Kuhnke PG 674 Instruction Manual

Kuhnke Electronics

Instruction Manual

E 390 GB

PG 674

Operating Terminal for KUAX 674 / 673

4 April 1996 / 65.135

This manual is primarily intended for the use of the designing engineer, the

project planning engineer, and the developing engineer. It does not give any

information about delivery possibilities. Data is only given to describe the

product and must not be regarded as guaranteed properties in the legal sense.

Any claims for damages against us – on whatever legal grounds – are excluded

except in instances of deliberate intent or gross negligence on our part.

We reserve the rights for errors, omissions or modifications.

Reproduction even of extracts only with the editor's express and written prior

consent.

Contents - 1

Table of contents

Table of contents

1. Introduction................................................................ 1-1

2. Reliability, Security...................................................... 2-1

2.1. Target group ............................................................................ 2-1

2.2. Reliability ................................................................................ 2-1

2.3. Notes...................................................................................... 2-2

2.3.1. Danger................................................................................. 2-2

2.3.2. Dangers caused by high contact voltage .................................. 2-2

2.3.3 Important information / cross reference..................................... 2-2

2.4. Security ................................................................................... 2-3

2.4.1. To be observed during project planning and installation............. 2-3

2.4.2. To be observed during maintenance and servicing .................... 2-4

2.4.3. Measures for the prevention of electrostatic charge.................... 2-4

3. Design of the PG 674..................................................3-1

3.1. Display and operating elements.................................................. 3-1

3.2. Hand-held terminal PG 674 (674.001.00) .................................. 3-2

3.3. Built-in terminal PG 674 (674.010.00) ....................................... 3-3

3.3.1. Design and Dimensions .......................................................... 3-3

3.3.2. Installation ............................................................................ 3- 4

3.3.2.1. Front panel cutout............................................................... 3- 4

3.3.2.2. Inserting the built-in terminal................................................. 3-4

3.4. Technical specifications ............................................................. 3-5

Contents - 2

Table of contents

4. The PG 674 as a programming device ..........................4-1

4.1. General information on the operating terminal ............................. 4-2

4.2. Front view................................................................................ 4-3

4.3. Key pad .................................................................................. 4- 4

4.3.1. Function keys ........................................................................ 4- 4

4.4. Operating modes of the operating terminal PG 674 ..................... 4-6

4.4.1. Restricted operating mode ...................................................... 4 -6

4.5. Display window of the operating terminal PG 674 ....................... 4-7

4.5.1. Standard display ................................................................... 4- 7

4.6. Commands of the operating terminal PG 674 .............................. 4-8

4.6.1. Activating the open mode (entering the key code)...................... 4-8

4.6.2. Exiting the open operating mode ............................................. 4-8

4.6.3. Displaying the key code ......................................................... 4- 9

4.6.4. Changing the key code .......................................................... 4- 9

4.6.5. System information .............................................................. 4-10

4.6.6. Displaying status and error messages..................................... 4-10

4.6.7. Choosing a program............................................................ 4-11

4.6.7.1. Giving access to the choice of program function .................. 4-11

4.6.7.2. Changing the program number ......................................... 4-13

4.6.8. Initializing the cam control unit.............................................. 4-14

4.6.9. Choosing an output ............................................................. 4-15

4.6.10 Programming cams ............................................................. 4-16

4.6.11. Optimizing cams ............................................................... 4-18

4.6.12. Displaying cams ................................................................ 4-19

4.6.13. Deleting cams ................................................................... 4-20

4.6.14. Deleting outputs................................................................. 4-21

4.6.15. Deleting programs ............................................................. 4-21

4.6.16. Copying programs............................................................. 4-22

4.6.17. Program transfer................................................................ 4-23

4.6.18. Activating the dynamic mode of outputs ............................... 4-24

4.6.19. Deadtime compensation ..................................................... 4-25

4.6.20. Time cams ........................................................................ 4-26

4.6.21. Encoder speed reduction – electronic gearing ....................... 4-27

4.6.22. Choice of language ........................................................... 4-28

Contents - 3

Table of contents

4.6.23. Setting the display contrast (as from version 2.0) ................... 4-29

4.6.24. Self-test of the operating terminal (as from version 2.0) .......... 4-30

4.6.25. Self-test of the operating terminal (versions < 2.0).................. 4-32

Index....................................................................... Index-1

