Kunzle & Tasin Bona Belt Series Operating Manual

Bona Belt

Operating manual

Bedienungsanleitung

Manual de funcionamiento

Manuel d’utilisation

Manual de funcionamento

Instruktionsbok

Manuale d'uso e manutenzione

EN

DE

FR

ES

SE

PT

IT

Foreword

ATTENTION:

This manual contains important information on the safe use and

operation of this machine.

Carefully read through the entire user manual before you

begin working with the machine. This machine is intended for

professional or commercial use. Failure to read this manual

before operating, adjusting or servicing this machine could

cause injury or damage to persons or objects.

Bona Belt Manual

Anybody operating the machine should understand how to use

and operate it before starting it up. If anything is unclear, turn to

your reseller with condence or directly to Bona AB. Keep this

manual for future reference.

This manual is an English translation of the original version in

Italian.

For a new manual contact:

Bona AB

Murmansgatan 130

P.O. Box 21074

SE-200 21 Malmö, Sweden

Tel +46 40 38 55 00

www.bona.com

22

Table of Content

Machine Specifications 4

Machine Symbols Key 4

Operator Safety 5

Storage 6

Introduction 7

Safe and correct use 7

Machine data plate 7

Commencing Operation 8

Instructions for assembly 8

Dismantling the machine 9

Instructions for electrical connection 9

Cables, extensions and plugs 10

Instruction on removing sawdust generated during use 10

Prevention Measures for Users 10

Personal safety measures 10

Compliance with safety measures and warnings 11

Instructions on Correct Machine Use 11

Machine Warnings 12

Prohibited use 12

The Machine's Field of Application 12

Usage technique 12

Starting the Machine 13

Machine Adjustment Procedures 13

Regulation drum pressure 13

Changing the sanding belt 14

Adjusting the sanding belt 14

Setting the drum lever 15

Setting the height of the handle shaft 15

Changing the sanding drum 16

Dust collection 16

Routine Maintenance 17

Troubleshooting (for the user) 19

Safety Regulation when using Bona Belt 20

Service, Maintenance and Spare Parts 21

Service and maintenance 21

Spare Parts 21

Warranty 21

Declaration of Conformity 22

Disposal 23

Bona Belt Manual

3EN3

Machine Specications

Bona Belt Manual

Motor Type: 1 phase

Voltage (±10%): 230 V

Frequency: 50 Hz

Power: 2.2 kW

Rated Current: 12.9 A

Recommended fuses: Class C 16 A

Insulation class: F

Protection class: IP54

Abrasive Drum Speed: 1750 rpm normal load

Weight Machine Frame: 48 kg

Weight Motor: 23.5 kg

Condensers: Start 25 µF, operation 50 µF

Drum Width: 250 mm, alt. 200 mm

Hour Counter: 99 999 hours

Total Weight: 74 kg

Dust Emission: <2 mg/m³ air

Format Sanding Belt: 250 mm x 750 mm

or 200 mm x 750 mm

Height/Width/Length: 1000 mm/360 mm/960 mm

Machine Symbols Key

Read the instructions

contained in this user

and maintenance

manual before using

the machine.

Hearing protection

during use is

recommended.

Protection of the

airways during use

is recommended.

Hazard due

to electricity.

Hazard due to

moving parts.

44

Operator Safety

Bona Belt Manual

HAZARD means:

Serious injury or death may

occur to the operator or

others if 'HAZARD' warnings

on the machine or in this

manual are ignored or not

kept to. Read and follow all

'HAZARD' warnings on this

machine or in this manual.

Failure to read the Bona Edge machine manual before

operating, adjusting or performing maintenance operations on the machine could cause injury or damage to

persons or objects.

Anyone operating the machine should understand how to use

and operate it before starting it up.

KEEP AWAY FROM CHILDREN

Children should be supervised to ensure that they do not

play with the appliance. This machine is not intended for use

by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge

unless they have received instructions regarding the use and

are supervised by a person responsible for their safety.

Sanding may create an explosive environment. Cigarettes,

cigars, pipes, lighters, pilot ames, or any other source of re

may create an explosion, if lit during sanding operations. All

sources of ignition should be removed entirely from the work

area.

Poorly ventilated work areas may create an explosive

environment, when some combustible materials (solvents,

thinners, alcohol, fuel, some paints, wood dust, etc) are

present in the atmosphere. Floor sanding may cause various

materials and fumes to ignite. Read the manufacturer’s

instructions for each chemical product used and establish its

combustibility.

WARNING means:

Injury may occur to the

operator or others if

'WARNING' notices on the

machine or in this manual are

ignored or not kept to. Read

and follow all 'WARNING'

notices on this machine or in

this manual.

CAUTION means:

Damage may occur to

the operator or others if

'CAUTION' alerts on the

machine or in this manual are

ignored or not kept to. Read

and follow all 'CAUTION'

alerts on this machine or in

this manual.

Always keep the work area well-ventilated.

Striking nails when sanding may generate an explosion or

fire. Always ensure all nails are sunk before sanding surfaces.

Serious injury and/or death due to electrocution may occur,

if the power supply circuit trips repeatedly or is undersized.

Have the fuses, safety circuit and power supply line checked

by an authorized electrician.

Performing maintenance and/or repairing the machine,

when it is not fully disconnected from the power supply,

may cause serious injury and/or death due to electrocution.

Disconnect the power supply before carrying out any

maintenance and/or repair work.

The use of this machine on a circuit which is not grounded

may cause serious injury and/or death due to electrocution.

Never disconnect or disable the grounding conductor. Consult

an electrician, if the ground conductor is missing or it is

suspected that the circuit is not suitably grounded.

The use of this machine with a damaged power supply

cable may cause electric shock. Check the power supply

cable regularly for damage, such as splitting or wear and tear.

DO NOT use the machine, if the power supply cable is

damaged. DO NOT use the electric cable to move

the machine. DO NOT close a door on cord. DO NOT pull

cord around sharp edges or corners.

5EN5

Operator Safety (Cont).

Bona Belt Manual

DO NOT unplug by pulling on power supply cable. To unplug

grasp the plug. DO NOT handle plug or operate machine with

wet hands. DO NOT put any objects into motor openings.

Serious injury and/or death due to electrocution may occur

if the machine runs over the power supply cable and it

becomes damaged. Keep the cable away from the sanding

tool. Always keep the power supply cable raised above the

machine and sand away from the power supply cable.

Performing maintenance or

replacing the dust bag may

cause injury to the operator

or people nearby, if the

machine is connected to the

power supply. Always unplug

the machine when not in use.

DO NOT use solvents or

other ammable products to

clean this machine.

Dry use only. DO NOT use for

liquid recovery, which could

result in motor failure, electric

shock, and electrocution.

Never become distracted

during sanding operations,

check what is happening

continually. Use common

sense. DO NOT use the

machine, if you are tired,

have consumed alcohol or

have taken medication that

may affect your judgement

or your body control.

DO NOT smoke during

sanding operation.

The moving parts on this machine may cause serious injury

and/or damage. Keep hands, feet and loose clothing away

from all moving parts of the machine.

Operating the machine without all guards, doors, or covers in

place can cause an injury or damage.

DO NOT pass with the machine on objects that are hot,

burning or smoking, such as cigarettes, matches or cinders.

DO NOT use this machine to

sand steps or furniture. DO

NOT ride on this machine.

DO NOT put any objects into

openings. DO NOT use with

blocked openings. Keep

free from dust, lint, hair or

anything that may reduce

airow.

Storage

It is advisable to store the machine in its original packaging.

Doing so makes it possible to form a column of two packages

maximum, with one on top of the other.

If the machine is removed from the original packaging and is

not used for some time ensure the wheels and drum are not in

contact with the ground.

66

This equipment is for dry use only and must not be used or

kept outside in wet conditions. Store the machine in a dry

building, otherwise the machine could be damaged.

Storage temperature from -20°C to 50°C.

Introduction

Safe and correct use

Bona Belt Manual

This instruction manual should be read carefully before

using the Bona Belt wood flooring sander for the first

time.

The instruction manual contains important information

on safety and preventing improper use of the machine

and will resolve any doubts or questions, making

possible to operate the machine safely and with ease.

Removing safety features could cause death or physical

injury. Familiarize yourself with the machine before

using it for the first time.

Machine Data Plate

The following information can be found

on the machine data plate:

1) Name of the manufacturer

2) Machine model

3) Year of manufacturer (see 7)

4) Motor power

5) Supply voltage and frequency

6) Rated current

7) Serial number:

• The rst two numbers refer to the year of

• The second group of three numbers indicates the

• The last two numbers indicate the progressive

The Bona Belt wood ooring sander is suitable for the dry

sanding of wood oors. Any other use without the consent of

the manufacturer is prohibited. DO NOT use on wet oors.

See ‘Machine Warnings’ on page 12.

Keep hands and clothing away from moving mechanical parts.

The work area is protected via the base frame and the mobile

cover on the abrasive drum.

