Kushlan 600 Series, 350 Series, 600W, 350WSB Operating Instructions Manual

Operating Instructions

and Parts Manual for

350/600W Model Series &

Optional Tri-Pod Stand

DO NOT ATTEMPT TO START OR OPERATE

THE MACHINE UNTIL ALL THE

INSTRUCTIONS HAVE BEEN READ AND

UNDERSTOOD BY THE OPERATOR.

FAILURE TO DO SO COULD RESULT IN

SERIOUS BODILY INJURY AND/ OR

PROPERTY DAMAGE!

WARNING

Kushlan

Products, LLC

12010 Dairy Ashford Road, Suite 160 , Sugar Land, TX 77478 281-313-2506 1-800-469-4178

SHOULD YOU REQUIRE ANY SET-UP OR OPERATING ASSISTANCE WITH YOUR PRODUCT, DO NOT RETURN TO ORIGINAL PLACE OF PURCHASE.

After referring to the operation manual, if assistance is still needed, please consult our web

Site at www.kushlanproducts.com

From our web site you may e-mail us directly

If assistance is still required, please call our customer service department at 1-800-469-4178

Safety Alert Symbol: This safety alert symbol is used to

attract your attention!

Personal Safety is involved when you see this symbol, Pay extra

attention, become alert-be sure to follow it’s message. Failure to

do so may lead to serious personal injury or damage may occur.

Warnings and safety instruction: If these warnings and safety

instructions are not read and carefully followed, serious personal

injury could occur.

WARNINGS

1

1. Do not use, start, or attempt to operate this machine until all of the instructions have been read

and fully understood.

2. Never allow anyone to operate this machine unless the person is well acquainted with these rules

of safe operation.

3. Never operate this machine without all guards in place and firmly attached to the machine.

4. Make certain that the mixing drum is clear of obstructions and stand clear of the machine without

all guards in place and firmly attached to the machine.

5. When cleaning, lubricating, or adjusting the mixer, disconnect the power plug.

6. Keep all people (except operator) a minimum of 5 ft. away from the machine during operation.

7. Always make certain that the mixer is connected to a properly grounded electric circuit to protect

the operator from possible electric shock.

8. Do not plug or unplug the motor while standing in or around damp or wet ground.

9. Do not start the motor if the drum is fully loaded.

10. Do not overload the mixer.

11. Never attempt to move the mixer while the motor is on.

1. Keep hands and clothing away from moving parts at all times.

2. Do not operate this machine under the influence of alcohol or while taking medication that impairs

the senses or reactions.

3. Make certain that the work area around the machine is clear of debris and obstructions.

4. Keep all unauthorized and untrained people away from the machine at all times.

5. Never let the mixer run unattended even for a brief moment.

6. Turn off the motor when you leave the machine.

7. Only use or operate the mixer on level ground to prevent the mixer from tipping over.

8. Do not abuse the power cord; i.e. Never yank on the cord to disconnect it. Keep the cord away

from heat, oil, and sharp edges.

9. Do not over reach while working with the mixer. Keep proper footing and balance at all times when

loading or unloading the mixer.

10. Never allow children or inexperienced operators to operate or repair the mixer.

11. Use only factory authorized parts for replacement.

12. Keep these operation instructions with the machine at all times.

13. Always wear safety glasses and safety shoes when operating and moving equipment.

SAFETY INSTRUCTIONS

For the safety of yourself and others around you, it is extremely

important that you observe the following notes.

2

A. Lubrication: There are grease fittings (item 23) on all models. Apply any type of multipurpose

grease until grease begins to come out of the bushings in housing and bearings on wheels.

B. Extension Cord: Use only outdoor approved, 14 gauge or larger, grounded extension cords.

C. Gear Adjustment: If the gear on the jackshaft (item 9) is not meshing properly with the ring gear and

plate(14), adjustment can be made by loosening the whizlock screws and attaching the jackshaft

housing (10) and sliding the housing tube until proper alignment is obtained. If removal of pulley

guard is necessary, make certain it is reattached to the machine before using.

D. General: Check all screws for tightness before each use.

E. Motor Adjustment/Belt Tensioning: To adjust belt tension, loosen the four screws that attach the

motor to the frame. Make adjustments and retighten screws. V-belt tensioning should be retightened

after the first 20 hours of use. The belt should be tightened until the belt deflects approximately 1/4"

with regular thumb pressure. Replace covers and guards before using the machine.

F. Concrete Mixing: Do not insert sharp objects into the plastic mixing drum. Doing so will damage the

drum.

G. Cleaning: Do not spray water on or into the motor. Thorough cleaning of the mixer after each use is

recommended and will add to the service life.

