Page 1

Kuhnke Electronics

Instruction Manual

Ventura Vico / Scout 401

Toucht Terminal / Panel PLC

E 802 GB 10 December 2013

Page 2

2

This technical information is directed primarily to specialists involved in the conception, design and construction of machines. It does

not indicate any information about availability of products. The technical specifications stated herein are only of descriptive nature and

do not represent a guarantee as to the ability or usability of a product in a legal sense. Such specific assurances are subject to individual contractual agreements. We do not accept any claims for compensation of damages for whatever reason, unless substantial proof

of intention or gross negligence is provided. Complete or partial reproduction of this document requires the written consent of the author. All rights concerning changes, omissions and misconceptions are reserved. Ilustrations similar.

Microsoft® Windows® and the Windows logo are registered trademarks of Microsoft Corporation in the USA and other countries.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Additional info

rmation on the PLCopen organization can be found at www.plcopen.org.

CiA® and CANopen® are registered community trade marks of CAN in Automation e.V.

All rights reserved by the individual copyright holders.

Reproduction even of extracts only with the editor's express and written prior consent.

Page 3

3

Table of Contents

1 Introduction ....................................................................................................................................5

2 Reliability, Safety ...........................................................................................................................6

2.1 Intended Use......................................................................................................................6

2.2 Target Group......................................................................................................................6

2.3 Reliability............................................................................................................................6

2.4 Symbols .............................................................................................................................6

2.4.1 Danger..............................................................................................................................7

2.4.2 Attention ...........................................................................................................................7

2.4.3 Note..................................................................................................................................7

2.4.4 Under Construction ..........................................................................................................7

2.4.5 Instruction.........................................................................................................................7

2.5 Safety .................................................................................................................................7

2.5.1 Project Planning and Installation......................................................................................8

2.5.2 Maintenance and Servicing ..............................................................................................8

2.6 Electromagnetic Compatibility............................................................................................9

2.6.1 Definition ..........................................................................................................................9

2.6.2 Interference Emission ......................................................................................................9

2.6.3 General Notes on Installation ...........................................................................................9

2.6.4 Electrical Immission Safeguard ......................................................................................10

2.6.5 Cable Routing and Wiring ..............................................................................................10

2.6.6 Location of Installation ...................................................................................................10

2.6.7 Particular Sources of Interference..................................................................................10

3 System Description......................................................................................................................12

3.1 Design ..............................................................................................................................12

3.2 Technical Properties ........................................................................................................13

Mechanical properties.................................................................................................................15

BIOS and operation systems ......................................................................................................15

3.3 Internal battery .................................................................................................................16

3.3.1 Replacement of the internal battery ...............................................................................16

4 Connectors ..................................................................................................................................17

4.1 Ethernet/PoE (X24) ..........................................................................................................17

4.2 Power (X1) .......................................................................................................................17

4.3 RS-232/RS-485 or CAN (X9) ...........................................................................................18

4.3.1 Option: RS-232/RS-485 .................................................................................................18

4.3.2 Option: RS-232/CAN ......................................................................................................18

4.4 USB - Host (X12) .............................................................................................................18

4.5 USB - OTG.......................................................................................................................19

External USB - OTG (X14) ......................................................................................................19

4.6 Speaker (X9/X10).............................................................................................................19

Keypad/SPI (X16) .......................................................................................................................19

Standard: Keypad/SPI.............................................................................................................19

Option: Keypad/SPI/I²C ...........................................................................................................20

4.7 Protective Earth Conductor ..............................................................................................21

5 Product geometry ........................................................................................................................27

5.1 Ventura VICO / Scout 401 ...............................................................................................27

6 Appendix......................................................................................................................................28

6.1 Safety instructions............................................................................................................28

6.2 Disposal ...........................................................................................................................29

Page 4

KUHNKE Automation

4

6.3

Trademarks and service marks........................................................................................30

6.4 Technical Data .................................................................................................................31

6.5 Specifications ...................................................................................................................31

6.5.1 Basic Units .....................................................................................................................31

6.5.2 Accessories ....................................................................................................................31

6.6 Index ...........................................................................Fehler! Textmarke nicht definiert.

6.7 Sales & Service................................................................................................................32

6.7.1 Malente Headquarters....................................................................................................32

6.7.2 Customer Service......................................................Fehler! Textmarke nicht definiert.

Page 5

5

1 Introduction

General functionality

The days of simple text displays and multi-functional control buttons

are gone. A modern and attractive design is required. But such investments into the future have often been rejected for commercial

reasons previously. However, with increasing functionality, the demands of the machine users rise in terms of handling, visualization

and diagnosis.

With the Ventura Vico KUHNKE Automation now offers a very cost effective way to use a comfortable operation panel which is directly fitted

on the machine. Your small machine or automatic system will immediately receive an added value. Other typical applications are a second

work station in conjunction with a panel or industrial PC in large or distributed machines and visualization of drive controllers programmed

with CODESYS. With its low depth, the Ventura Vico is particularly

suitable for control and display tasks in confined spaces.

A truly modern visualization system, consisting of a coordinated hardware and software package should not only master the basic functionality. It should also enable well-designed user interfaces with sophisticated ergonomics. Concept creator, operator and service technicians

should form a perfect team and work together with a tool that allows

them all opportunities. Customers always have good ideas, so change

management must be easy.