Sales & Service

Contents - 4

Table of contents

1 - 1

Introduction

1. Introduction

The PG 674 is a small, handy device with a keyboard and twoline display. It is used for operating the electronic cam control

units Posi Control KUAX 674 and KUAX 673. It is separated

from the cam control unit to allow variable use. It can be connected with the cam control unit via the programming interface

at any time, even when the machine is running. This makes it

easy to check or modify the programs at the machine.

Choic e of prog

Choic e of outpu t

Outputs off

Delete

Outputs on

Gear

Time cam

Show errors

Set cam

Choice of cam

1 - 2

Introduction

The PG 674 is available in two designs:

Hand-held terminal

As a portable hand-held terminal it can easily be transported

and connected to the control device. The integrated buffered

memory allows you to load programs from one controller and

transfer them to another controller.

Built-in terminal

As a built-in terminal the device is firmly built into i.e. the

door of the switching cabinet and is thus permanently available

as an operating and display device.

The present operating manual exclusively describes the hardware of the PG 674 and how you use it to operate controllers.

The control devices themselves are described elsewhere:

Controller Instruction manual

KUAX 674 E 375 GB

KUAX 673 E 293 GB

.

2 - 1

Reliability/Security

2. Reliability, Security

2.1. Target group

This instruction manual contains all information necessary for

the use of the described product (control device, software, etc.)

according to instructions. It is written for the

personnel of thepersonnel of the

personnel of thepersonnel of the

personnel of the

construction, project planning, service and commissioningconstruction, project planning, service and commissioning

construction, project planning, service and commissioningconstruction, project planning, service and commissioning

construction, project planning, service and commissioning

departmentsdepartments

departmentsdepartments

departments. For proper understanding and error-free applica-

tion of technical descriptions, instructions for use and particularly of notes of danger and warning,

extensive knowledge ofextensive knowledge of

extensive knowledge ofextensive knowledge of

extensive knowledge of

automation technologyautomation technology

automation technologyautomation technology

automation technology is compulsory.

2.2. Reliability

Reliability of Kuhnke controllers is brought to the highest possible standards by extensive and cost-effective means in their

design and manufacture.

Amongst which are:

· selecting high-quality components,

· quality arrangements with our sub-suppliers,

· measures for the prevention of static charge during the handling of MOS circuits,

· Worst-Case dimensioning of all circuits,

· inspections during various stages of fabrication,

· computer aided tests of all assembly groups and their

coefficiency in the circuit,

· stress-test in raised ambient temperatures during 72 hours

realtime with nominal load on the outputs,

· statistic assessment of the quality of fabrication and of all returned goods for immediate taking of adjustment measures.

Despite these measures, the occurrence of errors in electronic

control units - even if most highly improbable - must be taken

into consideration.

Text muß n

2 - 2

Reliability/Security

2.3. Notes

Please pay particular attention to the additional notes which we

have marked by symbols in this instruction manual:

2.3.1. Danger

This symbol warns you of dangers which may cause

death, (grievous) bodily harm or material damage if the

described precautions are not taken.

2.3.2. Dangers caused by high contact voltage

This symbol warns you of dangers of death or (grievous)

bodily harm which may be caused by high contact

voltage if the described precautions are not taken.

2.3.3 Important information / cross reference

This symbol draws your attention to important additional

information concerning the use of the described product.

It may also indicate a cross reference to information to be

found elsewhere.

2 - 3

Reliability/Security

2.4. Security

Our product normally becomes part of larger systems or installations. The following notes are intended to help integrating the

product into its environment without dangers for man or material/equipment.

