Page 1

User Manual

KUNBUS-COM EtherCat

PR100033 • 16/09/2015

Page 2

Table of Contents KUNBUS GmbH

ii KUNBUS-COM EtherCAT

Table of Contents

1 General information ........................................................................................................................4

1.1 Disclaimer..................................................................................................................................4

1.2 Notes regarding this user manual..............................................................................................4

1.3 Validity.......................................................................................................................................5

1.4 Limitation of Liability ..................................................................................................................5

1.5 Customer Service......................................................................................................................5

2 Safety Guidelines ............................................................................................................................6

2.1 User...........................................................................................................................................6

2.2 Symbols.....................................................................................................................................6

2.3 General Safety Guidelines.........................................................................................................7

2.4 Environmental Conditions..........................................................................................................7

3 Overview ..........................................................................................................................................8

3.1 Introduction................................................................................................................................8

3.2 Spacer bolt ................................................................................................................................9

3.3 Application Interface................................................................................................................11

3.4 Fieldbus Connection Socket....................................................................................................15

3.5 Status LEDs.............................................................................................................................16

4 Components ..................................................................................................................................18

4.1 Module Components ...............................................................................................................18

4.2 Storage Unit.............................................................................................................................19

4.3 Data Broker .............................................................................................................................20

4.4 Fieldbus Interface....................................................................................................................28

4.5 CDI - Configuration and Debug Interface................................................................................28

4.6 DPR - Dual Port RAM..............................................................................................................29

4.7 SDI - Serial Data Interface.......................................................................................................31

4.8 Synchronous serial interface ...................................................................................................32

4.9 Scripter ....................................................................................................................................44

5 Commissioning .............................................................................................................................45

5.1 Installation ...............................................................................................................................45

5.2 Configuration ...........................................................................................................................46

5.3 Firmware Update.....................................................................................................................46

6 Memory Register ...........................................................................................................................47

6.1 Overview of the Memory Register ...........................................................................................47

6.2 General Device Parameters ....................................................................................................50

6.3 Register for the Mapping .........................................................................................................75

6.4 Memory of the Communication Channels ...............................................................................78

6.5 Fieldbus specific Registers......................................................................................................81

6.6 Reserve Register.....................................................................................................................89

Page 3

KUNBUS GmbH Table of Contents

KUNBUS-COM EtherCAT iii

7 Communication model .................................................................................................................90

7.1 EtherCAT Object Directory......................................................................................................90

8 CDI .................................................................................................................................................93

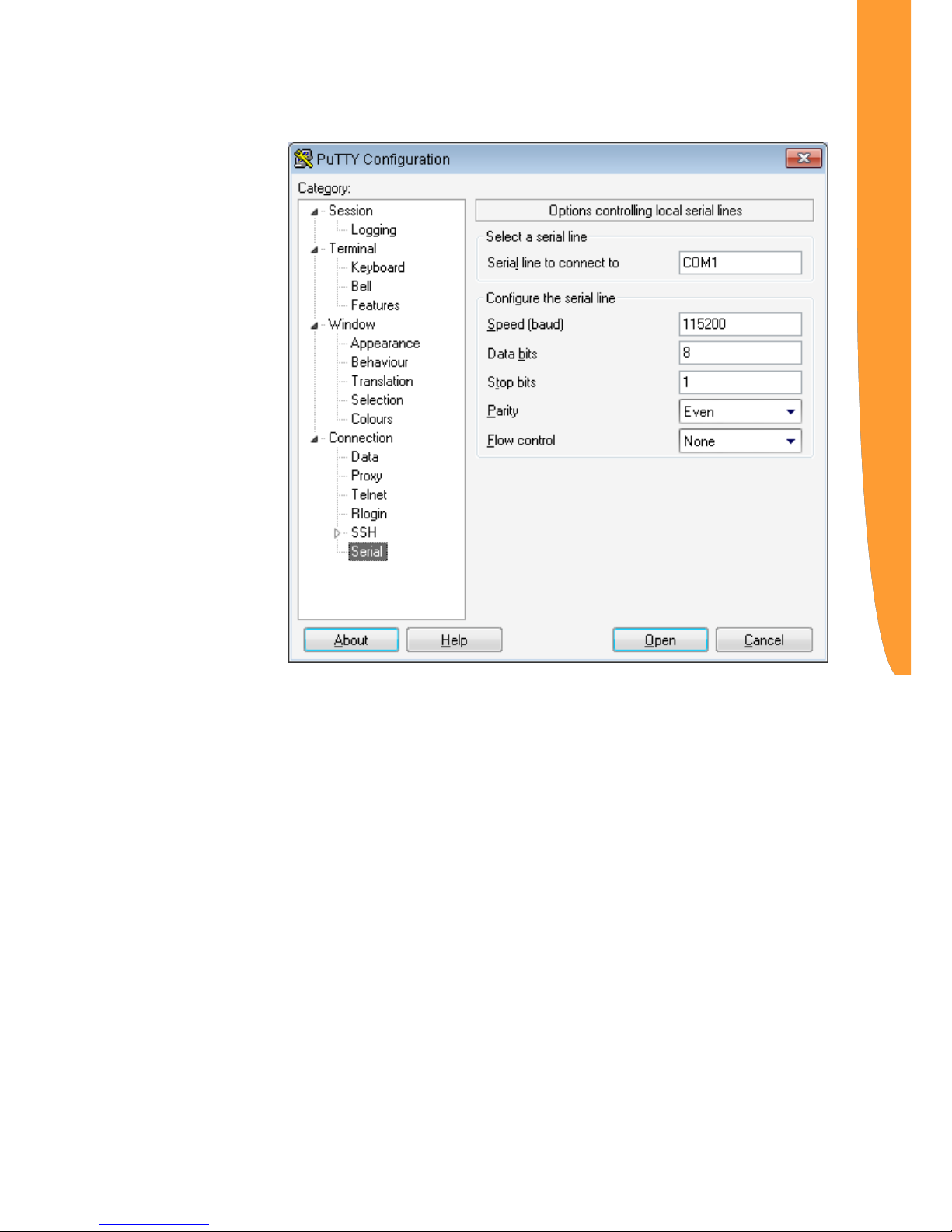

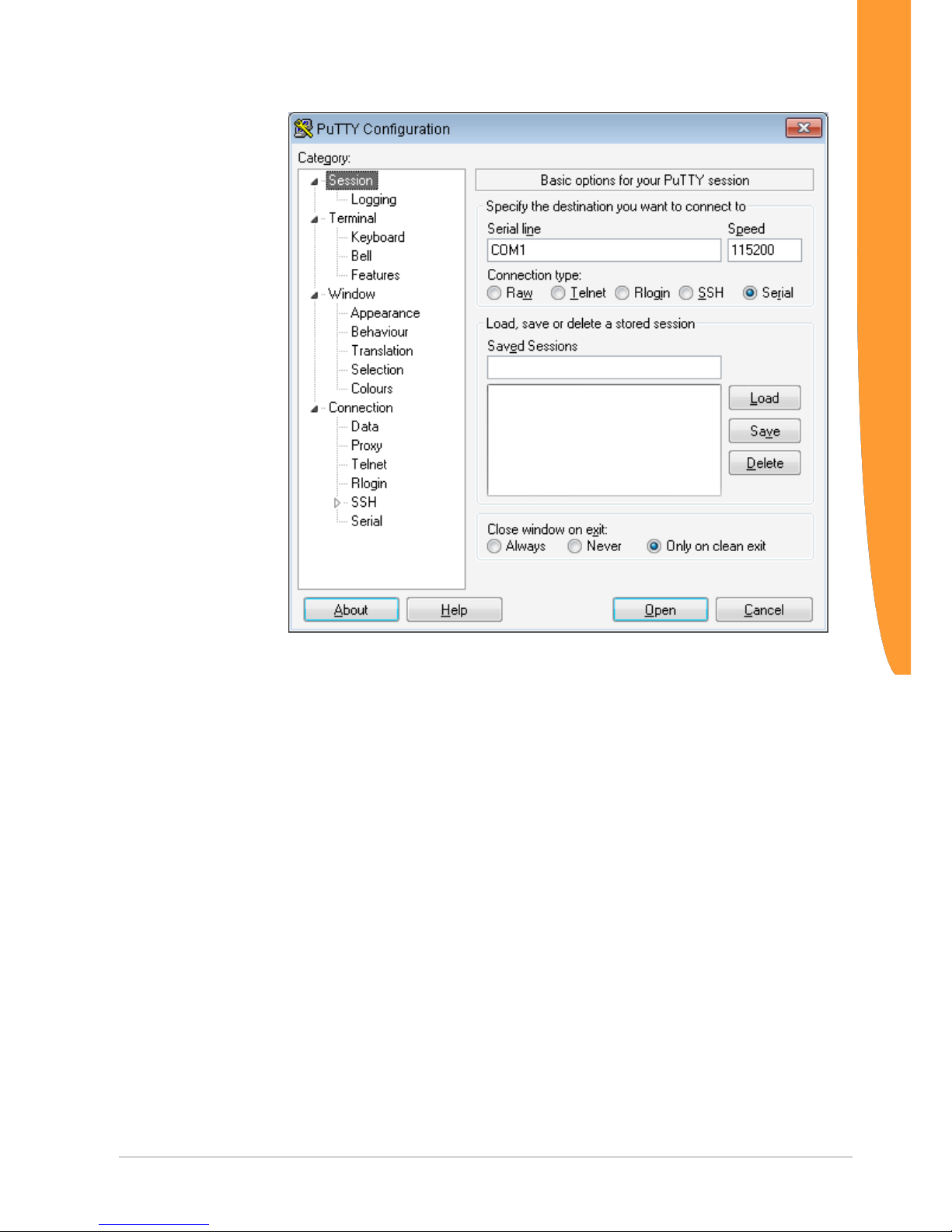

8.1 Setting up a Serial Connection................................................................................................93

8.2 CDI Menus...............................................................................................................................96

9 Disposal .......................................................................................................................................132

9.1 Dismantling and Disposal......................................................................................................132

10 Technical data .............................................................................................................................133

10.1Technical data .......................................................................................................................133

11 Appendix ......................................................................................................................................134

11.1Configuration via Modpoll ......................................................................................................134

Page 4

KUNBUS-COM EtherCAT

4 / 135

1 General information

1.1 Disclaimer

© 2015 KUNBUS GmbH, Denkendorf (Deutschland)

The contents of this user manual have been prepared by the

KUNBUS GmbH with the utmost care. Due to the technical

development, the KUNBUS GmbH reserves the right to change or

replace the contents of this user manual without prior notice. You can

always obtain the latest version of the user manual at our homepage:

www.kunbus.de

The KUNBUS GmbH shall be liable exclusively to the extent

specified in General Terms and Conditions (www.kunbus.de/

agb.html).

The contents published in this user manual are protected by

copyright. Any reproduction or use for the in-house requirements of

the user is permitted. Reproduction or use for other purposes are not

permitted without the express, written consent of the KUNBUS

GmbH. Contraventions shall result in compensation for damages.

Trademark protection

– KUNBUS is a registered trademark of the KUNBUS GmbH

– Windows® and Microsoft® are registered trademarks of the Microsoft,

Corp.

– Modbus is a registered trademark of the Modbus-IDA Organization.

KUNBUS GmbH

Heerweg 15 c

73770 Denkendorf

Deutschland

www.kunbus.de

1.2 Notes regarding this user manual

This user manual provides important technical information that can

enable you, as a user, to efficient, safe and convenient integration of

the COMS-Module into your applications and systems. It is intended

for trained, qualified personnel, whose sound knowledge in the field

of electronic circuits and expertise of EtherCATTM is assumed.

As an integral part of the module, the information provided here

should be kept and made available to the user.

General information

Page 5

KUNBUS-COM EtherCAT 5 / 135

1.3 Validity

This document describes the application of the KUNBUS COMSModuls with the product number:

– PR100033, Release 02

1.4 Limitation of Liability

Warranty and liability claims will lapse if:

– the product has been used incorrectly,

– damage is due to non-observance of the operating manual,

– damage is caused by inadequately qualified personnel,

– damage is caused by technical modification to the product (e.g.

soldering).

1.5 Customer Service

If you have any questions or suggestions concerning this product,

please do not hesitate to contact us:

KUNBUS GmbH

Heerweg 15 C

+49 (0)711 3409 7077

support@kunbus.de

www.kunbus.de

General information

Page 6

KUNBUS-COM EtherCAT

6 / 135

2 Safety Guidelines

2.1 User

The Modul may only be assembled, installed and put into operation

by trained, qualified personnel. Before assembly, it is absolutely

essential that this documentation has been read carefully and

understood. Expertise in the following fields is assumed:

– Electronic circuits,

– Basic knowledge of EtherCAT,

– work in electrostatic protected areas,

– Locally applicable rules and regulations for occupational safety.

2.2 Symbols

The symbols used have the following meaning:

DANGER

Hazard

Observe this information without fail!

There is a safety hazard that can lead to serious injuries and death.

CAUTION

Caution

There is a safety hazard that can result in minor injuries and material

damage.

