SOFTWARE

KR C...

Error messages / troubleshooting

KUKA System Software (KSS)

Issued: 10.Oct.2004 Version: 01

Fehlermeldungen 09.02.01 en

1 of 135

e Copyright KUKA Roboter GmbH

This documentation or excerpts therefrom may not bereproduced or disclosed to third parties without the express permission of the publishers.

Other functions not described in this documentation may be operable in the controller. The user has no claim to these functions, however, in

the case of a replacement or service work.

We have checked the content of this documentation for conformity with the hardware and software described. Nevertheless, discrepancies

cannot be precluded, for which reason we are not able to guarantee total conformity. The information in this documentation is checked on a

regular basis, however, and necessary corrections will be incorporated in subsequent editions.

Subject to technical alterations without an effect on the function.

PD Interleaf

Fehlermeldungen 09.02.01 en

2 of 135

Contents

1 Error messages / troubleshooting 4.................................

1.1 Message groups 4...............................................................

1.2 Message time 4.................................................................

1.3 Message number 5..............................................................

1.4 Originator 5.....................................................................

1.5 Message text 5..................................................................

1.6 List of error messages 5..........................................................

Fehlermeldungen 09.02.01 en

3 of 135

Error messages / troubleshooting

1 Error messages / troubleshooting

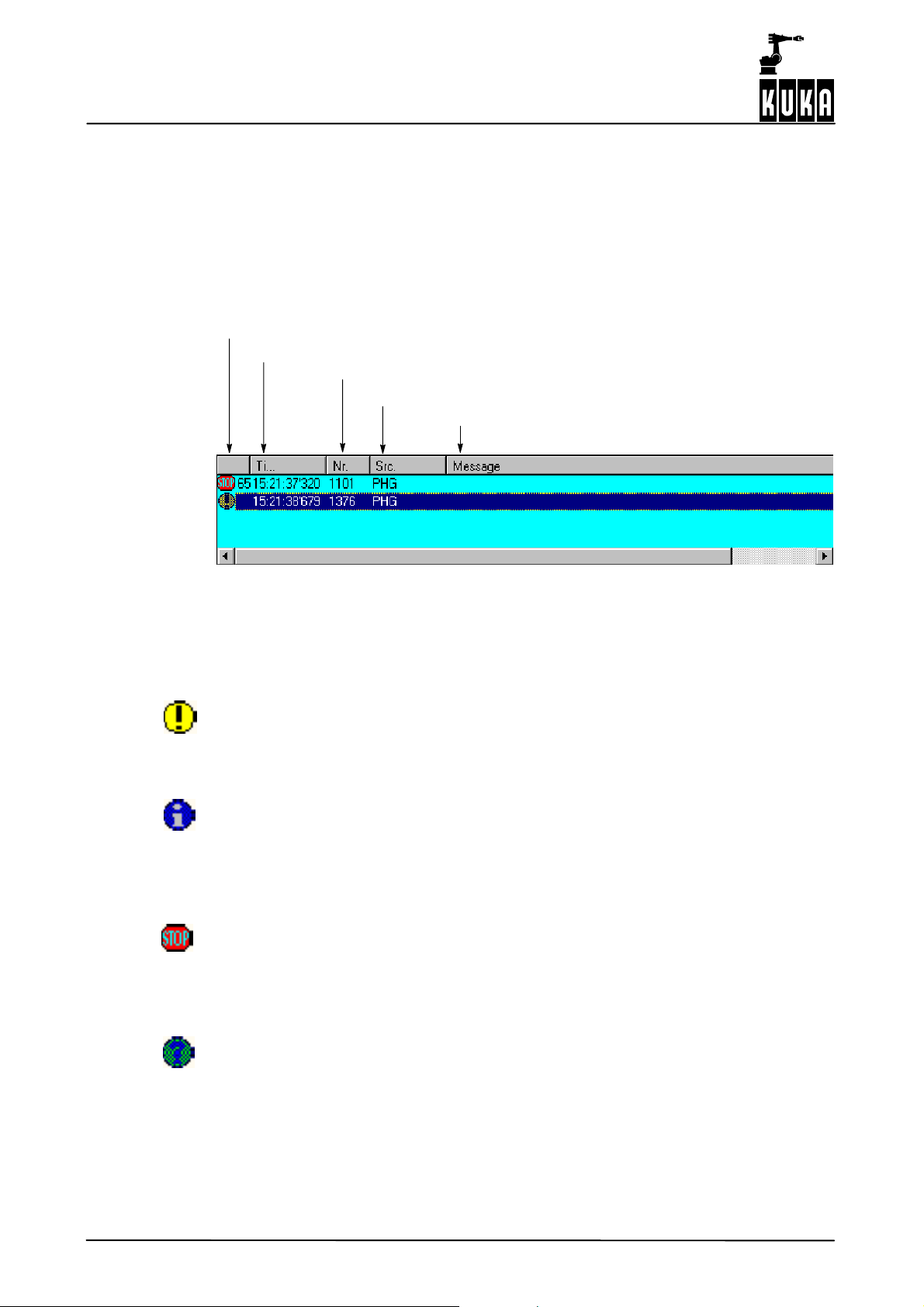

Messages of all categories are displayed in the message window. These can be either

informative messages that do not need to be acknowledged or messages that have to be

acknowledged.

A message consists of the following items of information, for example:

Message group

Message time

Message number

Originator

Message text

COMMAND ACCELERATION EXCEEDED A2

ACTIVE COMMANDS INHIBITED

1.1 Message groups

Hint messages

provide the operator with explanatory information, for example, if an illegal key has been

pressed.

Operational messages

signal the status of the system that has led to a control reaction, e.g. Emergency Stop. The

message is cleared once its cause has been eliminated. In some cases, a secondary signal

that has to be acknowledged is set for reasons of safety.

Acknowledgement messages

indicate a situation that must in all instances be recognized and acknowledged with the

acknowledge key. They are often a consequence of a status (operational) message. An

acknowledgement message stops a movement or prevents further operation.

Dialog messages

require confirmation by the operator (“Yes” or “No” softkeys). The message is cleared after

it has been confirmed.

1.2 Message time

The message time indicates the time at which the message was generated.

4 of 135

Fehlermeldungen 09.02.01 en

1.3 Message number

With the aid of the message number, the corresponding cause, effect and remedy can quickly

be located in the list of error messages.

1.4 Originator

The origin of the error is indicated in this field.

1.5 Message text

The text of the error message is shown here.

1.6 List of error messages

To make it easier to find error messages in the following list, the message number is shown

first, unlike on the display. By referring to this message number, it is possible to obtain further

information on an error and the appropriate remedial action. This information is subdivided

into:

1 Error messages / troubleshooting (continued)

Message text

is the actual text of the error message as displayed.

Cause

gives a detailed description of the cause of the error.

Monitor

indicates when the conditions for generation of the message are checked.

Effect

describes how the controller reacts to the error.

Remedy

describes what action the user can take to eliminate the error.

Fehlermeldungen 09.02.01 en

5 of 135

Error messages / troubleshooting

1 Message text EMERGENCY STOP

Cause -- Emergency Stop pushbutton pressed.

-- Emergency Stop initiated by the software.

Monitor -- Cyclic.

Effect -- Path--maintaining stop.

-- All active commands inhibited.

Remedy -- Check the Emergency Stop pushbutton and Emergency Stop circuit.

-- Release the Emergency Stop pushbutton.

-- Rectify and acknowledge the signalled fault.

2

Message text Internal error

Cause -- Internal KRL software test.

Monitor -- Within the KRL software.

Effect -- All active commands inhibited.

Remedy -- Acknowledge message.

3

Message text MESSAGE BUFFER OVERFLOW

Cause -- The message buffer, which contains the currently active messages

(acknowledgement and status messages), is full up to a specific limit.

Monitor -- Cyclic.

Effect -- Ramp--down braking.

-- All active commands inhibited.

Remedy -- Rectify and acknowledge the signalled faults.

4

Message text BUFFER BATTERY VOLTAGE LOW xx

Cause -- Voltage of the backup battery too low.

Monitor -- At “Power off”.

-- Cyclic.

Effect -- The battery voltage is checked when the power is switched off. When

the message is displayed, it is necessary to wait until the battery has

recharged. Only then may the controller be switched off.

-- Cyclic --> none.

Remedy -- Change the battery.

-- After the battery has been charged, the message “Ackn. batt. voltage”

is displayed --> acknowledge.

5

Message text Malfunction <HPU or RCP>

Cause -- KCP defective.

Monitor -- Cyclic.

Effect -- Ramp--down braking.

-- All active commands inhibited.

Remedy -- Replace KCP.

6 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

6 Message text Transmission error <HPU or RCP>

Cause -- Fault in KCP connection.

Monitor -- Cyclic.

Effect -- Ramp--down braking.

-- All active commands inhibited.

Remedy -- Check the KCP cable.

7

Message text TPBASIS

Cause -- The point could not be created

8

Message text System time invalid

Cause -- The system time is invalid after TIME_HW_FAILURE and has been

set to the initial value.

Monitor -- When the controller is booted.

Effect -- The system time is initialized with 01.01.93 00:00:00,00.

Remedy -- Update the system time with the form “systime”.

9

Message text MFC overtemperature

10

11

12

Cause -- The temperature sensor on the MFC has been triggered.

