Operating Instructions

and Parts Manual for

350/600W Model Series &

Optional Tri-Pod Stand

DO NOT ATTEMPT TO START OR OPERATE

THE MACHINE UNTIL ALL THE

INSTRUCTIONS HAVE BEEN READ AND

UNDERSTOOD BY THE OPERATOR.

FAILURE TO DO SO COULD RESULT IN

SERIOUS BODILY INJURY AND/ OR

PROPERTY DAMAGE!

WARNING

Kushlan

Products, LLC

12010 Dairy Ashford Road, Suite 160 , Sugar Land, TX 77478 281-313-2506 1-800-469-4178

SHOULD YOU REQUIRE ANY SET-UP OR OPERATING ASSISTANCE WITH YOUR PRODUCT, DO NOT RETURN TO ORIGINAL PLACE OF PURCHASE.

After referring to the operation manual, if assistance is still needed, please consult our web

Site at www.kushlanproducts.com

From our web site you may e-mail us directly

If assistance is still required, please call our customer service department at 1-800-469-4178

Safety Alert Symbol: This safety alert symbol is used to

attract your attention!

Personal Safety is involved when you see this symbol, Pay extra

attention, become alert-be sure to follow it’s message. Failure to

do so may lead to serious personal injury or damage may occur.

Warnings and safety instruction: If these warnings and safety

instructions are not read and carefully followed, serious personal

injury could occur.

WARNINGS

1

1. Do not use, start, or attempt to operate this machine until all of the instructions have been read

and fully understood.

2. Never allow anyone to operate this machine unless the person is well acquainted with these rules

of safe operation.

3. Never operate this machine without all guards in place and firmly attached to the machine.

4. Make certain that the mixing drum is clear of obstructions and stand clear of the machine without

all guards in place and firmly attached to the machine.

5. When cleaning, lubricating, or adjusting the mixer, disconnect the power plug.

6. Keep all people (except operator) a minimum of 5 ft. away from the machine during operation.

7. Always make certain that the mixer is connected to a properly grounded electric circuit to protect

the operator from possible electric shock.

8. Do not plug or unplug the motor while standing in or around damp or wet ground.

9. Do not start the motor if the drum is fully loaded.

10. Do not overload the mixer.

11. Never attempt to move the mixer while the motor is on.

1. Keep hands and clothing away from moving parts at all times.

2. Do not operate this machine under the influence of alcohol or while taking medication that impairs

the senses or reactions.

3. Make certain that the work area around the machine is clear of debris and obstructions.

4. Keep all unauthorized and untrained people away from the machine at all times.

5. Never let the mixer run unattended even for a brief moment.

6. Turn off the motor when you leave the machine.

7. Only use or operate the mixer on level ground to prevent the mixer from tipping over.

8. Do not abuse the power cord; i.e. Never yank on the cord to disconnect it. Keep the cord away

from heat, oil, and sharp edges.

9. Do not over reach while working with the mixer. Keep proper footing and balance at all times when

loading or unloading the mixer.

10. Never allow children or inexperienced operators to operate or repair the mixer.

11. Use only factory authorized parts for replacement.

12. Keep these operation instructions with the machine at all times.

13. Always wear safety glasses and safety shoes when operating and moving equipment.

SAFETY INSTRUCTIONS

For the safety of yourself and others around you, it is extremely

important that you observe the following notes.

2

A. Lubrication: There are grease fittings (item 23) on all models. Apply any type of multipurpose

grease until grease begins to come out of the bushings in housing and bearings on wheels.

B. Extension Cord: Use only outdoor approved, 14 gauge or larger, grounded extension cords.

C. Gear Adjustment: If the gear on the jackshaft (item 9) is not meshing properly with the ring gear and

plate(14), adjustment can be made by loosening the whizlock screws and attaching the jackshaft

housing (10) and sliding the housing tube until proper alignment is obtained. If removal of pulley

guard is necessary, make certain it is reattached to the machine before using.

D. General: Check all screws for tightness before each use.

E. Motor Adjustment/Belt Tensioning: To adjust belt tension, loosen the four screws that attach the

motor to the frame. Make adjustments and retighten screws. V-belt tensioning should be retightened

after the first 20 hours of use. The belt should be tightened until the belt deflects approximately 1/4"

with regular thumb pressure. Replace covers and guards before using the machine.

F. Concrete Mixing: Do not insert sharp objects into the plastic mixing drum. Doing so will damage the

drum.

G. Cleaning: Do not spray water on or into the motor. Thorough cleaning of the mixer after each use is

recommended and will add to the service life.

