Instruction Manual

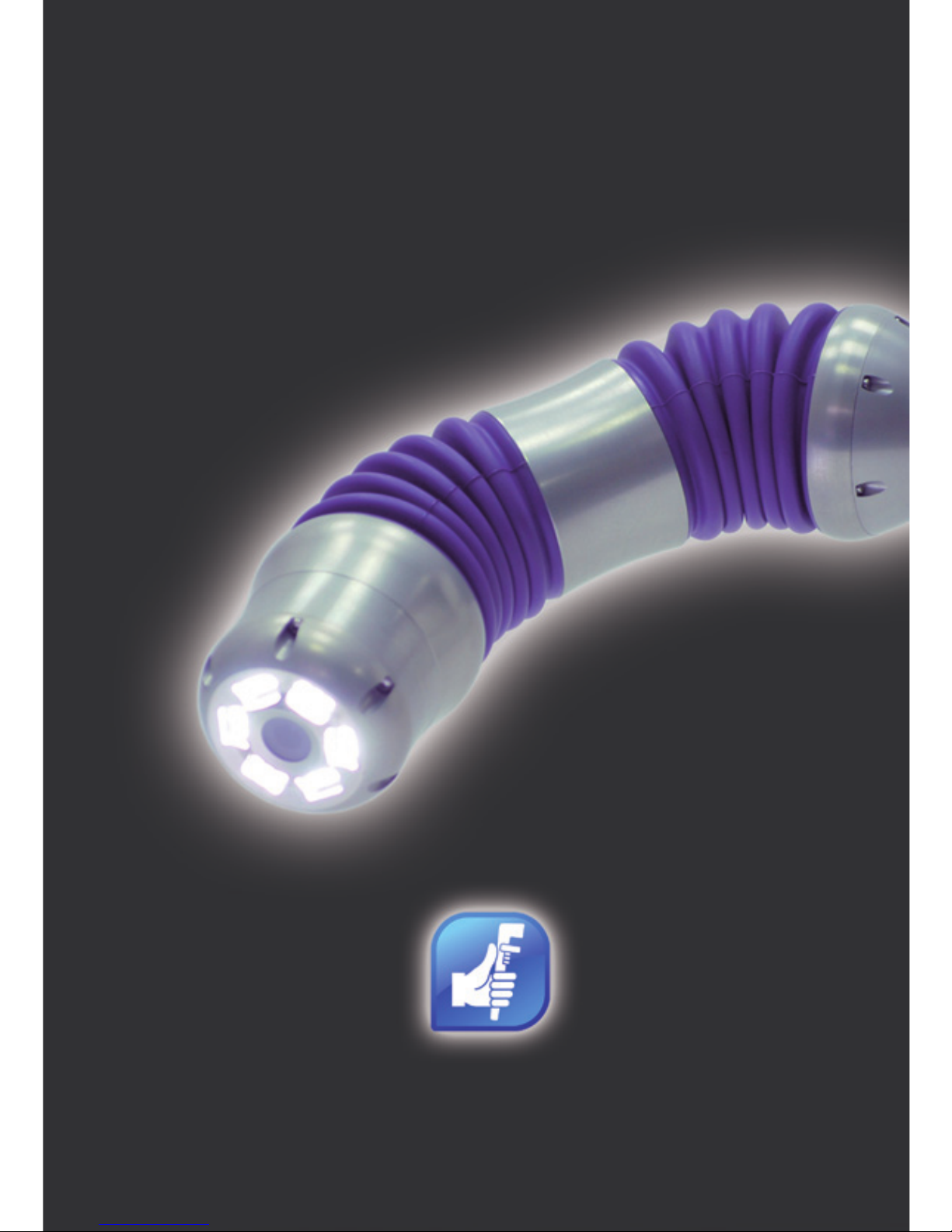

CamFlex

®

Art.-No. 9900

2

Contents

1 General Information

1.1 About the Manual .............................................................................................. 3

1.2 Manufacturer .....................................................................................................3

1.3 Explanation of Symbols Used ............................................................................ 3

1.3.1 Safety Instructions .................................................................................... 3

1.3.2 Tips and Recommendations .....................................................................4

1.4 Limitation of Liability .......................................................................................... 4

1.5 Copyright ...........................................................................................................4