Monitor -- Cyclic.

Effect -- Path--maintaining braking.

Remedy -- Check fan. Exchange MFC if necessary.

Message text ERROR DIGITAL OUTPUTS @P1@

Cause -- Short circuit at outputs 1--8 or 9--16.

Monitor -- Cyclic.

Effect -- Maximum braking.

Remedy --

Message text PROGRAM STACK OVERFLOW

Cause -- KRL program contains too many nested structures or too many recur-

sive subprogram calls! The C--stack of the R--INT would otherwise

overflow.

Monitor -- In program processing.

Effect -- Ramp--down braking.

Remedy -- Change the structure of the program.

Message text TOO MANY MESSAGES

Fehlermeldungen 09.02.01 en

Cause -- Too many messages have been cyclically generated.

Monitor -- When a message is generated.

Effect -- All active commands are cancelled and cannot be restarted.

Remedy -- The KRC has to be booted.

7 of 135

Error messages / troubleshooting

13 Message text ERROR SAFETY LOOP

Cause -- A channel has failed or more than one enabling switch has been

pressed.

Monitor -- Cyclic.

Effect -- Path--maintaining braking, active commands inhibited.

Remedy --

14

Message text SOFTPLC: @P1@

Cause --

Monitor --

Effect --

Remedy --

15

Message text OUTPUT MONITORING DC BUS VOLTAGE KPS: @P1@

Cause -- DC bus voltage of a KPS overloaded.

Monitor --

Effect --

Remedy --

16

Message text Error while reading “O file”

17

18

Cause -- Error during loading/reading of “ident_vx.o”: memory or file not found.

Monitor -- In the write function “w_ident_state”.

Effect -- Jump to the end in load data program.

Remedy -- Copy the file “ident_vx.o” to the directory “/ir_spec/l_ident”,

or increase memory by changing the value “VxWinRAM” in the registry.

Message text WRONG/UNKNOWN HARDWARE FOUND

Cause -- During setup, the wrong control hardware (KR C1, KR C1A, KR C2)

was selected or the hardware configuration is invalid.

Monitor --

Effect -- The controller is inoperable.

-- Robot traversing not possible.

Remedy -- Carry out setup again or make appropriate changes to

hardware configuration.

Message text Servobus DSE--No. %1 participant No. %2 unknown

Cause -- An unknown device which cannot be supported has been inserted in

Interbus

Monitor -- DSE ID, device ID

Effect -- The robot can no longer be traversed

Remedy -- Remove unknown device from servo bus

8 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

19 Message text FAILURE OF MOTOR PHASE <axis>

Cause -- Power module, intermediate circuit voltage discharged.

Monitor -- Cyclic.

Effect -- Dynamic braking.

-- All active commands inhibited.

Remedy -- Switch on drives.

-- Check power module, DSE.

20

Message text EXTERNAL EMERGENCY STOP PRESSED

Cause -- Emergency Stop button pressed.

-- Emergency braking triggered by software.

Monitor -- Cyclic.

Effect -- Path--maintaining braking.

-- All active commands inhibited.

Remedy -- Check the Emergency Stop pushbutton.

-- Rectify and acknowledge the signalled fault.

21

Message text Second motorcable not connected

Cause -- Second motor cable is not connected or is incorrectly connected; the

additional cable contains two wires which are connected to the robot;

the return signal is connected to the KPS X114, pin 7

Monitor -- Cyclic.

Effect -- The robot cannot be traversed

Remedy -- Check second motor cable and return signal at KPS X114, pin 7

Fehlermeldungen 09.02.01 en

9 of 135

Error messages / troubleshooting

100 Message text RDW ** BOOT UP FAILURE

Cause -- The resolver/digital converter (RDW) could not be initialized when

the controller was booted.

Monitor -- At runup.

Effect --

Remedy -- Replace RDW, DSE or cable between RDW and DSE.

101

Message text DSE ** BOOT UP FAILURE

Cause -- The DSE could not be initialized when the controller was booted.

Monitor -- At runup.

Effect -- Maximum braking (dynamic braking).

Remedy -- Replace DSE, MFC or motherboard.

102

Message text ENCODER CABLE FAILURE **

Cause -- Cable defective (e.g. loose connection).

-- RDW defective.

-- Encoder defective.

Monitor -- Cyclic.

Effect -- Maximum braking (dynamic braking).

-- Low signal at “$ALARM_STOP” output.

-- All active commands inhibited.

Remedy -- Check encoder cable.

-- Check motor, resolver.

-- Possibly replace RDW.

103

Message text WATCHDOG INTERPOLATION CYCLE **

104

Cause -- DSE has not triggered software watchdog in the DP--RAM.

Monitor -- Cyclic.

Effect -- Maximum braking.

-- Low signal at “$ALARM_STOP” output.

-- All active commands inhibited.

Remedy -- Replace DSE or MFC.

-- Software error.

Message text SYNCHRONIZATION ERROR WITH DSE **

Cause -- DSE has not received feed command value for 1 interpolation cycle

although servo--control is active.

Monitor -- Cyclic.

Effect -- Maximum braking.

-- Low signal at “$ALARM_STOP” output.

-- All active commands inhibited.

Remedy -- Error in the DSE or PC area.

-- Software error.

10 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

105 Message text TRANSMISSION ERROR DSE -- RDW **

Cause -- Open--circuit between RDW and DSE.

-- Transmission malfunctions.

Monitor -- Cyclic.

Effect -- Maximum braking.

-- Low signal at “$ALARM_STOP” output.

-- All active commands inhibited.

Remedy -- Check shielding of encoder cable.

-- Check serial interface DSE--RDW.

106

Message text PERFORM MASTERING ** !

Cause -- Position actual value difference after restart too great and sensor

mastering not possible because sensor location run has not been

performed.

Monitor -- At “Power on”.

-- During mastering.

Effect -- All active commands inhibited.

Remedy -- Perform mastering.

107

Message text EMERGENCY STOP DUE TO DIAL ADJUSTMENT

108

109

Cause -- Softkeys for dial adjustment pressed.

-- Value assignment “$TURN = 1”.

-- Encoder setting, absolute or incremental.

Monitor -- When “$TURN” instruction is executed.

Effect -- Dynamic braking.

-- 0 signal at “$ALARM_STOP” output

-- All active commands inhibited.

Remedy -- Leave the mastering menu by pressing the Recall key twice.

Message text DYNAMIC BRAKING ACTIVE

Cause -- If the controller detects a request for maximum (dynamic) braking, it

geneates the status (operational) message “DYNAMIC BRAKING

ACTIVE”, which remains active until all axies have stopped.

Monitor -- Cyclic.

Remedy -- The status message “DYNAMIC BRAKING ACTIVE” is reset by the

controller when the robot is at standstill without a secondary message

being generated.

Message text CLEAR FAST MEASURING INPUT @P1@

Cause -- Rapid gauging has been switched on.

Monitor -- During rapid gauging.

Effect -- Rapid gauging becomes active when measuring tool has been

moved free.

Remedy -- Move measuring tool free.

Fehlermeldungen 09.02.01 en

1 1 of 135

Error messages / troubleshooting

110 Message text ADVANCED PATH PROFILE NOT POSSIBLE WITH LINKED EXTER-

NAL AXES

Cause -- Coupling of external axes in higher motion profile.

Monitor -- During command and program execution.

Effect --

Remedy --

111

Message text TEPRO INACTIVE

Cause -- SBC no longer sending a signal to KRC.

Monitor -- Cyclic.

Effect -- SBC interface inoperable.

Remedy -- Re--initialize SBC program.

112

Message text INVALID $TOOL: WORKING ENVELOPE SURVEILLANCE NOT

POSSIBLE

Cause -- “$TOOL” invalid when working envelope monitoring is activated.

Monitor -- Cyclic.

Effect -- None.

Remedy -- Assign “$TOOL” or switch off working envelope monitoring.

113

Message text RANGE OVERFLOW ** **

114

115

Cause -- Overflow of the actual value of an endless axis: actual value > +/--

90*10E15 increments or --99999000 < $REVO_NUM < 999999000

Monitor -- Cyclic in the interpolation cycle.

Effect -- Path--maintaining Emergency Stop.

Remedy -- Turn back or remaster the axis concerned.

Message text WORKING ENVELOPE NO. @P1@ VIOLATED

Cause -- TCP is inside a working envelope with MODE INSIDE STOP or outside

a working envelope with MODE OUTSIDE STOP.

Monitor -- Cyclic.

Effect -- Path--maintaining braking;

-- All active commands inhibited.

Remedy -- Switch off working envelope or use key on the KCP to override work

envelope monitoring, move free in T1 mode.

Message text DRIVE FREE WORK ENVELOPE %1

Cause -- TCP is inside a working envelope with

MODE INSIDE STOP or outside a working envelope with MODE

OUTSIDE STOP and the working envelope monitoring is overridden.

Monitor -- Cyclic.

Effect --

Remedy -- Free work envelope.

12 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

116 Message text DSE WATCHDOG COMMAND **

Cause -- DSE has not executed a command.

Monitor

Effect -- Ramp--down braking.

Remedy -- Check hardware in the DSE, MFC area.

117

Message text TORQUE EXCEEDED AXIS @P1@

Cause

Monitor

Effect

Remedy

118

Message text HEAT SINK TEMPERATURE **

Cause -- Thermostatic switch on the heat sinks of the servo output stage is

tripped due to overheating of the output stage transistors.

