Kuppersbusch TKD, TKD 988.1, TKDEM 988.1 Instructions For Use And Installation Instructions

Page 1

BEDIENUNGSANWEISUNG

mit Montageanweisungen

Instructions for use and installation instructions

Instructions d’ utilisation et avis de montage

Gebruiksaanwijzing en montagehandleiding

Istruzioni di uso e di montaggio

Instrucciones de uso y de montaje

TKD/TKDEM 988.1

53 82 91 G61

Page 2

12 GKS 324.0/GKS 644.0 G51

For your information...

You should carefully read the information in this manual before you use your

cooker hood. Here you will find important notes concerning safety and how to

use, look after and service your appliance so that it enjoys a long service life.

Should a fault arise, please first consult chapter “What to do if trouble occurs...”. You can often remedy minor faults yourself and thus save unnecessary service costs.

Always keep these instructions in a safe place and pass them on to new

owners for their information and safety.

The following symbols are used in this operating manual:

=

The warning triangle draws your attention to possible risks for your

health or damages that might be caused at your appliance.

F

Here you will find information and notes.

Conditions of guarantee

The conditions of guarantee applicable for this product are subject to those

published by the representative in the relevant country.

Details regarding same may be obtained from the dealer from whom the

appliance was purchased. For claims under guarantee the sales receipt must

be produced.

Content

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

For connections and functions

For operating your cooker hood

For operating the hood with stoves and

heating appliances with a naked flame

General advice for use. . . . . . . . . . . . . . . . . . . . . . . . . 13

Your appliance at a glance. . . . . . . . . . . . . . . . . . . . . . 14

Using the hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

The power supply of the control panel

Before using the hood the first time

Remote control (optional accessory)

Switching the lighting On/Off

Switching on the ventilation

Changing the ventilation setting

Switching the ventilation off

The intensive button

Activating the automatic delayed stop

Cleaning, care and maintenance. . . . . . . . . . . . . . . . . . 15

Cleaning the hood

Cleaning the metal fat filters

Changing the activated charcoal filter (in recirculation mode)

Replacing a halogen lamp

Changing the battery of the remote control

What to do if trouble occurs... . . . . . . . . . . . . . . . . . . . 16

Rating label

Installation preconditions . . . . . . . . . . . . . . . . . . . . . . . 16

Scope of delivery

Dimensions for installation

Walls suitable for mounting/suitable fixings

Electric connection

Possible extraction versions

Chimney attachment and length of chimney

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Unpacking of the components

Screwing the switching unit to the hood body

Mounting a steel rear panel (optional)

Marking the drill holes

Installing the hood body and chimney attachment

Recirculation mode only: adjust deflector and ducting

Extraction mode only: attach the ducting

TKDEM 988.1 only

Electric connection

Mounting the chimney

Inserting the filters

Function testing of the hood

Guideline for extraction paths. . . . . . . . . . . . . . . . . . . . 20

Extraction path through the walls

Extraction through the kitchen ceiling and roof

Extraction into an existing exhaust shaft

Please note:

Page 3

GKS 324.0/GKS 644.0 G51 13

Safety instructions

For connections and functions

■ Maintenance and repair work may only be carried out by an authorised

technician in accordance with the applicable safety regulations. Work which

has been performed improperly can endanger your safety.

■ Extraction appliances must not be connected to smoke or fume chimneys

or to shafts used for ventilating rooms where stoves have been installed.

Before extracting fumes into a smoke or fume chimney which is not in use,

please obtain approval from your local chimney sweep. When extracting

fumes, please observe the official regulations.

■ The minimum distance between the cooker hood and the cooker is

650 mm.

■ For cleaning and maintenance work the hood must be deactivated by

switching off the household fuse.

For operating your cooker hood

■ The fat filter must be cleaned regularly. There is a danger of fire if the ap-

pliance is used with a saturated fat filter!

■ Only use the hood when the fat filters have been installed.

■ Never flambé dishes under the cooker hood!

