Kuhns mfg EGF8 Owner's Manual

Owner’s Manual

EGF8 Grabber

2017

MADE IN THE USA

Read and Understand the manual. This manual provides information and

procedures to safely operate and maintain the Grabber.

CONTENTS

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Intended Usage . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Operator Orientation. . . . . . . . . . . . . . . . . . . . 4

1.3 Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Serial Number Location . . . . . . . . . . . . . . . . . 4

1.5 Owner/Operator Manual Storage . . . . . . . . . . 4

1.6 Product Improvements . . . . . . . . . . . . . . . . . . 5

1.7 Disposal of Equipment at End of Useful Life . 5

1.8 Unanswered Questions . . . . . . . . . . . . . . . . . 5

2. SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Safety Alert Symbol . . . . . . . . . . . . . . . . . . . .6

2.3 Safety Icons Nomenclature . . . . . . . . . . . . . . 7

2.3.1 Personal Protection/Important

Information . . . . . . . . . . . . . . . . . . . .7

2.3.2 Prohibited Actions . . . . . . . . . . . . . . .7

2.3.3 Hazard Avoidance . . . . . . . . . . . . . . .7

2.4 General Operating Safety. . . . . . . . . . . . . . . . 8

2.5 Safety Signs . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Practice Safe Maintenance . . . . . . . . . . . . . . 8

2.7 Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.8 Hydraulic Safety . . . . . . . . . . . . . . . . . . . . . . . 9

2.9 Sign-Off Form . . . . . . . . . . . . . . . . . . . . . . . . 9

2.10 Operation Safety . . . . . . . . . . . . . . . . . . . . . 11

2.11 Transporting Safety . . . . . . . . . . . . . . . . . . . 11

2.12 Storage Safety . . . . . . . . . . . . . . . . . . . . . . . 11

2.13 Maintenance Safety . . . . . . . . . . . . . . . . . . . 11

3. SAFETY SIGNS AND LABELS . . . . . . . . . . . . . 12

3.1 General Information . . . . . . . . . . . . . . . . . . . 12

3.2 Contact Information . . . . . . . . . . . . . . . . . . . 12

3.3 How to Install Replacement Safety Signs . . 12

3.4 Safety Sign Locations. . . . . . . . . . . . . . . . . . 13

3.5 Safety Signs . . . . . . . . . . . . . . . . . . . . . . . . . 13

5. OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 User Safety Training. . . . . . . . . . . . . . . . . . . 15

5.2 Tractor Requirements. . . . . . . . . . . . . . . . . . 15

5.2.1 Equipment and Capabilities. . . . . . . 15

5.2.2 Tractor Safety Devices . . . . . . . . . . 15

5.2.3 ROPS and Seat Belt . . . . . . . . . . . . 16

5.3 Pre-Operation Checklist . . . . . . . . . . . . . . . 16

5.4 Attaching to Loader . . . . . . . . . . . . . . . . . . . 16

5.5 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.5.1 Adjustable Crowd Bar . . . . . . . . . . . 17

5.6 Field Operation. . . . . . . . . . . . . . . . . . . . . . .17

5.7 Detaching From Loader . . . . . . . . . . . . . . . . 18

6. TRANSPORTING. . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 General Safety . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Highway and Transport Operations . . . . . . . 19

6.3 Pre-transport Checklist. . . . . . . . . . . . . . . . . 19

7. STORAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.1 Placing in Storage . . . . . . . . . . . . . . . . . . . . 20

7.2 Removing from Storage . . . . . . . . . . . . . . . . 20

8. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8.1 Maintenance Safety . . . . . . . . . . . . . . . . . . . 21

8.2 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.3 Bolt Torque Requirements . . . . . . . . . . . . . . 22