Such requirements place high demands on process visualization. It

must be intuitively usable, easy to learn and clearly structured. For

visualization of data from a CODESYS control unit the Ventura Vico is

optionally equipped with the software package CODESYS V3 HMI or

VisiWinNET. Ventura Vico offers an elegant and cost-effective solution

to match all these requirements

Page 6

KUHNKE Automation

6

2 Reliability, Safety

2.1 Intended Use

Ventura Vico/Scout is a HMI with for the control of operating and

monitoring actions in industrial areas.

For other applications, please consult us. KUHNKE is not liable for

any possible damages resulting from use in other than the designated

applications. The same applies to utilization in networks the user has

insufficiently secured against unauthorized access. Such risk lies entirely with the user.

Observance of the operation instructions is considered as part of the

units’ designated use.

2.2 Target Group

This instruction manual contains all information necessary for the use

of the described product (control device, control terminal, software,

etc.) according to instructions. It is written for design, project planning,

servicing and commissioning experts. For proper understanding and

error-free application of technical descriptions, instructions for use and

particularly of notes of danger and warning, extensive knowledge of

automation technology is compulsory.

2.3 Reliability

Reliability of Kuhnke products is brought to the highest possible standards by extensive and cost-effective means in their design and

manufacture.

These include:

• selecting high-quality components,

• quality agreements with our suppliers,

• actions to avoid static charges when handling MOS circuits,

• worst case planning and design of all circuits,

• visual inspections at various stages of fabrication,

• computer-aided tests of all assemblies and their interaction in

the circuit,

• statistical assessment of the quality of fabrication and of all re-

turned goods for the immediate taking of appropriate corrective actions.

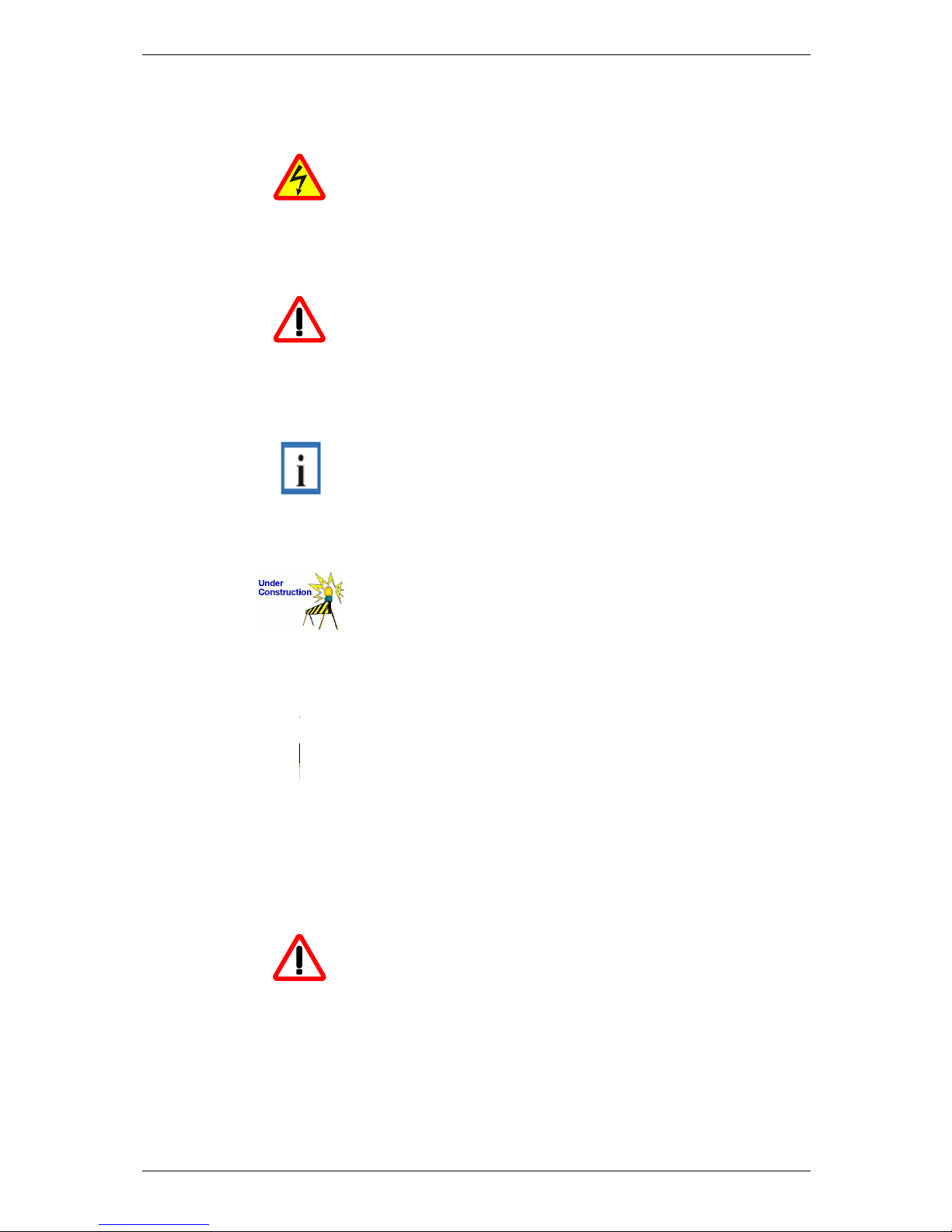

2.4 Symbols

Despite the actions described in section 2.3, the occurrence of faults

or errors in electronic control units - even if most highly improbable must be taken into consideration.