■ Ignited rings of gas cookers and gas hobs must always be covered by pots

or pans.

■ Keep an eye on deep-fat fryers while in operation. Fat and oil which ignites

due to overheating can set fire to the cooker hood.

■ The fume trap should not bear excessive or one-sided loads. If the glass

breaks, there may be a danger of injury from falling pieces of glass!

For operating the hood with stoves and

heating appliances with a naked flame

This relates, for example, to gas, oil or coal-fired heating appliances,

continuous flow heaters and hot water tanks: If the cooker hood is operated

in extraction mode, such appliances may no longer have sufficient air required

for combustion and there is a danger of intoxication or explosion!

Operation is perfectly safe if the cooker hood and the stove are being used

simultaneously in rooms where a negative pressure of 0.04 mbar is not

exceeded. This ensures that the fumes from the stove are not sucked back

into the room.

This can be achieved if there are non-airtight openings in windows and doors,

ventilation wall boxes (supplying/extracting air) or other technical

devices, e. g. interlock devices so that a sufficient supply of combustion air

can flow back into the room.

When assessing the ventilation requirements, the ventilation system of your

entire home must always be taken into account. This means, for example, the

above regulations for operating cooking appliances (e.g. hobs and gas cookers)

are not applied. If in doubt, please consult your local chimney sweep.

■ If the cooker hood is only used in recirculation mode - with activated

charcoal filter - there are no restrictions on operation.

Example of how to use the cooker hood and the stove in

complete safety:

■ A switch at the window prevents the cooker hood from being operated when

the window is closed.

General advice for use

Remember that the ventilation problem in the kitchen is often not solved

merely by installing a cooker hood. For optimum effect and maximum

ventilation efficiency the cooker hood requires a sufficient supply of air from

the correct sources. Disappointing performance and the development of loud

noises are almost always the result of planning or operating errors.

Example:

■ Insufficient supply of fresh air

Result: The speed of the ventilation motor increases, the air capacity

decreases and the noises become louder.

Solution: Ensure that there is an adequate supply of fresh air through structural measures or by opening the window when the cooker hood is in operation.

■ Saturated filters

Result: The air capacity of the cooker hood decreases and the fumes are

insufficiently cleaned.

Solution: Clean the filters regularly before the air capacity decreases.

in extraction

mode

in recirculation

mode

Appliance

switch on

appliance

on starting

cooking

on starting

cooking

switch off

appliance

approx. 5 min.

after finishing

cooking

approx. 15 min.

after finishing

cooking

Position of door open closed

window closed open

The room air is

cleaned of

humidity X -heat X -fat X X

odours X X

Page 4

14 GKS 324.0/GKS 644.0 G51

Your appliance at a glance

Using the hood

=

Please observe the safety instructions on page 13.

The power supply of the control panel

=

Always push the glas fume screen in, when the hood is not operated.

The operating fascia at the glas fume screen is not directly connected to the

control unit of the hood. It is supplied with the current required for the contact

to the control unit from an accumulator that is charged as long as the glas fume

screen is closed (due to the contact with the transformer at the hood body).

If the hood shows no response when you press the buttons after having pulled

out the glas fume screen, the accumulator has been discharged. Push the glas

fume screen in so that the accumulator is charged. In the meantime, the hood

can beoperated with retracted glas fume screen. The accumulator is fully recharged after approx. 8 hours (without hours of use) and the hood can be

operated with pulled-out glas fume screen again.

Before using the hood the first time

– Please clean the cooker hood before using it for the first time as described

in “Cleaning, care and maintenance” on page 15.

=

Leave the glas fume screen in the retracted position for at least 8 hours

after installation so that the accumulator of the control panel can be recharged.

If the hood is not activated when the glas fume screen is pulled out,

please operate the hood with retracted glas fume screen (see “The power

supply of the control panel” above).

Remote control (optional accessory)

The remote control serves for switching on and off the lighting and ventilation

and for changing the ventilation setting. All other functions of the hood must

be activated or deactivated directly at the control panel.