8.3.1 Standard Torque Values . . . . . . . . . 22

8.4 Welding Repairs. . . . . . . . . . . . . . . . . . . . . . 22

8.5 Service Record . . . . . . . . . . . . . . . . . . . . . .23

9. PARTS SECTION. . . . . . . . . . . . . . . . . . . . . . . . . 24

9.1 Ordering Parts . . . . . . . . . . . . . . . . . . . . . . . 24

9.2 Contact Information . . . . . . . . . . . . . . . . . . . 24

9.3 Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.4 Parts Detail. . . . . . . . . . . . . . . . . . . . . . . . . . 25

4. NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . 14

EGF8 Grabber 3 Kuhns Manufacturing (877-296-5851)

1. Introduction

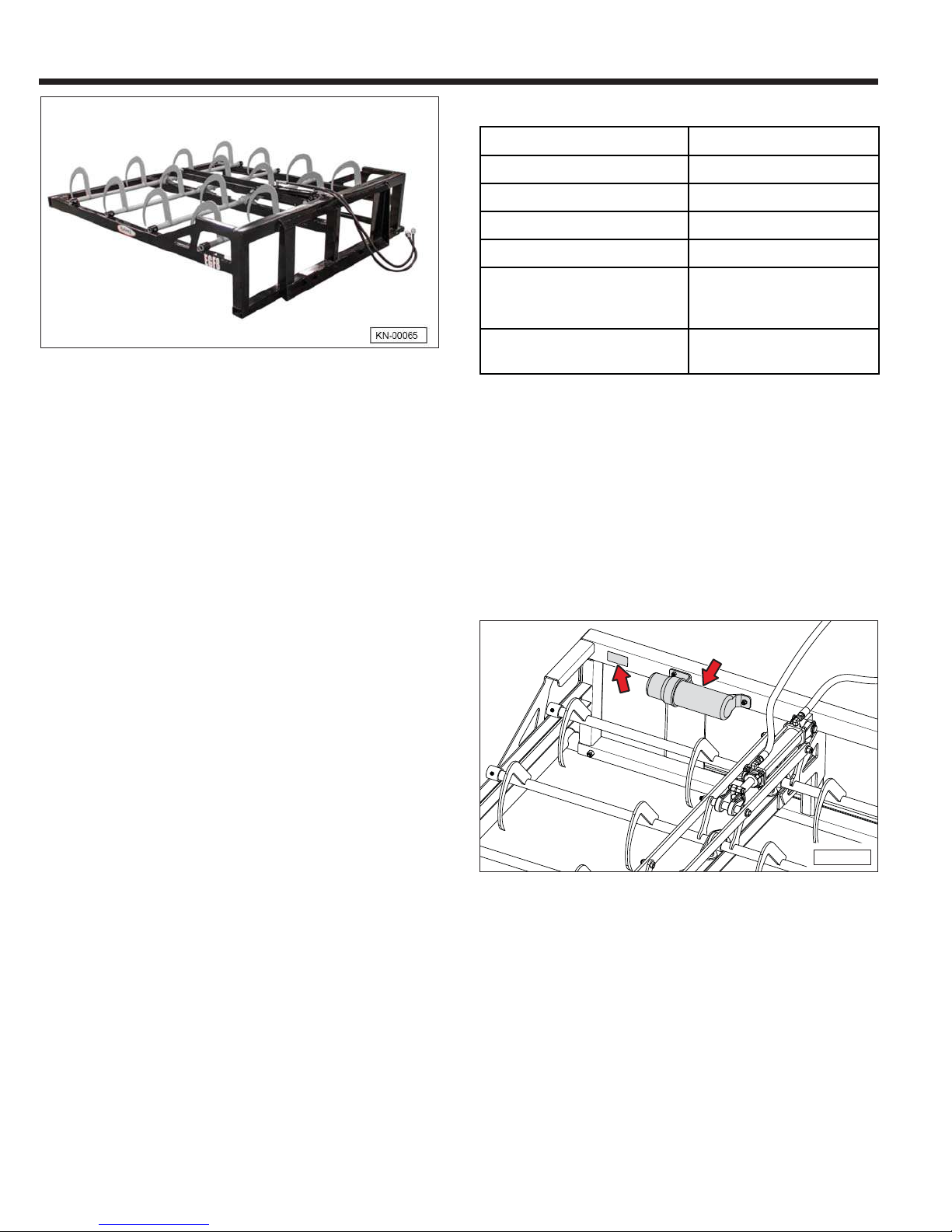

1.3 Specifications

Overall Width 68"

