Kushlan Products KPRC160 User Manual

OPERATOR’S MANUAL

KPRC160 PLATE COMPACTOR

WARNING !

To reduce the risk of injury, all operators and maintenance personnel must read and understand these

instructions, before operating, changing accessories, or performing maintenance on our equipment. All

possible situations can not be covered in these instructions. Care must be exercised by everyone using,

maintaining or working near this equipment.

INTRODUCTION

Thank you for your selection for our equipment.

We have taken care in the design, manufacture and testing of this product. It is covered by a six month

warranty. Should service or spare parts be required, prompt and efficient service is available from our

company or our agent.

GENERAL SAFETY INSTRUCTION FOR THE OPERATION OF POWER EQUIPMENT

The goal of our company is to produce power equipment that helps the operator work safety and

efficiently. The most important safety device for this or any tool is the operator. Care and good judgment

are the best protection against injury. All possible hazards can not be covered here, but we have tried to

highlight some of the important items, individuals should look for and obey caution. Warning and Danger

signs placed on equipment, and displayed in the workplace. Operators should read and follow safety

instructions packed with each product. Learn how each machine works. Even if you have previously used

similar machines, carefully check out each machine before you use it. Get the “feel” of it and know its

capabilities. Limitations, potential hazards, how it operates, and how it stops.

APPLICATIONS

Trench compaction Earth works

Road maintenance Landscaping

Brickpaving Driveway toppings

FUNCTIONS AND CONTROLS

The motor is controlled by an ON/OFF switch or push button which is mounted on the motor below the

fuel tank.

Tension of the drive belt is adjustable. Loosen the four nuts on the bolts which secure the motor to the

base plate. Adjust the set screws which bear against the motor crankcase to achieve the required belt

tension. Ensure that the four nuts and the set screw locknuts are tightened after adjustment.

ACCESSORIES

Transportation Trolley-facilitates handling, Hooks into the base plate. Fitted with 200mm rubber tyres.

HAZARDS AND RISKS

NEVER allow any person to operate the machine without adequate instruction.

ENSURE all operators read, understand and follow the operating instructions.

SERIOUS INJURY could result from improper or careless use of this machine.

Plates compactors are heavy units and should be positioned by two people of appropriate strength.

Using the lifting handles provided on the machine. along with correct lifting techniques.

MECHANICAL HAZARDS!

DO NOT operate the machine unless all protective guards are in place.

KEEP handles and feet clear of rotating and moving parts as they will cause injury if contacted.

ENSURE that the motor operation switch is in the OFF position and the spark plug ignition lead is

disconnected before removing the guards or making adjustments.

ENSURE both the machine and the operator are stable by setting up on level terrain and the machine will

not tip over .slide off all while in operation or unattended.

DO NOT leave the machine in operation while it is unattended.

ENSURE that the walls of a trench are stable and will not collapse due to the action of the vibration, prior

to commencing compaction.

EUSURE that the area to be compacted does not contain any "live" electrical cables, gas, water or

communication services which many be damaged by the action of vibration.

EXERCISE CARE when operating unit. Exposure to vibration or repetitive work actions may be harmful

to hands and arms.

NEVER stand on the unit while it is operating.

DO NOT increase the governed no-load motor speed above 3,500 r/min. Any increase may result in

personal injury and damage to the machine.

BE CAREFUL not to come in contact with the muffler, when the engine is hot, since it can cause severe

burns.

ENSURE that the repairs to the motor and machine are carried out by COMPETENT personnel.

FIRE & EXPLOSION HAZARDS!

PETROL is extremely flammable and explosive under certain conditions;

ENSURE that the petrol is only stored in an approved storage container.

DO NOT refuel the motor while it is in operation or hot.

DO NOT refuel the motor in the vicinity of sparks, a naked flame or a person smoking.

DO NOT over fill the fuel tank and avoid spilling petrol when refueling .Spilled petrol or petrol vapor may

ignite. If spillage occurs, ensure that the area is dry before starting the motor,

ENSURE that the fuel tank cap is securely fitted after refueling.

CHEMICAL HAZARDS!

DO NOT operate or refuel a petrol or diesel motor in a confined area without adequate ventilation.

CARBON MONOXIDE exhaust gases from internal combustion motor driven units can cause death in

confined spaces.

NOISE HAZARDS!

EXCESSIVE NOISE can lead to temporary or permanent loss of hearing.

WEAR an approved hearing protection device to limit noise exposure. As required by Occupational

Health and Safety regulation.

PROTECTIVE CLOTHING

ALWAYS wear approved hearing protection when working in a confined work space. Protective goggles

and a dust mask should be worn when working in a dusty environment. Protective clothing and footwear

may also be desirable when working with hot mix bitumen.