Mixer Instructions

KUSHLAN PRODUCTS, LLC

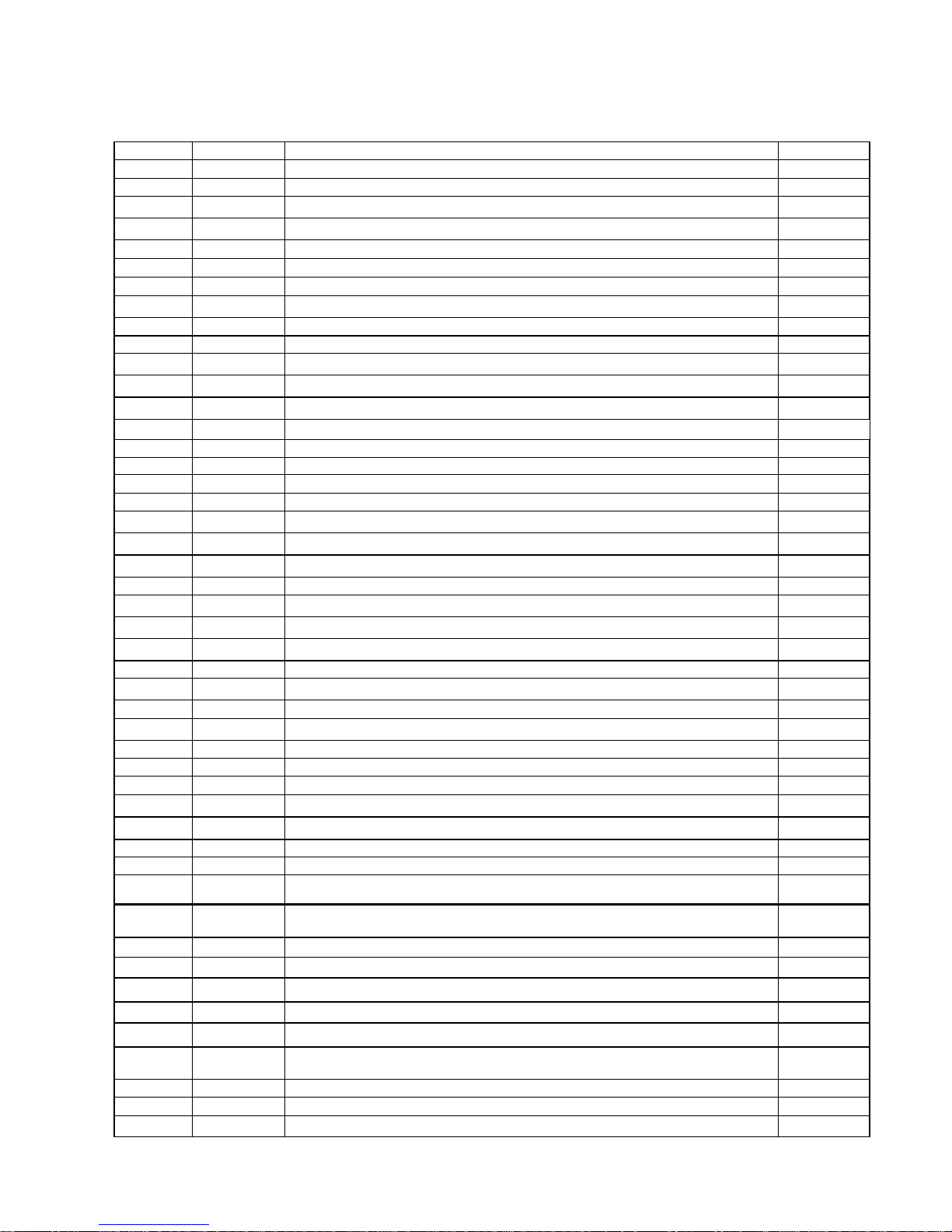

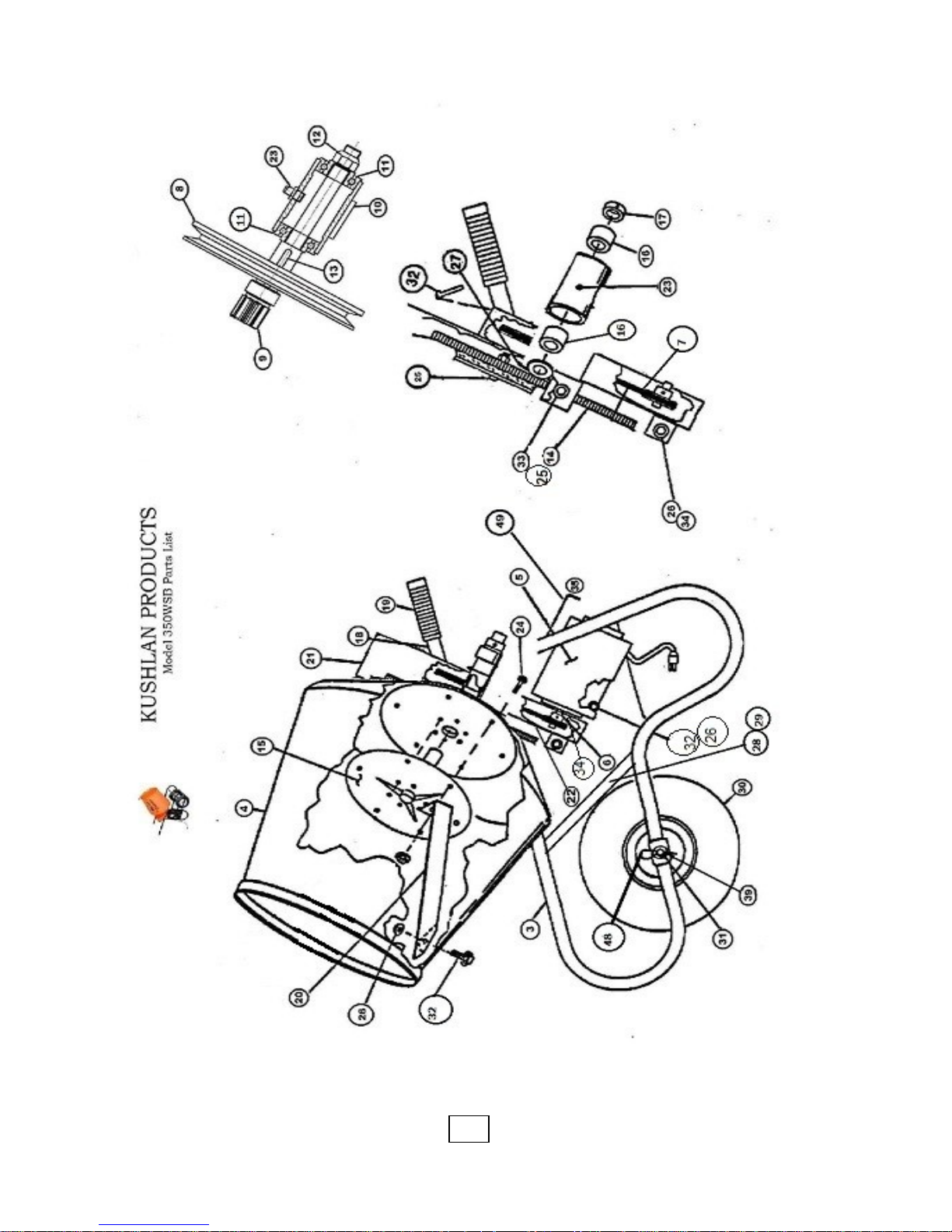

Model 350WSB & 350WSB With Stand Parts List

ITEM PART NO DESCRIPTION QTY

350WSB 350WSB Wheelbarrow Mixer X

3 35-1 Frame assembly 1

4 35-2 Polyethylene 3.5 cf drum with side holes 1

5 35-3 3/4 hp Electric motor with power cord 1

6 35-4 1 1/2" pulley 1

7 35-5 28" V-belt 1

8 35-6 6" pulley 1

9 35-7 Jackshaft with pinion 1

10 35-8 Jackshaft Bearing Housing 1

11 35-9 1/2” Ball Bearings 2

12 35-10 1/2" X 20 thread nut 1

13 35-11 3/16’’ Square key 1

14 35-12 Ring gear & plate assembly 1

15 35-13 Drum plate & shaft assembly 1

16 35-14 Drum shaft bushing 2

17 35-15 1" Locking collar 1

18 35-16 Wheelbarrow handle 2

19 35-17 Handle grip 2

20 35-18 350WSB mixing blades 2

21 35-19 Poly ring gear guard 1

22 35-20 Guard for Pulley 1

23 35-21 Grease fitting M8 2

24 35-22 3/8" x 1-1/4" whizlock screw 12

25 35-23 Hex flange lock nut 3/8" 3

26 35-24 Hex flange lock nut 5/16" 11

27 35-25 1" Metal thrust washer 1

28 35-26 Wheelbarrow axle 1

29 35-27 Axle spacer tube 1

30 35-28 300 x 8 Wheel 2

