Kurtz Ersa HR 100 A Operating Instructions Manual

Ersa Rework System

HR 100 A

Operating Instructions

3BA00174 • 2014-02-06 • Rev. 5

HR 100 1 / 2

Contents

1. Introduction 4

2. Technical data 5

3. Concerning your safety 8

3.1 Explanations on pictograms and symbols 8

3.2 Intended use 9

3.3 Target group of readers 9

3.4 Safety notes 10

4. Transport, storage and waste disposal 13

5. Start-up 14

5.1 Scope of delivery 14

5.1.1 Hybrid Rework System HR100A (0IRHR100A) 14

5.1.2 Hybrid Rework System HR100A with heating plate (0IRHR100A-HP) 14

5.2 Control elements, displays and connections 15

5.2.1 Front view of base station 15

5.2.2 Rear view of base station 16

5.2.3 The Hybrid Tool 17

5.3 Placing and connecting the device 17

5.4 Switching on 18

5.5 Firmware 18

6. Description of function 19

6.1 Notes on operation 19

6.1.1 Base station 19

6.1.2 Hybrid tool 20

6.1.3 The three programs AD1, AD2, AD3 21

6.1.3.1 Heating time Hybrid Tool and heating plate 22

6.1.3.2 Heating plate energy level 23

3BA00174 • 2014-02-06 • Rev. 5

HR 100 1 / 3

Contents

6.1.4 The expert program AD0 24

6.1.4.1 Heating time Hybrid Tool and heating plate 24

6.1.4.2 Heating plate energy level 25

6.1.4.3 Energy level Hybrid Tool 27

6.1.4.4 Blower speed Hybrid Tool 27

6.1.4.5 Selecting the temperature sensor 28

6.1.4.6 Heating power rise speed 29

6.1.4.7 Temperature monitoring Hybrid Tool 32

6.2 Changing a Hybrid adaptor 33

6.3 Working with the Hybrid Tool 35

6.3.1 Soldering and desoldering 35

6.3.2 Using the vacuum pipette 37

6.4 Working with tool holder 38

6.4.1 Soldering and desoldering 38

6.5 Connecting a PC 39

6.6 Sensitive components 40

6.7 Brief instructions 41

7. Treatment of faults 42

7.1 General faults 42

7.2 Other faults 42

7.3 Table of error codes 43

7.4 Factory settings [Default] 44

8. Maintenance, repair 45

8.1 Important service tasks 45

9. Spare parts and Accessories 46

10. Warranty 47

3BA00174 • 2014-02-06 • Rev. 5

HR 100 1 / 4

1. Introduction

We would like to thank you for purchasing this high quality Rework System. With the HR 100A

Ersa offers a microprocessor controlled cutting edge handheld rework system for standard and

lead-free rework applications. It is intended for use in industrial manufacturing, repairs and

laboratory applications.

The combination of radiant and convection heat with contactless transfer to the components,

is characteristic for the hybrid technology. Due to its optimal heat transfer this technology is

most suitable for all SMT-Rework processes.

Three modes of operation enable optimal adaptation to the required purpose of use:

• Time base

• Time base with temperature measurement

• Programmable temperature control (control either through base station or with IRSoft via

PC.

An integrated laser pointer facilitates exact positioning of the heat source. With the

straightforward menu guidance settings can be comfortably edited and saved.

A rotary encoder with momentary contact function serves the purpose of programming and

operation.

The extensive range of accessories enables you to set up a flexible and modern Rework-System

for highest quality demands.

