MA KR 30, 60 HA, KR C4 04.11.02 en 1 of 122

ROBOT

KR 30, 60 HA with KR C4

Assembly Instructions

Issued: 20 May 2015 Version: 02

2 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

e Copyright 2015

KUKA Roboter GmbH

Zugspitzstrasse 140

D-- 86165 Augsburg

This documentation or excerpts therefrom may not be reproduced or disclosed to third parties without the express permission of the publishers.

Other functions not described in this documentation may be operable in the controller. The user has no claims to these functions, however, in

the case of a replacement or service work.

We have checked the content of this documentation for conformity with the hardware and software described. Nevertheless, discrepancies

cannot be precluded, for which reason we are not able to guarantee total conformity. The information in this documentation is checked on a

regular basis, however, and necessary corrections will be incorporated in subsequent editions.

Subject to technical alterations without an effect on the function.

Translation of the original documentation

3 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Contents

1 Introduction 7.....................................................

1.1 Robot documentation 7...........................................................

1.2 Representation of warnings and notes 7............................................

2 Purpose 9.........................................................

2.1 Intended use 9..................................................................

2.2 Target group 10..................................................................

3 Product description 11..............................................

3.1 General 11.......................................................................

3.2 Wrist 12.........................................................................

3.3 Arm 13..........................................................................

3.3.1 Wrist axis motor units A4 to A6 14..................................................

3.4 Link arm 15......................................................................

3.4.1 Main axis motor units A1 to A3 17...................................................

3.5 Rotating column 18...............................................................

3.6 Base frame 19...................................................................

3.7 Working range limitation for A1 to A3 20.............................................

3.8 Working range monitoring for A1 and A2 21..........................................

3.9 Energy supply system 21..........................................................

4 Technical data 23...................................................

4.1 General 23.......................................................................

4.2 Principal data 25..................................................................

5 Safety 43...........................................................

5.1 Representation of warnings and notes 43............................................

5.2 General 43.......................................................................

5.2.1 Liability 44.......................................................................

5.2.2 Intended use of the industrial robot 44...............................................

5.2.3 EC declaration of conformity and declaration of incorporation 45........................

5.2.4 T erms used 46...................................................................

5.3 Personnel 47.....................................................................

5.4 Workspace, safety zone and danger zone 48.........................................

5.5 Overview of protective equipment 49................................................

5.5.1 Mechanical end stops 49..........................................................

5.5.2 Mechanical axis range limitation (optional) 50.........................................

5.5.3 Axis range monitoring (optional) 50..................................................

5.5.4 Options for moving the manipulator without drive energy 50............................

Assembly Instructions

4 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

5.5.5 Labeling on the industrial robot 52..................................................

5.6 Safety measures 52...............................................................

5.6.1 General safety regulations 52......................................................

5.6.2 Transportation 54.................................................................

5.6.3 Start--up and recommissioning 54...................................................

5.6.4 Manual mode 55..................................................................

5.6.5 Automatic mode 56...............................................................

5.6.6 Maintenance and repair 56.........................................................

5.6.7 Decommissioning, storage and disposal 58...........................................

5.7 Applied norms and regulations 59...................................................

6 Transportation 61...................................................

7 Installation, connection 65..........................................

7.1 General 65.......................................................................

7.2 Information for planning 66.........................................................

7.3 Principal loads 67.................................................................

7.4 Mounting variants 68..............................................................

7.4.1 Variant 1, mounting base with centering 71...........................................

7.4.2 Variant 2, machine frame mounting 74...............................................

7.4.3 Variant 3, adapter plate 76.........................................................

7.5 Connection 77....................................................................

7.5.1 Floor--mounted manipulators 77....................................................

7.5.2 Ceiling--mounted manipulators 80...................................................

7.6 Moving the manipulator without drive energy 83.......................................

8 Electrical installations 85............................................

8.1 Description 85....................................................................

8.2 Cabling plans and wiring diagrams 88...............................................

9 Connecting cables 97...............................................

9.1 Description 97....................................................................

9.2 Routing of cables 99..............................................................

9.3 Junction boxes on the manipulator 100...............................................

9.3.1 Coding 100.......................................................................

9.4 Connector panel on the control cabinet 101...........................................

9.5 Configuration of the connecting cables 102............................................

9.6 Wiring diagrams 103...............................................................

10 Tightening torques 105...............................................

11 Consumables, safety data sheets 107.................................

1 1.1 Safety data sheet for Optitemp RB1 cable grease 107..................................

1 1.2 Safety data sheet for Optimol Olit CLS lubricating grease 1 10............................

5 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

1 1.3 Safety data sheet for Optigear Synthetic RO 150 oil 1 13................................

1 1.4 Safety data sheet for Microlube GL 261 lubricant 120...................................

Assembly Instructions

6 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

1 Introduction

7 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Valid for KR 30 HA

KR 60 HA

KR 60 L45 HA

KR 60 L30 HA

with KR C4

1 Introduction

1.1 Robot documentation

The documentation of this robot comprises the following parts:

-- Assembly instructions for KR 30, 60 HA, KR C4

-- Parts catalog on storage medium

Each of these parts is a separate document that is attached to the robot.

The assembly instructions and parts catalog for the controller are not part of this documentation.

1.2 Representation of warnings and notes

Warnings marked with this pictogram are relevant to safety and must be observed.

Danger!

These warnings mean that it is certain or highly probable that death or severe

injuries will occur, if no precautions are taken.

Warning!

These warnings mean that death or severe injuries may occur, if no precautions

are taken.

Caution!

These warnings mean that minor injuries may occur, if no precautions are taken.

Notice!

These warnings mean that damage to property may occur, if no precautions are

taken. They contain references to safety--relevant information or general safety

measures. These warnings do not refer to individual hazards or individual precautionary measures.

Information!

These hints serve to make your work easier or contain references to further information.

Assembly Instructions

8 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

2 Purpose

9 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

2 Purpose

2.1 Intended use

Use

Handling of tools or fixtures for processing or transferring components or products, e.g.

-- Machining

-- Handling

-- Assembly

-- MIG/MAG welding

-- YAG laser beam welding

Use is only permitted under the environmental conditions specified in Chapter 4.

Misuse

Any use or application deviating from the intended use is deemed to be impermissible misuse; examples of such misuse include:

-- Transportation of persons and animals

-- Use as a climbing aid

-- Operation outside the permissible operating parameters

-- Use in potentially explosive environments

-- Use in underground mining

Notice!

Changing the structure of the manipulator, e.g. by drilling holes, etc., can result

in damage to the components. This is considered improper use and leads to

loss of guarantee and liability entitlements.

Notice!

Deviations from the operating conditions specified in the technical data or the

use of special functions or applications can lead to premature wear. KUKA Roboter GmbH must be consulted.

Assembly Instructions

10 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

2.2 Target group

This documentation is aimed at users with the following knowledge and skills:

-- Advanced knowledge of mechanical engineering

-- Advanced knowledge of electrical and electronic systems

-- Knowledge of the robot controller system

Information!

For optimal use of our products, we recommend that our customers take part in a

course of training at KUKA College. Information about the training program can be

found at www.kuka.com or can be obtained directly from our subsidiaries.

3 Product description

1 1 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

3 Product description

Information!

This description applies analogously to all of the industrial robots listed in Chapter 1,

regardless of the variant or model shown in the illustrations.

3.1 General

The industrial robot consists of the manipulator (= robot arm and electrical installations), control cabinet, teach pendant (KUKA smartPAD) and connecting cables (Fig. 1). The manipulator is dealt with in this document.

The control cabinet, teach pendant and connecting cables are described in separate documentation.

1 Manipulator

2 Control cabinet

3 Connecting cables

1

2

3

Fig. 1 Industrial robot (example: floor--mounted)

This section is subdivided in accordance with the breakdown of the manipulator into its main

subassemblies.

Assembly Instructions

12 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

3.2 Wrist

The manipulator is equipped with a triple--axis in--line wrist (Fig. 2) for a payload of 30, 45

or 60 kg, depending on the type. The wrist is fastened onto the arm via the flange (4). The

axes 6, 5, 4 are driven by shafts (1, 2, 3). An end effector can be attached to the mounting

flange (5) of axis 6. Each axis has ameasuring device (6), through whichthe mechanical zero

of the respective axis can be checked by means ofan electronic probe (accessory) and transferred to the controller. For the direction of rotation of the axes, see Chapter 4, “Technical

Data”.

123

4

5

6

30/45/60 kg

1 Shaft 4 Flange

2 Shaft 5 Mounting flange

3 Shaft 6 Measuring device

Fig. 2 In-- line wrist

3 Product description (continued)

13 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

3.3 Arm

The arm assembly (Fig. 3/2) embodies the driven element of axis 3 of the manipulator. The

arm is flange--mounted to the side of the link arm (7) through a gear unit with integrated bearings and is driven by main axis motor unit A3 (6). The swivel axis (3) of the arm has been

so selected that with the rated payload there is no need for an additional counterweight to

balance the masses on the arm.

