Page 1

Kuhnke Electronics

Instruction Manual

Modules of Controllers

KUAX 680I, KUAX 680C, KDT 680CT

E 326 GB

7 May 1997 / 39.785

Page 2

This manual is primarily intended for use by design, project, and development

engineers. It does not give any information about delivery possibilities. Data

is only given to describe the product and must not be regarded as guaranteed

properties in the legal sense. Any claims for damages against us - on whatever

legal grounds - are excluded except in instances of deliberate intent or gross

negligence on our part.

We reserve the rights for errors, omissions and modifications.

Reproduction even of extracts only with the editor's express and written prior

consent.

Page 3

Table of contents

Table of contents

1. Introduction............................................................... 1-1

1.1. Manual breakdown ................................................................. 1-2

1.2. Further modules....................................................................... 1-3

2. Safety and Reliability.................................................. 2-1

2.1. Target group ........................................................................... 2-1

2.2. Reliability ............................................................................... 2-1

2.3. Notes..................................................................................... 2- 2

2.3.1. Danger................................................................................ 2- 2

2.3.2. Dangers caused by high contact voltage ................................. 2-2

2.3.3 Important information / cross reference.................................... 2-2

2.4. Safety .................................................................................... 2- 3

2.4.1. To be observed during project planning and installation............ 2- 3

2.4.2. To be observed during maintenance and servicing ................... 2-4

2.5. Electromagnetic compatibility .................................................... 2-5

2.5.1. Definition............................................................................. 2-5

2.5.2. Resistance to interference ...................................................... 2-5

2.5.3. Interference emission ............................................................. 2-6

2.5.4. General notes on installation.................................................. 2-6

2.5.5. Protection against external electrical influences ........................ 2-7

2.5.6. Cable routing and wiring....................................................... 2-7

2.5.7. Location of installation ........................................................... 2-8

2.5.8. Particular sources of interference ............................................ 2-8

3. Modules and slots ...................................................... 3-1

3.1. Design.................................................................................... 3-2

3.2. Screw-type locking connectors................................................... 3-3

3.2.1. Coding................................................................................ 3-3

3.3. Slots....................................................................................... 3-4

3.3.1. Function slots ....................................................................... 3-4

3.4. Service modules ...................................................................... 3-5

3.4.1. Transfer address ranges ........................................................ 3-5

3.4.2. Interrupt modules .................................................................. 3-5

3.5. Power supply of inputs and outputs............................................ 3-6

3.6. Differences between KUAX 680C/KDT 680CT and KUAX 680I.... 3- 7

Contents - 1

Page 4

Table of contents

4. Digital inputs and outputs............................................ 4-1

4.1. Plugging digital input and output modules .................................. 4- 2

4.1.1. Addressing (input/output groups and channels)........................ 4-2

4.1.2. Reserved slots ...................................................................... 4-3

4.2. Digital input modules ............................................................... 4 -4

4.2.1. Input module, 24 V DC, 8 inputs ............................................ 4-5

4.2.1.1. Technical specifications ...................................................... 4-6

4.2.2. Input module, 24 V DC, 8 inputs, with real-time clock ............... 4-7

4.2.2.1. Real-time clock .................................................................. 4-7

4.2.2.2. Parameters of KUBES module “CLOCK” ............................... 4-8

4.2.2.3. Programming suggestion for the real-time clock ................... 4-10

4.2.2.4. Technical specifications .................................................... 4-11

4.2.3. Input module, 24 V DC, 16 inputs ........................................ 4-12

4.2.3.1. Technical specifications .................................................... 4-13

4.2.4. Input module, 24 V DC, 8 inputs, 1 ms ................................. 4-14

4.2.4.1. Technical specifications .................................................... 4-15

4.2.5. Input module, 24 V DC, 16 inputs, 1 ms ............................... 4-16

4.2.5.1. Technical specifications .................................................... 4-17

4.2.6. Input module, 24 V DC, 16 inputs, interrupt capability............ 4-18

4.2.6.1. Signal delay ................................................................... 4-18

4.2.6.2. Interrupt inputs ................................................................ 4-20

4.2.6.3. Technical specifications .................................................... 4-23

4.3. Digital output module, 24 V DC, 0.5 A, 8 outputs ..................... 4-24

4.3.1 Technical specifications ........................................................ 4-26

4.4. Digital input/output module, 24 V DC, 8/8.............................. 4-27

4.4.1. Technical specifications ....................................................... 4-28

4.5. Pneumatic output module, 4 outputs 3/2 way ........................... 4-29

4.5.1. Technical specifications ....................................................... 4-30

5. Analogue inputs and outputs ....................................... 5-1

5.1. Plugging analogue input and output modules .............................. 5-2

5.1.1. Addressing (anal. input/output groups and channels) ............... 5 -2

5.1.2. Reserved slots ...................................................................... 5-3

5.2. Analogue input modules........................................................... 5-5

5.2.1. Analogue input module, 0...10 V, 10 bit, 4 channels ............... 5-5

5.2.1.1. Slots................................................................................. 5-5

5.2.1.2. Connectors ....................................................................... 5-6

5.2.1.3. Representation of the analogue value................................... 5-6

5.2.1.4. Technical specifications ...................................................... 5-7

5.2.2. Analogue input module, 0(4)...20 mA, 10bit, 4 channels.......... 5-8

Contents - 2

Page 5

Table of contents

5.2.2.1. Slots ................................................................................. 5-8

5.2.2.2. Connections ...................................................................... 5-9

5.2.2.3. Representation of the analogue value................................... 5-9

5.2.2.4. Transfer address ranges ................................................... 5-10

5.2.2.5. Technical specifications.................................................... 5-11

5.2.3. Analogue input module, PT100, 0...300 °C, 10 bit,............... 5-12

5.2.3.1. Slots ............................................................................... 5-12

5.2.3.2. Connectors ..................................................................... 5-13

5.2.3.3. Transfer address ranges ................................................... 5-14

5.2.3.4. Evaluation in the user program .......................................... 5-15

5.2.3.5. Technical specifications.................................................... 5-16

5.2.4. Analogue input module, thermocouple NiCrNi (type K),.......... 5-17

5.2.4.1. Slots ............................................................................... 5-17

5.2.4.2. Connections .................................................................... 5-18

5.2.4.3. Transfer address ranges ................................................... 5-19

5.2.4.4. Evaluation in the user program .......................................... 5-20

5.2.4.5. Technical specifications.................................................... 5-21

5.2.5. Analogue input module, potentiometer, 10bit, 4 channels ....... 5-22

5.2.5.1. Slots ............................................................................... 5-22

5.2.5.2. Connectors ..................................................................... 5-23

5.2.5.3. Representation of the analogue value................................. 5-24

5.2.5.4. Technical specifications.................................................... 5-25

5.3. Analogue output modules ....................................................... 5-27

5.3.1. Analogue output module, 0...10 V, 8 bit, 4 channels ............. 5-27

5.3.1.1. Slots ............................................................................... 5-27

5.3.1.2. Connectors ..................................................................... 5-28

5.3.1.3. Repesentation of the analogue value.................................. 5-28

5.3.1.4. Technical specifications.................................................... 5-29

5.3.2. Analogue output module, 0(4)...20 mA, 8bit, 4 channels........ 5-31

5.3.2.1. Slots ............................................................................... 5-31

5.3.2.2. Connectors ..................................................................... 5-32

5.3.2.3. Repesentation of the analogue value.................................. 5-32

5.3.2.4. Transfer address ranges ................................................... 5-33

5.3.2.5. Technical specifications.................................................... 5-34

5.4. Analogue input/output modules .............................................. 5-35

5.4.1. Analogue I/O module, 2 I 0...10 V, 2 O 0...±10V ................ 5-35

5.4.1.1. Slots ............................................................................... 5-36

5.4.1.2. Connectors ..................................................................... 5-37

5.4.1.3. Representation of the analogue value................................. 5-38

5.4.1.4. Technical specifications.................................................... 5-39

Contents - 3

Page 6

Table of contents

5.4.2. Analogue I/O module, 2 I 0...20 mA, 2 O 0...±10V ............. 5-40

5.4.2.1. Slots............................................................................... 5-40

5.4.2.2. Connectors ..................................................................... 5-41

5.4.2.3. Representation of the analogue value................................. 5-42

5.4.2.4. Transfer address ranges of the analogue inputs................... 5-43

5.4.2.5. Technical specifications .................................................... 5-44