3BA00174 • 2014-02-06 • Rev. 5

HR 100 1 / 5

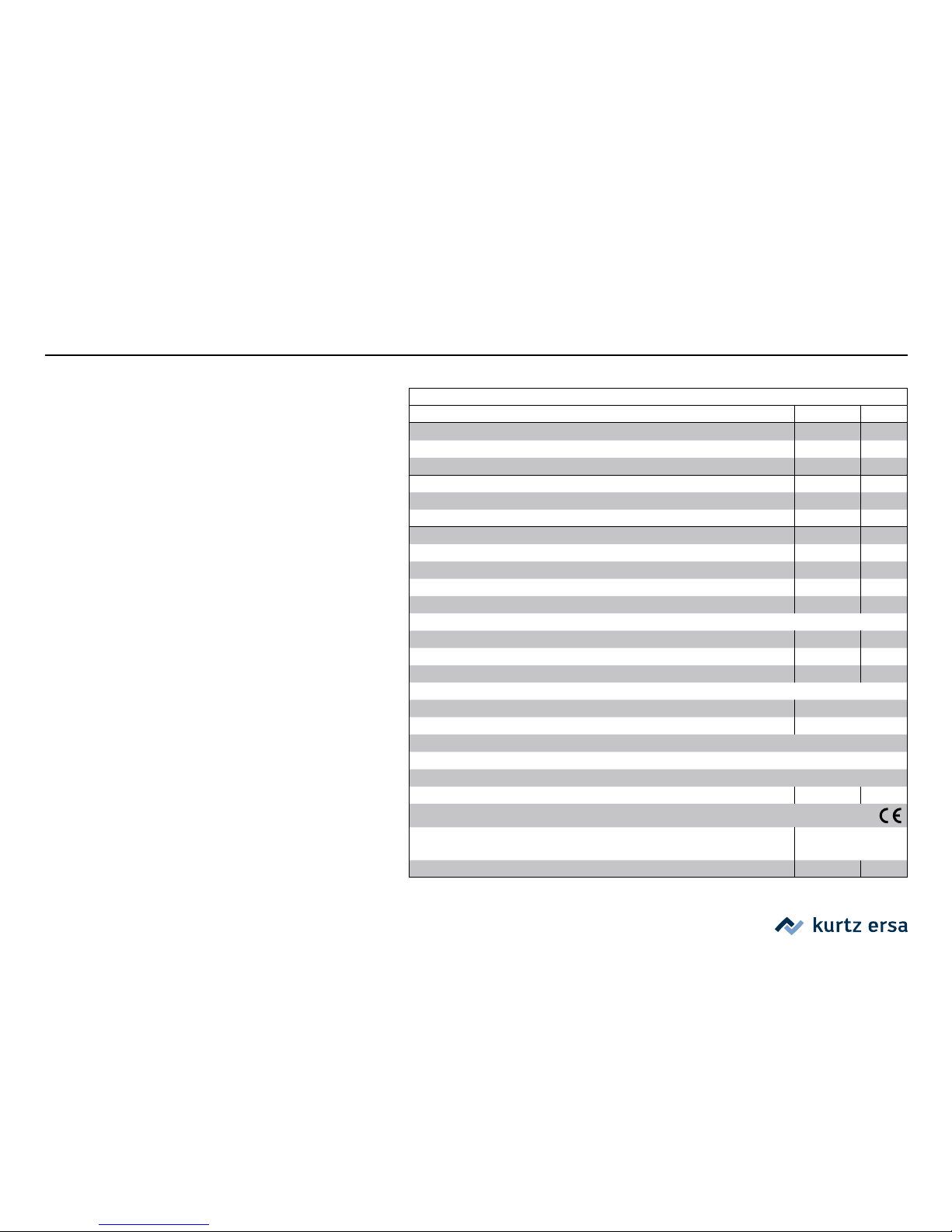

2. Technical data

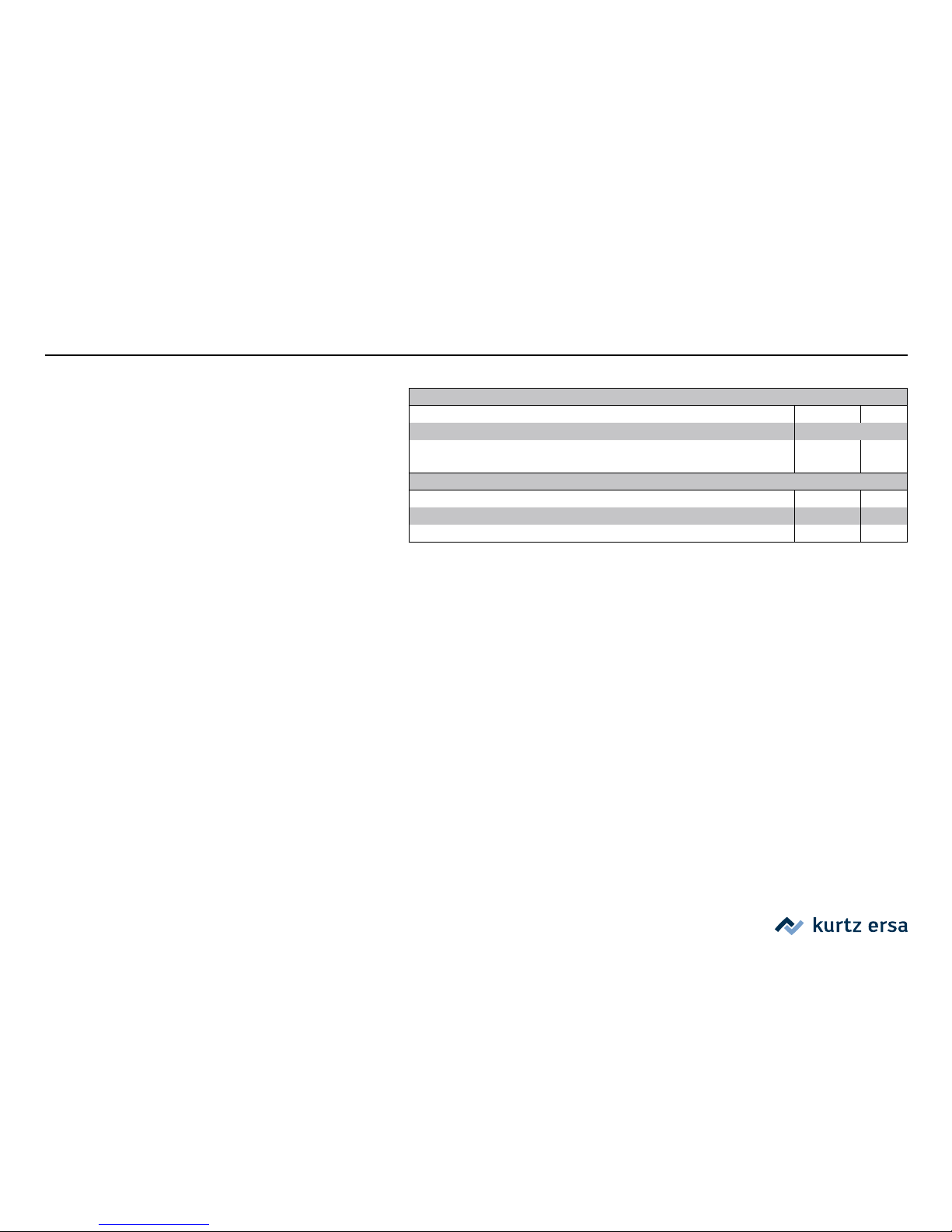

Hybrid Rework-System HR 100A, base station

Designation Value Unit

Mains voltage 220-240 VAC

Mains frequency 50-60 Hz

Fuse (slow blow) 2 A

Mains voltage 110-120 VAC

Mains frequency 50-60 Hz

Fuse (slow blow) 4 A

Secondary voltage 13 VAC

Maximum heating power 200 W

Safety class I Permissible ambient temperature 0-40 °C

Temperature range at outlet 30-550 °C

Air volume

With hybrid adaptor AD1 15...35 l/min

With hybrid adaptor AD2 6...11 l/min

With hybrid adaptor AD3 3...9 l/min

Miscellaneous

Function display LED display

PC interface Mini USB

Supply cable 2m, PVC, with appliance connector

Operation via rotary encoder with momentary contact function

Antistatic surface, suitable for use in ESD-environment, EMC-tested*.

