Page 1

Installation & Operation Guide

P/N DL640-95, REV C

Model:

DL640

DL430

CT640

CT430

Page 2

KURT INDUSTRIAL PRODUCTS

VERVIEW OF

O

"640, 430" VISES

The new DoubleLock vises from Kurt include improvements that simplify

its operations. Please read this entire instruction manual to fully understand the

new features of the DoubleLock vise. You will find modifications have been

made that are different from the past DoubleLocks.

Kurt's new DoubleLock has a design that fits current user needs and meets

their expectations of a simple, functional vise. The new DL640, DL430,

CT640, and CT430 maintains the 3", and 4" opening, same bed height with the

DL430 and DL640, and same accuracy and has superior features over past

Kurt DoubleLock style vises. Listed are the re-designed features of the new

DoubleLock vise. Please refer to the page listed on index for setup instructions.

1. Clutch design- The new clutch has a recoil spring attached to the

clutch. It's designed to return the clutch back into the correct position

automatically. It resets into the correct position every time the vise jaws

are opened. No more timing problems ever!

2. New Holding Block- The function of the holding block is to give the

end user the adjustment features to clamp dissimilar size parts and

provides front or back part spring loaded pre-clamping. The new

holding block is completely self-adjusting that includes a double preload. This means the user may clamp one part first, front or back station

before loading the second part. No need to adjust for dissimilar parts.

Also included is a pre-load range adjustment nut that will give the user

the option to choose how much pre-load range they need. (.010 min to

.150" max) When setting to minimum range, this will reduce the amount

of handle turns needed when opening or closing the Vise.

NOTE

: This vise has been assembled to factory settings and no further

PLEASE

adjustments are required. The holding block pre-load and pre-load

adjustment nut are new features of this products design and allows

adjustment for a specific setup. Please see "Holding Block Pre-Load"

and "Pre-Load range adjustment nut" setup sections in this guide.

New Overall length

3.

and 18.5" (17.5" with internal hex) on the DL430.

- DL640 is 22.5"(21.5" with optional internal hex),

1

Page 3

4. New Chip Guard system- The center clamping area is fully covered

100% of the time. Note: The stationary chip guard may need to be

removed when the vise is used with the optional conversion kit. See

conversion kit assemble section.