Monitor -- Cyclic.

Effect -- Ramp--down braking. Program processing stopped.

Remedy -- Eliminate the fault and reset it by pressing the acknowledge key on the

KCP.

-- Clean the heat sinks.

119

Message text MOTOR TEMPERATURE **

120

121

Cause -- PTC thermistor (measuring shunt) in the motor winding has been

tripped (motor temperature too high).

Monitor -- Cyclic.

Effect -- Ramp--down braking. Program processing stopped.

Remedy -- Eliminate the fault and reset it by pressing the acknowledge key on the

KCP.

-- Program more movement breaks.

Message text ACKN. MOTOR BLOCKED **

Cause -- As soon as the torque command value supplied by the speed controller

exceeds 30% of the max. torque command value, integration is

started, and when the value of i*t reaches approx. 0.75 [(torque

command value / max. torque command value) * sec] the control is

switched off (i*t -- monitoring).

Monitor -- Cyclic.

Effect -- Ramp--down braking. Program processing stopped.

Remedy -- Eliminate the fault and reset it by pressing the acknowledge key on the

KCP.

-- Check that the axis is moving freely.

Message text OVERCURRENT **

Cause -- The current of each axis is monitored and the amplifier--internal current

protection is tripped if the power consumption is too high.

Monitor -- Cyclic.

Effect -- Ramp--down braking. Program processing stopped.

Fehlermeldungen 09.02.01 en

13 of 135

Error messages / troubleshooting

Remedy -- Eliminate the fault and reset it by pressing the acknowledge key on the

122

Message text BRAKE FAULT **

Cause -- The brake cable is monitored for short--circuit, overload and cable

Monitor -- Cyclic.

Effect -- Ramp--down braking. Program processing stopped.

Remedy -- Eliminate the fault and reset it by pressing the acknowledge key on the

123

Meldungstext UNDERVOLTAGE <axis number>

Cause -- The internal operating voltage (+15V) of the servo output stage is

Monitor -- Cyclic.

Effect -- Ramp--down braking. Program processing stopped.

Remedy -- Eliminate the fault and reset it by pressing the acknowledge key on the

124

Message text OVERVOLTAGE <power module number>

KCP.

break.

-- With the PM6, all axes are supplied from one brake driver.

KCP.

monitored. Undervoltage results in power failure.

KCP.

125

126

127

Cause -- The intermediate--circuit voltage is too high. Possible causes are a de-

fective ballast (feedback) resistor or ballast fuse, a defective power

module, brake ramp too steep etc.

Monitor -- Cyclic.

Effect -- Ramp--down braking. Program processing stopped.

Remedy -- Eliminate the fault and reset it by pressing the acknowledge key on the

KCP.

Message text i2--t MONITORING, CURRENT LIMIT OF THE MOTOR CABLE

<string1> AFTER <string2> s EXCEEDED 100%

Cause -- Axis overloaded. The value for the maximum permissible limit current

is specified in the machine data by “$CURR_MON[]”.

Monitor -- Cyclic.

Effect -- Ramp--down braking, active commands inhibited.

Remedy -- Reduce load.

Message text REGULATOR LIMIT EXCEEDED <axis number>

Cause -- Following error too great. The axis does not follow the command value.

Monitor -- Cyclic in the position controller.

Effect -- Maximum braking.

Remedy -- Check the axis.

Message text <axis number> DETACHED EXTERNAL AXIS

14 of 135

Cause -- Auxiliary (external) axis is operated as an asynchronous axis.

Monitor -- Cyclic.

Effect

Fehlermeldungen 09.02.01 en

128

129

130

1 Error messages / troubleshooting (continued)

Remedy

Message text SOFTWARE LIMIT SWITCH OF DETACHED EXTERNAL AXIS

<motion direction> <axis number>

Cause -- Asynchronous axis has tripped the pos. or neg. software limit

switch.

Monitor -- The software limit switch is checked cyclically if the axis is operated

as an asynchronous axis.

Effect

Remedy

Message text i2--t MONITORING, CURRENT LIMIT OF THE MOTOR CABLE

<string1> AFTER <string2> s EXCEEDED 95%

Cause -- Axis overloaded. The value for the maximum permissible limit current

is specified in the machine data by “$CURR_MON[]”.

Monitor -- Cyclic.

Effect -- Ramp--down braking, active commands inhibited.

Remedy -- Reduce load.

Message text K1 CONTACT FAIL TO OPEN <KPS number>

131

132

133

Cause -- The K1 contact is welded.

Monitor --

Effect -- The energy supply system is not interrupted.

Remedy -- Exchange contactor, KPS.

Message text BUS VOLTAGE CHARGING UNIT IS DEFECTIVE <KPS number>

Cause -- The optocoupler on the KPS is not registering current flow.

Monitor --

Effect -- Intermediate circuit cannot be loaded.

Remedy -- Exchange KPS.

Message text BRAKE DEFECTIVE <axis ...>

Cause -- Wear on brakes, defective brake.

Monitor --

Effect -- Axis moves in an uncontrolled manner.

Remedy -- Exchange motor.

Message text MONITORING OF THE ACTUAL VELOCITY @P1@

Cause -- Fault in control loop:

-- motor cables of two axes interchanged;

-- error in the axis assignment;

-- power module defective;

-- resolver unmastered.

Monitor -- Cyclic.

Effect -- Robot remains motionless.

Remedy -- Rectify the corresponding error in the control loop.

Fehlermeldungen 09.02.01 en

15 of 135

Error messages / troubleshooting

134 Message text DN CH ... WRONG FASTWRITE MACID IN INI FILE

Cause --

Monitor --

Effect --

Remedy --

135

Message text DN CH ... MODULE ERROR ...

Cause --

Monitor --

Effect --

Remedy --

136

Message text DN CH ... SLAVE ERROR ...

Cause --

Monitor --

Effect --

Remedy -- Exchange contactor, KPS.

137

Message text DN CH ... FIRMWARE ERROR

138

139

140

Cause --

Monitor --

Effect --

Remedy --

Message text DN CH ... HARDWARE ERROR

Cause --

Monitor --

Effect --

Remedy -- Exchange contactor, KPS.

Message text DN CH ... BUS ERROR ...

Cause --

Monitor --

Effect --

Remedy --

Message text DN CH ... WATCHDOG ERROR

Cause --

Monitor --

Effect --

Remedy --

16 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

141 Message text DN CH ... USER ERROR ...

Cause --

Monitor --

Effect --

Remedy --

142

Message text DN CH ... CONFIGURATION MODE ENABLED

Cause --

Monitor --

Effect --

Remedy --

143

Message text Ixtservodrive%1exceedvalue%2%%

Cause -- If the defined Ixt monitoring warning value of a drive servo is exceeded,

the robot must be brought to a standstill; otherwise, the drive servo is

deactivated when the maximum value of 100% is exceeded

Monitor -- Cyclic, the warning bit on the drive servo

Effect -- The robot is stopped in a controlled manner.

Remedy -- Verify load data

-- If necessary, reduce the load cycle (wait time)

-- Use stronger robot

146

147

Message text Wrong amplifier %1

Cause -- Drive module of a slave axis does not correspond to drive module on

the associated master axis

Monitor -- Cyclic.

Effect -- Traversing not possible

Remedy -- Shut down controller, exchange drive module for one corresponding to

the master axis and reboot controller

Message text DRIVE FREE AXIS WORK ENVELOPE NO. %1

Cause -- The robot is inside a working envelope with MODE INSIDE STOP or

outside a working envelope with MODE INSIDE STOP and the working

envelope monitoring is overridden.

Monitor -- Cyclic.

Effect --

Remedy -- Free axis work envelope

Fehlermeldungen 09.02.01 en

17 of 135

Error messages / troubleshooting

148 Message text Axis work envelope No. %1 violated

Cause -- The robot is inside a working envelope with MODE INSIDE STOP or

outside a working envelope with MODE OUTSIDE STOP

Monitor -- Cyclic.

Effect -- Path--maintaining braking, all active commands inhibited

Remedy -- Switch off axis working envelope or override work envelope monitoring

in T1 mode and move free

155

200

201

202

Message text <axis> DECOUPLED AUXILIARY AXIS

Cause --

Monitor --

Effect --

Remedy --

Message text DRIVES CONTACTOR OFF

Cause -- Power module, intermediate--circuit voltage discharged.

Monitor -- Cyclic.

Effect -- Maximum braking.

-- All active commands inhibited.

Remedy -- Switch drives on.

-- Check power module, check DSE.

-- Emergency Stop is active, drives circuit is interrupted.

Message text KCP DEADMAN SWITCH

Cause -- The safety (deadman) switch has been released during an active

function (motion of an axis) in mode T1 or T2.

Monitor -- Cyclic.

Effect -- Maximum braking.

-- All active commands inhibited.

Remedy -- Press safety switch.

-- Check KCP, safety logic.

Message text I/O RECONFIGURATION

18 of 135

Cause -- An I/O reload command has been transmitted via the KCP.

Monitor --

Effect -- Path--maintaining braking.

Remedy -- After successful reconfiguration, the normal operating state is

automatically restored.

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

203 Message text GENERAL MOTION ENABLE

Cause -- Low signal at $MOVE_ENABLE input.