Vacuum -0,2...-0,4 bar

Conformity

Dimensions WxHxD

211 x 220 x 188

mm

Weight 4,5 kg

3BA00174 • 2014-02-06 • Rev. 5

HR 100 1 / 6

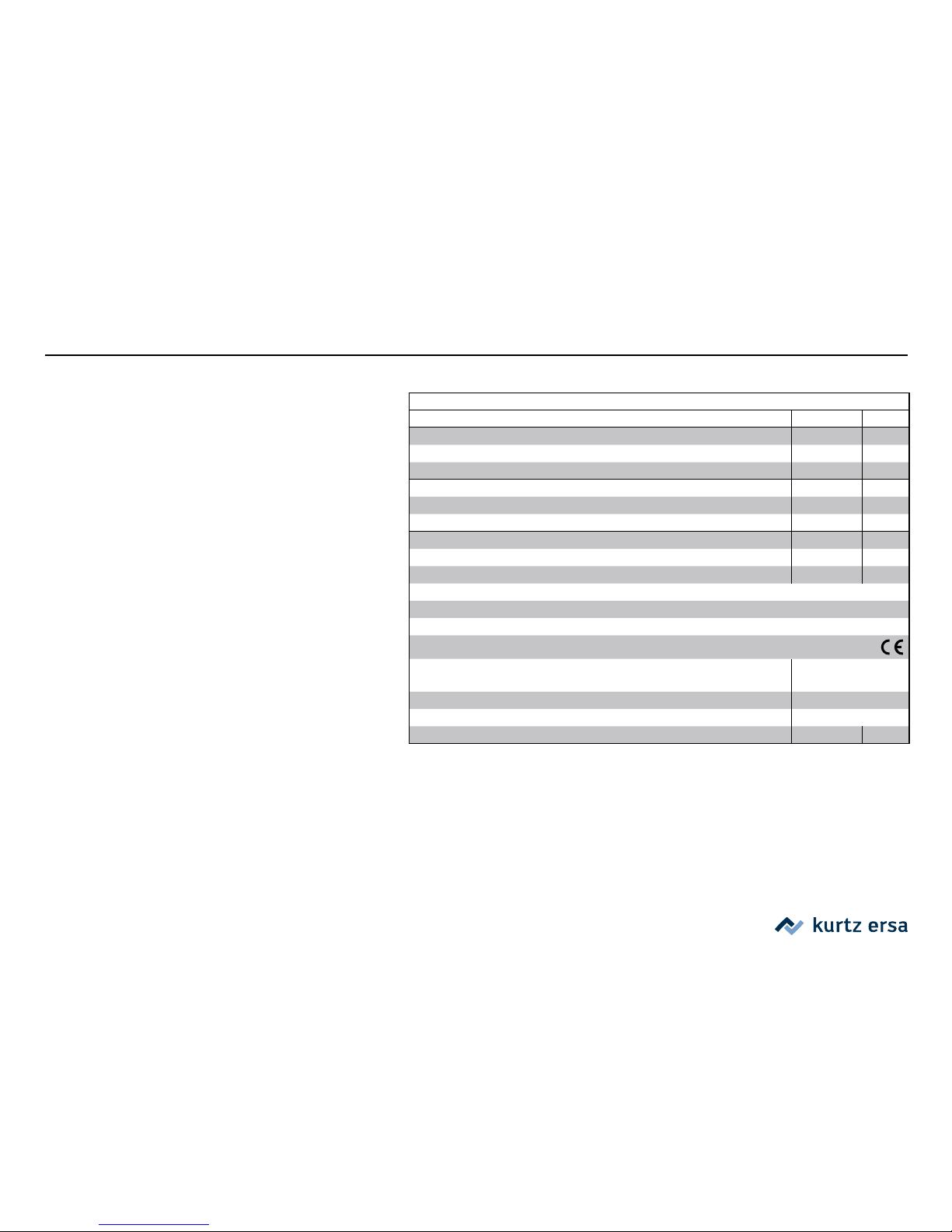

2. Technical data

Hybrid Tool

Length of supply cable 1,35 m

Dimensions WxHxD 230x25x25 mm

Weight

approx.