1.6 Warranty Conditions ..........................................................................................4

2 Safety

2.1 Proper Use ........................................................................................................ 4

2.2 Basic Risks ........................................................................................................ 5

2.3 Behaviour in the Event of Danger and Accidents ..............................................6

2.4 Responsibility of the Owner ............................................................................... 6

2.5 Personnel Requirements ................................................................................... 7

2.5.1 Qualifi cations ............................................................................................7

2.5.2 Training ..................................................................................................... 7

2.6 Personal Protective Equipment ......................................................................... 7

2.7 Spare Parts ........................................................................................................ 8

3 Specifi cations

3.1 Specifi cations Push Rods/Reels H-XL75 and H-XXL100 .................................. 8

3.2 Specifi cations CamFlex® ....................................................................................9

4 Overview and Brief Description

4.1 Overview CamFlex® ........................................................................................... 9

4.2 Brief Description CamFlex® .............................................................................10

4.3 Overview Push Rods/Reels H-XL75 and H-XXL100 ....................................... 10

4.4 Brief Description Push Rods/Reels H-XL75 and H-XXL100 ............................10

5 Transport, Packaging and Storage

5.1 Safety Instructions for Transport ...................................................................... 11

5.2 Inspection upon Receipt .................................................................................. 11

5.3 Packaging ........................................................................................................ 11

5.4 Storage ............................................................................................................12

6 Mounting and Dismounting the Camera

6.1 Safety Instructions for Mounting/Dismounting the Camera ............................. 12

6.2 Mounting/Dismounting the Camera ................................................................. 12

7 Initial Operation

7.1 Putting the Camera into Operation .................................................................. 14

7.2 Working with the Camera ................................................................................ 14

7.2.1 Normal Operation Mode .........................................................................14

7.2.2 Halt Position Operation Mode ................................................................. 14

7.2.3 Calibrating the Camera ........................................................................... 15

7.2.4 Pulling Back the Camera ........................................................................ 15

7.3 Work Conclusion .............................................................................................. 15

8 Cleaning and Maintenance

8.1 Cleaning and Maintenance CamFlex® ............................................................. 16

8.2 Cleaning and Maintenance Push Rod/Reel ..................................................... 16

9 Troubleshooting ....................................................................................................16

10 Disposal ................................................................................................................. 17

11 Accessories ........................................................................................................... 18

3

1 General Information

1.1 About the Manual

This manual ensures the safe operation of the device. The manual is an integral part of the

product and must be kept with the device, immediately accessible for any personnel.

All personnel are to carefully read and understand the manual before taking up work. As a

precondition for safe operation, all safety instructions and operational procedures given in

this manual must be observed.

Furthermore, the local accident prevention regulations and safety provisions applicable for

the device’s range of use are to be heeded.

Illustrations in this manual are intended to better represent the facts explained and may

differ from the actual design of the device.

1.2 Manufacturer

Address: Contact:

Kummert GmbH Phone: +49 (0) 9382 - 9727 - 0

Albert-Einstein-Str. 8 Fax: +49 (0) 9382 - 9727 - 900

D - 97447 Gerolzhofen Email: info@kummert.de

Internet: www.kummert.de

1.3 Explanation of Symbols Used

1.3.1 Safety Instructions

Safety instructions in this manual are indicated by means of symbols. The safety instructions are being preluded by signal words, which express the extent of the hazard.

NOTE

This combination of symbol and signal word identifi es a possibly

dangerous situation, which may cause damage to property and

environment if not avoided.

Warning!

This combination of symbol and signal word identifi es a possibly dangerous

situation, which may cause death or severe injuries if not avoided.

Caution!

This combination of symbol and signal word identifi es a possibly dangerous

situation, which may cause minor or slight injuries if not avoided.

4

1.3.2 Tips and Recommendations

1.4 Limitation of Liability

All information and instructions given in this manual were compiled in consideration of

applicable standards and regulations, the current state-of-the-art technical development

and our long-term insights and experiences.

The manufacturer is not liable for damage in the following cases:

• nonobservance of this manual

• improper use of the device

• assignment of untrained personnel

• unauthorized modifi cations

• technical alterations

• use of unauthorized spare parts

The manual was translated to the best of our knowledge. However, we are not liable for any

translation errors. The German version of this manual overrides any translation.