NOTICE

Note

Here you will find important information without a safety hazard.

Safety Guidelines

Page 7

KUNBUS-COM EtherCAT 7 / 135

2.3 General Safety Guidelines

DANGER

Danger of electric shock

If unsuitable power supply is used, this can cause an electric shock.

Ø This can cause death, serious injuries and material damage to your

systems and modules.

èOnly use a power supply that complies with the regulations for safety

extra-low voltage (SELV) or protective extra-low voltage (PELV).

CAUTION

Fault due to mechanical load

A continuous mechanical load of over 5G or shock loads of over 15G can

cause faults on your modules.

èComply with these load limits and avoid any unnecessary loads.

CAUTION

Fault due to missing or unsuitable spacer bolt

Incorrect or missing spacer bolts can result in high mechanical loads on

your module and control board. This can cause faults.

èAlways use spacer bolts suitable for the connector height of the circuit

board so that the module does not lie on the circuit board.

You can find detailed information in section "Spacer bolt [}9]"

CAUTION

Damage due to subsequent processing

Avoid subsequent processing of theCOMS-Modul.

Ø Soldering can cause components to become detached and thus

damage or destroy the module.

Ø Please note that the warranty shall become invalid if the products are

changed technically.

èSpeak to your contact person at the KUNBUS GmbH about customised

solutions.

2.4 Environmental Conditions

Operate the COMS-Modul only in an environment that complies with

the operating conditions in order to prevent any damage.

Suitable Environmental Conditions:

Operating temperature 0 to +60°C

Humidity 0% not 95%, non-condensing

Safety Guidelines

Page 8

KUNBUS-COM EtherCAT

8 / 135

3 Overview

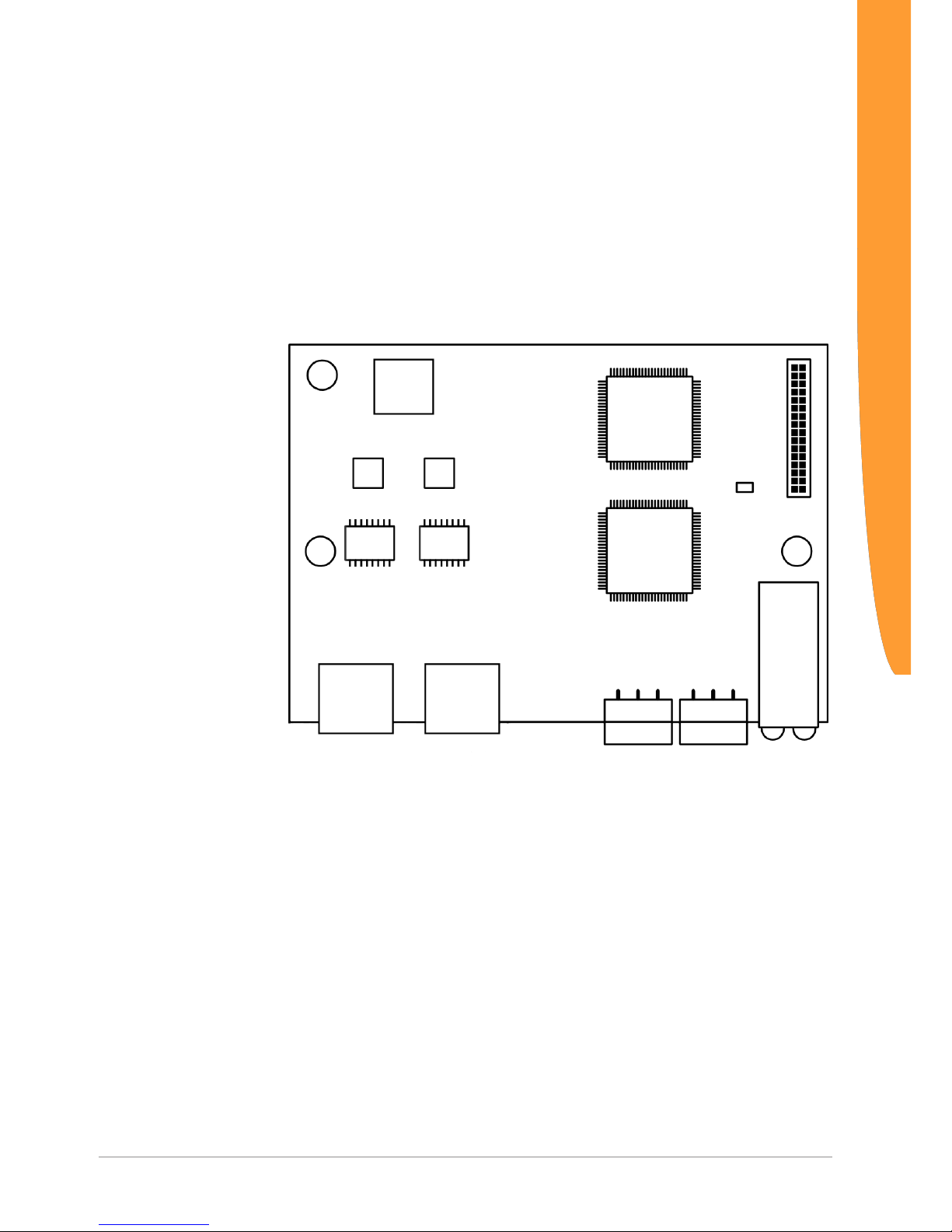

3.1 Introduction

With the KUNBUS COMS-Modul you can make a sensor or actuator

fieldbus-capable. To do this, simply insert the module into your

application and connect it to the fieldbus.

The COMS-Modul thereby saves you time-consuming in-house

developments.

Illustration1: Overall view

Overview

Page 9

KUNBUS-COM EtherCAT 9 / 135

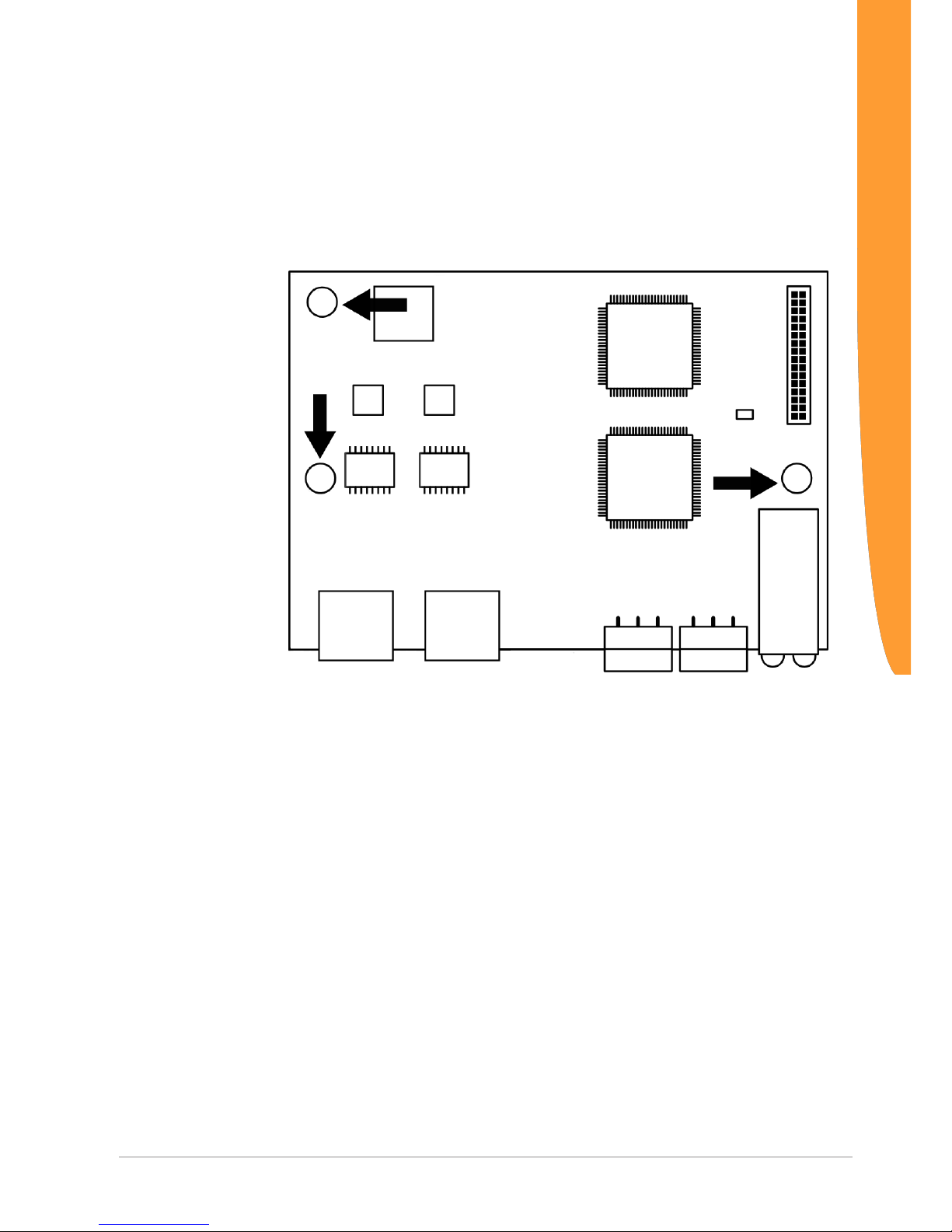

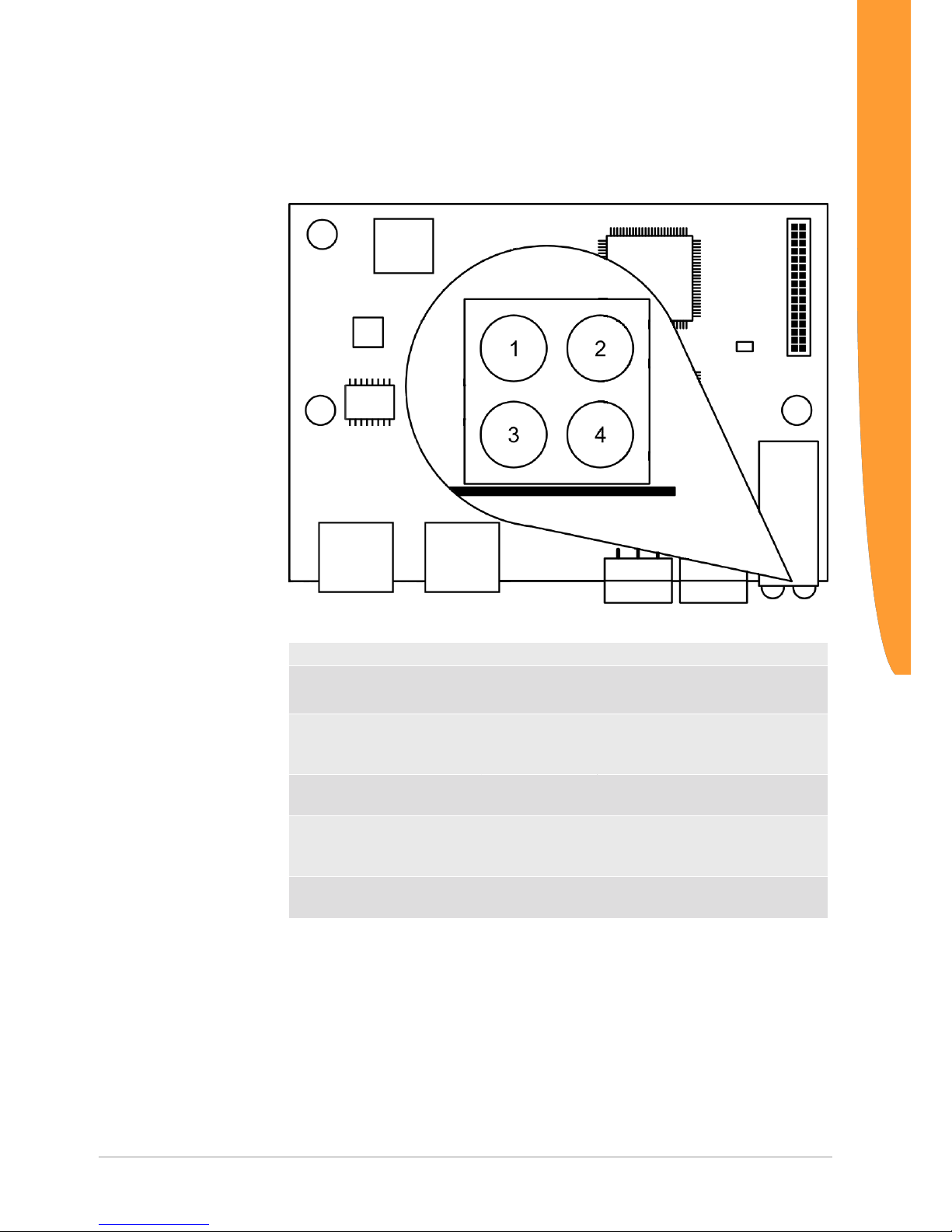

3.2 Spacer bolt

There are three holes on the module for spacer bolts. These spacer

bolts have 2 tasks:

– they stabilise the COMS module with a direct connection to the main

board

– they are part of the earthing concept.