Overall Length 72"

Overall Height 9”

The EGF8 Grabber picks up bales arranged 4 wide

and 2 long on their strings, using 16 hooks mounted

on 4 bars.

Bales that are 36″ long can be cross stacked with

the EGF8 Grabber.

The low weight requirement for the Grabber allows

for the use of a small loader.

Please read the manual carefully to become familiar

with your new Kuhns Grabber. This manual has

been developed through our experience with the

equipment and feedback from our customers.

Ultimately it is our desire that you will be operating

your Grabber as a seasoned professional in no time!

Overall Weight

Bale Capacity

Lift Capacity

Bale Size

Specifications subject to change without notice.

Note: Lift Capacity may be

limited by loader Lift Capacity

415 lb.

8

1150 lb.

14 x 18” or 16 x 18”,

32 to 38” long

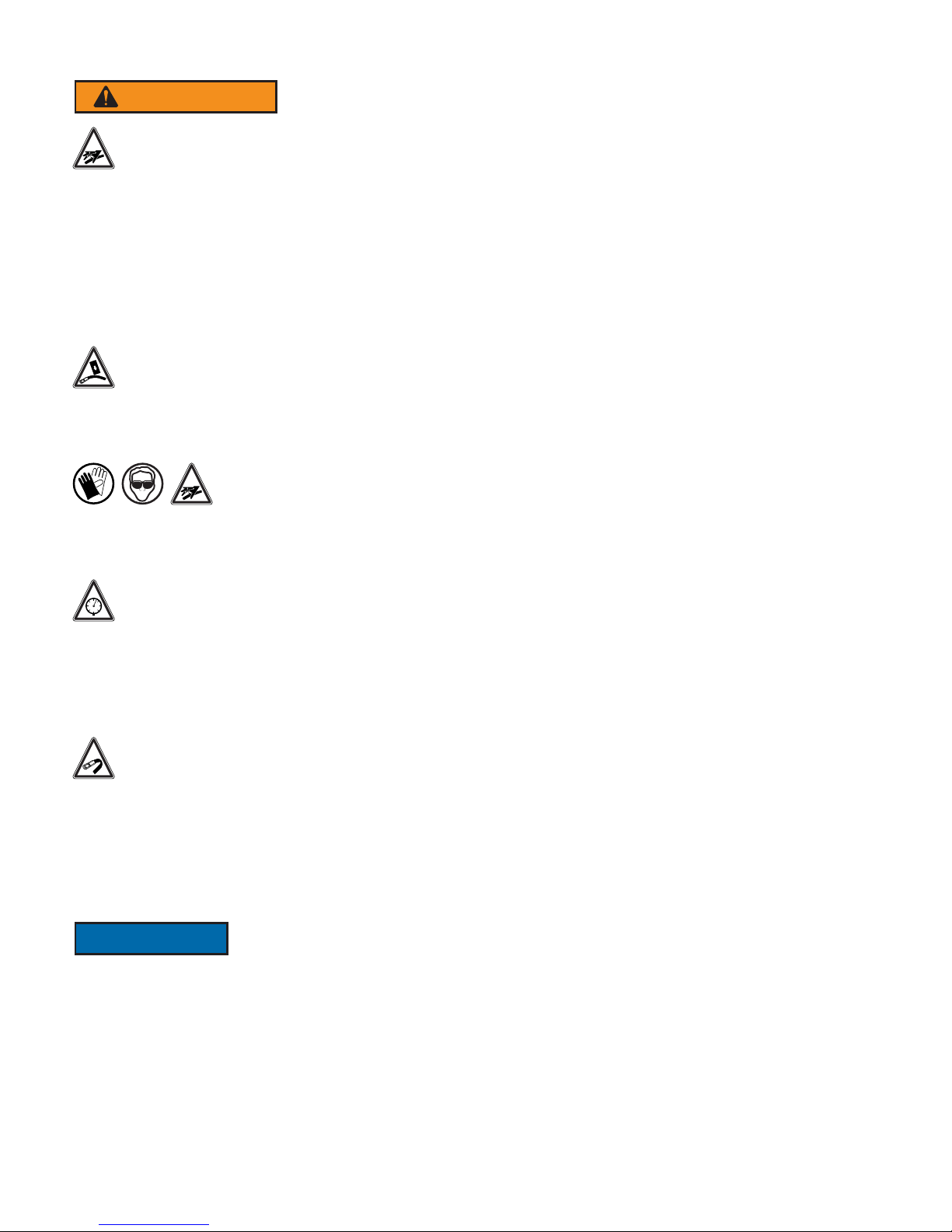

1.4 Serial Number Location

The Grabber’s serial number is located on the

upper right corner of the Grabber Frame. Please

use this number when requesting service, seeking

information, or ordering parts. Record the serial

number in the space provided for easy reference

when contacting Kuhns Manufacturing LLC with

questions.

1.1 Intended Usage

Do not use this Grabber for any other purpose than

its intended use of picking up bales that have been

arranged into groups with an Accumulator, and

moving them to wagons or storage facilities.

KN-00058

1.2 Operator Orientation

The directions left, right, front, and rear, as

mentioned throughout this manual, are as seen from

the tractor operator’s seat and facing in the direction

of travel.

Serial Number ______________________________

Date of Purchase ___________________________

1.5 Owner/Operator Manual Storage

Store the Owner/Operator manual and other

operating materials in the document storage tube,

located next to the serial no. decal.