If a situation arises which has not been described in this

manual, contact your distributor or Bona Representative.

manufacture

(14 = 2014)

day of the year the machine was manufactured

(127 = May 7th)

number of machines produced that day of

manufacture (13 = 13th machine produced that

day)

7EN7

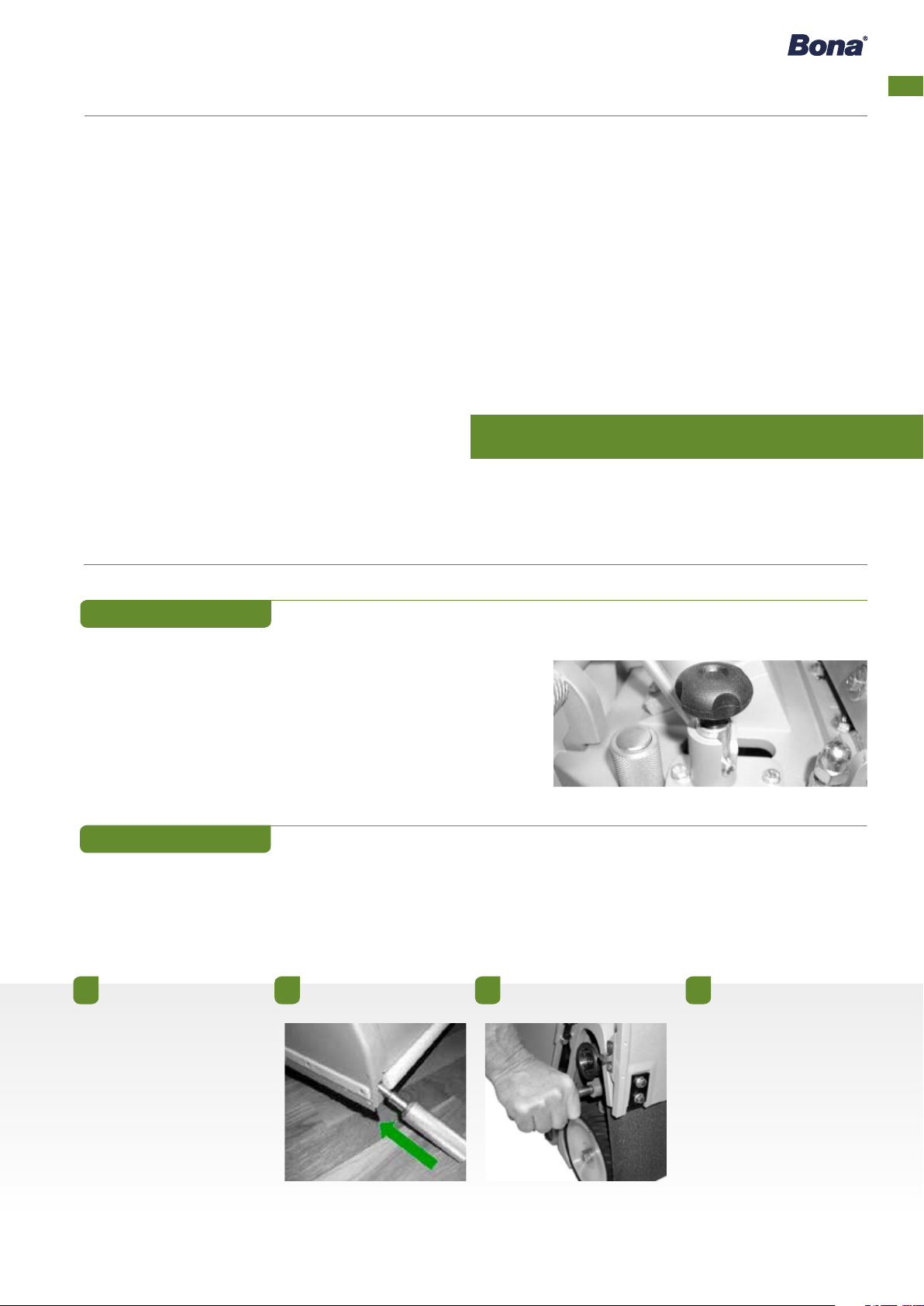

Commencing Operation

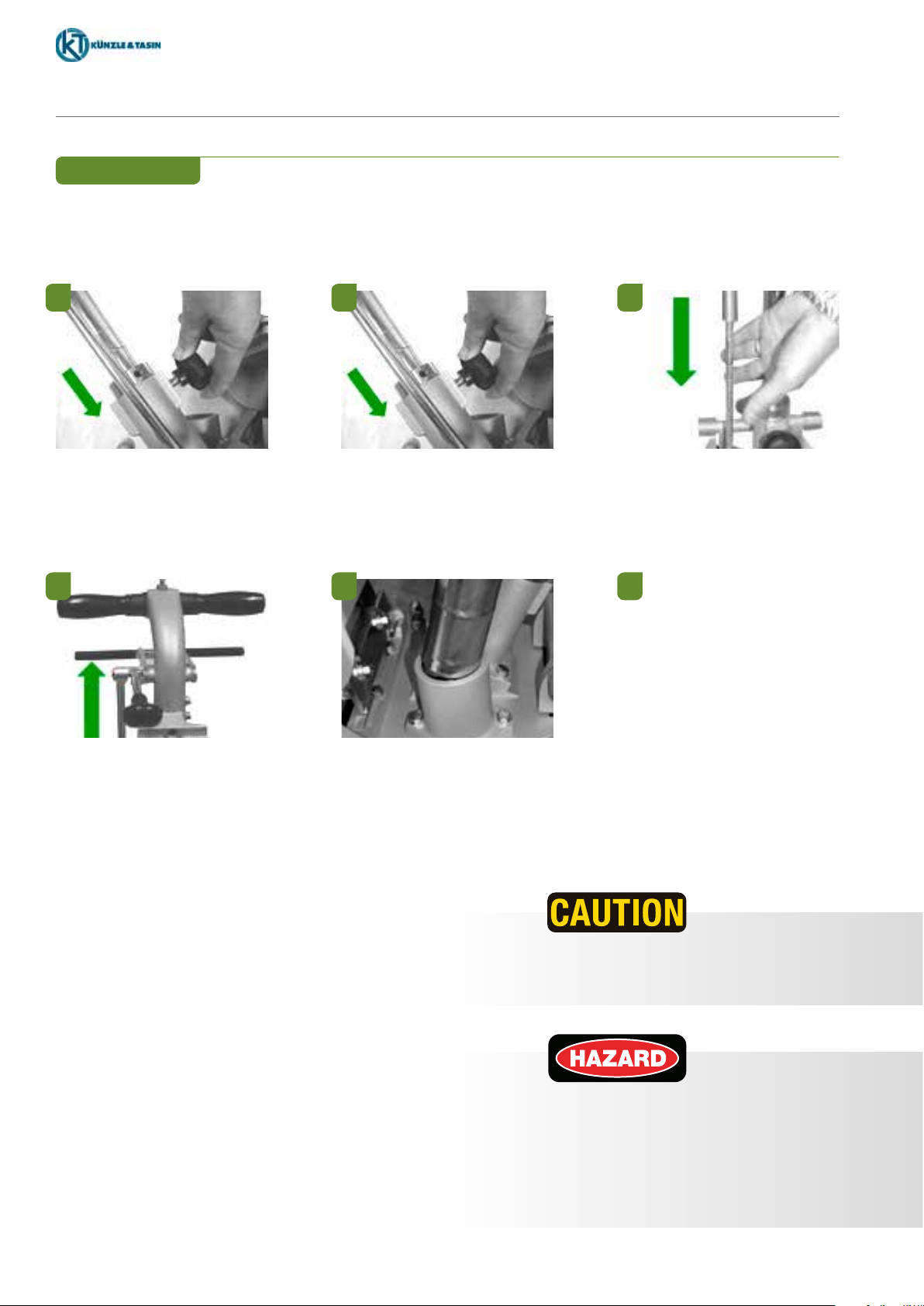

Instructions for assembly

Assembly an new Machine

Bona Belt Manual

1.

Push together the handle

shaft with the shaft holder.

4.

Lift the control lever to the

uppermost position.

2.

Screw and tighten locking wheel

5.

Push down the dust pipe in the

pipe holder.

3.

Put together the upper and lower

control rod and pass the sliding

sleeve over the lower control rod.

6.

Then afx a dust

bag to the dust pipe.

If the machine has been disassembled before transport then assemble the motor as follows:

1) Grab hold of the motor's carry handle. Place the motor on

the machine frame and fasten the motor's hinge in the rear

holder.

2) Roll on and tighten the driving belt using the eccentric

tightener. Lift up the belt protector. Mount the dust pipe with

the dust bag in the pipe holder.

88

Excessive belt tension may cause the

premature failure of the ball bearings.

Using the machine when not fully assembled may cause injury

or damage to people or objects. DO NOT use the machine when

it is not fully assembled. Keep all ttings tightly closed. Maintain

machine settings in accordance with the specications.

Commencing Operation (Cont.)

Dismantling the machine

Bona Belt Manual

1) The machine can be taken apart into four parts for

transport.

2) Put down the belt protector.

3) Reduce the tension on the driving belt by loosening the

eccentric tightener.

4) Roll off the driving belts.

5) Hold onto the motor handle and lift up the motor from the

rear motor bracket.

Instructions for electrical connections

6) Push the control lever forward and down

7) Pull up the sliding sleeve.

8) Loosen the locking wheel and pull up the handle shaft.

9) Lift up the dust bag together with the dust pipe upward until

it loosens from the pipe holder.

10) Carry the machine frame by holding the handle and the tilt

support.

.

This machine only operates

with the voltage and

frequency shown on the

machine data plate. Before

connecting the cable to

the power supply ensure

the correct voltage and

frequency are available.

DO NOT expose the machine to rain. This machine is

intended for dry use only. Keep the machine in a dry building

and DO NOT use it in damp or wet places.

If the machine is not connected correctly to the electricity

network, death due to electrocution may occur. To prevent

electric shocks always use a grounded three wire electrical

system. For maximum protection against electric shocks use

a circuit protected with a differential cut-out switch.

Tampering with the grounding plug in any way may result

in death from electrocution. DO NOT cut, remove or break

the grounding plug. If the socket does not match the plug

consult a qualied electrician.

If the machine is used with a

damaged plug or power supply cable, death may occur

from electrocution. If cables or

plugs are worn or damaged in

any way, have them replaced

by the manufacturer or

certied machine repair center

in order to prevent risks to

safet y.

9EN9

Commencing Operation (Cont.)

Cables, extensions and Plugs

Bona Belt Manual

Only use approved cables. The maximum

recommended cable length is 10m; for greater lengths

use cables with a larger cross-section.

MACHINE WITH 230 V~50 Hz MOTOR 2.2 kW

For machines with a 230 V~50 Hz motor, a HO5VV-F-3x2,.5

mm2 HAR-approved power supply cable must be used along

with an approved SCHUKO 2P+E 16 A 200÷-250 V plug.

Instruction on removing sawdust generated during use

For minimized dust environment use a vacuum cleaner intended

for wooden dust.

Using the machine with unsuitable and/or excessively long

cables may cause injury or damage to people or objects.

The machine must never be moved using its cable and the cable

must never be pulled when disconnecting from the socket.