Illustration2: Holes for spacer bolts

Suitable spacer bolts

Suitable spacer bolts have the following properties:

– Conductive material

– Holes for M3 screws

– Diameter: maximum 8mm

Connections

These spacer bolts are an important part of the earthing concept of

the COMS-Modul.

– Connect hole 1 to protective earth on the fieldbus side

– Hole 2 is not electrically connected.

– Connect the spacer bolts of hole 3 to GND (earth power supply)

Overview

Page 10

KUNBUS-COM EtherCAT

10 / 135

Height of spacer bolts

The height of the spacer bolts depends on the height of the plug

connector used on the application side.

We recommend using the ERNI 254589 plug connector. The spacer

height for this plug connection is 10.75 to 12.3 mm above the circuit

board.

WARNING

Fault due to missing or unsuitable spacer bolt

Incorrect or missing spacer bolts can result in high mechanical loads on

your module and control board. This can cause faults.

èAlways use spacer bolts suitable for the connector height of the circuit

board so that the module does not lie on the circuit board.

Overview

Page 11

KUNBUS-COM EtherCAT 11 / 135

3.3 Application Interface

The main board is connected to the device controller via a 32-pin

connector strip. You have the option to plug the module in directly.

CAUTION

Mechanical loads can lead to faults on the module

èUse suitable spacer bolts to prevent mechanical loads. (e.g.

Ord.No.9774110360 from Würth Elektronik).

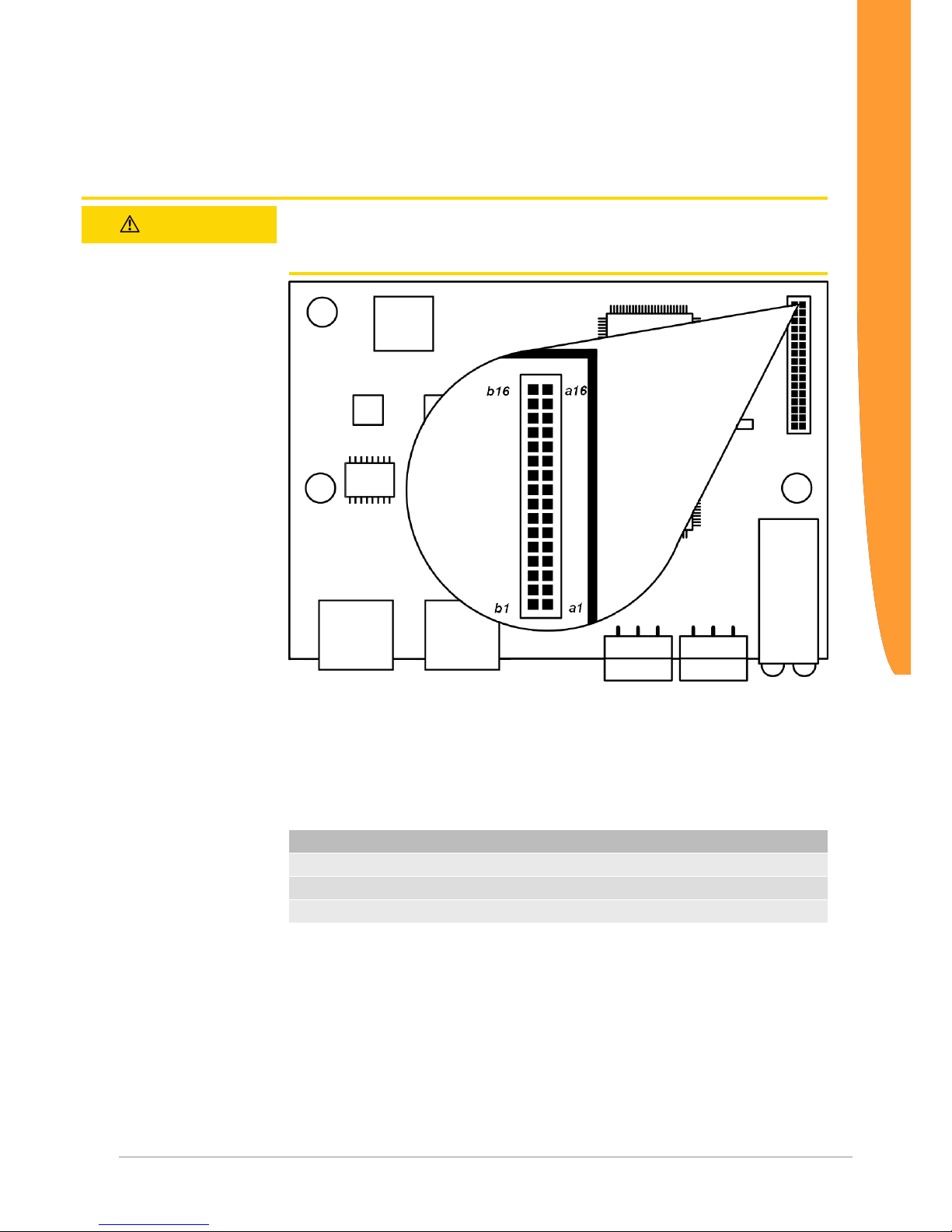

Illustration3: Application Interface

Pin assignment on the

application interface

The module can be operated in serial or parallel mode. In serial

mode you can choose whether you want to use the module as

master or slave.

You can activate the modes via logical levels:

Mode Switchover level

Serial slave mode "a14": +3.3V, "a6" +3.3V

Serial master mode "a14": +3.3V, "a6": 0V

Parallel mode "a"14" GND

You can change over the operating mode via pin a14.

Overview

Page 12

KUNBUS-COM EtherCAT

12 / 135

Slave Mode ("a14": +3.3V, "a6" +3.3V)

Pin Designation Direction Comment

a1 CDI.TX [OUT] Send CDI

a2 receive CDI.RX [IN] CDI

a3 GND Supply

a4 SPI.SCK [IN] SPI Clock

a5 SPI.MOSI [IN] SPI Data In

a6 SPI.MODE.DIR [IN] SPI Mode

1 = Slave

a7 SPI.MID [IN] SPI Middle

a8 UART.TX [OUT] Send SDI

a9 UART.TE [OUT] SDI 1 = transmitter activ-

ated

for RS485 operation

a10-a13 Reserved Do not connect!

a14 MODE [IN] Mode-Select

1 = Serial Mode

a15 RESET [IN] Module-Reset ( low-active )

a16 GND Supply

b1-b2 Reserved Do not connect!

b3 GND Supply

b4 SPI.MISO [OUT] SPI Data Out

b5 SPI.CS [IN] SPI Chip-Select

b6 SPI.READY [OUT] SPI Ready

b7 SPI.RESET [OUT] Reset signal for the SSC

b8 UART.RX [IN] Receive SDI

b9-b15 Reserved Do not connect!

b16 +3V3 Supply

Overview

Page 13

KUNBUS-COM EtherCAT 13 / 135

SSC Master ("a14": +3.3V "a6": 0V)

Pin Designation Direction Comment

a1 CDI.TX [OUT] Send CDI

a2 receive CDI.RX [IN] CDI

a3 GND Supply a4 SPI.SCK [OUT] SPI Clock

a5 SPI.MOSI [OUT] SPI Data Out

a6 SPI.MODE.DIR [IN] SPI Mode

0 = Master

a7 SPI.MID [IN] SPI Middle

a8 UART.TX [OUT] Send SDI

a9 UART.TE [OUT] SDI 1 = transmitter activ-

ated

for RS485 operation

a10-a13 Reserved Do not connect!

a14 MODE [IN] Mode-Select

1 = Serial Mode

a15 RESET [IN] Module-Reset ( low-active )

a16 GND Supply

b1-b2 Reserved Do not connect!

b3 GND Supply b4 SPI.MISO [IN] SPI Data In

b5 Reserved Do not connect!

b6 SPI.LOAD [OUT] Load signal for the SSC

b7 SPI.RESET [OUT] Reset signal for the SSC

b8 UART.RX [IN] Receive SDI

b9-b15 Reserved Do not connect!

b16 +3V3 Supply

Overview

Page 14

KUNBUS-COM EtherCAT

14 / 135

Parallel Operating Mode ("a"14" GND)

Pin Designation Direction Comment

a1 CDI.TX [OUT] Send CDI

a2 receive CDI.RX [IN] CDI

a3 GND Supply

a4 ADDR0 [IN] Address-Bit 0

a5 ADDR1 [IN] Address-Bit 1

a6 ADDR2 [IN] Address-Bit 2

a7 ADDR3 [IN] Address-Bit 3

a8 ADDR4 [IN] Address-Bit 4

a9 ADDR5 [IN] Address-Bit 5

a10 ADDR6 [IN] Address-Bit 6

a11 ADDR7 [IN] Address-Bit 7

a12 ADDR8 [IN] Address-Bit 8

a13 ADDR9 [IN] Address-Bit 9

a14 MODE [IN] Mode-Select

0 = Parallel Mode

a15 RESET [IN] Module-Reset ( low-active )

a16 GND Supply

b1-b2 Reserved Do not connect!

b3 GND Supply

b4 DATA0 [IN/OUT] Databus-Bit 0

b5 DATA1 [IN/OUT] Databus-Bit 1

b6 DATA2 [IN/OUT] Databus-Bit 2

b7 DATA3 [IN/OUT] Databus-Bit 3

b8 DATA4 [IN/OUT] Databus-Bit 4

b9 DATA5 [IN/OUT] Databus-Bit 5

b10 DATA6 [IN/OUT] Databus-Bit 6

b11 DATA7 [IN/OUT] Databus-Bit 7

b12 CS_B [IN] Chip-Select

(low-active)

b13 WR_B [IN] Write-Enable

(low-active)

b14 RD_B [IN] Read-Enable

(low-active)

b15 Reserved Do not connect!

b16 +3.3V Supply

Overview

Page 15

KUNBUS-COM EtherCAT 15 / 135

3.4 Fieldbus Connection Socket

The module has a two Ethernet sockets for connecting to the

fieldbus.

Illustration4: Fieldbus Connection Socket

Pin assignment forEtherCAT

Pin Assignment

1 TX+

2 TX3 RX+

4 Not assigned.

Pin 4 and 5 are interconnected and

laid via a filter on PE for better EMC

response.

5

6 RX7 Not assigned.

Pin 4 and 5 are interconnected and

laid via a filter on PE for better EMC

response.

8

Overview

Page 16

KUNBUS-COM EtherCAT

16 / 135

3.5 Status LEDs

The COMS-Module are fitted with LEDs for status indication.

Lightpipes guide the LED signals to the side.

Illustration5: Status LEDs

No. LED Status Meaning Note

1 Module Error

(red)

Off No error has

occurred

Flashing

Configuration

error

At least one system component

does not function due to a configuration error.

On Internal system

error

A fatal, internal error has occurred.

Flashing

Start-up phase At least one system component

has not yet finished the start-up

phase.

On A serious error

has occurred

A fatal error has occurred.

Overview

Page 17

KUNBUS-COM EtherCAT 17 / 135

2 Operating

Mode (green)

Off Module not

running

Flashing

Start-up phase At least one system component

has not yet finished the start-up

phase.

On Normal opera-

tion

All system components function

faultlessly.