31 35-29 Locking pin 2

32 35-30 Whizlock screw 5/16”x 1” 11

33 35-31 Whizlock screw 3/8”x 3/4” 3

34 35-32 Motor cover 1

35 35-33 On/Off switch 1

37 35-35 Weather seal for Cord 1

39 35-37 Support Brace for Tri-Pod Stand 1

40 35-38 Vertical Pipe Support for Tri-Pod 1

41 35-39 Horizontal Rest Bracket for Tri-Pod 1

42 35-40 Leg Support 1 Pipe for Tri-Pod 1

43 35-41 Leg Support 2 Pipe for Tri-Pd 1

44 35-42 Whizlock Screw for Tri-Pod 2

45 35-43 Parts book 1

46 35-44 5/8 “ Washer 2

47 35-45 “R” Clip for washer 2

48 35-46 5/8” Wheel Bearing 4

49 35-50 Strain Relief 1

4

ITEM PART NO DESCRIPTION QTY

600W 600W Wheelbarrow Mixer X

3 60-1 Frame assembly 1

4 60-2 Polyethylene 6.0 cf drum 1

5 60-3 3/4 hp Electric motor with power cord 1

6 60-4 1 1/2" pulley 1

7 60-5 30" V-belt 1

8 60-6 6" pulley 1

9

60-7 Jackshaft with pinion 1

10

60-8 Jackshaft bearing housing 1

11

60-9 9/16” Ball Bearings 2

12

60-10 1/2" X 20 thread nut 1

13 60-11 3/4'' square key 1

14 60-12 Ring gear & plate assembly 1

15 60-13 Drum plate & shaft assembly 1

16

60-14

Drum shaft bushing 2

17 60-15 1" locking collar 1