Mixer Instructions

KUSHLAN PRODUCTS, LLC

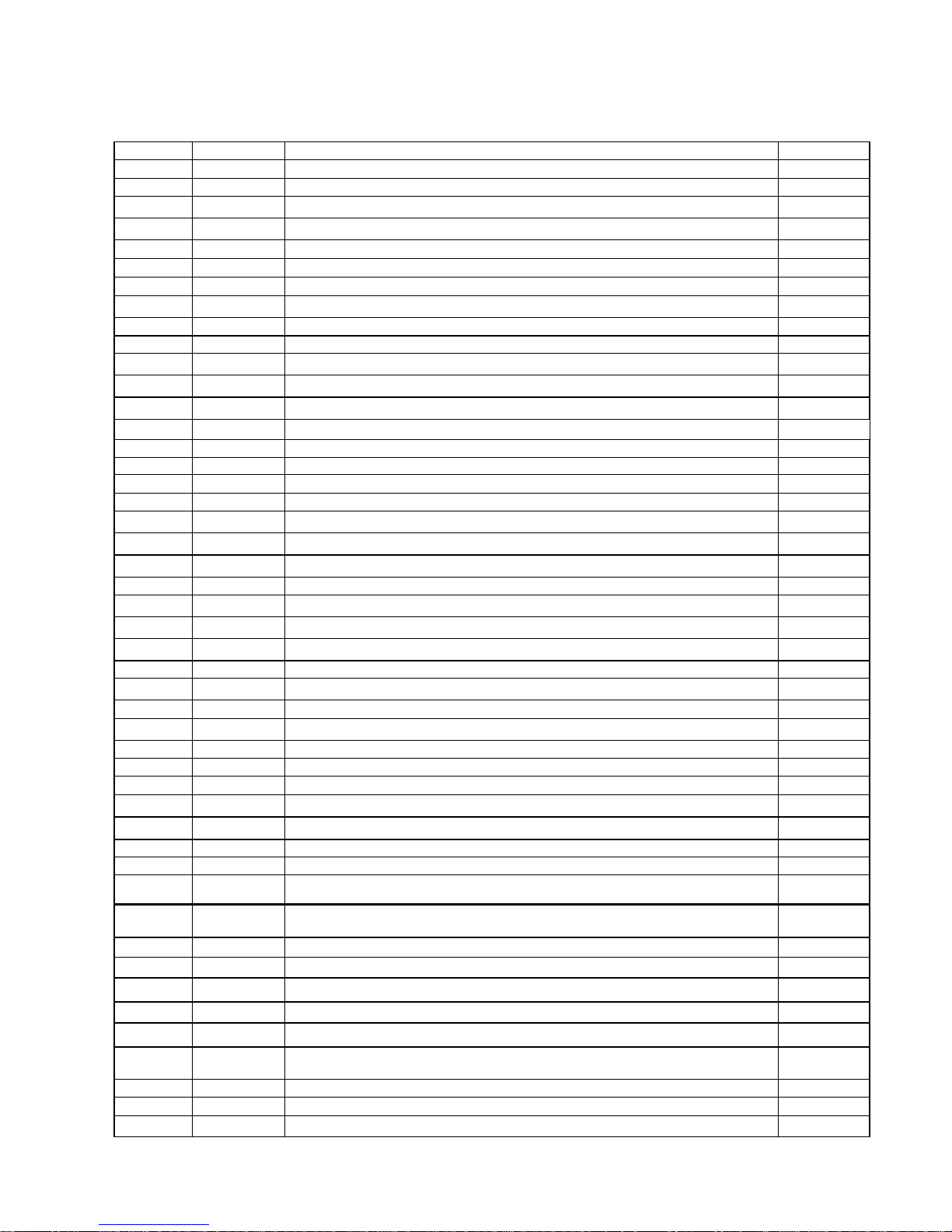

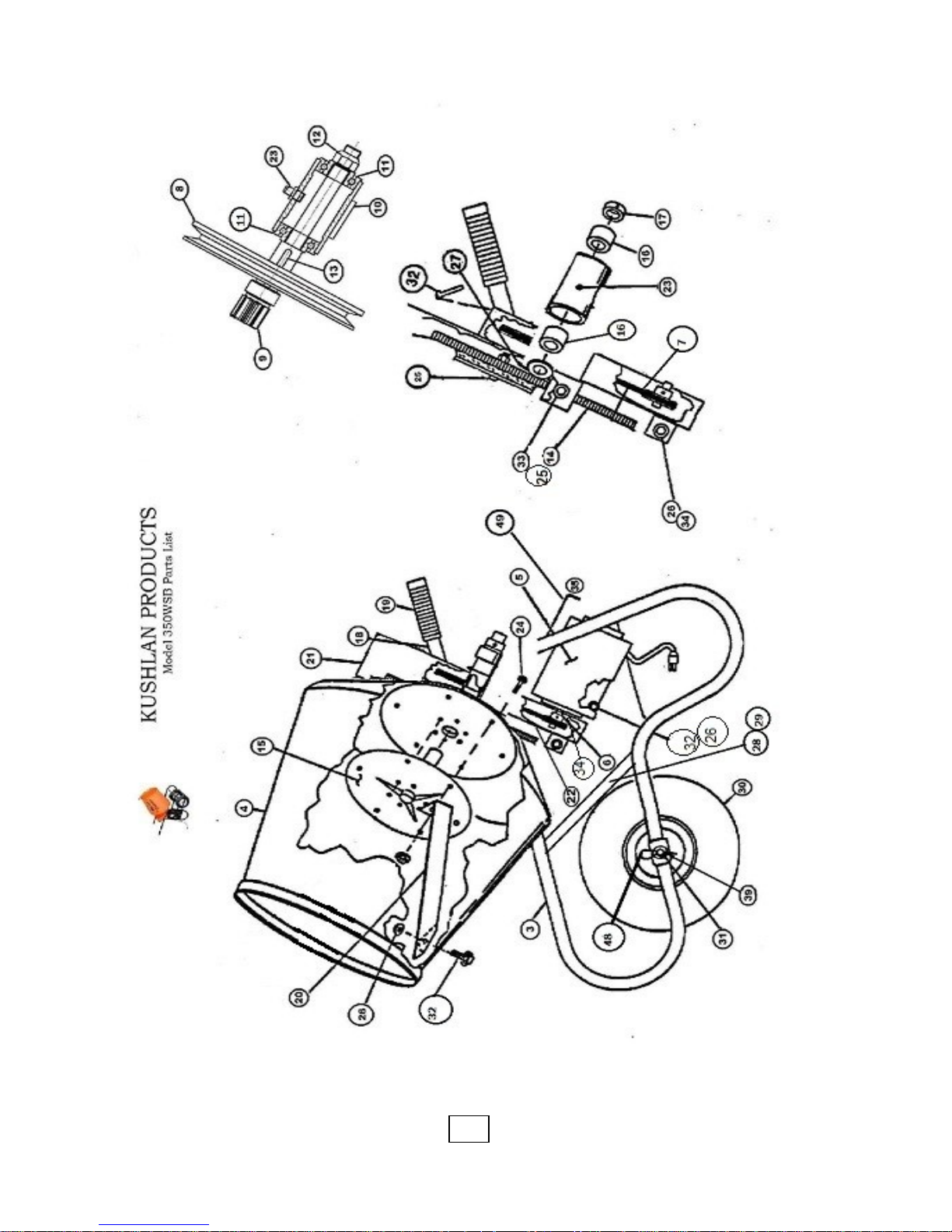

Model 350WSB & 350WSB With Stand Parts List

ITEM PART NO DESCRIPTION QTY

350WSB 350WSB Wheelbarrow Mixer X

3 35-1 Frame assembly 1

4 35-2 Polyethylene 3.5 cf drum with side holes 1

5 35-3 3/4 hp Electric motor with power cord 1

6 35-4 1 1/2" pulley 1

7 35-5 28" V-belt 1

8 35-6 6" pulley 1

9 35-7 Jackshaft with pinion 1

10 35-8 Jackshaft Bearing Housing 1

11 35-9 1/2” Ball Bearings 2

12 35-10 1/2" X 20 thread nut 1

13 35-11 3/16’’ Square key 1

14 35-12 Ring gear & plate assembly 1

15 35-13 Drum plate & shaft assembly 1

16 35-14 Drum shaft bushing 2

17 35-15 1" Locking collar 1

18 35-16 Wheelbarrow handle 2

19 35-17 Handle grip 2

20 35-18 350WSB mixing blades 2

21 35-19 Poly ring gear guard 1

22 35-20 Guard for Pulley 1