In case of special versions, utilization of additional ordering options or newest technical

modifi cations, the actual scope of delivery may differ from the product explained and illu-

strated in this document. If you have any questions, please contact the manufacturer.

1.5 Copyright

The contents of this manual are protected by copyright and may be utilized only for work

on or with the device. Any improper use is prohibited without the manufacturer’s written

certifi cate of release.

1.6 Warranty Conditions

The warranty conditions are included in the manufacturer’s General Terms and Conditions,

which you can fi nd under www.kummert.de

2 Safety

2.1 Proper Use

The camera CamFlex® is solely intended to be used for the inspection of cleaned private

sewer and drains connections in combination with original accessories and components

made by Kummert GmbH.

Observing all instructions given in this manual constitutes yet another aspect of proper use.

Any use of the device beyond and/or other than the above specifi ed application is conside-

red improper use.

Tip

This symbol highlights useful tips and information for an effi cient and trouble-

free operation of the device.

5

2.2 Basic Risks

The following chapter lists residual risks which remain, even when the device is used in a

proper manner.

To reduce the risk of personal injuries and property damage and avoid dangerous situa-

tions, the safety instructions listed below as well as the safety instructions listed in the

sections to come are to be observed strictly!

Warning!

Risk of blinding by LEDs!

If the camera is outside of a pipe, its LEDs may blind you and others. Therefore:

- Never point the camera light at passing vehicles!

- Never look directly into the camera light or point the camera at an individual’s

eyes!

Warning!

Risk of injury from push rod!

The push rod is a glass-fi ber reinforced plastic rod. By reason of energy stored

in the rod, it may suddenly lash out, e.g. when the rod has gotten stuck.

- Keep the rod as short as possible outside of the pipe to be inspected.

- Reel the push rod in immediately after use.

Caution!

Risk of injury from dirt and scattered objects!

Dirt and scattered objects constitute slip and stumble hazards. Falling accidents

may cause injuries. Therefore:

- Always keep work area clean.

- Remove objects no longer needed from work area, particularly from ground

level.

- Mark unavoidable stumble-risk areas with noticeable tape.

Warning!

Hazard of chemical or biological materials/liquids!

When inspecting pipes that hazardous materials/liquids run through, observe

the following:

- Start the inspection only once it has been determined that no danger will

arise from the materials or liquids.

- Rinse pipes before the inspection with a suitable liquid (e.g. water).

- Adhere to the Material Safety Data Sheets (MSDS) on the chemical or

biological materials/liquids.

- Clean the push rod thoroughly after each use.

6

2.3 Behavior in the Event of Danger and Accidents

First-aid equipment (fi rst-aid kit, eye rinsing bottle, etc.) and a fi re extinguisher must be

stored in close proximity. All personnel must be familiar with the use and location of safety,

accident reporting, fi rst-aid and rescue equipment. This ensures the prevention of dangers

and the best possible help in the event of accidents.

The device requires a responsible and circumspect operation. Incorrect operation or

operation by unauthorized individuals endangers others.

2.4 Responsibility of the Owner

Owner is the person, who him-/herself operates the device for industrial or business

purposes or leaves the device to a third party to be used, and who, during the device’s

operation, bears legal product responsibility for the protection of the operator, all

personnel or third parties.

Owner responsibilities

The device is being deployed in the industrial fi eld. Therefore, the owner of the device is

required to comply with occupational safety regulations.

In addition to the safety instructions in this manual, the regulations for safety and accident

prevention, as well as the environmental regulations, effective at the device’s area of

application must be observed.

Furthermore, the following applies:

• The owner is to gather information on the applicable occupational safety regula-

tions and to identify additional risks, which result from specifi c working conditions at

the device’s place of operation, in a risk assessment. In a company directive, the

owner is to specify any additional procedure and safety instructions resulting from

the risk assessment.

• During the device’s entire time of operation, the owner is to verify, whether the

company directives issued by him/her comply with the current version of regula-

tions, and to conform them if necessary.

Warning!

Explosion hazard!

The device is not explosion-proof. Therefore:

- Never operate the device in an explosive atmosphere. In this context, also

make sure that the pipes to be inspected do not contain or leak explosive

gases/liquids.

Warning!

Electrical hazard!