The effective software swivel range extends for all manipulators from +158° to --120°,referred to the electrical zero position of axis 3, which is given when the longitudinal axes of

the arm and link arm run parallel. The swivel range is limited by mechanical limit stops with

a buffer function in addition to the software limit switches.

Attached to the rear of the arm housing (8) are the motor units for wrist axes 4 to 6. Arm variants are available which are 200 mm (KR 60 L45 HA) or 400 mm (KR 60 L30 HA) longer than

the standard arm. These arm extensions involve a reduction in the rated payloads and the

individual axis speeds.

The arm housing consists -- as do the housings of the link arm and rotating column -- of a

light alloy construction optimized by means of CAD and FEM.

Mounted on the front end of the arm via a standardized interface is the in--line wrist (4), which

is driven by the wrist axis motor units (1) through push--on shafts (5) located inside the arm.

1 Motor units for wrist axes 6 Main axis motor unit A3

2Arm 7Linkarm

3 Rotational axis A3 8 Arm housing

4 In--line wrist

5 Shaft

123

567

8

4

Fig. 3 Arm

Assembly Instructions

14 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

3.3.1 Wrist axis motor units A4 to A6

The wrist axes are driven by three motor units. These are fastened to the arm (Fig. 4/4) by

means of screws. Motor units A4 (3) and A5 (1) are of the same design and drive the respective wrist axes via toothed belts and shafts. Wrist axis A6 is driven directly by motor unit

A6 (2) via a push--on shaft (5).

Each motor unit for the wrist axis drives consists of a brushless AC servomotor with apermanent--magnet single--disk brake and a hollow--shaft resolver (both integrated).

1 Motor unit A5

2 Motor unit A6

3 Motor unit A4

4Arm

5 Shaft

4

5

1

A4

A6

A5

23

Fig. 4 Wrist axis motor units A4 to A6

3 Product description (continued)

15 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

3.4 Link arm

The link arm (Fig. 5/1) is the driven element of axis 2. It pivots about rotational axis 2 (3)

through an effective software range from +35° to --135°⎯referred to the zero position of

axis 2, which corresponds to the horizontal position of the link arm in Fig. 5. The effective

software swivel range is limited by mechanical limit stops with a buffer function in addition

to the software limit switches.

1Linkarm

2 Main axis motor unit A2

3 Rotational axis 2

1

3

+35°

2

--135˚

Fig. 5 Link arm with turning range

The link arm (Fig. 6/6) houses gear unit A3 (2) at its upper end, and gear unit A2 (3) at its

lower end. The gear units (2, 3) are used both as drive elements and to support the arm and

link arm assemblies. The reference notch (1) and the gauge cartridge (4) are provided to define and locate the mechanical zero position of axes 2 and 3. The cables for energy supply

and signal transmission are routed in the interior of the link arm housing from the rotating

column to the arm.

Assembly Instructions

16 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

1 Reference notch A3 5 Rotational axis 2

2 Gear unit A3 6 Link arm

3 Gear unit A2 7 Rotational axis 3

4 Gauge cartridge A2

1

2

3

4

5

6

7

Fig. 6 Structure of link arm

3 Product description (continued)

17 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

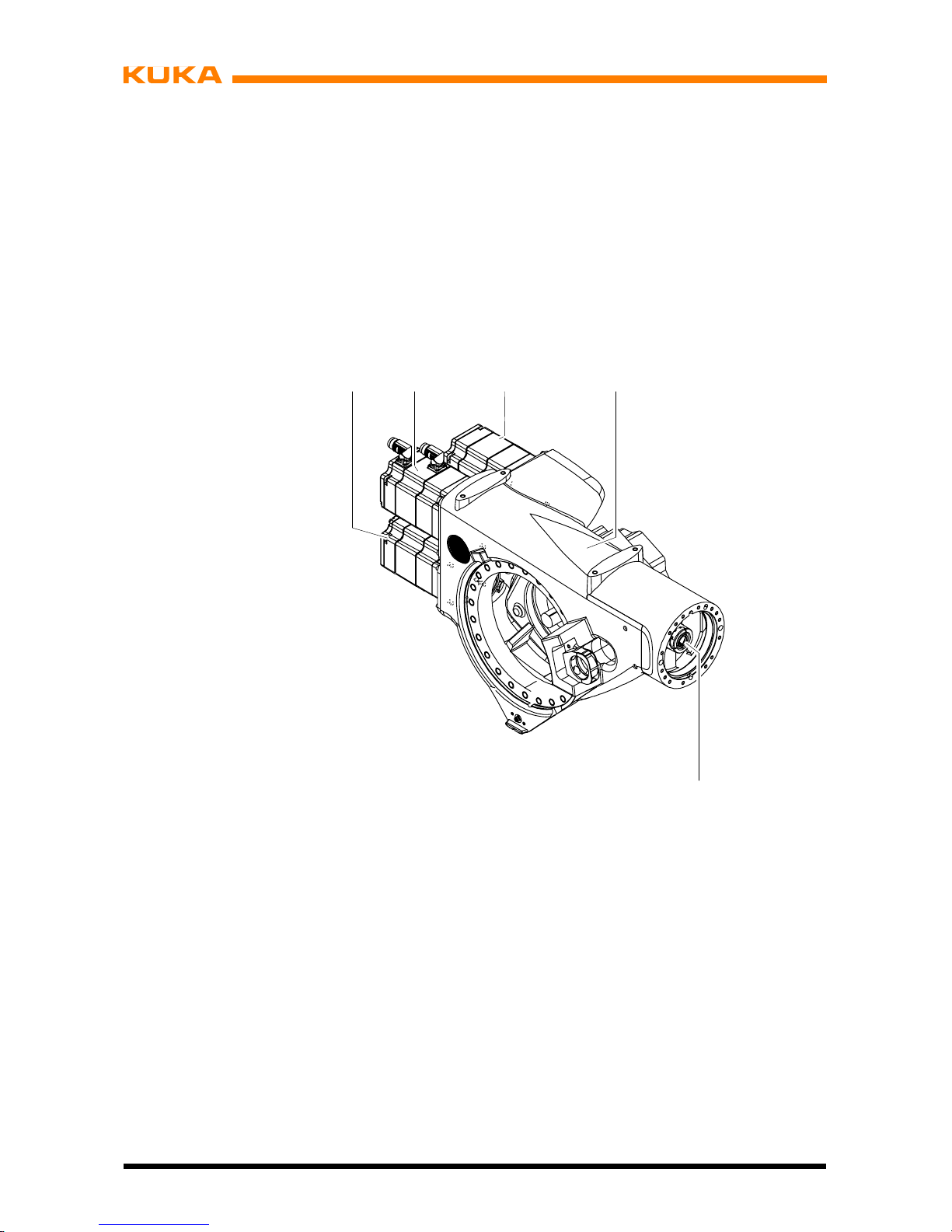

3.4.1 Main axis motor units A1 to A3

The robot axes 1, 2 and 3 are driven by motor units as shown in Fig. 7. Each motor unit for

the main axis drives consists of a brushless AC servomotor (1) with a permanent--magnet

single--disk brake and hollow--shaft resolver (2), both integrated. The motor units for

axes 1, 2 and 3 are of the same design.

Axis 2 of the KR 60 is equipped with a more powerful motor unit.

1

2

2

1ACservomotor

2 Hollow--shaft resolver

Fig. 7 Motor unit for main axis drive

Assembly Instructions

18 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

3.5 Rotating column

The rotating column (Fig. 8/2) is the assembly located between the link arm and the base

frame. Screwed to the base frame (4) through a special reduction gear unit (3), which allows

it to rotate, it performs movements about rotational axis 1 (1). It has an effective software

turning range of 185° in both the (+) and (--) directions, measured from the zero position of

axis (6). This range is limited by mechanical limit stops with a buffer function in addition to

the software limit switches. This limit stop system operates with a trailing stop acting on both

sides, which is installed in the base frame and mechanically limits the large turning range of

185˚ in both directions.

1 Rotational axis 1

2 Rotating column

3 Special reduction gear unit

4Baseframe

5 Main axis motor unit A2

6 Zero position A1

6

5

--185°

+185°

2

3

4

1

Fig. 8 Rotating column with turning range (shown here: KR 30 HA)

3 Product description (continued)

19 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

The main axis motor unit for axis 1 (Fig. 9/3) is installed in the rotating column with a special

reduction gear unit (4), and the main axis motor unit for axis 2 (1) is mounted on the side of

the rotating column with its special reduction gear unit (2).