3 Link Activity

OUT

off No connection

flashesConnection

and data traffic

on Connection

4 Link Activity IN off No connection

flashesConnection

and data traffic

on Connection

Overview

Page 18

KUNBUS-COM EtherCAT

18 / 135

4 Components

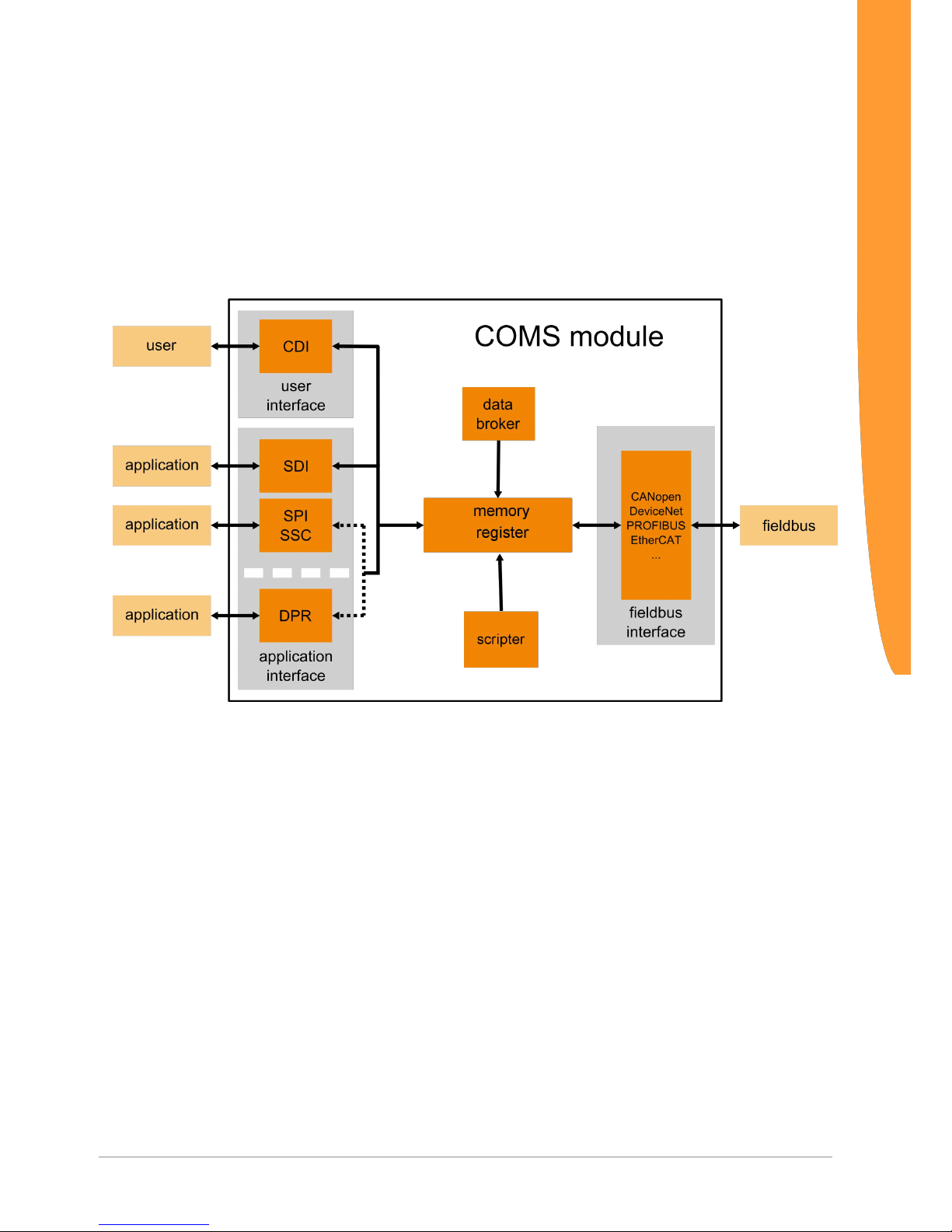

4.1 Module Components

The module is divided into independent components to ensure a high

level of flexibility in the application.

The following pages describe the individual components:

Illustration6: Components

Components

Page 19

KUNBUS-COM EtherCAT 19 / 135

4.2 Storage Unit

The storage unit is the central component for all functions of the

COMS-Module. It is subdivided into individual Memory Register with

a width of 16 bits each. In these Memory registers the following

information is stored:

– Input and output data

– Configuration settings

– Module Status

– Error states

The functionality of the addressing was incorporated from Modbus.

The register assignment depends on the application and is not

specified by the Modbus specification. A Memory Register according

to this specification has a register number between 1 (0x0001) and a

maximum of 65536 (0x10000), of which the module only uses a small

part, however.

With 8-bit values, 1 byte remains unused. 32-bit values are stored in

2 registers.

The 16-bit values are stored internally in the memory in Little Endian

order. This must be taken into account when you access data via the

fieldbus interface, SDI or SSC.

NOTICE!In the description of the individual memory registers

and CDI, the memory registers are also referred to as Modbus

registers.

In section Overview of the Memory Register [}47] we have

compiled a detailed overview of registers for you.

Components

Page 20

KUNBUS-COM EtherCAT

20 / 135

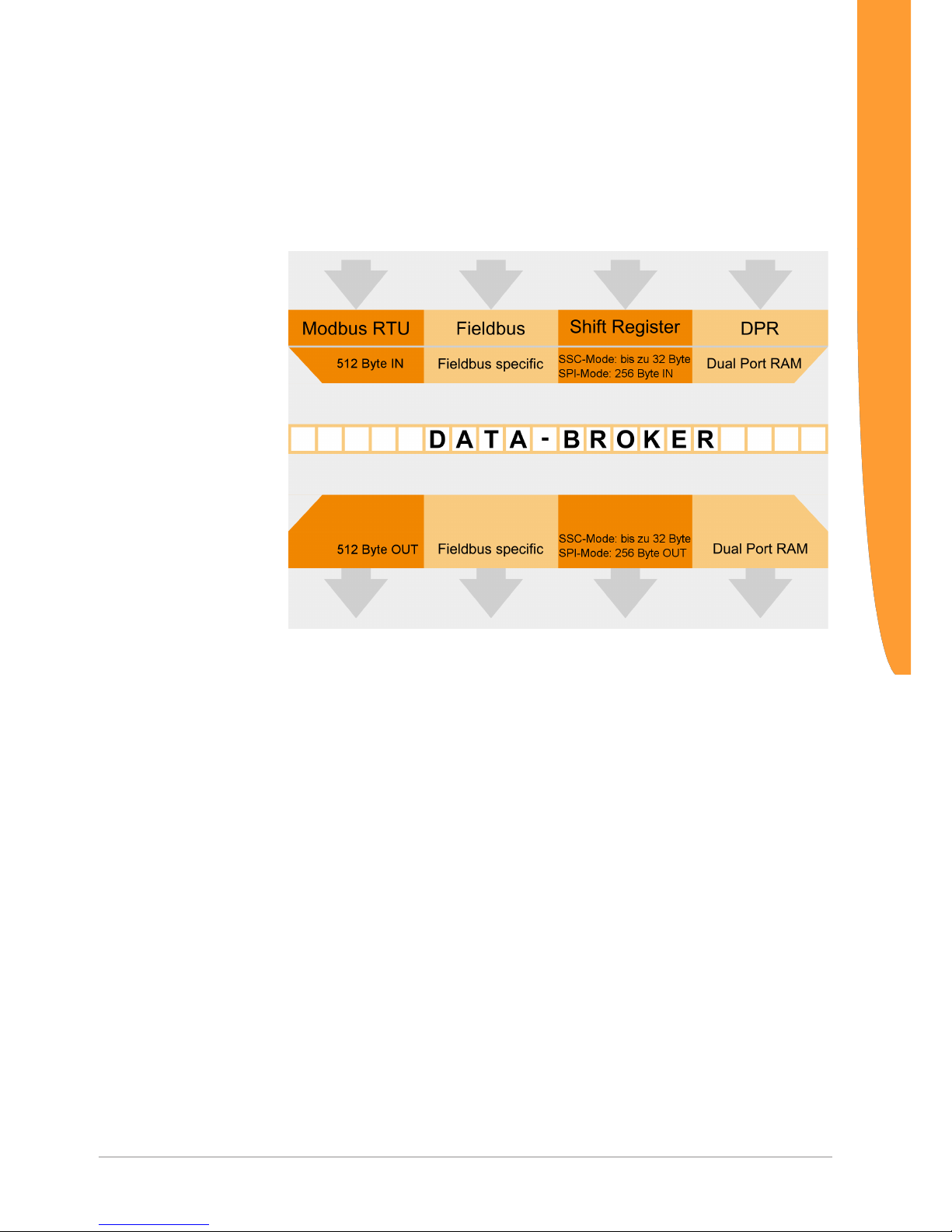

4.3 Data Broker

The Data Broker decouples individual components from each other

and distributes the data streams between the interfaces. The

targeted forwarding of the data ensures a high level of functionality

between the data sources and data sinks of the module.

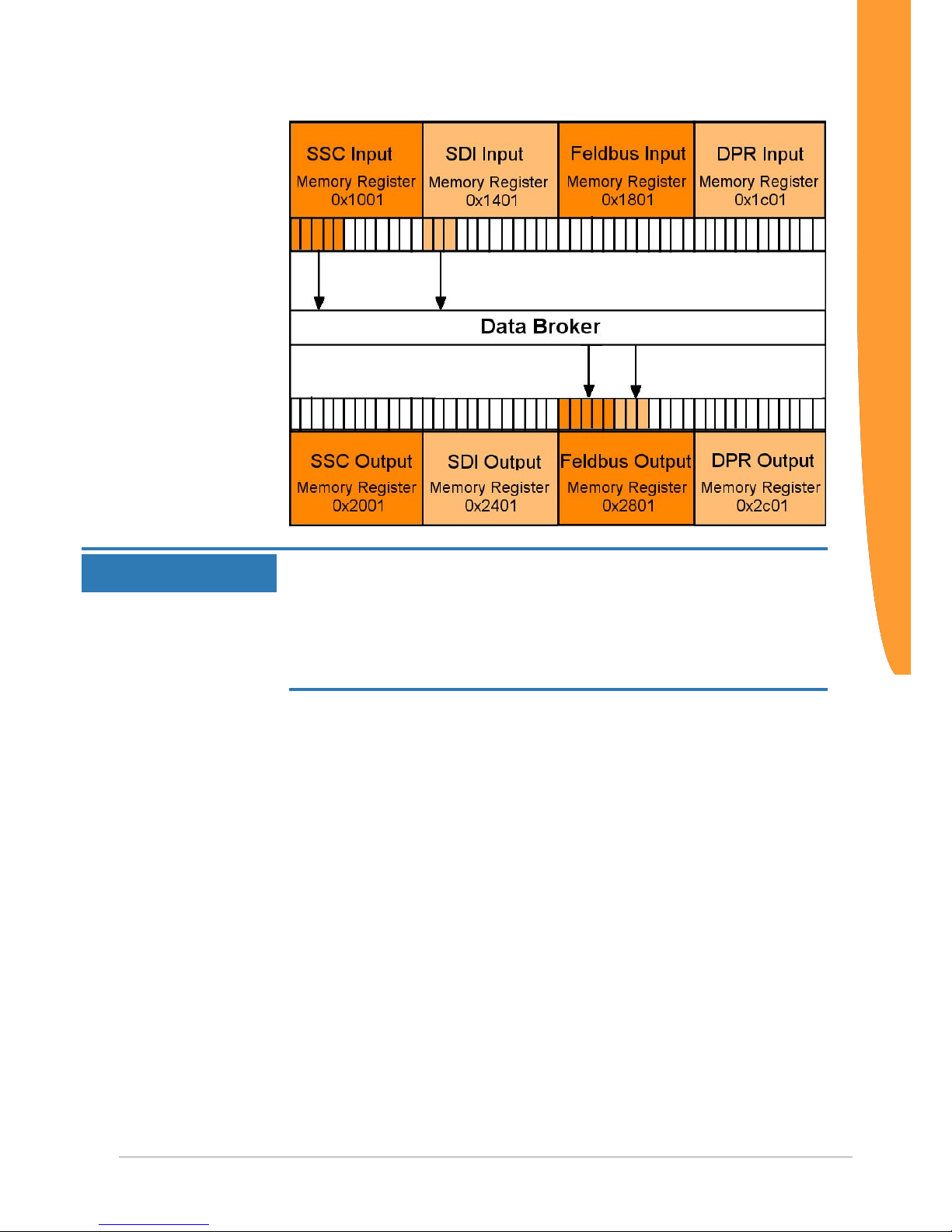

Illustration7: Internal mapping by the Data Broker

Mapping

You have the option to define the allocation (mapping) yourself. This

allows you to define which input register the Data Broker should

accept data from and which output register it should transfer data to.

You can define up to 8 register areas with freely definable lengths in

the respective output register area for each of the interfaces. Any

register area of the same length is assigned to the output register

areas from one of the input register areas of all interfaces. Here, the

8 target areas are always on consecutive output register positions,

starting with the lowest register address for the respective interface.