Kuhns Manufacturing (877-296-5851) 4 EGF8 Grabber

1.6 Product Improvements

Because Kuhns Manufacturing LLC maintains

an ongoing program of product improvement, we

reserve the right to make improvements in design

or changes in specifications without incurring any

obligation to install them on units previously sold.

1.7 Disposal of Equipment at End of Useful

Life

The Kuhns Mfg. LLC Grabber has been designed for

the specific purpose of picking up bales that have

been arranged into groups with an Accumulator,

and moving them to wagons or storage facilities.

When this unit is no longer capable of performing its

intended use, it should be dismantled and scrapped.

Do not use any materials or components from this

unit for any other purpose.

1.8 Unanswered Questions

If you have any questions not answered in this

manual, require additional copies, or the manual is

damaged, please contact your dealer or:

Kuhns Manufacturing LLC

4210 Kinsman Road NW

North Bloomfield, OH 44450

Phone: 877-296-5851

Fax: 440-693-4336

E-mail: parts@kuhnsmfg.com

The manual is also available for download at:

www.kuhnsmfg.com

EGF8 Grabber 5 Kuhns Manufacturing (877-296-5851)

2. Safety

2.1 General

Most work related accidents are caused by failure

to observe basic safety rules or precautions. An

accident can often be avoided by recognizing

potentially hazardous situations before an accident

occurs. As you operate and maintain the Grabber

you must be alert to potential hazards.

Improper operation and/or maintenance of this

unit could cause a dangerous situation that

results in injury or death.

Do not use this unit until you read and

understand the information contained in this

manual. Do not use the Grabber for anything

other than its intended purpose.

WARNING

Do not use the unit until you read and

understand the information contained in

this manual and all related equipment

manuals.