Part of the manipulator electrical installations is routed inside the rotating column.

1 Main axis motor unit A2

2 Special reduction gear unit A2

3 Main axis motor unit A1

4 Special reduction gear unit A1

1

4

2

3

Fig. 9 Structure of rotating column

3.6 Base frame

The base frame (Fig. 10) is the stationary part of the manipulator, on which the rotating column turns with the link arm, the arm and the wrist. Its base flange (5) features through-holes (4) for holding the manipulator down and twolocating boreholes (6), with which the manipulator can be placed on two locating pins (accessories, see Chapter 7, “Installation”).

Attached to a flange inside the base frame housing (3) is the special reduction gear unit (1)

of axis 1. Also integrated into this flange is the double--acting trailing stop, which together with

a stop block on the rotating column mechanically safeguards the software--limited movement

range of 370° about rotational axis 1.

In the base frame, the installation cables leading to the rotating column are routed stress-free about rotational axis 1 of the manipulator in a flexible tube. The space between the rotating column and the base frame is provided with two detachable, one--piece covers (2, 8).

The sockets for the connecting cables from the manipulator to the control cabinet are located

on the RDC box (10) and MFH (7).

The reference notch (11) necessary for determining the mechanical zero position is found

on the bracket (9).

Assembly Instructions

20 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

1 Special reduction gear unit A1 7 Junction box

2 Cover 8 Cover

3 Base frame housing 9 Bracket

4 Attachment holes (6x) 10 MFH, multi-- function housing

5 Base flange 11 Reference notch

6 Locating boreholes (2x)

1

2

3

4

6

7

5

88

9

11

10

Fig. 10 Structure of base frame

3.7 Working range limitation for A1 to A3

Mechanical stops for task--related limitation of the respective working range for axes 1 to 3

can be supplied as the “Working range limitation” accessory (see documentation “Working

Range Limitation”).

Axis 1: with two supplementary stops:

from +58° to +185° and --58° to --185°, adjustable in steps of 15°.

Axis 2: from +5° to +65° and --5° to --20°, adjustable in steps of 15°.

Axis 3: from +3° and --108° to --153° or --33° to --153°, adjustable in steps of 15°.

3 Product description (continued)

21 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

3.8 Working range monitoring for A1 and A2

Axes 1 and 2 can be equipped with position switches and slotted rings to which adjustable

cams are attached (see documentation “Working Range Monitoring”). This allows the position of the manipulator to be continuously monitored.

Up to three sectors of the movement range can be monitored on axis 1, and a maximum of

one sector on axis 2.

3.9 Energy supply system

For use in certain production technologies, the industrial robot can be equipped with an energy supply system installed between the base frame and axis 6. The energy supply system

consists of a dress package (cable and hose bundle) for transmitting the energy and fluids

typical for the specific application, and the “Group of holders for energy supply system” required for attaching it to the manipulator. The energy supply system accommodates the

cables and hoses and ensures that they are guided with minimum stress throughout the permitted working envelope. The design of the energy supply system is suitable for the majority

of applications in terms of reach and resistance to wear. There may, of course, be applications for which this version is of only limited use. A special version is required in such cases,

or a corresponding adaptation of the energy supply system.

The energy supply system is described in separate documentation.

Assembly Instructions

22 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

4 Technical data

23 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

4 Technical data

Information!

This description applies analogously to all of the industrial robots listed in Chapter 1,

regardless of the variant or model shown in the illustrations.

4.1 General

The industrial robots are six--axis manipulators for installation on the floor or on the ceiling.

They are suitable for all continuous--path controlled tasks. The main areas of applicationare:

-- Machining

-- Handling

-- Assembly

-- MIG/MAG welding

-- YAG laser beam welding

Notice!

Using the manipulator for purposes other than those mentioned above is consi-

dered contrary to its designated use (see Chapter 2, “Purpose”).

Fig. 11 shows the industrial robot with the manipulator (= robot arm and electrical installa-

tions) and the control cabinet.

The following data apply, unless otherwise indicated, to both floor--mounted and ceiling-mounted robots.

Assembly Instructions

24 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

1 Arm 5 Base frame

2 In--line wrist 6 Connecting cables

3 Link arm 7 Control cabinet (see

4 Rotating column separate documentation)

12

3

4

5

6

3

7

Fig. 11 Principal robot components

4 Technical data (continued)

25 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

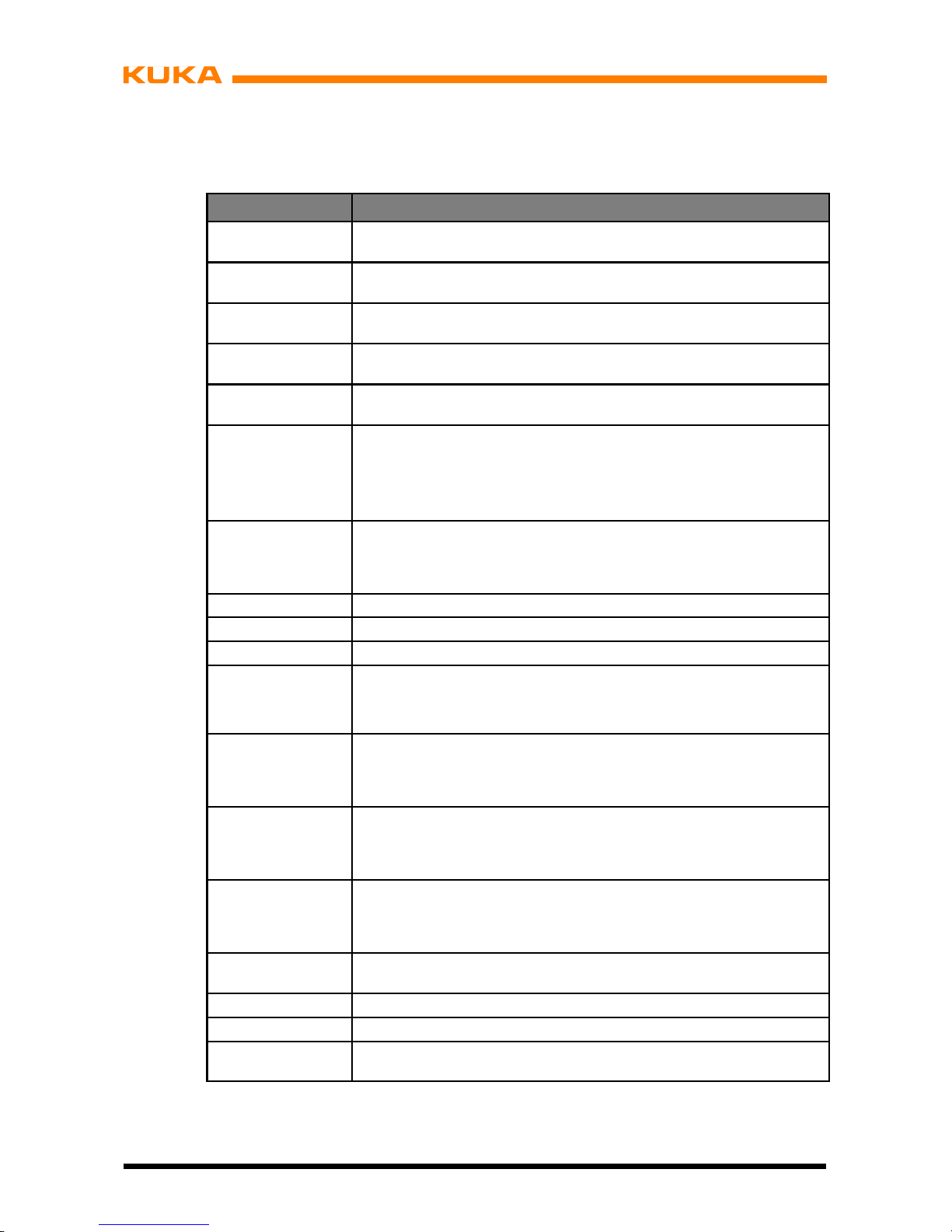

4.2 Principal data

Type KR 30 HA

KR 60 HA

KR 60 L45 HA

KR 60 L30 HA

Number of axes 6 (Fig. 13)

Load limits see following table and Fig. 12

Robot type

KR 30 HA KR 60 HA

KR 60 L45

HA

KR 60 L30

HA

Wrist (IW)

1

IW 30/45/60 IW 30/45/60 IW 30/45/60 IW 30/45/60

Rated payload [kg] 30 60 45 30

Max. supplementary

load with rated payload

[kg]

35 35 35 35

Max. total load [kg] 65 95 80 65

1

IW = In--line wrist III

Payload

Max. total load

P

Suppl. load

Fig. 12 Load distribution

Axis data See the following table.