Components

Page 21

KUNBUS-COM EtherCAT 21 / 135

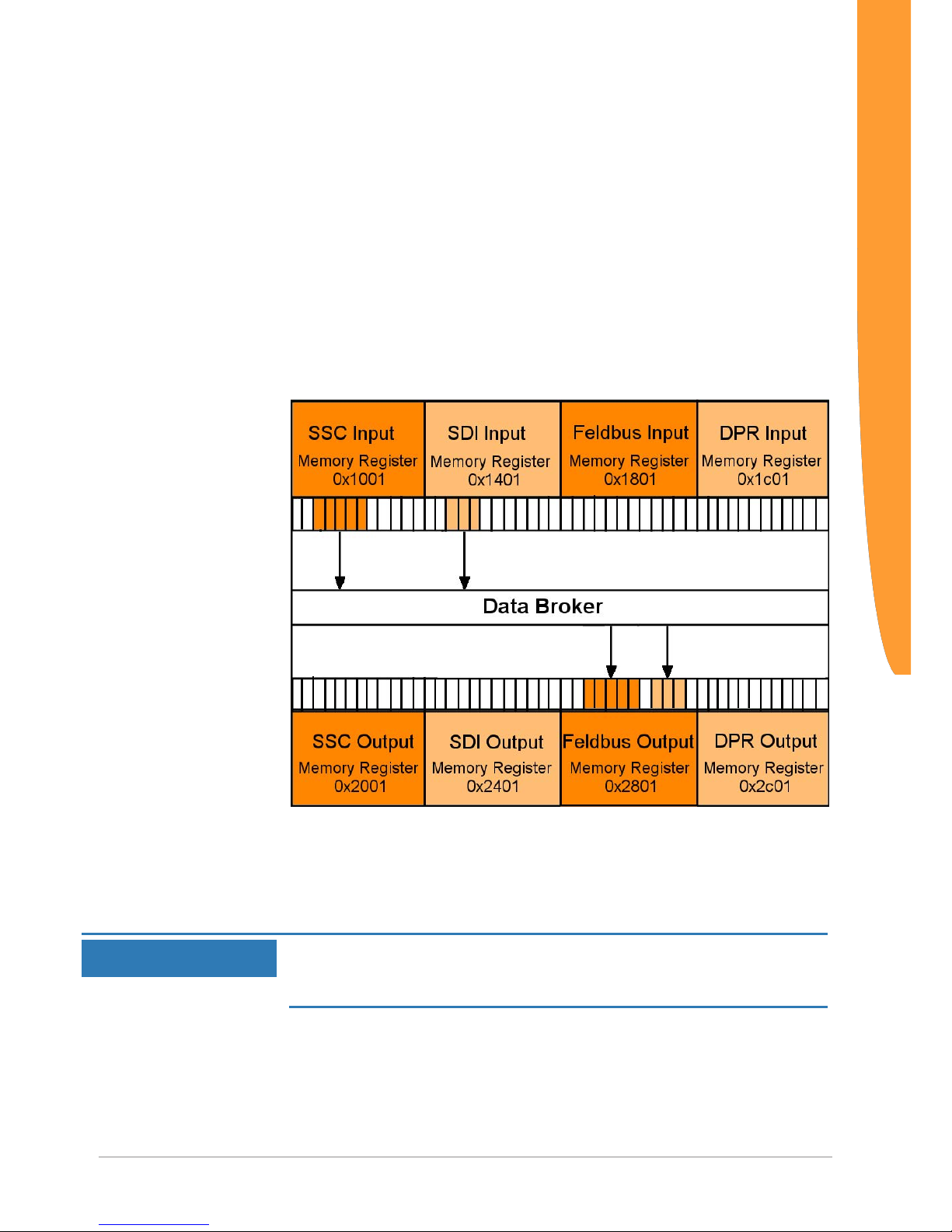

Illustration8: Mapping

NOTICE

Viewpoint

Please note that the description of the input and output values is written

from the perspective of the module and not from the perspective of the

overall system or controller.

èOutput: Values that the module sends to the fieldbus or application.

èInput: Values that the module receives from the fieldbus or application.

You can configure standard values that the Data Broker writes in the

relevant output register instead of an input register in the event of a

failure of a data provider. That has the advantage that the data

processing cannot abort uncontrollably.

The module uses the Little Endian byte order for the internal

processing. You can also configure the Data Broker so that it

exchanges the high and low byte when copying if necessary. To do

this, add the value 0x8000 or 32768 for the required mapping area

(see details below).

Extended Mapping

Some applications work with data that is viewed bit by bit. To make

the mapping for such applications even more flexible, an "Extended

Mapping" is provided. This mapping basically works in the same way

as the mapping described above:

Components

Page 22

KUNBUS-COM EtherCAT

22 / 135

Individual areas of the output Memory Register are assigned from

areas of the input Memory registers. In Extended Mapping you define

such assignments for up to 16 areas. When doing so, enter a number

of consecutive bits for each of these areas.

The limit of a register must not be exceeded: The area may be up to

1024 bits long. Unlike the simple mapping described above,

however, the 16 target areas do not necessarily have to be at

consecutive addresses. You are totally free to define the position of

the first bit of the target area by entering an output register address

and the corresponding bit position (0 to 15). The source area is also

defined by entering the input register and a start bit position.

Illustration9: Extended Mapping

All mapping areas are processed sequentially. The Data Broker first

copies all simple mapping areas cyclically. After that, it executes the

Extended Mapping. In the course of this, it is quite possible to

intentionally overwrite a target area by several sources of data.

NOTICE

It is possible that bits are overwritten unintentionally by various input

sources.

Make sure that the target areas do not overlap unintentionally.

Components

Page 23

KUNBUS-COM EtherCAT 23 / 135

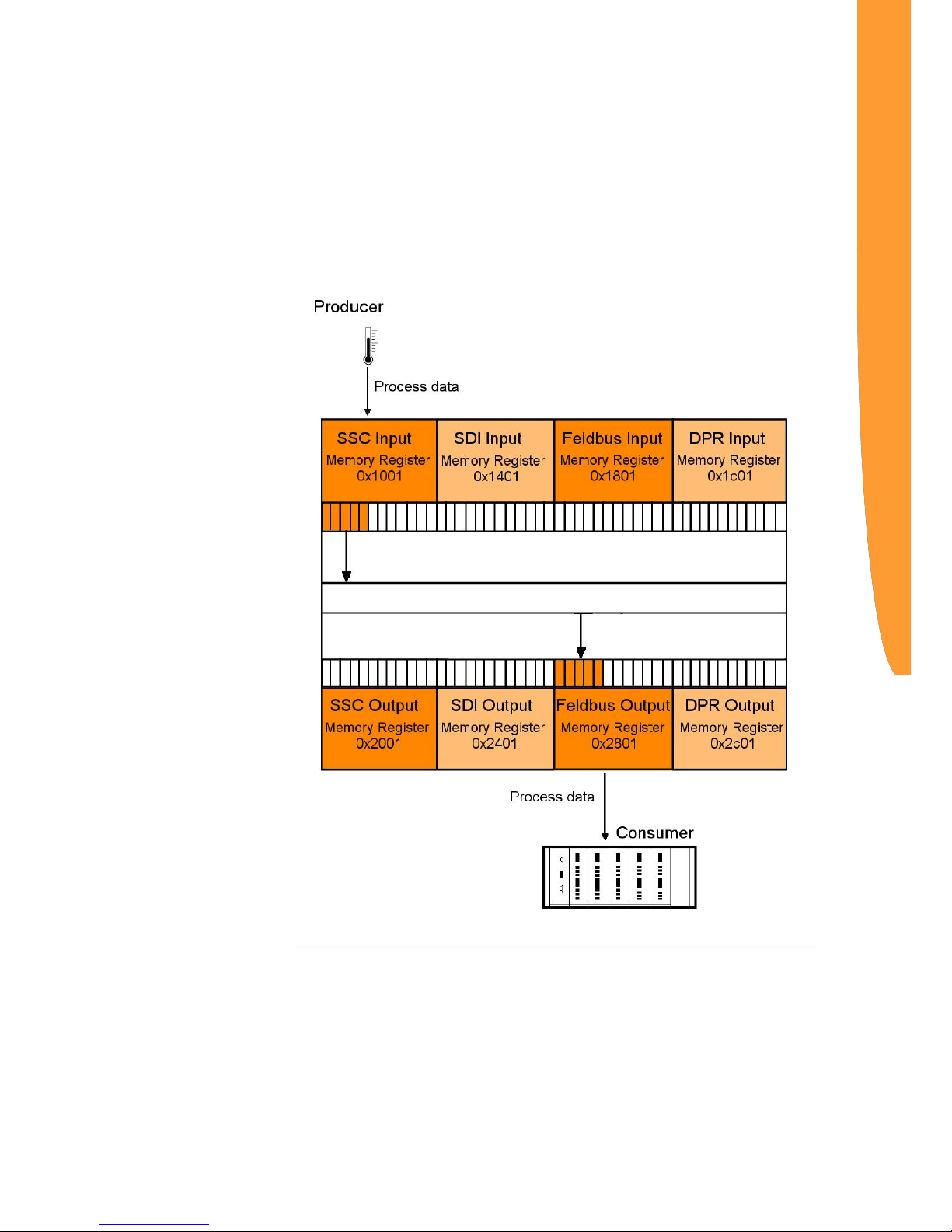

Validity period of the process data

Data sources that write data to the input area of the central memory

are called producers because they produce process data. The Data

Broker collects this data and copies it into the output area of the

central memory. From there, the data is sent to its target, the socalled consumer, via the corresponding interfaces.

Illustration10: Distribution to producers/consumers

Process data is normally exchanged cyclically between producers

and consumers. If a producer fails (e.g. a connector is removed or a

cable is broken), the consumer must be able to deal with this

situation appropriately. For this reason, you can define in advance

which values the producer will receive in exchange for the failed

process data.

Components

Page 24

KUNBUS-COM EtherCAT

24 / 135

The COMS-Module allow a separate validity period to be defined for

each producer (SDI, SSC, EtherCAT , DPR ). When a producer

supplies new process data, a stopwatch is started. If the producer

does not supply any new process data before the predefined validity

period expires, then the old data is invalid after this time.

Each consumer predefines which data he is to receive from the Data

Broker in such a case:

– All bytes at 0

– All bytes at 1

– retain the last valid data

The set validity periods from COMS-Modul are saved permanently in

the Memory registers. They are also available after a restart.

Likewise, the rule defined for a consumer, as to how to proceed if the

validity period is exceeded. The respective time values of the validity

period must be adapted, of course, to the cycle time of the interface

concerned.

– For EtherCAT this cycle time is determined by parameters of the

master.

– For SSC interface the time is determined from the shift register chain

length, the cycle frequency, and for short or fast register chains, it is

determined by the cycle time of the COMS module.

– During SPI slave mode and SDI transfer, the master determines the

cycle time of the respective interface, as well the base board when

using the DPR.

Example of a Mapping

The following example explains, step-by-step, how to map the first

three SDI input registers and the first five SSC input registers to the

field output register.

If you would like to participate in this example, you will need a

functional CDI connection. Section "Setting up a Serial Connection

[}93]" explains how this works.

Input options in the CDI menu:

You can enter hexadecimal (with prefixed 0x) or decimal numbers in

the CDI menu.

[Esc] Go back one level

[Enter] Confirm input/selection

[b] Value is displayed in binary code

[h] Value is displayed in hexadecimal

code

[d] Value is displayed in decimal

code

Components

Page 25

KUNBUS-COM EtherCAT 25 / 135

◦ Open the main menu of the CDI as described in the Appendix "Setting

up a serial connection using PuTTY".

Main Menu

The main menu is your access point for operating the module using

the CDI. After a reset, the module transmits this main menu to the

terminal.

-------------------------------------------------KUNBUS-COM – Main Menu

-------------------------------------------------1 – Module Information

2 – Interface Configuration

3 - Monitor Communication

4 – Module Status

------------------------------------------------->

Configuration menu

◦ In the main menu enter [2]+[Return].

ð You will be taken to the configuration menu "2-Interface Configuration"

In this menu you have the option to set the mapping for the data

broker and the operational parameters for the different interfaces.

– Select "Fieldbus Output Mapping" to define the data source for the

fieldbus output register.

-------------------------------------------------KUNBUS-COM – Interface Configuration

-------------------------------------------------Operating Mode: Config

1 - SDI Communication

2 - CDI Communication

3 - SSC Communication

4 - DPR Configuration

6 - SDI Output mapping

7 - SSC Output mapping

8 - Fieldbus Output mapping

9 - DPR Output mapping

11 - Fieldbus Specific

12 - Set Arbitrary Register

13 - Script Interpreter

14 - Reset Module

15 - Reset to Factory Settings

16 - Extended Mapping

------------------------------------------------->

Components

Page 26

KUNBUS-COM EtherCAT

26 / 135

– With the selection 1-8 are 8 positions available to create a mapping.

-------------------------------------------------KUNBUS-COM - Fieldbus Outputmapping

-------------------------------------------------Src Register Number

1 - 1 (0x0001) | 0

2 - 1 (0x0001) | 0

3 - 1 (0x0001) | 0

4 - 1 (0x0001) | 0

5 - 1 (0x0001) | 0

6 - 1 (0x0001) | 0

7 - 1 (0x0001) | 0

8 - 1 (0x0001) | 0

9 - Default Data: all zero

10 - Valid Time: disabled

------------------------------------------------->

◦ Enter [1] + [Return].

◦ Specify the first 3 registers of the SDI input register as data source

(start address 0x1401).

◦ Confirm your entry with [Return]

ð After confirming, you will return automatically to the "Fieldbus Output

Mapping" menu

You can find an overview of the start addresses in the section

"Overview of the Memory Register [}47]".

-------------------------------------------------KUNBUS-COM – Edit one map entry

-------------------------------------------------Source Register: 0x1401

Number of Registers: 3

◦ Create another mapping at the next free position

◦ Select the first 5 registers of the SSC input register as data source (start

address 0x1001)

-------------------------------------------------KUNBUS-COM – Edit one map entry

-------------------------------------------------Source Register: 0x1001

Number of Registers: 5

Components

Page 27

KUNBUS-COM EtherCAT 27 / 135

In the menu for fieldbus outputmapping, you can see the finished

mapping.

-------------------------------------------------KUNBUS-COM - Fieldbus Outputmapping

-------------------------------------------------Src Register Number

1 - 1521 (0x1401) | 3

2 - 4097 (0x1001) | 5

3 - 1 (0x0001) | 0

4 - 1 (0x0001) | 0

5 - 1 (0x0001) | 0

6 - 1 (0x0001) | 0

7 - 1 (0x0001) | 0

8 - 1 (0x0001) | 0

9 - Default Data: all zero

10 - Valid Time: disabled

------------------------------------------------->

The new mapping becomes active after a restart of the module. To

perform a restart, you have the following options:

1. Switch the module off and on again.

2. [Esc] takes you to the CDI menu [2] "Interface Configuration".