Switching the lighting On/Off

– Press the button ! to switch the halogen lamps on.

– Press the button ! again to switch the halogen lamps off.

Switching on the ventilation

– Press the button # . The ventilation is switched on with the setting that

has been activated when the hood was switched off.

Changing the ventilation setting

The hood can be switched to four ventilation settings (1 to 4).

– Press the

+ button (or ) to increase the ventilation setting.

– Press the

- button or ( ) to reduce the ventilation setting.

Switching the ventilation off

– Press the button # when the ventilation is running.

The intensive button

F

The intensive button cannot be activated via the remote control. Use the

remote control to increase the ventilation setting step-by-step until setting

“4” is reached.

If the intensive button is pressed, the cooker hood is switched to the maximum

ventilation setting (“4”).

– Press the button 8 . The chiffre “4” is indicated in the display.

Activating the automatic delayed stop

F

If you have finished cooking and wish to operate the hood for another

10 minutes by using the automatic delayed stop, already push in the glas

fume screen, if possible, so that the accumulator of the control panel can

be immediately recharged.

The automatic delayed stop can be activated with any ventilation setting. It

switches the cooker hood completely off (ventilation and lighting) after 10 minutes.

– Press the button # , until a small dot is flashing next to the chiffre.

Chimney

Glas fume screen

Control buttons

Transformator

Metal fat filter

Halogen spotlights

V

enting slots (in re-

circulation mode)

Hood body

Control buttons at the glas fume screen

Buttons at the remote control

A Display

B Ventilation on/off

C Lighting on/off

D/E Ventilation setting

F Intensive button

Page 5

GKS 324.0/GKS 644.0 G51 15

Cleaning, care and maintenance

=

Caution! For repair work or cleaning the inside of the hood, switch off

the household fuse or pull out the mains plug.

=

Do not use any scouring agents or aggressive cleaners.

Cleaning the hood

Control panel

– Carefully wipe the control panel now and again with a soft cloth which is

free of fluff. Make sure that no water penetrates into the slots between the

control buttons.

Glass surfaces

– Clean the glass surfaces with a damp cloth and a little hand detergent or

one of the usual glass cleaning agents.

Stainless steel parts

– Clean stainless steel parts with a damp cloth and a little hand detergent.

Then wipe dry.

– Use one of the usual stainless steel cleaning agents from time to time.

Remote control

=

The remote control must not be put into water!

– Only clean it with a damp cloth and, if required, with a little hand detergent.

Cleaning the metal fat filters

Important! If you use the hood in recirculation mode, you must also renew

the activated charcoal filter roughly about 120 h of use. You can obtain original filters from your dealer or direct from KÜPPPERSBUSCH.

Filter saturation indicator

=

Saturated fat filters reduce the performance of the hood and may ignite

due to naked flames or great heat.

Both filter inserts must be simultaneously cleaned when the letter “F” is

indicated in the display (after 30 operating hours).

– Switch off the filter saturation indicator by pressing the button 8 when the

ventilation is switched off until the “0” is no longer displayed.

Cleaning the metal filters

– Hold each metal filter by the

handle and push back lightly. To

remove pull down out of the

bracket.

– Clean the metal filters in the

dishwasher or wash by hand

with a mild detergent. Rinse

well and dry before refitting.

– Recirculation mode: Change the

activated charcoal filter,

whenever nessesary.

– To refit the filters, place in the

slot at the rear and push up.

They will then click into place.

Changing the activated charcoal filter (in recirculation mode)

F

The activted charcoal filter is only required in the recirculation mode. It

must not be used in the extraction mode.

Filter saturation indicator

After approx. 120 hours of use, the letter “F” flashes in the display of the

control panel. The activated charcoal filter cannot be cleaned or regenerated.

It must be replaced.

– Switch the saturation indicator off by pressing the button 8 when the

ventilation is switched off until the “0” is no longer displayed.