Electric current can cause severe injuries or death. In case of damaged insulation or other components, there is a risk of death by electric shock. Therefore:

- Always disconnect the camera from the push rod or the reel from the base

unit before performing work on the camera (e.g. cleaning it).

7

• The owner must precisely direct and defi ne the responsibilities in respect of

installing, operating, trouble-shooting and cleaning the device.

• The owner is to ensure that all individuals handling the device have read and

understood this manual. Furthermore, the owner must periodically train all

personnel and inform them about the dangers.

• The owner has to provide the personnel with the necessary protective equipment

and must require the mandatory wear thereof.

Furthermore, the owner bears responsibility that the device is in a technically sound state

at all times. Therefore the following applies:

• The owner is to ensure that the instructions on transporting, storing and cleaning

the device are being observed as described in this manual.

2.5 Personnel Requirements

2.5.1 Qualifi cations

Only individuals who can be expected to do their work in a reliable manner are authorized

to work on or with the device. Individuals, whose reactions are impaired, e.g. by drugs,

alcohol or medication, are not authorized.

2.5.2 Training

The owner must periodically train all personnel. For best-possible tracking purposes,

training minutes must be drawn up with the following minimal contents:

• date of training

• name of trainee(s)

• training objectives

• name of trainer

• signatures of trainee(s) and trainer

2.6 Personal Protective Equipment

Personal Protective Equipment protects individuals against occupational health and safety

infringements.

Throughout work with or on the device, all personnel are required to wear their personal

protective equipment, which is, in particular, being pointed out in the individual chapters of

this manual.

Warning!

Risk due to insuffi ciently qualifi ed individuals!

Insuffi ciently qualifi ed individuals cannot assess the risks when handling the

device and subject themselves and others to the risk of severe or deadly injuries.

- All work must be conducted by qualifi ed individuals only.

- Insuffi ciently qualifi ed individuals must be kept out of the work area.

8

Description of personal protective equipment:

Protective Gloves

Protective gloves protect hands against friction, abrasions, punctures or deeper injuries,

as well as contact with hot surfaces.

2.7 Spare Parts

Spare parts can be obtained from authorized dealers or directly from the manufacturer

(see chapter “1.2 Manufacturer”).

3 Specifi cations

3.1 Specifi cations Push Rods/Reels H-XL75 and H-XXL100

Warning!

Risk of injury due to using incorrect spare parts!

The use of incorrect or faulty spare parts may pose a risk to the personnel, as

well as cause damage, malfunctions or breakdown. Therefore:

- Use only original spare parts supplied by or spare parts authorized by the

manufacturer.

- Always contact the manufacturer in case of questions.

Information

Loss of warranty!

Use of unauthorized spare parts will void the manufacturer’s warranty.

H-XL75 H-XXL100

Weight: 12 kg 15 kg

Diameter: 9 mm 9 mm

Length: 75 m 100 m

Reel diameter: 67 cm 67 cm

Meter counter: refl ex light barriers and micro controller

Brake: adjustable freewheel brake, reel lock

Bending radius: max. 250 mm

Storage temperature: 0° to +50° C

Operating temperature: 0° to +40° C

9

3.2 Specifi cations CamFlex

®

4 Overview and Brief Description

4.1 Overview CamFlex

®

Weight: 1050 g

Diameter: 72 mm

Length: 30 cm

Camera: ¼“ Color-CCD; 0.5 Lux; 350 lines

Lens: 2.4 mm

Focus: controlled by motor

Range of use: DN100 to DN200

Bending range: 90° in all directions

Depth of fi eld: 5 mm to infi nite

Illumination: 18 white high-power LEDs

Sealing: O-rings, waterproof up to 1 bar

Storage temperature: 0° to +50° C

Operating temperature: 0° to +40° C

Special features: automatic self-leveling

slope measurement with 0.1° accuracy loss

gyro sensor for taking bend measurements

1 connecting socket

2 bellows

3 camera head

4 lens with LEDs

5 carrying case

10

4.2 Brief Description CamFlex

®

The camera CamFlex® was specifi cally developed for the inspection of branched sewer

systems. It stands out due to its capacity to bend itself from a straight position to a 90°

angle. Thus, nearly all laterals from DN100 to DN200 can be navigated. The vermicular

camera also moves through bends easily. Even 90° bends are possible from DN125.