2.4.1. To be observed during project planning and installation

- 24V DC power supply:

· provide sufficient separation of low voltage,

· apply power packs in accordance with IEC 364-4-41 or

CENELEC HD 384.4.41 (VDE 0100, Part 410) respectively.

- In case of power breakdowns or power fades: the program has

to be structured in such a way as to create a defined state at

restart that excludes dangerous states.

- Emergency switches or other emergency installations have to

be realized in accordance with EN 60204/IEC 204

(VDE 0113). They have to be effective at any time.

- Safety and precautions regulations for qualified applications

have to be observed.

- Please pay particular attention to the notes of warning (→

2.3. Notes) which, at relevant places, will make you aware of

possible sources of errors.

- The relevent standards and VDE regulations are to be observed in every case.

- Control elements have to be installed in such a way as to exclude unintended operation.

- Control cables have to be layed in such a way as to exclude

interference (inductive or capacitive) which could influence

the operation of the controller.

To achieve a high degree of conceptual safety in planning

and installing an electronic controller it is essential to

follow the instructions given in the manual exactly because wrong handling could lead to rendering measures

against dangerous failures ineffective or to creating

additional dangers.

2 - 4

Reliability/Security

2.4.2. To be observed during maintenance and servicing

- During measuring and checking operations on a controller in

a power-up condition, precaution regulation VBG 4.0 has to

be observed and §8 (Admissible deviations during working on

parts) in particular.

- Repairs must only be executed by the trained Kuhnke personnel (usually in the main factory in Malente). Warranty expires in any other case.

- Spare parts:

Only use parts approved of by Kuhnke. Only genuine Kuhnke

modules must be used in modular controllers.

- Modules must only be connected to or disconnected from the

controller with no voltage supplied. Otherwise they may be

destroyed or (possibly not immediately recognizably!) detracted from their proper functioning.

- Always deposit batteries and accumulators as special waste.

2.4.3. Measures for the prevention of electrostatic charge

Electrostatic charge is dangerous for components and assembly

groups. It is a peculiarity of electrostatics to not destroy the sensitive components but to damage them in a not immediately

conceivable way. It is because of this that devices stop functioning after some time of service.

The ESD measures (ESD = electrostatic discharge) executed in

the factory are only guaranteed to be effective if they are also

regarded by the user (service).

Please note:

- Only store parts in their factory-packing or in an antistatic

packing of similar quality.

- Assembly groups must only be touched by persons who are

grounded via a wrist bracelet and/or a discharging mat and

shoe-grounding strips ( observe protection of people!).

- Only ship assembly groups in their factory-packing or in an

antistatic packing of similar quality.

Reference to literature (Fa. 3M Deutschland GmbH,

Neuss): Information brochure

Interesting Facts about Electrostatics in Micro-Electronics

3 - 1

Hardware

Choic e of pr o g

Choic e of ou t pu t

Outputs off

Delete

Outputs on

Gear

Time cam

Show errors

Set cam

Choice of cam

3. Design of the PG 674

The operating terminal PG 674 is used for programming the

cam control unit (see "4. The PG 674 as a programming device").

It can be supplied as a portable hand-held terminal and as a

built-in terminal.