ADDITIONAL HAZARDS!

Slip/Trip/Fall is a major cause of serious injury or death. Be aware of uneven or slippery work surfaces.

Exercise care when working in the vicinity of unprotected holes or excavations.

OPERATION

Pre start-up inspection

The following Pre-start-up inspection must be performed before the start of each work session or after

every four hours of use. Which ever is first. If any fault is discovered, the compactor must not be used

until the fault is rectified.

1. Thoroughly inspect the compactor for signs of damage. Check components are present and secure.

Pay special attention to the belt drive safety guard fitted between the engine and the vibrator unit.

2. Check the engine oil level and top up as necessary

3. Check the engine fuel level and top up as necessary

4. Check for fuel and oil leaks

Start and stop Procedure for Petrol Engine

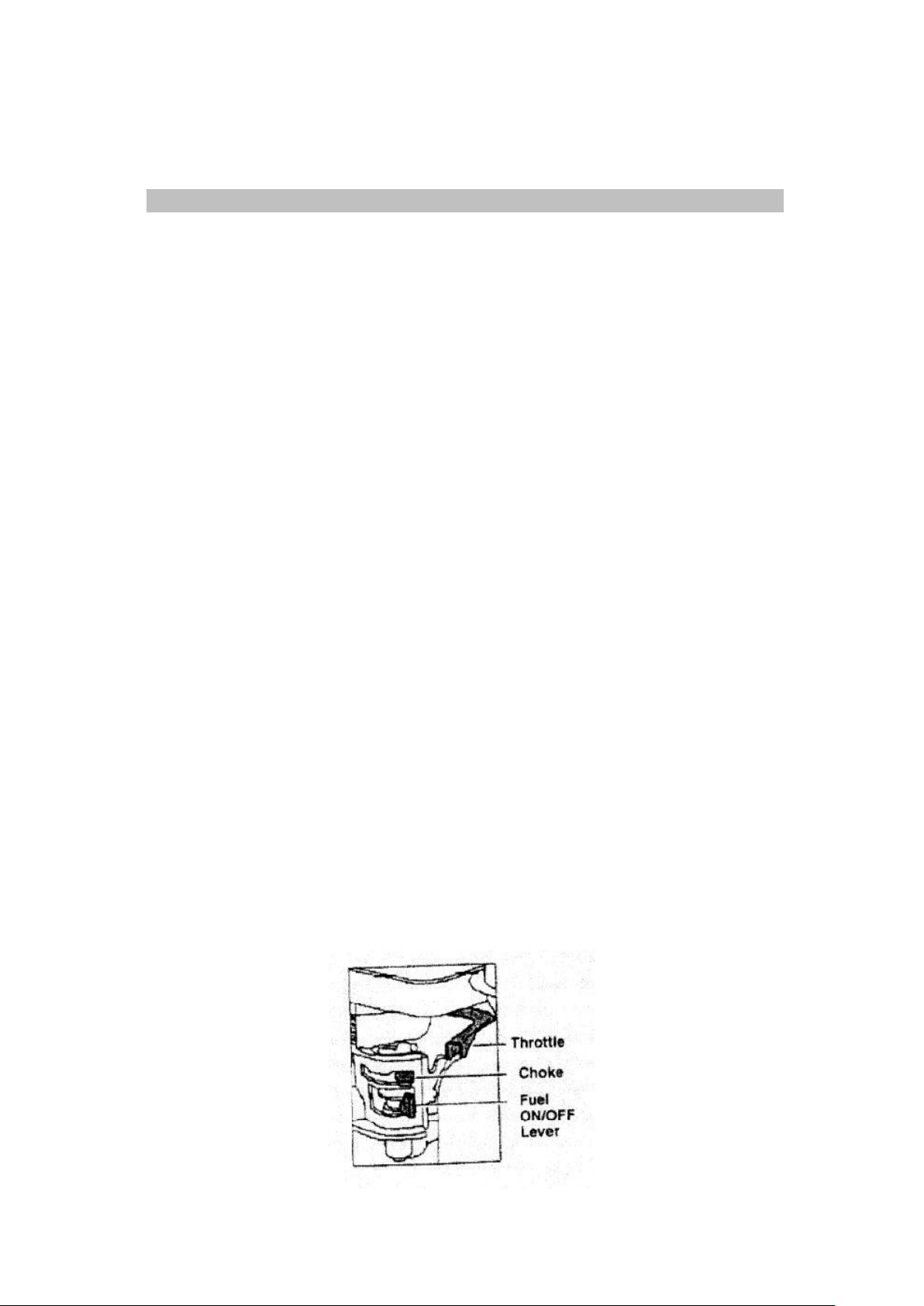

1. Open the fuel tap by moving the fuel ON/OFF lever fully to the right.

2. If starting the engine from cold, set the choke ON by moving the choke lever fully to the left. If

restarting a warm engine, he choke is usually not required. However, if the engine has cooled to a

degree, partial choke may be required.