Monitor -- Cyclic.

Effect -- Ramp--down braking.

-- All active commands inhibited.

Remedy -- Check the input.

204

Message text HARDWARE LIMIT SWITCH / +24V MISSING

Cause -- The hardware limit switch has been tripped.

Monitor -- Cyclic.

Effect -- Maximum braking.

Remedy -- Shunt out the hardware limit switch and move axis off limit switch.

205

Message text SOFTWARE LIMIT SWITCH <motion direction> <axis number>

Cause -- The software limit switch of the axis indicated has been tripped in the

direction indicated. (The message is effective only after “Robot

synchronized”).

Monitor -- Cyclic.

Effect -- Maximum braking.

-- Movement in the direction indicated is inhibited.

Remedy -- Move the axis in the opposite direction (no change to the robot--specific

coordinate system takes place).

206

Message text SERVO PARAMETERS <axis> LINE <integer> INCORRECT

207

208

Cause -- The parameters in the servo file are incorrect.

Monitor -- While loading machine data.

Effect --

Remedy -- Correct the parameters.

Message text OPERATOR SAFETY / GATE OPEN

Cause -- Operator safety has been tripped in the AUTOMA TIC or EXTERNAL

mode (input at the peripheral interface).

Monitor -- Cyclic.

Effect -- Ramp--down braking.

-- All active commands inhibited.

Remedy -- Switch to mode T1 or T2 (in these modes the robot can be moved

when the signal is low).

-- Close the safety gate.

-- Check the input.

Message text FAILURE IN ESC SAFETY LOOP

Cause -- Emergency Stop button pressed.

-- Emergency braking triggered by software.

Monitor -- Cyclic.

Fehlermeldungen 09.02.01 en

19 of 135

Error messages / troubleshooting

Effect -- Path--maintaining braking.

Remedy -- Check the Emergency Stop pushbutton;

209

Message text PASSIVE STOP <RCP or teach pendant>

Cause -- Stop from a passive operator control unit (the message is displayed

Monitor -- Cyclic.

Effect -- Ramp--down braking.

Remedy -- Acknowledge the message “Passive Stop”.

210

Message text STOP KEY <RCP or teach pendant>

Cause -- The start key or a traversing key has been actuated while the stop

Monitor -- Cyclic.

Effect -- Ramp--down braking.

Remedy -- Check the stop key.

211

Message text CHECK SAFETY LOGIC. DRIVES OFF TIMEOUT DURING EMER-

Cause --

Monitor --

Effect --

Remedy --

212

Message text ERROR WRITING TO PERCEPTRON

-- All active commands inhibited.

-- Rectify and acknowledge the signalled fault.

only if an active process has been stopped).

-- All active commands inhibited.

key is depressed.

-- All active commands inhibited.

GENCY STOP OCCURRED

--

213

214

20 of 135

Cause --

Monitor --

Effect --

--

Remedy --

Message text ERROR WRITING TO BOSCH

Cause --

Monitor --

Effect --

--

Remedy --

Message text COMMON DRIVES ERROR <axis number>

Cause --

Monitor --

Fehlermeldungen 09.02.01 en

215

216

217

1 Error messages / troubleshooting (continued)

Effect --

--

Remedy --

Message text COMMON DRIVES ERROR <axis number>

Cause --

Monitor --

Effect --

--

Remedy --

Message text DRIVES ERROR ... NO.: ...

Cause -- The Start key or a direction key was activated while the Stop key

was pressed.

Monitor -- Cyclic.

Effect -- Ramp--down braking.

-- All active commands inhibited.

Remedy -- Check Stop key.

Message text EMERGENCY STOP FROM KRC ( ALARM STOP )

218

219

Cause -- An alarm stop has been initiated by the KRL system software;

another serious error has occurred.

Monitor -- Cyclic.

Effect -- Maximum braking. All active commands inhibited.

Remedy -- Eliminate and acknowledge the signalled fault (serious error).

Message text FEEDBACK SWITCH TOO LONG ON **

Cause -- The energy of the axis to be braked was too high.

Monitor

Effect -- Ramp--down braking.

Remedy -- Power module ballast (feedback) switch defective.

-- Brake ramp in the program too steep.

Message text CABINET TEMPERATURE TOO HIGH **

Cause -- The cabinet temperature has risen above the permissible limit value.

Monitor -- Cyclic.

Effect -- Ramp--down braking.

Remedy -- Reduce the external temperature.

-- Change the site of installation.

-- Check the fans.

-- Clean the heat exchanger.

Fehlermeldungen 09.02.01 en

21 of 135

Error messages / troubleshooting

220 Message text DRIVES CONTACTOR OFF, INTERMEDIATE CIRCUIT LOADED !!!

Cause -- The drives contactor drops out. The energy in the intermediate circuit

is sufficient to ensure a path--maintaining stop. Caution: the

intermediate circuit is still charged! The intermediate circuit is

discharged after about 2 minutes. The message “DRIVES NOT

READY” is then displayed.

Monitor -- Cyclic.

Effect -- Path--maintaining Emergency Stop

Remedy -- Switch drives on again.

-- Check drives circuit for faults.

221

Message text MODE NOT ALLOWED

Cause -- E2 keyswitch in AUTO mode.

Monitor

Effect

Remedy

222

Message text PARITY ERROR POWERMODULE **

223

224

225

Cause -- A parity error has occurred more than five times in succession when

reading the power module register.

Monitor -- Cyclic.

Effect -- Ramp--down braking.

Remedy -- Too much interference at the power module interface, or power module

defective. Check cable, check shielding, replace power module.

Message text POWER MODULE AXIS ** NOT OR WRONGLY PLUGGED

Cause -- The axis is incorrectly plugged into the power module or not connected

at all.

Monitor -- At runup.

Effect -- Active commands inhibited.

Remedy -- Connect the axis correctly (high or low power).

Message text POWER FAIL

Cause -- The cabinet voltage has been switched off, the mains voltage is

interrupted.

Monitor

Effect -- Path--maintaining Emergency Stop, buffering of the mastering data,

saving all data on HDD.

Remedy -- Check the mains voltage.

Message text MOTOR CABLE **

22 of 135

Cause --

Monitor --

Effect --

Remedy --

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

226 Message text FAILURE OF HEAT SINK TEMPERATURE SENSOR **

Cause --

Monitor --

Effect --

Remedy --

227

Message text FAILURE OF CABINET INTERIOR TEMPERATURE SENSOR <AXIS

NUMBER>

Cause --

Monitor --

Effect --

Remedy --

228

Message text DRIVES PARAMETER DATA ** INVALID

Cause --

Monitor --

Effect --

Remedy --

229

Message text FAILURE OF MOTOR TEMPERATURE SENSOR <AXIS NUMBER>

230

231

232

Cause --

Monitor --

Effect --

Remedy --

Message text WRONG DRIVES PARAMETER <AXIS NUMBER> **

Cause --

Monitor --

Effect --

Remedy --

Message text ERROR SYNC. INPUT DRIVE <AXIS>

Cause --

Monitor --

Effect --

Remedy --

Message text SYNCHRONISATION ERROR DRIVE <AXIS>

Cause --

Monitor --

Effect --

Remedy --

Fehlermeldungen 09.02.01 en

23 of 135

Error messages / troubleshooting

233 Message text <AXIS> WITHOUT PO WER

Cause --

Monitor --

Effect --

Remedy --

234

Message text COMMON DRIVES ERROR <AXIS NUMBER>

Cause --

Monitor --

Effect --

Remedy --

235

Message text COMMON DRIVES ERROR <AXIS NUMBER>

Cause --

Monitor --

Effect --

Remedy --

236

Message text COMMON DRIVES ERROR <AXIS NUMBER>

237

238

239

Cause --

Monitor --

Effect --

Remedy --

Message text COMMON DRIVES ERROR <AXIS NUMBER>

Cause --

Monitor --

Effect --

Remedy --

Message text COMMON DRIVES ERROR <AXIS NUMBER>

Cause --

Monitor --

Effect --

Remedy --

Message text LOADING ** SERVO PARAMETERS **

Cause -- Loading drive servo parameters

Monitor --

Effect --

Remedy --

24 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

240 Message text PLEASE SWITCH OFF THE CABINET

Cause -- The drive servo parameters have been loaded, but will not take effect

until the next reboot.

Monitor --

Effect --

Remedy --

241

Message text SERVOFILE CONFIGURATION ** DOES NOT FIT THE ** RELEASE

**

Cause -- The servo file configuration contains parameters for the drive servos

which are not supported by the firmware.

Monitor --

Effect --

Remedy -- Upgrade drive servo firmware or servo files.

242

Message text ** FIRMWARE RELEASE **

Cause -- Information about the firmware release of the axis in question.

Monitor --

Effect --

Remedy -- Upgrade drive servo firmware or servo files.

243

Message text SOFTWARE OF DSE ** DOES NOT FIT THE HARDWARE OR

DEFECTIVE DSE

Cause -- The wrong software was configured for the DSE

DSEAT and KR C1A/KR C2.

Monitor --

Effect --

Remedy -- Configure the correct software.

244

Message text ** SOFTWARE VERSION INCORRECT

245

246

Fehlermeldungen 09.02.01 en

Cause -- DSE software and kernel system do not work together.