The CamFlex® has another strong point in its outstanding stability. The concave shape

minimizes the outer shell’s wear and tear as it reduces the contact area in the pipe. Furthermore, the high-tech materials used protect the camera’s interior.

During the inspection, the CamFlex® facilitates a constant upright image for a best possible orientation. The integrated sensors collect all data for creating an automatic and

real-time 3D pipe plan. Perfectly illuminated images in excellent quality are the key to a

sophisticated CCTV inspection.

In-between uses and during transport, the camera is optimally protected in the supplied

carrying case.

4.3 Overview Push Rods/Reels H-XL75 and H-XXL100

1 push rod

2 reel basket

3 reel lock

4 freewheel brake

5 tubular

6 connecting plug

7 reel fastening hooks

4.4 Brief Description Push Rods/Reels H-XL75 and H-XXL100

The reel H-XL75 consists of a 75-meter push rod, the reel H-XXL100 of a 100-meter push

rod. This rod is made of glass-fi ber-reinforced plastic with a thickness of 9 mm.

An integrated impulse transmitter facilitates a precise length measurement in connection

with a micro controller. The adjustable freewheel brake prevents unwanted coasting of

the push rod during an inspection. Furthermore, a tubular attached to one side of the reel

houses the mounted camera.

All cameras and push rods in the Kummert CamMobile® line are interchangeable. However, to guarantee optimal push performance and pipe bend mobility, the manufacturer’s

recommendations for the combination of camera and push rod should be followed:

DN100 and up = push rod H-XL75 + CamFlex® or push rod H-XXL100 + CamFlex

®

11

5 Transport, Packaging and Storage

5.1 Safety Instructions for Transport

5.2 Inspection upon Receipt

We recommend inspecting the entire delivery for completeness and possible transport

damage immediately upon receipt.

If damage is externally visible, take the following steps:

• Do not accept delivery or accept it under reserve only.

• Indicate the suspected damage in the carrier’s documents of transport or delivery

slip.

• Institute a claim.

5.3 Packaging

The devices are being delivered in different packaging.

Packaging materials primarily consist of cardboard and plastics (foil, foam). Packaging

may also comprise materials added to the packages for the protection against moisture or

frost (e.g. silica gel bags, antifreezing agents).

Unless recovery of packaging has been agreed upon, the packaging materials remain

with the customer.

NOTE

Property damage due to improper transport!

Improper transport may damage the camera, reel and push rod.

- Always transport the push rod reeled in.

- Always transport the camera in the carrying case.

- When transporting the reel in a vehicle, secure it against falling over.

Information

Legal times for claims

Report every fault as soon as it has been discovered. Claims for damages can

only be asserted within the legal time for claims.

The manufacturer is not liable for transport damage.

NOTE

Danger to the environment due to incorrect disposal!

Packaging materials are precious resources and, in many cases, can be reused

or recycled. Incorrect disposal of packaging materials may cause damage to the

environment.

- Dispose of packaging materials in an environmentally safe manner.

- Dispose of packaging materials according to applicable legal regulations and

local directives. If necessary, a specialist fi rm must be commissioned to

dispose of the materials.

12

5.4 Storage

Always store the CamFlex

®

and push rod/reel under the following conditions:

• Do not store outdoors.

• Always store the camera in the carrying case or, at least, with the protective cap

mounted to the connector.

• Store in a dry and dust-free place.

• Do not expose to aggressive media.

• Do not expose to direct sunlight.

• Storage temperature CamFlex

®

: 0° to +50° C

• Storage temperature push rod/reel: 0° to +50° C

• When storing the device for more than 3 months, periodically check the general

condition of all parts.

6 Mounting and Dismounting the Camera

6.1 Safety Instructions for Mounting/Dismounting the Camera

6.2 Mounting/Dismounting the Camera

Mounting

The reels possess a freewheel brake to regulate the push rod’s free movement. Thus,

unwanted coasting of the push rod and unreeling impediments can be avoided.

NOTE

Property damage due to faulty mounting and dismounting!

Faulty mounting and dismounting of the camera may cause property damage or

breakdown.

- Prior to mounting, ensure that the connectors are completely dry.

- Prior to connecting, check the connectors for dirt and damage.

• If the connectors are dirty, clean them.

• If the connectors are damaged, refrain from mounting and using the

device and arrange for repair.