Changing the activated charcoal filter

– Remove the metal fat filters (see “Cleaning the metal fat filters”) and clean

them.

– Push the activated charcoal filter to

the rear and take it out by moving

it downwards.

– Install the new activated charcoal

filter by inserting the two metal noses into the recesses at the rear side.

– Insert the activated charcoal filter

into the bracket at the front so that it tightly fits.

Replacing a halogen lamp

=

Caution! The halogen lamps become very hot after being in use for some

time. Therefore, the lamps should be changed when they have cooled

down.

=

Only replace the halogen lamps with lamps of the same type.

F

Do not grip the halogen lamps with your bare hands. Finger marks burn

into the lamp glass and reduce the light intensity and service life of the

lamps.

– Remove the lamp cover from the bracket by turning it in a clockwise direc-

tion.

– Remove the halogen bulb from its socket.

– Hold the new bulb with a cloth (e.g. tissue) and

push into the socket.

– Reinstall the cover.

Changing the battery of the remote control

– When the hood no longer reacts to the

buttons on the remote control, you

probably have to change the battery in the

remote control.

– Remove the cover of the remote control.

– Undo the battery connections.

– Remove the battery, insert a new one

(9V E-block) and connect it.

– Close the cover again.

Page 6

16 GKS 324.0/GKS 644.0 G51

What to do if trouble occurs...

=

The cooker hood may only be repaired by an authorised technician.

=

For repair work the appliance must be disconnected from the power supply by pulling out the mains plug or unscrewing the household fuse.

You can deal with some problems that occur yourself. First check whether

there has been any operating error. Repairs during the guarantee period are

not free of charge, when they are caused by operating errors or non-observance of the following instructions:

Rating label

The rating label can be seen when you have removed the fat filter or the

activated charcoal filters. Please make a note of the following data on the

rating label before or while installing the cooker hood in case you have to

consult our Customer Service:

Installation preconditions

=

The cooker hood may only be installed and the electrics connected by a

qualified technician. Pay attention to the notes on safety on page 13!

=

Danger! For all installation and maintenance work the cooker hood must

be disconnected from the power supply. As the mains plug is no longer

accessible after installation, you must switch off the relevant household

fuse.

Scope of delivery

TKD 988.1:

Hood body with extendable glass fume trap, motor housing and switching unit

Chimney, recirculated air deflector, reduction piece (150-125 mm).

Fastening material and drill hole template, instructions for use and installation.

TKDEM 988.1:

Hood body with extendable glass fume trap, motor housing (without motor and

fan) and switching unit, chimney.

Fastening material and drill hole template, instructions for use and installation.

Dimensions for installation

Walls suitable for mounting/suitable fixings

=

The fitter is always responsible for selecting the correct fastening material. The fastening method must be suitable for the weight of the hood.

Please also observe the “Guideline for extraction paths” on page 20.

The cooker hood can be mounted directly on the wall or on a steel rear panel.

■ The enclosed dowels and screws are suitable for walls made of perforated

bricks or concrete bricks which are 20 mm thick.

■ For solid concrete walls you must use special concrete dowels from a

specialist store.

■ For solid wooden walls you must use wood screws of sufficient thickness

and length.

Problem Cause Remedy

It is not possible to switch

off the cooker hood.

Electronic component

is defective.

Pull out mains plug or

switch off fuse.

Reconnect or switch on

again after approx. 2 minutes.

In case the fault has not

been reset, call the Customer Service.

=

Pull out mains plug or

switch off fuse.

Breakdown of the

microcontroller

A lamp does not work. Lamp defective. Replace lamp.

Hood does not work when

fume trap is extended.

Accumulator of the

operating fascia is

discharged.

See “The power supply of

the control panel” on

p. 14.

Performance of the cooker hood is reduced.

Filters are very

clogged.

Clean the filters.

“F“ in the display. No defect. See “Cleaning the metal

fat filters” on page 15.

Flashing “F” in the

display.