Keep the cable away from sources of heat, oil and sharp edges.

Sawdust can ignite spontaneously and cause injury or damage.

It must be disposed of appropriately. Always empty the sawdust

into metal containers which are located outside the building.

Preventing Measures for Users

Personal safety measures

Sawdust can spread through the air and be inhaled when

using the sanding machine. Always wear a dust mask of at

least class P2, when using the sanding equipment.

The eyes and/or body may suffer injury if personal safety

clothing is not used.

Sawdust can ignite spontaneously and cause injury or damage.

Empty the contents of the dust bag when it is 1/3 full. Empty the

dust bag at the end of each machine use. Never leave the dust

bag unattended when it contains sawdust. Do not empty the

contents of the dust bag above a re.

It is adviceble to wear safety goggles, protective clothing

during sanding operations.

Lengthy exposure to noise levels during sanding operations

may damage the hearing. Always use EN-ISO approved ear

protectors (earmuffs) during sanding operations.

1010

Preventing Measures for Users (Cont.)

Compliance with safety measures and warnings

Bona Belt Manual

Using the machine when not fully assembled may cause

injury or damage to people or objects. DO NOT use the

machine when it is not fully assembled. Keep all ttings tightly

closed. Maintain machine settings in accordance with the

specications.

Failure to comply with instructions on this machine and in

this manual may cause serious injury and/or damage. Read

and comply with all safety instructions. Ensure that all plates,

labels, warnings and instructions are secured to the machine.

New plates can be obtained from an authorized Bona dealer.

Preventing Measures for Users (Cont.)

Read this manual carefully and become familiar with

the machine.

The equipment is suitable for industrial use (e.g. in hotels,

schools, hospitals, ofces, factories and shops). The following

information highlights particularly hazardous situations for the

Injury or damage may occur if maintenance operations or

repairs are carried out by any unauthorized personnel.

operator and/or machine. Understand when these conditions

may be present. Removing safety features could cause

death or physical injury. Take all steps necessary to instruct

personnel who may use the machine. Report any damage on

the machine or incorrect operation immediately.

1) Keep hands and clothes away from rotating parts.

2) Keep hands on the handle when the motor is operating.

3) DO NOT leave the machine unattended when the

motor is operating.

4) Always disconnect the power supply cable from the

machine before performing maintenance.

5) Transport the machine with care, due to the heavy

weight of the individual parts making up the machine.

6) Always use the machine in well-ventilated areas.

7) Always keep the work area well-lit.

8) Always dispose of the sanding dust appropriately.

9) DO NOT detach the dust bag when the motor

is operating.

10) Always dispose of the sawdust appropriately.

11) Use the type and amount of abrasive

specied in the instruction manual.

12) The use of accessories other than those

recommended in this manual may cause injury.

13) The machine is for indoor use only.

11EN11

Machine Warnings

Prohibited use

Bona Belt Manual

Children should be

supervised to ensure that

they do not play with the

appliance. This machine

is not intended for use

by persons (including

children) with reduced

physical, sensory or mental

capabilities, or lack of

experience and knowledge

unless they have received

instructions regarding the

use and are supervised by a

person responsible for their

safet y.

This equipment is not

suitable for collecting

hazardous dust.

The Machines Field of Application

The machine is intended for sanding wooden oors, parquet

ooring and cork oors. Either when the oor is newly laid and

untreated or when the oor is used and treated with nishes

or oil. The machine has been developed in accordance with

Using the machine to move objects or moving on an incline may

cause injury or damage. The machine must only be used to sand

dry oors which are level or have a maximum incline of 2%. DO

NOT use the machine to sand furniture. Work surfaces may be

seriously damaged if the machine is left turning on one point while

the tool is in contact with the surface. To avoid damaging the

surface approach the cutting line carefully. DO NOT stop when

lowering and raising the equipment, keep moving at constant

speed.

the latest ndings with respect to ergonomics, safety and

efciency. The machine is thoroughly inspected and tested

before it leaves the factory.

Usage technique

1) Begin sanding by lifting the control handle up at the same

time as the control lever is moved forward/downward.

2) Then roll the machine forward at the same time as the

control handle is lowered to the lowest position, then lower

the sanding drum down to the oor and the sanding has

begun. Sanding can be carried out both when the machine

is moved forward and backward.

3) Lift the control handle slightly each time the sanding

direction is changed, then immediately lower the control

handle again, as soon as the new sanding direction has

begun.

1212

4) Finish the sanding while the machine is in motion by lifting

up the control handle, thus lifting the sanding drum from the

oor.

5) Then move the control lever up/backward to the start

position.

6) Stop the motor by pressing the stop button.

7) Keep the power cable away from the machine’s sanding

area.

The sanding technique must be adapted to suit the floor

type, pattern and the floor's condition.

Starting the Machine

To start the machine proceed as follows:

Bona Belt Manual

1) Become familiar with the machine and read all instructions &

safety notices. Ensure that all operators read this manual.

2) Start/Stop occurs via the I/O switch. Operating mode is

obtained directly after start. If the motor, e.g. if cold, or

when the machine is new, should be difcult to start button

can be held in until the motor has come up into its normal

operating mode.

The motor is equipped with no volt release and overload

protection If the protection has triggered, the motor can start

normally after several minutes.

Always use original cableage, 1-phase 3x2.5 mm²

(ASO9 04014).

NOTE! Never lower the sanding drum before

the motor is up in the correct running mode.

Machine Adjustment Procedures

Regulation Drum pressure

1) Using the control wheel, the drum pressure can be regulated at high,

medium and low in accordance with the following:

Highest position = low drum pressure ~23 kg

Medium position = medium drum pressure ~27 kg

Lowest position = high drum pressure ~32 kg

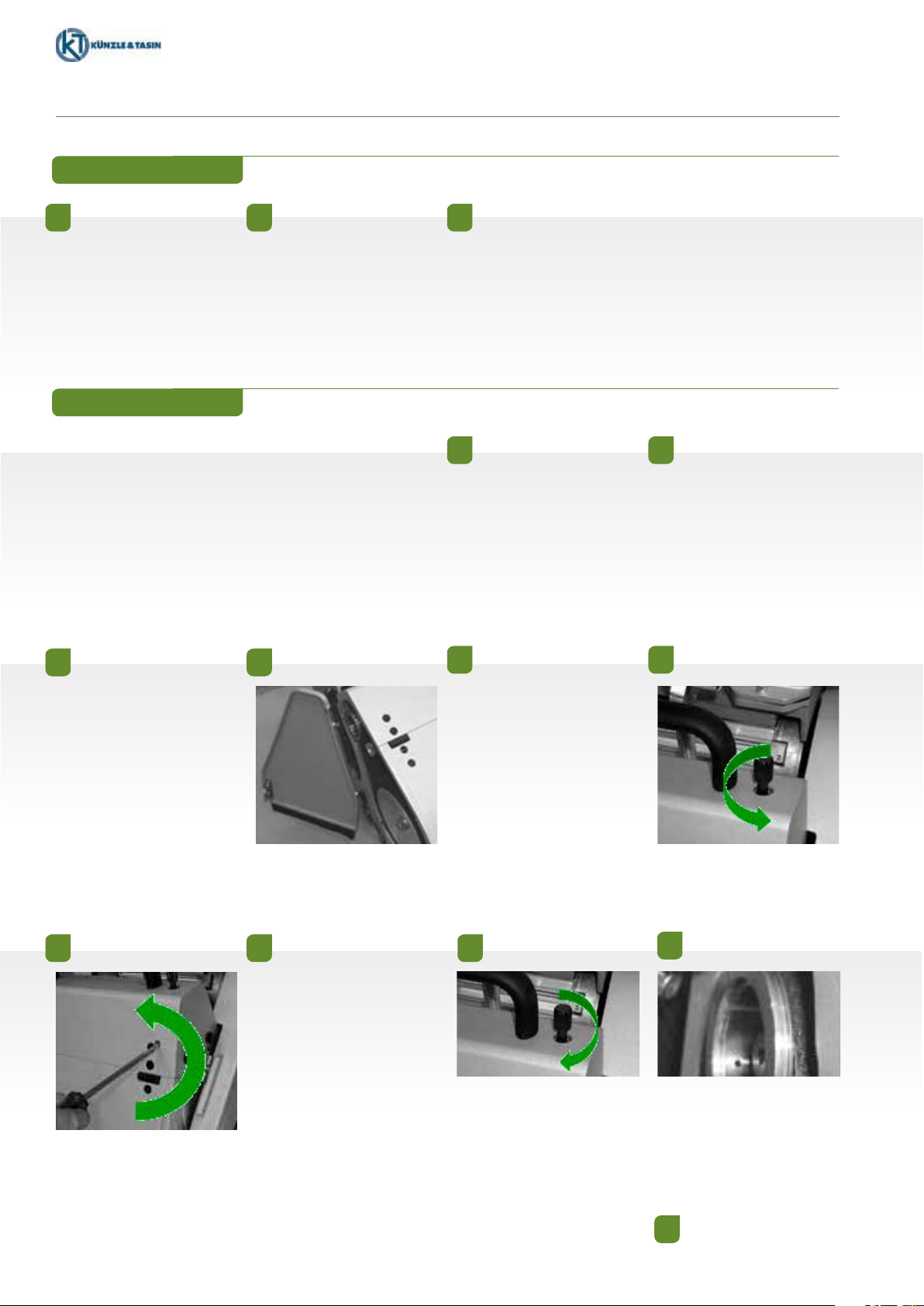

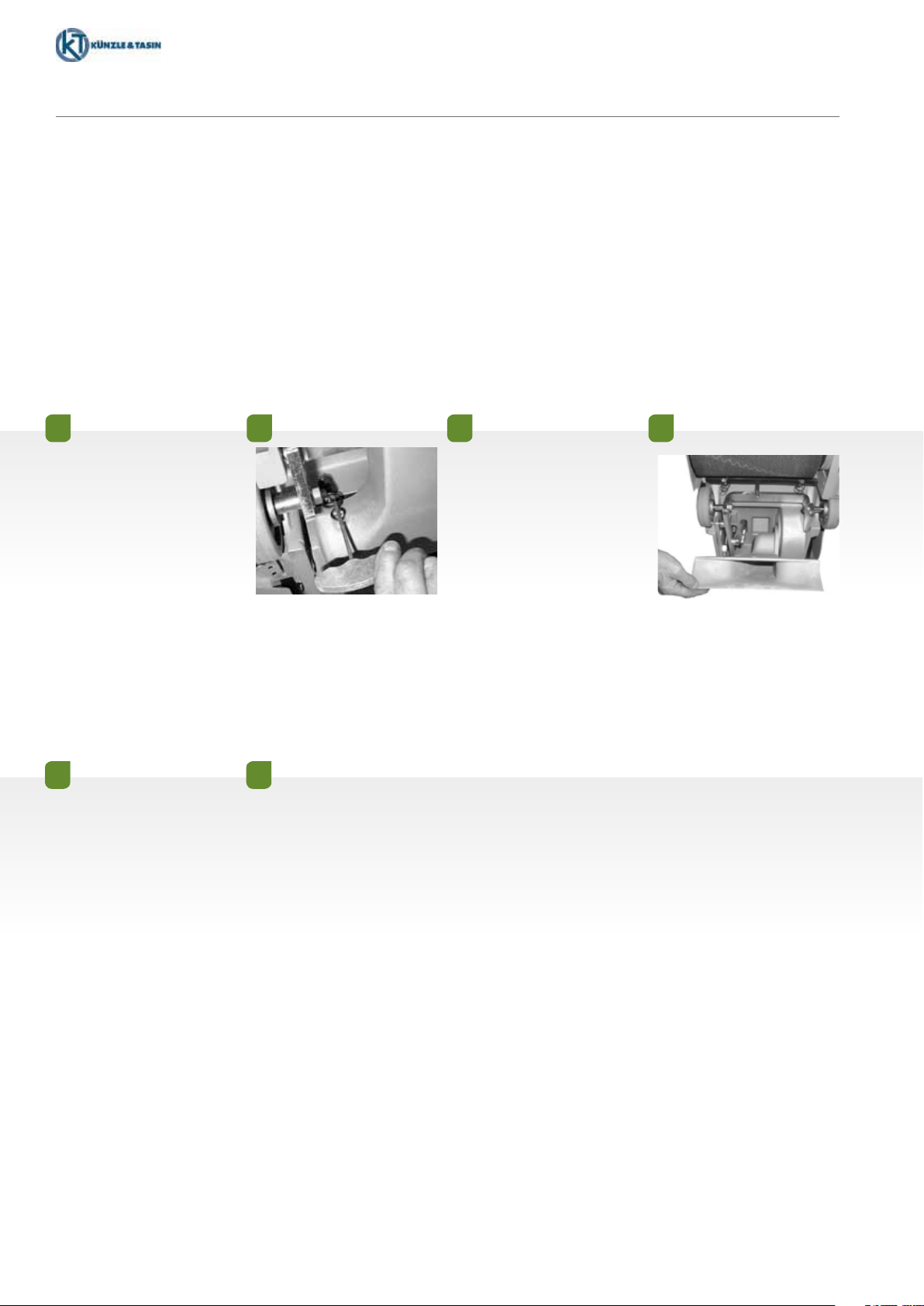

Changing the sanding belt

A sanding belt is mounted upon delivery. When changing to

another belt, do the following:

1.

Remove the power

cable from the motor.

2.

Unlocking the side cover

and open it.

3. 4.

Press the tool directly down

until the mechanism locks in

the bottom position.

Push in the tool until it

reaches the bottom of the

hole on the belt tensioner

arm.

13EN13

Machine Adjustment Procedures (Cont.)

Changing the sanding belt

5. 6. 7.

Bona Belt Manual

Remove the existing belt and

insert the new belt with the

arrow marking in rotation

direction above the sanding

drum and the belt tensioner

respectively.

Adjusting the sanding belt

If the sanding belt does not center, after

adjustment may be necessary:

If the sanding belt still is not centred, then do the following:

1. 2.

Stop the machine

Pull the tool out directly with

a tug the sanding belt will

tighten automatically.

Ensure that the belt is

centered in relation to the belt

tensioner and the sanding

drum.

1. 2.

In order to move the sanding

belt outward toward the

machine’s side hatch, turn

the ne adjustment screw

counter clockwise.

3. 4.

Put on ne sanding paper

(100-120).

The control lever must

always be in the rear

raised position when the

machine starts.

In order to move the sanding

belt inward, turn the ne

adjustment screw clockwise.

5. 6.

Remove the plastic plug

protecting the large adjustment

screw; stick a screwdriver in the

hole in the machine frame.

14

Open the side cover. Stand in

front of the machine.

Start the machine.

7.

Turn the large adjustment

screw counter clockwise

so that the sanding belt

is moved toward to outer

edge control. Then turn an

additional ½ turn.

Turn the ne adjustment

screw counter clockwise until

it stops.

8.

Then adjust using the ne

adjustment screw clockwise

so that the sanding belt only

lies slightly against the outer

edge control.

Replace the plastic plug.

9.

Machine Adjustment Procedures (Cont.)

Setting the drum lever

When correctly set, the sanding drum grinds equally across the drum width. If this is not the case, then

do the following:

Bona Belt Manual

1. 2.

Then turn the domed nut

clockwise and the drum will

grind more on the right side.

Loosen the lock nut on the

threaded rod.

Setting the height of the handle-shaft

The height of the handle shaft can be adjusted:

1. 2.

Push the control lever forward

and down. Pull up the sliding

sleeve.

Loosen the locking wheel.

3. 4.

Turn the domed nut counter

clockwise and the drum will

grind more on the left side.

3. 4.

Fix the new level by screwing

the locking nut into place.

Pull up the handle shaft to

the higher position. Tighten

the Allen screws.

5. 6.

Put the machine backward so

that it rests on the tilt support.

Loosen the nut that holds

the control rod against the

slewing bracket using a

wrench.

Loosen the Allen screws

using a 4 mm Allen wrench.

7.

Thread up the control rod

to the corresponding level,

tighten the nut, put together

the control rods, and tighten

the slewing bracket.

8.

Lift up the control lever.

15EN15

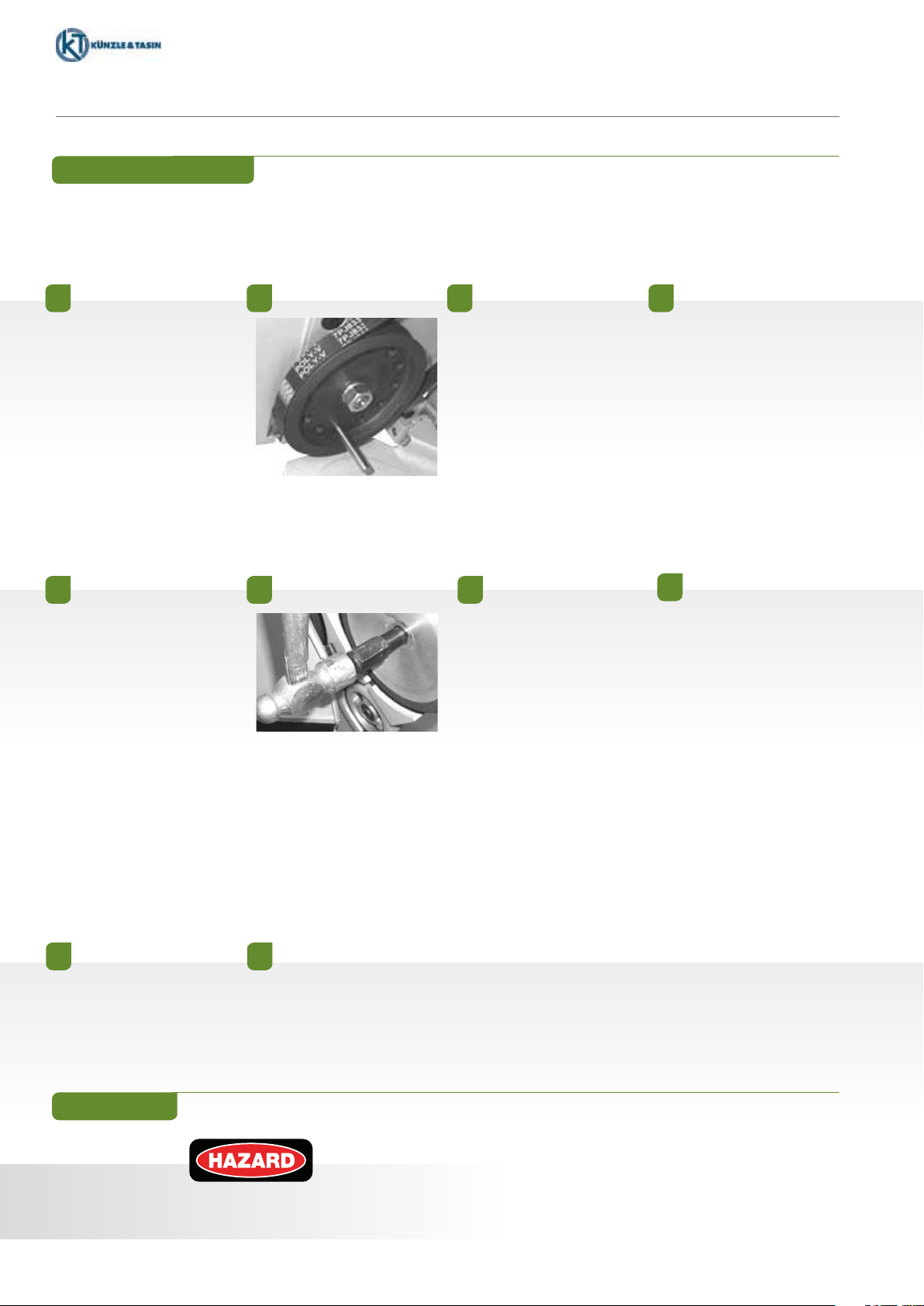

Machine Adjustment Procedures (Cont.)

Changing the sanding drum

If the sanding drum needs to be removed for cleaning or replacement, then do the following:

Bona Belt Manual

1. 2. 3.