Here, enter [14] + [Return].

In CDI menu [2] "Interface Configuration" under menu item

"Set Arbitrary Register" you now have the option to write the

values in the SDI-In data area. The registers 0x1401 - 0x1500 are

available to you for this purpose.

In menu [3] "Monitor Communication", under menu item "

Arbitrary Register" you can view the fieldbus output register

from address 0x2801.

NOTICE

Fault due to fine settings

Some settings lead to malfunctioning of the module.

If you already want to test some settings now, read section CDI Menus

[}96]CDI Menus.

Also see about this

2 [}75]

2 Register for the Mapping [}75]

2 Setting up a Serial Connection [}93]

Components

Page 28

KUNBUS-COM EtherCAT

28 / 135

4.4 Fieldbus Interface

The fieldbus interface connects the Modul to EtherCAT.

It also enables access to the fieldbus specific Memory Register.

You can find the overview of the available Modbus registers in the

section "Overview of the Memory Register".

Also see about this

2 Overview of the Memory Register [}47]

2 Overview of the Memory Register [}47]

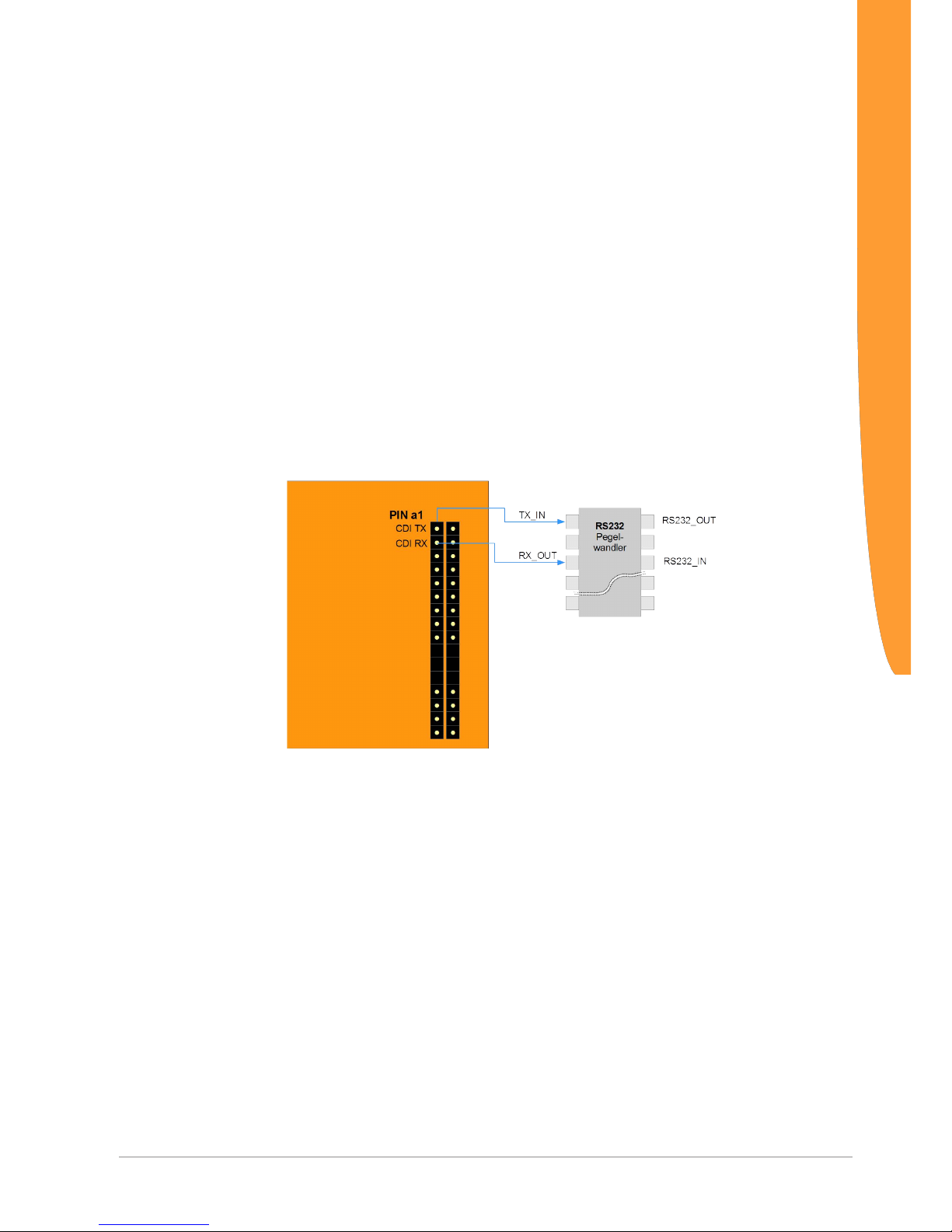

4.5 CDI - Configuration and Debug Interface

At the application interface, serial cables are available (RS232

interface with 3.3 V logic levels). You can connect these cables to a

terminal or PC with terminal simulation (e.g. PuTTY) using an

interface IC on the main board (see the application sample circuit

diagram, Appendix 2). You can read and change parameters using

structured menus. The CDI is also used for downloading scripts and

firmware updates.

The CDI is suitable for configuration during the development and for

diagnostic purposes. To configure several modules automatically, we

recommend performing the settings with "Modpoll". "Modpoll" is

freely-available software. You can find an introduction and example

of this in the Appendix Configuration via Modpoll [}134].

The serial interface is located at the application interface. The

respective cables are provided there with 3.3V logic levels. To

connect these cables, you have the following options:

– Connect the cables directly with the UART inputs of the microprocessor

on the main board

– Convert the cables to standardised levels using level converters or

interface ICs. Afterwards, place the converted levels onto connectors for

connecting a PC or terminal.

We deliver the Modul to you with the following default settings to

enable access via the CDI :

• 115200 bit/s

• 8 data bits

• 1 stop bit

• Even parity (Even)

In section CDI Menus [}96], we have compiled a detailed

description of the menus for you.

Components

Page 29

KUNBUS-COM EtherCAT 29 / 135

4.6 DPR - Dual Port RAM

-The COMS-Modul contains a special memory module (RAM with 1

Kbyte length), whose memory addresses the processor of the

module can also access, like an external processor, which is

connected to the module via the DPR interface.

If the application where the COMS-Modul is used should exchange

extensive data quickly, then this type of communication between the

base board and COMS-Modul is ideal. This absolutely requires the

use of a microprocessor on the base board, however, which operates

the DPR interface.

Many pins of the application interface are required for this parallel

access to the DPR. This results in a different PIN assignment in the

DPR mode of the module (this is switched on and off via the logic

level on PIN a14). In parallel access mode, no SSC or SDI interfaces

are available.

The data exchange between application circuitry and the COMSModul via DPR can take place in two different ways:

– Process data is read in and read out cyclically from the Data Broker via

two fixed address ranges for input and output data. In this case, the

DPR reacts like another communication interface, as a producer and

consumer. The data is distributed according to the specifications set in

the Data Broker.

– Messages are exchanged via two address ranges for an input and

output "mailbox" by means of defined handshaking. The messages

include:

– Commands for writing and reading the memory registers

– Addresses of the memory registers

– Data lengths

– Register contents to be written or read

This communication via mailboxes replaces the Modbus

communication via SDI in parallel access mode (which is not

available in this mode). All parameters in parallel access mode can

only be read or written via CDI interface or DPR mailboxes.

To enable these two types of communication, the 1Kbyte

memory of the DualPortRAM interface is subdivided into five

areas:

Dual Port RAM

Configuration Incoming

mailbox

Outgoing

mailbox

Process data

input

Process data

output

Components

Page 30

KUNBUS-COM EtherCAT

30 / 135

The size of the individual areas can be adapted to the respective

application and is saved non-volatile in parameter registers. The

configuration area has a fixed length and provides the necessary

address offsets as well as handshaking data for external access to

the remaining areas.

We recommend using our Evaluation Board and the C source files

provided with this as a template for developing the application side of

a DPR interface. Upon request, we can also provide you with the

documents and source codes of the Evaluation Board separately.

Therefore, in this section we will only describe the basic procedure

when using the DPR interface.

Each mailbox controls and coordinates the data transmission

individually during communication by means of corresponding control

values, length specifications and error codes in the relevant headers

of the data packets. The process data of memory areas also

coordinates the exchange of data between the base board and

COMS module by means of a corresponding data header.

NOTICE

Important instructions on using the DPR

èYou can operate the KUNBUS-COMS module either in DPR mode or in

SPI/SSC mode.

ð You determine the mode by setting the logic level on PIN a14 (+3.3

V = 1 = SPI/SSC mode, GND = 0 = DPR mode). you will find

information about the current interface mode in the CDI menu: "4 Module Status > 1 - Common Status"

èIf you use the Scripter [}44] in DPR mode, you must bear in mind that

the scripter can only communicate via the CDI.

ð Changes to parameter registers are then still only possible via the

DPR mailboxes.

Components

Page 31

KUNBUS-COM EtherCAT 31 / 135

4.7 SDI - Serial Data Interface

The serial data interface allows the application to access the

individual Memory Register via the Modbus-RTU protocol. This

allows you to configure the COMS-Modul automatically and to write

productive data in the input registers or to read it from the output

registers.

The serial data interface is located at the application interface. The

respective cables are provided there with 3.3V logic levels. To

connect these cables, you have the following options:

– Connect the cables directly with the UART inputs of the microprocessor

on the main board

– Convert the cables to standardised levels using level converters or

interface ICs. Afterwards, place the converted levels onto connectors for

connecting a PC or terminal.

We deliver the Modul to you with the following default settings to

enable access via the SDI :

• automatic baudrate detection

• 8 data bits

• 1 stop bit

• Even parity (Even)

Automatic bitrate detection means that the module tests the following

bitrates until it has received a correct Modbus-RTU telegram:

• 2400 bit/s

• 4800 bit/s

• 9600 bit/s

• 19200 bit/s

• 38400 bit/s

• 57600 bit/s

• 115200 bit/s

NOTICE!During automatic bitrate detection the module does not

send a reply to the master until the correct bitrate has been

detected. This procedure can require up to 40 polls of the

master.

TIP: Set a fixed bitrate if the automatic bitrate detection lasts too

long for you.

You can make the settings optionally using theCDI [}96] or in

thememory register 0x0005 [}54].

Components

Page 32

KUNBUS-COM EtherCAT

32 / 135

4.8 Synchronous serial interface

A synchronous serial interface is available to you on the application

interface. To use this interface, you have to set the logical level of pin

a14 to high (3.3V).

The synchronous serial interface can be used in 2 operating modes.

Select the operating mode you require via the logical level on pin a6:

– 0 (GND) = SPI Slave for connecting to an SPI Master

– 1 (3.3V) = SSC Master for connecting to a shift register chain

The following pins are available for operating as an SPI Slave for

connecting to an SPI Master:

– a4 SPI Clock (input)

– a5 SPI Data in (MOSI, input)

– b4 SPI Data out (MISO, output)

– b5 SPI Chip Select (CS, input)

– b6 SPI ready (output)

The following pins are available for operating as an SSC Master for

connecting to a shift register chain:

– a4 SSC Clock (output)

– a5 SSC Data out (MOSI, output)

– a7 SSC centre tap (MID, input)

– b4 SSC Data in (MISO, input)

– b6 SSC Strobe Signal (LOAD, output)

– b7 SSC Reset (output)

Output data from the Data Broker is written to the SSC output

register area and input data is read from the SSC input register area

in both operating modes. The SPI Slave operating mode also allows

an SPI Master write and read access to all other Memory Register

that are enabled for this. This section describes how this functions in

detail.

Operating mode as SPI Slave

In SPI Slave mode, the transmission of the process data between an

SPI Master and the SSC Input or Output registers takes place in data

blocks, which, in addition to the actual process data, also contain

metadata (e.g. for indicating the register addresses for source and

target areas). Such data blocks are transmitted with a hardware

handshake. The actual data transmission lines MOSI, MISO and

Clock are used with 3.3 V logic in the usual manner, as described

below in the document S12SPIV4 "SPI Block Guide" von Motorola /

Freescale®. Here, you can freely select the normally alterable

Components

Page 33

KUNBUS-COM EtherCAT 33 / 135

parameters CPOL (Clock polarity) and CPHA (Clock Phase) in

COMS-Modul and define these permanently via the CDI Menu

[}102] or memory register [}60]. The bit sequence (MSB first or

MSB last) is fixed for COMS modules, the module always starts the

transmission with the MSB (bit of highest value) of a byte. All bytes

belonging to a block are transmitted in a continuous sequence. The

clock signal required is input to PIN a4 externally from the Master.

The COMS-Modul can process maximum clock frequencies of

20MHz.

Handshaking

The handshaking lines ensure that a Master first sends the

subsequent transmission block after the module has processed the

block that was received previously.