Please pay particular attention to the additional notices which we have

marked by symbols throughout this instruction manual. While some of

these notices make you aware of possible dangers, others are intended as a means of orientation. They are described further down

below in descending order of importance.

Page 7

KUHNKE Automation

7

2.4.1 Danger

This symbol warns you of dangers which may cause death or grievous bodily

harm if operators fail to implement the precautions described.

2.4.2 Attention

This symbol draws your attention to information you must take a look at to

avoid malfunctions, possible material damage or dangerous states.

2.4.3 Note

This symbol draws your attention to additional information concerning the

use of the described product. This may include cross references to information found elsewhere (e.g. in other manuals).

2.4.4 Under Construction

This symbol tells you that the function described was not or not fully available at the time this document went to press.

2.4.5 Instruction

Wherever you see these symbols in the left margin, you will find a list of

steps instructing you to take the appropriate computer or hardware actions.

They are intended as a means of orientation wherever working steps and

background information alternate (e.g. in tutorials).

2.5 Safety

Our products normally become part of larger systems or installations.

The information below is intended to help you integrate the product

into its environment without dangers to humans or material/equipment.

To achieve a high degree of conceptual safety in planning and installing an

electronic controller, it is essential to exactly follow the instructions given in

the manual because wrong handling could lead to rendering measures

against dangers ineffective or to creating additional dangers.

Page 8

KUHNKE Automation

8

2.5.1 Project Planning and Installation

• 24 VDC power supply: generate as electrically safely sepa-

rated low voltage. Suitable devices include split-winding transformers built in compliance with European Standard EN 60742

(corresponds to VDE 0551).

• Power breakdowns or power fades: the program structure is to

ensure that a defined state at restart excludes all dangerous

states.

• Emergency-off installations must comply with EN 60204/IEC

204 (VDE 0113). They must be operative at any time.

• Safety and precautions regulations for qualified applications

have to be complied with.

• Please pay particular attention to the notices of warning

which, at relevant places, will make you aware of possible

sources of dangerous mistakes or faults.

• Relevant standards and VDE regulations are to be complied

with in every case.

• Control elements are to be installed in such a way as to ex-

clude unintended operation.

• Lay control cables such that interference (inductive or capaci-

tive) is excluded if this interference could influence controller

operation or its functionality.

2.5.2 Maintenance and Servicing

• Precautions regulation VBG 4.0 to be observed when measur-

ing or checking a controller after power-up. This applies to

section 8 (Admissible deviations when working on parts) in

particular.

• Repairs must be carried out by specially trained Kuhnke staff

only (usually in the main factory in Malente). Warranty expires

in every other case.

• Spare parts:

• Only use parts approved of by Kuhnke. Only genuine Kuhnke

modules must be used in modular controllers.

• Modular systems: always plug or unplug modules in a power-

down state. You may otherwise damage the modules or (possibly not immediately recognisably!) inhibit their functionality.

• Always dispose of (rechargeable) batteries as hazardous

waste.

Page 9

KUHNKE Automation

9

2.6 Electromagnetic Compatibility

2.6.1 Definition

Electromagnetic compatibility is the ability of a device to function satisfactorily in its electromagnetic environment without itself causing any

electromagnetic interference that would be intolerable to other devices

in this environment.

Of all known phenomena of electromagnetic noise, only a certain

range occurs at the location of a given device. These kinds of noise

are specified in the applicable standards.

Refer to IEC 61131-4, User's Guideline, for general installation instructions

to be complied with to ensure that hardware interface factors and the ensuing noise voltages are limited to tolerable levels.

2.6.2 Interference Emission

DIN EN 6100-6-4

2.6.3 General Notes on Installation

As component parts of machines, facilities and systems, electronic

control systems must comply with valid rules and regulations, depending on their field of application.

General requirements concerning the electrical equipment of machines and aiming at the safety of these machines are contained in

Part 1 of European Standard EN 60204 (corresponds to VDE 0113).

For safe installation of our control system please observe the information

contained in the next chapters ( 2.6.4 ff).

Page 10

KUHNKE Automation

10

2.6.4 Electrical Immission Safeguard

To bleed electromagnetic interference, connect the controller to operative earth and ensure best-practice wiring.

Susceptibility to noise

Electromagnetic Compatibility (EMC) - Part 6-2: Generic standards Immunity for industrial environments (IEC 61000-6-2:2005);

2.6.5 Cable Routing and Wiring

Keep power circuits separate from control circuits:

• DC voltages 60 V ... 400 V

• AC voltages 25 V ... 400 V

Joint laying of control circuits is allowed for:

• shielded data signals

• shielded analogue signals

• unshielded digital I/O lines

• unshielded DC voltages < 60 V

• unshielded AC voltages < 25 V

2.6.6 Location of Installation

Ensure that temperatures, contaminations, impact, vibration or electromagnetic interference are no impediment to the installation.

2.6.6.1 Temperature

Consider heat sources such as general heating of rooms, sunlight,

heat accumulation in assembly rooms or control cabinets.

2.6.6.2 Contamination

Use suitable casings to avoid possible negative influences due to humidity, corrosive gas, liquid or conducting dust.

2.6.6.3 Impact and Vibration

Consider possible influences caused by motors, compressors, transfer

lines, presses, ramming machines and vehicles.