300

g

Laser

Class II Wavelength 660-680 nm

Output max. 1 mW

3BA00174 • 2014-02-06 • Rev. 5

HR 100 1 / 7

2. Technical data

Heating plate IRHP100A

Designation Value Unit

Mains voltage 220-240 VAC

Mains frequency 50-60 Hz

Fuse (slow blow) 4 A

Mains voltage 110-120 VAC

Mains frequency 50-60 Hz

Fuse (slow blow) 8 A

Control voltage 5 Vss

Maximum heating power 800 W

Safety class I -

Miscellaneous

Supply cable 2m, PVC, with appliance connector, control cable with RCA (Cinch) connector.

Antistatic surface, suitable for use in ESD-environment, EMC-tested.

Conformity

Dimensions WxHxD

200 x 260 x 53,5

mm

Height of tool suspension 214,5 mm

Dimension of holder for printed circuit board W x D 330 x 250 mm

Weight 2,5 kg

* Strong signals in the frequency range of 80...230 MHz can cause interferences in the base station display!

3BA00174 • 2014-02-06 • Rev. 5

HR 100 1 / 8

3. Concerning your safety

Ersa products are developed, manufactured and tested in compliance with general

requirements concerning health and safety.

However, residual risk do remain!

You should therefore read this instruction manual before you start to operate the device for

the first time. It will help you to learn the functions of the device and to use it in the most

optimal way. Keep this instruction manual at a place that can be accessed by all users at any

time!

3.1 Explanations on pictograms and symbols

In this instruction manual pictograms are used to highlight dangers.

Special information or mandatory instructions and prohibitions with the aim

of preventing personal injury or extensive damage to property are identified

by a pictogram, followed by hierarchically structured text with words written

in bold:

Warning! Is used for warnings of immediate danger. Consequences may be

death or personal injuries.

Attention! Is used for warnings of possibly dangerous situations.

Consequences may be personal injury, damage to property or environment.

Caution! Used for application related recommendations. Negligence may

result in material damage.

3BA00174 • 2014-02-06 • Rev. 5

HR 100 1 / 9

3. Concerning your safety

In addition to the hierarchically structured warning notes described above, we

use the following symbols:

Used to highlight any texts containing explanations, information or hints.

■

This symbol identifies

- action that is strictly required, or

- instructions that must be strictly complied with.

3.2 Intended use

Thermal tools from Ersa must only be used for the processing of soft solder. However, if

explicitly described in the operating instructions of the respective thermal tool, some thermal

tools may, in exceptional cases, be used for the processing of plastic materials.

In case of unintended use and tampering with the device, any warranty and liability claims of

the buyer against the manufacturer will become null and void.

3.3 Target group of readers

This instruction manual addresses persons with knowledge in the field of reflow soldering.

3BA00174 • 2014-02-06 • Rev. 5

HR 100 1 / 10

3. Concerning your safety

3.4 Safety notes

Attention! Check all components before each use. Have damaged parts

only repaired by a specialist or the manufacturer. Unprofessional repairs

cause a risk of accident. Always use original Ersa spare parts for possible

repairs.

Attention! Thermal tools get very hot. Before heating up the device check

whether the tool insert (e.g. soldering tip, modelling insert, etc.) is correctly

connected with the thermal tool. The hot tool insert should never come in

contact with skin, hair or any heat-sensitive and combustible materials. Make

sure you use a sufficiently heat proof work base.

Attention! Keep unauthorized persons at a safe distance. Make sure that

unauthorized persons, especially children, have no access to the thermal

tools.

Attention! Fire hazard. Before heating up the thermal tool remove any

combustible objects, fluids and gases from the working range of the thermal

tool. Always place the thermal tool into the storage stand provided for this

purpose. Disconnect the thermal tool from the mains supply after use. Do

not leave your hot thermal tool unattended. Please remember that it will take

quite same time for the tool insert to cool down to a harmless temperature,

after the device has been switched off.