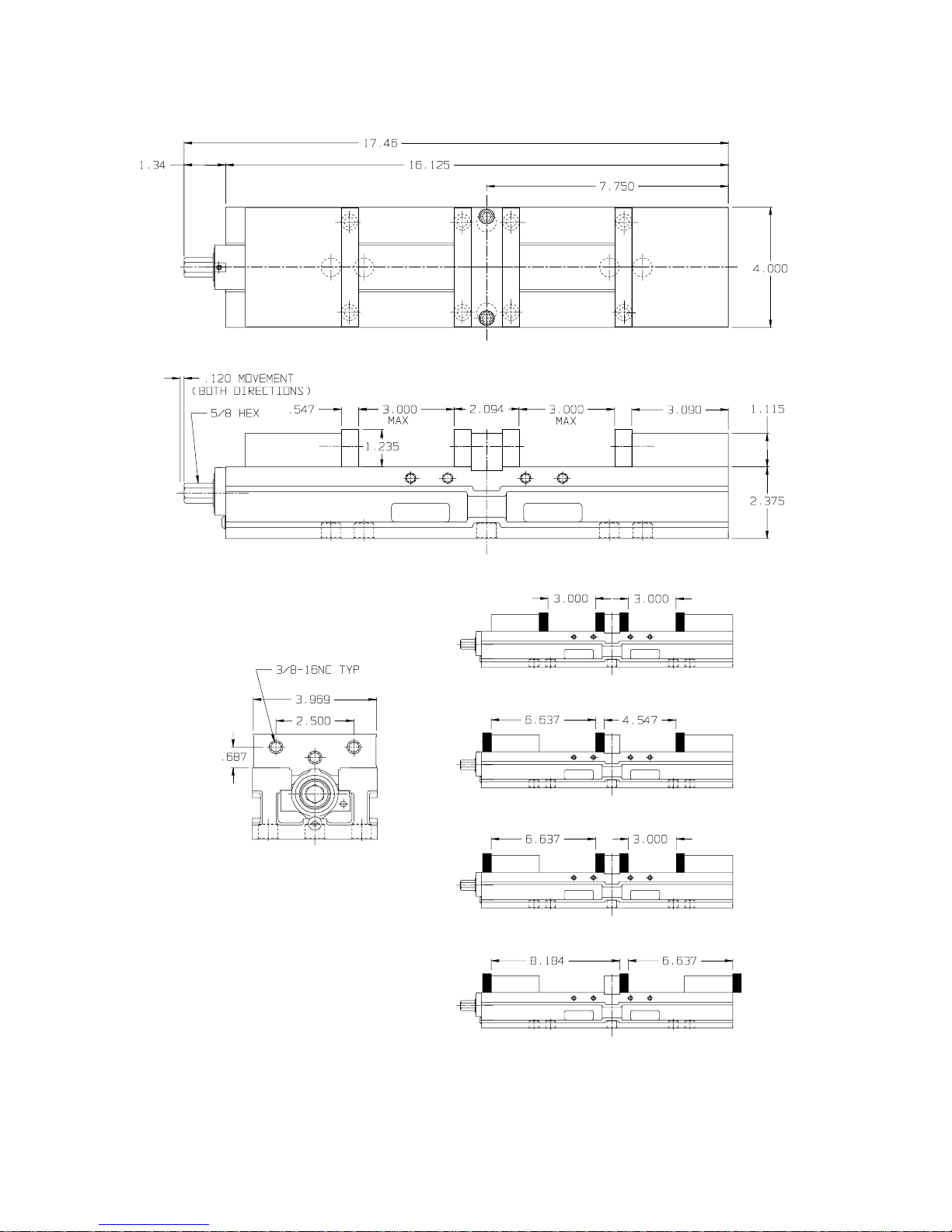

5. New Locating hole patterns- The clamp down mounting holes that

will fit a standard 2" grid pattern found in sub-plates available through

several industrial suppliers. The base includes four precision 5/8" holes

in the bottom for accurate re-location. Also available are two 16mm

holes that will fit a 100mm and/or 200mm grid patterns found in metric

sub-plates. (See locating and mounting hole sketch for reference). The

use of Sine Keys would also provide mounting the Vise to machine

tables with key slots if needed.

New Stationary Jaw

6.

- The DoubleLock vise has a precision locator for

accurate repeatability. This gives the Stationary Jaws exact relocation

when used with interchangeable Stationary Jaw setups or re-setup from a

convertible model.

7. Convertible models- When the DL640 or DL430 is needed for a single

large part clamping, the maximum opening is 10.69" to a minimum of

2.69", and 8.20" to 2.1" on the DL430. This is a continuous travel

opening.

Kurt offers quick change one-sided Aluminum carvable Moveable Jaws for

conversion into a carvable vise. Optional internal hex is also available. (Contact

factory for information and costs).

These important features and functions make Kurt's new DoubleLock an

accurate, durable, affordable "user friendly" vise. Combined with the industries

only ten (10) year warranty. The Kurt DoubleLock vises fills all your CNC

WorkHolding needs.

2

Page 4

DOUBLE LOCK

INSTALLATION AND MOUNTING INSTRUCTIONS

INSTALLATION

The Kurt DoubleLock Vise offers two clamping stations. This vise is ideal

for clamping parts of the same size or dissimilar size, and can perform first

and secondary operations simultaneously. It is packaged to prevent any

damage to its components. Please inspect the vise carefully for any shipping

damage and, if necessary report it to your carrier.

After inspection, follow these steps to install your DoubleLock Vise:

1. Position the vise on your machine table, pallet or sub-plate using the

Precision bored holes located on the bottom of the vise for alignment.

See figure 2 on page 4 for locating hole patterns.

2. A couple of options to mount the vise in place. One option is to use

external clamps on the clamp groove on each side of the vise. NOTE: To

reduce any possible deflection while clamping parts, mount external

clamps on each side towards the center of the vise in the clamp grooves.

