7

46207

Spacer

1

8

46208

Worm Gear

1

9

46209

Bearing 207

1

10

46210

Key 10x8x28

1

11

46211

Oil Seal NAK20x40x7

1

12

46212

Key 10x8x28

1

13

46213

Washer

Some

14

46214

Oil Seal NAK35x54x8

1

15

46215

Drain plugM16x1.5

1

16

46216

Washer 16(Cu)

1

17

46217

Worm Shaft

1

18

46218

Key 6x6x32

1

19

46219

Fill plug M16x1.5

1

20

46220

Washer 16(Cu)

1

21

46221

Sight Plug

1

22

46222

Screw M6x16

12

23

46223

Relief Valve

1

24

46224

Main Shaft

1

25

46225

End Cap

1

26

46226

Bearing 30304

1

27

46227

Bearing 304

1

28

46228

Flange

1

29

46229

Gearbox

1

Item Part No.

Part name

Qty

1

46601

Bolt M8×45

8

2

46602

Gasket 8

12

3

46603

Trowel arm

4

4

46604

Bushing

8

5

46605

Trowel blade assembly

4

6

46606

Bolt M8×16

4

7

46607

Lift lever

4

8

46608

Carriage bolt

4

9

46609

Nut M10

4

10

46610

Spider plate

1

11

46611

Grease fitting

4

12

46612

Screw M12×30

1

13

46613

Cap plug

1

14

46614

Retainer

1

15

46615

Screw M10×16

4

16

46616

-ring 20×2.4

4

17

46617

M8X40

4

18

46618

Bolt M8×40

4

Item Part No.

Part name

Qty

1

46501

Pressure plate cap

1

2

46502

Bearing 51209

1

3

46503

Bushing

1

4

46504

Pressure plate

1

Item Part No.

Part name

Qty

1

46701

Clutch-ring

4

2

46702

Spring

1

3

46703

Cover

1

4

46704

Screw M8×16

2

5

46705

Bushing

1

6

46706

Spacer

1

7

46707

Gasket 8

1

8

46708

Bolt 5/16”×40

1

9

46709

Friction Wheel A

1

10

46710

Lubrication bearing

1

11

46711

Bearing

1

12

46712

Friction Wheel A

1

Gearbox Part List

Spider Plate Part List

17

Clutch Part List

6 Clutch assembly

Pressure Plate

Loading...

Loading...