Monitor --

Effect --

Remedy -- Configure the correct DSE software.

Message text SERVO BUS DISTURBANCE DSE **

Cause -- Defective bus cable.

Defective bus module.

Defective bus driver.

Monitor -- Rectify fault.

Effect --

Remedy --

Message text SERVO BUS DISTURBANCE DSE **, NO BUFFERING AND

AUTOMATIC DATA STORAGE POSSIBLE

Cause -- Buffering is activated via the servo bus on the KPS. If communication

with the KPS is faulty, the buffering cannot be activated and switch--off

takes place immediately.

25 of 135

Error messages / troubleshooting

Monitor --

Effect --

Remedy -- Re--establish communication with the KPS.

247

Message text SERVO BUS DISTURBANCE **

Cause --

Monitor --

Effect --

Remedy --

248

Message text SERVO BUS DISTURBANCE **

Cause --

Monitor --

Effect --

Remedy --

249

Message text $MOVE_ENABLE INPUT (1025) NOT ALLOWED

250

251

252

Cause --

Monitor --

Effect --

Remedy --

Message text INCORRECT SERVO PARAMETER <AXIS>

Cause --

Monitor --

Effect --

Remedy --

Message text <variable> OVERLAPPING OUTPUT SIGNALS

Cause -- Interface unit outputs assigned twice.

Monitor -- At “Power On”.

After editing the machine data.

After loading the machine data.

Effect -- No RC Ready.

Remedy -- Value assignment.

Message text <variable> INTERFACE--I/O ASSIGNMENT ERROR <correct index>

26 of 135

Cause -- Double assignment of interface controller output.

Monitor -- At “Power on”.

-- After editing the machine data.

-- After loading the machine data.

Effect -- No RC ready.

Remedy -- Correct the indicated machine datum.

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

253 Message text ERRONEOUS DSE AXIS ASSIGNMENT <axis number>

Cause -- Machine datum $IFACE_DRV[6] has been assigned twice to a drive

interface, or a non--existent interface has been addressed.

-- KTL encoders have been entered in IFACE_DRV[6] without connecting APC interfaces, or ADAR axes have been entered in $ADAR_AXIS

without connecting ADAR interfaces.

Monitor -- At “Power on”.

-- After editing the machine data.

-- After loading the machine data.

Effect -- No RC ready.

Remedy -- Correct the machine datum.

254

Message text DSE FILE <program name> NOT AV AILABLE

Cause -- The DSE program entered in the RD_HWINF.INI file does not exist.

Monitor

Effect

Remedy -- Enter or alter the DSE program.

255

Message text <$ variable> INVALID VALUE

256

Cause -- The machine data loader has detected that a variable contains an

incorrect value:

a) Limit monitoring tripped.

b) Machine data not logically coherent.

Monitor -- At “Power on”.

-- After editing the machine data.

-- After loading the machine data.

Effect -- No RC ready.

Remedy -- Correct the value assignment.

Message text CHECK MACHINE DATA !

Cause -- It cannot be assured that the machine data loaded during a cold

start are valid for the connected robot.

Monitor -- Generated at cold start.

Effect -- No RC ready.

-- Controller is in its initial state, i.e. tasks dependent on machine data

are not generated.

Remedy -- Either edit or copy the machine data or option data file.

Fehlermeldungen 09.02.01 en

27 of 135

Error messages / troubleshooting

257 Message text ERRONEOUS USER DATA

Cause -- The user data loader has detected that a variable contains an incorrect

value:

a) Limit monitoring tripped.

b) Data not logically coherent.

Monitor -- At “POWER ON”.

-- After editing the user data.

-- After loading the user data (DEFDAT $CUSTOM PUBLIC).

Effect -- No RC ready.

Remedy -- Correct value assignment of the indicated variable.

258

Message text ERRONEOUS OPTION DATA

Cause -- The option data loader has detected that a variable contains an incor-

rect value:

a) Limit monitoring tripped.

b) Data not logically coherent.

Monitor -- At “POWER ON”.

-- After editing the option data.

-- After loading the option data (DEFDAT $OPTION PUBLIC).

Effect -- No RC ready.

Remedy -- Correct value assignment of the indicated variable.

259

Message text ** MACHINE DATA LOADER ABORTED

260

Cause -- The errors detected by the machine data loader exceed the capacity

of the message buffer.

Monitor -- At “POWER ON”.

-- After editing the machine data.

-- After loading the machine data.

Effect -- No RC ready.

Remedy -- Correct value assignment of the indicated variable.

Message text USER DATA LOADER ABORTED

Cause -- The errors detected by the user data loader exceed the capacity of

the message buffer.

a) Limit monitoring tripped.

b) Data not logically coherent.

Monitor -- At “POWER ON”.

-- After editing the user data.

-- After loading the user data.

Effect -- No RC ready.

Remedy -- Correct value assignment of the indicated variable.

28 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

261 Message text OPTION DATA LOADER ABORTED

Cause -- The errors detected by the option data loader exceed the capacity of

the message buffer.

a) Limit monitoring tripped.

b) Data not logically coherent.

Monitor -- At “POWER ON”.

-- After editing the option data.

-- After loading the option data.

Effect -- No RC ready.

Remedy -- Correct value assignment of the indicated variable.

262

Message text ERRONEOUS <path> MACHINE DATA

Cause -- The machine data loader has detected a variable with an illegal value.

a) Limit monitoring tripped.

b) Data not logically coherent.

Monitor -- At “POWER ON”.

-- After editing the machine data.

-- After loading the machine data.

Effect -- No RC ready.

263

Message text ERRONEOUS CORRECTION DATA

264

265

Cause -- The correction data loader has detected a variable with an illegal value.

a) Limit monitoring tripped.

b) Data not logically coherent.

Monitor -- POWER ON after editing the correction data, after loading the

correction data (DEFDAT $ROBCOR).

Effect -- No RC ready.

Remedy -- Correct value assignment of the indicated variable.

Message text <path> CORRECTION DATA LOADER ABORTED

Cause -- The errors detected by the correction data loader exceed the capacity

of the message buffer.

Monitor -- At “POWER ON”.

-- After editing the correction data.

-- After loading the correction data.

Effect -- No RC ready.

Remedy -- Correct value assignment of the indicated variable.

Message text RDW FILE <program name> NOT AV AILABLE

Cause -- The RDW program entered in the RD_HWINF.INI file does not exist.

Monitor

Effect

Remedy -- Enter the RDW program correctly in the INI file.

Fehlermeldungen 09.02.01 en

29 of 135

Error messages / troubleshooting

266 Message text OVERTEMPERATURE FEEDBACK RESISTOR <power module no.>

OR FAN

Cause -- The ballast (feedback) resistor has overheated. In the motion program

the robot is cyclically accelerated and decelerated without a break.

Monitor -- Cyclic.

Effect -- Ramp--down braking.

Remedy -- Insert wait times into the program, reduce the acceleration.

267

Message text WATCHDOG POWER MODULE <power module number>

Cause -- The watchdog on the power module has dropped out. The watchdog

is triggered by the DSE every 0.125ms.

Monitor -- Cyclic.

Effect -- Dynamic braking.

Remedy -- Troubleshooting in the DSE and power module area.

268

Message text MEMORY TEST ERROR DSE <DSE number 1 --4>

Cause -- The memory test on the DP--RAM of the DSE detected an error.

Monitor -- Runup.

Effect -- Active commands inhibited.

Remedy -- Replace DSE or MFC.

269

Message text DSE <DSE number 1--4> NOT AVAILABLE

270

271

Cause -- The bit on the MFC indicating whether a DSE is inserted is not set

although axes are allocated to this DSE.

Monitor -- At runup.

Effect -- Active commands inhibited.

Remedy -- Insert DSE, replace MFC or DSE.

Message text INCORRECT POWER MODULE SETTING <axis>

Cause -- Double assignment of $PMCHANNEL or incorrect channel.

Monitor -- When loading the robot machine data.

Effect -- Machine data loader aborted.

Remedy -- Correct $PMCHANNEL.

Message text ROBOT NO. ** DOES NOT CORRESPOND TO CALIBRATION FILE

**

Cause --

Monitor --

Effect --

Remedy --

30 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

272 Message text NO ROBOT NUMBER PROGRAMMED

Cause --

Monitor --

Effect --

Remedy --

273

Message text MORE THAN ONE CALIBRATION FILE AVAILABLE

Cause --

Monitor --

Effect --

Remedy --

274

Message text Check robot number

Cause --

Monitor --

Effect --

Remedy --

275

Message text SET ROBOT NUMBER – PROGRAM ROBOT NAME

276

277

Cause --

Monitor --

Effect --

Remedy --

Message text WRONG MACHINE DATA FOR THIS ROBOT TYPE

Cause -- The machine data do not correspond to the robot type stored in the

robot base.

Monitor -- Run--up.

Effect --

Remedy -- Load the correct machine data.

-- Reprogram the robot type.

Message text AUTOMATIC REPOSITIONING

Cause -- $MOT_STOP_OPT = TRUE. Robot not on path.

In EXTERN, $MOT_STOP (flag that the robot is not on path) has

been set by the user (via the GUI) to FALSE, so that the robot automatically moves on path at process velocity.

Monitor --

Effect -- Only a message that the robot is moving on the path in EXTERN.