All specifications in the “Range of motion” column are referred to the electrical zero of the robot axis concerned.

Assembly Instructions

26 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

KR 30 HA

D In--line wrist, rated payload 30 kg

Axis

Range of motion,

software--limited

Speed

1 ±185˚ 140˚/s

2 +35˚

to

--135˚

126˚/s

3 +158˚

to

--120˚

140˚/s

4 ±350˚ 260˚/s

5 ±119˚ 245˚/s

6 ±350˚ 322˚/s

KR 60 HA

D In--line wrist, rated payload 60 kg

Axis

Range of motion,

software--limited

Speed

1 ±185˚ 128˚/s

2 +35˚

to

--135˚

102˚/s

3 +158˚

to

--120˚

128˚/s

4 ±350˚ 260˚/s

5 ±119˚ 245˚/s

6 ±350˚ 322˚/s

KR 60 L45 HA

D In--line wrist, rated payload 45 kg

Axis

Range of motion,

software--limited

Speed

1 ±185˚ 128˚/s

2 +35˚

to

--135˚

102˚/s

3 +158˚

to

--120˚

128˚/s

4 ±350˚ 260˚/s

5 ±119˚ 245˚/s

6 ±350˚ 322˚/s

4 Technical data (continued)

27 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

KR 60 L30 HA

D In--line wrist, rated payload 30 kg

Axis

Range of motion,

software--limited

Speed

1 ±185˚ 128˚/s

2 +35˚

to

--135˚

102˚/s

3 +158˚

to

--120˚

128˚/s

4 ±350˚ 260˚/s

5 ±119˚ 245˚/s

6 ±350˚ 322˚/s

A1

Fig. 13 Rotational axes and their directions of rotation

Assembly Instructions

28 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Pose repeatability KR 30 HA ± 0.05 mm

(ISO 9283) KR 60 HA ± 0.05 mm

KR 60 L45 HA ± 0.05 mm

KR 60 L30 HA ± 0.05 mm

Mounting position floor, ceiling

Floor--mounted and ceiling--mounted manipulators must be

calibrated for the respective installation position.

Principal dimensions see Fig. 18 and Fig. 19.

Working envelope The shape and dimensions of the working envelope maybe

noted from Fig. 18 and Fig. 19.

Volume of working envelope KR 30 HA approx. 27.24 m

3

KR 60 HA approx. 27.24 m

3

KR 60 L45 HA approx. 36.89 m

3

KR 60 L30 HA approx. 47.78 m

3

The reference point is the intersection of axes 4 and 5.

Load center of gravity P seeFig.14toFig.16.

For the rated payload, the horizontal distance of the load

center of gravity P from the face of the mounting flange is

150 mm; the vertical distance from rotational axis 6 is

120 mm (nominal distance in each case).

Weight KR 30 HA approx. 665 kg

KR 60 HA approx. 665 kg

KR 60 L45 HA approx. 671 kg

KR 60 L30 HA approx. 679 kg

Principal dynamic loads See Fig. 21

Drive system Electromechanical, with transistor--controlled ACservomo-

tors.

Installed motor capacity approx. 14.9 kW

Protection classification of the robot

IP 64

ready for operation, with connecting cables plugged in

(according to EN 60529).

Protection classification of the in--line wrist

(standard) IP 65 (according to EN 60529)

4 Technical data (continued)

29 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Ambient temperature during operation:

283 K to 328 K (+10 °Cto+55°C),

during storage/transportation:

233 K to 333 K (--40 °Cto+60°C).

Other temperature limits available on request.

Humidity class DIN EN 60721--3--3, Class 3K3

Sound level < 75 dB (A) outside the working envelope

(Fig. 18 and Fig. 19)

Color Manipulator

Manipulator overall: KUKA --Orange 2567

Motors: Black (RAL 9005)

Cover A1 Black (RAL 9005)

Plates seeFig.22toFig.30.

Special consumables none

Stopping distances and times

see separate documentation

Assembly Instructions

30 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Notice!

Concerning Fig. 14 to Fig. 16:

These loading curves and the values in the table correspond to the maximum

load capacity. Both values (payload and principal moment of inertia) must be

checked in all cases. Exceeding this capacity will reduce the service life of the

robot and generally overload the motors and the gears; in any such case KUKA

must be consulted beforehand.

Information!

The values determined here are necessary for planning the application.

For commissioning the robot, additional input data are required in accordance with the

KUKA software documentation.

-- X

Lz

Lx

Ly

+X

-- Y

+Y

+Z

-- Z

Load center of gravity

Lxy

Lxy = Lx2+ Ly

2

Robot flange coordinate system

Permissible mass inertia at the

design point

(Lxy = 180 mm,

Lz = 150 mm)

9kgm

2

.

CAUTION: The mass inertia must be

verified using KUKA Load. It is

imperative for the load data to be

entered in the controller!

Lxy (mm)

100 200 300 400 500 700600

100

200

300

400

Lz (mm)

500

A4

A5

A6

KR 30 HA

KR 60 L30 HA

30 kg

27 kg

24 kg

21 kg

18 kg

15 kg

13 kg

Fig. 14 Load center of gravity P and loading curves for KR 30 HA; KR 60 L30 HA

4 Technical data (continued)

31 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Information!

The values determined here are necessary for planning the application.

For commissioning the robot, additional input data are required in accordance with the

KUKA software documentation.

-- X

Lz

Lx

Ly

+X

-- Y

+Y

+Z

-- Z

Load center of gravity

Lxy

Lxy = Lx2+ Ly

2

Robot flange coordinate system

Permissible mass inertia at the

design point

(Lxy = 180 mm,

Lz = 150 mm)

18 kgm

2

.

CAUTION: The mass inertia must be

verified using KUKA Load. It is

imperative for the load data to be

entered in the controller!

Lxy (mm)

100 200 300 400 500 700600

100

200

300

400

Lz (mm)

500

A4

A5

A6

KR 60 HA

60 kg

55 kg

35 kg

50 kg

45 kg

40 kg

25 kg

30 kg

Fig. 15 Load center of gravity P and loading curves for KR 60 HA

Assembly Instructions

32 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Information!

The values determined here are necessary for planning the application.

For commissioning the robot, additional input data are required in accordance with the

KUKA software documentation.

-- X

Lz

Lx

Ly

+X

-- Y

+Y

+Z

-- Z

Load center of gravity

Lxy

Lxy = Lx2+ Ly

2

Robot flange coordinate system

Permissible mass inertia at the

design point

(Lxy = 180 mm,

Lz = 150 mm)

13.5 kgm

2

.

CAUTION: The mass inertia must be

verified using KUKA Load. It is

imperative for the load data to be

entered in the controller!

Lxy (mm)

100 200 300 400 500 700600

100

200

300

400

Lz (mm)

500

A4

A5

A6

KR 60 L45 HA

45 kg

41 kg

37 kg

33 kg

29 kg

25 kg

21 kg

Fig. 16 Load center of gravity P and loading curves for KR 60 L45 HA

4 Technical data (continued)

33 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Mounting flange DIN/ISO1mounting flange (Fig. 17). The mounting flange

is depicted with axes 4 and 6 in the zero position. The symbol

indicates the position of the locating element (bushing). M8 screws of grade 10.9 are to be used for attaching

payloads. The grip length of the screws in the flange must

be at least 1.5 x nominal diameter.

Depth of engagement: min. 12 mm

max. 14 mm

1

DIN/ISO 9409-- 1--A100

ø100

ø125

ø63

H7

170

to center A 4 / A 5

A

Section A -- A

A

X

m

Ø8H78 deep

Ø0.04

A

B

h8

Ø0.02

B

AB

M8 fastening screws,

grade 10.9

Depth of engagement: min. 12 mm

max. 14 mm

8.5

+0.3

0

7.5 ¦0.1

∅115 ¦0.05

12

Fig. 17 DIN/ISO mounting flange for in--line wrist 30/45/60 kg

Assembly Instructions

34 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

1218

1362

1446

180

150

2429

145

850

820, 1020, 1220 170

2498

1084

815

350

815

2230

2033

3003

983

2894

2695

3795

3398

868

1480

1281

NOTE: The supplementary load center of

gravity must be located as close as possible

to rotational axis 3 and to line a in Fig. 20.

The reference point for the working

envelope is the intersection of axes 4 and 5.

View Y, see Fig. 20.

IMPORTANT: The interferenceradius

(safe area) lies approx. 181 mm

beyond the reference point for the

working envelope.

Y

Fig. 18 Principal dimensions and working envelope (software values)

4 Technical data (continued)

35 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

--- 185˚

+185˚

R=181 mm

IMPORTANT: The interferenceradius

(safe area) lies approx. 181 mm

beyond the reference point for the

working envelope.