- Check the O-rings for damage like tears and porosity to ensure that the plug and-socket connection will seal correctly.

- Check the camera’s bellows for tears and other damage.

• In case of tears or other damage, refrain from mounting and using the

camera and arrange for repair.

NOTE

Before connecting or exchanging the camera head, the reel must be disconnected from the base unit. Otherwise, interferences may be the result.

13

1. Turn the wing nut (fi g. 1) counterclockwise

to reduce the braking force of the freewheel

brake.

2. Turn the knob for the reel lock (fi g. 2) while

holding on to the push rod or reel. The lock

pin releases the reel.

3. Slightly unreel the push rod and turn the

knob for the reel lock (fi g. 2) to set the reel

lock again.

4. Connect the camera socket to the push

rod’s plug. Make sure the connecting pins

are positioned correctly (fi g. 3).

5. When screwing the plug-and-socket

connection together, it is imperative that

you hold the camera tight and turn the

reel’s sleeve only (fi g. 4).

Only hand-tighten the sleeve

.

Dismounting

To dismount the camera, proceed in the reverse order.

fi g. 1

fi g. 2

fi g. 3

NOTE

Property damage due to faulty mounting!

Failure to observe points 4 and 5 may cause damage to the plug-and-socket

connection.

fi g. 4

14

7 Initial Operation

7.1 Putting the Camera into Operation

Protective equipment: protective gloves

1. Mount the camera (see chapter “6.2 Mounting/Dismounting the Camera“).

2. Connect the reel’s plug with the socket on the base unit.

3. Switch on the base unit.

7.2 Working with the Camera

The maximum illuminated pipe diameter depends greatly on the degree of refl ection of

the pipe’s inner wall. Generally, a dark surface absorbs the light; a bright and wet surface

refl ects the light more intensely. Illumination in larger pipe diameters is improved by a

stronger refl ection.

7.2.1 Normal Operation Mode

As long as the CamFlex

®

is being pushed through the pipe in-between fi ndings, the

camera should always be in normal operation mode. In this mode, if the camera is controlled via joystick, it moves in a quick and fl uent manner and returns to its straight shape

once the joystick is being released.

7.2.2 Halt Position Operation Mode

When measuring laterals and bends, the CamFlex® automatically switches to the halt

position mode of operation. In this mode, the camera moves very slowly and stays bent,

even if the joystick is being released.

To manually switch from normal to halt position mode of operation and vice versa, refer to

the Hardware Manual CamMobile® Profi 3.

NOTE

Property damage due to faulty initial operation and use!

Faulty initial operation and use of the camera may cause property damage or

breakdown. Therefore:

- Never push or pull the rod across sharp edges.

- The rod may only be used to operate the camera. It must not be used as a

towing rope.

- Never bend the rod more than the designated radius of 250 mm.

NOTE

An inspection with the CamFlex® should generally be conducted against the fl ow

direction. Only then can the camera navigate into laterals.

NOTE

Property damage due to constant halt position mode of operation!

In the halt position mode of operation, the motors are exposed to great strain.

Therefore, do not operate the camera in the halt position mode for a lengthy period of time to keep the wear and tear as minimal as possible.

15

7.2.3 Calibrating the Camera

During an inspection, the CamMobile® Profi 3 automatically calibrates the CamFlex®

several times if the need arises.

This happens before the fi rst lateral or bend is being measured, as well as every time

before measurements are taken and the camera’s temperature has changed by 5° C or

more since the last measurement.

A window pops up showing a „ticking clock“, the quality of the calibration and the drift

resulting thereof. Furthermore, the calibration will be reconducted automatically, if the

recorded measurements strongly deviate from an admissible tolerance.

During calibration, the camera best lay still.

7.2.4 Pulling Back the Camera

If the camera is pulled back through the pipe without the camera movement being adju-

sted via the joystick, the slip clutch may engage when navigating a lateral or bend. This

happens to protect the motors inside the camera, yet results in the camera then staying

bent.

To straighten out the camera, push the aligning-button on

the CamMobile

®

Profi 3 twice (fi g. 5/1).

If the camera remains bent, please contact our

Technical Support using the

phone no. +49 (0) 9382 9727 - 710.