Put the machine backward

so that it rests on the tilt

support and handle.

Pull the tool out directly with

a tug the sanding belt will

tighten automatically.

5. 6.

Unscrew the nut and remove

the plate.

Lock the sanding drum by

pushing the steel pin into the

hole in the pulley and into the

corresponding hole in the

machine frame.

7.

Thoroughly clean the drum

axle and the drum cone on

the drum axle before putting

the drum back on again.

4.

Remove the sanding belt.

8.

Turn the drum so that the

wedge shaped groove

passes over the groove on

the axle and push on the

drum.

Screw on the removal tool to

the bottom of the axle. Then

use a plastic club or hammer

directly on the tool, loosen

the tool. The drum will now

loosen from the conical axle

and can be pulled out for

cleaning or replacement.

9. 10.

Thread on the washer and

tighten the nut

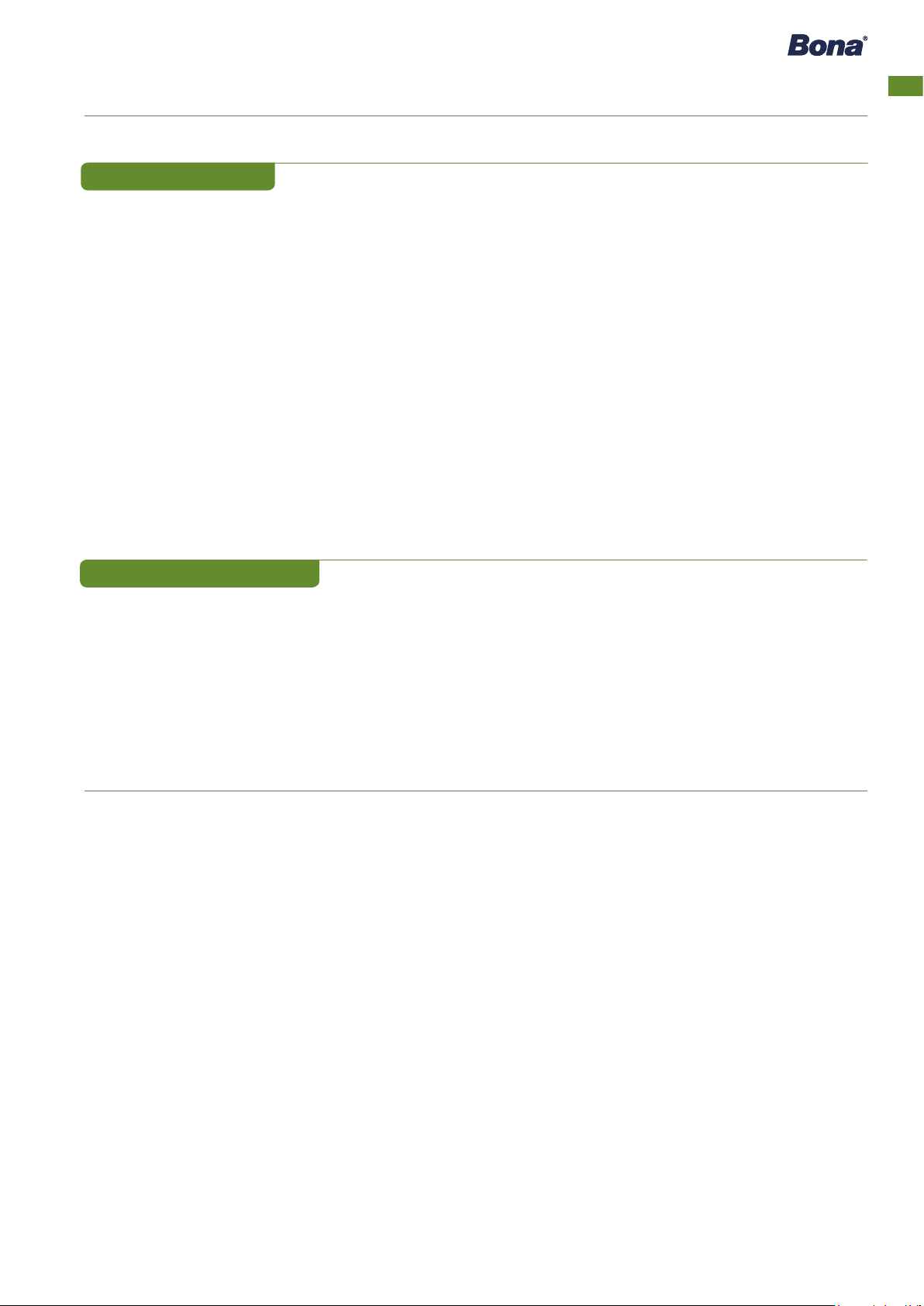

Dust Collection

Once sanding is complete, the dust bag must be emptied and the

contents stored outdoors due to explosion risk and re hazard.

1616

Remove the lock pin from the

sander belt plate and lift up

the belt protector.

For minimal dust discharge Bona's original

dust bags shall always be used. The dust bag

must be emptied when it is filled to max 1/3.

Routine Maintenance

Bona Belt Manual

Before performing any service and maintenance the

power cable must be removed from the wall socket.

The motor is equipped with no volt release and overload

protection If the protection has triggered, the motor can start

normally after several minutes.

Always use original cableage, 1-phase 3x2.5 mm²

(ASO9 04014).

1. 2. 3.

Loosening the eccentric

tightener, lift off the motor

and loosen the M16 screw

nut on the eccentric tightener.

Then turn the entire eccentric

tightener clockwise ½ turn.

Replace the motor and

tighten the eccentric tightener

and check the belt tension.

(Repeat the procedure until

the correct belt tension is

achieved).

17EN17

Routine Maintenance (Cont.)

Bona Belt Manual

Regularly clean the sanding drum, tensioning device, the hole

for the tool and the machine wheel.

The driving belts should be adjusted now and then using the

tensioning screw so that the sanding effect is not reduced.

If the sanding result still is unsatisfactory the belt tensioner

device should be cleaned. Loosen the sanding drum; see the

section “Changing the sanding drum” on pages 16 – 17.

1. 2. 3.

Tilt the machine backward

(see the instructions under

getting started).

Loosen the draw springs with

the draw handle from the

screws that hold the suction

head against the chassis.

Loosen the three bolts that keep the belt tensioner device on

the chassis and the aggregate can easily be removed from the

machine frame.

Check regularly that the suction head is not lled with dust,

varnish/paint, wood remnants, etc. and that the sealing

brushes and whole and function properly.

Do as follows:

4.

Loosen the draw springs ½

turn on the wing nut.

Grab hold of the suction head

and pull it downward so that

it loosens from the control

axle. Clean/scrape clean or

if needed blow the inside of

the suction head clean using

compressed air.

5. 6.

If needed the suction head

can be completely removed

by unscrewing the wing nuts

from the fan housing

.

Remount the suction head in

reverse order after cleaning.

Close the drum cover and

tilt the machine forward(see

the instructions under getting

started).