Remedy -- The message is deleted as soon as BCO is reached.

Fehlermeldungen 09.02.01 en

31 of 135

Error messages / troubleshooting

278 Message text Error Power Relay K1

Cause -- Correct program.

-- The contact in drive contactor K1 is stuck.

Monitor --

Effect -- Path--maintaining braking.

-- All active commands inhibited.

Remedy -- Change power module.

279

Message text Feedback switch too long on <KPS number> while charging

Cause --

Monitor --

Effect -- Maximum braking.

-- All active commands inhibited.

Remedy -- Check the hardware.

280

Message text Overvoltage <kps number> while charging

281

Cause --

Monitor --

Effect -- Maximum braking.

-- All active commands inhibited.

Remedy -- Check the hardware.

Message text Check accumulator <kps number>

Cause -- Message comes directly from the KPS.

-- Accu voltage is under 19V.

-- The accu is not charged correctly anymore.

-- The accu is to old or broken.

Monitor --

Effect -- Eventually loss of reference.

-- Cold boot.

-- Active commands inhibited.

Remedy -- Exchange accu.

32 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

282 Message text Undervoltage <kps number> while charging

Cause -- Message comes directly from the KPS.

-- Intermediate circuit could not be charged correctly.

Monitor --

Effect -- Maximum braking.

-- All active commands inhibited.

Remedy -- Check supply voltages of KPS (especially three--phase current)

if there are interferences.

-- Exchange KPS.

283

Message text Brake error <KPS number> channel <brake channel>

Cause -- Brake error

Monitor --

Effect -- Path--maintaining braking.

-- All active commands inhibited.

Remedy -- Check the hardware for faults.

284

Message text Accu--voltage at <kps number> below <voltage level> during last

buffering

Cause -- The accu voltage was too low at the last switch off to buffer the

shutdown.

-- The accu is not charged correctly anymore.

-- The accu is to old or broken.

Monitor --

Effect -- Eventually loss of reference.

-- Cold boot.

-- Active commands inhibited.

Remedy -- Exchange accu.

285

Message text RIO configuration change: controller reboot necessary

Fehlermeldungen 09.02.01 en

Cause -- In order for the RIO configuration change to take effect, it is

necessary to restart the system.

Monitor --

Effect --

Remedy -- Restart the controller.

33 of 135

Error messages / troubleshooting

286 Message text Warning: PC fan below nominal speed

Cause -- PC controller cooling is still sufficient, but could soon become critical

Monitor -- Cyclic.

Effect -- None

Remedy -- Check PC fan and exchange if necessary

287

288

289

Message text PC fan error

Cause -- PC controller cooling is no longer sufficient; continued operation

could cause damage to components

Monitor -- Cyclic.

Effect -- The robot is stopped and can no longer be traversed

Remedy -- Check PC fan immediately and exchange if necessary

Message text Over temperature feedback resistor %1

Cause -- The feedback resistor has got too hot

-- The robot is cyclically accelerated and braked in the motion program

without a pause

Monitor -- Cyclic.

Effect -- Ramp--down braking

Remedy -- Reduce acceleration, introduce wait times

Message text Overtemperature fan %1

Cause -- One of the two fans in the cabinet is defective

Monitor -- Cyclic.

Effect -- Ramp--down braking

Remedy -- Exchange the fan in question

300

34 of 135

Message text OPERATING MODE CHANGE

Cause -- The mode selector switch is set to an illegal position.

Monitor -- In command processing.

Effect -- Maximum braking.

-- All active commands inhibited.

Remedy -- Set mode selector switch to a permissible position. The status

(operational) message is then reset.

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

301 Message text STOP WHILE MEASUREMENT ACTIVE -- MOVEMENT WILL BE

HANDLED AS TEST

Cause --

Monitor --

Effect --

Remedy --

302

Message text *<command name> ACTIVE

Cause -- OBJH command is being executed.

Monitor -- In command processing.

Effect -- None.

Remedy -- Wait until OBJH is free again.

303

Message text LIMIT <signal name>

Cause -- The value for the corresponding analog output lies outside thestandard

range and has therefore been limited to the maximum or minimum

value.

Monitor -- Cyclic, when writing to analog outputs.

Effect -- None.

Remedy -- The message remains set until the value of the analog output

concerned lies within the standardized range and therefore no

limitation occurs.

304

Message text START UP

305

306

307

Cause -- Startup (setup) menu selected.

Monitor -- In command processing.

Effect -- Program processing not possible.

Remedy -- Quit the setup menu using the ESC key.

Message text COMPLETE COMPILATION ACTIVE

Cause --

Monitor --

Effect --

Remedy --

Message text SELECTION ACTIVE

Cause -- New selection requires deselection/linking.

Monitor -- Command processing (RUN command).

Effect -- None.

Remedy -- Wait until the linking procedure is finished, i.e. until the message

disappears.

Message text ERRORS AT COMPLETE COMPILATION -- ERR FILES EXIST

Cause --

Monitor --

Fehlermeldungen 09.02.01 en

35 of 135

Error messages / troubleshooting

Effect --

Remedy --

308

Message text PALLETIZING MODE: MOVE AXIS <axis> <motion direction> INTO

Cause -- Axes 4 and 5 have palletizing mode ( $PAL_MODE = TRUE ), but

Monitor -- Cyclic.

Effect -- None.

Remedy -- Move axes into position in the specified direction.

309

Message text BLOCK SELECT : BCO REACHING IN T1/T2 REQUIRED

Cause --

Monitor --

Effect --

Remedy --

1000

Message text USER--MEMORY DELETED (**)

Cause --

Monitor --

Effect --

Remedy --

1001

Message text INTERNAL ERROR (DEFAULT MESSAGE)

POSITION

not the right position, i.e. A4=0 degrees and A5=90 degrees.

1002

1003

Cause -- Internal; the message data have not been correctly set.

Monitor

Effect

Remedy

Message text REBOOT AFTER POWERFAIL

Cause -- Controller is turned on again or voltage has returned.

Monitor --

Effect --

Remedy --

Message text LEVEL OVERFLOW <IP,PCP>

Cause -- Computing time overload of CPU.

Monitor -- Cyclic.

Effect -- Maximum braking.

-- Low signal at “$ALARM_STOP” output.

-- All active commands inhibited.

Remedy -- Increase basic cycle.

-- Increase interpolation cycle or position control cycle, depending on the

indicated parameter.

36 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

1004 Message text CAN CONTROLLER @P1@ FAILURE

Cause --

Monitor --

Effect --

Remedy --

1005

Message text NO MORE SYSTEM MEMORY AVAILABLE

Cause -- There is not enough memory available for the command “SHOW VAR”

or “SET INFO” to be executed (the control requires a certain amount

of memory for these commands, dependent on the length of the output

value.)

Monitor -- In form processing.

Effect -- Command is not executed.

Remedy -- Save and delete programs that are not required.

1006

Message text NO MORE USER MEMORY AVAILABLE

Cause -- No more memory is available for copying objects.

Monitor -- In command processing.

Effect -- Command is not executed.

Remedy -- Delete objects that are not required.

1007

Message text CHANNEL <channel name> CANNOT BE ASSIGNED

1008

1009

Cause -- The selected channel cannot be assigned.

Monitor -- In command processing.

Effect -- Command is not executed.

Remedy -- Free channel at another point (should occur only with printer channel).

Message text CONTROLLER BOOTED

Cause -- Controller is booted for the first time (not reboot after power failure).

Monitor --

Effect --

Remedy --

Message text POINT CONVERSION IMPOSSIBLE WITHOUT ABSOLUTE

ACCURACY MODEL

Cause -- $ABS_ACCUR = FALSE and $ABS_CONVERT = TRUE conversion

impossible without model. If $ABS_CONVERT is TRUE, then

$ABS_ACCUR must also be TRUE!

Monitor --

Effect --

Remedy -- $ABS_ACCUR = TRUE or $ABS_CONVERT = FALSE

Fehlermeldungen 09.02.01 en

37 of 135

Error messages / troubleshooting

1010 Message text INTERNAL ERROR <system error number> (<task ID>, <status>)

Cause -- Internal test of KRC.

-- Software.

Monitor -- Within the KRC.

-- Software.

Effect -- RC Ready reset during processing.

Remedy -- Acknowledge message.

1011

Message text SYNTAX ERROR IN FILE <filename> IN ROW <contents of the line>

Cause -- Syntax error when interpreting the parameter file (absolutely accurate

robot).

Monitor -- When loading $OPTION.DAT or defining $LOAD or $LOAD_A3.

Effect --

Remedy -- Load file, boot controller.

1012

Message text GENERAL ERROR: <error no.> <function> <additional info>

1013

1014

1015

Cause -- Unknown feedback from a function in the object.

Monitor -- In command processing.

Effect -- None.

Remedy -- Inform service department.

Message text FILE <file name> NOT FOUND

Cause -- Parameter file for absolutely accurate robot is not available.

Monitor -- When loading $OPTION.DAT.

Effect --

Remedy -- Load file, boot controller.

Message text UNKNOWN COMPILER ERROR: <error class>

Cause -- Compiler software has detected an error.

Monitor -- In command processing.

Effect -- None.

Remedy -- Inform service department.

Message text OBJH ERROR: <localization>

Cause -- Internal error in the OBJH.

Monitor -- In command processing.

Effect -- None.