3BA00174 • 2014-02-06 • Rev. 5

HR 100 1 / 11

3. Concerning your safety

Attention! Lead containing solders are toxic. Lead containing solders

entering into the organism will have a toxic effect. Eating, drinking and

smoking is therefore strictly prohibited. For the reasons mentioned above

you should always wash your hands thoroughly after having worked with lead

containing solder.

Attention! Ventilation and extraction. Working and auxiliary materials may

put your health at risk. Ensure sufficient ventilation or extraction. Follow the

relevant safety data sheets.

Warning! Protect the supply cables. Do not use the power supply cable to

pull out the plug or to carry the device. Keep power supply cables clear of

heat, oil or sharp edges. Damaged power supply cables may cause fire, short

circuit or electric shock and must therefore be replaced.

Attention! Consider environmental influences. Protect your device against

any type of fluid and moisture. Otherwise there is a danger of fire or electric

shock.

Caution! Take care of your thermal tool. Always keep your Ersa product in

a safe and dry place, out of the reach of children. Follow the maintenance

instructions. Check your device in regular intervals. Use only original

accessories and spare parts from Ersa.

3BA00174 • 2014-02-06 • Rev. 5

HR 100 1 / 12

3. Concerning your safety

Attention! Laser beam! The device contains a class II laser radiation source.

Do not look into the direct laser beam and do not direct the laser beam

towards the eyes of other people!

Attention! Physically and/or mentally handicapped persons must only use

the device under the supervision of trained expert personnel! Children are not

allowed to play with the device!

National and international health and safety regulations as well as occupational health and

accident prevention regulations must be complied with.

3BA00174 • 2014-02-06 • Rev. 5

HR 100 1 / 13

4. Transport, storage and waste disposal

The device is delivered in a sturdy cardboard box. Please use only the original packaging for

transportation and intermediate storage. Strictly avoid jerky movements, impacts or putting

down. The device must be adequately protected against weather influences like rain, fog or

sea air, etc. For longer storage in high humidity environments the device must be packed up

air tight, together with a dehumidifying agent. Damage caused by unprofessional transport or

storage are not covered under warranty.

Notes on waste disposal acc. to the directive 2002/96/EG of the European

Parliament and the Committee from 27th of January 2003 for for used

electric and electronic appliances:

Products marked with a crossed out waste bin must not be disposed of

together with unsorted domestic waste. The municipalities established

special collecting points for this type of waste. Please consult your council

and ask for available possibilities for the separated collection of old

appliances. You thereby contribute to the reuse or other forms of use of old

appliances, with the aim of protecting the environment and human health.

3BA00174 • 2014-02-06 • Rev. 5

HR 100 1 / 14

5. Start-up

Before start-up: Please check the contents in the package for completeness. Should any of

the listed components be damaged or incomplete, you should immediately consult the supplier.

5.1 Scope of delivery

5.1.1 Hybrid Rework System HR100A (0IRHR100A)

• HR 100A digital control unit with power supply cable, vacuum pipette with suction elements, these operating instructions

• Hybrid Tool with connecting cable, Hybrid adaptor AD1, AD2, AD3 and adaptor changer.

• Optional accessory: Option: Stand 0IRHR-ST050, please read paragraph [Spare Parts and

Accessories].

5.1.2 Hybrid Rework System HR100A with heating plate

(0IRHR100A-HP)

• HR 100A digital control unit with power supply cable, vacuum pipette with suction elements, these operating instructions.

• Hybrid Tool with connecting cable, Hybrid adaptor AD1, AD2, AD3 and Adaptor changer.

• 800 W IR-heating plate complete with tool suspension for Hybrid Tool and holder for printed circuit boards, Flexpoint TE-holder and AccuTC thermocouple.

• Software package IRSoft on CDRom, USB cable.

For further accessories please refer to chapter 9.