KR 30 HA R=2033

KR 60 HA R=2033

KR 60 L45 HA R=2230

KR 60 L30 HA R=2429

Fig. 19 Turning range A1

Assembly Instructions

36 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

View Y from Fig. 18

114

160

375

195

M8 (4x)

16 deep

Center A 3

82

Max. dimension for suppl. load

Support brackets for suppl. load (2x)

a

Fig. 20 Attachment holes for supplementary load

4 Technical data (continued)

37 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Maximum load Normal load

F

v

= Vertical force F

vmax

= 13 600 N F

v normal

= 9 000 N

F

h

= Horizont force F

hmax

= 12 300 N F

h normal

= 6 950 N

M

k

= Tilting moment M

kmax

= 21 600 Nm M

k normal

= 11 900 Nm

M

r

= Turning moment about axis 1 M

rmax

= 18 400 Nm M

r normal

= 6 850 Nm

Total mass = robot + total load for type

665kg + 65kg KR30HA

665kg + 95kg KR60HA

671 kg + 80 kg KR 60 L45 HA

679 kg + 65 kg KR 60 L30 HA

F

v

F

h

M

k

M

r

F

v

The specified forces and moments already include the payload and the inertia force

(weight) of the manipulator.

Fig. 21 Principal loads acting on floor and ceiling due to robot and total load

Assembly Instructions

38 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

2

1

5

4

1

2

3

6

7

8

5

6

7

5

6

7

Fig. 22 Plates on robot (see also Fig. 23 to Fig. 30)

T ransportstellung:

T ransport position:

Position de transport:

A6

A5

A4A3A2A1

ATTENTION!WARNING!ACHTUNG!

D/GB/F

Vor dem Lösen der

Fundamentbefestigungsschrauben

muss der Roboter in

Transportstellung

gebracht werden!

The robot must be

in the transport

position before the

holding--down bolts

are slackened!

Le robot doit être

amené en position

de transport avant de

desserrer les boulons

de fixation des

fondations!

1

2xArtikel--Nr. 00 --118-- 545

0° --- 1 3 5 ° +158° +90°0°

Fig. 23 Transport position plate

4 Technical data (continued)

39 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

ATTENTION!WARNING!ACHTUNG!

Vor dem Entfernen des Motors Roboterachse

gegen Kippen sichern!

Only remove motor when robot axis is secured!

Avant démontage du moteur bloquer l’axe

concerné!

2

2x

D/GB/F

Artikel--Nr. 00 --118-- 545

Fig. 24 Instructions for safeguarding against toppling of A2 and A3

3

Typ e

Serial No.

XXXX kg

Baujahr

Poids

XXXXXXXXXXXXXXXXXXXXXXXXXX

Gewich t

No. d’articleArtikel--Nr.

Anneedefabric.

XXXXXXXXXXXXXXXXXXXXXXXXXXX

Serie--Nr.

XXXX--XX

Weight

Typ e

No. Se’rie#

$TRAFONAME[]=”#.....”

Article No.

XXXXXXXXXXXXXXXXXXXXXXXXXXX

Typ

Date

...\MADA\

XXXXXXXXX

XXXXXX

Traglast Load Charge

XXX kg

ReichweiteRange Portee

XXXX MM

^

^

^

de/en/fr

Roboter GmbH

Zugspitzstraße 14 0

86165 Augsburg.Germany

Fig. 25 Robot identification plate (example)

Assembly Instructions

40 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Vor Aufstellung, Inbetriebnahme, Montage-- und

Wartungsarbeiten die Betriebsanleitung und

Sicherheitshinweise lesen und beachten!

Before installation, start--up, maintenance or

disassembling read and follow the safety

directions and operating instructions!

Avant installation, mise en service, réparation et

maintenance veuillez lire les châpitres

correspondants du manuel ainsi que les

consignes de sécurité et les respecter!

ATTENTION!WARNING!ACHTUNG!

D/GB/F

4

Artikel--Nr. 00 --118-- 545

Fig. 26 Reference to operating instructions

5

Fig. 27 High voltage warning sign

6

4x on each motor

Fig. 28 Hot surface warning sign

4 Technical data (continued)

41 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

.................

...........................................................

................................................

...........................................................

................................................

...........................................................

.................................................

On all motors.

7

Fig. 29 Drive motor rating plate

8

3x on base frame

00--104--232

Fig. 30 Danger zone

Assembly Instructions

42 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

5 Safety

43 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

5 Safety

5.1 Representation of warnings and notes

Safety

These warnings are relevant to safety and must be observed.

Danger!

These warnings mean that it is certain or highly probable that death or severe

injuries will occur, if no precautions are taken.

Warning!

These warnings mean that death or severe injuries may occur, if no precautions

are taken.

Caution!

These warnings mean that minor injuries may occur, if no precautions are taken.

Notice!

These warnings mean that damage to property may occur, if no precautions are

taken. They contain references to safety--relevant information or general safety

measures. These warnings do not refer to individual hazards or individual precautionary measures.

Information!

These hints serve to make your work easier or contain references to further information.

5.2 General

Notice!

This “Safety” chapter refers to a mechanical component of an industrial robot.

If the mechanical component is used together with a KUKA robot controller, the “Safety”

chapter of the operating instructions or assembly instructions of the robot controller

must be used!

This contains all the information provided in this “Safety” chapter. It also contains additional safety information relating to the robot controller which must be observed.

Where this “Safety” chapter uses the term “industrial robot”, this also refers to the individual mechanical component if applicable.

Assembly Instructions

44 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

5.2.1 Liability

The device described in this document is either an industrial robot or a component thereof.

Components of the industrial robot:

G Manipulator

G Robot controller

G Teach pendant

G Connecting cables

G External axes (optional), e.g. linear unit, turn--tilt table, positioner

G Software

G Options, accessories

The industrial robot isbuilt using state--of--the--art technology and in accordance with the recognized safety rules. Nevertheless, misuse of the industrial robot may constitute a risk to life

and limb or cause damage to the industrial robot and to other material property.

The industrial robot may only be used in perfect technical condition in accordance with its

intended use and only by safety--conscious persons who are fully aware of the risks involved

in its operation. Use of the industrial robot is subject to compliance with this document and

with the declaration of incorporation supplied together with the industrial robot. Any functional

disorders affecting the safety of the robot system must be rectified immediately .

Safety information

Safety information cannot be held against KUKA Roboter GmbH. Even if all safety instructions are followed, this is not a guarantee that the industrial robot will not cause personal injuries or material damage.

No modifications may be carried out to the industrial robot without the authorization of KUKA

Roboter GmbH. Additional components (tools, software, etc.), not supplied by KUKA Roboter GmbH, may be integrated into the industrial robot. The user is liable for any damage

these components may cause to the industrial robot or to other material property.

In addition to the Safety chapter, this document contains further safety instructions. These

must also be observed.

5.2.2 Intended use of the industrial robot

The industrial robot is intended exclusively for the use designated in the “Purpose” chapter

of the operating instructions or assembly instructions.

Information!

Further information is contained in the “Purpose” chapter of the operating instructions

or assembly instructions of the industrial robot.

Using the industrial robot for any other or additional purpose is considered impermissible

misuse. The manufacturer cannot beheld liable for any damageresulting from such use. The

risk lies entirely with the user.

Operating the industrial robot and its options within the limits of its intended use also involves

observance of the operating and assembly instructions for the individual components, with

particular reference to the maintenance specifications.

5 Safety (continued)

45 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Misuse

Any use or application deviating from the intended use is deemed to be impermissible misuse.

This includes e.g.:

G Transportation of persons and animals

G Use as a climbing aid

G Operation outside the permissible operating parameters

G Use in potentially explosive environments

G Operation without additional safeguards

G Outdoor operation

G Underground operation

5.2.3 EC declaration of conformity and declaration of incorporation

This industrial robot constitutes partly completed machinery as defined by the EC Machinery

Directive. The industrial robot may only be put into operation if the following preconditions

are met:

G The industrial robot is integrated into a complete system.

Or: The industrial robot, together with other machinery, constitutes a complete system.

Or: All safety functions and safeguards required for operation in the complete machine

as defined by the EC Machinery Directive have been added to the industrial robot.

G The complete system complies with the EC Machinery Directive. This has been con-

firmed by means of an assessment of conformity.

Declaration of conformity

The system integrator must issue a declaration of conformity for the complete system in accordance with the Machinery Directive. The declaration of conformity forms the basis for the

CE mark for the system. The industrial robot must be operated in accordance with the applicable national laws, regulations and standards.

The robot controller is CE certified under the EMC Directive and the Low Voltage Directive.

Declaration of incorporation

The industrial robot as partly completed machinery is supplied with a declaration of

incorporation in accordance with Annex II B of the EC Machinery Directive 2006/42/EC. The

assembly instructions and a list of essential requirements complied with in accordance with

Annex I are integral parts of this declaration of incorporation.