2.6.6.4 Electromagnetic Interference

Consider electromagnetic interference from various local sources: motors, switching devices, switching thyristors, radio-controlled devices,

welding equipment, arcing, switched-mode power supplies, converters

/ inverters.

2.6.7 Particular Sources of Interference

2.6.7.1 Inductive Actuators

Switching off inductances (such as from relays, contactors, solenoids

or switching magnets) produces surge voltages. It is mandatory to

throttle these noise voltages to an admissible amount.

Throttling elements could be diodes, Z-diodes, varistors or RC ele-

Page 11

KUHNKE Automation

11

ments. Their rating should conform to the specifications provided by

the manufacturer or supplier of the actuators.

Page 12

System Description KUHNKE Automation

12

3 System Description

VENTURA VICO is an Embedded System used as human machine interface (HMI) in various applications. Please refer to Appendix for further information. The system is equipped with a large number of industrial interfaces. A wide variety of options is available as well.

3.1 Design

The following illustration shows the boxed version with 7” display and

is meant for your orientation.

MicroSD card slot

Aluminium frame

Front cover

Resistive touch

Back cover

Fixation for internal speaker

2x installation brackets

Ground tags for power/RS485

Fitting

Connectors and interfaces

Page 13

KUHNKE Automation System Description

13

3.2 Technical Properties

CPU

Type Freescale ARM926EJ-STM i.MX27

Clock/Frequency 400 MHz

Specifications 32 bit with MMU

Memory

ROM 256 MB NAND-Flash

RAM 128 MB DDR-SDRAM

Storage Card Slot 4 bit MMC/SDIO/SD/SDHC up to 4 GB

Graphics

Controller Programmable LCD controller

Resolution Up to 800 x 600 pixel

Colours 16 bit (65,536 colours)

Supported Orientation Horizontal/vertical

LCD

Display

and Resist

ive Touch

1

Size (inch / mm) 4.3 / 109.3

Width x Height (pixels) 480 x 272

Colours 24 bit (16.7 Mio. colours)

Backlight Unit LED

Luminance 350 cd/m²

Active Area W x H (mm) 95.04 x 53.86

Viewing Direction 6 o’clock

Viewing Angle (Typ.) 125° (V) / 140° (H)

Backlight t.b.d. Lifetime

Touch 1,000,000 (finger) touches

Properties Anti-glare Surface

Hardness 3H

Standard 4 wire resistive analogue Touch Technology

PCT Option Projective capacitive for open frame versions only

Interfaces

Network 1x 10/100 Mbit/s Ethernet (RJ45)

16-bit 48 kHz

External 1x S/PDIF (RCA jack)

1x Line-out (3.5 mm jack)

1x Speaker, 1 Watt RMS (8Ω)

Audio

Internal 1x Micro-In

1x Line-In

1x RS-232 (RX/TX/CTS/RTS)

1x RS-485

Serial Interfaces

RS485 Option 1x RS-485 instead of CAN

CAN Fieldbus CAN Option 1x CAN (ISO/DIS 119898) instead of RS-485

USB 2.0 1x 12 Mbit/s Full-Speed Host (Type A)

1x 480 Mbit/s High-Speed OTG (Type Micro-AB)

Max. output 500 mA

Standard

Multiplex mode 1

1x 8x8

1x 5x5 Keypad, 1x SPI

Keypad/SPI/I²C

I²C Option Multiplex mode 2 Multiplex

mode 3

1x 7x7 Keypad, 1x I²C

1x 4x4 Keypad, 1x I²C,

1x SPI

Page 14

System Description KUHNKE Automation

14

Digital I/O 1x Digital Out (0.7 A)

Power Supply and Consumption

Supply Nom. 12/42 V DC

t.b.d. t.b.d.

t.b.d. t.b.d.

Consumption

t.b.d. t.b.d.

Type 3 V Li-Ion Type CR1220

Internal Backup Battery

(RTC)

Lifetime >10 years, depending on application

1

Display specification may vary due to customization. For further questions, please contact technical

support.

Page 15

KUHNKE Automation System Description

15

Mechanical properties

Housing

Metal parts 1.4016 high quality steel

Thickness 0.75 mm

Surface treatment Polished

Front (boxed versions only)

Frame Material 4 mm AlMg3

Surface treatment Natural anodized, E6/EV1

Material Polyester film with antiglare coating

4C silk screen printing from behind

Structured front coating

Thickness 180 µ

Chemical Resistance Resistant to alcohols, dilute acids, dilute alkalis,

esters, hy

drocarbons, ketones, household cleaning

agents

Dielectric strength 125 µ: 125 kV/mm (15.6 kV) / 175 µ: 105 kV/mm

(18.4 kV)

Surface resistivity >1013 Ω/sq 500 Vd.c

Switch life >5 million flexes

Pencil hardness 3H

Maximum long term

use temperature

@ low humidity (<10% RH): 85° C

@ high humidity (10 ~ 95% RH): ≤60° C

Décor cover

Min. use temperature -40° C

Protection Class IP64 (according to supplier’s statement, not yet approved)

Environmental Conditions

Storage Temperature -20 ~ +70° C

Operating Temperature 0° ~ +60° C

Relative Humidity 95% (non condensating)

Dimensions

Width (mm) 130.2

Height (mm) 67.2

Depth (mm) 25.4

Weight (g) 320

For drawings, please refer to chapter 7 Product geometry.