18 60-16 Wheelbarrow handle 2

19 60-17 Handle grip 2

20 60-18 600W mixing blades 3

21

60-19

Poly ring gear guard 1

22 60-20 Guard for Pulley 1

23 60-21 Grease fitting M8 2

24 60-22 3/8" x 1-1/4" whizlock screw 12

25 60-23 Hex flange lock nut 3/8" 3

26 60-24 Hex flange lock nut 5/16" 12

27 60-25 1" Metal thrust washer 1

28 60-26 1'' Plastic thrust washer 1

29 60-27 Wheelbarrow axle 1

30 60-28 Axle spacer tube 1

31 60-29 400 x 8 Wheel 2

32 60-30 Locking pin 2

33 60-31 Whizlock screw 5/16 x 1” 12

34 60-32 Whizlock screw 3/8 x 3/4" 3

35 60-33 Motor cover 1

36 60-34 On/Off switch 1

38 60-36 Weather seal for cord 1

40 60-39 Support brace for Tri-Pod Stand 1

41 60-38 Horizontal rest bracket for Tri-Pod Stand 1

42 60-40 Vertical Pipe Support for Tri-Pod Stand 1

43 60-41 Whizlock screw for Tri-Pod Stand 2

44 60-42 Leg support 1 pipe for Tri-Pod Stand 1

45 60-43 Leg support 2 pipe for Tri-Pod Stand 1

46 60-44 Parts book 1

47 60-45 5/8'' Washer 2

48 60-46

" R '' Clip for washer

2

49 60-47 Wheel Bearing for 400x 8 Wheel 4

50 60-50 Strain Relief 1

KUSHLAN PRODUCTS, LLC

Model 600W & 600W With Stand Parts List