5.4.3. Analogue I/O module, 2 I 0...10 V, 2 O 0...20 mA .............. 5-45

5.4.3.1. Slots............................................................................... 5-46

5.4.3.2. Connectors ..................................................................... 5-47

5.4.3.3. Representation of the analogue value................................. 5-48

5.4.3.4. Transfer address ranges of the analogue inputs................... 5-49

5.4.3.5. Technical specifications .................................................... 5-50

5.4.4. Anal. I/O module, 2 I 0...20 mA, 2 O 0...20 mA................. 5-51

5.4.4.1. Slots............................................................................... 5-51

5.4.4.2. Connectors ..................................................................... 5-52

5.4.4.3. Representation of the analogue value................................. 5-53

5.4.4.4. Transfer address ranges ................................................... 5-54

5.4.4.5. Technical specifications .................................................... 5-55

6. Counter modules........................................................ 6-1

6.1. Counter module, 1 or 2 multi-function counters, 24bit .................. 6-2

6.1.1. Functions ............................................................................. 6-2

6.1.2. Slots.................................................................................... 6-2

6.1.3. Counter modules with 24V inputs ........................................... 6-3

6.1.3.1. Connectors ....................................................................... 6-3

6.1.3.2. Technical specifications ...................................................... 6-5

6.1.4. Counter module with RS422 interface ..................................... 6 -6

6.1.4.1. Connectors ....................................................................... 6-6

6.1.4.2. Technical specifications ...................................................... 6-7

6.1.5. Programming ....................................................................... 6-8

6.1.5.1. Transfer address ranges and interrupt modules...................... 6- 8

6.1.5.2. Control flags ................................................................... 6-10

6.1.5.3. Setting the counter to the preset value / to 0....................... 6-10

6.1.5.4. Setting the reference value................................................ 6-10

6.1.5.5. Counter control ............................................................... 6-11

6.1.5.6. Reference value............................................................... 6-11

6.1.5.7. Interrupt.......................................................................... 6-12

6.2. Counter module, 2 event counters, 16bit .................................. 6-13

6.2.1. Slots.................................................................................. 6-13

6.2.2. Connectors ........................................................................ 6-14

Contents - 4

Page 7

Table of contents

6.2.3. Technical specifications....................................................... 6-15

6.2.4. Programming ..................................................................... 6-16

6.2.4.1. Transfer address ranges ................................................... 6-16

6.2.4.2. Setting the counter to the preset value / to 0....................... 6-18

6.2.4.3. Switching the counter on / off........................................... 6-18

6.2.4.4. Selecting the counting direction ......................................... 6-18

6.2.4.5. Selecting the counting mode ............................................. 6-18

6.2.4.6. Clearing the count ........................................................... 6-18

6.2.4.7. Evaluating the count......................................................... 6-18

6.3. SSI module, 24 bit, for 2 absolute value devices ....................... 6-19

6.3.1. Slots.................................................................................. 6-19

6.3.2. Connectors ........................................................................ 6-20

6.3.3. Technical specifications....................................................... 6-21

6.3.4. Programming ..................................................................... 6-22

6.3.4.1. Transfer address ranges ................................................... 6-22

6.3.4.2. User program.................................................................. 6-24

7. Communication modules............................................. 7-1

7.1. V.24 (RS 232) module ............................................................. 7-1

7.1.1. Slots.................................................................................... 7-1

7.1.2. Connector ............................................................................ 7 -2

7.1.3. Technical specifications......................................................... 7-3

7.2. TTY module (20 mA) ................................................................ 7-4

7.2.1. Slots.................................................................................... 7-4

7.2.2. Connector ............................................................................ 7 -5

7.2.3. Technical specifications......................................................... 7-6

7.3. RS 485 module ....................................................................... 7-7

7.3.1. Slots.................................................................................... 7-7

7.3.2. Connector ............................................................................ 7 -8

7.3.3. Technical specifications......................................................... 7-9

7.4. Programming the V.24, TTY and RS 485 modules ..................... 7-10

7.4.1. Communication programs SE 680I, KUSI680, RS485 ............. 7-10

7.4.2. KUBES modules V24XE, V24XS, V24XSTRG .......................... 7-11

7.4.2.1. Parameters of the KUBES modules ..................................... 7-12

7.4.2.2. Example program ............................................................ 7-15

7.5. PROFIBUS modules ................................................................ 7-21

Contents - 5

Page 8

Table of contents

8. Stepper motor modules without processor ..................... 8-1

8.1. Plugging stepper motor modules ................................................ 8-2

8.2. Service modules ...................................................................... 8-3

8.2.1. Transfer address ranges ....................................................... 8-3

8.2.2. Assignment of transfer addresses ............................................ 8-4

8.3. Software................................................................................. 8-5

8.3.1. Representation of a run diagram ............................................ 8 -5

8.3.2. Terminology and functions ..................................................... 8- 6

8.3.2.1. Start/stop ramp SLx01.08 (RAMP)....................................... 8-6

8.3.2.2. Start/stop frequency SLx01.10 (ST_STO_F) .......................... 8-6

8.3.2.3. Travelling frequency SLx01.12 (MOV_FRQ) .......................... 8-7

8.3.2.4. Actual position SLx00.04 (RP_LW)....................................... 8 -7

8.3.2.5. Destination position SLx00.00 (DP_LW)................................ 8-7

8.3.2.6. Preset value step counter SLx01.00 (SV_LW) ......................... 8-8

8.3.2.7. Mode of positioning operations SLx01.14 (MODE) ............... 8 -8

8.3.2.8. Control functions SLx01.07 (CONTROL)............................ 8-10

8.3.2.9. Error messages................................................................ 8-12

8.4. Stepper motor module, 1 channel ............................................ 8-13

8.4.1. Connection of the signal lines .............................................. 8-13

8.4.2. Technical specifications ....................................................... 8-14

8.5. Stepper motor module, 2 channels........................................... 8-15

8.5.1. Connection of the signal lines .............................................. 8-15

8.5.2. Technical specifications ....................................................... 8-16

8.6. Example program .................................................................. 8-17

9. Stepper motor module with processor ........................... 9-1

9.1. Plugging stepper motor modules ................................................ 9-2

9.2. Service modules ...................................................................... 9-2

9.2.1. Transfer address ranges ........................................................ 9-2

9.2.2. Assignment of transfer addresses ............................................ 9-3

9.3. Software................................................................................. 9-4

9.3.1. Representation of a run diagram ............................................ 9 -4

9.3.2. Terminology and functions ..................................................... 9- 5

9.3.2.1. Start/stop ramp SLx01.08 (RAMP)....................................... 9-5

9.3.2.2. Start/stop frequency SLx01.10 (ST_STO_F) .......................... 9-5

9.3.2.3. Travelling frequency SLx01.12 (MOV_FRQ) .......................... 9-6

9.3.2.4. Actual position SLx00.04 (RP_LW)....................................... 9 -6

9.3.2.5. Destination position SLx00.00 (DP_LW)................................ 9-6

9.3.2.6. Preset value step counter SLx01.00 (SV_LW) ......................... 9-7

9.3.2.7. Mode of positioning operations SLx01.14 (MODE) ............... 9 -7

Contents - 6

Page 9

Table of contents

9.3.2.8. Timing diagrams of run jobs ............................................... 9-9

9.3.2.9. Control functions SLx01.07 (CONTROL) ............................ 9-10

9.3.2.10. Error messages.............................................................. 9-12

9.4. Stepper motor module, 2 channels........................................... 9-13

9.4.1. Connection of the signal lines .............................................. 9-13

9.5.2. Technical specifications ....................................................... 9-14

9.5. Example program .................................................................. 9-15

Appendix

A. Power consumption of the modules...............................A-1

A.1. Power supply .......................................................................... A-1

A.1.1. 24 V DC system supply ......................................................... A-1

A.1.2. Supply of digital outputs and inputs ........................................ A-1

A.2. Load on the power supply by the modules.................................. A-2

B. Order specifications ................................................... B-1

C. Literature list..............................................................C-1

Index.......................................................................Index-1

Sales & Service

Contents - 7

Page 10

Table of contents

Contents - 8

Page 11

1. Introduction

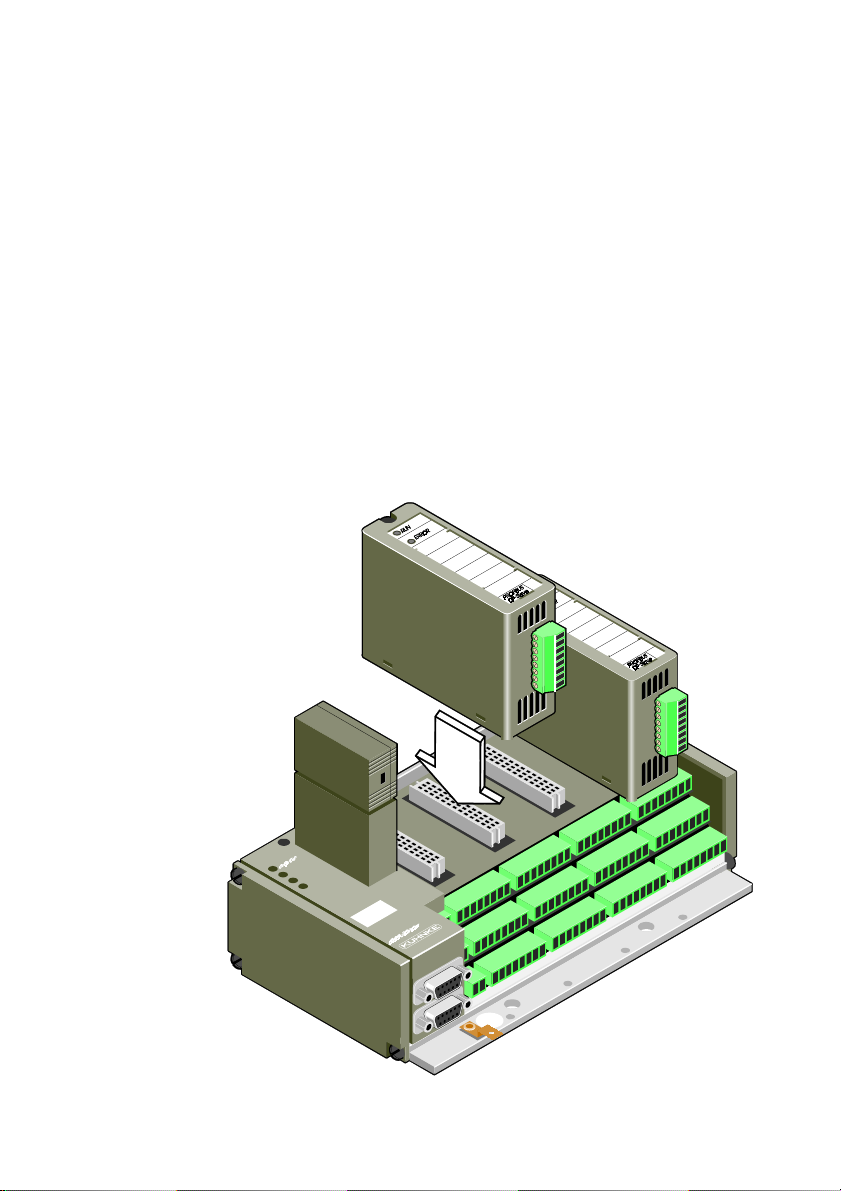

KUAX 680I, KUAX 680C and KDT 680 CT are efficient,

modularly constructed minicontrollers. They are equipped with

modules which communicate with the user program in the controller either directly or via transfer addresses (SLx...). KUAX

680C and KDT 680CT also have built-in inputs and outputs

which are not, however, described in this instruction manual.