Remedy -- Inform service department.

38 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

1016 Message text HARDWARE LIMIT--SWITCH / +24V MISSING

Cause -- The interface module monitoring function has detected that a common

input for hardware limit switches has been set.

Monitor -- Cyclic in interface module monitoring.

Effect -- The roboter is stopped with maximum braking and the active

commands are inhibited until this message has been acknowledged.

Remedy -- Move robot off limit switch and acknowledge message.

!!!Caution!!! Moving the robot off the limit switch correctly is the

operator’s responsibility, since no axis--specific interlocks are set.

1017

Message text ABSOLUTE ACCURACY ROBOT: POINT CONVERSION ONLY POS-

SIBLE IN T1 MODE

Cause -- $ABS_CONVERT = TRUE and no T1 mode

Point conversion must be carried out carefully .

Monitor --

Effect -- Ramp--down braking.

Active commands inhibited.

Remedy -- Set variable $ABS_CONVERT in $CUSTOM.DAT to FALSE or select

T1 mode.

1018

Message text ERROR OCCURRED WHILE READING IDF FILE

1019

1020

1021

Cause --

Monitor --

Effect --

Remedy --

Message text PALLETIZING MODE NOT POSSIBLE WITH THIS ROBOT TYPE

Cause -- Palletizing is only possible with floor and ceiling--mounted robots. If

$ROBROOT A or B <> 0, palletizing is not possible.

Monitor -- Write function.

Effect -- Maximum braking.

Remedy -- Enter correct $ROBROOT or $PAL_MODE = FALSE.

Message text INTERNAL ERROR <error number> (<task ID>, <return status>)

Cause -- Internal software error.

Monitor

Effect

Remedy

Message text INTERNAL ERROR WHEN ACCESSING <object name>

Cause -- An internal error has occurred when accessing a file (acknowledge-

ment message already set). The action was not c orrectly carried out.

Monitor -- In object processing.

Effect

Remedy

Fehlermeldungen 09.02.01 en

39 of 135

Error messages / troubleshooting

1022 Message text COMMUNICATION <operator control device> – KRC INTERRUPTED

Cause -- Communication between the active operator control unit and the KRC

has been interrupted while a motion was being executed in the test

mode.

Monitor -- In command processing.

Effect -- Maximum braking.

Remedy -- Re--establish the connection.

1023

Message text INPUT BUFFER OVERFLOW **

Cause --

Monitor --

Effect --

Remedy --

1024

Message text ERROR DURING READING OF INI FILE ** **

Cause -- Error in INI file.

Monitor -- At system start.

Effect -- All commands are inhibited.

Remedy -- Correct INI file.

1025

Message text CONFIGURATION ERROR I/O DRIVER <driver name>

1026

1027

1028

Cause -- Error in the INI file.

Monitor -- In system runup.

Effect

Remedy -- Check io_int.ini.

Message text ERROR DIGITAL INPUT READING PORT: **

Cause

Monitor

Effect

Remedy -- Check I/O components.

Message text ERROR WRITE DIGITAL OUTPUTS PORT: **

Cause

Monitor

Effect -- Maximum braking.

Remedy -- Check the corresponding I/O hardware.

Message text ERROR RESTART I/O <bus/driver name>

Cause -- Field bus error is still present.

Monitor

Effect -- Bus I/O still not available.

Remedy -- Eliminate field bus error (hardware).

40 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

1029 Message text SEN: <string> ** **

Cause -- Hint message of a sensor that does not require a stop.

Monitor

Effect

Remedy

1030

Message text SEN: <string> ** **

Cause -- Sensor error that requires ramp--down braking.

Monitor

Effect

Remedy -- Depends on sensor concerned.

1031

Message text SEN: <string> ** **

Cause -- Sensor error that requires ramp--down braking.

Monitor

Effect

Remedy

1032

Message text SEN: **

1033

1034

1035

Cause -- Sensor error that requires ramp--down braking.

Monitor

Effect

Remedy

Message text ERROR ON READING, DRIVER: ** **

Cause --

Monitor --

Effect --

Remedy --

Message text ERROR ON WRITING, DRIVER: ** **

Cause --

Monitor --

Effect --

Remedy --

Message text SINGULARITY--LESS MOTION: MAX. ORIENTATION ERROR

Cause --

Monitor --

Effect --

Remedy --

Fehlermeldungen 09.02.01 en

41 of 135

Error messages / troubleshooting

1036 Message text CHECK SAFETY LOGIC. DRIVES OFF TIMEOUT DURING EMER-

GENCY STOP

Cause --

Monitor --

Effect --

Remedy --

1037

Message text LOCAL EMERGENCY STOP BUTTON PRESSED

Cause --

Monitor --

Effect --

Remedy --

1038

Message text INVALID OPERATING MODE

Cause -- STARTMINUSwaspressedinAUTorEXT.OnlypossibleinT1or

T2.

Monitor -- Command execution.

Effect --

Remedy --

1039

Message text BACKWARD MOTION EXECUTION NOT POSSIBLE: TRACE EMPTY

1040

1041

1042

Cause -- All recorded motions have already been executed.

Monitor -- Command execution.

Effect --

Remedy -- Forward motion.

Message text BACKWARD MOTION EXECUTION NOT POSSIBLE: NO TRACE

Cause -- No points were executed and recorded in the forwards direction, or

the traces were rejected.

Monitor -- Command execution.

Effect --

Remedy -- Forward motion.

Message text SOFTPLC: **

Cause --

Monitor --

Effect --

Remedy --

Message text ACKN K1 CONTACT FAIL TO OPEN < KPS number>

Cause -- The K1 contact is welded.

Monitor --

Effect -- The energy supply is not interrupted.

Remedy -- Exchange contactor, KPS.

42 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

1043 Message text ACKN BUS VOLTAGE CHARGING UNIT IS DEFECTIVE <KPS number>

Cause -- The optocoupler on the KPS is not registering current flow.

Monitor --

Effect -- Intermediate circuit cannot be loaded.

Remedy -- Exchange KPS.

1044

Message text ACKN BRAKE DEFECTIVE **

Cause -- Wear on brakes, defective brake.

Monitor --

Effect -- Axis moves in an uncontrolled manner.

Remedy -- Exchange motor.

1045

Message text SERVO INDEPENDENT COMMAND EXECUTION

Cause --

Monitor --

Effect --

Remedy --

1046

Message text BLOCKING OF OUTPUTS IN AUT/EXT IS ENABLED

1047

1048

1049

Cause -- Variable $BLK_IO_AUT is set to TRUE (setting outputs in AUT/EXT

is blocked). The user nevertheless tries to set the outputs by hand.

Monitor --

Effect --

Remedy --

Message text SERVO INDEPENDENT COMMAND EXECUTION ONLY POSSIBLE

IN TESTING MODE

Cause -- Robot simulation not allowed in operating modes #AUT or #EXT.

Monitor --

Effect -- No program execution/simulation possible.

Remedy -- Change operating mode.

Message text ACKN. OUTPUT MONITORING DC BUS VOLTAGE KPS: **

Cause -- DC bus voltage of a KPS overloaded.

Monitor --

Effect --

Remedy --

Message text PROFIBUS MASTER IS IN STATE AUTOCLEAR. PLEASE EXECUTE

RESET COMMAND

Cause -- Bus error in Profibus. Option AUTOCLEAR is set. This means that the

bus no longer starts again automatically. A Profibus reset is necessary.

Monitor --

Effect -- Indication that a bus reset is necessary since the bus does not start

again automatically (the corresponding option is not set).

Remedy -- Rectify bus error and carry out RESET via the menu.

Fehlermeldungen 09.02.01 en

43 of 135

Error messages / troubleshooting

1050 Message text PROFIBUS : ERROR IN MASTER CIRCUIT ** **

Cause --

Monitor --

Effect --

Remedy --

1051

Message text PROFIBUS: ERROR IN SLAVE CIRCUIT

Cause --

Monitor --

Effect --

Remedy --

1052

Message text KCP: CAN BUS ERROR

Cause -- Transmission error in CAN BUS.

Monitor -- Teach pendant task.

Effect -- Path--maintaining braking.

Remedy -- Acknowledge.

1053

Message text CP VEL. REDUCTION POINT ** ** BY **

1054

1055

1056

Cause --

Monitor --

Effect --

Remedy --

Message text ACKN. DN CH ** TOO MANY MODULE ERRORS **

Cause --

Monitor --

Effect --

Remedy --

Message text TRACE BUFFER EMPTY, START WITH BACKWARD SCAN

Cause -- Empty trace for backward motion, switching to SCAN method.

Monitor -- When START minus is pressed.

Effect -- Active commands inhibited.

Remedy -- Acknowledge.

Message text ACKN. SERVOBUS DSE--NO.: <DSE no.> PARTICIPANT NO.: <IBS

device> UNKNOWN

Cause -- An unknown device which is not supported was inserted in Interbus.

44 of 135

Monitor -- DSE ID, device ID.

Effect --

Remedy -- Remove the device causing the fault from the bus system.

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

1057 Message text ACKN. FAILURE OF MOTOR PHASE <axis>

Cause -- Backup battery voltage low.

Monitor -- At “Power on”.

-- Cyclic.

Effect -- At “Power on” --> automatic general reset, and in addition the message

“User memory deleted” is displayed (machine data, user data, application programs must be reloaded).