6

7

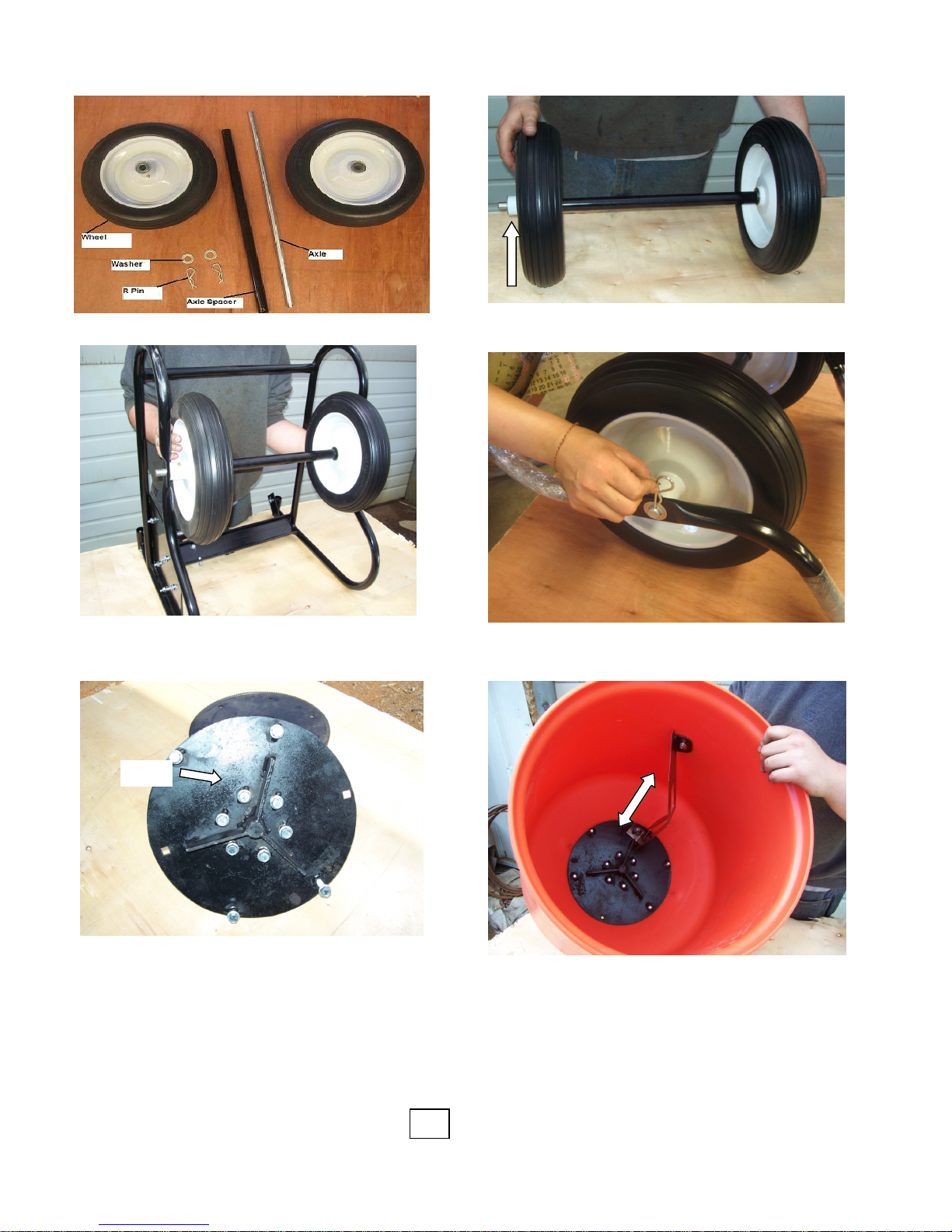

Step 2. With the long end of wheel hub facing out assemble

Step 1. Wheel Assembly

Step 3. Install Wheels as shown, pushing axle rod end

out and the other end into the frame.

Step 4. Put washers on the axle, then fix R clips into

holes.

Step 5. Take apart and remove all bolts from drum plate.

Step 6. Put the shaft through the hole in the

drum. Turn drum until the holes line up. Put in

3/8 x 1 1/2’’ whizlock screws. Then install blade.

Note: Do NOT tighten until all bolts are all in.

350 drum has 2 blades.

Bolts

8

Step 8. Install motor with (4) 5/16 x 1’’ whizlock screws

as shown. Do not over tighten belt about 1/4’’ deflec-

tion.

Step 9. Install black guard with 5/16”x 1” whizlock

screws.

Step 10. Install ring gear guard with 3/8 x 3/4”

whizlock screws

Step 11. Install black motor cover with (2) 5/16”x 1”

whizlock screws

Note: 600W drum has 3 blades as shown.

Step 7. Slide drum on frame. Then install pinion housing. Line up

front of pinion with front large gear

(Note: Do not put pinion too far forward, so gear will not dig into

drum. )