23 35-21 Grease fitting M8 2

24 35-22 3/8" x 1-1/4" whizlock screw 12

25 35-23 Hex flange lock nut 3/8" 3

26 35-24 Hex flange lock nut 5/16" 11

27 35-25 1" Metal thrust washer 1

28 35-26 Wheelbarrow axle 1

29 35-27 Axle spacer tube 1

30 35-28 300 x 8 Wheel 2

31 35-29 Locking pin 2

32 35-30 Whizlock screw 5/16”x 1” 11

33 35-31 Whizlock screw 3/8”x 3/4” 3

34 35-32 Motor cover 1

35 35-33 On/Off switch 1

37 35-35 Weather seal for Cord 1

39 35-37 Support Brace for Tri-Pod Stand 1

40 35-38 Vertical Pipe Support for Tri-Pod 1

41 35-39 Horizontal Rest Bracket for Tri-Pod 1

42 35-40 Leg Support 1 Pipe for Tri-Pod 1

43 35-41 Leg Support 2 Pipe for Tri-Pd 1

44 35-42 Whizlock Screw for Tri-Pod 2

45 35-43 Parts book 1

46 35-44 5/8 “ Washer 2

47 35-45 “R” Clip for washer 2

48 35-46 5/8” Wheel Bearing 4

49 35-50 Strain Relief 1

4

Loading...

Loading...