BIOS and operation systems

Software

BIOS RedBoot BIOS

Operating System Windows Embedded CE 6.0

For more software information, please refer to Fehler! Verweis-

quelle konnte nicht gefunden werden. Fehler! Verweisquelle

konnte nicht gefunden werden..

Page 16

System Description KUHNKE Automation

16

3.3 Internal battery

The internal baseboard is equipped with a Lithium battery (CMOS battery, type CR2032), which has a typical lifetime longer than 10 years.

Danger of explosion when replaced with wrong type of battery.

Replace the battery only with a Lithium battery that has the same or

equivalent type recommended by KUHNKE Automation.

Do not dispose of used CMOS batteries in domestic waste.

Dispose of the battery according to the local regulations dealing with

the disposal of these special materials (e. g. to the collecting points

for disposal of batteries).

3.3.1 Replacement of the internal battery

• The internal battery is placed as per figure below.

• For replacement, the SD-card and the back cover have to be

removed.

• The device shall be opened by authorized and skilled person-

nel only.

Danger of electric hazard! First before opening, please make sure

that the unit is completely disconnected from any power supply, direct or indirect. In order to remove the back cover all other connectors must be removed as well. Please make sure that the SD-card

has been removed as it blocks the cover. Furthermore take care

about the socket and connectors. Especially the micro-USB connector might be damaged easily.

Position of the battery

2 screws for the back cover

Page 17

KUHNKE Automation System Description

17

4 Connectors

Pos. Description

Pos. Description

1 Ethernet (X8) 5 USB - OTG (X14)

2 Power/Digital out (X1) 6 Speaker (X5/X6)

3 RS-232/RS-485 or CAN (X9) 7 Line out (X20)

4 USB - Host (X12) 8 S/PDIF (X7)

4.1 Ethernet/PoE (X8)

Pin Name Description Level

1 Tx+

2 Tx-

3 Rx+

4 SPARE1 Power Supply (PoE)

5 SPARE1 Power Supply (PoE)

6 Rx-

7 SPARE2 Power Supply (PoE)

8 SPARE2 Power Supply (PoE)

Header: RJ45

4.2 Power (X1)

Pin Name Description Level

1 GND Ground

2 GND Ground

3 Vcc_In Input voltage 9-42V

4 DIO_OUT Digital Out Vcc_In

Header: Molex_43045-0400 Micro-Fit 4p

Plug: Molex_43025-0400 Micro-Fit 4p, crimp contact Molex 43030-0007

Only attach the unit to a 24 VDC power supply source if the source is guaranteed to meet safe extra low voltage requirements (SELV).

To make the phase fired controller work properly, pin L-

must have the same

potential as the neutral point of the power supply.

Page 18

System Description KUHNKE Automation

18

4.3 RS-232/RS-485 or CAN (X9)

4.3.1 Option: RS-232/RS-485

Pin Name Description Level

1 GND Ground

2 RS232_TXD1 Port#1: Transmit data (Output)

3 RS232_RXD1 Port#1: Receive data (Input)

4 RS232_RTS1 Port#1: Request-to-send (Output)

5 RS232_CTS1 Port#1: Clear-to-send (Input)

6 Vref Vref out 5V

7 GND Ground

8 RS485_Y TX+

9 RS485_Z TX-

10 RS485_A RX+

To enable Half-Duplex: bridge with RS485_Y

11 RS485_B RX-

To enable Half-Duplex: bridge with RS485_Z

12 RS485_TERM To enable RS485-Termination: bridge with

RS485_A

Header: Molex_43045-1200_Micro-Fit_12p

Plug: Molex_43025-1200_Micro-Fit_12p, crimp contact Molex 43030-0007

4.3.2 Option: RS-232/CAN

Pin Name Description Level

1-5 RS-232 Identical to RS-485 option (s. 4.3.1.)

6 Vref Vref out 5V

7 GND Ground

8 CAN1_H CAN bus 1 high

9 CAN1_L CAN bus 1 low

10 CAN1_TERM To enable CAN1-Termination, bridge with

CAN1_L

11 n.a.

12 n.a.

4.4 USB - Host (X12)

Pin Name Description Level

1 Vcc Power supply 5 V

2 D- Data minus

3 D+ Data plus

4 GND Ground

Page 19

KUHNKE Automation System Description

19

Header: USB Type A

4.5 USB - OTG

This interface can be used either as external OTG port or as second USB Host port for internal use.

External USB - OTG (X14)

Pin Name Description Level

1 Vcc Power supply 5 V

2 D- Data minus

3 D+ Data plus

4 ID Device ID

5 GND Ground

Header: Micro-USB Type AB

4.6 Speaker (X9/X10)

Pin Name Description Level

1 VO+ External speaker out +

external (X5)

2 VO- External speaker out -

Header: JST S2B-PH-SM3-TB, side entry, RM = 2.0, 2-pin

Plug: JST PHR-2, crimp contact BPH-002T-P0.5S

Pin Name Description Level

1 VO+ Internal speaker out +

internal (X6)

2 VO- Internal speaker out -

Header: JST B2B-ZR-SM4-TF, top entry, RM = 1.5, 2-pin

Plug: JST ZHR-2, crimp contact SZH-002T-P0.5

Keypad/SPI (X16)