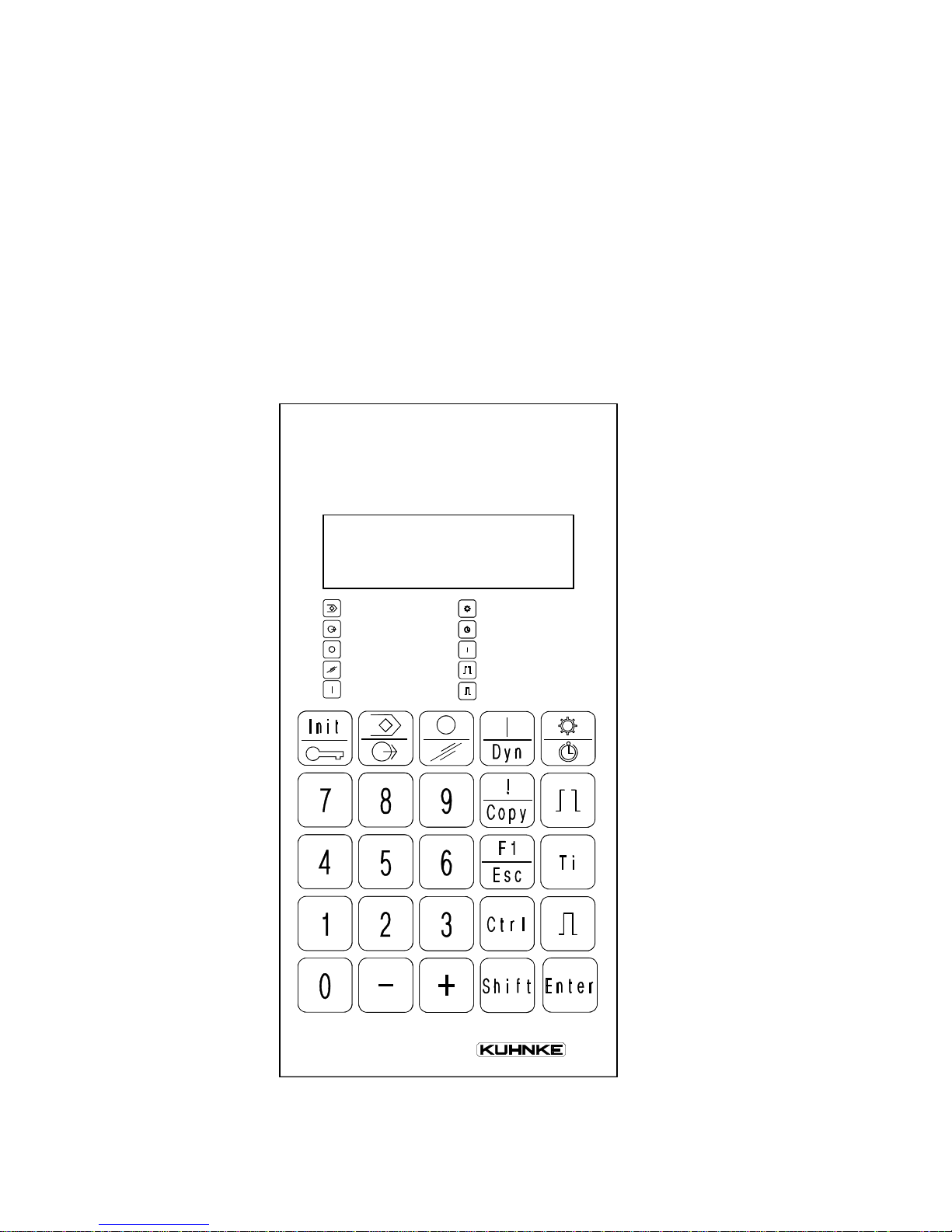

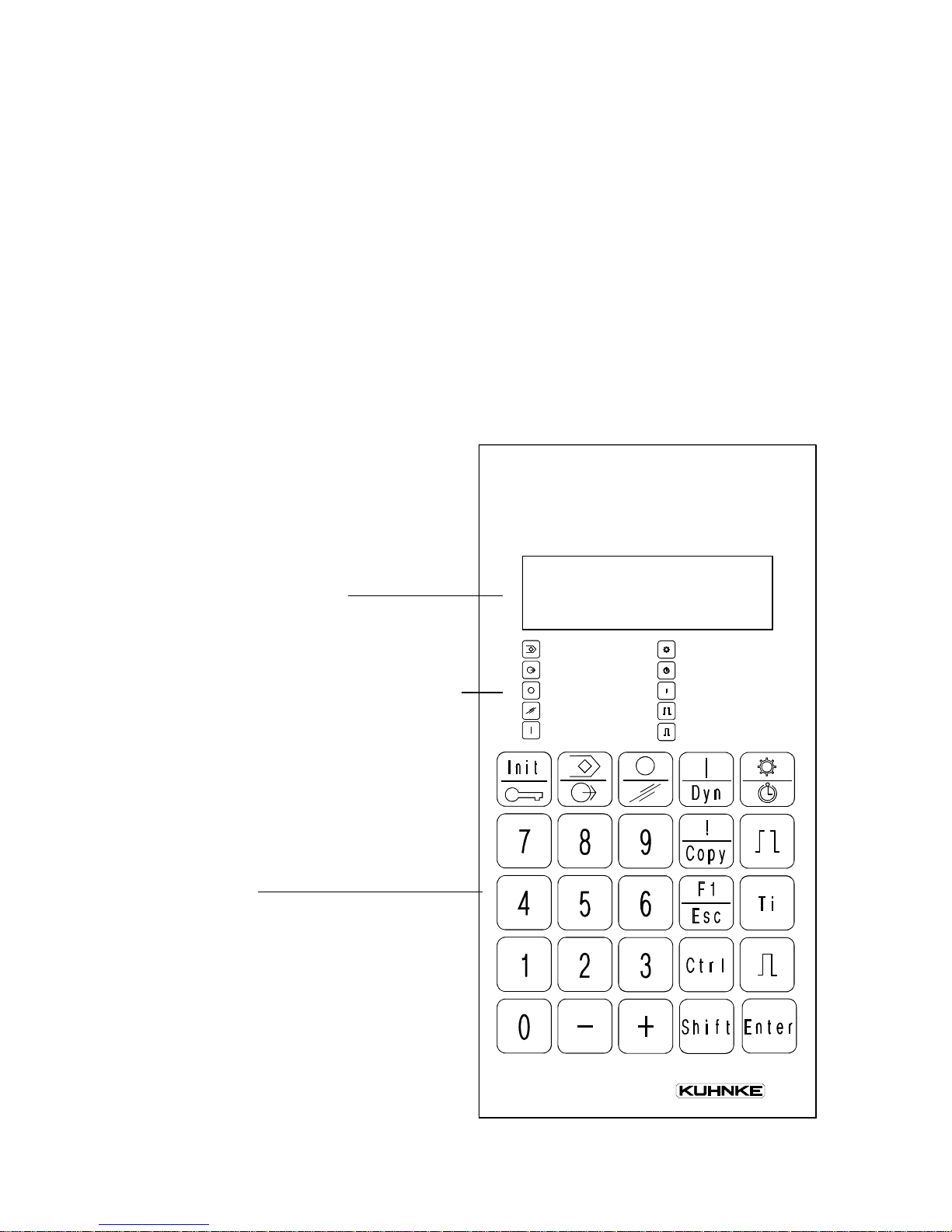

3.1. Display and operating elements

LCD display (see ch. 4)

Short description of the function keys

Keyboard

(for function see ch. 4)