There are connectors for three-conductor connections so that

proximity switches or other similar devices can be supplied via

the same cable as the signal line. Additional terminal strips are

thus made redundant. Simply plug the modules into the appropriate slots from above:

Fig.: KUAX 680I

Introduction

1

1 - 1

Page 12

Introduction

1.1. Manual breakdown

- Table of contents

- Chapter 1

Introduction

- Chapter 2

Some comments on the reliability of the described products

and their safe use

- Chapter 3

Basic information about application and design of the modules as well as about slots and plug connectors

- Chapter 4

Digital input and output modules

- Chapter 5

Analogue input and output modules

- Chapter 6

Counter modules and SSI module

- Chapter 7

Communication modules V.24 (RS 232), TTY (20 mA) and

RS 485, without processor

- Chapter 8

Stepper motor modules without processor

- Chapter 9

Stepper motor modules with processor

1 - 2

- Appendix A

Power supply and load characteristics of the controllers

- Appendix B

Module ordering information (summary)

- Appendix C

References to general literature and to Kuhnke instruction

manuals

- Index

Page 13

This manual only describes the modules. Please refer to the relevant instruction manuals to find out more about the actual

controllers:

Controller Instruction manual

KUAX 680I E 380 GB

KUAX 680C E 399 GB

KDT 680CT E 414 GB

1.2. Further modules

Some modules are not described in this manual but, for subject

matter reasons, have their own instruction manuals:

- PROFIBUS module 680.440.05

Instruction manual: E 509 GB

- Positioning module 680.454.06

Instruction manual: E 416 GB

- Servo counter module 680.454.05

Instruction manual: E 416 GB

Introduction

1 - 3

Page 14

Introduction

1 - 4

Page 15

2. Safety and Reliability

2.1. Target group

This instruction manual contains all information necessary for

the use of the described product (control device, software, etc.)

according to instructions. It is written for the personnel of the

construction, project planning, service and commissioning

departments. For proper understanding and error-free applica-

tion of technical descriptions, instructions for use and particularly of notes of danger and warning, extensive knowledge of

automation technology is compulsory.

2.2. Reliability

Reliability of Kuhnke controllers is brought to the highest possible standards by extensive and cost-effective means in their

design and manufacture.

These include:

selecting high-quality components,

quality arrangements with our sub-suppliers,

measures for the prevention of static charge during the handling of MOS circuits,

worst case dimensioning of all circuits,

inspections during various stages of fabrication,

computer aided tests of all assembly groups and their

coefficiency in the circuit,

statistic assessment of the quality of fabrication and of all returned goods for immediate taking of corrective action.

Safety and Reliability

Despite these measures, the occurrence of errors in electronic

control units - even if most highly improbable - must be taken

into consideration.

2 - 1

Page 16

Safety and Reliability

2.3. Notes

Please pay particular attention to the additional notes which we

have marked by symbols in this instruction manual:

2.3.1. Danger

This symbol warns you of dangers which may cause death,

(grievous) bodily harm or material damage if the described

precautions are not taken.

2.3.2. Dangers caused by high contact voltage

This symbol warns you of dangers of death or (grievous) bodily

harm which may be caused by high contact voltage if the described precautions are not taken.

2.3.3 Important information / cross reference

This symbol draws your attention to important additional information concerning the use of the described product. It may also

indicate a cross reference to information to be found elsewhere.

2 - 2

Page 17

Safety and Reliability

2.4. Safety

Our product normally becomes part of larger systems or installations. The following notes are intended to help integrating the

product into its environment without dangers for man or material/equipment.

2.4.1. To be observed during project planning and installation

- 24V DC power supply:

Generate as electrically safely separated low voltage. Suitable

devices are, for example, split transformers constructed to

correspond to European standard EN 60742 (corresponds to

VDE 0551)

- In case of power breakdowns or power fades: the program has

to be structured in such a way as to create a defined state at

restart that excludes dangerous states.

- Emergency switch-off installations or other emergency installations have to be realized in accordance with EN 60204/

IEC 204 (VDE 0113). They must be effective at any time.

- Safety and precautions regulations for qualified applications

have to be observed.

- Please pay particular attention to the notes of warning which,

at relevant places, will make you aware of possible sources of

dangerous mistakes or failures.

- The relevent standards and VDE regulations are to be observed in every case.

- Control elements have to be installed in such a way as to exclude unintended operation.

- Control cables have to be layed in such a way as to exclude

interference (inductive or capacitive) which could influence

the operation of the controller.

To achieve a high degree of conceptual safety in the planning

and installation of electronic controllers it is essential to follow the instructions given in the manual exactly because wrong

handling could lead to rendering measures against dangerous

failures ineffective or to creating additional dangers.

2 - 3

Page 18

Safety and Reliability

2.4.2. To be observed during maintenance and servicing

- Precaution regulation VBG 4.0 must be observed, and section

8 (Admissible deviations during working on parts) in particular, when measuring or checking a controller in a power-up

condition.

- Repairs must only be made by specially trained Kuhnke staff

(usually in the main factory in Malente). Warranty expires in

every other case.

- Spare parts:

Only use parts approved of by Kuhnke. Only genuine Kuhnke

modules must be used in modular controllers.

- Modules must only be connected to or disconnected from the

controller with no voltage supplied. Otherwise they may be

destroyed or (possibly not immediately recognisably!) detracted from their proper functioning.

- Always deposit batteries and accumulators as hazardous

waste.

2 - 4

Page 19

2.5. Electromagnetic compatibility

2.5.1. Definition

Electromagnetic compatibility is the ability of a device to function satisfactorily in its electromagnetic environment without

itself causing any electromagnetic interference that would be

intolerable to other devices in this environment.

Of all known phenomena of electromagnetic noise, only a certain range occurs at the location of a given device. This noise

depends on the exact location. It is determined in the relevant

product standards.

The international standard regulating construction and degree

of noise resistance of programmable logic controllers is IEC

1131-2 which, in Europe, has been the basis for European

standard EN 61131-2.

2.5.2. Resistance to interference

Safety and Reliability

Electrostatic discharge, ESD

in accordance with IEC 801-2, 3rd degree of sharpness

Fast transient interference, Burst

in accordance with IEC 801-4, 3rd degree of sharpness

Irradiation resistance of the device, HF

in accordance with IEC 801-3, 3rd degree of sharpness

Immunity to damped oscillations

in accordance with IEC 255-4 (1 MHz, 1 kV)

2 - 5

Page 20

Safety and Reliability

2.5.3. Interference emission

Interfering emission of electromagnetic fields, HF

in accordance with EN 55011, limiting value class A, group 1

If the controller is designed for use in residential districts, then

high-frequency emissions must comply with limiting value class

B as described in EN 55011.

Fitting the controller into an earthed metal cabinet and equipping the supply cables with filters are appropriate means for

keeping the corresponding limiting values.

2.5.4. General notes on installation

As component parts of machines, facilities and systems, electronic control systems must comply with valid rules and regulations, depending on the relevant field of application.

General requirements concerning the electrical equipment of

machines and aiming at the safety of these machines are contained in Part 1 of European standard EN 60204 (corresponds

to VDE 0113).

2 - 6

For safe installation of our control system please observe the

following notes:

Page 21

Safety and Reliability

2.5.5. Protection against external electrical influences

Connect the control system to the protective earth conductor to

eliminate electromagnetic interference. Ensure practical wiring

and laying of cables.

2.5.6. Cable routing and wiring

Separate laying of power supply circuits, never together with

control current loops:

DC voltage 60 V ... 400 V

AC voltage 25 V ... 400 V

Joint laying of control current loops is allowed:

data signals, shielded

analogue signals, shielded

digital I/O lines, unshielded

DC voltages < 60 V, unshielded

AC voltages < 25 V, unshielded

2 - 7

Page 22

Safety and Reliability

2.5.7. Location of installation

Make sure that there are no impediments due to temperatures,

dirt, impact, vibrations and electromagnetic interference.

Temperature

Consider heat sources such as general heating of rooms, sunlight, heat accumulation in assembly rooms or control cabinets.

Dirt

Use suitable casings to avoid possible negative influences due

to humidity, corrosive gas, liquid or conducting dust.

Impact and vibration

Consider possible influences caused by motors, compressors,

transfer routes, presses, ramming machines and vehicles.

Electromagnetic interference

Consider electromagnetic interference from various sources

near the location of installation: motors, switching devices,

switching thyristors, radio-controlled devices, welding equipment, arcing, switched-mode power supplies, converters / inverters.