A preferred option would be to use the eight cap screw holes through

the vise bed. To gain access to the holes, open both stations to the full

opening. Remove the Jaw Plates mounted to the center Stationary Jaw

and two Moveable Jaws sets. See figure 1, page 4 for mounting hole

pattern. Note: The four mounting holes toward the center Stationary is

required when using this mounting option. The four mounting holes

under Moveable Jaws are an addition to mounting with this setup.

If desired both mounting options may be used.

3

Page 5

4

Page 6

Holding Block Pre-load setup

*PRE-LOAD PARTS.

(* Is defined as ability to clamp one part first with limited pressure before

second part is installed.)

Caution: Pre-Load places only enough spring pressure to hold one part

and are not intended to clamp part for machining. Both stations must be

clamped to achieve clamping pressures.

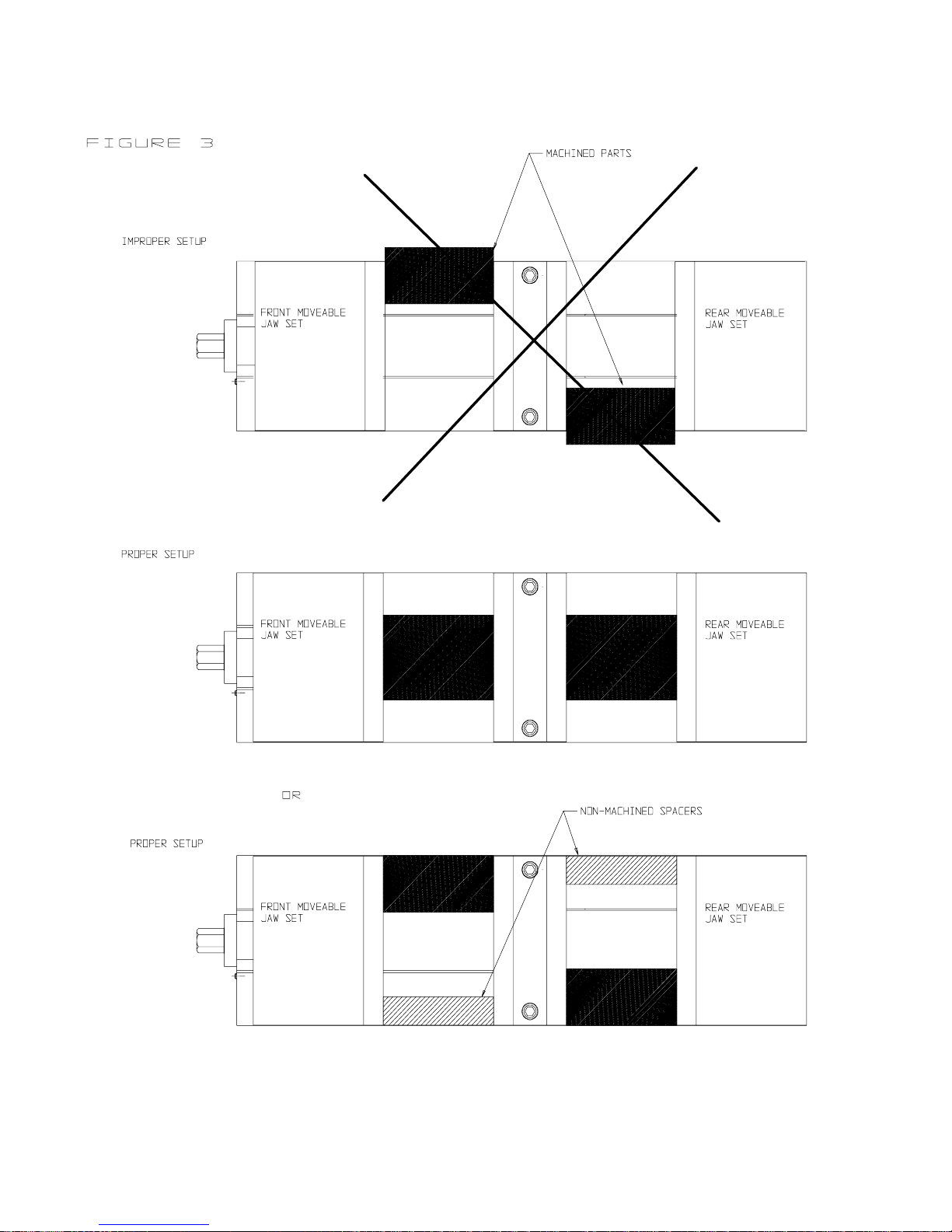

NOTE 1: In all jaw settings, unless both parts are the same size, the Widest

part must always be mounted in the Rear Jaw Set. See figure 3 page 6.

NOTE 2: Same size part, Pre-load must be setup to clamp front part.

Horizontal vise position

(reference sketches on page #6)

1. Open both Moveable Jaws sets to accept part being clamped.

2. Place one part into each station and close.

3. Open only enough to release pressure from each parts.

4. Remove the part that is planned to be pre-loaded. (Vertical vise position

see caution below)

5. Leaving the opposite part in the vise, begin to close allowing the Holding

block to slide 3/16" minimum. See figure 4 page 6.

6. Begin to open and both Movables will open.

7. Remove all parts in the vise.

8. Your Pre-load is now set.

9. Place part to be Pre-loaded in and begin to close until part is clamped.

Install opposite part and clamp.

Vertical vise position

Caution: In this position, the horizontal vise position setup is used but we

recommend to always setup with the pre-load in the top station. The

Stationary Jaw is a fixed stop where the bottom Moveable Jaw will have

movement and part could appear to be pre-loaded and part could move

causing personal injury. Please use caution at step #4.

5