3 - 2

Operating terminal PG 674

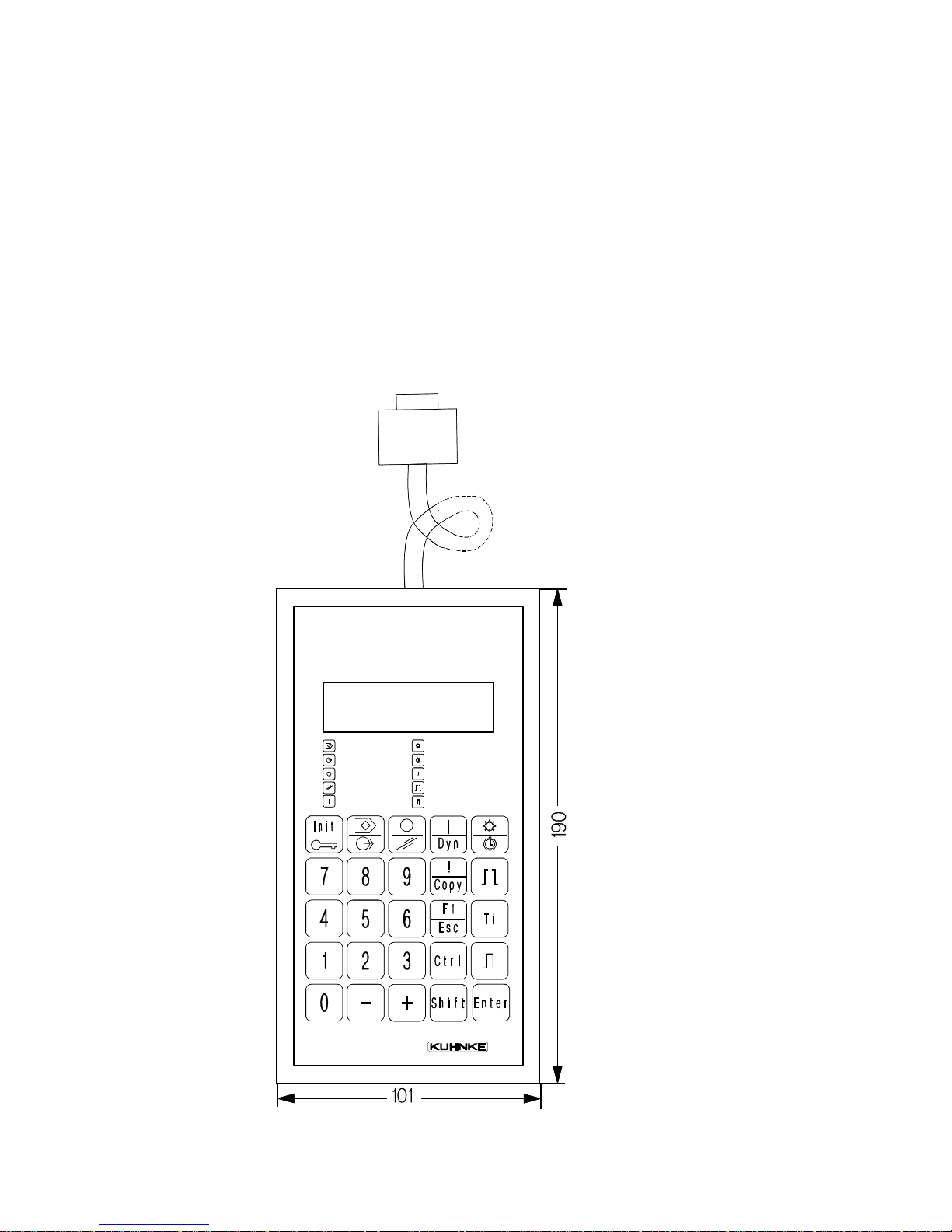

3.2. Hand-held terminal PG 674 (674.001.00)

The hand-held terminal can be connected to and disconnected

from the cam control unit during operation.

The connecting cable is firmly attached to the hand-held terminal. It serves both communication with the cam control unit and

supplying power to the hand-held terminal (24 V DC), which

are supplied by the cam control unit.

Gear

Time c am

Show errors

Set cam

Choice of cam

Choice of prog

Choice of output

Outputs off

Delete

Outputs on

3 - 3

Hardware

3.3. Built-in terminal PG 674 (674.010.00)

As a built-in terminal, the PG 674 has a connector on the rear

side for the connecting cable to the cam control unit. The 24 V

DC supply voltage is separately connected to a 2-pin screw-type

locking connector.

The built-in terminal is expected to be available as from

Version 2.0 in the spring of 1995.