2.2 Safety Alert Symbol

This is the safety alert symbol. It is used to

alert you to potential personal injury

hazards. Obey all safety messages that

follow this symbol to avoid possible injury

or death.

This manual contains WARNINGS, CAUTIONS,

NOTICES, SAFETY INSTRUCTIONS, and NOTES

which must be followed to prevent the possibility

of improper service, damage to the equipment,

personal injury, or death. The following key words

call the readers attention to potential hazards.

Hazards are identified by the “Safety Alert Symbol”

and followed by a signal word such as “WARNING”

or “CAUTION”.

WARNING

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Safety precautions and warnings are

provided in this manual and on the unit. If

these hazard warnings are not heeded,

bodily injury or death could occur to you or to

other persons.

Kuhns Manufacturing LLC cannot anticipate

every possible circumstance that might

involve a potential hazard. The warnings in

this manual and on the product are, therefore,

not all-inclusive. If a method of operation not

specifically recommended by us is used, you

must satisfy yourself that it is safe for you and

for others. You should also ensure that the unit

will not be damaged or be made unsafe by the

methods that you choose.

The information, specifications, and illustrations in

this manual are based on the information that was

available at the time this material was written and

can change at any time.

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury.

NOTICE

Indicates that equipment or property damage

can result if instructions are not followed.

SAFETY

INSTRUCTIONS

Safety instructions (or equivalent) signs indicate

specific safety-related instructions or

procedures.

Note: Contains additional information important to a

procedure.

Kuhns Manufacturing (877-296-5851) 6 EGF8 Grabber

2.3 Safety Icons Nomenclature

OEM

This manual and the equipment has numerous

safety icons. These safety icons provide important

operating instructions which alert you to potential

personal injury hazards

2.3.1 Personal Protection/Important Information

Read the manual

Maintenance procedure

No riders

No children

No alcohol

No drugs

2.3.3 Hazard Avoidance

Eye protection

Hearing protection

Hand protection

Foot protection

First aid kit

Use proper tools

OEM

Use OEM parts

Use ROPS and seat belt

AR

N

I

NG

Maintain safety signs

Place in park

Crushing hazard

Crushing hazard

Slipping hazard

Tripping hazard

Falling hazard

Hose damage hazard

Explosive separation hazard

Safety alert symbol

Trapped air hazard

High pressure fluid hazard

Remove key

STOP

Stop engine

Visibility

Set parking brake

2.3.2 Prohibited Actions

Do not alter or modify

Do not leave out tools

Do not weld

EGF8 Grabber 7 Kuhns Manufacturing (877-296-5851)

Defective or broken part

Chock wheels

Maintain safe distance

Pinch point hazard

Crush hazard

Rollover hazard

2.4 General Operating Safety

2.5 Safety Signs

WARNING

Read And Understand Manual

To prevent personal injury or even death,

be sure you read and understand all of the

instructions in this manual and other related

OEM equipment manuals! This Grabber (unit)

was designed for a specific application; DO NOT

modify or use this unit for any application other

than that for which it was designed. Units

operated improperly or by untrained personnel

can be dangerous! Inexperienced operators

should receive instruction from someone

familiar with the equipment before being allowed

to operate the unit.

Do Not Operate

Do not use the unit if it is in need

of repair. If you believe the unit

has a defect which could cause injury or

death, you should immediately stop using the

unit.

Fall Hazard

Do not use the unit as a platform. Do not

stand on top of the unit at any time. Do

not ride on the unit or allow others to ride on it.

Pinch Point Hazard

Keep hands and feet away from any

moving parts to prevent them from getting

pinched.

Impaired User Hazard

Do not attempt to operate or

maintain the Grabber under the

influence of drugs or alcohol. Consult your

doctor before using the Grabber while taking

prescription medications.

Falling Hazard

Do not allow riders on the loader or

Grabber at any time. Falling can

result in severe injuries or death.