The module indicates by the "low" level on the SPI ready line that a

transmission cycle has been completed, the status of the last

transmission is waiting to be retrieved and the Master can trigger the

next cycle. The Master starts this cycle by setting the SSC Chip

Select line to "high" to indicate to the module that data is ready for

transmission and the following data block is meant for the module

(theoretically, a master can address several modules). Once the

module is now ready for this data transmission, it sets the SPI ready

line to "high" and the Master can start transmission of the block

immediately. A maximum delay between setting the CS signal and

releasing by the ready signal of the module is 10ms. All bytes of a

data block are now transmitted directly in succession at the rate

preset by the Master. After the last bit of the data block has been

transmitted, the Master indicates the end of the transmission by

resetting the SPI Chip Select line to "low". The module responds to

this by resetting the SPI Ready line to "low". This happens at the

earliest, however (maximum 10 ms after resetting CS), when the

data has been processed insofar as the status was determined and

is ready in the SPI output buffer so that the next transmission can

start. This must first be requested, however, by the Master (as

described above) by setting the SPI Chip Select line to "high".

Chip Select

(Master)

Ready

(Slave)

Data

(Master & Slave)

Components

Page 34

KUNBUS-COM EtherCAT

34 / 135

Protocol

KUNBUS has defined a separate protocol for the data exchange via

the synchronous serial interface. This protocol allows you to perform

various read and write access operations. Here, the Master first

always sends a transmission block with at least 5 bytes. The first 3 to

5 bytes of this transmission block consist of meta data (target

address, etc.). Depending on the access type, another transmission

block of variable data length follows the first block. Write and read

access to the memory register of the module is performed. Only

memory registers that have been enabled can be written or read, of

course. The following areas cannot be written:

Input data areas:

– Fieldbus

– SDI

– DPR

Output data areas:

– Fieldbus

– SSC

– SDI

– DPR

When writing to the SSC input data area, the time monitoring is reset

for this area (see Valid Time, Section "Data Broker [}20]").

Read access to the DPR areas is fundamentally not possible. The

module can never be in SPI/SSC mode and DPR mode at the same

time. Consequently, access to DPR areas would make no sense.

The various access types are explained below.

Writing 1 byte

This access type is used if 1 byte is written to a memory register of

the module by the Master.

The Master first sends a transmission block with a fixed length of 5

bytes, which have the following content:

Transmission block with fixed length

Command

code

(1 byte)

Address area

(2 bytes)

Data area

(1 byte)

Mask area

(1 byte)

Description

0x01 0x0000-0xFFFF 0x00-0xFF 0x00-0xFF WRITE_LOW_BYTE

0x02 0x0000-0xFFFF 0x00-0xFF 0x00-0xFF WRITE_HIGH_BYTE

0x00 0xXXXX 0xXX 0xXX NO_OPERATION*

Theoretically, you could use all memory register addresses between

0 and 0xFFFF. In practice, however, the write access is limited to

registers that are enabled for this purpose. The byte can be written to

the high or low byte position of the 16-bit wide register by selecting

Components

Page 35

KUNBUS-COM EtherCAT 35 / 135

the associated command code. The mask byte only makes it

possible to write single bits to the target register. Thereby, only bits

that are set to "1" in the mask are transferred from the data byte (i.e.

these bits are set to the value as found in the data byte). All other bits

are left unchanged in the register.

During transmission of this first block, the module sends the status of

the previous data transmission. The module first returns the status

for the previous access when sending the next transmission block. If,

however, no further write or read operation should follow the write

access, then the Master must send another transmission block with

the command code 0 ("NO_OPERATION") for retrieving the status,

in which the module returns the status for the last write access

operation.

The status response from the module is structured as follows for all

write access types:

Transmission block with fixed length

Status code

(1 byte)

Error code

(2 bytes)

Not used

(2 bytes)

Description

0x00 0xXXXX 0xXXXX NO_PREVIOUS_OPERATION

0x01 0x0000 0xXXXX WRITE_SUCCESS

0x02 ERROR_CODE

1

0xXXXX WRITE_FAILURE

1

See Table "ErrorCode"

The first byte returns the status. If it is set to "0", the Master then

indicates that it cannot return any current status information since

there was no previous operation (this is usually the response to the

very first block transmission). A "1" indicates the successful

completion of the previous transmission. In the case of a 2, the

module sends the error code of an error in the subsequent byte,

which occurred during the previous block transmission. The possible

error codes are listed at the end of this subsection.

Writing 2 bytes (Word)

This access type basically proceeds as when writing 1 byte. It differs

in the following points:

– Instead of a mask byte, the second byte of the 16-bit wide user data is

transmitted with the data block. Access to individual bits in the target

register is not possible with this access type.

– The 16-bit wide register content to be written must be prepared by the

Master in such a way that the higher-value byte is transmitted as the 4th

byte and the lower-value byte is transmitted as the 5th byte ("BigEndian" or "Motorola format").

Components

Page 36

KUNBUS-COM EtherCAT

36 / 135

Transmission block with fixed length

Command

code

(1 byte)

Address area

(2 bytes)

Data area

(2 byte)

Description

0x04 0x0000-0xFFFF 0x0000-0xFFFF WRITE_WORD

0x00 0xXXXX 0xXXXX NO_OPERATION*

The status response has the same structure and meaning as write

access with 1 byte

Writing more than 2 bytes

with one access (bulk-write)

This access type is suitable for larger volumes of data. The number

of target registers to be written and start address are transmitted with

the first transmission block. As with the previous access types, the

first transmission block also has a fixed length of 5 bytes here. After

this block with metadata, the user data follows in a separate

transmission block with variable length. The maximum permitted

number of target registers to be written depends on the target area: A

maximum of 128 registers (each 16-bit = 1 word) are permitted for

writing to the SSC input register area. A maximum of 16 registers per

block is to be written for all other target areas.

All 16-bit wide register contents to be written must be prepared by

the Master in such a way that the higher-value byte is transmitted as

the first byte and the lower-value byte is transmitted as the second

byte ("Big-Endian" or "Motorola format"). The register contents must

be sent in ascending address order, i.e. the start address first.

Transmission block with fixed length

Command

code

(1 byte)

Address area

(2 bytes)

Data length

(2 bytes)

Description

0x08 0x0000-0xFFFF 1-16/128 WRITE_BULK

0x00 0xXXXX 0xXXXX NO_OPERATION*

NOTICE

The maximum data length for writing in the SSC input data area is 128

registers (256 bytes).

If this value is exceeded, errors in the data communication will result.

In the case of a transmission block of variable length, the module

sends bytes with the value 0 to the master.

The status response has almost the same structure and meaning as

write access with 1 byte. In the event of an error, a 16-bit wide

register address is at position 4 and 5 for this transmission type, at

which the first error occurred. The status is transmitted in the first

transmission block that follows the data block with variable length.

Components

Page 37

KUNBUS-COM EtherCAT 37 / 135

Transmission block with fixed length

Status code

(1 byte)

Error code

(2 bytes)

Address area**

(2 bytes)

Description

0x00 0xXXXX 0xXXXX NO_PREVIOUS_OPERATION

0x01 0x0000 0xXXXX WRITE_SUCCESS

0x02 ERROR_CODE10x0000-0xFFFF WRITE_FAILURE

1

See Table "ErrorCode"

** Address where an error occurs

Reading 2 bytes (Word)

This access type is used if just 1 register is to be read from a

memory register of the module by the Master. The Master first sends

a data block with a fixed length of 5 bytes, which have the following

content:

Transmission block with fixed length

Command

code

(1 byte)

Address area

(2 bytes)

Not

used

(2 bytes)

Description

0x10 0x0000-0xFFFF 0xXXXX READ_WORD

0x00 0xXXXX 0xXXXX NO_OPERATION*

* This command allows the master to request the status of a read

request without an additional read or write request having to be

executed.

Theoretically, you could use all memory register addresses between

0 and 0xFFFF. In practice, however, the write access is limited to

registers that are enabled for this purpose.

During transmission of the first data block, the module sends the

status of the previous data transmission. The module first returns the

data to be read when sending the next data block. If, however, no

further write or read operation should follow the read access, then

the Master must send another data block with the command code 0

("NO_OPERATION") for retrieving the data to be read, in which the

module returns the status for the last write access operation.

The response from the module is structured as follows for all read

access operations:

Transmission block with fixed length

Status code

(1 byte)

Error code

(2 bytes)

Data area

(2 byte)

Description

0x00 0xXXXX 0xXXXX NO_PREVIOUS_OPERATION

0x01 0x0000 0x0000-0xFFFF READ_SUCCESS

0x02 ERROR_CODE10xXXXX READ_FAILURE

1

See Table "ErrorCode"

Components

Page 38

KUNBUS-COM EtherCAT

38 / 135

The first byte returns the status. If it is set to "0", the Master then

indicates that it cannot return any current status information since

there was no previous operation (this is usually the response to the

very first block transmission). A "1" indicates the successful

completion of the previous transmission. In the case of a 2, the

module sends the error code of an error in the subsequent byte,

which occurred during the previous block transmission.

If the status is "1", the 2 bytes after that at position 4 and 5 contain

the content of the memory register to be read at the address that was

transmitted at the last block with the read command. The 16-bit wide

register content read is prepared by the module in such a way that

the higher-value byte is transmitted as the 4th byte and the lowervalue byte is transmitted as the 5th byte ("Big-Endian" or "Motorola

format").

In the case of status "0" or "2", both data bytes at position 4 and 5

are invalid and must be discarded by the Master.

Reading more than 2 bytes

(Bulk-Read)

In this access type, the number of source registers to be read as well

as the start address are transmitted with the first transmission block

that has a fixed length of 5 bytes. After this block with metadata, the

transmission of the read data follows in a separate transmission

block with variable length. Therefore, this access type is suitable

primarily for larger volumes of data. The maximum permitted number

of source registers to be read depends on the source area: A

maximum of 128 registers (each 16-bit = 1 word) are permitted for

reading from the SSC output register area. A maximum of 16

registers per block is to be read for all other source areas. Byte

order:

All 16-bit wide register contents read are prepared by the module in

such a way that the higher-value byte is transmitted as the first byte

and the lower-value byte is transmitted as the second byte ("BigEndian" or "Motorola format"). The register contents are sent in

ascending address order, i.e. the start address first.

Transmission block with fixed length

Command

code

(1 byte)

Address area

(2 bytes)

Data length

(2 bytes)

Description

0x20 0x0000-0xFFFF 1-16/128/256 READ_BULK

0x00 0xXXXX 0xXXXX NO_OPERATION*

The Master sends a block of variable length with 0 bytes to the

module.

Components

Page 39

KUNBUS-COM EtherCAT 39 / 135

The status response has almost the same structure and meaning as

read access with 1 byte. In the event of an error, a 16-bit wide

register address is at position 4 and 5 for this transmission type, at

which the first error occurred. The status is transmitted in the first

transmission block that follows the data block with variable length.

In the event of an error during bulk access (status "2"), the data

transmitted by the module from the data block with variable length is

invalid and must be discarded by the Master.

Transmission block with fixed length

Status code

(1 byte)

Error code

(2 bytes)

Address area

(2 bytes)

Description

0x00 0xXXXX 0xXXXX NO_PREVIOUS_OPERATION

0x01 0x0000 0xXXXX READ_SUCCESS

0x02 ERROR_CODE10x0000-0xFFFF READ_FAILURE

1

See Table “ Error code“

** Address where an error occurs

Transmission block with variable length (1-16/128 words)

Data area

0x0000-0xFFFF"

Simultaneous reading and

writing of more than 2 bytes

with one access (bulk read/

write)

In this access type, the number of source registers to be read or

target registers to be written are transmitted with the first

transmission block that has a fixed length of 5 bytes. After this block

with metadata, the transmission of the read data follows in a

separate transmission block with variable length. Unlike with BulkRead or Bulk-Write, no random start address can be defined for this

access type. The start address for the block to be read is preset with

0x2001 (SSC input register) and with 0x1001 (SSC output register)

for the block to be written. Byte order:

All 16-bit wide register contents to be read or written are prepared by

the module in such a way that the higher-value byte is transmitted as

the first byte and the lower-value byte is transmitted as the second

byte ("Big-Endian" or "Motorola format"). The register contents are

sent in ascending address order, i.e. the start address first.

Transmission block with fixed length

Command code

(1 byte)

Not

used

(2 bytes)

Data length

(2 bytes)

Description

0x40 0xXXXX 1-128 READ_WRITE_BULK

0x00 0xXXXX 0xXXXX NO_OPERATION*

Components

Page 40

KUNBUS-COM EtherCAT

40 / 135

Transmission block with variable length (1-16/128 words)

Data area

0x0000-0xFFFF"

The status response has almost the same structure and meaning as

read access with 1 byte. In the event of an error, a 16-bit wide

register address is at position 4 and 5 for this transmission type, at

which the first error occurred when reading or writing. The status is

transmitted in the first transmission block that follows the data block

with variable length.