Standard: Keypad/SPI

Description

Pin Name

Standard mode Multiplexed mode 1

Level

1 GND Ground Ground

2 GND Ground Ground

3 KP_ROW0 Keypad row 0 Keypad row 0

4 KP_COL0 Keypad column 0 Keypad column 0

5 KP_ROW1 Keypad row 1 Keypad row 1

6 KP_COL1 Keypad column 1 Keypad column 1

7 KP_ROW2 Keypad row 2 Keypad row 2

8 KP_COL2 Keypad column 2 Keypad column 2

9 KP_ROW3 Keypad row 3 Keypad row 3

10 KP_COL3 Keypad column 3 Keypad column 3

11 KP_ROW4 Keypad row 4 Keypad row 4

12 KP_COL4 Keypad column 4 Keypad column 4

13 KP_ROW5_DMA Keypad row 5 SPI Interrupt Request

14 KP_COL5_SS1 Keypad column 5 SPI Slave Select 1

15 KP_ROW6_MISO Keypad row 6 SPI Master in Slave out

16 KP_COL6_MOSI Keypad column 6 SPI Master out Slave in

Page 20

System Description KUHNKE Automation

20

17 KP_ROW7_SLK Keypad row 7 SPI Serial Clock

18 KP_COL7_SS0 Keypad column 7 SPI Slave Select 0

19 GND Ground Ground

20 GND Ground Ground

Header: JST SM20B-SRDS-G-TF, side entry, RM = 1.00

Plug: JST SHDR-20V-S-B, crimp contact: SSH-003GA-P0.2

Option: Keypad/SPI/I²C

Description

Pin Name

Multiplexed mode 2 Multiplexed mode 3

Level

1-10 Identical to standard (pls. see 4.9.1.)

11 KP_ROW4 I²C SDA I²C SDA

12 KP_COL4 I²C SCL I²C SCL

13 KP_ROW5_DMA Keypad row 5 SPI Interrupt Request

14 KP_COL5_SS1 Keypad column 5 SPI Slave Select 1

15 KP_ROW6_MISO Keypad row 6 SPI Master in Slave out

16 KP_COL6_MOSI Keypad column 6 SPI Master out Slave in

17 KP_ROW7_SLK Keypad row 7 SPI Serial Clock

18 KP_COL7_SS0 Keypad column 7 SPI Slave Select 0

19 GND Ground Ground

20 GND Ground Ground

Page 21

KUHNKE Automation System Description

21

4.7 Protective Earth Conductor

The Ventura Vico is designed for installation in a switching cabinet whose

IP 20 housing provides sufficient protection against direct contact.

Attach a protective earth conductor to provide for protection against indirect contact in case of a fault to frame. Connection is made to the 4 mm

bolt on top of the device. Be sure to use a matching eyelet connector with

an inside diameter of 4.3 mm to DIN 46234.

The cross-section of the PE conductor not to be less than:

• 2.5mm² Cu or 16mm² Al if protection against mechanical damage

is included,

• 4mm² Cu or 16mm² Al if protection against mechanical damage is

NOT included.

Try to keep the lead to the earthing terminal as short as possible.

Installation to conform to the protective earth connection regulations of EN

50178!

Do not plug, mount, unplug or touch the connectors during operation!

You may otherwise provoke destruction or malfunction. Turn off all power

sources before working on the modules. This also applies to any peripherals

connected such as encoders, programming devices with external power

source, etc.

Page 22

System Description KUHNKE Automation

22

5 Services and utilities

The standard OS image includes several useful services for flexible application handling. Some of them are just run-once services directly after the

OS has been started, others are available permanently.

5.1 Services

5.1.1 Autocopy

This service is executed after the OS has booted and when a storage medium has been inserted. This service provides a comfortable installation

and/or update functionality as well as copy mechanism for specific files

that are not included in the OS (e.g. for runtime libraries).

Subfolders and files within a folder named “autocopy” on a USB stick, SD

card or in the NAND flash will be copied to the root of the device resp. its

equivalent targets. Non-existing folders will be created automatically.

5.1.2 Autostart

This service is executed after the OS has booted and when a storage medium has been inserted. It checks the NAND flash partition as well as the

USB stick and SD-card for an existing autostart folder. All applications

found therein will be executed.

5.1.3 ResolveLNK

The service ResolveLNK in the Startup folder allows the OS to handle

links in the Autostart folder. A link is a special type of file that contains a

reference to another file or directory of the Vico/Scout.[

If you want to make a WINCE shortcut directly on the device, simply

highlight the file in Windows Explorer, select Edit->Copy, then browse the

desired target location, select Edit->Paste Shortcut.

5.2 Utilities

5.2.1 DisableSerialConsole.exe

By default, the serial interface is configured as debug console. This enables also the RedBoot functionality via terminal console. In this mode, it is

not available as serial interface. To switch between both modes, please

use the tool that is located in

My Device\Windows\DisableSerialconsole.exe

Page 23

KUHNKE Automation System Description

23

To disable the serial debug output means to operate the COM1 as serial

interface. After changing the mode, a reset is required. After that, the

COM1 is ready for use as serial interface. To turn on the debug messages

again, repeat the procedure with “No”.

5.2.2 VNC

Virtual Network Computing (VNC) is a graphical desktop sharing system to

remotely control another computer. It transmits the keyboard and mouse

events from one computer to another, relaying the graphical screen updates back in the other direction, over a network.

The EfonVNC server is an open source remote control tools, which is

based on RealVNC. It make the GUI based remote controling on Windows

CE family become more simple. It is freely available to download and use.

5.2.3 Additional serial ports via USB adapter

RS-232, RS485, RS 422

You can use the USB ports to add further serial interfaces to the unit. FTDI

chip set driver used by many USB-to-serial converters is integrated in the

unit's operating system.