CAUTION

Legible Safety Signs

AR

N

I

NG

Keep safety signs clean and legible at all

times. Replace any safety sign or

instruction sign that is missing or not legible.

Refer to the Safety Sign Location section for

additional information.

Replacement parts that displayed a safety sign

should also display the current sign.

Replacement safety signs (labels) are available

from your authorized Dealer Parts Department

or the factory at no cost.

2.6 Practice Safe Maintenance

SAFETY

INSTRUCTIONS

Understand service procedures before

doing any work. Keep the work area clean

and dry.

Keep all parts in good working

condition and properly installed.

Replace worn or broken parts

immediately.

Do not modify the unit or its safety

devices. Do not weld on the unit.

Unauthorized modifications may impair its

function and safety.

2.7 Training

Anyone who will be using and/or maintaining the

Grabber must read, clearly understand, and follow

ALL safety, operation, and maintenance information

presented in this manual, other related OEM

manuals, and the safety signs

If you do not understand any information in this

manual, see your dealer or contact Kuhns Mfg. LLC

before proceeding.

Do not use or allow anyone else to use this Grabber

until all information has been reviewed. Annually

review this manual before the season start-up.

Make periodic reviews of SAFETY and OPERATION

a standard practice. An untrained operator is not

qualified to use this Grabber.

Kuhns Manufacturing (877-296-5851) 8 EGF8 Grabber

2.8 Hydraulic Safety

2.9 Sign-Off Form

WARNING

High-Pressure Fluid Hazard

Hydraulic fl uid escaping under pressure

can penetrate the skin. Openings in the

skin and minor cuts are susceptible to infection

from hydraulic fl uid. If injured by a concentrated

high-pressure stream of hydraulic fl uid, seek

medical attention immediately. Without

immediate medical treatment, serious infection

or toxic reaction can develop if hydraulic fl uid

penetrates the surface of the skin.

Before applying pressure to the system,

make sure all components are tight and

that the hydraulic lines, hoses, and

couplings are not damaged. Replace any worn,

cut, abraded, fl attened, or crimped hoses.

Wear proper hand and eye

protection when searching for

a high-pressure hydraulic leak.

Use a piece of wood or cardboard as a backstop

instead of hands to identify and isolate a leak.

Kuhns Mfg LLC follows the general Safety

Standards specified by the Farm Equipment

Manufacturers Association (FEMA), and the

American National Standards Institute (ANSI).

Anyone who will be using and/or maintaining the

Grabber must read and clearly understand ALL

safety, operation and maintenance information

presented in this manual.

Do not use or allow anyone else to use this

equipment until all information has been reviewed.

Annually review this manual before the season startup.

Make periodic reviews of SAFETY and OPERATION

of the Grabber a standard practice. An untrained

operator is not qualified to use this Grabber.

This sign-off sheet is provided for your records to

show that all personnel who will be working with

the equipment have read and understand the

information in this Operation and Parts Manual

and have been instructed in the operation of the

equipment.

Trapped Air Hazard

When installing, replacing, or repairing

hydraulic system cylinders or parts, make

sure that the entire system is charged and free

of air before resuming operations. Failure to

bleed the system of all air can result in improper

machine operation, causing severe injury.

Explosive Separation Hazard

Do not make any temporary repairs to the

hydraulic lines, fi ttings, or hoses using

tape, clamps, or adhesives. The hydraulic

system operates under extremely high pressure

and temporary repairs may fail suddenly and

create a hazardous/dangerous situation.

NOTICE

Make sure components in the hydraulic system

are kept clean and in good working condition.

The most common reason for hydraulic component

failure is contamination of the oil. Keep all hydraulic

access areas completely clean, such as around the

hydraulic oil fi ller cap, fi lter, and connection points.

Repair any fi ttings, hoses, or other components

where leakage is observed. Clean up any spilled

hydraulic oil.

EGF8 Grabber 9 Kuhns Manufacturing (877-296-5851)

Loading...

Loading...