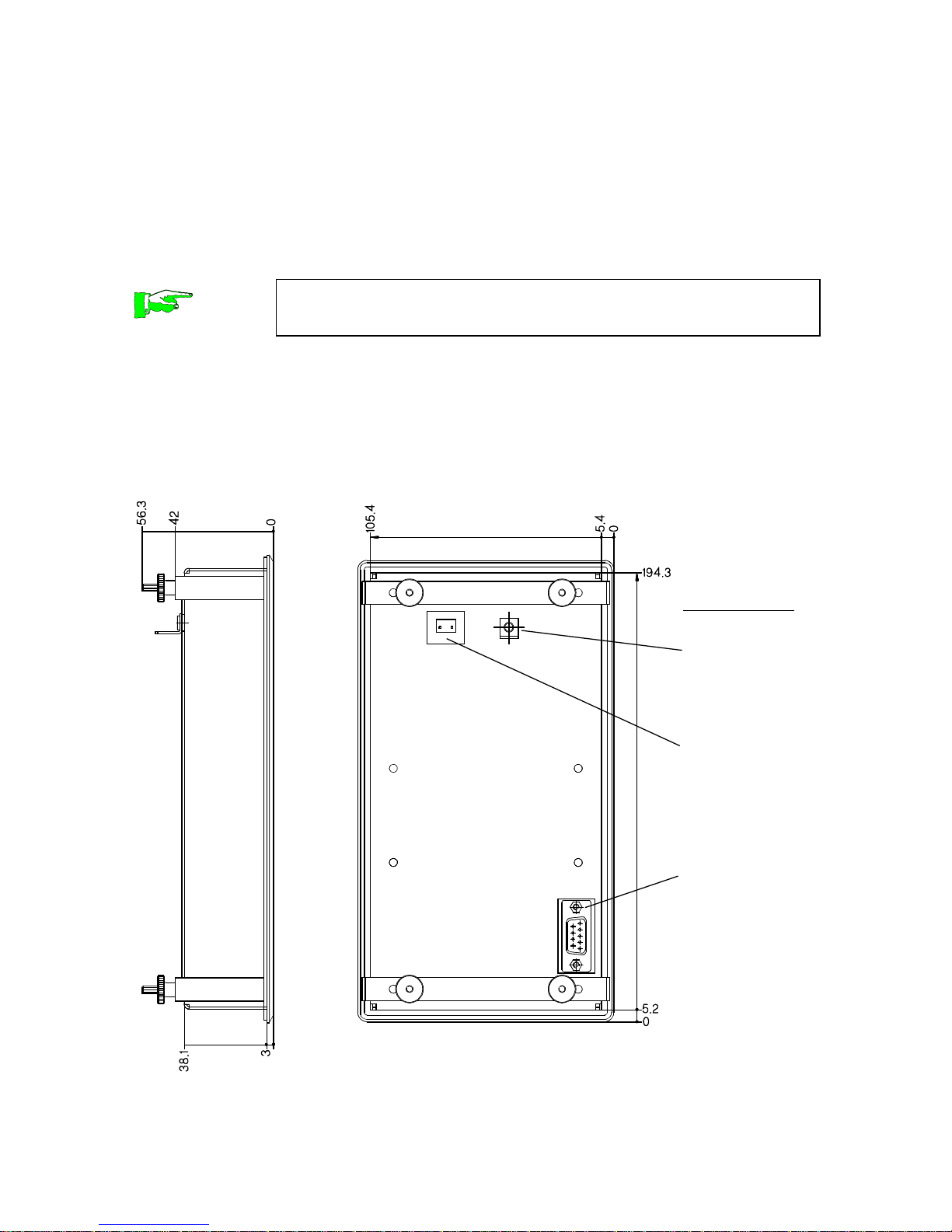

3.3.1. Design and Dimensions

Side view Rear view

Connections:

Faston connector for protective ground

Screw-type

locking connector for 24 V DC

supply

Sub-D connector for connecting cable to the

cam control

unit

Cable order no.: 674.150.31

+24V 0 V

3 - 4

Operating terminal PG 674

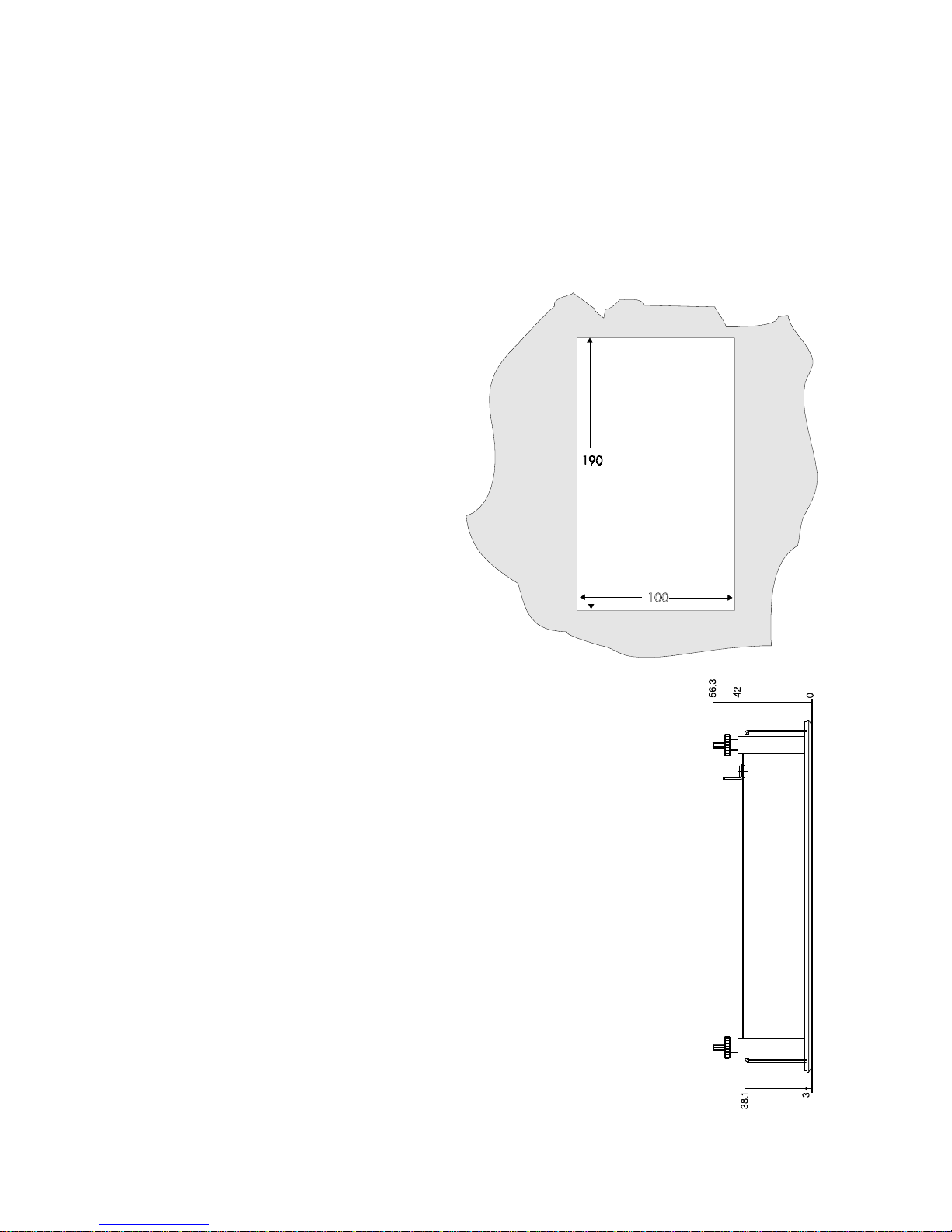

3.3.2. Installation

The PG 674 is installed in a front panel (i.e. switching cabinet

door).

To do this you must cut out an opening in the front panel:

3.3.2.1. Front panel cutout

3.3.2.2. Inserting the built-in terminal

- Remove the rear mounting brackets of the PG

674:

to do this unscrew the 4 nuts.

- Push the PG 674 from the front into the front

panel cutout.

- Screw the mounting brackets on again.

Loading...

Loading...