No defect. See “Changing the activa-

ted charcoal filter (in recirculation mode)” on p. 15.

Remote control (optional)

does not work.

Battery discharged or

not inserted.

Insert a new battery. See

p. 15.

Serial number:

Model designation:

Recirculation mode

Extraction mode

Page 7

GKS 324.0/GKS 644.0 G51 17

Electric connection

The hood is fitted with a normal mains plug and there should therefore be a

socket outlet (230 V alternating current) in the chimney path. The associated

dimensional drawing is to be found in the next chapter “Possible extraction

versions”.

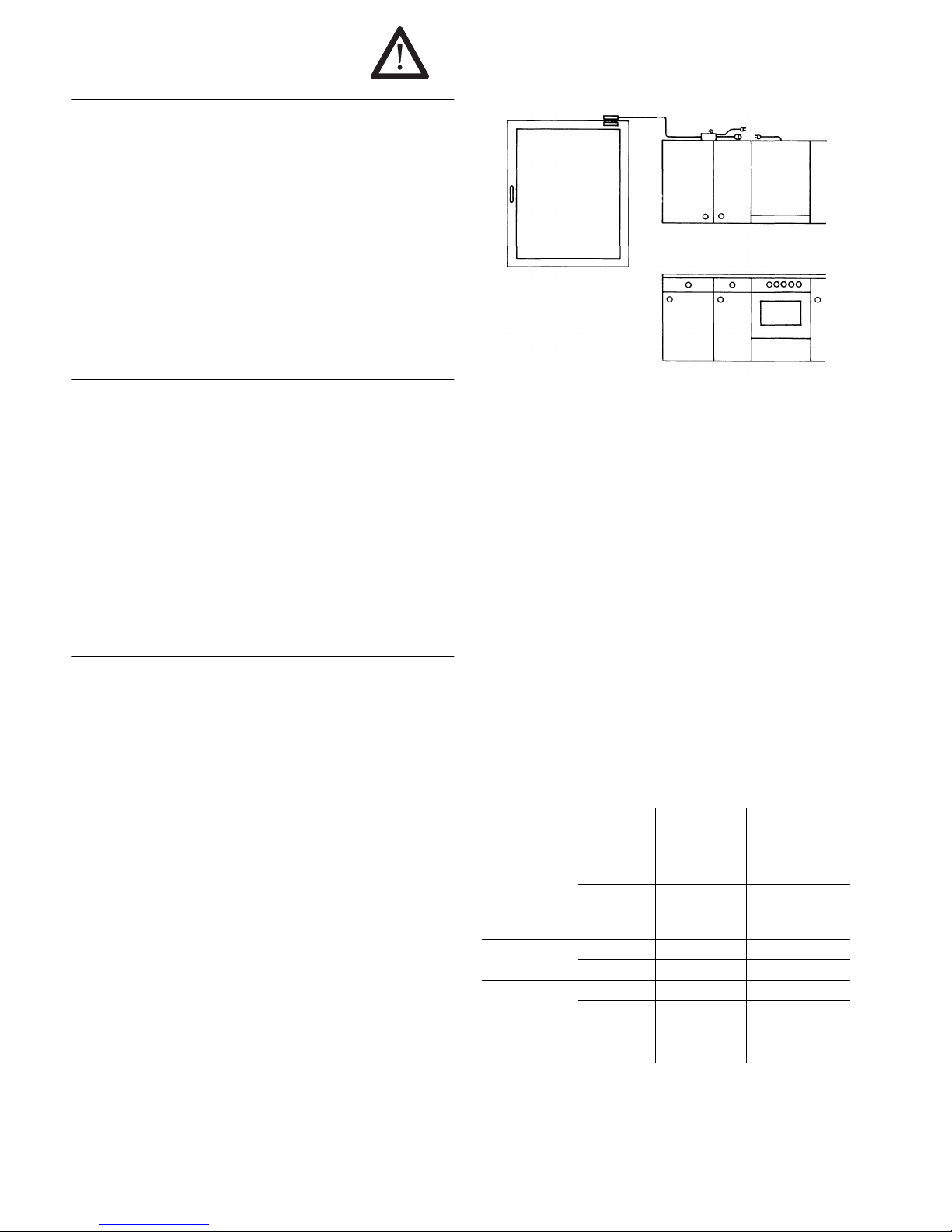

Possible extraction versions

– Determine the position of the socket outlet and, if required, the position of

the exhaust hole, by means of the respective dimensional drawing.