The declaration of incorporation declares that the start--up of the partly completed machinery

remains impermissible until the partly completed machinery has been incorporated into machinery, or has been assembled with other parts to form machinery, and this machinery complies with the terms of the EC Machinery Directive, and the EC declaration of conformity is

present in accordance with Annex II A.

The declaration of incorporation, together with its annexes, remains with the system integrator as an integral part of the technical documentation of the complete machinery.

Assembly Instructions

46 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

5.2.4 Terms used

Term Description

Axis range Range of each axis, in degrees or millimeters, within which it may

move. The axis range must be defined for each axis.

Stopping distance Stopping distance = reaction distance + braking distance

The stopping distance is part of the danger zone.

Workspace The manipulator is allowed to move within its workspace. The work-

space is derived from the individual axis ranges.

Operator (User) The user of the industrial robot can be the management, employer or

delegated person responsible for use of the industrial robot.

Danger zone The danger zone consists of the workspace and the stopping dis-

tances.

Service life The service life of a safety--relevant component begins at the time of

delivery of the component to the customer.

The service life is not affected by whether the component is used in a

robot controller or elsewhere or not, as safety--relevant components are

also subject to ageing during storage.

KCP KUKA Control Panel

Teach pendant for the KR C2/KR C2 edition 2005

The KCP has all the operator control and display functions required for

operating and programming the industrial robot.

KCP smartPAD see “smartPAD”

Manipulator The robot arm and the associated electrical installations.

Protected space The safety zone is situated outside the danger zone.

smartPAD Teach pendant for the KR C4

The smartPAD has all the operator control and display functions

required for operating and programming the industrial robot.

Stop category 0 The drives are deactivated immediately and the brakes are applied.

The manipulator and any external axes (optional) perform path--oriented braking.

Note: This stop category is called STOP 0 in this document.

Stop category 1 The manipulator and any external axes (optional) perform path--main-

taining braking. The drives are deactivated after 1 s and the brakes are

applied.

Note: This stop category is called STOP 1 in this document.

Stop category 2 The drives are not deactivated and the brakes are not applied. The ma-

nipulator and any external axes (optional) are braked with a normal

braking ramp.

Note: This stop category is called STOP 2 in this document.

System integrator

(plant integrator)

System integrators are people who safely integrate the industrial robot

into a complete system and commission it.

T1 Test mode, Manual Reduced Velocity (<= 250 mm/s)

T2 Test mode, Manual High Velocity (> 250 mm/s permissible)

External axis Motion axis which is not part of the manipulator but which is controlled

using the robot controller, e.g. KUKA linear unit, turn--tilt table, Posiflex.

5 Safety (continued)

47 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

5.3 Personnel

The following persons or groups of persons are defined for the industrial robot:

G User

G Personnel

Notice!

All persons working with the industrial robot must have read and understood

the industrial robot documentation, including the safety chapter.

User

The user must observe the labor laws and regulations.

This includes e.g.:

G The user must comply with his monitoring obligations.

G The user must carry out instructions at defined intervals.

Personnel

Personnel must be instructed, before any work is commenced, in the type of work involved

and what exactly it entails as well as any hazards which may exist. Instruction must be carried

out regularly. Instruction is also required after particular incidents or technical modifications.

Personnel includes:

G System integrator

G Operators, subdivided into:

-- Start--up, maintenance and service personnel

-- Operating personnel

-- Cleaning personnel

Notice!

Installation, exchange, adjustment, operation, maintenance and repair must be

performed only as specified in the operating or assembly instructions for the

relevant component of the industrial robot and only by personnel specially

trained for this purpose.

System integrator

The industrial robot is safely integrated into a complete system by the system integrator.

The system integrator is responsible for the following tasks:

G Installing the industrial robot

G Connecting the industrial robot

G Performing risk assessment

G Implementing the required safety functions and safeguards

G Issuing the declaration of conformity

G Attaching the CE mark

G Creating the operating instructions for the complete system

Assembly Instructions

48 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Operator

The operator must meet the following preconditions:

G The operator must be trained for the work to be carried out.

G Work on the industrial robot must only be carried out by qualified personnel. These are

people who, due to their specialist training, knowledge and experience, and their familiarization with the relevant standards, are able to assess the work to be carried out and

detect any potential hazards.

Example

The tasks can be distributed as shown in the following table:

Tasks Operating

personnel

Programmer System

integrator

Switch robot controller

on/off

x x x

Start program x x x

Select program x x x

Select operating mode x x x

Calibration (tool, base) x x

Master the manipulator x x

Configuration x x

Programming x x

Commissioning x

Maintenance x

Repair x

Decommissioning x

Transportation x

Notice!

Work on the electrical and mechanical equipment of the industrial robot may

only be carried out by specially trained personnel.

5.4 Workspace, safety zone and danger zone

Working zones are to be restricted to the necessary minimum size. A workspace must be

safeguarded using appropriate safeguards.

The safeguards (e.g. safety gate) must be situated inside the safety zone. In the case of a

stop, the manipulator and external axes (optional) are braked and come to a stop within the

danger zone.

The danger zone consists of the workspace and the stopping distances of the manipulator

and external axes (optional). It must be safeguarded by means of physical safeguards to prevent danger to persons or the risk of material damage.

5 Safety (continued)

49 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

(1) Workspace

(2) Manipulator

(3) Stopping distance

(4) Safety zone

Fig. 31 Example: axis range A1

5.5 Overview of protective equipment

The protective equipment of the mechanical component may include:

G Mechanical end stops

G Mechanical axis range limitation (optional)

G Axis range monitoring (optional)

G Release device (optional)

G Labeling of danger areas

Not all equipment is relevant for every mechanical component.

5.5.1 Mechanical end stops

Depending on the robot variant, the axis rangesof the main andwrist axes of the manipulator

are partially limited by mechanical end stops.

Additional mechanical end stops can be installed on the external axes.

Notice!

If the manipulator or an external axis hits an obstruction or a mechanical end

stop or axis range limitation, this can result in material damage to the industrial

robot. The manipulator must be taken out of operation and KUKA Roboter GmbH

must be consulted before it is put back into operation.

Assembly Instructions

50 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

5.5.2 Mechanical axis range limitation (optional)

Some manipulators can be fitted with mechanical axis range limitation in axes A1 to A3. The

adjustable axis range limitation systems restrict the working range to the required minimum.

This increases personal safety and protection of the system.

In the case of manipulators that are not designed to be fitted with mechanical axis range limitation, the workspace must be laid out in such a way that there is no danger to persons or

material property, even in the absence of mechanical axis range limitation.

If this is not possible, the workspace must be limited by means of photoelectric barriers, photoelectric curtains or obstacles on the system side. There must be no shearing or crushing

hazards at the loading and transfer areas.

Information!

This option is not available for all robot models. Information on specific robot models

can be obtained from KUKA Roboter GmbH.

5.5.3 Axis range monitoring (optional)

Some manipulators can be fitted with dual--channel axis range monitoring systems in main

axes A1 to A3. The positioner axes may be fitted with additional axis range monitoring systems. The safety zone for an axis can be adjusted and monitored using an axis range monitoring system. This increases personal safety and protection of the system.

Information!

This option is not available for all robot models and not for the KR C4. Information on

specific robot models can be obtained from KUKA Roboter GmbH.

5.5.4 Options for moving the manipulator without drive energy

Caution!

The system user is responsible for ensuring that the training of personnel with

regard to the response to emergencies or exceptional situations also includes

how the manipulator can be moved without drive energy.

Description

The following devices are available for moving the manipulator after an accident or malfunction:

G Release device (optional)

The release device can be used for the main axis drive motors and, depending on the

robot variant, also for the wrist axis drive motors.

G Brake release device (optional)

The brake release device is designed for robot variants whose motors are not freely

accessible.

G Moving the wrist axes directly by hand

There is no release device available for the wrist axes of variants in the low payload

category. This is not necessary because the wrist axes can be moved directly by hand.

5 Safety (continued)

51 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Information!

Information about the options available for the various robot models and about how to

use them can be found in the assembly and operating instructions for the robot or requested from KUKA Roboter GmbH.

Notice!

Moving the manipulator without drive energy can damage the motor brakes of

the axes concerned. The motor must be replaced if the brake has been damaged.

The manipulator may therefore be moved without drive energy only in emergencies or exceptional situations, e.g. for rescuing persons.

Assembly Instructions

52 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

5.5.5 Labeling on the industrial robot

All plates, labels, symbols and marks constitute safety--relevant parts of the industrial robot.

They must not be modified or removed.