A USB converter featuring FTDI's chip set FT232R is recognised automatically and can afterwards be addressed by the entry added to the registry.

To use a new interface in CODESYS

CODESYS provides a library called SysLibCom which allows you to use

the new serial interface. Before doing so, you must run the Library Manager to add the new library to your project.

SysLibCom library commands (subset)

Open port: SysComOpen

Write data: SyysComWrite

Read data: SysComRead

Page 24

System Description KUHNKE Automation

24

Close port: SysComClose

By default, the system assigns COM 5 to the first serial interface you add.

FTDI Chip has a range of various converters in a variety of designs.

Further information at:

http://www.ftdichip.com

6 CODESYS

CODESYS is a complete development environment for your PLC.

CODESYS puts a simple approach to the powerful IEC language at the

disposal of the PLC programmer. Use of the editors and debugging functions is based upon the proven development program environments of advanced programming languages (such as Visual C++).

6.1 Installing CODESYS on the Programming PC

To install the CODESYS software on your programming PC:

• Select CODESYS...exe either from Windows Explorer or via 'Run' from

the Windows Start menu.

• Run the program.

• The CODESYS installer runs to request your preferred settings and in-

stall the application in the target system.

6.1.1 Installing a CODESYS Target

Before you can run CODESYS to create a Ventura project you must first

install the Target Support Package (TSP) "Scout.tnf" by running the installer called InstallTarget.

A TSP contains all configuration and extension files required to use an application for operating a certain controller (target system).

A configuration includes the code generator, the memory layout, the set of

functions provided by the controller and the I/O modules.

The libraries, gateway drivers, error and ini files for the PLC browser etc.

are also installed.

• Run the target installer delivered with your CODESYS package.

• Go to the folder containing the TSP called "Scout" and choose

"Scout.tnf".

• Click to select "Scout_XXX_01.tnf" and "Install" it.

Page 25

KUHNKE Automation System Description

25

Following successful installation, "KUHNKE PC Control Ventura" appears

in column "Installed target systems. The programming system can now access the Ventura controller.

6.2 CODESYS Programming PC Setup

6.2.1 Ethernet Connections of Ventura IPC

• To directly connect the IPC with the programming PC, please use a

CAT5 crossover cable.

• To operate Ventura Scout in a network, please use a CAT5 patch cable.

• CODESYS communication should go through Ventura Scout's X2 port.

6.2.1.1 Programming PC's Ethernet Interface Setup

Network connection

No settings should have to be made or changed to program the IPC via a

network.

Windows XP, direct connection

• Go to Windows Start and choose

Start – Settings –

Network Connections: pick "LAN connection" from list,

then "Properties".

• Go to tab "General", find the list of elements, choose "Internet protocol

(TCP/IP)" and click on Properties.

• Still on tab "General" choose "Use this IP address" and enter any IP

address as appropriate,

e.g.: "172.25.224.10", subnet mask "255.255.255.0"

A direct connection requires the "File and printer release" to be ticked and a

firewall, if any, to be disabled at least for the time of this connection.

Page 26

System Description KUHNKE Automation

26

6.2.1.2 CODESYS Program Communication Parameter Setup

Use the 'Communication Parameters' dialog you access from the 'Online'

menu to select and configure the communication channel.

• Pick 'Online' from the menu to display the 'Communication Parameters'

dialog.

• Press New.

A dialog called 'Communication Parameters: New Channel' is displayed.

The box next to "Name" defaults to the name of the channel you entered

last. The name in the box can be edited. Channel names are for your information only. Whereas you are not obliged to assign unique names, you

are still advised to do so.

Check the table under 'Device' to find the device drivers registered with the

gateway computer. The contents of this list depends on your personal configuration and the device drivers it includes.

• To define an Ethernet link to Ventura Scout, pick "Tcp/Ip (Level 2 Rou-

te)" from the list.

• Enter Ventura Touch's IP address as the "Address". The address is

shown on the 'IP Config' Service Menu page.

• Disable the "Motorola byte order" by setting the option to "No"

Example of Ethernet communication parameter setup

Page 27

KUHNKE Automation System Description

27

7 Product geometry

The drawings on the following pages are non-binding and shall provide a

first impression of the original size and construction of the products. For all

products we provide 3D CAD models.

7.1 Ventura VICO / Scout 401

Page 28

KUHNKE Automation

28

8 Appendix

8.1 Safety instructions

Please read this section carefully and observe the instructions for your

own safety and correct use of the device. Observe the warnings and

instructions on the device and in the manual. Kuhnke Automation

GmbH Co. KG embedded system have been built and tested by us

and left the company in a perfectly safe condition. In order to maintain

this condition and ensure safe operation, the user must observe the

instructions and warnings contained in this manual.

General handling

• Don’t drop or strike the unit: The PCB, display and/or other

parts might be damaged.

• Keep away from water and other liquids, the unit is not pro-

tected against.

• Operate the unit under electrical and environmental conditions

according to the technical specification.

• The electrical installations in the room must correspond to the

requirements of the local(country-specific) regulations.

• Take care that there are no cables, particularly power cables,

in areas where persons can trip over them.

• Do not place the device in direct sunlight, near heat sources

or in a damp place.

• All plugs on the connection cables must be screwed or locked

to the housing.