7.3 Work Conclusion

1. Dismount the camera (see chapter “6.2 Mounting/Dismounting the Camera“).

2. Check the camera and the bellows, in particular, for tears and damage.

3. Clean the camera (see chapter “8 Cleaning and Maintenance“).

4. Store the camera in the carrying case until the next use.

Tip

To read more on how to use the CamFlex® in connection with the CamMobile®

Profi 3 and the software can3D®, please refer to the “Hardware Manual CamMobile®

Profi 3“ and the “Quick User Guide - Software CamMobile® Profi 3“.

NOTE

Clean the push rod with a clean cloth as soon as the reeling in starts to avoid

soiling of the reel.

fi g. 5

16

8 Cleaning and Maintenance

8.1 Cleaning and Maintenance CamFlex

®

The camera must be cleaned under running water after each use. To keep moisture away

from the connecting socket, seal it with the supplied protective cap prior cleaning.

Clean the bellows with a soft brush made of synthetic material. Never use a wire brush!

In-between uses, store the camera in the carrying case to protect it against dirt and

damage.

8.2 Cleaning and Maintenance Push Rod/Reel

In order to keep dirt and moisture away from the connectors, cover them with protective

caps, which are either supplied or available from our range of accessories.

Never fully immerse the entire reel or its axis, in particular, in water. Moisture will pene-

trate and cause damage.

The push rod must be cleaned with a moist, clean cloth as soon as reeling in starts.

9 Troubleshooting

camera

poor image clean the camera lens

image interferences ensure that either reel H-Xl75 or H-XXL100 is

connected – if another reel is being used,

suffi cient voltage supply is not guaranteed.

no image switch on the base unit, check the power supply,

check the plug connection

NOTE

Property damage due to incorrect cleaning!

Incorrect cleaning may cause damage or breakdown. Therefore:

- Clean the camera and reel only in a de-energized state.

- Never use a high-pressure washer or similar means for cleaning.

- Do not use abrasive, corrosive or other aggressive detergents.

- Clean the camera and push rod after each use.

- Make sure that no moisture penetrates the connectors.

- Do not soak camera in disinfectant or rubbing alcohol over a longer period

(e.g. overnight).

NOTE

Bellows

Prior to cleaning the camera, it is imperative to check the bellows for tears and

damage! Water penetrating the camera’s interior through the bellows will cause

severe damage and result in high repair costs.

17

poor illumination clean the lighting dome

camera bent push the aligning-button on the CamMobile

®

Profi 3 twice

(see chapter “7.2.4 Pulling Back the Camera”)

push rod/reel

reel is blocked check if object extents into the basket and

remove it, if needed;

release reel lock pin

push rod unreels with diffi culty loosen freewheel brake

push rod does not unreel release reel lock pin and/or loosen freewheel

brake

push rod unreels uncontrollably fasten freewheel brake

other faults Please contact our Technical Support:

Phone: +49 (0) 9382 9727 - 710

10 Disposal

When the device has reached the end of its useful life, it has to be disassembled and

disposed of in an environmentally safe manner.

Unless both parties agreed otherwise on recycling or disposal, all components must be

properly dismantled and recycled as follows:

• Scrap any metal parts.

• Recycle any plastic parts in the appropriate manner.

• Dispose of all other components separately depending on the nature of material.

NOTE

Danger to environment due to incorrect disposal!

Incorrect disposal may cause dangers to the environment. Therefore:

- Electrical waste, electronic components, lubricants and other substances may

only be disposed of by certifi ed specialist companies.

- When in doubt, ask for information on environmentally safe disposal at your

local authorities or specifi c waste management companies.

18

11 Accessories

• Protective cap for the HR-plug of the

rod and locating transmitter (camera

side)

Art.-No. 5916

• Protective cap for the HR-plug of the

cameras, centering trolley with

additional lighting and locating

transmitter (rod side)

Art.-No. 5917

• Protective cap for the 7-pin plug of the

reel

Art.-No. 7298

• HR-70 locating transmitter, 512 Hz,

4 m locating range, can be mounted

between camera and reel

Art.-No. 10392

19

Notes:

BAL-CamFlex 06-2011

Distributor:

Manufacturer:

Kummert GmbH

Albert-Einstein-Straße 8

D - 97447 Gerolzhofen

Phone.: +49 (0) 9382 97 27 - 0

Fax: +49 (0) 9382 97 27 - 900

info@kummert.de

www.kummert.de

Loading...

Loading...