Placement of pinion gear

9

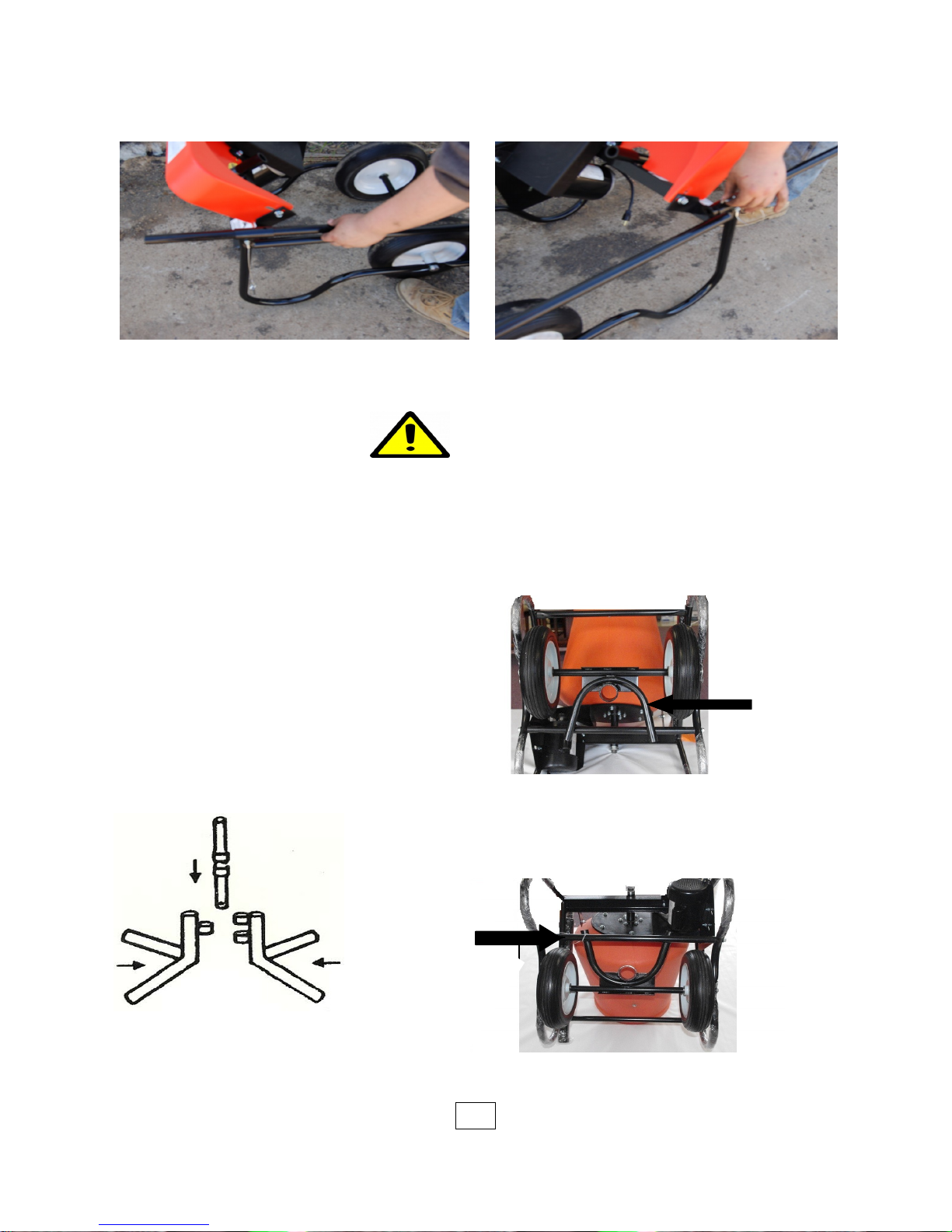

Step 12. Slide handle in place lining up the hole in the

handle and the housing. Slide the pin through the holes.

Step 13. Slide the pin through the holes. Soak Grips in

boiling water for 1 minute to soften the heavy duty

rubber.