1818

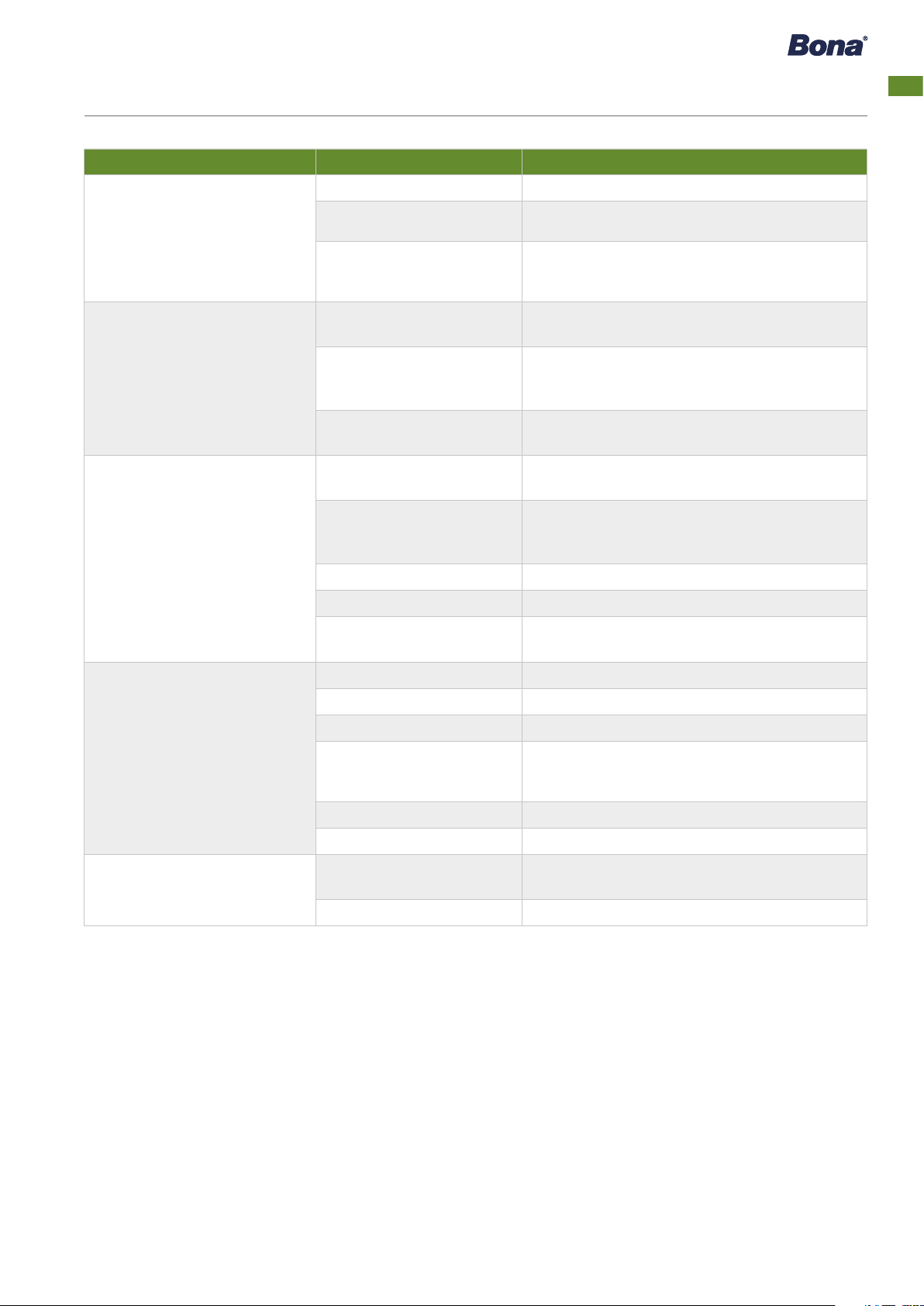

Troubleshooting for the User

PROBLEM CAUSES SOLUTIONS

Voltage too low Check the power supply and fuses

Problem with power supply Check the breaker and condensers

The machine does not start

If the machine has cut off due to

overload protection

Allow the machine to cool for several minutes before

restarting

Bona Belt Manual

The machine tries to start but does not

rev up

The machine vibrates heavily

The machine produces dust

Motor too cold

Voltage too low

The fuse blows

Coating on the sanding drum and

belt tensioner device

The belts moves

Sanding belt damaged Replace the sanding belt

Damaged driving belts Replace the cone belt

Machine blocked by shavings, dust

and grime

Dust bag overlled Empty the dust bag

Dust bag mounted incorrectly Put on the dust bag as the instructions

Dust bag damaged Replace the dust bag

Machine blocked by shavings, dust

and grime

Allow the machine to warm up to room temperature in a

warm room. Give the belts some slack

Check the power cable quality and power cable length.

Avoid using power cables with an inadequate power cable

diameter and power cables that are too long

Give the belts some slack. Ensure that nothing else is on the

same circuit

Clean, scrape away the coating and vacuum

Adjust using the ne adjustment screw and if necessary the

rough adjustment screw. If necessary change the tensioning

device

Clean the machine and suction head

Clean the machine and suction head

Poor sanding results

The fan belt is damaged Replace the fan belt

The sealing brushes are worn Replace the sealing brushes

Sanding drum damaged

Uneven wheel Clean and/or replace the wheel

Check the sanding drum. Clean or if necessary replace the

drum

19EN19

Safety Regulation when using Bona Belt

Bona Belt Manual

Always use the earth fault breaker!

When using electrical machines basic safety regulations

should always be followed in order to reduce the risk of re,

electrical accidents and personal injury. Therefore, read all of

1) For safer use

Keep the work area clean. A messy workplace increases the

risk of accidents.

2) Pay attention to the surroundings

Do not allow the machine to come into contact with water or

moisture. Do not use the machine near ammable uids or gases.

3) Protect against electrical accidents.

Always use the earth fault breaker! Avoid contact with

unearthed objects or surfaces, such as wires, pipes, electric

ovens, refrigerators, etc.

4) Belt/safety belt

Use a belt/safety belt to maintain better control over the machine

at the same time as it provides relief for the back and arms.

5) Protective and drum covers

Never operate the machine without mounted and closed

protective and drum covers.

6) Keep unauthorized persons away from the work site

Do not allow unauthorized persons come into contact with

machines and power cables.

7) Storing the machine

When the machine is not in use it should be stored in a dry area,

preferably in a locked area.

8) Do not overstrain the machine

The machine works best when it is used according to its

capacity and design. Allow the motor to “rest” during periods of

heavier use. The motor will cool better, thus increasing its lifespan.

Use fuses with the correct ampere number in relation to the motor.

9) Use the correct machine

Do not allow a smaller machine or accessories do the work of a

larger machine. Never use a machine for anything other than its

intended use.

the instructions before the machine is used. Then save the

instructions!

by holding the power cable. Do not pull the power cable out

of the machine or the power socket. Protect the power cables

against heat, oil and sharp edges. Keep the power cable away

from the machine’s grinding area.

12) Disconnect the machine when it is not in use

Ensure that the machine does not start unintentionally. Never

carry a connected machine with a hand on the switch. Ensure

that the switch is not on when the machine is connected to the

power socket. Never use the machine if the breaker does not

function as it should.

13) Remove service tools before starting the machine.

Check to ensure no tools are on the machine when starting or

running the machine.

14) Use personal safety equipment

Use a P2 face mask. Use approved ear protection.

15) Inspect the machine regularly

If broken parts are discovered these should be replaced

immediately. If needed, contact the manufacturer or a

manufacturer authorized distributor or service company.

Note! Usage of other accessories than what is recommended

can lead to the risk of personal injury and/or cause damage to

the machine.

16) Keep the machine in good working order

Keep the machine clean for better and safer use. Follow the

given instructions concerning lubrication and replacement of

accessories. Inspect the machine regularly. In the event of

damage, repair or replace the faulty parts. Keep the handle

clean and free from grease.

17) Emptying the dust bag after sanding

After sanding, the dust bag must be emptied completely and

the contents stored safely outdoors and in a safe place due to

re hazard. Explosions may occur in certain concentrations of

sanding dust.

10) Use the correct clothing

Do not wear loosely tting clothing as these can become stuck

in the machine.

11) Be careful with power cables

Always use the correct power cable and the correct power

cable length. (See the accessories list). Never carry the machine

2020

18) Be aware when you work

Use common sense. Never use the machine if you are tired,

have consumed alcohol or if you take medications that can

impair your sight, you judgment or motor control. Due to

sanding dust, smoking is not permitted when sanding.

Service, Maintenance and Spare Parts

Service and Maintenance

Bona Belt Manual

Bona Belt is a high quality machine and is tested by authorized

test staff at the factory before delivery. However, electrical and

mechanical parts wear down and age during long-term use.

In order to keep the machine in a safe and functioning

condition, service must be performed every 250 work hours

or least once a year. This service includes control of wheels,

cable stand, motor, tension device, sanding disc function is

controlled.

Only Bona's original parts may be used because the machine

is considered unique, otherwise safety functions can become

impaired.

Always disconnected the power cable to the machine before

it is cleaned, tools are changed, maintenance is performed or

when worn parts are replaced.

Spare Parts and exploded Views

On the Internet, you will nd a list of spare parts and exploded

views for Bona Belt and other machines in our product range.

Visit http://spareparts.bona.com/

During the factory warranty period, repairs may only be carried

by Bona or staff approved by Bona. Other repairs (after the

When you contact Bona or staff approved by Bona in the

event of a fault or to order spare parts, always specify the type

and serial number of your machine. This information is located

on the data plate of the machine.

The machine may never be cleaned using a high pressure

washer or hose.

All maintenance must be done on neutral machine!

Unplug from the wall outlet. Check cable and connectors

regularly. Always replace a damaged cord (slots, jacks or cable

connections) with a new original cable.

warranty period) of mechanical or electrical parts on the

machine may only be carried out by Bona or staff approved by

Bona who has experience and knowledge concerning safety

regulations.

Warranty

A 24 month factory warranty (from the date of invoice) against

material and manufacturing faults applies to Bona machines

and Bona DCS with accessories manufactured after 01-01-

2008.

Bona pledges to rectify material and manufacturing faults free

of charge provided that the machine, with paid freight, is sent

to us with the relevant warranty claim form describing the fault.

The factory warranty only covers new sales.

We do not undertake any other form of compensation or

liability to damages.

Transport damage or transport costs will not be compensated.

In the event of transport damage it is up to the receiver to

contact the relevant transport company for compensation.

The warranty does NOT cover faults that have occurred via

normal wear, incorrect spare parts, carelessness, incorrect

use, procedures without Bona approval or that the machine is

connected to incorrect current.

THE WARRANTY DOES NOT COVER:

• Consumable materials such as wheels, electric cables,

abrasives, lamps, coal brushes, etc.

• Indirect damage, damage and errors that occur due to

external damage, accidents, poor maintenance, overload,

repairs performed outside of our knowledge and approval, or

damages for another reason outside of our control.

• With the use of parts produced by another company outside

of our control.

• Electrical components with current variations beyond what

has been specied in the manual.

• If payment for the machine is not made according to

agreement

In the event of a warranty claim, the machine or the agreed

part must be returned to us or our dealer for warranty testing

and for potential warranty repair or replacement.

During the factory warranty period, service or repairs may only

be carried out upon approval by a manager at Bona and only

performed by staff at Bona AB or approved staff at Bona AB .

21EN21

Declaration of Conrmity

2006/42 EC, 2014/30 EU, 2011/65 EU, 2012/19 EU

Bona Belt Manual

KUNZLE & TASIN S.r.l.We

Registered Headquarters

Via Circonvallazione Est. 2/6

27023 Cassolnovo (PV) - Italy

Manufacturer and entity authorized to compile and maintain the technical le,

declare that under our sole responsibility the product

WOOD FLOORING SANDER

to which this declaration refers, is compliant with the following Directives:

2006/42 EC (Machinery Directive), 2014/30 EU (EMC Directive), 2011/65 EU (RoHS Directive), 2012/19 EU (WEEE Directive).

Safety of machinery - General principles for design - Risk

assessment and risk reduction - EN ISO 12100

Household and similar electrical appliances - Safety - Part 1:

General requirements - EN IEC 60335-1

Business Management and Production Site

Via Cajkovskij, 14

20092 – Cinisello Balsamo (MI) - Italy

Bona Belt

- Requirements for household appliances, electric tools and

similar apparatus - Part 2: Immunity - EN 55014-2

- Part 3-2: Limits - Limits for harmonic current emissions

(equipment input current ≤ 16 A per phase) - EN IEC 61000-3-2

Household and similar electrical appliances - Safety - Part

2-67: Particular requirements for oor treatment machines,

for commercial use - EN IEC 60335-2-67

Electromagnetic compatibility (EMC):

- Requirements for household appliances, electric tools and

similar apparatus - Part 1: Emission - EN 55014-1

CASSOLNOVO (PV) – 07/07/2014

(The place and date of issue) Michela Caresana - CHIEF EXECUTIVE OFFICER

2222

- Part 3-11: Limits - Limitation of voltage changes, voltage

uctuations and icker in public low-voltage supply systems -

Equipment with rated current ≤ 75 A and subject to conditional

connection - EN IEC 61000-3-11

Disposal

Bona Belt Manual

Smaltimento di apparecchiature da rottamare da parte di privati nell’Unione Europea. Questo simbolo

che appare sul prodotto o sulla confezione indica che il prodotto non deve essere smaltito assieme ad

altri riuti domestici. Gli utenti devono provvedere allo smaltimento delle apparecchiature da rottamare,

portandole al luogo di raccolta indicato per il riciclaggio delle apparecchiature elettriche ed elettroniche.