Recirculation mode

There are no further preconditions for the customer, as there is no extraction

path through the wall or ceiling. The socket outlet can be located within the

marked area.

Extraction path to the rear

There must be an exhaust channel 150 mm in diameter through the wall

inside the marked chimney surface.

Extraction path upwards

There must be an exhaust channel 150 mm in diameter in the ceiling above

the installation point of the hood in accordance with the following drawing.

Extraction mode with external motor TKDEM 988.1

In addition to the exhaust channel, the control line for the external motor must

be guided through the exhaust hole. Since the external motor is powered via

the cooker hood, a socket outlet must also be available here.

Chimney attachment and length of chimney

The chimney attachment is flush with the chimney’s upper edge. It can be

mounted at the ceiling or on the wall. In the ideal case, the chimney ends at

the ceiling.

The maximum chimney length amounts to 1020 mm in extraction mode and

1200 mm in recirculation mode, the minimum length amounts to 850 mm in

both cases. (See “Dimensions for installation” at p.16.)

The lower edge of the hood must be located at least 650 mm above the cooking top in order to prevent the fat in the fat filter from igniting.

Determine the required chimney length by means of the dimensional drawing

and check whether it can be realised.

Installation

F

In the described installation it is assumed that there is already an exhaust

hole in the wall/ceiling.

=

Please observe the “Installation preconditions” on p.16!

Unpacking of the components

Unpack the components and check them for completeness.

■ In case you should find any transport damages or other damages of the

components, please immediately contact the supplier.

■ The packing has to be properly disposed of.

Screwing the switching unit to the hood body

For transport reasons, the switching unit is not yet screwed to the hood body.

– Fasten the switching unit at

the hood body by using one

of the 3 small sheet metal

screws included in the scope

of supply.

Mounting a steel rear panel (optional)

– Insert the bottom edge of the rear panel behind the worktop or the

built-in hob. The rear panel must rest on the worktop.

– With a telescopic rear panel set the length you want. Pay attention, that

when the hood is installed, the distance between the hood and the hob must

be at least 650 mm.

– Mark the drill holes.

– Drill the holes and insert dowels.

– Guide the power cable and the control line of the external motor, if eqipped,

through the opening in the rear panel and screw on the panel.

Then fasten the cooker hood in the same way as it is fastened onto a wall.

socket outlet

socket outlet

exhaust hole

exhaust hole

socket outlet

Page 8

18 GKS 324.0/GKS 644.0 G51

Marking the drill holes

The hood body is hung into a wall hook and additionally fastened by means

of four locking screws.

■ The wall mounting must be aligned with a spirit level. Correct alignment of

the hood is only possible if you perform this work accurately.

– Use a perpendicular to mark the centre above the cooking top in the area

that is covered later.

– Place the drill hole template centrally above the hob. The lowest line of the

template corresponds with the lower edge of the hood.

Pay attention, that when the hood is installed, the distance between the

hood and the hob must be at least 650 mm.

– Mark the holes for the wall hook.

– Set the chimney attachement to the

width of 260 mm with the screws

(E).

– Mark the holes for the chimney at-

tachment centrally above the holes

for the wall hook.

For this purpose, the chimney attachment must be held in the desired position.

Installing the hood body and chimney attachment

– Drill the holes for the wall hook with ∅ 8 and insert dowels.

– Fasten the wall hook by means of the

wall screws. The marked triangle in

the hook must be located on the

marked centreline.

– Attach the hood body to the wall hook.