Pivot Mount

Plate

Frame

Stop

Figure 2– Tip mixer up, Pivot Mount Plate freely rotates down

Figure 3– Rotate Pivot Mount Plate onto Frame Stop

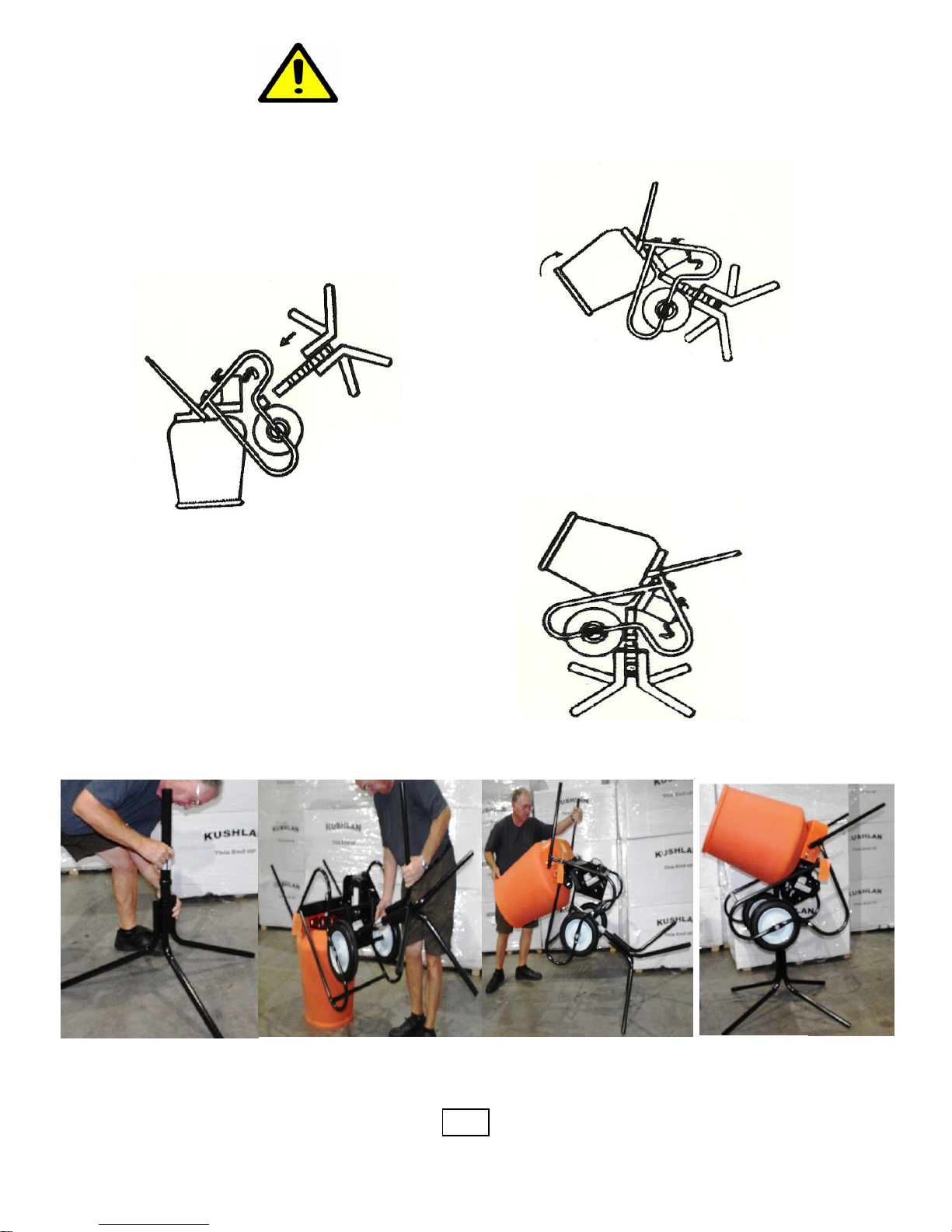

Tri-Pod Stand Assembly:

1. Place two halves of the support

legs together and insert pivot tube

through the center of the legs to

join together. (Figure 1)

2. Insert locking pin through bottom

of pivot tube.

Figure 1– Stand Assembly

Attaching Tri-Pod Stand to Mixer

Pivot Mount Plate Will Rotate Freely About Axle When Tipping Mixer Onto Opening

Of Drum. Stand Clear Of Wheel Axle Or Personal Injury Could Occur.

WARNING

1. Tip mixer, as if dumping contents, and place squarely on opening of drum. The pivot

mount plate will rotate freely about the wheel axle from its wheelbarrow stowed position.

(figure 2)

2. Rotate pivot mount plate away from drum and onto frame stop. (figure 3)

Optional Stand for 350/600 Mixer

10

3/8”x 1 1/2” Whizlock Screw

3/8”x 1 1/2” Whizlock Screw

11

WARNING

Do not tilt mixer upright onto stand on a wet, uneven or slippery surface. Failure to follow this instruction could result in personal injury or damage to equipment.

3. Insert pivot tube of tri-pod stand assembly through

pivot mount. (Figure 4)

Figure 4– Insert tri-pod stand assembly through

pivot mount plate

4. Once the stand has been attached, move to the

opening side of the drum and begin tilting the

mixer upright onto the stand. Always bend your

knees and use correct posture for lifting. Always

tilt from the front of the mixer. (Figure 5)

Figure 6– Unit ready for mixing.

5. Once mixer has been tilted upright

onto the stand, the mixer should be

tipped back into mixing position before

operating. (Figure 6)

Figure 5– Tilt mixer upright onto stand.

Insert pipe into

legs of the stand

Insert stand

Lift up mixer to stand up

Kushland Products, LLC Limited Warranty Policy

Kushlan Products makes every effort to assure that its products meet high quality and durability standards and

w a r ra n ts t o t h e o r ig i na l r e t ai l c o n s u me r p u rc h a se r o f ou r pr o d u c t s ( yo u ) t ha t e a ch su c h

product be free from defects in materials and workmanship as follows:

ONE( 1)Y EAR li mited wa rranty on motors. This warranty covers repla cement of part s foun d to be

defective in material or workmanship for a period of 90 days from the date of purchase. This warranty

does not apply to typical replacement of parts or assemblies that fail as a consequence of normal wear

and tear. For example: bushings, tires, belts, and pinion gears.