La raccolta e il riciclaggio separati dalle apparecchiature da rottamare in fase di smaltimento favoriscono

la conservazione delle risorse naturali e garantiscono che tali apparecchiature vengano rottamate

nel rispetto dell’ambiente e della tutela della salute. Per ulteriori informazioni sui punti di raccolta delle

apparecchiature da rottamare, contattare il proprio comune di residenza, il servizio di smaltimento dei

riuti locale o il negozio presso il quale è stato acquistato il prodotto. Specica etichetta ssata sulla

macchina indica che il prodotto comporta requisiti speciali di smaltimento e l’eventuale presenza di una

fonte di alimentazione esterna.

Disposal of Waste Equipment by Users in Private Households in the European Union. This symbol on

the product or packaging indicates that it must not be disposed of with other household waste. It is

your responsibility to dispose of your waste by bringing it to a designated collection point that recycles

electrical and electronic equipment waste. The separate collection and recycling of waste at the time of

disposal helps to conserve natural resources and ensures it is recycled in a manner that safeguards health

and the environment. For more information about where to take waste equipment for recycling, please

contact your local council ofce, household waste disposal service or retailer where you purchased

the product. Specic label attached to the machine indicates that the product has special disposal

requirements and possible presence of a power supply.

Entsorgung von Ausschusselektrogeräten durch Benutzer in privaten Haushalten in der EU. Dieses

Symbol auf dem Produkt oder dessen Verpackung gibt an, dass das Produkt nicht zusammen mit dem

Restmüll entsorgt werden darf. Es obliegt daher Ihrer Verantwortung, das zum Verschrotten bestimmte

Gerät an einer für die Entsorgung oder Wiederverwertung von Elektrogeräten aller Art entsprechenden

Stelle abzugeben. Die separate Sammlung und das Recycling Ihrer zur Entsorgung bestimmten

Elektrogeräte trägt zum Schutz der Umwelt bei und gewährleistet, dass sie auf eine Art und Weise

recycelt werden, die keine Gefährdung für die Gesundheit des Menschen und der Umwelt darstellt.

Für weitere Informationen darüber, wo Sie alte Elektrogeräte zum Recyceln abgeben können, setzen

Sie sich sie mit den örtlichen Behörden, Wertstoffhöfen im Kontakt oder fragen Sie dort, wo Sie das

Gerät erworben haben. ie an der Maschine angebrachte spezische Etikette zeigt an, dass das Produkt

spezielle Entsorgungsvorschriften beachten muss und dass eine externe Stromquelle eventuell vorhanden

ist.

Évacuation des équipements usagés par les utilisateurs dans les foyers privés au sein de l’Union

européenne. La présence de ce symbole sur le produit ou sur son emballage indique que vous ne pouvez

pas vous débarrasser de ce produit de la même façon que vos déchets courants. Au contraire, vous êtes

responsable de l’évacuation de vos équipements usagés et à cet effet, vous êtes tenu de les remettre à

un point de collecte agréé pour le recyclage des équipements électriques et électroniques usagés. Le tri,

l’évacuation et le recyclage séparés de vos équipements usagés permettent de préserver les ressources

naturelles et de s’assurer que ces équipements sont recyclés dans le respect de la santé humaine et

de l’environnement. Pour plus d’informations sur les lieux de collecte des équipements usagés, veuillez

contacter votre mairie, votre service de traitement des déchets ménagers ou le magasin où vous avez

acheté le produit. Étiquette spécique xée à l’arrière du produit, signale qu’il doit être évacué selon une

procédure particulière et la présence d’une alimentation externe.

23EN23

Vorwort

ACHTUNG:

Dieses Handbuch enthält wichtige Informationen zum sicheren

Gebrauch und Betrieb dieser Maschine.

Vor der Benutzung der Maschine ist das gesamte Handbuch

aufmerksam durchzulesen. Diese Maschine ist für den

professionellen oder gewerblichen Gebrauch vorgesehen.

Vor dem Betrieb, der Einstellung oder der Wartung der Maschine

ist dieses Handbuch durchzulesen, um Verletzungen von

Personen oder Schäden an Gegenständen zu vermeiden.

Bona Belt Handbuch

Jeder Bediener sollte vor Inbetriebnahme der Maschine wissen,

wie sie zu bedienen und zu verwenden ist.

Bei Unklarheiten wenden Sie sich bitte an den Fachhändler Ihres

Vertrauens oder direkt an Bona AB. Dieses Handbuch ist für den

späteren Gebrauch aufzubewahren.

Für dieses Handbuch wurde die englische Übersetzung der

italienischen Originalversion ins DEUTSCHE übersetzt.

Für ein neues Handbuch wenden Sie sich bitte an:

Bona AB

Murmansgatan 130

P.O. Box 21074

SE-200 21 Malmö, Suécia

Tel.: +46 40 38 55 00

www.bona.com

24

Inhalt

Technische Daten 26

Maschinensymbole 26

Bedienersicherheit 27

Lagerung 28

Einleitung 29

Sicherer und ordnungsgemäßer Gebrauch 29

Maschinentypenschild 29

Inbetriebnahme 30

Montageanleitung 30

Demontage der Maschine 31

Hinweise zum elektrischen Anschluss 31

Kabel, Verlängerungskabel und Stecker 31

Hinweise zur Entfernung des anfallenden Schleifstaubs 31

Vorsichtsmaßnahmen für Bediener 32

Persönliche Sicherheitsvorkehrungen 32

Einhaltung von Sicherheitsbestimmungen und Warnungen 33

Anleitungen zum korrekten Gebrauch der Maschine 33

Warnhinweise 34

Unzulässige Verwendung 34

Anwendungsbereich der Maschine 34

Verwendung 34

Inbetriebnahme der Maschine 35

Einstellungen an der Maschine 35

Walzendruck regulieren 35

Schleifband wechseln 35

Schleifband einstellen 36

Walzenhebel einstellen 37

Höhe der Handgriffstange einstellen 37

Schleifwalze wechseln 38

Staubentfernung 38

Regelmäßige Wartung 39

Fehlersuche (Bediener) 41

Sicherheitsbestimmungen für die Verwendung der BonaBelt 42

Service, Wartung und Ersatzteile 43

Service und Wartung 43

Ersatzteile 43

Garantie 43

Konformitätserklärung 44

Entsorgung 45

Bona Belt Handbuch

DE

25

Technische Daten

Bona Belt Handbuch

Motortyp: Einphasenmotor

Spannung (±10%): 230 V

Frequenz: 50 Hz

Leistung: 2.2 kW

Nennstrom: 12.9 A

Empfohlene Sicherungen: Klasse C 16 A

Isolationsklasse: F

Schutzklasse: IP54

Drehzahl der Schleifwalze: 1.750 U/min Normallast

Gewicht Maschinenrahmen: 48 kg

Gewicht Motor: 23.5 kg

Kondensatoren: Start 25 µF, Betrieb 50 µF

Walzenbreite: 250 mm, alternativ 200 mm

Stundenzähler: 99.999 Stunden

Gesamtgewicht: 74 kg

Staubemission: <2 mg/m³ Luft

Format Schleifband: 250 mm x 750 mm oder

200 mm x 750 mm

Höhe/Breite/Länge: 1.000 mm/360 mm/960 mm

Maschinensymbole

Vor der Verwendung

der Maschine

dieses Handbuch

mit Gebrauchs- und

Wartungsanweisungen

lesen.

Gehörschutz

verwenden.

Atemschutzmaske

verwenden.

Gefahr durch

elektrischen Strom.

Gefahr durch

bewegliche Teile.

26

Bedienersicherheit

Bona Belt Handbuch

DE

GEFAHR bedeutet:

Dem Bediener oder

anderen Personen drohen

schwere oder sogar tödliche

Verletzungen, wenn die

Warnhinweise auf der

Maschine oder in diesem

Handbuch, die mit GEFAHR

kenntlich gemacht sind,

ignoriert oder missachtet

werden. Alle mit GEFAHR

kenntlich gemachten Hinweise

auf der Maschine und in

diesem Handbuch sind zu

lesen und zu befolgen.

Vor dem Betrieb, der Einstellung oder der Wartung ist das

Handbuch der BonaEdge durchzulesen, um Verletzungen

von Personen oder Schäden an Gegenständen zu

vermeiden.

Jeder Bediener sollte vor Inbetriebnahme der Maschine wissen,

wie sie zu bedienen und zu verwenden ist.

WARNUNG bedeutet:

Dem Bediener oder

anderen Personen drohen

Verletzungen, wenn die

Hinweise auf der Maschine

oder in diesem Handbuch,

die mit WARNUNG kenntlich

gemacht sind, ignoriert oder

missachtet werden. Alle

mit WARNUNG kenntlich

gemachten Hinweise auf

der Maschine und in diesem

Handbuch sind zu lesen und

zu befolgen.

VORSICHT bedeutet:

Dem Bediener oder

anderen Personen drohen

Verletzungen, wenn die

Hinweise auf der Maschine

oder in diesem Handbuch,

die mit VORSICHT kenntlich

gemacht sind, ignoriert oder

missachtet werden. Alle

mit VORSICHT kenntlich

gemachten Hinweise auf

der Maschine und in diesem

Handbuch sind zu lesen und

zu befolgen.

Entammbarkeit zu bestimmen, sind die Herstellerangaben zu

allen verwendeten chemischen Produkten zu lesen. Es ist stets auf

eine gute Belüftung des Arbeitsbereichs zu achten.

Das Überfahren von Nägeln beim Schleifen kann eine Explosion

auslösen oder einen Brand verursachen. Vor dem Abschleifen ist

zu überprüfen, dass alle Nägel versenkt sind.