The marked triangle in the attachment

must be located exactly on the marked centreline.

– Align the hood body in an exact

horizontal position by means of the

adjusting screws.

– Mark the four holes for the locking

screws.

– Take the hood body off from the wall

again.

– Drill the holes for the locking screws

with ∅ 8 and insert dowels.

– Drill the holes for the chimney

attachment.

– Fasten the chimney attachement with

the angle cover facing upwards with

wall screws and dowels. Mount the

attachement directly under the ceiling

so that the chimney is flush with the

ceiling.

Alternative: Screw it to the angle

covers at the ceiling.

– Attach the hood body to the wall

hook again and centrally align it.

– Tighten the locking screws.

If required, unscrew the switching

unit for this purpose in order to be

able to tighten the locking screws.

– Then tighten the two other screws

of the switching unit.

Recirculation mode only: adjust deflector and

ducting

– Screw the air deflector firmly to the

upper chimney section, so that the

deflector openings are in line with

the venting slots. The open side of

the deflector must adjoin the

chimney.

– Put the attached reduction

piece onto the motor opening.

– Connect the reduction piece and the deflector to an exhaust line

(∅ 125 mm).

Extraction mode only: attach the ducting

– Fasten the exhaust line (∅ 150 mm) at the fan opening.

– Connect the exhaust line to the exhaust hole in the wall or ceiling.

Page 9

GKS 324.0/GKS 644.0 G51 19

TKDEM 988.1 only

– Guide the control cable of the

external motor through the

exhaust hole.

– Remove the cover of the

switching and control unit.

– Connect the control line.

– Recover the switching and

control unit.

– Connect the other end of the

control cable to the external

motor, if not pre-assembled.

Electric connection

=

The household fuse must still be switched off!

– Plug the mains plug into the socket.

Mounting the chimney

In case of hoods with recirculation mode the venting slots in the upper

chimney section are turned to the top, in case of hoods with extraction mode

to the bottom.

– Insert the upper and lower chimney parts into each other in the right way.

– Put the chimney onto the hood body with

the lower edge inserted into the recess.

– Extend the upper chimney

upwards and screw tight to the

chimney attachement with the

screws (F).

Inserting the filters

Before you install the filters again, you should read off the serial number and

the model designation on the rating label and enter them on page 16.

Only appliances with recirculation mode:

Insert an activated charcoal filter. See “Changing the activated charcoal filter

(in recirculation mode)” on page 15.

All appliances:

Insert the metal fat filters again.

Function testing of the hood

– Switch the household fuse on.

– Check the lighting and ventilation.

If the hood does not operate when the glas fume screen is opened,

the accumulator of the operating fascia is not recharged. Push the

glas fume screen fully in. The hood should now operate properly!

Extraction mode Recirculation mode

Page 10

20 GKS 324.0/GKS 644.0 G51

Guideline for extraction paths

Use round pipes with a 150 mm diameter or rectangular extraction channels

with a cross section of 90 x 220 mm.

You should use the following schematic diagrams as a guide for the extraction

paths:

Extraction path through the walls

Here a telescope wall chock which can be adjusted to different wall

thicknesses is built into the wall. The exhaust pipe should bend outwards

slightly so that the condensation water can flow away easily.

Extraction through the kitchen ceiling and roof

The height of the exhaust pipe must not exceed 2.5 m. The pipe must be heat

insulated or an air-trap seal must be installed.

Extraction into an existing exhaust shaft

The exhaust air must only be introduced into an existing exhaust shaft if this

is insulated against damp and is not already used for fuel purposes. Have the

chimney sweep responsible approve the use of the shaft.

Please note:

If the extraction channel is led through cold rooms, condensation may form.

If the extraction channel has several bends, is very long or has a very small

diameter, the suction power can be considerably reduced. The motor may

become loud and irregular.

The crucial factor is the correct transition of the exhaust channel into the

chimney:

view from the side

view from above

FALSE! Good Best Solution

Loading...

Loading...