Labeling on the industrial robot consists of:

G Identification plates

G Warning labels

G Safety symbols

G Designation labels

G Cable markings

G Rating plates

Information!

Further information is contained in the technical data of the operating instructions or

assembly instructions of the components of the industrial robot.

5.6 Safety measures

5.6.1 General safety regulations

The industrial robot may only be used in perfect technical condition in accordance with its

intended use and only by safety--conscious persons. Operator errors can result in personal

injury and damage to property.

It is important to be prepared for possible movements of the industrial robot even after the

robot controller has beenswitched off andlocked. Incorrect installation (e.g. overload) or mechanical defects (e.g. brake defect) can cause the manipulator or external axes to sag. If

work is to be carried out on a switched--off industrial robot, the manipulator and external axes

must first be moved into a position in which they are unable to move on their own, whether

the payload is mounted or not. If this is not possible, the manipulator and external axes must

be secured by appropriate means.

Danger!

In the absence of operational safety functions and safeguards, the industrial

robot can cause personal injury or material damage. If safety functions or

safeguards are dismantled or deactivated, the industrial robot may not be

operated.

Danger!

Standing underneath the robot arm can cause death or serious injuries. For this

reason, standing underneath the robot arm is prohibited!

Caution!

The motors reach temperatures during operation which can cause burns to the

skin. Contact must be avoided. Appropriate safety precautions must be taken,

e.g. protective gloves must be worn.

5 Safety (continued)

53 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

KCP/smartPAD

The user must ensure that the industrial robot is only operated with the KCP/smartPAD by

authorized persons.

If more than one KCP/smartPAD is used in the overall system, it must be ensured that each

device is unambiguously assigned to the corresponding industrial robot. They must not be

interchanged.

Warning!

The operator must ensure that decoupled KCPs/smartPADs are immediately

removed from the system and stored out of sight and reach of personnel

working on the industrial robot. This serves to prevent operational and

non--operational EMERGENCY STOP devices from becoming interchanged.

Failure to observe this precaution may result in death, severe injuries or

considerable damage to property.

External keyboard, external mouse

An external keyboard and/or external mouse may only be used if the following conditions are

met:

G Start--up or maintenance work is being carried out.

G The drives are switched off.

G There are no persons in the danger zone.

The KCP/smartPAD must not be used as long as an external keyboard and/or external

mouse are connected to the control cabinet.

The external keyboard and/or external mouse must be removed from the control cabinet as

soon as the start--up or maintenance work is completed or the KCP/smartPAD is connected.

Modifications

After modifications to the industrial robot, checks must be carried out to ensure the required

safety level. The valid national or regional work safety regulations must be observed for this

check. The correct functioning of all safety circuits must also be tested.

New or modified programs must always be tested first in Manual Reduced Velocity mode

(T1).

After modifications to the industrial robot, existing programs must always be tested first in

Manual Reduced Velocity mode (T1). This applies to all components of the industrial robot

and includes modifications to the software and configuration settings.

Faults

The following tasks must be carried out in the case of faults in the industrial robot:

G Switch off the robot controller and secure it (e.g. with a padlock) to prevent unauthorized

persons from switching it on again.

G Indicate the fault by means of a label with a corresponding warning (tagout).

G Keep a record of the faults.

G Eliminate the fault and carry out a function test.

Assembly Instructions

54 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

5.6.2 Transportation

Manipulator

The prescribed transport position of the manipulator must be observed. Transportation must

be carried out in accordance with the operating instructions or assembly instructions of the

robot.

Robot controller

The prescribed transport position of the robot controller must be observed. Transportation

must be carried out in accordance with the operating instructions or assembly instructions

of the robot controller.

Avoid vibrations and impacts during transportation in order to prevent damage to the robot

controller.

External axis (optional)

The prescribed transport position of the external axis (e.g. KUKA linear unit, turn--tilt table,

etc.) must be observed. Transportation must be carried out in accordance with the operating

instructions or assembly instructions of the external axis.

5.6.3 Start--up and recommissioning

Before starting up systems and devices for the first time, a check must be carried out to ensure that the systems and devices are complete and operational, that they can be operated

safely and that any damage is detected.

The valid national or regional work safety regulations must be observed for this check. The

correct functioning of all safety circuits must also be tested.

Notice!

The passwords for logging onto the KUKA System Software as “Expert” and

“Administrator” must be changed before start--up and must only be communicated to authorized personnel.

Danger!

The robot controller is preconfigured for the specific industrial robot. If cables

are interchanged, the manipulator and the external axes (optional) may receive

incorrect data and can thus cause personal injury or material damage. If a system consists of more than one manipulator, always connect the connecting

cables to the manipulators and their corresponding robot controllers.

Notice!

If additional components (e.g. cables), which are not part of the scope of supply

of KUKA Roboter GmbH, are integrated into the industrial robot, the user is responsible for ensuring that these components do not adversely affect or disable

safety functions.

Notice!

If the internal cabinet temperature of the robot controller differs greatly from the

ambient temperature, condensation can form, which may cause damage to the

electrical components. Do not put the robot controller into operation until the

internal temperature of the cabinet has adjusted to the ambient temperature.

5 Safety (continued)

55 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Function test

The following tests must be carried out before start--up and recommissioning.

It must be ensured that:

G The industrial robot is correctly installed and fastened in accordance with the specifica-

tions in the documentation.

G There are no foreign bodies or loose parts on the industrial robot.

G All required safety equipment is correctly installed and operational.

G The power supply ratings of the industrial robot correspond to the local supply voltage

and mains type.

G The ground conductor and the equipotential bonding cable are sufficiently rated and

correctly connected.

G The connecting cables are correctly connected and the connectors are locked.

Machine data

It must be ensured that the rating plate on the robot controller has the same machine data

as those entered in the declaration of incorporation.

The machine data on the rating plate of the manipulator and the external axes (optional) must

be entered during start--up.

Danger!

The industrial robot must not be moved if incorrect machine data are loaded.

Death, severe injuries or considerable damage to property may otherwise result.

The correct machine data must be loaded.

5.6.4 Manual mode

Manual mode is the mode for setup work. Setup work is all the tasks that have to be carried

out on the industrial robot to enable automatic operation. Setup work includes:

G Jog mode

G Teach

G Programming

G Program verification

The following must be taken into consideration in manual mode:

G If the drives are not required, they must be switched off to prevent the manipulator or

the external axes (optional) from being moved unintentionally.

New or modified programs must always be tested first in Manual Reduced Velocity

mode (T1).

G The manipulator, tooling or external axes (optional) must never touch or project beyond

the safety fence.

G Workpieces, tooling and other objects must not become jammed as a result of the in-

dustrial robot motion, nor must they lead to short--circuits or be liable to fall off.

G All setup work must be carried out, where possible, from outside the safeguarded area.

Assembly Instructions

56 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

If the setup work has to be carried out inside the safeguarded area, the following must be

taken into consideration:

In Manual Reduced Velocity mode (T1):

G If it can be avoided, there must be no other persons inside the safeguarded area.

If it is necessary for there to be several persons inside the safeguarded area, the

following must be observed:

-- Each person must have an enabling device.

-- All persons must have an unimpeded view of the industrial robot.

-- Eye--contact between all persons must be possible at all times.

G The operator must be so positioned that he can see into the danger area and get out

of harm’s way .

In Manual High Velocity mode (T2):

G This mode may only be used if the application requires a test at a velocity higher than

Manual Reduced Velocity.

G Teaching and programming are not permissible in this operating mode.

G Before commencing the test, the operator must ensure that the enabling devices are

operational.

G The operator must be positioned outside the danger zone.

G There must be no other persons inside the safeguarded area. It is the responsibility of

the operator to ensure this.

5.6.5 Automatic mode

Automatic mode is only permissible in compliance with the following safety measures:

G All safety equipment and safeguards are present and operational.

G There are no persons in the system.

G The defined working procedures are adhered to.

If the manipulator or an external axis (optional) comes to a standstill for no apparent reason,

the danger zone must not be entered until an EMERGENCY STOP has been triggered.

5.6.6 Maintenance and repair

After maintenance and repair work, checks must be carried out to ensure the required safety

level. The valid national or regional work safety regulations must be observed for this check.

The correct functioning of all safety circuits must also be tested.

The purpose of maintenance and repair work is to ensure that the system is kept operational

or, in the event of a fault, to return the system to an operational state. Repair work includes

troubleshooting in addition to the actual repair itself.

The following safety measures must be carried out when working on the industrial robot:

G Carry out work outside the danger zone. If work inside the danger zone is necessary,

the user must define additional safety measures to ensure the safe protection of personnel.

G Switch off the industrial robot and secure it (e.g. with a padlock) to prevent it from being

switched on again. If it is necessary to carry out work with the robot controller switched

on, the user must define additional safety measures to ensure the safe protection of

personnel.