3BA00174 • 2014-02-06 • Rev. 5

HR 100 1 / 15

HYBRID TECHNOLOGY

VAC

RAMP

2x PUSH

5. Start-up

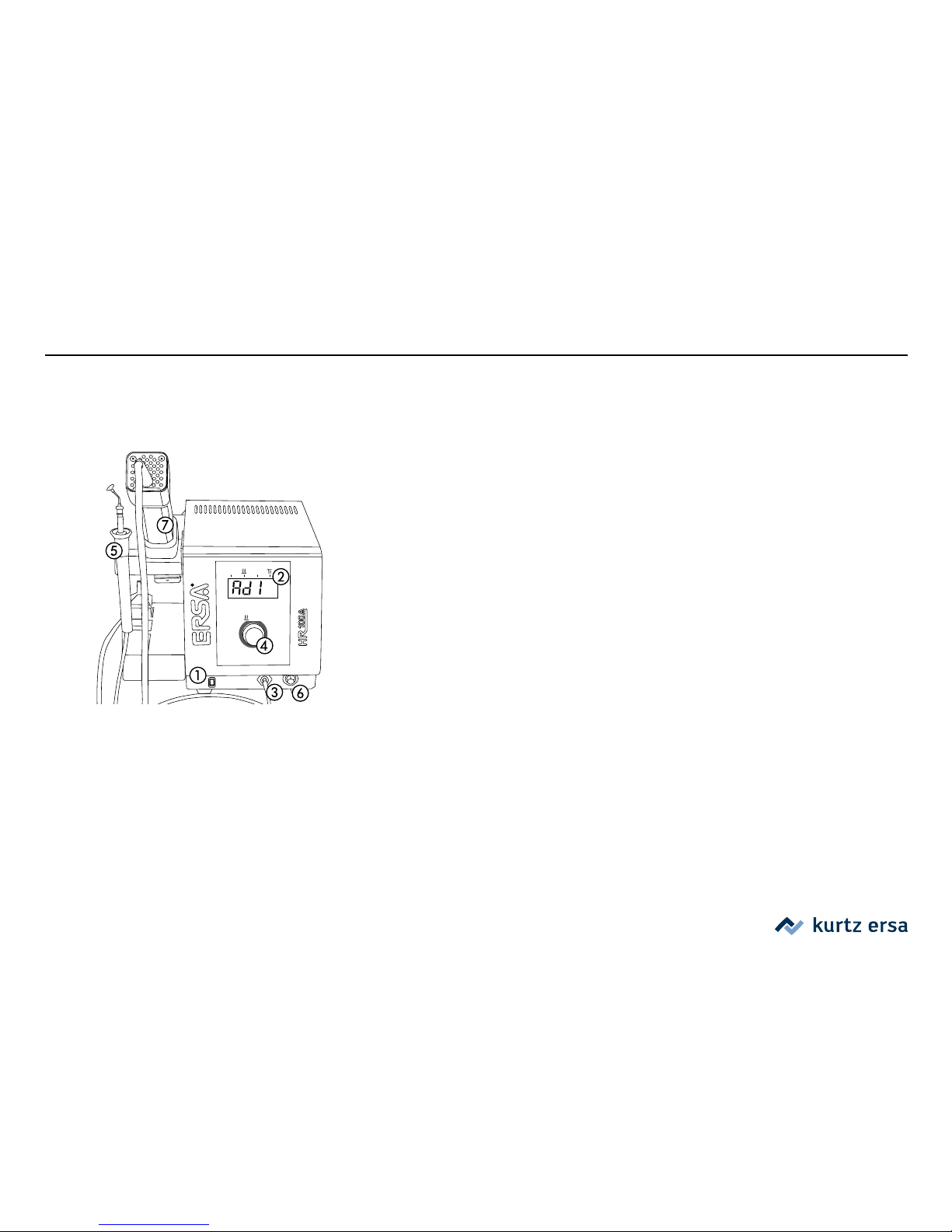

5.2 Control elements, displays and connections

5.2.1 Front view of base station

The base station contains the following control and display elements:

a Mains switch

b Display

c Connection for vacuum pipette

d Rotary encoder with momentary contact function

e Vacuum pipette

f Switch for vacuum pump

g Hybrid Tool

Loading...

Loading...