3. Turn the engine ON/OFF switch clockwise to the "1" position.

4. Set the throttle to the idle position by moving the throttle lever fully to the right. Do not start the engine

on full throttle, As the compactor will vibrate as soon as the engine starts.

5.Taking a firm hold o the control handle with one hand, grasp the recoil starter handle with the other.,

pull the recoil starter until engine resistance is felt. Then let starter return.

6. Taking care not to pull starter's cope fully out. pull the starter handle briskly.

7. Repeat until the engine fires.

8. Once the engine fires gradually, set the choke lever to the OFF position by moving It to the right.

9. If the engine fails to fire after several attempts, follow the trouble-shooting guide on page 5.

10. To stop the engine, set the throttle to idle and turn the engine ON/OFF switch anticlockwise o the "0"

position.

11. Turn the fuel off

The machine is best suited to the compaction of bituminous and granular materials e.g. granular soils

such as silt and clay are best compacted using the impact force produced by a vibrating rammer.

Where possible the site should be graded and leveled before commencing compaction.

For more information of starting and correct operating procedures o the motor, refer to the motor

operation manual supplied with the unit.

Increase the motor sped to the maximum setting using the hand throttle lever, before commencing

compacting. The machine should be controlled by grasping the handle with supplied with the unit.

Increase the motor sped to the maximum setting using the hand throttle lever, before commencing

compacting.

The machine should be controlled by grasping the handle with both hands and applying restraint to

control the forward motion.

Steer the machine by moving the handle sideways to the right or left;

ALWAYS maintain good footing so that you do not slip and loose control when starting or operating the

machine;

Inspection the water hose and its connections to ensure that they do not leak.

CARE AND PREVENTIVE MAINTENANCE

Check the oil level in the motor crankcase daily.

Check the vibrator oil level weekly.

Inspect the rubber anti vibration mounts for wear or deterioration.

Inspection the water hose and its connections to ensure that they do not leak.

Clean the underside of the plate regularly to prevent a build up of material.

Use unleaded grade petrol and ensure that the fuel is free from contamination.

The vibratory motion provides a self propelling action.

Position the handle at the opposite end of the machine to the vibrator.

Start the motor using the recoil starter.(If the motor is fitted with an on/off switch this must first be turned

to ON before starting.)

Correct moisture content in soil is vital to proper compaction.

Water acts as a lubricant to help slide soil particles together.

Too little moisture means inadequate compaction; too much moisture leaves water-filled voids that

weaken the soil's load bearing ability.

Compaction of dry materials will be facilitated by moistening with a water hose fitted with a sprinkler.

Excessive watering or water content will cause the machine to stall.

The optional water tank kit is recommended when the machine is used on bituminous surfaces as the

water fulm prevents

A build up of material on the underside of the plate.

CAUTION

Inspection and other services should always be carried out on hard and level ground with the

ITEM

Hours of Operation

(Starting Check)

Every8 hours ( every day)

Loosened of lost screws

Every8 hours ( every day)

Damage of any part

Every8 hours ( every day)

Function of controlling system part

Every8 hours ( every day)

Vibrator oil check

Every 100 hours

Vibrator oil replacement

Every 100 hours

V-belt (Clutch) Check

Every 100 hours

( For details, see separate engine manual)

ITEM

Hours of Operation

Leakage of oil fuel

Every8 hours ( every day)

Tightness of fastening Threads

Every8 hours ( every day)

Engine oil check and replenishment

Every8 hours ( every day)

(Replenish to specified Max. Level)

Engine oil replenishment

At first 20 hours, then every 100 hours

Air cleaner cleaning

Every 50 hours

engine shut down.

Inspection and maintenance Service Tables

To make sure your plate compactor is always in good working condition before using. carry out the

maintenance inspection in accordance with Tables 1 through 3.

TABLE 1. MACHINE INSPECTION

TABLE 2. ENGINE CHECK

CAUTION

These inspection intervals are for operation under normal conditions. Adjust your inspection

intervals based on the number hours plate compactor is in use, and particular working conditions.

CAUTION

Fuel piping and connections should be replaced every 2 years.

Daily Service

Check for leakage of fuel or oil.

Loading...

Loading...