• Repairs may only be carried out by qualified specialist per-

sonnel authorized by Kuhnke Automation GmbH Co. KG

GmbH or their local distributors.

• Maintenance or repair on the open device may only be carried

out by qualified personnel authorized by Kuhnke Automation

GmbH Co. KG GmbH which is aware of with the associated

dangers.

LCD handling

• Due to the soft surface of the resistive touch screen, don’t use

stencils and/or other devices fortouch operation. There are

special pens available in commercial shops.

• Protect the LCD/touch against scratches and sharp edges.

The warranty does not cover pixel failures resulting from noncompliant handling.

• Clean the LCD with a soft cotton cloth with alcohol. Don’t use

organic solvents, acid or alkali solutions.

• Water drops, finger fat or any similar fouling should be re-

moved immediately from the LCD and metal frame to avoid

any staining.

Electricity

• The embedded systems may only be opened in accordance

with the description in this user’s manual for replacing of the

Lithium battery and/or configuration of the RS-485 interface

• These procedures have to be carried-out only by qualified

specialist personnel.

• When accessing internal components the device must be

switched off and disconnected from the power source.

Page 29

KUHNKE Automation

29

• When purchased core or basic versions without protecting

back cover, don’t touch the PCB directly with your fingers. Especially these products need to be handled with very carefully.

• Don’t operate or handle the unit without typical ESD protection

measures, such as ground earthing.

• Operate the unit according to the technical specification only.

Damage or permanent malfunction

• It must be assumed that a safe operation is no longer possi-

ble, in case,the device has visible damage or the display is

dark or shows strange pattern for longer period the device

doesn’t react after a reset

• In these cases the device must be shut down and secured

against further use

8.2 Disposal

Disassembly

Disposal requires the device to be disassembled and entirely taken

apart. All metal components can be given to metal recycling.

Electronic scrap

Electronic components such as circuit boards etc. are kept and disposed of separately.

For details on proper disposal please check your national laws and

regulations making sure that your method of disposal complies with

them.

Page 30

KUHNKE Automation

30

8.3 Trademarks and service marks

There are a number of proprietary logos, service marks, trademarks,

slogans and product designations("Marks") used in this document. By

making the Marks available in this document, Kuhnke Automation

GmbH Co. KG is not granting you a license to use them in any fashion.

Product or service names may be the property of third parties. Marks

owned by third parties include those listed below. This list is not comprehensive; the absence of a Mark from the list does not constitute a

waiver of intellectual property rights established by the owner of a

Mark.

Freescale and the Freescale logo are trademarks of Freescale Semiconductor, Inc., Reg. U.S. Pat. & Tm. Off.

ARM is the registered trademark of ARM Limited. ARMWXYZ is the

trademark of ARM Limited.

Dolby Digital, Dolby Surround®, Pro Logic® and the double-D symbol

are registered trademarks of Dolby Laboratories; Dolby Digital is manufactured under license from Dolby Laboratories.

Java™ and all other Java-based marks are trademarks or registered

trademarks of Sun Microsystems, Inc. in the United States and/or

other countries.

eCosCentric and eCos are registered trademarks of eCosCentric Ltd.

Microsoft, Windows, Windows Embedded CE, Windows NT, Visual

Studio, Visual C++, Visual C#, MFC and Visual C++ are registered tra-

demarks, trademarks or products of Microsoft Corporation in the United States and/or other countries.

Sharp is a registered trademark of Sharp Electronics Europe GmbH.

RedBoot is a registered trademark of Red Hat Inc.

Linux is a registered trademark of Linus Torvalds.

Their use is subject to national and international laws and agreements. Every use of these names in this documentation occurs subject to the legal regulations. While trademark symbols may be omitted

for the purpose of simplification, they are implied when the names of

the trademarks are used in the remainder of this document and should

be interpreted as present.

Page 31

KUHNKE Automation

31

8.4 Technical Data

8.5 Specifications

8.5.1 Basic Units

Ventura

Ventura Vico 401 Visi

677 700 25

Web Terminal,

4,3" TFT Widescreen mit LED Backlight

Flash disk 256 MB, Micro SD (HC) up to 2GB

Windows CE, VisiWinNET mit 250 Tags

Ventura Vico 401 V3 HMI

677 700 04

Touch Terminal,

4,3" TFT Widescreen mit LED Backlight

Flash disk 256 MB, Micro SD (HC) up to 2GB

Windows CE, CODESYS V3 HMI

Ventura Scout 401 V2 TV

677 700 01

Panel PLC,

4,3" TFT Widescreen mit LED Backlight

Flash disk 256 MB, Micro SD (HC) up to 2GB

Windows CE, CODESYS V2 Target Visualisierung

Ventura Scout 401 V2 TV WV

677 700 01

Panel PLC,

4,3" TFT Widescreen mit LED Backlight

Flash disk 256 MB, Micro SD (HC) up to 2GB

Windows CE, CODESYS V2 Target Visualisierung, Web-Visualisierung

8.5.2 Accessories

Ventura Smart Solution

Page 32

8.6 Sales & Service

Please visit our Internet site to find a comprehensive overview of our

sales and service network including all the relevant addresses.

www.kuhnke.com

Feel free to also contact us at our headquarters in Malente/Germany:

8.6.1 Malente Headquarters

Kendrion Kuhnke Automation GmbH

Lütjenburger Straße 101

D - 23714 Malente

Tel. 04523 / 402 0

Fax 04523 / 402 201

Loading...

Loading...