-- Cyclic --> none.

Remedy -- Exchange battery. After exchange, the message

“Ackn. check accumulator” appears --> acknowledge.

1058

Message text BCO MOTION: PRESS START PLUS

Cause -- An attempt was made to carry out BCO motion with START MINUS.

Monitor -- When START MINUS is pressed.

Effect -- The robot does not start.

Remedy -- Use START PLUS or set Implicit_BCO = TRUE in BACKWARD.INI.

1059

Message text FINISHED SUBROUTINE: SKIP MOTIONS

1060

1061

Cause -- During backward motion, the interpreter encounters a subprogram

which has already been completely executed.

Monitor -- Each time before backward motion is started.

Effect -- Active commands inhibited.

Remedy -- Acknowledge.

Message text $BWDSTART NOT IN FOLD. NO TOOL AND BASE INFORMATION

FOUND

Cause -- Backward motion in SCAN method: a $BWDSTART assignment must

be programmed as the first instruction in a motion fold. From this line

onwards, all following instructions up to the motion are executed before

backward motion is carried out.

Monitor -- Each time before backward motion is started.

Effect -- Active commands inhibited.

Remedy -- Correct program or set the entry BACKWARDSTART = FALSE in

BACKWARD.INI. In this case, however, BASE and TOOL changes

cannot be carried out during backward motion.

Message text Rapid EMERGENCY STOP with fixed braking ramps

Cause -- In the event of EMERGENCY STOP with dynamic model, the fixed

braking ramp strategy is used as this brakes the robot significantly

more quickly

Monitor -- In the event of EMERGENCY STOP with dynamic model

Effect -- EMERGENCY STOP brakes the robot more quickly than the strategy

based on the dynamic model

Remedy -- Verify load data and correct if necessary

-- Verify machine data

Fehlermeldungen 09.02.01 en

45 of 135

Error messages / troubleshooting

1062 Message text Ackn. second motorcable not connected

Cause -- Second motor cable was not connected or was connected incorrectly

Monitor --

Effect --

Remedy -- Acknowledge message

1063

Message text Ackn. over temperature feedback resistor %1

Cause -- The feedback resistor has got too hot

-- The robot is cyclically accelerated and braked in the motion program

without a pause

Monitor -- Cyclic.

Effect --

Remedy -- Acknowledge message

1064

Message text Ackn.: over temperature fan %1

Cause -- One of the two fans in the cabinet is defective

Monitor -- Cyclic.

Effect -- Ramp--down braking

Remedy -- Acknowledge message

1065

Message text Ackn. mainboard overtemperature

1066

1067

Cause -- The cabinet fan has failed

-- The ambient temperature is too high

Monitor -- Cyclic.

Effect --

Remedy -- Acknowledge message

Message text Mainboard temperature reached warning level

Cause -- PC controller cooling is still sufficient, but could soon become critical

Monitor -- Cyclic.

Effect -- None

Remedy -- Check fan

-- Exchange fan filter

Message text Mainboard temperature check not available

Cause -- Motherboard does not support temperature monitoring

Monitor -- O n c e

Effect -- No monitoring

Remedy -- Exchange motherboard

-- Switch temperature monitoring off

46 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

1068 Message text INTERBUS: Watchdog Time expired!

Cause -- The Interbus driver read function was not called in the time defined

Monitor -- Cyclic.

Effect -- Inputs and outputs are not set

Remedy -- Terminate the Watchdog by reconfiguring the I/Os

-- De--energize controller board

-- Watchdog cycle time possibly set too low

-- Fault in the KRC system since the read function of the driver was not

called cyclically

1071

Message text MOTOR HOLDING TORQUE %1 EXCEEDED

Cause -- The motor holding torque of the axis is not sufficient to keep the robot

motion permanently stopped at a point.

Monitor -- Not cyclic, during path planning

Effect -- Interpreter stop

Remedy -- Correct or reduce load data

-- Verify machine data

1072

1073

Message text BRAKE HOLDING TORQUE %1 EXCEEDED

Cause -- The brake holding torque on the axis is not sufficient to keep the robot

motion permanently stopped at a point.

Monitor -- Not cyclic, during path planning

Effect -- Interpreter stop

Remedy -- Correct or reduce load data

-- Verify machine data

Message text COMMANDED GEAR TORQUE %1

Cause -- Permissible gear torque exceeded, dependent on dynamic data

$DYN_DAT()

Monitor -- Cyclic.

Effect -- Path--maintaining braking

-- Output ”$ALARM_STOP” 0 signal

-- Active commands inhibited.

Remedy -- Verify load data and reduce if necessary, reduce programmed accel-

eration, reduce programmed velocity; acknowledge message

Fehlermeldungen 09.02.01 en

47 of 135

Error messages / troubleshooting

1074 Message text COMMANDED MOTOR TORQUE %1

Cause -- Permissible motor torque exceeded, dependent on dynamic data

$DYN_DAT()

Monitor -- Cyclic.

Effect -- Path--maintaining braking

-- Output ”$ALARM_STOP” 0 signal

-- Active commands inhibited.

Remedy -- Verify load data and reduce if necessary, reduce programmed accel-

eration, reduce programmed velocity; acknowledge message

1075

Message text MAXIMUM KINETIC ENERGY %1

Cause -- Permissible kinetic energy for crash exceeded, dependent on dynamic

data $DYN_DAT()

Monitor -- Cyclic.

Effect -- Path--maintaining braking

-- Output ”$ALARM_STOP” 0 signal

-- Active commands inhibited.

Remedy -- Verify load data and reduce if necessary, reduce programmed velocity;

acknowledge message

1078

Message text Ackn. servobus DSE--No. %1 participant No. %2 not available

1079

1100

Cause -- The device number in the servo bus was too low

Monitor --

Effect --

Remedy -- Acknowledge message

Message text Ackn. servobus DSE--No. %1 participant No. %2 not available

Cause -- The device number in the servo bus was higher than the number

defined in the machine data

Monitor --

Effect --

Remedy -- Acknowledge message

Message text STOPPED <axis number>

Cause -- Axis has beeen moved out of the standstill position according to the

machine data. Positioning window ($IN_POS_MA) times standstill

window minus factor ($IN_STILL_MA).

Monitor -- With robot “in position”.

Effect -- Maximum braking.

-- Low signal at “$ALARM_STOP” output.

-- All active commands inhibited.

Remedy -- Check manipulator.

-- Check output stage, check motor brake.

-- Acknowledge message.

48 of 135

Fehlermeldungen 09.02.01 en

1 Error messages / troubleshooting (continued)

1101 Message text COMMAND ACCELERATION EXCEEDED <axis number>

Cause -- Permissible command acceleration exceeded; e.g. because robot

has been moved through singularity in cartesian mode.

Monitor -- Cyclic.

Effect -- Maximum braking.

-- Low signal at “$ALARM_STOP” output.

-- All active commands inhibited.

Remedy -- Check program for alpha5 transitions (singularity).

-- Reduce path velocity.

-- Reduce path acceleration.

-- Acknowledge message.

1102

Message text COMMAND VELOCITY EXCEEDED <axis number>

Cause -- Permissible command velocity exceeded; e.g. because robot has

been moved through singularity in cartesian mode.

Monitor -- Cyclic.

Effect -- Maximum braking.

-- Low signal at ”$ALARM_STOP” output.

-- All active commands inhibited.

Remedy -- Reduce path velocity.

-- Reduce path acceleration.

1103

Message text DATA EXCHANGE WITH TEPRO MISSING

1104

1105

Cause -- The SBC is not transmitting cyclic data on time (TEPRO =

Technological Process).

Monitor -- Cyclic by transfer task.

Effect -- Ramp--down braking; interruption of the SBC interface.

Remedy -- Re--initialize the SBC program or eliminate the error in the SBC program.

Message text ACKN. REGULATOR LIMIT EXCEEDED <axis number>

Cause -- The set value of the machine datum $COM_VAL_MI has been exceed-

ed. The position controller output has gone into limitation. The axis

does not follow the command value.

Monitor -- Cyclic.

Effect -- Maximum braking.

-- Low signal at “$ALARM_STOP” output.

-- All active commands inhibited.

Remedy -- Check power module.

-- The brake control must be checked (LED on PM) if the error occurs on

more than one axis.

Message text POSITIONING MONITOR <axis number>

Cause -- Positioning window $IN_POS_MA has not been reached within the

set positioning time $TIME_POS.

Monitor -- When positioning.

Fehlermeldungen 09.02.01 en

49 of 135

Error messages / troubleshooting

Effect -- Maximum braking.

Remedy -- Enlarge positioning window.

1106

Message text TOOL WEIGHT NOT YET LEARNT

Cause -- During EMT mastering a check run was carried out for a tool whose

Monitor -- During EMT mastering.

Effect --

Remedy -- “Learn” tool weight.

1107

Message text WORKING ENVELOPE SURVEILLANCE CAN ONLY BE OVERRIDDEN

Cause -- An attempt was made to define the variable $WBOXDISABLE in

Monitor -- Cyclic.

Effect --

Remedy -- Change operating mode.

1108

Message text DYNAMIC BRAKING ERROR <axis number>

-- All active commands inhibited.

-- The axis has the status “in position” after the message has been

acknowledged.

-- Lengthen positioning time.