Transmission block with fixed length

Status code

(1 byte)

Error code

(2 bytes)

Not used

(2 bytes)

Description

0x00 0xXXXX 0xXXXX NO_PREVIOUS_OPERATION

0x10 0x0000 0xXXXX READ_WRITE_SUCCESS

0x20 ERROR_CODE10xXXXX READ_WRITE_FAILURE

In the event of an error during bulk access (status "2"), the data

transmitted by the module from the data block with variable length is

invalid and must be discarded by the Master.

Error Codes

Error code Designation Description

0x01 INVALID_DATA_

ADDRESS

Invalid data address

The master tries to access an invalid address.

The slave ignores the instruction.

0x02 INVALID_DATA_

LENGTH

Invalid data length

The data length predefined by the master is

too great.

The slave ignores the instruction.

0x04 INVALID_DATA Invalid data

The master tries to write data containing

values outside a valid range.

The slave ignores the instruction.

0x08 INVALID_ACCESS Invalid access

The master tries to access an invalid area

or a valid address.

The slave ignores the instruction.

0x10 INVALID_RANGE Invalid range

The master tries to write beyond the limits

of an SSC input data area or to write beyond the limits of an SSC, SDI, FBS or DPR

output data area.

The slave ignores the instruction.

0x20 UNDEFINED_ERROR Undefined error

An undefined error has occurred.

The slave ignores the instruction.

Table1: Error Code

Components

Page 41

KUNBUS-COM EtherCAT 41 / 135

SSC Master Operating Mode

In this operating mode, output data is read from the SSC output

register area via the serial synchronous interface and input data is

written to the SSC input register area. This takes place via a

hardware shift register chain.

Illustration11: Hardware shift register chain, example with 4 inputs and outputs

The advantage of such an interface is the possibility of forwarding

input and output signals to the fieldbus without the need of

microprocessor controlled application circuitry. Switches, contacts,

relay coils or solenoid valves, for example, can therefore be

connected directly via EtherCAT without using a microprocessor.

The COMS-Modul with its clock (Pin a4) clocks the output data into

the input register of the chain via the MOSI line (Pin a5), where it is

shifted bit by bit until the end. At the same time, the input data is

shifted bit by bit via the MISO line into the COMS-Modul with the

same clock pulse. Prior to each such shift procedure, the module

sets the LOAD line to high (Pin b6). In this way, the parallel outputs

Components

Page 42

KUNBUS-COM EtherCAT

42 / 135

of all shift register modules receive the data from the input buffers in

the previous cycle. The input shift registers, on the other hand, utilise

the positive edges from the LOAD signal to copy all parallel input

values simultaneously to their output buffers. From there, they are

shifted bit by bit to the SSC input register area of the COMSModulduring the current cycle.

The clock rates of the COMS-Moduls can be adapted manually or

automatically in 3 levels and are about 300, 1200 or 4800 Kbit/s. The

load impulse is between 5 and 15 µs long (active low). The delay

between the load edge (positive edge of the load impulse) and the

first clock edge (from high to low) is between 1 and 2 µs. These

values are completely uncritical when using the shift register modules

74HC165 (Input) and 74HC594 (Output).

An optional RESET line (Pin b7, active low) initialises the shift

register modules during the starting process of the COMS-Moduls

(i.e. also during each reset of the module).

With an arrangement of the output and input shift register as shown

in this example, all registers are switched in series so that the

COMS-Modulhas its own output data shifted back into the input

register again for checking purposes. A test sample shifted through

the complete chain without a LOAD signal allows the COMS-Modulto

detect how long the entire chain is by means of the necessary clock

signals for such a shifting procedure. A centre pickoff between the

output and input modules allows the COMS-Modul to also detect the

corresponding number of inputs and outputs during this run of a test

sample. If bit errors occur, the clock rate is reduced in automatic

mode by one level. Hence, with such a structure the COMSModulcan find the right setting for the chain lengths and maximum

possible transmission rate independently. It is also possible,

however, to assign the lengths and clock rates manually via the CDI

menu. In this case, the centre pickoff can also be omitted (it is only

needed for determining the allocation between outputs and inputs).

The entire chain length is monitored constantly during ongoing

operation and must match the configured length. If the module

detects a difference, then it shuts down the SSC communication and

reports an error status via its status register.

The COMS-Modulcan operate a maximum of 32 input shift registers

plus 32 output shift registers. These limits must be observed.

Note on cycle time: The cycle time of the shift register interface is

normally independent of its chain length since theCOMS-Modulin its

work cycle only starts the transmission of a shift procedure. The shift

Components

Page 43

KUNBUS-COM EtherCAT 43 / 135

procedure itself then takes place independently of the work cycle of

the COMS-Moduls. Its length is determined by the number of cycles

as well as the clock rate. After completion of a shift procedure, the

next shift cycle starts with the next work cycle of the module. The

maximum delay between the completion and start of a shift cycle is

10ms.

Note ! If the shift procedure is longer than a work cycle of the

module, the cycle time is determined by the length and speed of the

shift register chain.

Components

Page 44

KUNBUS-COM EtherCAT

44 / 135

4.9 Scripter

The COMS-Modul includes a software component that allows you to

set up customer-specific data exchange protocols for SDI or CDI

serial interfaces. If, for example, the module is to communicate in an

application with a serial-controlled servomotor, this servomotor

expects a preset protocol to be processed in order to receive the

actuator values or to return sensor values. With the aid of the

Scripter you can load small executable program sequences into the

module that are then executed there cyclically. With the appropriate

data exchange protocol the module can receive such actuator values

e.g. via EtherCAT and transmit these via the serial interface of the

module (SDI or CDI) to the servomotor. The program sequences

required are loaded once into the module in the form of a script via

the CDI interface of the module and then always executed there

cyclically. KUNBUS provides you with a PC tool for creating and

testing such scripts. You can read all the necessary details in the

separate manual on the Scripter.

NOTICE!Please note that when using the Scripter and activating

a script the interface (CDI or SDI) selected for its communication

is always assigned for the Scripter. If you choose the CDI interface,

you can then no longer use this interface to check and enter module

parameters ("CDI menus" are then no longer available). If you

choose the SDI interface as a serial communication channel for the

Scripter, you can then no longer process any Modbus protocol with

access to the memory register via this interface.

As a reminder: The SDI interface is no longer available when the

module works in DPR mode.

Components

Page 45

KUNBUS-COM EtherCAT 45 / 135

5 Commissioning

5.1 Installation

To connect the module directly to the control board, proceed as

follows:

ü Attach suitable spacer bolts on the control board. Each module has

three identical holes for spacer bolts. These bolts stabilise the module

with a direct connection onto the control board.

◦ Fasten the module "head first" to the application contact strip of the

control board. The spacer bolts must be on the corresponding holes in

the board and the module kept parallel at a distance to the control

board.

◦ Fasten the module by screwing down the spacer bolts to the module

board

ð You have successfully integrated your application and can now

configure it.

Also see about this

2 Spacer bolt [}9]

Commissioning

Page 46

KUNBUS-COM EtherCAT

46 / 135

5.2 Configuration

This section describes how to configure the module and associated

components and applications.

NOTICE

Ø The module has no undo function.

èChanges are applied after a reset or start of the operating mode without

any further confirmation.

ð If you want to reset all values, use the function "Reset to factory

settings". [}116] Please note that all previous settings made will be lost.

Configuration using the CDI

To configure the Modul and put it into operation using the CDI, you

need a PC or notebook with a serial interface (RS-232) or USB/serial

adapter. Make sure that the adapter drivers are installed.

Communication with the CDI (Configuration and Debug Interface) of

the module takes place using a terminal program (e.g. PuTTY for

Microsoft Windows®).

TIPP!: Das CDI is suitable for configuration during the development

and for diagnostic purposes. To configure several modules

automatically, we recommend performing the settings with Modpoll.

You can find an introduction and example of this in the Appendix

Configuration via Modpoll [}134].

Configuration using the SDI

The COMS-Modul has a UART interface with 3.3 V logic levels. Your

main board must convert these lines to standardised RS-485 signals

so that Modbus/RTU devices can access these. Conversion to

standardised RS-232 signals is generally necessary for

communication with a PC. The base board of the evaluation board

has both interfaces that can each be selected via jumpers.

Configuration using the SDI requires a Modbus master device.

One of the following devices is suitable for this:

– Master computer,

– Control panel,

– Programming device,

– SPS with the possibility of Modbus-RTU communication.

To communicate with the SDI of the module using a PC, you need

Modbus software (e.g. Modpoll).

5.3 Firmware Update

If a firmware update is required, please contact our support

(support@kunbus.de). We will be delighted to provide you with all the

information you need for your product.

Commissioning

Page 47

KUNBUS-COM EtherCAT 47 / 135

6 Memory Register

6.1 Overview of the Memory Register

The storage unit is the central component for all functions of the

COMS-Module. It is subdivided into individual Memory Register with

a width of 16 bits each. In these Memory registers the following

information is stored:

– Input and output data

– Configuration settings

– Module Status

– Error states

The functionality of the addressing was incorporated from Modbus.

The register assignment depends on the application and is not

specified by the Modbus specification. A Memory Register according

to this specification has a register number between 1 (0x0001) and a

maximum of 65536 (0x10000), of which the module only uses a small

part, however.

With 8-bit values, 1 byte remains unused. 32-bit values are stored in

2 registers.

The 16-bit values are stored internally in the memory in Little Endian

order. This must be taken into account when you access data via the

fieldbus interface, SDI or SSC.

NOTICE!In the description of the individual memory registers

and CDI, the memory registers are also referred to as Modbus

registers.

Memory Register

Page 48

KUNBUS-COM EtherCAT

48 / 135

Bitwise access to input and

output data

Optionally, you can address input and output data areas bitwise. The

functions 01 Read Coil Status, 02 Read Input Status and 05 Force

Single Coil are defined in Modbus for this purpose. Since each bit

has a separate address, they are assigned to the bits in the registers

as follows: Coil 0x0001 corresponds to the lowest value bit 0 of

register 0x0001, Coil 0x0002 corresponds to bit 1, etc. coil 0x11 is

the bit 0 from register 0x0001 etc.

The table below shows the start addresses of the data areas:

Area Memory Register Coil/Input Address

Input SSC 0x1001 - 0x1080 0x0001 – 0x0800

Input SDI 0x1401 – 0x1500 0x2001 – 0x4000

Input FBS 0x1801 - 0x1880 0x4001 – 0x6001

Input DPR 0x1c01 … 0x6001 …

Output SSC 0x2001 – 0x2080 0x8001 – 0x8800

Output SDI 0x2401 – 0x2500 0xa001 – 0xb000

Output FBS 0x2801 - 0x2880 0xc001 – 0xe001

Output DPR 0x2c01 … 0xe001 …

Register assignment of the memory area

The following table contains a brief overview of the register

assignment of the general memory area. You can find a detailed

overview of the individual registers on the following pages.

Register number Assignment Description

0x0001 – 0x0100

[}50]

General Device

Parameters

e.g. Setting of the bitrates,

mailbox sizes etc.

0x0101 – 0x0e00 Reserved 0x0e01 – 0x0ea0

[}75]

Register for mapping

the output data

Each channel occupies

2 x 8 registers

0x0f01 – 0x0xf40

[}76]

Register for mapping of

the extended Data

Broker

16 mappings occupy

4 registers each

0x1001 – 0x2000

[}78]

Input memory of the

communication

channels

Each communication channel

has a preallocated memory

area of 128 - 256 registers.

0x2001 – 0x3000

[}79]

Output memory of the

communication

channels

Each communication channel

has a preallocated memory

area of 128 - 256 registers.

0x3001 – 0x4000 Reserved 0x4001 – 0x5000 Fieldbus-specific

(s. following table)

See the description of the

individual fieldbus variants

0x5001 – 0x10000 Reserved -

Memory Register

Page 49

KUNBUS-COM EtherCAT 49 / 135

The following table contains a brief overview of the register

assignment of the memory area for EtherCAT. You can find a

detailed overview of the individual registers on the following pages.

Register Designation Register Designation

0x4001 [}81]

Fieldbus Status

0x4002 [}81]

Module Status

0x4003 [}82]

Manufacturer ID,

High Byte

0x4004 [}82]

Manufacturer ID,

Low Byte

0x4007 [}82]

Fieldbus Version,

High Byte

0x4008 [}82]

Fieldbus Version,

Low Byte

0x4009 [}82]

Firmware Version

0x400a [}83]

Serial number,

High Byte

0x400b [}83]

Serial number,

Low Byte

0x400c [}83]

Physical Address

0x400f [}84]

Available Ports

0x4011 [}84]

Configuration

Bits, High Byte

0x4012 [}84]

Configuration

Bits, Low Byte

0x4014 [}86]

Product number,

High Byte

0x4015 [}86]

Product Number,

Low Byte

0x4016-0x4035 Product Name

0x4036 [}86]

Fieldbus Input

Size

0x4037 [}87]

Fieldbus Output

Size

0x4100 [}87]

Station Alias

Configured

0x4101 [}87]

Current Station

Alias

0x4103 [}87]

Station Alias from

SSC

0x4104 [}88]

Explicit Device ID

Configured

0x4105 [}88]

Current Explicit

Device ID

0x4106 [}88]

Explicit Device ID

from SSC