Th i s war ranty d oes no t apply to de f ects d ue dire ctly o r indi r ectl y to mi s u se, a b u se, n eglig e nce,

accident s, rep airs or al ter ati ons out side our faci lities or the la ck of mainten anc e. W E LIMI T ALL

IM P LIE D WARRANTIE S TO TH E PERIO D SPECI FIED ABOVE FR OM THE DAT E OUR PROD U CT

WA S PU RCHASED AT RETAI L EXCEPT AS STATED HERE IN. ANY IMPLIED WARR ANTI E S OF

M E RC HAN T A BI LI TY A ND FI T NE S S A R E E X CL U D E D. SO M E S T AT E S D O NO T AL LO W

LIMITATIONS ON HOW LONG THE IMPLED WARRANTY LASTS, SO THE ABOVE LI MIT ATION

MAY NOT APPL Y TO YOU. WE SH ALL , IN NO EVENT , BE LIAB LE FOR DEATH, INJURI ES TO

PERSONS OR PROPERTY OR FOR INCIDENTAL, CONTINGENT, SPECIAL OR CONSEQUENTIAL DAMAGES

ARISING FROM THE USE OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION

MAY NOT APPLY TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage prepaid,

to Kushlan Products. Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our inspection discloses a defect, we will either repair or replace the product, at our election, or

we may elect to refund the purchase price if we cannot readily and quickly provide you with repair or replacement, if you are willing to accept such refund. We will return the repaired product or replacement at

our expense, but if we determine there is no defect, or that the defect resulted from causes not within the

scope of our warranty, then you must bear the cost of storing and returning this product. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state. For service

contact Kushlan Products.

12010 Dairy Ashford Road, Suite 160, Sugar Land, TX 77478

Phone: 1-800-469-4178

12

Model 350WSB & 350WSB With Stand Parts List

ITEM PART NO DESCRIPTION QTY

350WSB 350WSB WHEELBARROR MIXER X

3 35-1 FRAME ASSEMBLY 1

4 35-2 POLYETHYLENE 3.5 DRUM WITH SIDE HOLES 1

5 35.3 3/4 HP MOTOR WITH POWER CORD 1

6 35-4 1 1/2” PULLEY 1

7 35-5 28” V-BELT 1

8 35-6 6” PULLEY 1

9 35-7 JACKSHAFT WITH PINION 1

10 35-8 JACKSHAFT BEARING HOUSING 1

11 35-9 1/2” BALL BEARINGS NUT 2

12 35-10 1/2” X 20 THREAD NUT 1

13 35-11 3/16” SQUARE KEY 1

14 35-12 RING GEAR & PLATE ASSEMBLY 1

15 35-13 DRUM PLATE & SHAFT ASSEMBLY 2

16 35-14 DRUM SHAFT BUSHING 1

17 35-15 1” LOCKING COLLAR 1

18 35-16 WHEELBARROW HANDLE 2

19 35-17 HANDLE GRIP 2

20 35-18 350WSB MIXING BLADES 2

21 35-19 POLY RING GEAR GUARD 1

22 35-20 GUARD FOR PULLEY 1

23 35-21 GREASE FITTING MB 2

24 35-22 3/8” X 1-14” WHIZLOCK SCREW 12

25 35-23 HEX FLANGE LOCK NUT 3/8” 3

26 35-24 HEX FLANGE LOCK NUT 5/16” 11

27 35-25 1” METAAL THRUST WASHER 1

28 35-26 WHEELBARROW AXLE 1

29 35-27 AXLE SPACER TUBE 1

30 35-28 300 X 8 WHEEL 2

31 35-29 LOCKING PIN 2

32 35-30 WHIZLOCK SCREW 5/16” X 1 11

33 35-31 WHIZLOCK SCREW 3/8”X 3/4” 3

34 35-32 MOTOR COVER 1

35 35-33 ON/OFF SWITHCH 1

36 35-35 WHEATHER SEAL FOR CORD 1

37 35-36 SUPPORT BRACE FOR TRI-POD STAND 1

38 35-38 VERTICAL PIPE SUPPORT FOR TRI-POD 1

39 35-39 HORIZONTAL REST BRACKET FOR TRI-POD 1

40 35-40 LEG SUPPORT 1 PIPE FOR TRI-POD 1

41 35-41 LEG SUPPOT 2 PIPE FOR TRI-POD 1

42 35-42 WHIZLOCK SCREW FOR TRI-POD 2

43 35-43 PARTS BOOK 1

44 35-44 5/8” WASHER 2

45 35-45 “R’ CLIP FOR WASHER 2

46 35-46 5/8” WHEEL BEARING 4

47 35-47 STRAIN RELIEF 1

Loading...

Loading...