Page 7

elease rear part

st.

ont part

st.

Front Jaw Rear Jaw

This setup will always clamp

front part first . Once set it will

fir

r

Front Jaw

Front Jaw

Rear Jaw

This setup will always clamp rear

part first . Once set it will release

fir

fr

Rear Jaw

6

Page 8

Pre-Load rangeAdjustment Nut

Refer to sketch below for direction of adjustment

To remove Pre-Load range (Reducing the amount of turns of the handle

when clamping or unclamping parts).

1. Loosen but do not remove the (socket head set screw) on top of Holding

Block.

2. With the use of a spanner wrench, begin to turn the Adjustment Nut

clockwise. Each full turn will reduce Pre-Load amount by appoximitly

.04. NOTE: Maximum reduction is .100/.150 or approximately 3-3/4

turns of the Nut. NOTE: If adjustment Nut turns to a complete stop

before the 3-3/4 turns, maxim um reduction range is complete.

3. Turn counterclockwise Aligning the first slot on the Adjustment Nut with

the SHSS and tighten.

To add Pre-Load range (Increase the amount of turns of the handle)

1. Loosen but do not remove the SHSS on top of the Holding Block.

2. With a spanner wrench turn the adjustment nut counter clockwise until

threads on the Adjustment Nut begin to show.

3. Align the slot on the Adjustment Nut with the SHSS and tighten.

7

Page 9

Conversion Kit Assemble - DL640, DLM640 / DL430, DLM430

Refer to Conversion Kit Sketch on this page for setup preference.

CAUTION

USE CAUTION WHEN HANDING CHIP GUARD MATERIAL. EDGES AND

CORNERS ARE SHARP AND MAY CAUSE PERSONAL INJURY IF NOT

HANDLED PROPERLY.

1. Before beginning setup, clean the backside of the Rear Moveable Jaw set and the

Body surface opposite the handle where Conversion Plate will be mounted.

2. Remove Stationary Jaw. Note: Stationary Jaws widths are fitted to each body and

are "letter" stamped on the side of the Stationary Jaw and in the Body keyway.

When reinstalling the letter stamped must match the body for proper fit.

3. Mount the Conversion Plate to the Body using the provided Socket Head Cap

Screws (SHCS) and tighten.

4. Open the vise completely turning the screw counter clockwise until the back

Moveable Jaw set is at maximum travel.