2.5.8. Particular sources of interference

Inductive actuators

Switching off inductances (such as from relays, contactors, solenoids or switching magnets) produces overvoltages. It is necessary to reduce these extra voltages to a minimum.

Reducing elements my be diodes, Z-diodes, varistors or RC elements. To provide suitably designed reducing elements, we

recommend asking the manufacturer or supplier of the corresponding actuators for the relevant information.

2 - 8

Page 23

3. Modules and slots

KUAX 680I and 680C can be equipped with different types of

modules. The number of modules depends on the size of the

device:

- Devices with 4 slots: 4 modules (slots 0...3)

- Devices with 8 slots: 8 modules (slots 0...7)

(KUAX 680I only)

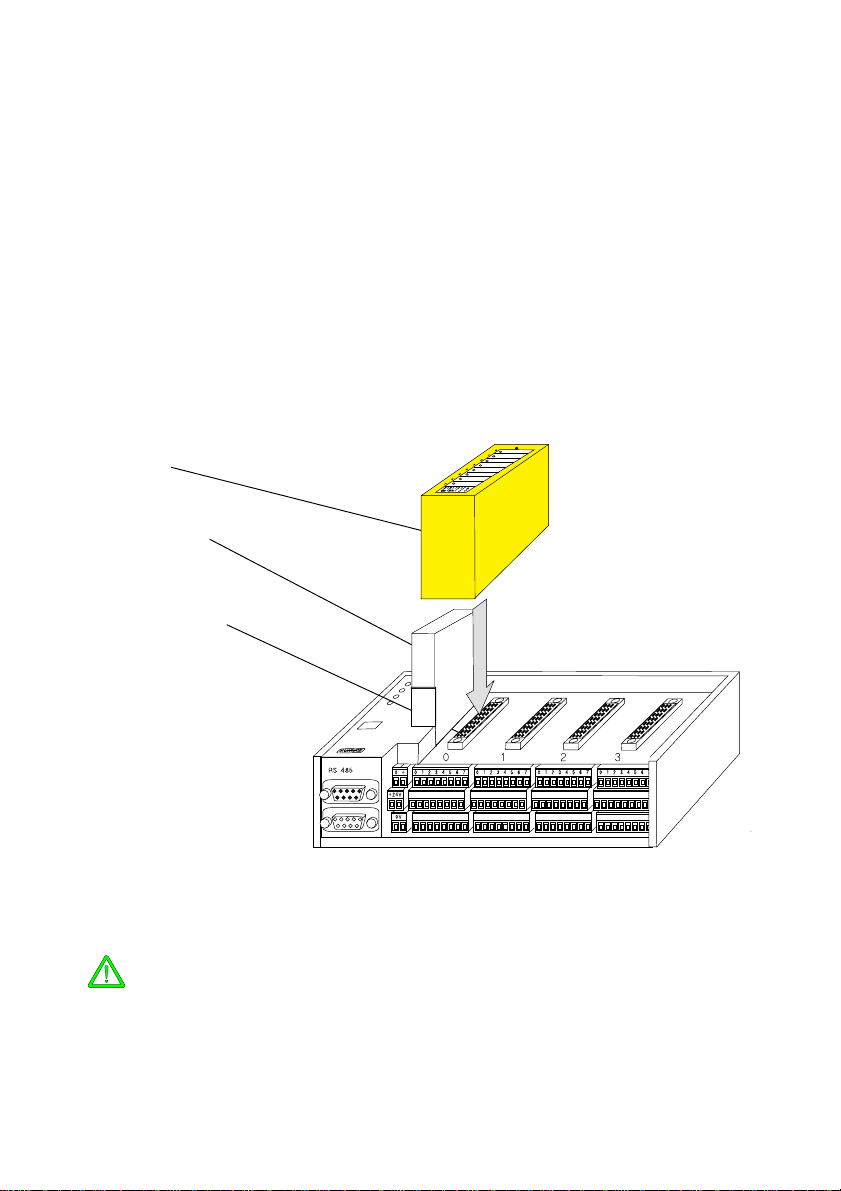

Modules are plugged into the top of the device. They are connected to the controller via the device bus plug (the figure below shows KUAX 680I):

Module

Memory module

Device bus plug

The following has to be observed when placing the modules:

- Only plug modules in/out in an idle state. Danger of destruction!

- Sequence modules from left to right (see also "3.3. Slots").

- The modules must be screwed into the device. They could otherwise become loose and then cause dangerous conditions.

3 - 1

Page 24

Modules

3.1. Design

Mounting

Labels

Status indicators

The modules are enclosed in a plastic casing. For cooling the

electronics, there are ventilation slots on the narrow edges. The

plug for the connection to the bus connector is on the bottom

side.

There is a screw sunk into the front side which is used to attach

the module to the device frame.

In KUAX 680C, KDT 680CT, and recent models of KUAX 680I

(part numbers 680.423.xx) the modules are additionally supported by plastic rests. Modules made before calendar week

27/95 do not fit into these devices because they have no bores

to place the plastic rests in.

A large area on the front side is saved for a label. The label can

be used to enter the symbolic designations of the input or output signals (cf. symbol table under KUBES) or the function of

the module.

There is a sufficient number of labels. They are delivered together with the KUAX 680I as perforated A4 tear-off blanks.

The line and column spacings are set in a way that makes an

inscription possible also for dot-matrix printers with a condensed print.

On the lefthand side of the labels there are left as many holes

as the module provides status indicators.

These holes fit across LEDs which are built into the actual

module casing to indicate, for example, signal states of inputs

or outputs.

By definition, light emitting diodes (also referred to as LEDs)

are "Class 1 light emitting diodes (in acc. with EN 60825_1)".

Channel numbers

3 - 2

On input and output modules, the corresponding channel numbers (0...3/7) are printed left to the LEDs. They correspond to

the inscription on the signal strip underneath the module. The

relation between terminal, LED and inscription is thus documented.

Page 25

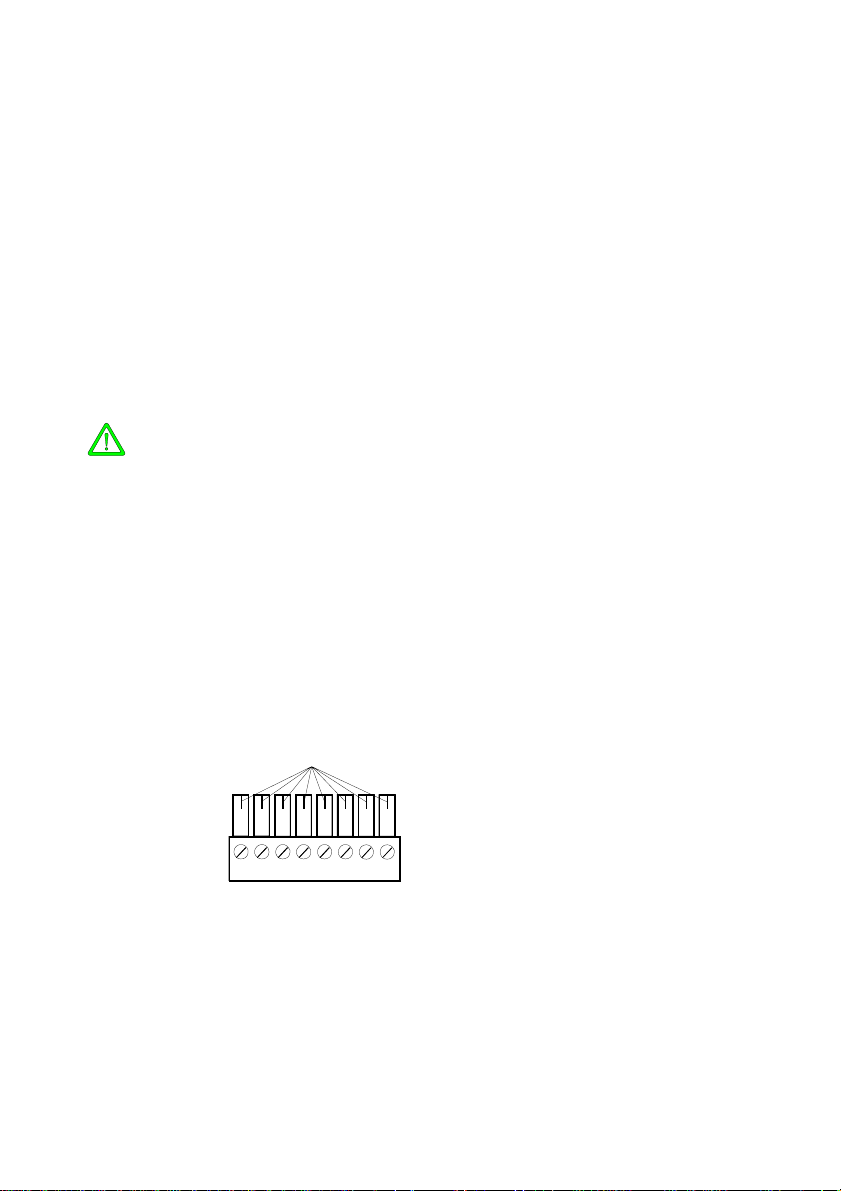

3.2. Screw-type locking connectors

Screw-type locking connectors (supplied by Phoenix) are used

to connect inputs and outputs to the device:

Connector type MINI-COMBICON, 3.81 mm matrix, connecting diameter 0.14...1,5 mm² , max. load 8 A

The green screw-type locking connectors sit very firmly in

their position to avoid them becoming loose due to vibrations.