G If it is necessary to carry out work with the robot controller switched on, this may only

be done in operating mode T1.

5 Safety (continued)

57 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

G Label the system with a sign indicating that work is in progress. This sign must remain

in place, even during temporary interruptions to the work.

G The EMERGENCY STOP systems must remain active. If safety functions or safe-

guards are deactivated during maintenance or repair work, they must be reactivated

immediately after the work is completed.

Warning!

Before work is commenced on live parts of the robot system, the main switch

must be turned off and secured against being switched on again by unauthorized personnel. The incoming power cable must be deenergized. The robot controller and mains supply lead must then be checked to ensure that it is deenergized.

If the KR C4 or VKR C4 robot controller is used:

It is not sufficient, before commencing work on live parts, to execute an EMERGENCY STOP or a safety stop, or to switch off the drives, as this does not disconnect the robot system from the mains power supply in the case of the drives

of the new generation. Parts remain energized. Death or severe injuries may result.

Faulty components must be replaced using new components with the same article numbers

or equivalent components approved by KUKA Roboter GmbH for this purpose.

Cleaning and preventive maintenance work is to be carried out inaccordance with the operating instructions.

Robot controller

Even when the robot controller is switched off, parts connected to peripheral devices may

still carry voltage. The external power sources must therefore be switched off if work is to

be carried out on the robot controller.

The ESD regulations must be adhered to when working on components in the robot controller.

Voltages in excess of 50 V (up to 600 V) can be present in various components for several

minutes after the robot controller has been switched off! To prevent life--threatening injuries,

no work may be carried out on the industrial robot in this time.

Water and dust must be prevented from entering the robot controller.

Counterbalancing system

Some robot variants are equipped with a hydropneumatic, spring or gas cylinder counterbalancing system.

The hydropneumatic and gas cylinder counterbalancing systems are pressure equipment

and, as such, are subject to obligatory equipment monitoring. Depending on the robot variant, the counterbalancing systems correspond to category 0, II or III, fluid group 2, of the

Pressure Equipment Directive.

The user must comply with the applicable national laws, regulations and standards pertaining

to pressure equipment.

Inspection intervals in Germany in accordance with Industrial Safety Order, Sections 14 and

15. Inspection by the user before commissioning at the installation site.

The following safety measures must be carried out when working on the counterbalancing

system:

G The manipulator assemblies supported by the counterbalancing systems must be se-

cured.

G Work on the counterbalancing systems must only be carried out by qualified personnel.

Assembly Instructions

58 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

Hazardous substances

The following safety measures must be carried out when handling hazardous substances:

G Avoid prolonged and repeated intensive contact with the skin.

G Avoid breathing in oil spray or vapors.

G Clean skin and apply skin cream.

Notice!

To ensure safe use of our products, we recommend that our customers regularly

request up--to--date safety data sheets from the manufacturers of hazardous substances.

5.6.7 Decommissioning, storage and disposal

The industrial robot must be decommissioned, stored and disposed of in accordance with

the applicable national laws, regulations and standards.

5 Safety (continued)

59 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

5.7 Applied norms and regulations

Name Definition Edition

2006/42/EC

Machinery Directive:

Directive 2006/42/EC of the European Parliament and of

the Council of 17 May 2006 on machinery, and amending

Directive 95/16/EC (recast)

2006

2004/108/EC

EMC Directive:

Directive 2004/108/EC of the European Parliament and of

the Council of 15 December 2004 on the approximation of

the laws of the Member States relating to electromagnetic

compatibility and repealing Directive 89/336/EEC

2004

97/23/EC

Pressure Equipment Directive:

Directive 97/23/EC of the European Parliament and of the

Council of 29 May 1997 on the approximation of the laws

of the Member States concerning pressure equipment

(Only applicable for robots with hydropneumatic counterbalancing system.)

1997

EN ISO 13850

Safety of machinery:

Emergency stop -- Principles for design

2008

EN ISO 13849--1

Safety of machinery:

Safety--related parts of control systems;

Part 1: General principles of design

2008

EN ISO 13849--2

Safety of machinery:

Safety--related parts of control systems;

Part 2: Validation

2008

EN ISO 12100

Safety of machinery:

General principles of design, risk assessment and risk reduction

2010

EN ISO 10218--1

Industrial robots: Safety

201 1

EN 614--1

Safety of machinery:

Ergonomic design principles -- Part 1: Terms and general

principles

2006

EN 61000--6--2

Electromagnetic compatibility (EMC):

Part 6--2: Generic standards; Immunity for industrial environments

2005

EN 61000--6--4

Electromagnetic compatibility (EMC):

Part 6--4: Generic standards; Emission standard for industrial environments

2007

EN 60204--1

Safety of machinery:

Electrical equipment of machines

Part 1: General requirements

2006

Assembly Instructions

60 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

6 Transportation

61 of 122

MA KR 30, 60 HA, KR C4 04.11.02 en

6 Transportation

Information!

This description applies analogously to all of the industrial robots listed in Chapter 1,

regardless of the variant or model shown in the illustrations.

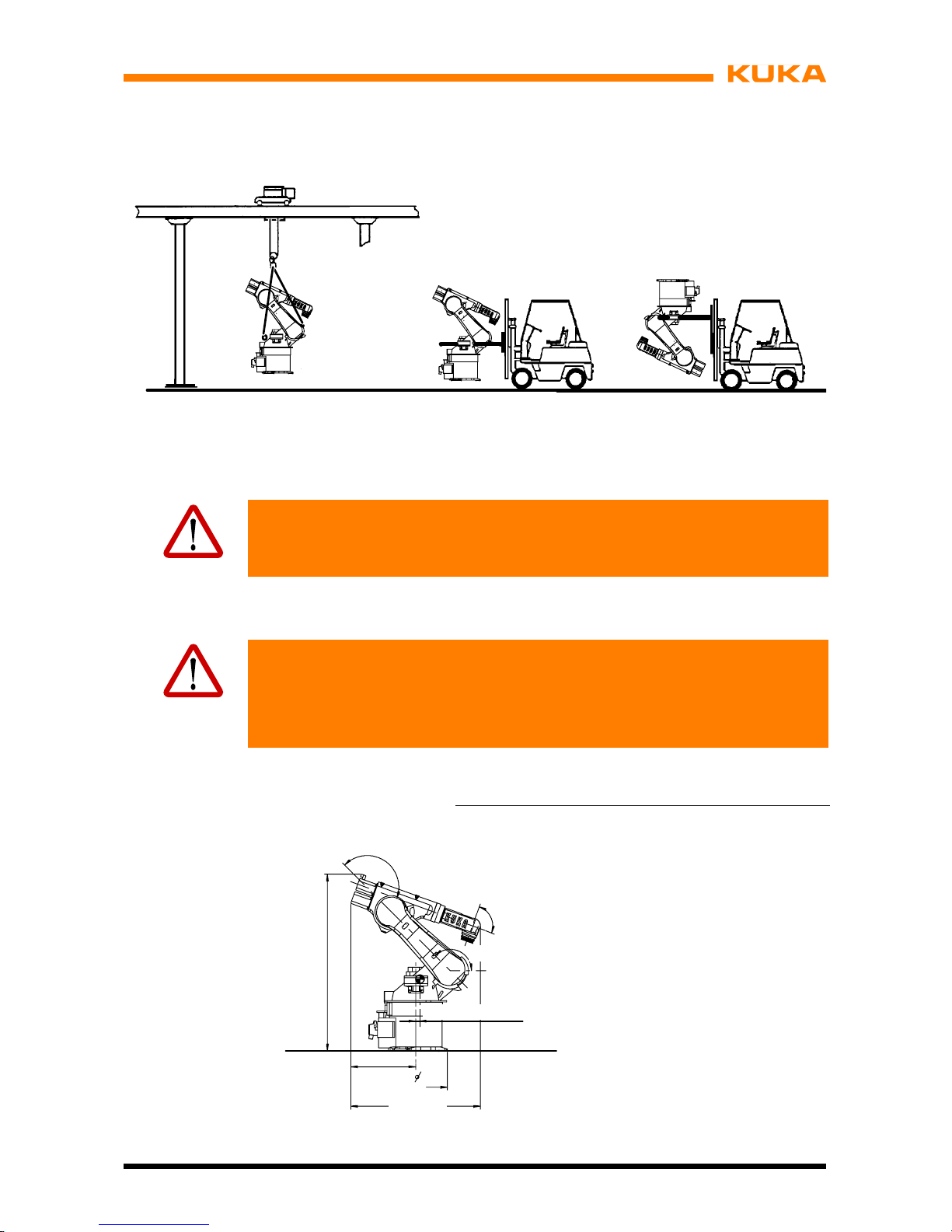

Caution!