5. Install SHSS and tighten to the Moveable Jaw set.

6. Depending on your setup, custom cut Chip Guard maybe required. Provided with

Conversion Kit is (2) standard length Chip Guard material that maybe used.

Contact factory for replacement or additional Chip Guard material. Note

Maximum opening and closing.

Examples of some conversion setups. All dimensions are referenced in inch.

NOTE: This vise is not to be used as a self-centering Vise

DLC640-INST.

04/26/00 rev 1

8

Page 10

General Cleaning/Maintenance Procedure

6/18/98 rev 1

DoubleLock Model #

DL640, CT640, DL430, CT430 (metric included)

TO ASSURE PROPER USAGE AND CONTINUOUS SERVICE OF

YOUR DOUBLELOCK VISE, IT IS IMPORTANT TO REGULARLY

CLEAN ANY MATERIAL BUILD UP THAT MAY HAVE OCCURED.

LITTLE OR NO MAINTENANCE COULD RESULT IN POOR VISE

FUNCTION.

A. DISASSEMBLY INSTRUCTIONS

1. Open both Moveable jaws to the maximum openings.

2. Loosen the setscrews in the backside of both the Front and Rear Movable

Jaw sets. Loosen only enough to allow Movable to pivot up off the Nut

and Screw assembly. (approx. 6 turns). NOTE: The Chip Guards are

attached to the Movables. Take care when removing Movables. Note:

Once the Movable Jaws have been removed, there is a segment shaped as

a half Ball in the cavity. Be careful not to mis-place while cleaning.

3. If maintaining more than one vise at a time, the Stationary Jaw is made

specifically for the base it is in. Note stamped letters on the side of the

Stationary and the inside of the hold down slot in body for re-assembly

reference.

4. Remove the (2) SHCS (Socket Head Cap Screw) holding the Stationary

Jaw and remove jaw.

5. Remove any remaining Chip Guards.

6. Clean disassembled parts as needed.

7. Note: The Nut & Screw assembly should not have to be removed if

regular maintenance is done. If required to remove for additional cleaning

remove the Button Head Cap Screw on Handle end of the V ise bed and

slide Screw and Nut assembly out. Caution: Disassemble of the Screw

and Nut assemble may result in improper function once re-assembled.

Important timing is involved w ith the internal springs. Please contact

factory for requirements.

B. ASSEMBLY INSTRUCTIONS

1. If Nut and Screw assemble was removed refer to sketch on page 10 for

Nut timing. Slide Screw and Nut assemble into the Body. Install Button

Head Cap Screw and tighten.

9

Page 11

2. Before placing the (2) Movable Jaws over the Nuts make sure the

segments are in the inside cavity using grease to hold them in place and

for lubrication.

3. Spread a small amount of oil to the bed of the vise where the Moveable

Jaws will be installed.

4. Place the Movable Jaw starting with the side with (2) holes into the

center way. In a slide motion, slide Movable Jaw over the Nut allowing

the Movable to drop over the Nut. NOTE: The 45-degree angle of the

Nut should be on the flat surface of the Movable Segment.

5. Snap the Chip Guard onto the pins underneath each Moveable. Note:

May need to lift up slightly to catch the pins with the Chip Guard.

6. Tighten the SHSS in the Movable until it makes contact with the Nut.

Turn back approximately ¼ turn. IMPORTANT: THIS SHSS SHOULD

NOT BE COMPLETELY TIGHT. THIS WILL ALLOW MOVEMENT

OF THE MOVABLE JAWS. SEE SKETCH ON NEXT PAGE.

7. Place the Stationary Chip Guard into place.

8. Install the Stationary Jaw and tighten in place using the (2) SHCS.

9. To seat the segments in the Movable Jaw, tighten vise with supplied

handle, and then open vise until close to full opening. If needed tighten

the SHSS in the back of Movable Jaws then loosen approxim a tely ¼ turn.

10. Vise is now ready for use.

10

Page 12

DL430

11

Page 13

DL640

12

Page 14

PRECAUTIONS

When using the DoubleLock Vise in production, remember the following

points:

• Never use this vise as a Self Centering Vise.