Should you find it difficult to pull them off with your fingers,

simply use a flat object such as a screwdriver with a wide blade

as a lever.

Never pull the wires to disconnect the plug. The wires might

otherwise slip out of the terminals or rip off even.

3.2.1. Coding

You can code the MINI-COMBICON connectors so that you do

not get them confused when putting them on (by conntecting

digital inputs to an SSI module, for example).

Push one or several coding profiles into the groove(s) provided

on the socket part of the connector for this purpose. Use a side

cutter, for example, to cut the corresponding coding element

off the plug part.

coding element

Kodierre i ter

Supply

There are some connectors in the basic device which are coded

in the factory. Please refer to the corresponding illustrations to

learn where such codings exist and what they look like.

3 - 3

Page 26

Modules

3.3. Slots

KUAX 680I can be equipped with slots for either 4 or 8 modules. KUAX 680C and KDT 680CT always have 4 slots (or

none).

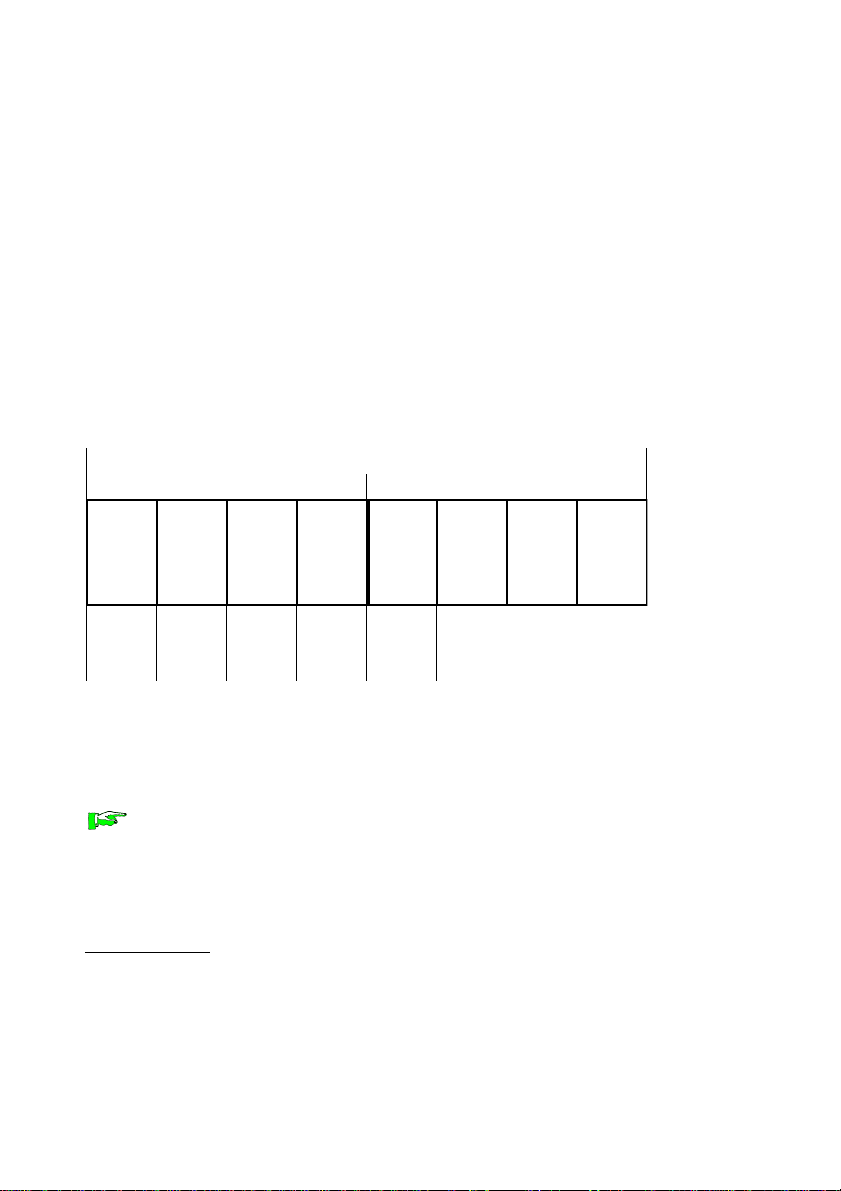

3.3.1. Function slots

Individual slots carry additional leads. They make the application of certain modules possible for using services provided by

the processor (counting, stepper motor control, analogue/digital

conversion...):

Device with 8 slots (KUAX 680I only)

Device with 4 slots

0 1 2 3 4 5 6 7

event

counter x 2

PWM x 2

analogue

input x 2

*3)

PWM x 2

*1)

analogue

input x 4

*2)

*1)

analogue

input x 4

*2)

*2)

These specifications do not limit the application of any other

module. If a function slot is not needed as such, it can also be

used for a slot-independent module such as a digital input or

output module.

*1) PWM stands for "pulse-width modulated output" for stepper motor control.

*2) This only concerns those analogue inputs with a resolution of 10bit that use the

A/D converter on the CPU.

3 - 4

Page 27

3.4. Service modules

Modules with more complex functions need software support to

be able to carry out these functions. In order to avoid the necessity for the user to write these often very complicated programs

himself, so-called service modules are embedded in the program to relieve the user.

As from release 4.00, these service modules are delivered with

KUBES as individual files under the name SERV_xx.BIN. The

KUBES installation program places these files in the same subdirectory as the program files (e.g. C:\KUBESEXE).

Configuration

When configuring KUAX 680I or 680C, you enter the modules

into a list in the same order in which they will be plugged in

later. KUBES can use this information to embed the necessary

service modules in the user program and to create the reference

to the modules.

3.4.1. Transfer address ranges

Service modules use so-called transfer address ranges (max. 32

byte) for each module for data exchange with the user program.

These are directly assigned to the module slots (see table on

next page). The service module assigned to the slot during configuration determines the assignment of the transfer addresses.

Service modules

3.4.2. Interrupt modules

Under certain conditions, some modules trigger an interrupt in

the CPU. Like this the service module, and sometimes also the

user program, can react particularly quickly to an event. An interrupt caused by a module calls up an interrupt module (see table on next page). This module can contain user-defined instructions to be carried out in case of an interrupt.

3 - 5

Page 28

Modules

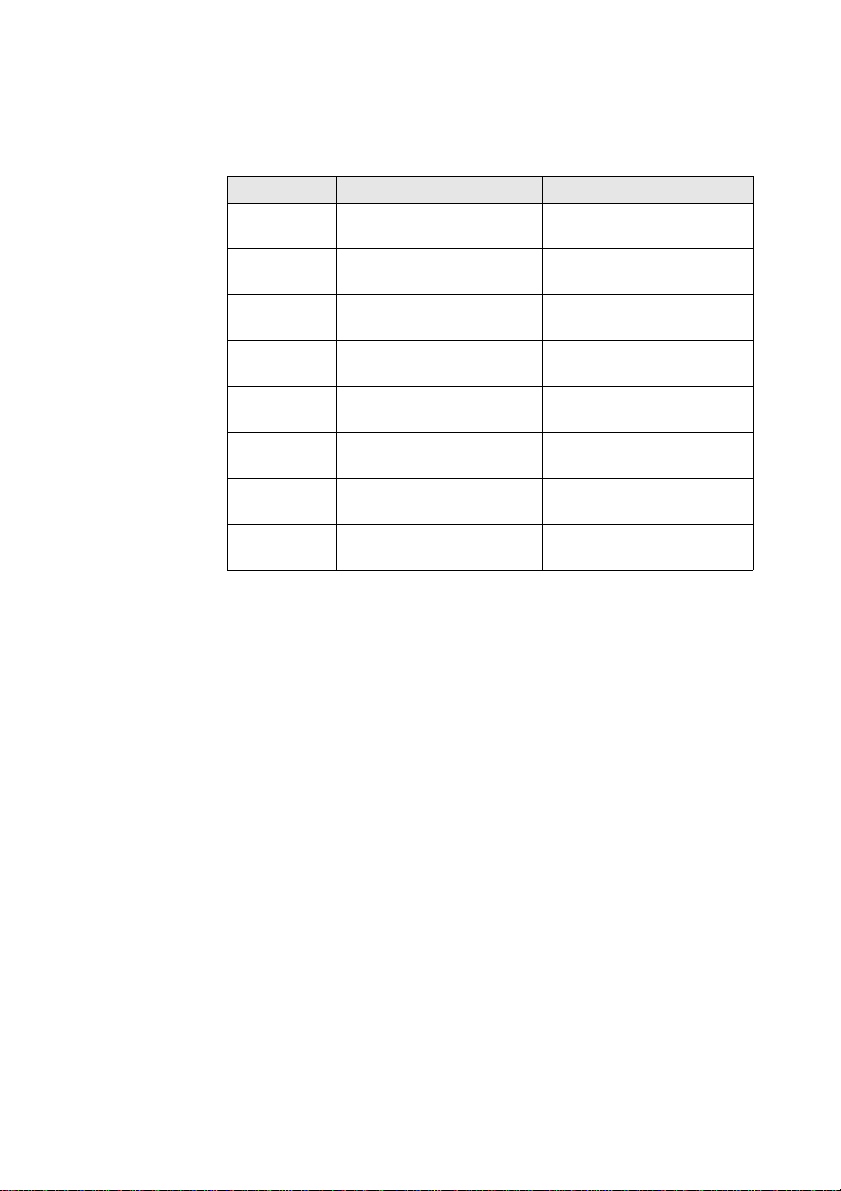

Assignment of transfer addresses and interrupt modules

Slot Transfer address range Interrupt module

0

1

2

3

4

5

6

7

SLA00.00...01.15

SLB00.00...01.15

SLC00.00...01.15

SLD00.00...01.15

SLE00.00...01.15

SLF00.00...01.15

SLG00.00...01.15

SLH00.00...01.15

SLI00.00...01.15

SLJ00.00...01.15

SLK00.00...01.15

SLL00.00...01.15

SLM00.00...01.15

SLN00.00...01.15

SLO00.00...01.15

SLP00.00...01.15

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

3.5. Power supply of inputs and outputs

All inputs and outputs as well as the relay for polarity safeguarding in the digital output modules are centrally supplied

via the corresponding terminals of the basic device (see the relevant instruction manuals of the individual controllers).