VON KINDERN FERNHALTEN.

Kinder sind stets zu beaufsichtigen, damit sie nicht mit dem Gerät

spielen. Diese Maschine darf nicht von Personen (einschließlich

Kindern) mit eingeschränkten körperlichen, sensorischen oder

geistigen Fähigkeiten, mangelnder Erfahrung bzw. fehlendem

Wissen benutzt werden, wenn diese keine Einweisung in den

Umgang mit der Maschine erhalten haben und von einer für ihre

Sicherheit verantwortlichen Person beaufsichtigt werden.

Durch das Schleifen kann eine explosionsfähige Atmosphäre

entstehen. Zigaretten, Zigarren, Pfeifen, Feuerzeuge,

Kontrolllampen und alle anderen Zündquellen können Explosionen

verursachen, wenn sie während des Schleifens entzündet werden.

Alle Zündquellen sollten aus dem gesamten Arbeitsbereich entfernt

werden.

In schlecht belüfteten Arbeitsbereichen kann eine explosionsfähige

Atmosphäre entstehen, wenn bestimmte entzündliche Stoffe

(Lösemittel, Verdünner, Alkohol, Treibstoff, einige Lacke, Holzstaub

usw.) in der Luft vorhanden sind. Durch Schleifarbeiten können

sich verschiedene Materialien und Dämpfe entzünden. Um die

Wenn die Stromversorgung häug unterbricht oder nicht

ausreichend dimensioniert ist, besteht Verletzungsgefahr und/

oder Lebensgefahr durch Stromschlag. In diesem Fall sind die

Sicherungen, der Schutzkreis und die Stromversorgung von einem

Elektriker zu überprüfen.

Wenn die Maschine bei Wartungs- und/oder Reparaturarbeiten

nicht vollständig von der Stromversorgung getrennt ist, besteht

Verletzungsgefahr und/oder Lebensgefahr durch Stromschlag. Vor

jeglichen Wartungs- und/oder Reparaturarbeiten ist die Maschine

von der Stromversorgung zu trennen.

Wird die Maschinen in einem ungeerdeten Stromkreis verwendet,

besteht Verletzungsgefahr und/oder Lebensgefahr durch

Stromschlag. Den Schutzleiter niemals trennen oder deaktivieren.

Wenn der Schutzleiter fehlt oder die Vermutung besteht, dass der

Stromkreis nicht ausreichend geerdet ist, bitte an einen Elektriker

wenden.

Wird die Maschine mit einem beschädigten Netzkabel verwendet,

besteht die Gefahr eines Stromschlags. Das Netzkabel ist

regelmäßig auf Bruchstellen und Verschleiß zu untersuchen.

27

Bedienersicherheit (Fortsetzung)

Bona Belt Handbuch

Die Maschine NICHT verwenden, wenn das Netzkabel beschädigt

ist. Die Maschine NICHT durch Ziehen am Netzkabel bewegen.

Das Kabel NIEMALS in geschlossenen Türen einklemmen. Das

Kabel NIEMALS um scharfe Ecken oder Kanten ziehen.

Den Stecker NIEMALS durch Ziehen am Netzkabel aus der

Steckdose entfernen. Zum Ausstecken immer am Stecker ziehen.

NIEMALS mit nassen Händen den Stecker berühren oder die

Maschine bedienen. NIEMALS Gegenstände in Motoröffnungen

einführen.

Es kann zu schweren Verletzungen oder Tod durch Stromschlag

kommen, wenn die Schleifmaschine über das Netzkabel fährt

und dieses beschädigt. Das Kabel ist von der Schleifmaschine

fernzuhalten. Das Netzkabel immer oberhalb der Maschine

entlangführen und vom Kabel weg schleifen.

Bei Wartungsarbeiten oder beim Auswechseln des Staubsacks

besteht Verletzungsgefahr für den Bediener und andere

Personen in der Nähe, wenn die Maschine nicht vollständig

von der Stromversorgung getrennt ist. Bei Nichtgebrauch der

Maschine stets den Netzstecker ziehen.

NIEMALS Lösemittel oder andere entzündliche Produkte zur

Reinigung dieser Maschine verwenden.

Nur für Trockenarbeiten zu verwenden. NIEMALS zum Aufsaugen

von Flüssigkeiten verwenden, da dies zu Motorversagen oder

Stromschlag führen kann.

Bewegliche Teile der Maschine können schwere Verletzungen und/

oder Sachschäden verursachen. Hände, Füße und lose Kleidung

sind von allen beweglichen Teilen der Maschine fernzuhalten.

Die Verwendung der Maschine ohne Schutzvorrichtungen, Türen

und Abdeckungen kann zu Verletzungen oder Sachschäden

führen.

NIEMALS mit der Maschine in die Nähe von heißen, brennenden

oder rauchenden Gegenständen, wie Zigaretten, Streichhölzer

oder Asche, kommen.

Keine Ablenkung während der

Schleifarbeiten zulassen und beim Arbeiten stets

aufmerksam sein. Immer

verantwortungsbewusst handeln. Die

Maschine NICHT bei

Müdigkeit oder unter

Einuss von Alkohol oder

Medikamenten verwenden,

die zu einer Beeinträchtigung

der Urteilsfähigkeit oder der

Körperbeherrschung führen

könnten.

Während des Schleifens

NICHT rauchen.

Die Maschine NICHT zum

Schleifen von Treppenstufen

oder Möbeln verwenden.

NICHT auf der Maschine

mitfahren.

NIEMALS Gegenstände

in Maschinenöffnungen

einführen. NIEMALS

verwenden, wenn die

Öffnungen blockiert sind.

Staub, Fusseln, Haare

oder andere Dinge, die den

Luftstrom beeinträchtigen

könnten, entfernen.

Lagerung

Es wird empfohlen, die Maschine in der Originalverpackung

zu lagern. Auf diese Weise können maximal zwei Pakete

übereinander gestapelt werden.

Wird die Maschine aus der Originalverpackung entnommen

und für einen längeren Zeitraum nicht verwendet, ist darauf zu

achten, dass die Räder und die Walze keinen Bodenkontakt

haben.

28

Diese Maschine darf nur für Trockenarbeiten eingesetzt

werden und darf nicht im Außenbereich oder bei feuchten

Umgebungsbedingungen verwendet oder gelagert werden.

Die Maschine ist in einem trockenen Raum aufzubewahren.

Andernfalls könnte sie Schäden davontragen.

Lagertemperatur zwischen -20 °C und 50 °C.

Temperatura de armazenamento de -20 °C a 50 °C.

Einleitung

Sicherer und ordnungsgemäßer Gebrauch

Bona Belt Handbuch

DE

Vor der erstmaligen Verwendung der BonaBelt

Schleifmaschine für Holzböden ist das Handbuch

aufmerksam zu lesen.

Das Handbuch enthält wichtige Hinweise zur Sicherheit

und zum sachgemäßen Gebrauch der Maschine und wird

Unsicherheiten oder Fragen klären, damit die Maschine

sicher und problemlos bedient werden kann. Die Entfernung

von Sicherheitsvorrichtungen kann zu Verletzungen oder

zum Tod führen. Machen Sie sich vor dem ersten Einsatz der

Maschine eingehend mit deren Funktionen vertraut.

Maschinentypenschild

Folgende Informationen sind auf dem Typenschild

der Maschine zu finden:

Die Bona Belt Schleifmaschine ist für das Trockenschleifen

von Holzböden geeignet. Jede andere Verwendung ohne

Zustimmung des Herstellers ist verboten. NICHT auf nassen

Böden verwenden.

Siehe „Warnhinweise“ auf Seite 34.

Hände und Kleidung von den beweglichen Teilen fernhalten.

Der Arbeitsbereich ist durch das Grundgestell und die

abnehmbare Abdeckung an der Schleifwalze geschützt.

Sollte sich eine Situation ergeben, die in diesem

Handbuch nicht beschrieben ist, kontaktieren Sie bitte

Ihren Vertriebspartner oder einen Vertreter von Bona.

1) Name des Herstellers

2) Maschinenmodell

3) Baujahr (siehe 7)

4) Motorleistung

5) Versorgungsspannung und Frequenz

6) Nennstrom

7) Seriennummer:

• Die ersten beiden Ziffern geben das Baujahr an

(14 = 2014)

• Die zweite Gruppe, bestehend aus drei Ziffern,

gibt den Tag der Herstellung an (127 = 7. Mai)

• die letzten beiden Ziffern entsprechen der

laufenden Nummer der an diesem Tag

hergestellten Maschinen (13 = die 13. Maschine,

die an diesem Tag gefertigt wurde)

29

Inbetriebnahme

Montageanleitung

Zusammenbau einer neuen Maschine

Bona Belt Handbuch

1.

Die Handgriffstange in den Schafthalter drücken.

4.

2.

Den Verriegelungsknauf drehen

und festziehen.

5.

3.

Den oberen und unteren Führungsstab zusammenbringen und die

Schiebehülse über den unteren

Führungsstab ziehen.

6.

Dann einen Staubsack am Staubrohr

anbringen.

Den Bedienhebel bis ganz nach oben

ziehen.

Wenn die Maschine vor dem Transport zerlegt wurde, muss der Motor wie folgt montiert werden:

1) Den Motor am Tragegriff fassen. Den Motor in den

Maschinenrahmen einsetzen und das Gelenk in der hinteren

Halterung befestigen.

2) Den Antriebsriemen mit dem Exzenterspanner aufziehen und

spannen. Den Riemenschutz anheben. Das Staubrohr mit

dem Staubsack in die Rohraufnahme stecken.

Das Staubrohr in die Rohraufnahme

stecken.

Eine zu hohe Riemenspannung kann zum vorzeitigen

Versagen der Kugellager führen.

Die Benutzung der nicht vollständig zusammengebauten Maschine

kann zu Verletzungen und Sachschäden führen. Die Maschine NICHT

verwenden, wenn sie nicht vollständig zusammengebaut ist. Alle

Verschraubungen sind anzuziehen. Die Maschineneinstellungen

müssen den Spezikationen entsprechen.

30

Loading...

Loading...