• See figure #3, page 14. Never

clamp parts opposite from each other.

• Always clamp directly across from each other or use a spacer to even

clamping pressure points.

• Use the Handle provided or Torque Wrench with your vise. The rated

clamping forces are obtained with these handles. Never

use an extension

or strike the handle with a hamme r. This will cause damage to the thrust

bearings.

• When using parallels or Step Jaws, select a size that keeps the BOTTOM

of the clamped part at or below the top surface of the Movable Jaw.

Clamping above this surface could result in Jaw lift and loss of accuracy.

• Never use a hamm e r, blunt object, or "cheater bar" in assisting when

clamping parts in the vise. Damages to the Thrust Bearing assembly, and

seals may accrue.

• Always use the handle provided, handle equivalent, or torque wr ench.

• Avoid using an impact wrench. Some impact wrenches cause internal

“shock” on moving components and increasing the wear significantly. If

an impact wrench is used, avoid rapid movement. Never use the impact

wrench to tighten the part. This increases the clamping forces above the

product capabilities and causes stress in areas not intended to except

stresses. A controllable torque impact wrench is acceptable only when

clamping forces needs to be consistence. Avoid over torquing.

• Clamp parts to the lowest position possible. Part nesting at the vise base

increases clamping forces and decreases the possibility of part distortion.

• Always clamp the part with the part at or near center of the vise width.

Clamping a part beyond center may cause inconsistent part clamping

pressures.

13

Page 15

14

Page 16

CUSTOMER SERVICE

For additional information or question about your vise, Please contact K urt

Manufacturing at 1-800-328-2565 between the hours of 7:30 a.m. and 4:30

p.m. Central Standard Time.

REPLACEMENT PARTS

Contact your Kurt Manufacturing representative for a complete list of

DoubleLock replacement parts and pricing. Your representative can also

provide you with a Kurt Manufacturing Product Catalog containing all

products and accessories for your Workholding needs.

FACTORY CONTACT

Kurt Manufacturing Company

1325 Quincy Street N.E.

Minneapolis, MN 55413

Phone: 612-572-4424

Toll free: 1-800-328-2565

Fax: 612-623-3902

Web site: www.kurt.com

15

Page 17

REVISION HISTORY

REVISION A

JULY 1998

COPYRIGHT 1998 KURT MANUFACTURING

THIS DOCUMENT IS CONFIDENTIAL AND IS THE PROPERTY OF KURT

MANUFACTURING. IT MAY NOT BE COPIED OR REPRODUCED IN ANY WAY

WITHOUT THE EXPRESS WRITTEN CONSENT OF KURT MANUFACTURING.

KURT MANUFACTURING INTENDS TO AND IS MAINTAINING THE WORK AS

CONFIDENTIAL INFORMATION. KURT MANUFACTURING ALSO MAY SEEK

TO PROTECT THIS WORK AS AN UNPUBLISHED COPYRIGHT. IN THE EVENT

OF EITHER INADVERTENT OR DELIBERATE PUBLICATION, KURT

MANUFACTURING INTENDS TO ENFORCE ITS RIGHTS TO THIS WORK

UNDER THE COPYRIGHT LAWS AS A PUBLISHED WORK. THOSE HAVING

ACCESS TO THIS WORK MAY NOT COPY, USE OR DISCLOSE THE

INFORMATION IN THIS WORK UNLESS EXPRESSLY AUTHORIZED BY KURT

MANUFACTURING.

PLEASE READ AND OBSERVE THE FOLLOWING SAFETY PRECAUTIONS

FOUND THROUGHOUT THIS MANUAL.

CAUTION

FAILURE TO OBSERVE MAY CAUSE MINOR OR MODERATE PERSONAL

INJURY OR DAMAGE TO THE EQUIPMENT.

CAUTION

USE CAUTION WHEN HANDING CHIP GUARD MATERIAL. EDGES AND

CORNERS ARE SHARP AND MAY CAUSE PERSONAL INJURY IF NOT

HANDLED PROPERLY.

Loading...

Loading...