3 - 6

Page 29

3.6. Differences between KUAX 680C/KDT 680CT and KUAX 680I

All examples given in this instruction manual refer to the use

of the relevant modules in KUAX 680I.

When working with KUAX 680C or KDT 680CT you will be

obliged to take note of some differences which are caused by

the I/Os available to the basic device.

Limited applicability

- You cannot use the counter module for event counters, order

no. 680.454.03; the reason being that in its standard configuration, the device is already equipped with two event

counters (internal inputs).

- Stepper motor modules and internal analogue outputs share

the same system resources, i.e. the PWM outputs of the processor:

PWM analogue output stepper motor module

1 AO00.00 680.444.01 and .02

2 AO00.01 680.444.02

Thus, if you are using a two-channel stepper motor module

(680.440.02) neither of the two internal analogue outputs can

be used. If you are working with a single-channel stepper

motor module (680.440.01), you still have the option of using internal analogue output AO00.01 at least.

Addressing

Please note that input and output groups are occupied already

by the internal I/Os. While plugged-in modules are numbered

in groups from left to right just like in KUAX 680I, they start

with different group numbers:

Modules first group

digital inputs I02

analogue inputs AI01

digital outputs O02

analogue outputs AO01

For further information please refer to the device manuals.

3 - 7

Page 30

Modules

3 - 8

Page 31

4. Digital inputs and outputs

Digital inputs and outputs are used for leading digital signals (1

or 0, High or Low, On or Off etc.) from the machine or system

into the controller (inputs) or vice versa (outputs).

These include:

Digital input signals from

- switches

- key-switches

- sensors

- etc.

Digital output signals for switching

- relays

- contactors

- magnetic valves

- etc.

There are only 2 possible states of digital signals:

- logical 0 (Low, Off...)

- logical 1 (High, On...)

These two signal states form the basis for most of the functions

of control engineering.

There are several digital input and output modules available for

adjusting the controller to the different types of signals.

4 - 1

Page 32

Digital inputs and outputs

4.1. Plugging digital input and output modules

As from monitor version 4.10 (KUBES version 4.01), KUAX

680I can also be equipped with 16pin modules. KUAX 680C as

from its first delivered machines.

All earlier versions of KUAX 680I only allow application of

8pin modules.

Digital input and output modules can be plugged into any slot

as long as this slot is not needed for another module (see

"3.3.1. Function slots"). Certain regulations must be regarded,

however:

4.1.1. Addressing (input/output groups and channels)

Upon switching the controller on, inputs and outputs of all

plugged-in modules are automatically numbered from left to

right in groups of 8 channels (.00... .07) each. Thus, the first in-

put group is assigned the group number I00, the second one is

assigned I01 etc. The output groups are treated in the same way

by the system: O00, O01 etc.

Example for KUAX 680I:

012 3

Legend:

4 - 2

0 input module, 8pin I00

1 output module, 8pin O00

2 input module, 16pin I01, I02

3 input/output module, 8/8pin I03, O01

Page 33

Groups

Inputs: I00...max. I15 (on 16pin modules)

Ouputs: O00...max. O07

In KUAX 680C, the first two input groups, I00 and I01, and the

first two output groups, O00 and O01, are allocated already to

the internal inputs and outputs. The modules for inputs and

outputs thus start with numbers I02 and O02.

Channels

Each group consists of 8 channels, i.e. inputs or outputs:

Inputs: Ixx.00...Ixx.07

Outputs: Oxx.00...Oxx.07

4.1.2. Reserved slots

Reserved slots for a module type of which there are modules

plugged in already (e.g. input modules) must always be located

after the last plugged-in module of the same type. Otherwise,

the module numbering (addressing) of the following modules

of the same type will change.

Addressing

Example: I I _ O

Reserved slot for an input module (I02.)

Reserved slots for later plugging of function modules or analogue input modules may also be located between modules of

one type.

Example: I _ I O

O00.

I01.

Reserved slot for a counter module

I00.

4 - 3

Page 34

Digital inputs and outputs

4.2. Digital input modules

Digital input modules are used for reading the signal states of

switches, key switches, relay contacts etc. When working with

proximity switches and semi-conductor sensors please make

sure to keep them running within the switching thresholds

given below.

Switching thresholds and filters

The input line is used to adjust the connected signals to the system voltage.

Defined signals:

Logical 0: ≤ 5 V

Logical 1: ≥ 15 V

(Hysteresis: 1...4 V)

Signal delay of inputs with normal (5ms) delay time:

In order to avoid voltage surges (noise pulses) being recog-

U[V]

24

nized as valid signals, thus executing wrong switching operations, they are filtered out.

15

layed by a nominal period of 5

ms:

Signal identification is thus de-

5

Raising delay *):

tve= 3.0 ... 7.0 ms

Signal

*) The input signals are read between individual program cycles and then written into the process image. To correctly determine the availability of the signals for the user program you would have to add

the program cycle time to the delay time.

5101520253035t[ms]

1

0

t

ve

t

va

Falling delay *):

tva= 4.0 ... 7.0 ms

4 - 4

Page 35

4.2.1. Input module, 24 V DC, 8 inputs

Signal line connection

Input voltage is 24 V DC. These signals are applied via plugscrew terminals on the signal strip underneath the module.

Input module, 8 inputs

Exx.00

Exx.01

Exx.02

Exx.03

Exx.04

Exx.05

Exx.06

Exx.07

*) read 'E' = 'I' (for Input)

*)

4 - 5

Page 36

Digital inputs and outputs

4.2.1.1. Technical specifications

Application: ............................................. KUAX 680I, 680C, 680S, KDT 680CT

Admissible ambient conditions

storage temperature ............................ -25...+70 °C

ambient temp. during operation: ....... 0...55 °C

relative humidity ................................ 50...95 %

Inputs: ....................................................... 8

Type (acc. to IEC 1131) .......................... 1

Potential separation ................................. no

Indicators .................................................. LEDs

colour .................................................. green

tapping point....................................... in the input circuit

signal states ........................................ 1: LED on

0: LED off

Addressing: .............................................. Ixx.00...Ixx.07

Input voltage: ........................................... 24 V DC -20%/+25%

(incl. residual ripple)

Surge immunity ........................................ ≤ 60 V DC (≤ 30 min.)

Signal recognition

logical 0: ............................................. ≤ 5 V DC

logical 1: ............................................. ≥ 15 V DC

Power consumption / input: .................... max. 10 mA

Weight:..................................................... c. 77 g

Part number:............................................. 680.451.01

4 - 6

Page 37

Input module, 8 inputs, with real-time clock

4.2.2. Input module, 24 V DC, 8 inputs, with real-time clock

These are the same inputs as described in chapter “4.2.1. Input

module, 24 V DC, 8 inputs” (see there for picture and connections).

Added is the function of the real-time clock which is realised

on this module.

4.2.2.1. Real-time clock

A clock module is integrated in the module which is supplied

by an accu in case of a voltage cut.

A KUBES module is available for setting and evaluating time

and date.

Name: CLOCK

Call from within the program:

JPK CLOCK

<actual time> <status indication>

<set>

The module should be called up in every PLC cycle. The program within the module is organized so as to updating the input

parameter “actual time” every second.

If there is a set command (first byte in data field “set” = 255),

the preset values are taken over immediately.

Output byte “status indication” reports any occurring errors.

4 - 7

Page 38

Digital inputs and outputs

4.2.2.2. Parameters of KUBES module “CLOCK”

The user has to reserve two data fields for the clock parameters

and one byte for status indication. It is helpful to enter these

operands into the symbol table (KUBES) at the beginning of

project planning.

The data fields must consist of subsequent operand ranges.

When programming the KUBES module, the first address of

each data field is entered.

We recommend to take over the symbols as shown in the 3 following tables:

Input parameter “Actual time”

Data field, 21 byte: current time and date (read only):

Byte

No Example Symbol

Actual value (decimal) for evaluation in the program:

1

SBM00.00 SECOND

2

SBM00.01 MINUTE

3

SBM00.02 HOUR

4

SBM00.03 WEEKDAY

5

SBM00.04 DAY

6

SBM00.05 MONTH

7

SBM00.06 YEAR

Actual value (ASCII) for transfer to text displays:

8

SBM00.07

9

SBM00.08

10

SBM00.09

11

SBM00.10

12

SBM00.11

13

SBM00.12

14

SBM00.13

15

SBM00.14

16

SBM00.15

17

SBM01.00

18

SBM01.01

19

SBM01.02

20

SBM01.03

21

SBM01.04

ASC_SEC

ASC_MIN

ASC_HOUR

ASC_WDAY

ASC_DAY

ASC_MON

ASC_YEAR

Significance

second 0...59

minute 0...59

hour 0...23

day of the week 0 (Sunday) ... 6 (Saturday)

day 1...31

month 1...12

year 0...99

second lowbyte

second highbyte

minute lowbyte

minute highbyte

hour lowbyte

hour highbyte

weekday lowbyte

weekday highbyte

day lowbyte

day highbyte

month lowbyte

month highbyte

year lowbyte

year highbyte

4 - 8

Page 39

Input parameter “Set”

Data field, 7 byte: clock flag, slot, preset time and preset date:

Input module, 8 inputs, with real-time clock

Byte

No Example Symbol

1

SBM01.05 CL_FLAG

2

SBM01.06 CL_SLOT

3

SBM01.07 SET_SEC

4

SBM01.08 SET_MIN

5

SBM01.09 SET_HOUR

6

SBM01.10 SET_WDAY

7

SBM01.11 SET_DAY

8

SBM01.12 SET_MON

9

SBM01.13 SET_YEAR

Significance

clock flag (255: write values in bytes 3...7 into the

clock)

slot number of the module (0...7)

preset value second: 0...59

preset value minute: 0...59

preset value hour: 0...23

preset value weekday: 0 (Sunday) ... 6 (Saturday)

preset value day: 1...31

preset value month: 1...12

preset value year: 0...99

Output parameter “Status indication”

1 byte: error message or OK, resp.

Byte

Example Symbol

SBM01.15 STATUS

Value Significace

0 okay message, no error

undefined clock state (no load on the accu,

identification cleared). Remedy: set the clock

1

again and recharge accu (approx. 72 h on the net)

2 set values outside the valid range

input parameters: the range of a data field is

3

exceeded

4 illegal slot number

5 6 7 8 -

4 - 9

Page 40

Digital inputs and outputs

4.2.2.3. Programming suggestion for the real-time clock

L n ;module slot (0...7)

= SBM01.06

JPK CLOCK

SBM00.00 SBM01.15

SBM01.05

L SBM01.15

CMP 0

JP<> ERROR ;for error evaluation

DISPLAY.

. ;display actual value

.

SET L Mxx.xx

= PPxx.xx

L PPxx.xx

JPCN ENDCLK ;to end of clock program

L 255

= SBM01.05

PREVAL .

. ;write preset value into oper.

. ;SET_SEC...SET_YEAR

JP ENDCLK

ERROR .

. ;error evaluation

.

ENDCLK.

. ;normal program

4 - 10

Page 41

Input module, 8 inputs, with real-time clock

4.2.2.4. Technical specifications

Application: ............................................. KUAX 680I, 680C, KDT 680CT

Admissible ambient conditions

storage temperature ............................ -25...+70 °C

ambient temp. during operation: ....... 0...55 °C

relative humidity ................................ 50...95 %

Inputs: ....................................................... 8

Type (acc. to IEC 1131) .......................... 1

Potential separation ................................. no

Indicators .................................................. LEDs

colour .................................................. green

tapping point....................................... in the input circuit

signal states ........................................ 1: LED on

0: LED off

Addressing: .............................................. Ixx.00...Ixx.07

Input voltage: ........................................... 24 V DC -20%/+25%

(incl. residual ripple)

Surge immunity ........................................ ≤ 60 V DC (≤ 30 min.)

Signal recognition

logical 0: ............................................. ≤ 5 V DC

logical 1: ............................................. ≥ 15 V DC

Power consumption / input: .................... max. 10 mA

Real-time clock: ....................................... second, minute, hour

weekday, day, month, year

Accumulator (buffering of clock)

buffer time: ......................................... ~ 3 months

charging time: .................................... ~ 72 h

Weight:..................................................... c. 85 g

Part number:............................................. 680.451.02

4 - 11

Page 42

Digital inputs and outputs

4.2.3. Input module, 24 V DC, 16 inputs

Low group number: High group number:

Status indic. (LEDs) Status indic. (LEDs)

Terminals Terminals

Signal line connection

The input voltage is 24 V DC. These signals are applied via

clamp-screw terminals. The terminals are located on the signal

strip underneath the module for the low group and on the module itself for the high group (see diagram).

4 - 12

low group number: high group number:

Exx(+1).07

Exx(+1).06

Exx(+1).05

Exx(+1).04

*)

Exx.00

Exx.01

Exx.02

Exx.03

Exx.04

Exx.05

Exx.06

Exx.07

Exx(+1).03

Exx(+1).02

Exx(+1).01

Exx(+1).00

*) read 'E' = 'I' (for Input)

*)

Page 43

Input module, 16 inputs

4.2.3. Technical specifications

Application: ............................................. KUAX 680I (as from version 4.10),

KUAX 680S (part no. 680.301.04/08)

KUAX 680C, KDT 680CT

Admissible ambient conditions

storage temperature ............................ -25...+70 °C

ambient temp. during operation: ....... 0...55 °C

relative humidity ................................ 50...95 %

Inputs: ....................................................... 16

Type (acc. to IEC 1131) .......................... 1

Potential separation ................................. no

Indicators .................................................. LEDs

colour .................................................. green

tapping point....................................... in the input circuit

signal states ........................................ 1: LED on

0: LED off

Addressing: .............................................. Ixx.00...Ixx.07

Ixx(+1).00...Ixx(+1).07

Input voltage: ........................................... 24 V DC -20%/+25%

(incl. residual ripple)

Surge immunity ........................................ ≤ 60 V DC (≤ 30 min.)

Signal recognition

logical 0: ............................................. ≤ 5 V DC

logical 1: ............................................. ≥ 15 V DC

Power consumption / input: .................... max. 10 mA

Weight:..................................................... c. 104 g

Part number:............................................. 680.451.03

4 - 13

Page 44

Digital inputs and outputs

4.2.4. Input module, 24 V DC, 8 inputs, 1 ms

These are basically the same inputs as described earlier in

chapter "4.2.1. Input module, 24 V DC, 8 inputs" (see there for

diagram and connectors).

The difference between the two modules is in the much reduced signal delay time of the module described in this chapter. This shorter signal delay makes it possible to register very

much increased signal sequences (e.g. fast counting impulses).

Please take into consideration that the shorter signal delay

time may lead to situations where noise pulses are not filtered

out and are therefore not registered by the CPU. We therefore

strongly recommend the use of shielded wires.

Signal delay:

In order to avoid voltage surges (noise pulses) being recognized as valid signals, thus executing wrong switching operations, they are filtered out.

Signal identification is thus delayed by nominally 1 ms:

U[V]

24

Raising delay*):

tve= 0.3 ... 1.0ms

Falling delay*):

15

tva= 0.4 ... 1.4ms

5

Signal

*) The input signals are read between the individual program cycles and then written into the process

image. To correctly determine the availability of the signals for the user program you would have to

add the program cycle time to the delay time.

5101520253035t[ms]

t

1

0

ve

t

va

4 - 14

Page 45

Input module, 8 inputs, 1 ms

4.2.4.1. Technical specifications

Application: ............................................. KUAX 680I, 680C, 680S, KDT 680CT

Admissible ambient conditions

storage temperature ............................ -25...+70 °C

ambient temp. during operation: ....... 0...55 °C

relative humidity ................................ 50...95 %

Inputs: ....................................................... 8

Type (acc. to IEC 1131) .......................... 1

Potential separation ................................. no

Indicators .................................................. LEDs

colour .................................................. green

tapping point....................................... in the input circuit

signal states ........................................ 1: LED on

0: LED off

Addressing: .............................................. Ixx.00...Ixx.07

Input voltage: ........................................... 24 V DC -20%/+25%

(incl. residual ripple)

Surge immunity ........................................ ≤ 60 V DC (≤ 30 min.)

Signal recognition

logical 0: ............................................. ≤ 5 V DC

logical 1: ............................................. ≥ 15 V DC

Max. voltage: ........................................... 28.8 V DC

Power consumption / input: .................... c. 10 mA

Weight:..................................................... c. 77 g

Part number:............................................. 680.451.04

4 - 15

Page 46

Digital inputs and outputs

4.2.5. Input module, 24 V DC, 16 inputs, 1 ms

These are basically the same inputs as described earlier in

chapter "4.2.3. Input module, 24 V DC, 16 inputs" (see there

for diagram and connectors).

The difference between the two modules is in the much reduced signal delay time of the module described in this chapter. This shorter signal delay makes it possible to register very

much increased signal sequences (e.g. fast counting impulses).

Please take into consideration that the shorter signal delay

time may lead to situations where noise pulses are not filtered

out and are therefore not registered by the CPU. We therefore

strongly recommend the use of shielded wires.

Signal delay:

In order to avoid voltage surges (noise pulses) being recognized as valid signals, thus executing wrong switching operations, they are filtered out.

Signal identification is thus delayed by nominally 1 ms:

U[V]

24

Raising delay*):

tve= 0.3 ... 1.0ms

Falling delay*):

15

tva= 0.4 ... 1.4ms

5

Signal

*) The input signals are read between the individual program cycles and then written into the process

image. To correctly determine the availability of the signals for the user program you would have to

add the program cycle time to the delay time.

5101520253035t[ms]

t

1

0

ve

t

va

4 - 16

Page 47

Input module, 16 inputs, 1 ms

4.2.5.1. Technical specifications

Application: ............................................. KUAX 680I (as from version 4.10),

KUAX 680S (part no. 680.301.04/08)

KUAX 680C, KDT 680CT

Admissible ambient conditions

storage temperature ............................ -25...+70 °C

ambient temp. during operation: ....... 0...55 °C

relative humidity ................................ 50...95 %

Inputs: ....................................................... 16

Type (acc. to IEC 1131) .......................... 1

Potential separation ................................. no

Indicators .................................................. LEDs

colour .................................................. green

tapping point....................................... in the input circuit

signal states ........................................ 1: LED on

0: LED off

Addressing: .............................................. Ixx.00...Ixx.07

Ixx(+1).00...Ixx(+1).07

Input voltage: ........................................... 24 V DC -20%/+25%

(incl. residual ripple)

Surge immunity ........................................ ≤ 60 V DC (≤ 30 min.)

Signal recognition

logical 0: ............................................. ≤ 5 V DC

logical 1: ............................................. ≥ 15 V DC

Power consumption / input: .................... max. 10 mA

Weight:..................................................... c. 104 g

Part number:............................................. 680.451.07

4 - 17

Page 48

Digital inputs and outputs

4.2.6. Input module, 24 V DC, 16 inputs, interrupt capability

These are basically the same inputs as described earlier in

chapter "4.2.3. Input module, 24 V DC, 16 inputs" (see there

for diagram and connectors).

The difference between the two modules is in the extended

functionality of the module described in this chapter concerning the registeration of fast input signals.

Please take into consideration that the shorter signal delay

time may lead to situations where noise pulses are not filtered

out and are therefore not registered by the CPU. We therefore

strongly recommend the use of shielded wires.

4.2.6.1. Signal delay

In order to avoid voltage surges (noise pulses) being recognized as valid signals, thus executing wrong switching operations, they are filtered out. Signal identification is thus delayed:

Inputs Ixx.00...03 (lower group, terminals underneath the module)

The first 4 outputs have interrupt

U[V]

24

capability and have a particularly short signal delay time of

nominally 0.3 ms.

15

Raising delay*):

tve= 0.09 ... 0.36ms

Falling delay*):

5

Signal

*) The input signals are read between the individual program cycles and then written into the process

image. To correctly determine the availability of the signals for the user program you would have to

add the program cycle time to the delay time.

5 1015202530 35t[ms]

t

1

0

ve

t

va

tva= 0.12 ... 0.39ms

4 - 18

Page 49

Input module, 16 inputs, interrupt capability

Inputs Ixx.04...07 (lower group, terminal underneath the module)

The next 4 outputs have a short signal delay time of nominally

1ms.

U[V]

24

Raising delay*):

tve= 0.3 ... 1.0ms

Falling delay*):

15

5

Signal

1

0

5101520253035t[ms]

t

ve

t

va

tva= 0.4 ... 1.4ms

Inputs Ixx(+1).04...07 (higher group, terminal on the module)

These 8 outputs have the normal signal delay time of nominally 5 ms.

U[V]

24

Raising delay*):

tve= 3.0 ... 7.0ms

Falling delay*):

15

tva= 4.0 ... 7.0ms

5

Signal

5101520253035t[ms]

1

0

t

ve

t

va

*) The input signals are read between the individual program cycles and then written into the process

image. To correctly determine the availability of the signals for the user program you would have to

add the program cycle time to the delay time.

4 - 19

Page 50

Digital inputs and outputs

4.2.6.2. Interrupt inputs

Inputs Ixx.00...03 (lower group, terminal underneath the module) support interrupt functions and have a particularly short

signal delay time of nominally 0.3 ms.

For enabling and registering interrupts, each module is automatically assigned a transfer address range (see "3.4. Service

modules") and an interrupt module for interrupt evaluation.

Transfer address ranges and interrupt modules

Slot Transfer address range Interrupt module

0 SLA00.00...01.15 1

1 SLC00.00...01.15 3

2 SLE00.00...01.15 5

3 SLG00.00...01.15 7

4 SLI00.00...01.15 9

5 SLK00.00...01.15 11

6 SLM00.00...01.15 13

7 SLO00.00...01.15 15

When enabled, each of the 4 inputs can trigger an interrupt in

the CPU by raising or falling signal edges. In this case, the

CPU immediately interrupts the normal program run and calls

up the interrupt module that is assigned to this module slot. In

this interrupt module you can get the information about the signal that triggered the interrupt and also start the necessary

measures. We recommend keeping the program in the interrupt

module as short as possible to avoid putting great loads on the

cycle time, especially if interrupts are used frequently.

4 - 20

The user program can also scan the status of the interrupt inputs via the normal input addresses, Ixx.00...03. This means

working with the signal delay that is extended by the cycle

time, however.

The functions of the transfer addresses are listed in the table on

the next page:

Page 51

Input module, 16 inputs, interrupt capability

Functions of the transfer addresses:

Address Symbol Function

SLx00.00

SLx00.01

SLx00.02

SLx00.03

SLx00.04

SLx00.05

SLx00.06

SLx00.07

SLx01.00

SLx01.01

SLx01.02

SLx01.03

SLx01.04

SLx01.05

SLx01.06

SLx01.07

SLx01.08

SLx01.14

SLx01.15

INT_LH_0

INT_LH_1

INT_LH_2

INT_LH_3

INT_HL_0

INT_HL_1

INT_HL_2

INT_HL_3

ENI_LH_0

ENI_LH_1

ENI_LH_2

ENI_LH_3

ENI_HL_0

ENI_HL_1

ENI_HL_2

ENI_HL_3

ENI_MOD

SET_ENI

INT_VERS

interrupt

triggered by:

positive edge

(Low->High)

interrupt

triggered by:

negative edge

(High->Low)

enable interrupt

trigger:

positive edge

(Low->High)

enable interrupt

trigger:

negative edge

(High->Low)

User program writes 255 to enable input module for processing interrupt

(0 for disabling)

User program writes 255 to transfer new settings SLx01.00...14 to CPU;

CPU acknowledges by writing 0

Software date (version) of service module

Example: Enabling the first input for interrupt H->L and L->H:

OK =1 M00.00 ;initialisation marker

Example: interrupt analysis

LH_0 L INT_LH_0 ;interrupt trigger Low->High?

HL_0 L INT_HL_0 ;interrupt trigger High->Low?

CONTINUE ...

input 00

input 01

input 02

input 03

input 00

input 01

input 02

input 03

input 00

input 01

input 02

input 03

input 00

input 01

input 02

input 03

CPU writes 255 after interrupt triggered

via this channel; user program analyses

information in interrupt module

User program writes '255' to enable

interrupt source, or '0' to disable interrupt

source.

Settings are transferred to CPU by 255 in

SLx01.14

L M00.00 ;initialisation marker

JPC OK

L 255

= ENI_MOD ;general interrupt enable

= ENI_LH_0 ;enable interrupt Low->High

= ENI_HL_0 ;enable interrupt High->Low

= SET_ENI ;transfer new settings

JPCN HL_0

... ;analysis program interrupt Low->High

CLR INT_LH_0 ;reset interrupt trigger

JPCN CONTINUE

... ;analysis program interrupt High->Low

CLR INT_HL_0 ;reset interrupt trigger

4 - 21

Page 52

Digital inputs and outputs

Interrupt frequency

Every interrupt lengthens the cycle time. If an overall program

cycle is longer than 70 ms, the monitor will trigger a watchdog

and interrupt the program run. Thus the interrupt frequency

must not exceed a maximum of 2.5 kHz for short periods of

time (approx. 10 ms). Taken over longer periods of time, the

maximum interrupt frequency must be no higher than 1 kHz. If

you are using the interrupt module as a counter you must make

sure not to exceed the interrupt frequency of 1 kHz.

4 - 22

Page 53

Input module, 16 inputs, interrupt capability

4.2.6.3. Technical specifications

Application: ............................................. KUAX 680I (as from version 4.17),

KUAX 680C, KDT 680CT

Admissible ambient conditions

storage temperature ............................ -25...+70 °C

ambient temp. during operation: ....... 0...55 °C

relative humidity ................................ 50...95 %

Inputs: ....................................................... 16

Type (acc. to IEC 1131) .......................... 1

Potential separation ................................. no

Indicators .................................................. LEDs

colour .................................................. green

tapping point....................................... in the input circuit

signal states ........................................ 1: LED on

0: LED off

Addressing: .............................................. Ixx.00...Ixx.07

Ixx(+1).00...Ixx(+1).07

Ixx.00...03 ........................................... filter 0.3 ms with interr. cap.,≤2.5 kHz

Ixx.04...07 ........................................... filter 1 ms

Ixx(+1).00...07 ................................... filter 5 ms

Input voltage: ........................................... 24 V DC -20%/+25%

(incl. residual ripple)

Surge immunity ........................................ ≤ 60 V DC (≤ 30 min.)

Signal recognition

logical 0:............................................. ≤ 5 V DC

logical 1:............................................. ≥ 15 V DC

Power consumption / input: .................... max. 10 mA

Weight:..................................................... c. 108 g

Part number:............................................. 680.451.06

4 - 23

Page 54

Digital inputs and outputs

4.3. Digital output module, 24 V DC, 0.5 A, 8 outputs

Function

Output modules provide the connection to external actuators

(relays, contactors, magnets, valves...).

Resistive and inductive loads can be connected. Freewheeling

diodes have been added to suppress inductive disable surges.

The switching state of the outputs is indicated by LEDs.

Signal line connection

The controller generates output signals of a voltage of 24 V

DC. These are picked up at the plug-screw terminals on the signal strip. Each module is assigned one block of 8 of these terminals. The block is placed directly underneath the module slot

(see diagram above).

Axx.00

Axx.01

Axx.02

*) read 'A' = 'O' (for Output)

4 - 24

*)

Axx.03

Axx.04

Axx.05

Axx.06

Axx.07

Page 55

Output module, 8 outputs

Polarity safeguard

If the connection is correct, a relay in the module switches the

supply of the outputs. A destruction of the module in case of

reversed polarity is thus avoided.